Assembled steel integrated bridge

An assembled, all-in-one technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

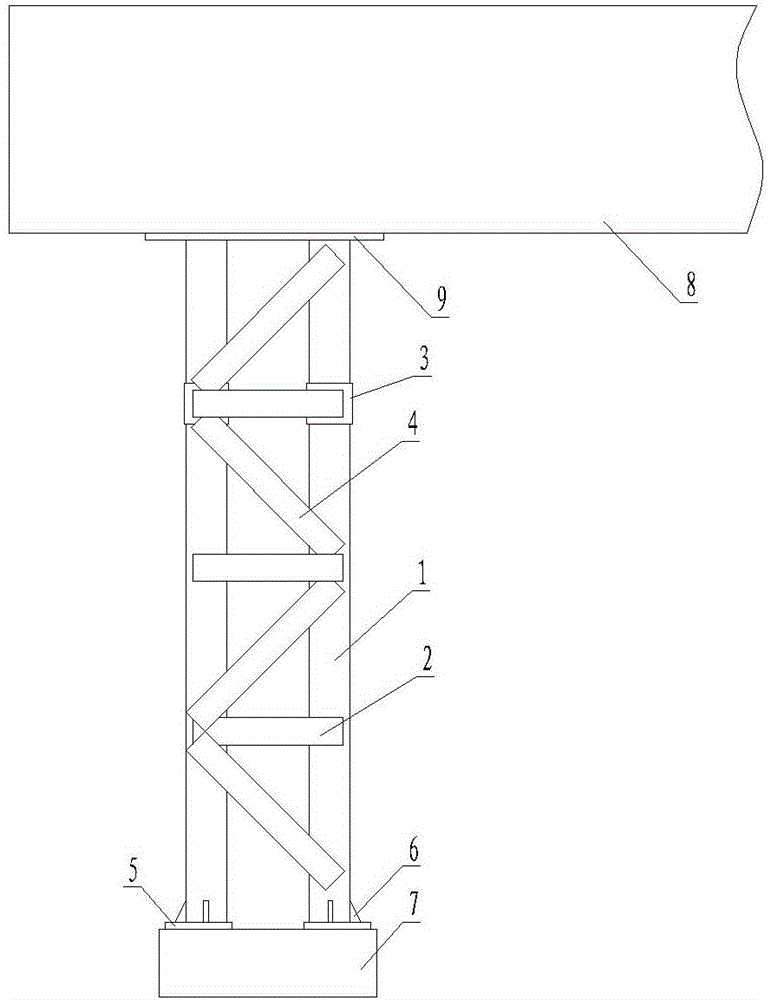

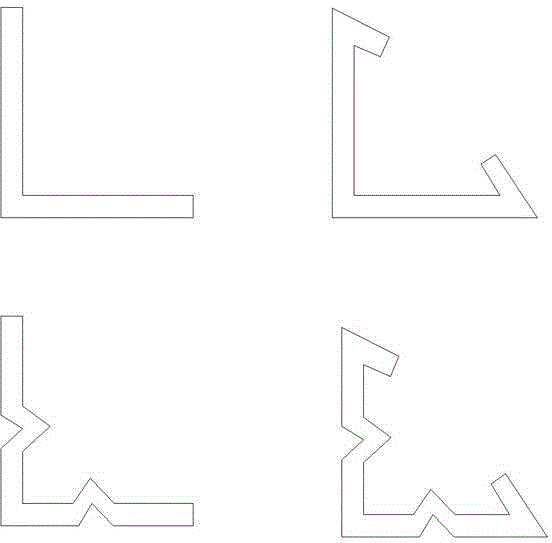

[0020] See attached figure 1 , an assembled steel integrated bridge, including a steel pier column fixed on the cap or pile foundation, a cover beam 8 on the top of the steel pier column, and a main beam fixed on the cover beam 8, the key lies in: the The steel pier column structure includes 4 or 5 steel columns 1 and energy-dissipating components connecting the steel columns 1 , and each steel column 1 is formed by connecting multiple sections of steel columns with the help of connectors 3 . Using the connecting piece 3 to connect the multi-segment steel columns into the steel columns 1 of the required height can achieve the purpose of quickly connecting to form the pier columns of the required height.

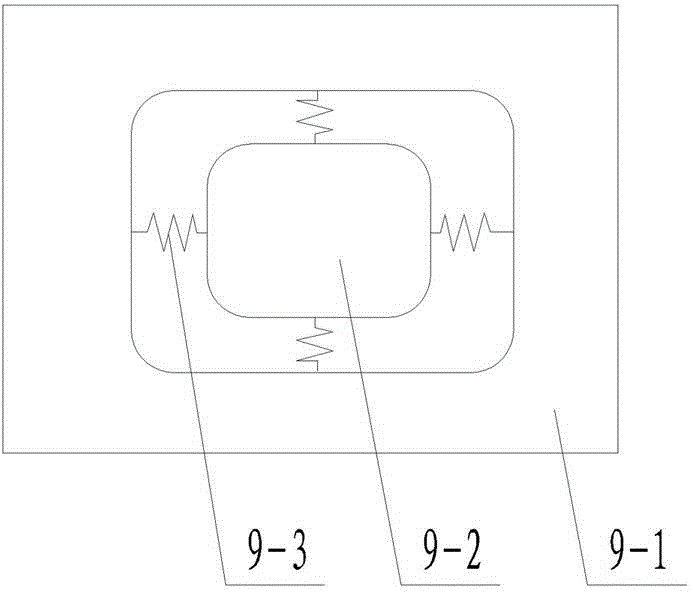

[0021] See attached image 3 , the steel pier column is fixed to the cover beam 8 by means of the connection assembly 9, the structure of the connection assembly 9 includes a mounting plate 9-1 fixed to the steel pier column, a slide plate 9-2 arranged in the groove of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com