Concrete material prepared by utilizing wastes and preparation method of concrete material

A concrete and waste technology, which is applied in the field of concrete materials and its preparation, can solve the problems of natural environmental pollution, occupation of land resources, waste of resources, etc., and achieve the effects of avoiding secondary pollution of the environment, simple production process, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preparation Example

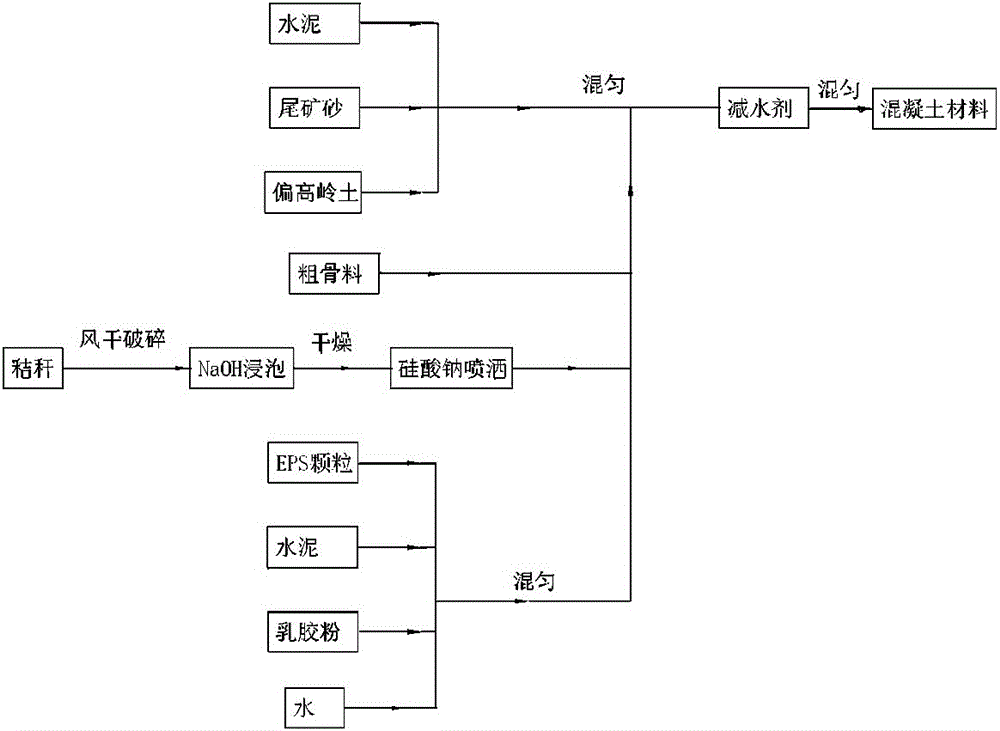

[0032] The present invention prepares concrete material according to the following method:

[0033] Step 1, material preparation: prepare materials according to the component raw materials in parts by weight shown in Table 1: wherein the mass concentration of the sodium hydroxide solution is 3.5%, and the mass concentration of the sodium silicate solution is 1.0%;

[0034] Among the raw materials, the coarse aggregate is natural stone with a particle size of 5-10mm, the particle size range of EPS particles is 2-4mm, and the bulk density is about 8kg / m 3 , the fineness modulus of the tailings sand is 2.5-3.0, and the discarded iron tailings sand (powder) of the mine can generally be used, which belongs to the range of medium sand; the iron tailings sand contains SiO 2 、Al 2 o 3 , Fe 2 o 3 Such ingredients can effectively improve the mechanical properties of concrete materials; the particle size of metakaolin is 5-10 μm, the whiteness is 75-80%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com