Patents

Literature

127results about How to "Easy assembly and construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portion waveshape steel web plate pre-stress steel-concrete continuous combined case beam

InactiveCN101255677AGood three-dimensional flexibilityImprove tensile propertiesBridge materialsBridge engineeringSheet steel

The present invention relates to a partial corrugated steel web prestressed steel-concrete continuous composite box-girder. The concrete roof plate is permanently connected with the steel box-girder through a connecting plate and a shear connector. In the steel box girder the steel diaphragm plates are installed respectively corresponding to each fulcrum. The whole steel box-girder is composed of a structural negative monument area segment and the structural positive moment area segment arranged at two ends. The concrete roof plate of the structural negative moment area segment is stretched with a longitudinal prestressed rib. A longitudinal stiffening rib is arranged in the steel baseboard. The web plates at two sides of the steel box-girder in the structural negative moment area are corrugated steel webs. The web plates of the steel box-girder in the structural positive moment area steel box-girder are plane steel web plate. The invention can overcome the problems of low efficiency of longitudinal pre-stress of negative moment area in the continuous composite box-girder and corrugated steel web PC composite box-girder, easily destabilization of the plane steel web plate or more arrangement of the longitudinal prestressed rib inside or outside the box-girder and complex construction and the like. The invention has broad applying prospect in the bridge engineering and long-span structure.

Owner:HUNAN UNIV

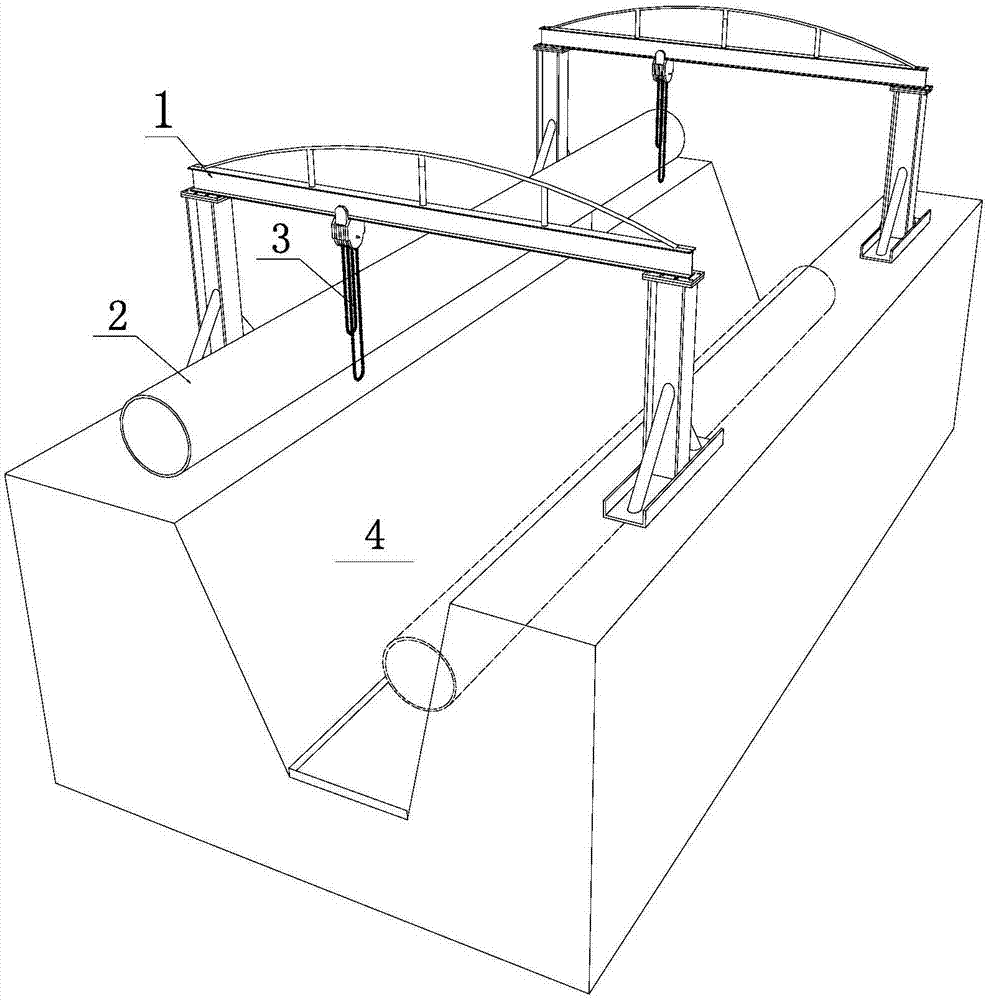

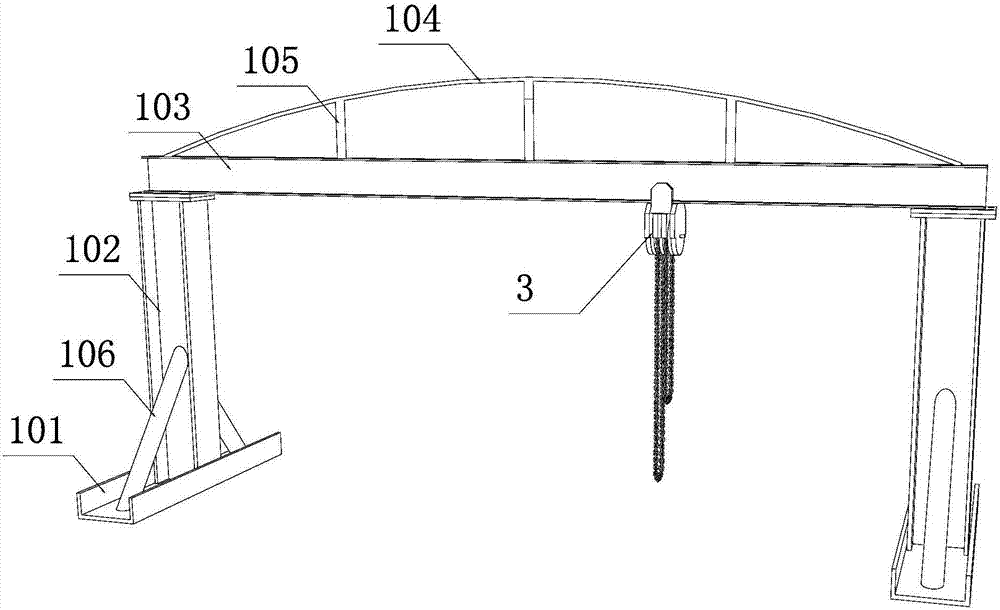

Buried pipeline construction method

ActiveCN107191676ASmall footprintEasy to liftPipe laying and repairBase supporting structuresArchitectural engineeringSmall footprint

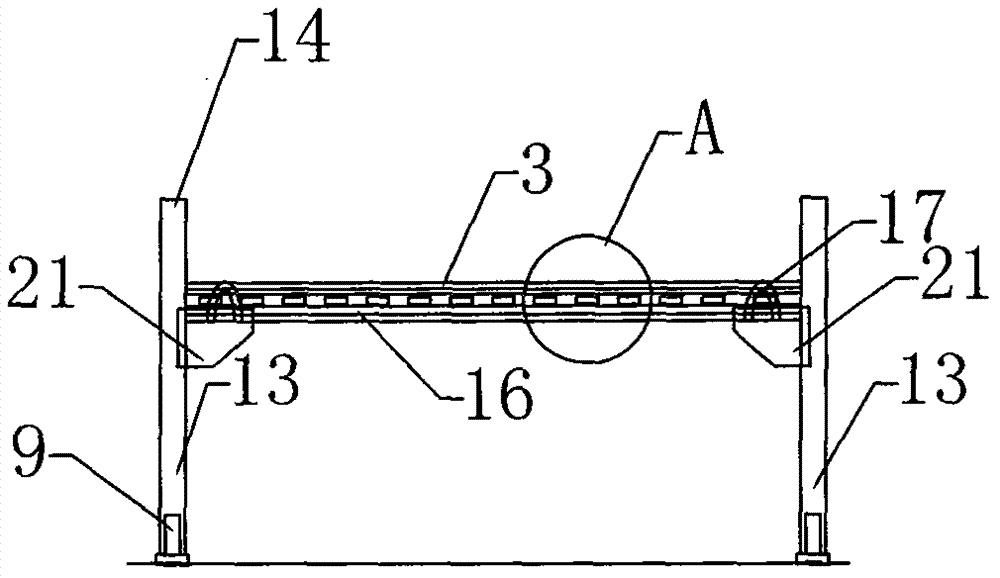

The invention relates to the field of pipeline construction and discloses a buried pipeline construction method. A pipe ditch pipeline transfer frame can be assembled on a construction site, the occupied area is small, site limitation is avoided, and construction can be carried out on a site where a large crane cannot arrive. At least two n-shaped frames are adopted for hoisting together, hoisting of long pipelines is facilitated, a space used for holding the pipelines is reserved between a base and a pipe ditch, thus splicing and corrosion resistant treatment of a very large part of pipelines can be conducted on the ground, operation difficulty is lowered to a large extent, construction efficiency can be improved, and a good protection effect can be achieved on finished pipelines. Compared with the prior crane hoisting mode, the buried pipeline construction method is good in hoisting stability and precision, easy assembly construction is ensured when the pipelines are put down to the ditch bottom, construction quality is greatly improved, and site construction can reduce mechanical machine-team cost and can also lower safety risk greatly.

Owner:CHINA 19TH METALLURGICAL CORP

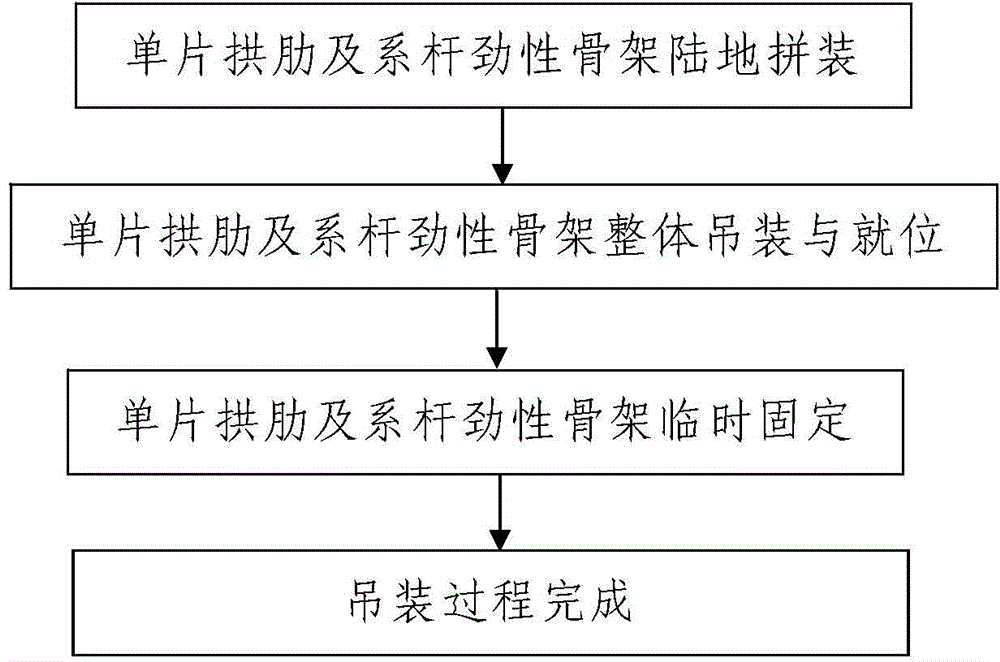

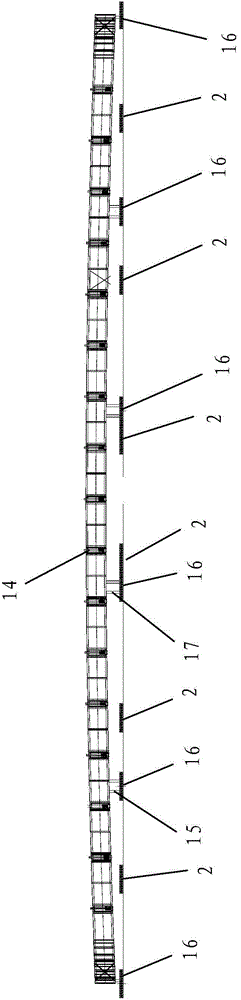

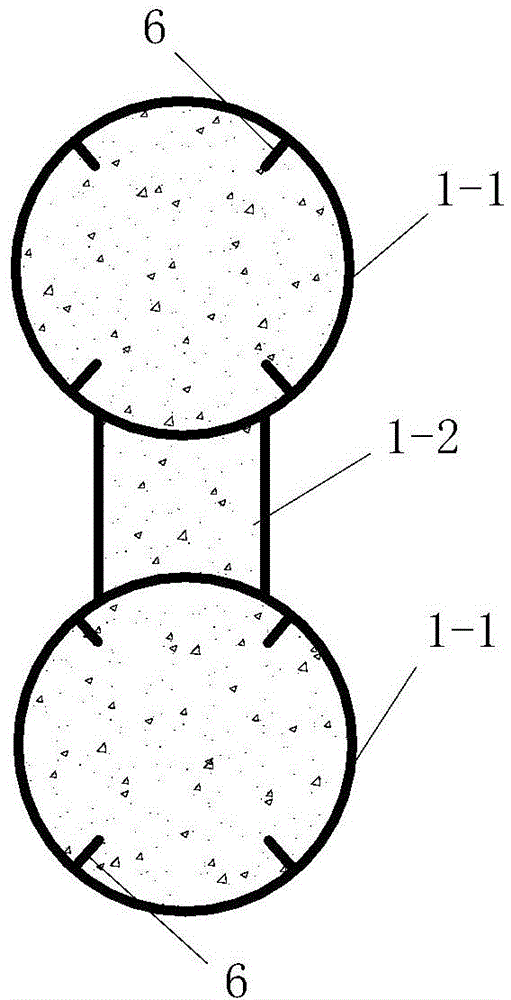

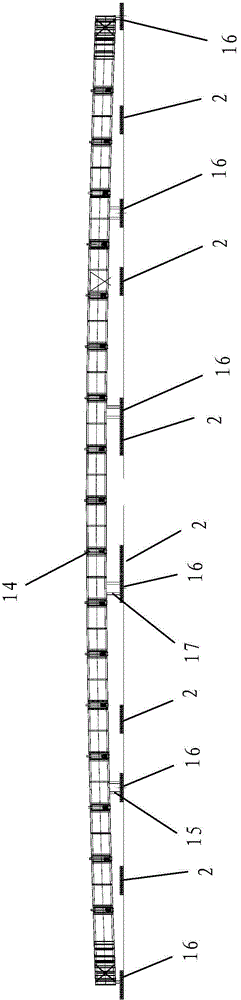

Large span steel tube arch bridge stents-free hoisting process

ActiveCN104404887AThe process steps are simpleReasonable designBridge erection/assemblyArch-type bridgeInsertion stentSpandrel

The invention discloses a large span steel tube arch bridge stents-free hoisting process, the large span steel tube arch bridge is the tied-arch bridge formed above the river and the bridge superstructure comprises arch ribs and a tie bar connected between two arch feet of the arch rib, a stiff skeleton is formed in the tie bar; the stents-free hoisting process for the large span steel tube arch bridge is as follows: 1, assembling the single arch rib with the stiff skeleton of the tie bar on the ground, on the assembling field at the bank side of one side of the river, assembling the arch steel tube stent of the arch rib with the stiff skeleton of the tie bar and obtaining the assembled single piece bridge superstructure; 2, integrally hoisting and positioning the single piece arch rib and the stiff skeleton of the tie bar; adopting floating crane shift platform for hoisting the assembled single piece bridge superstructure and transporting the structure to the bridge lower support structure. The large span steel tube arch bridge stents-free hoisting process is simple in technology process, reasonable in design, convenient in construction and good in construction effect; the large span steel tube arch bridge stents-free hoisting process can be finished simply and quickly, and the hoisting process is safe and reliable.

Owner:NO 1 ENG LIMITED OF CR20G

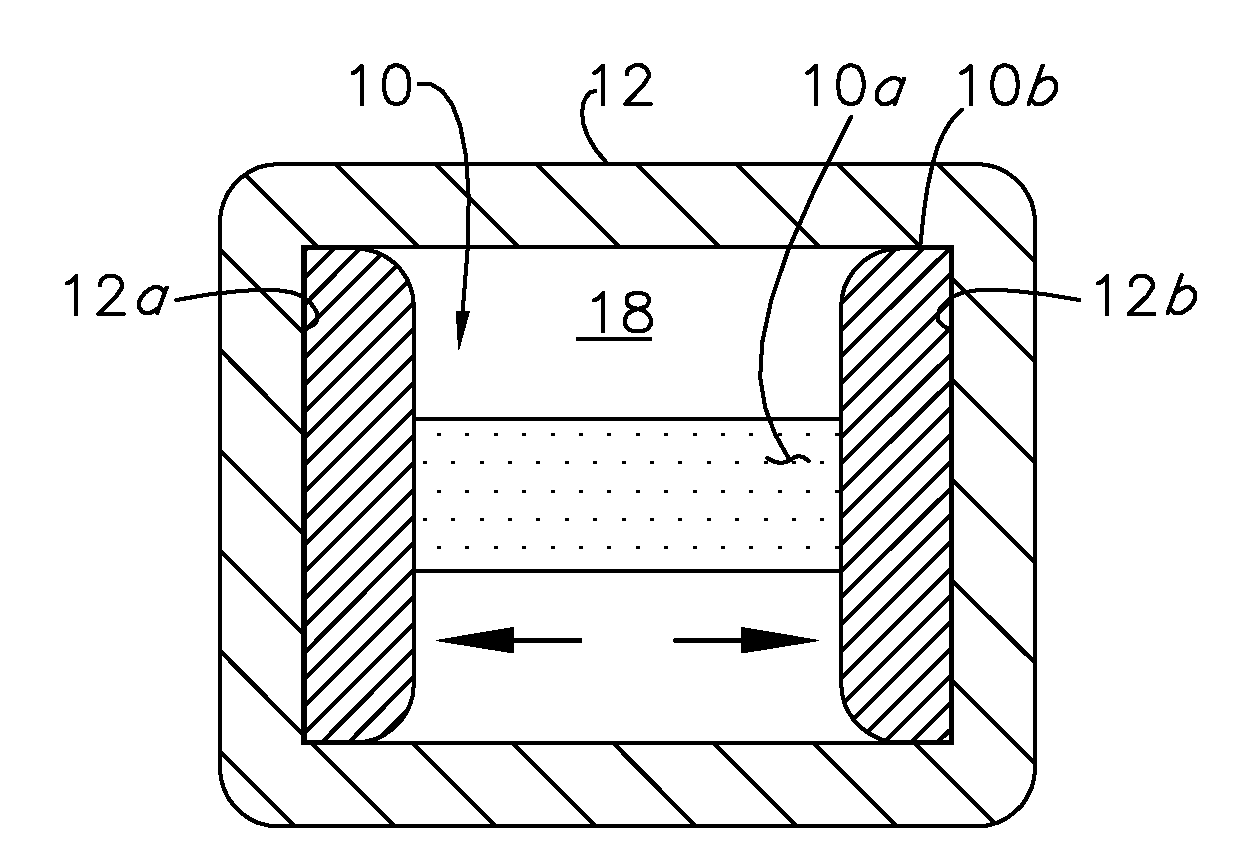

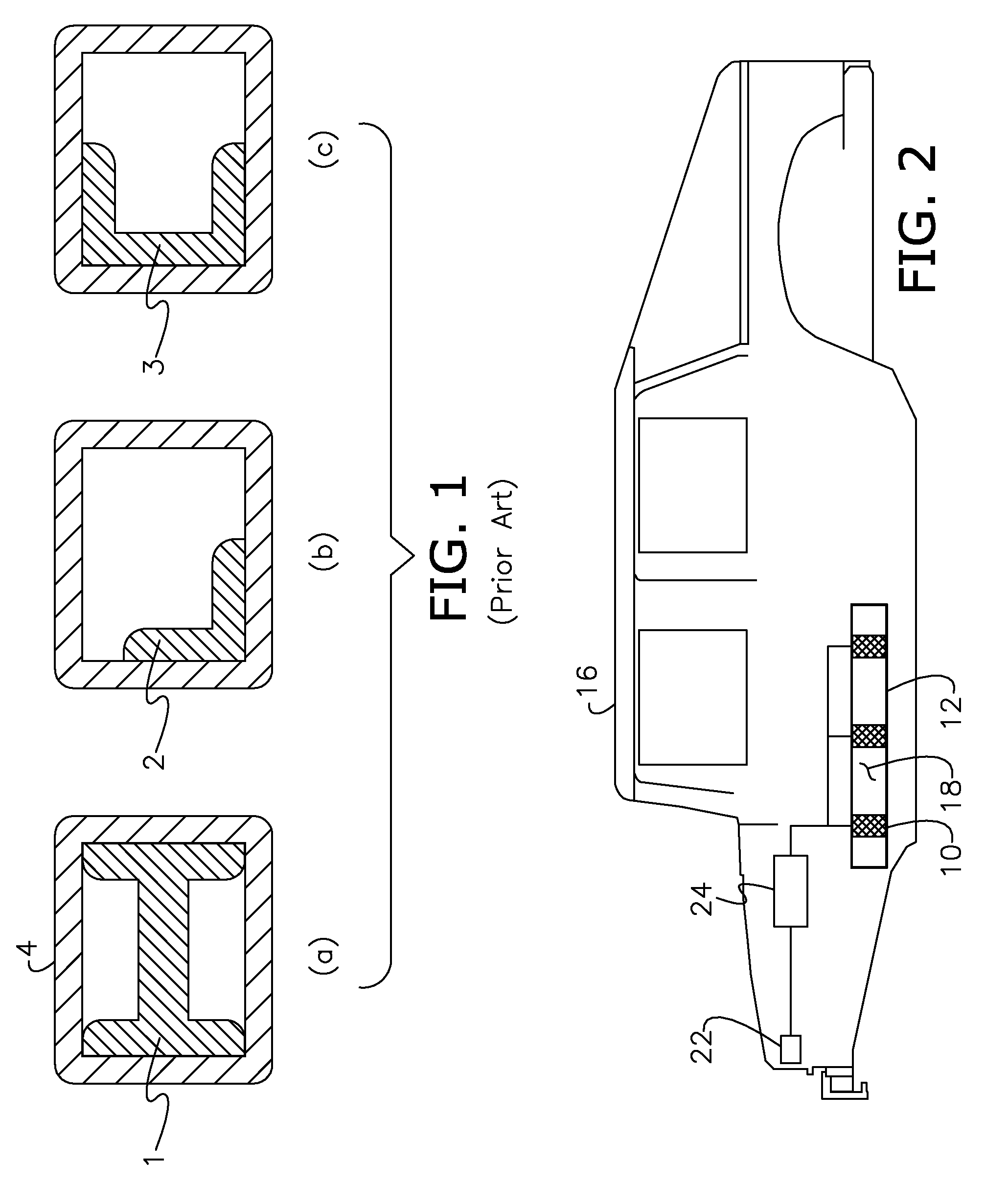

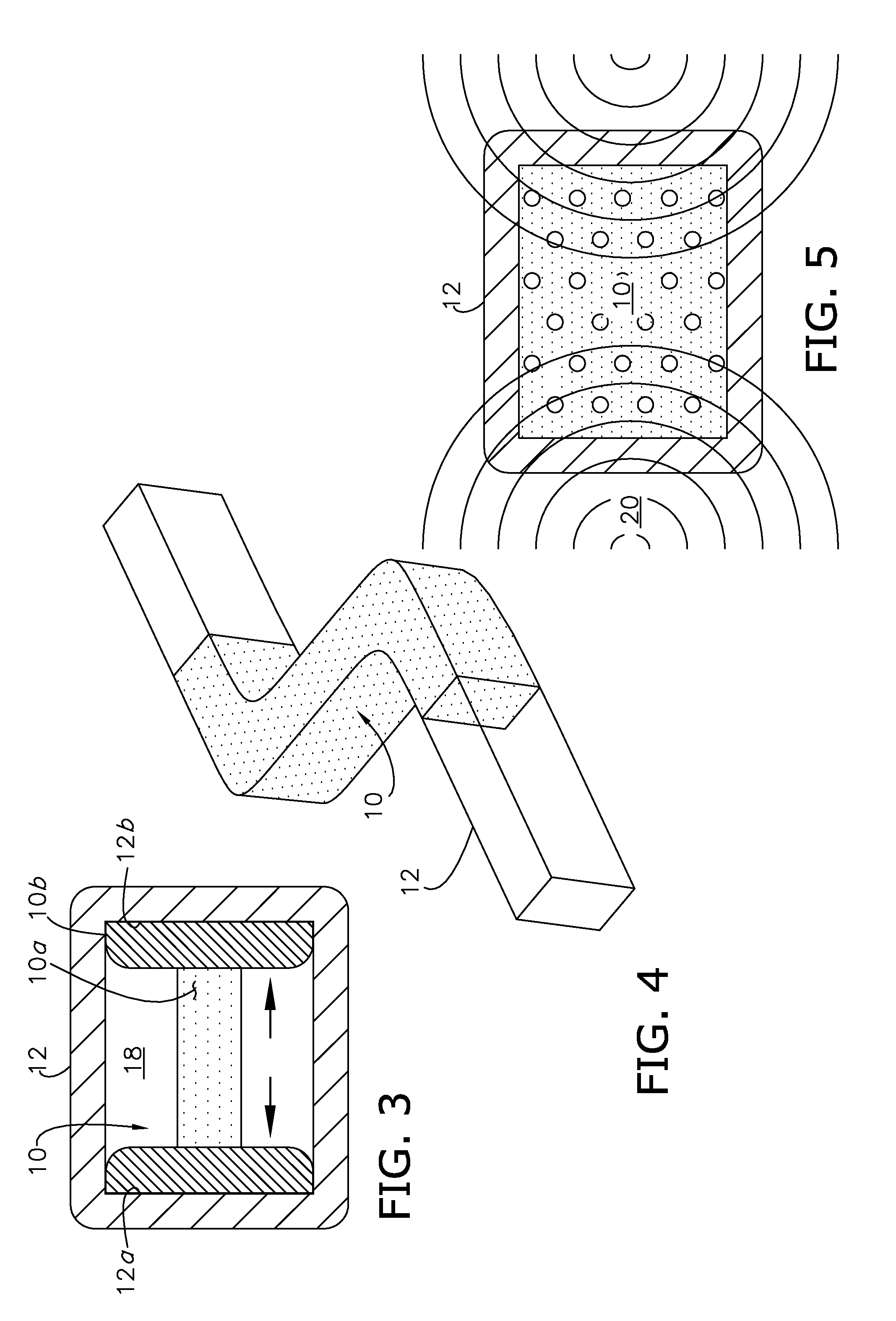

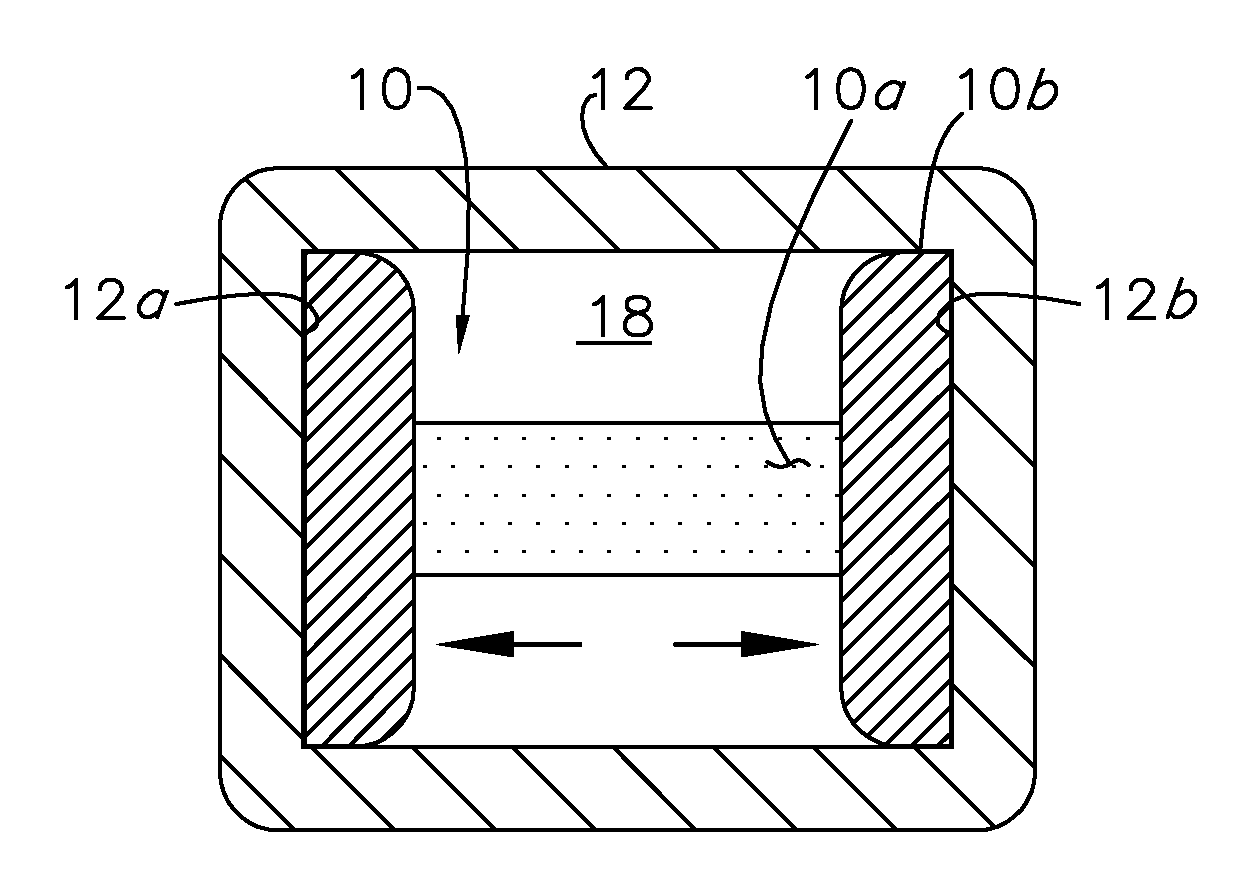

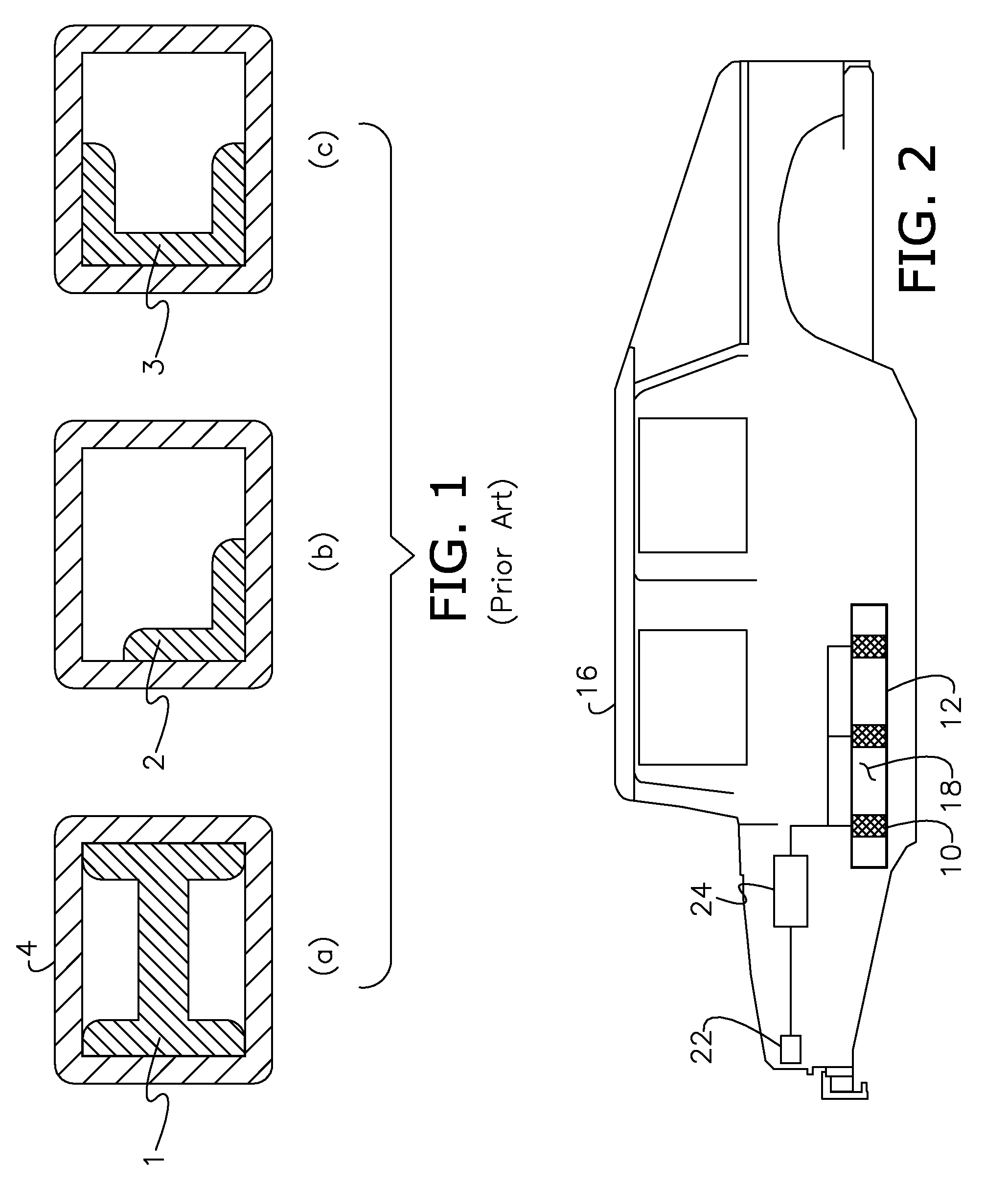

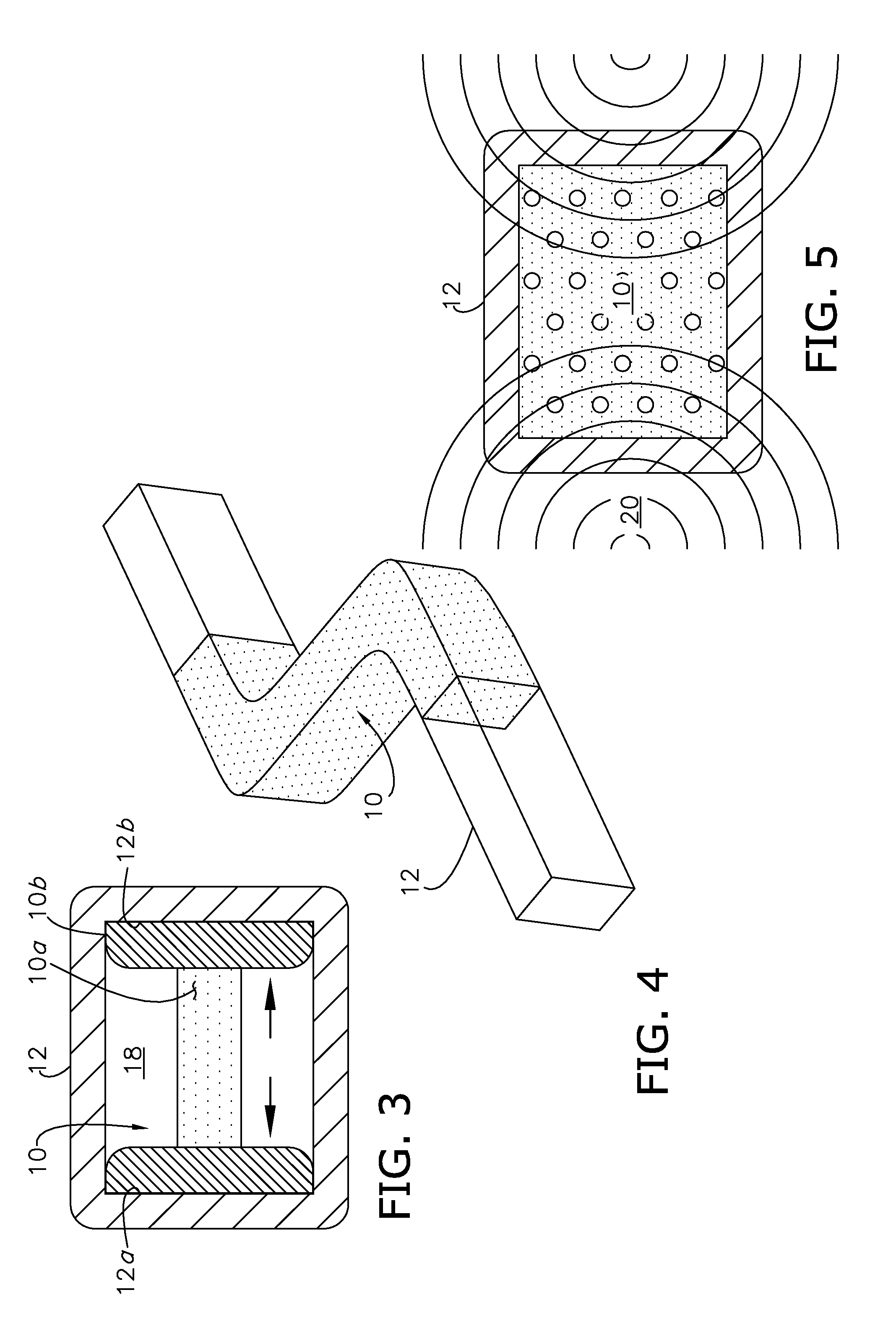

Active material inserts for use with hollow structures

ActiveUS20090066115A1Increase energy efficiencyReduce weight and complexityVehicle seatsUnderstructuresStructural elementEngineering

A modifiable structural assembly comprising an active material based insert positioned within a hollow structural member, wherein the insert defines a first insert dimension, is configured, when activated, to change the first insert dimension to a second insert dimension, and selectively achieving the first or second dimension facilitates positioning the insert, or changes a characteristic of the assembly, such as the stiffness, damping effect, or energy absorption rate, once the insert has been positioned.

Owner:GM GLOBAL TECH OPERATIONS LLC

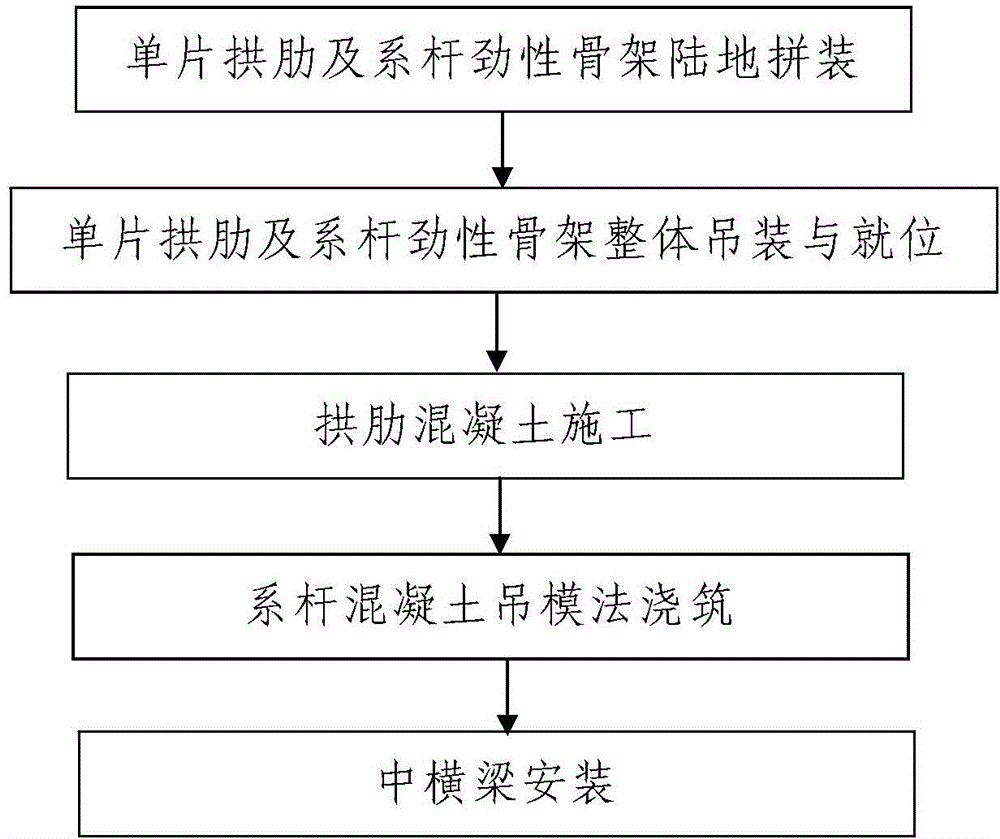

Construction process of large-span steel tube arch bridge without supports

ActiveCN104594197AThe process steps are simpleReasonable designBridge erection/assemblyArch-type bridgeSpandrelMarine navigation

The invention discloses a construction process of a large-span steel tube arch bridge without supports. The constructed large-span steel tube arch bridge is a tied-arch bridge erected on a river channel. A bridge upper structure of the tied-arch bridge comprises arch ribs and tie bars connected between every two arch pins of the arch ribs. Rigid frameworks are arranged in the tie bars. The construction process includes the following steps of firstly, splicing the single-piece arch ribs and the rigid frameworks of the tie rods on the land, wherein arch-shaped steel tube supports of the arch ribs and the rigid frameworks are spliced on a splicing field on a bank side of the river channel; secondly, hoisting the single-piece arch ribs and the rigid frameworks of the tie rods together and placing the arch ribs and the rigid frameworks in place; thirdly, constructing the arch ribs through concrete, wherein the arch pins and end beams are constructed, and concrete is symmetrically pressed and poured for the arch ribs; fourthly, conducting pouring through a tie rod concrete suspended form method; fifthly, installing middle beams. The construction process is simple in process step, reasonable in design, convenient to construct and good in construction effect; the construction process of the large-span steel tube arch bridge without supports can be easily, conveniently and rapidly completed without greatly influencing the navigation of the river channel.

Owner:NO 1 ENG LIMITED OF CR20G

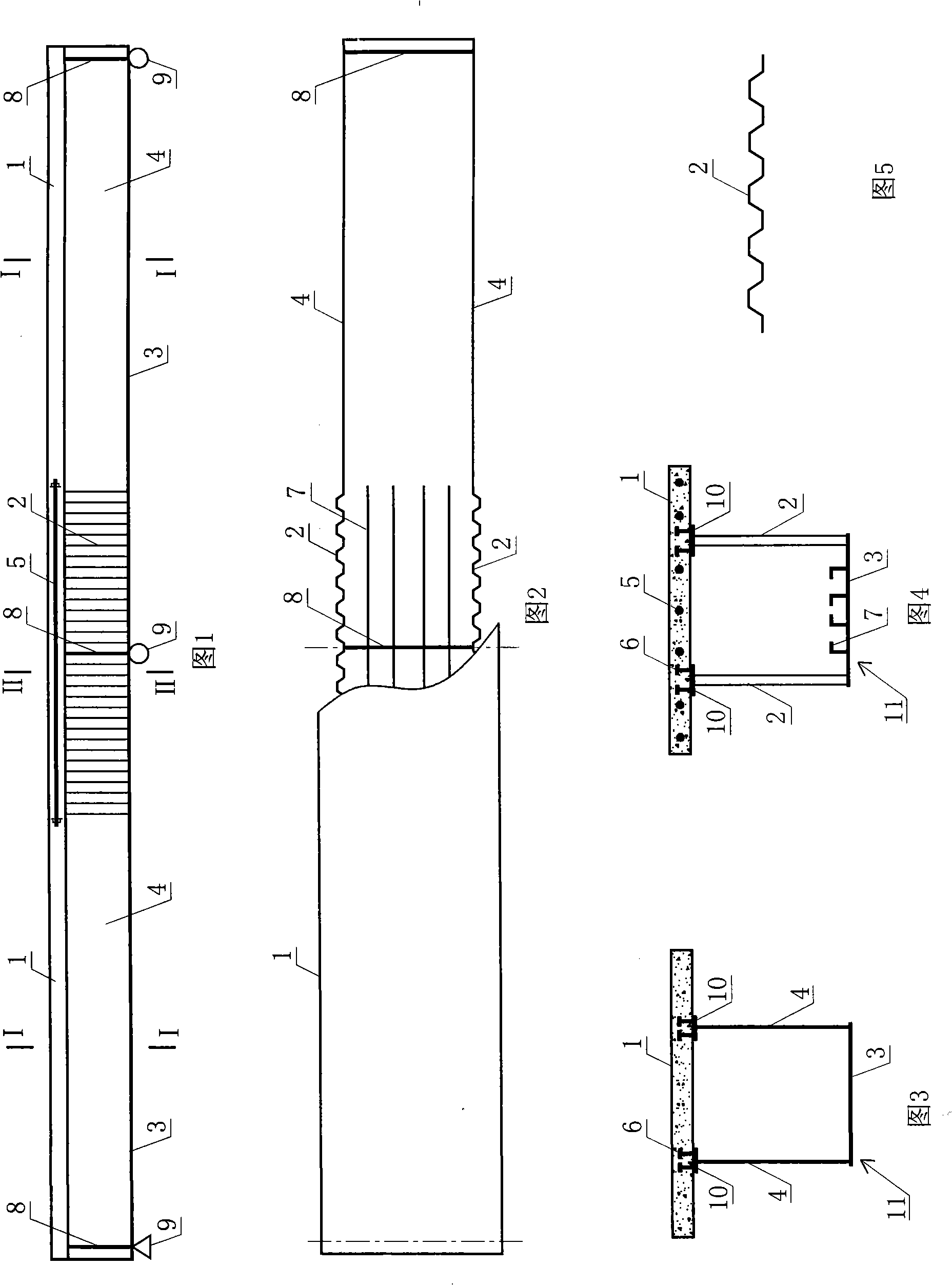

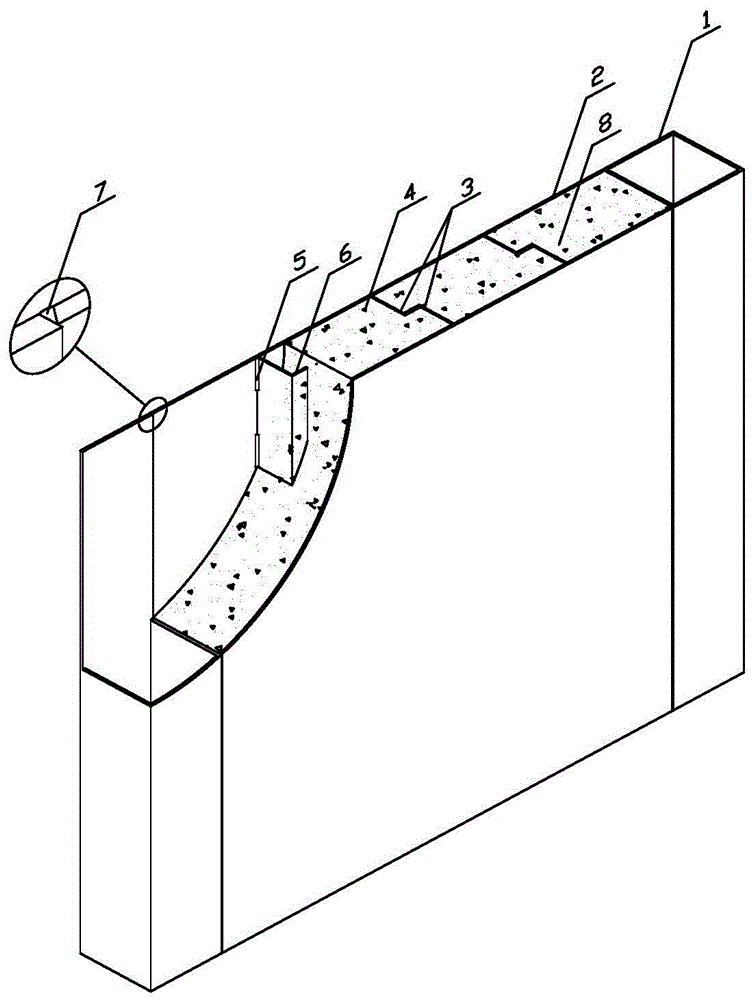

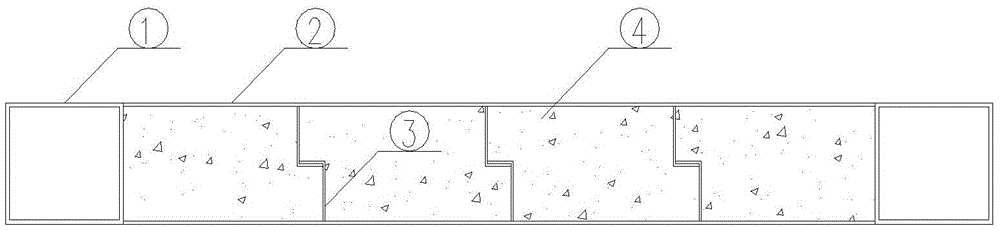

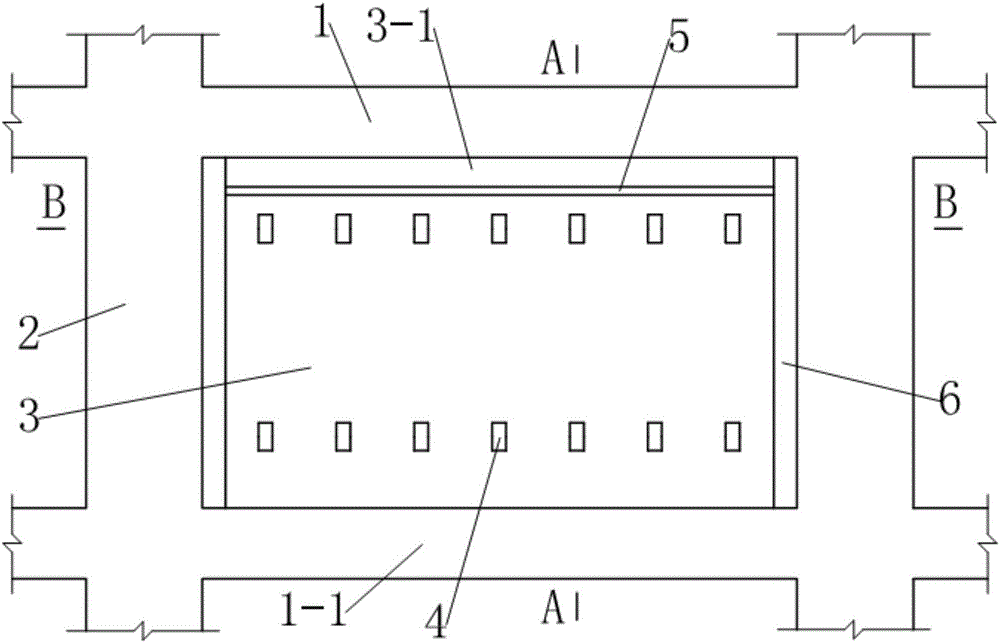

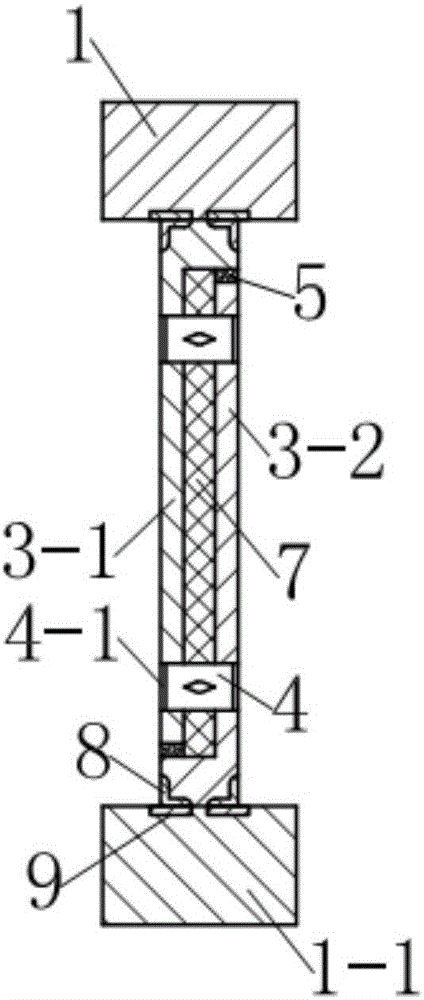

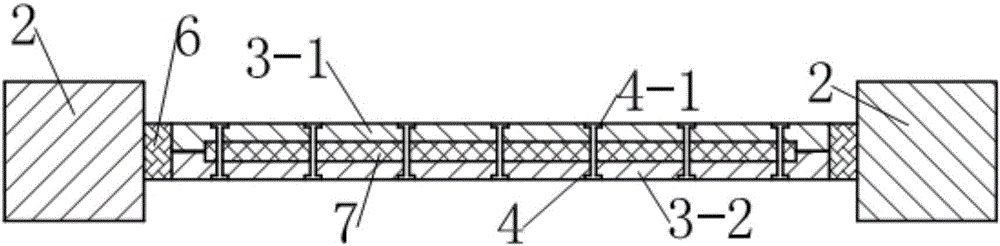

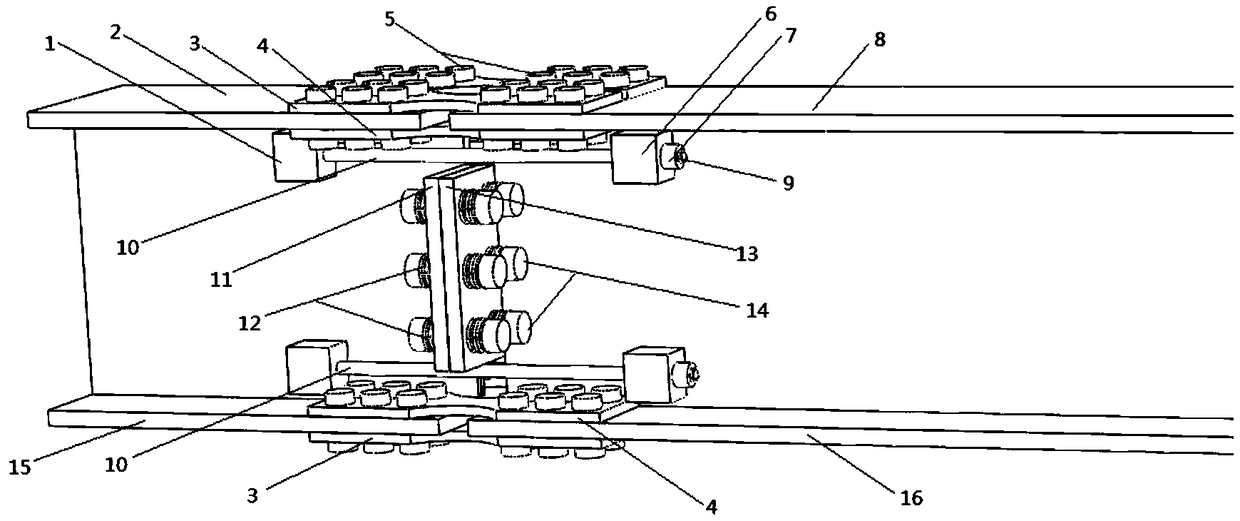

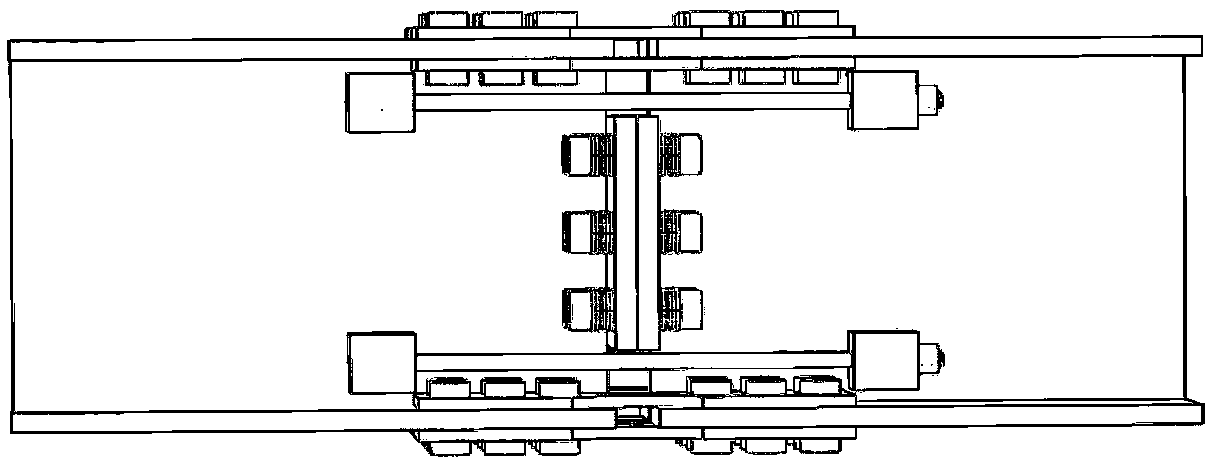

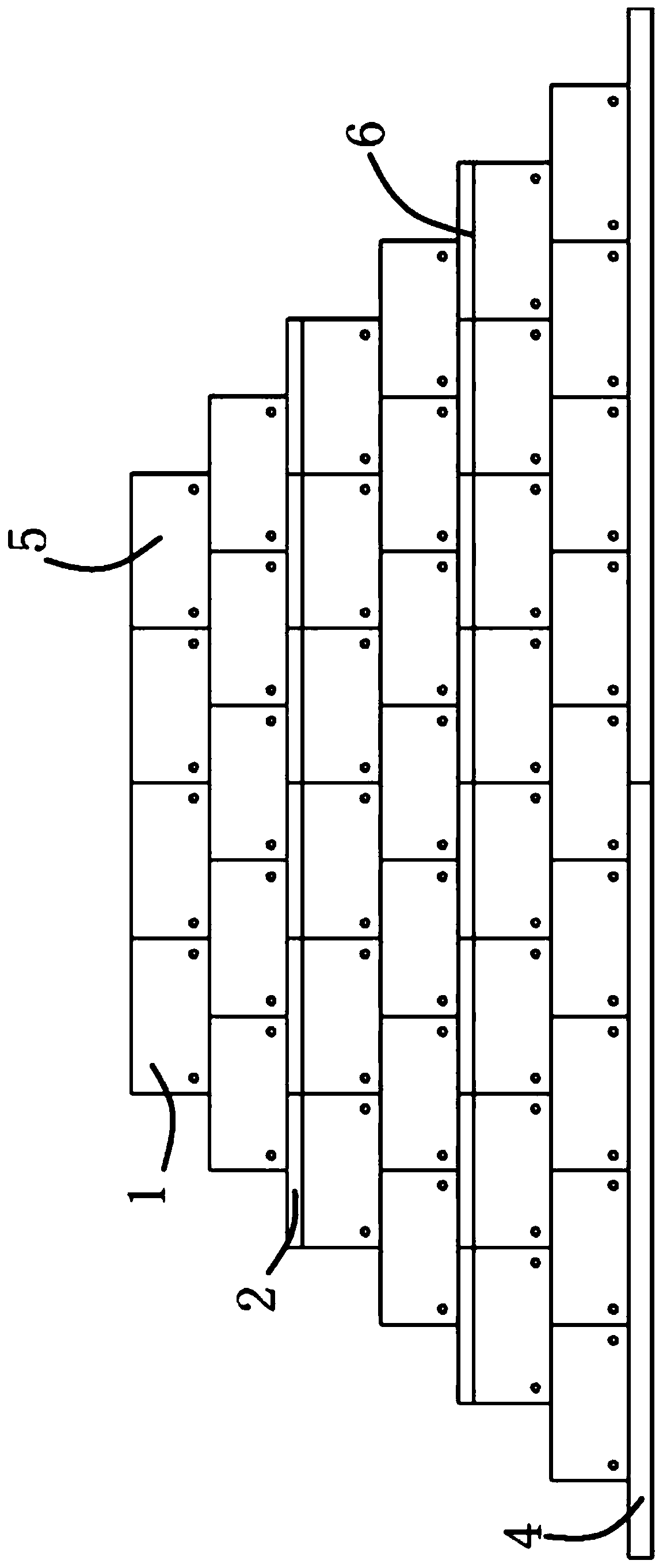

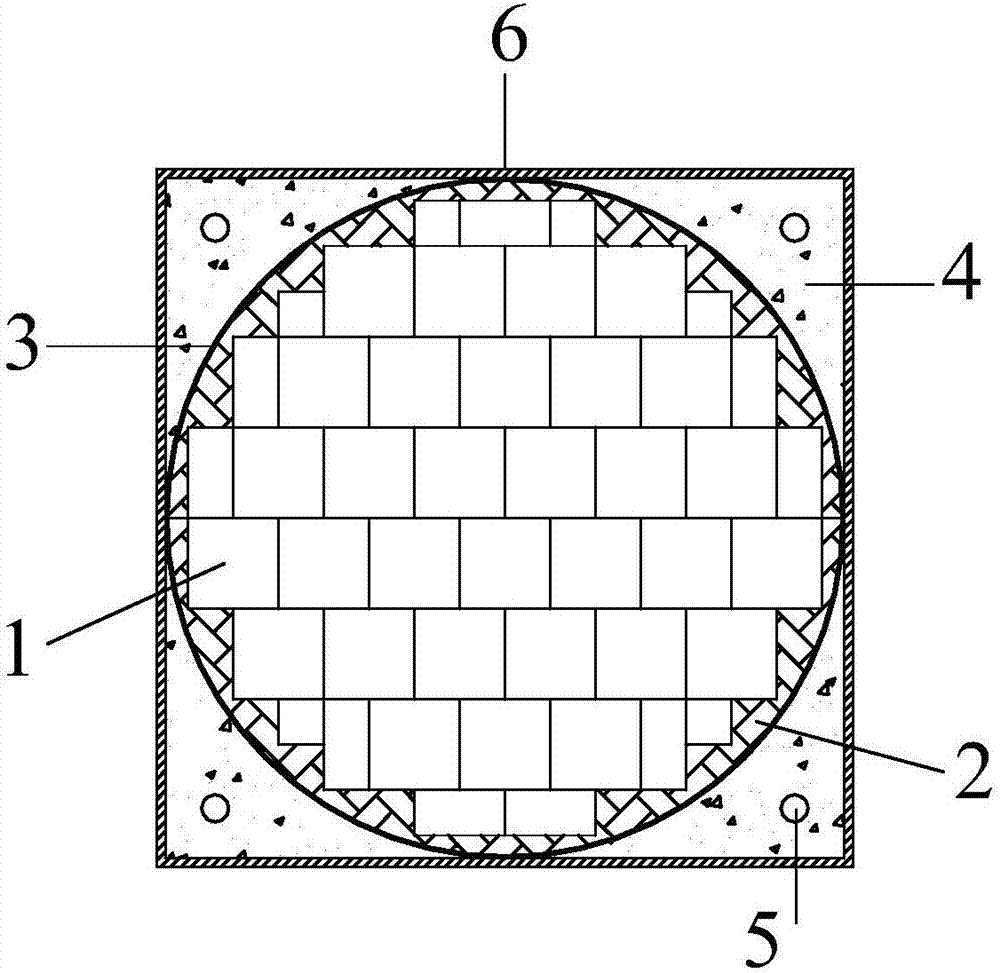

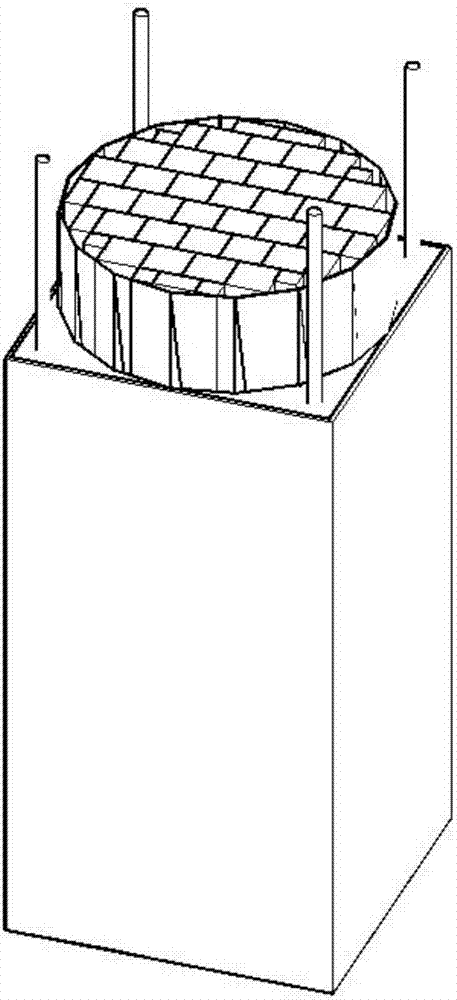

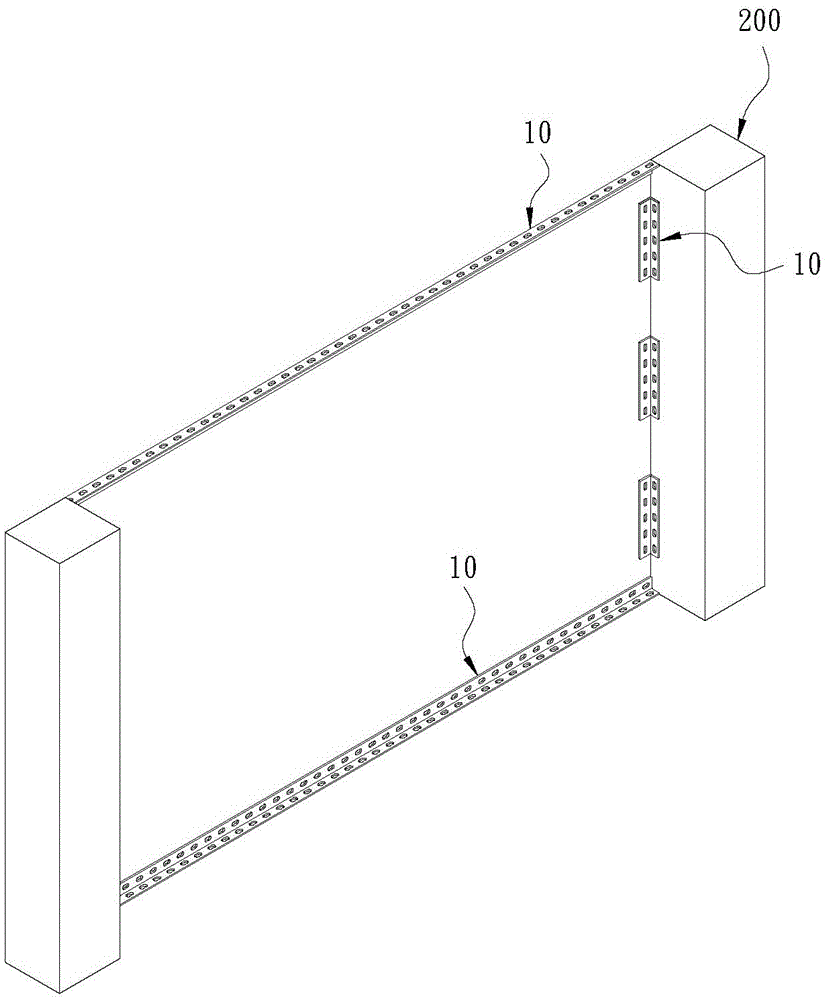

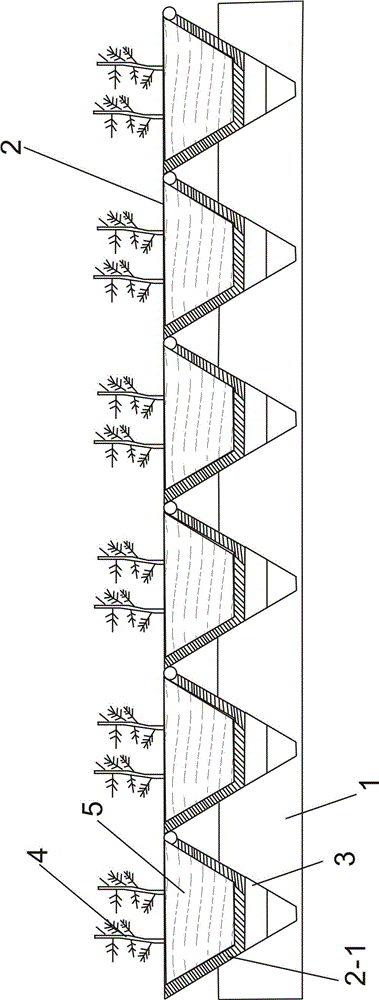

Pull-joint type double-steel-plate composite shear wall

The invention discloses a pull-joint type double-steel-plate composite shear wall, comprising steel pipe columns (steel pipe columns or concrete-filled steel tube columns) respectively arranged at the two ends, a pair of steel plates and at least one pull-joint type connecting piece. The pull-joint type connecting piece is firstly connected with the steel plates by staggered and intermittent one-side fillet welds in a welding way, and then a whole is assembled; the pull-joint type double-steel-plate composite shear wall has the advantages that the composite shear wall is simple in pull-joint structure, has a flat wall surface, and is less in welding workload, easy to operate and convenient to assemble; the stress performance of the composite shear wall is seldom affected by the welding quality since weld joints are positioned at construction parts; the composite shear wall is economical and safe; the steel plates and concrete are strong in cooperative work capability. A straight hook L shape, a sickle hook shape or hump hook shape can be adopted as the pull-joint way of the connecting piece, the pull-joint position can be positioned at the middle or side part of the thickness of the composite wall, and the pull-joint way is flexible and changeable, so that different engineering stress and use requirements are met. Riffled plates can be used as the wallboard steel plates and the pull-joint type connecting piece, so that the binding action between the wall steel plates and the concrete is effectively improved, and the co-working between steel components and the concrete is guaranteed.

Owner:HEFEI UNIV OF TECH +1

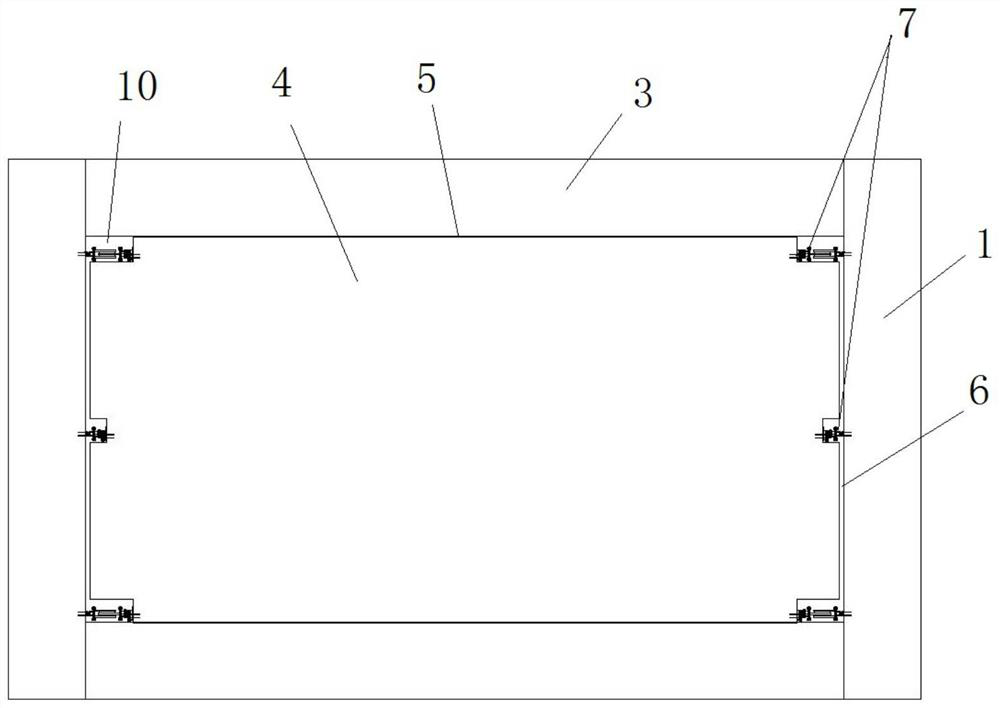

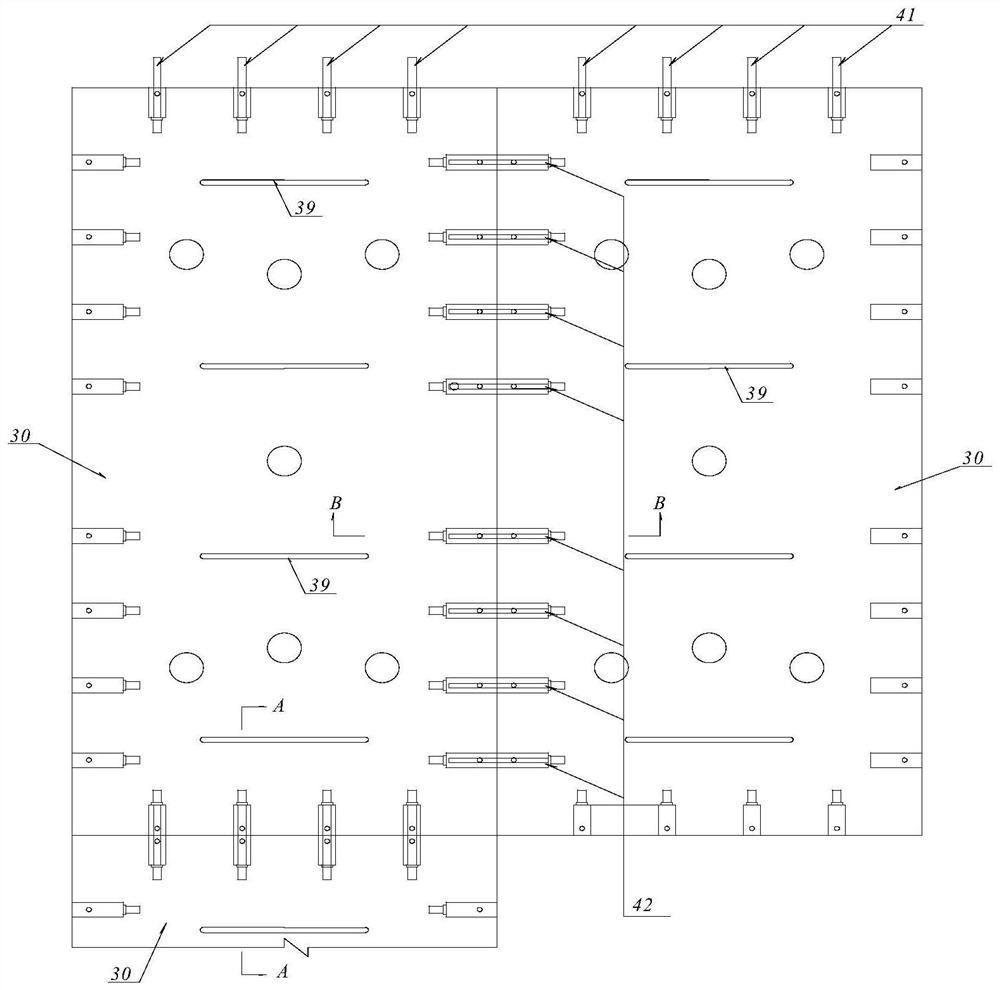

Energy dissipation and shock absorption assembly type infilled wallboard structure

PendingCN111749371ALimit collapseImprove energy consumptionWallsProtective buildings/sheltersEngineeringMechanical engineering

The invention discloses an energy dissipation and shock absorption assembly type infilled wallboard structure. The energy dissipation and shock absorption assembly type infilled wallboard structure comprises a wallboard, the wallboard is a rectangular wallboard, the wallboard comprises two L-shaped sub-wallboards with the same size and shape; the horizontal contact interfaces of the two L-shaped sub-wallboards are filled with damping layers and are connected with each other through a bending deformation energy dissipation device in the plane of a steel plate; and the vertical contact interfaces of the two L-shaped sub-wallboards are located in the middle of the wallboard, impact buffer layers are fixedly arranged on the vertical contact interfaces correspondingly, and the space between theimpact buffer layers is filled with flexible filler. The energy dissipation and shock absorption assembly type infilled wallboard structure is provided with different levels of energy dissipation structures, the wallboard structure has the shock absorption and energy dissipation effects under the action of small earthquakes, medium earthquakes and large earthquakes; the wallboard structure has good deformation ability, the wallboard can be effectively prevented from being damaged under the conditions of small earthquakes and medium earthquakes; and the wallboard structure can play a supporting role under the condition of large earthquakes to prevent a wall body from collapsing.

Owner:HUNAN UNIV

Active material inserts for use with hollow structures

ActiveUS8256829B2Easy assembly and constructionActive field controlled tunability of the characteristicVehicle seatsUnderstructuresEnergy absorptionEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Prefabricated energy dissipation and shock absorption filled wallboard

ActiveCN105780965AEasy to installDoes not affect relative displacementWallsShock proofingWall plateClosed space

The invention discloses a prefabricated energy dissipation and shock absorption filled wallboard which is provided with a masonry. A space enclosed by frame beams and columns is filled with the masonry; the masonry comprises a shock absorption concrete board and flexible waterproof fillers, the upper edge and the lower edge of the shock absorption concrete board are respectively fixed onto the frame beams, and the flexible waterproof fillers are arranged in structural joints between the shock absorption concrete board and the two side frame columns; the shock absorption concrete board comprises a face board with an inverted-L-shaped vertical section and a face board with a J-shaped vertical section, the two face boards coincide with each other, and a closed space with a rectangular vertical section is enclosed by the two face boards and is filled with flexible waterproof fillers; slip layers with waterproof rolls are arranged between the transverse edges of the inverted-L-shaped face board and the upper end surface of the J-shaped face board and between the transverse edges of the J-shaped face board and the lower end surface of the inverted-L-shaped face board; two to three rows of rod-shaped energy consuming riveting components are transversely penetratingly arranged on the shock absorption concrete board and are positioned in a belly of the closed space, and two ends of each energy consuming riveting component are respectively riveted on the two face boards.

Owner:吴从晓 +1

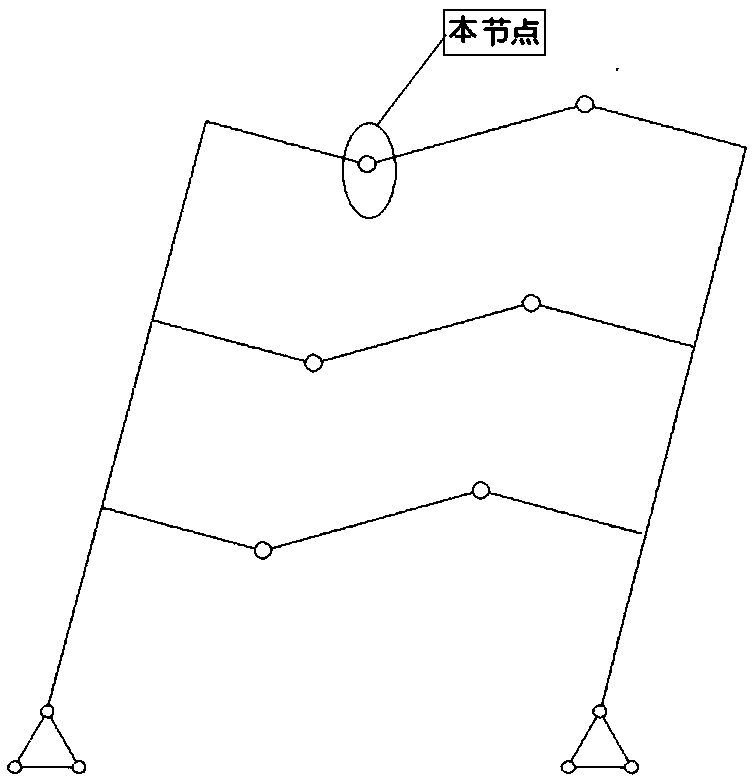

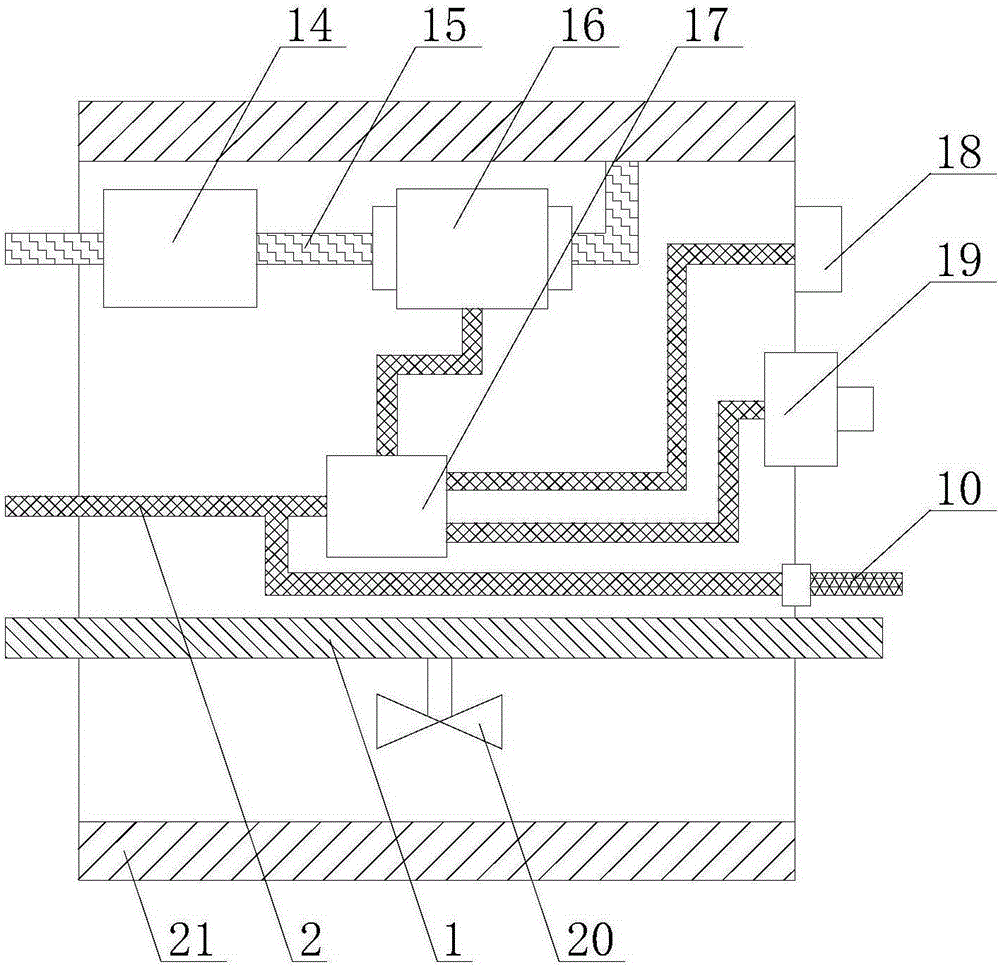

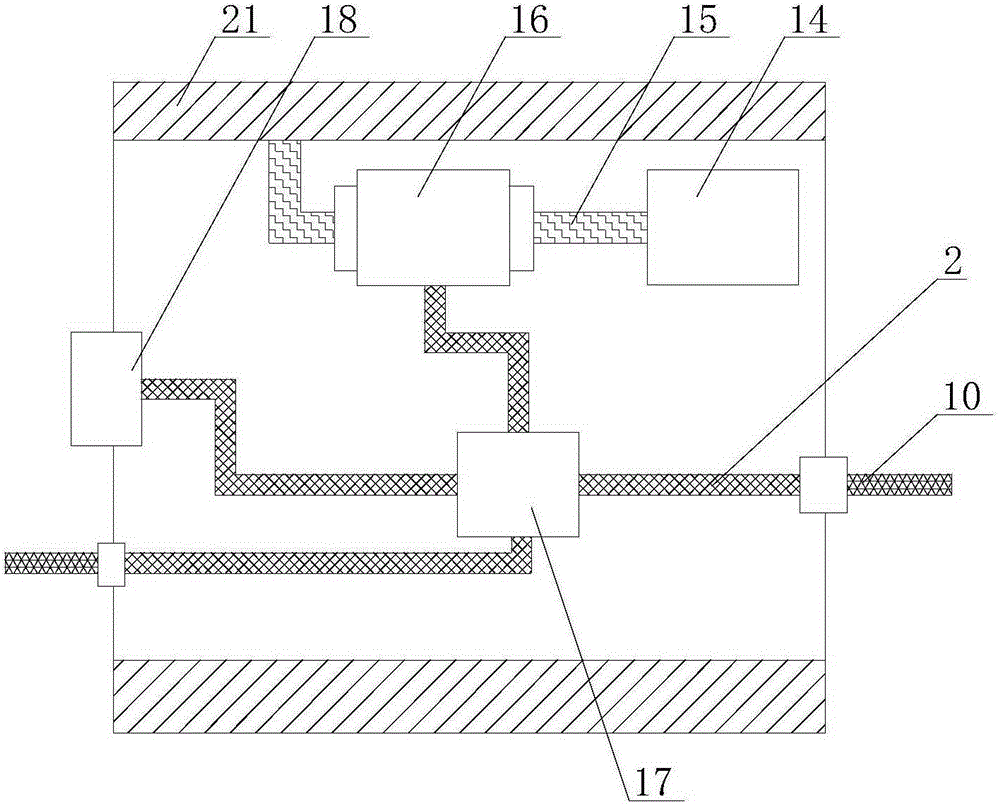

Assembly type joint based on austenite SMA-steel plate set and martensite SMA bars

ActiveCN109057026AImprove the problem of brittle failureGood self-resetting performanceProtective buildings/sheltersShock proofingSteel frameMartensite

The invention discloses an assembly type joint based on an austenite SMA-steel plate set and martensite SMA bars. The joint comprises I-shaped steel beams, friction type high-strength bolts, high-strength steel rectangular end plates, dog bone type connecting steel plates, austenite SMA dog bone type connecting plates, austenite SMA dish-shaped springs, the martensite SMA bars and anchoring blocks. The upper and lower flanges of the steel beams are connected with the friction type high-strength bolts through the steel-SMA dog bone type connecting plate set, and webs of the steel beams are connected with the high-strength rectangular end plates through the martensite SMA bars. Furthermore, one end of each martensite SMA bar is fixed to the corresponding anchoring block on the web of each steel beam through a thread, and the other end of each martensite SMA bar is fixed through the corresponding high-strength bolt and a nut, wherein pretightening force is exerted on the other end of eachmartensite SMA bar. With the SMA-steel plate set, the restorability of the joint is improved; with the martensite SMA bars, the energy dissipation capacity of the joint is improved; through simple heating, deformation recovery after an earthquake can be realized; the joint is applied to a steel frame for resisting to the earthquake to obviously improve the earthquake-proof performance of a structure, and lowers repairing difficulty and repairing costs.

Owner:HUNAN UNIV

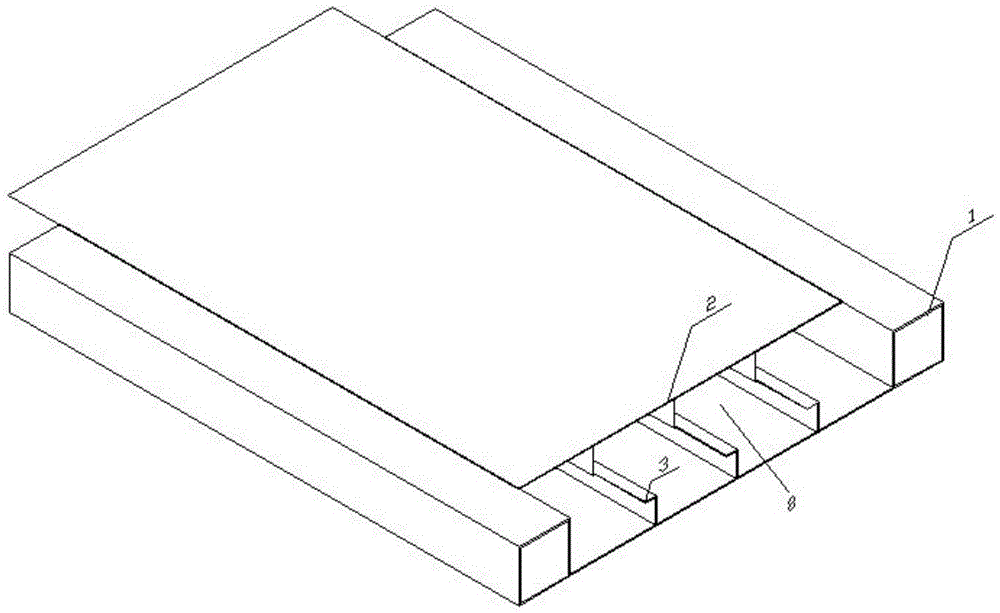

Assembly type pavement structure and construction method

PendingCN112626962AImprove connection securityHigh strengthSingle unit pavingsReinforced concreteArchitectural engineering

The invention discloses an assembly type pavement structure and a construction method, and aims to effectively improve the connection safety, the adjustment capability and the repairable capability of a prefabricated pavement, facilitate the manufacturing and transportation of the prefabricated pavement, and facilitate the assembly, repair, replacement and construction. Prefabricated pavement slabs are assembled on a roadbed to form an assembled pavement, each prefabricated pavement slab is of a prestressed reinforced concrete structure, longitudinal lower grooves are formed in the two longitudinal connecting ends of each prefabricated pavement slab at intervals in the width direction, and transverse lower grooves are formed in the two transverse connecting ends of each prefabricated pavement slab at intervals in the width direction. Rod-shaped connecting components are arranged in the corresponding longitudinal lower grooves or the corresponding transverse lower grooves of every two adjacent prefabricated pavement slabs. An isolation layer is laid on the surface of the roadbed, after the assembled prefabricated pavement slab is leveled, self-compacting concrete is densely poured into a gap between the laid isolation layer and the prefabricated pavement slab to form an adjusting layer, and positioning bosses which protrude upwards and are embedded into longitudinal lower grooves and transverse lower grooves of the prefabricated pavement slab are formed on the adjusting layer.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Environment-friendly atmospheric pressure wood assembly adhesive

InactiveCN105219307AGood adhesionHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesive cementEngineering

The invention relates to an environment-friendly atmospheric pressure wood assembly adhesive which comprises a component A and a component B, wherein the component B is a cross-linking agent; the component A is prepared from the following raw materials in parts by weight: 3-5 parts of polyvinyl alcohol, 20-40 parts of a polyvinyl acetate emulsion, 20-40 parts of a vinyl acetate-ethylene copolymerization emulsion, 0.3-0.5 part of a pH buffer agent, 0.1-0.3 part of nano particles, 0.05-0.2 part of a dispersing agent, 0.1-0.3 part of an antifoaming agent, 0.1-0.5 part of a preservative, 0.1-0.5 part of a wetting agent, 0.1-0.5 part of a flatting agent and 20-30 parts of water. The used polymer and auxiliary ingredients belong to chemicals which are low in toxicity, friendly to environment and beneficial to clean production; the environment-friendly atmospheric pressure wood assembly adhesive does not contain harmful components such as formaldehyde, and is an environment-friendly adhesive.

Owner:JIANGSU QIYANLI PAINT CO LTD

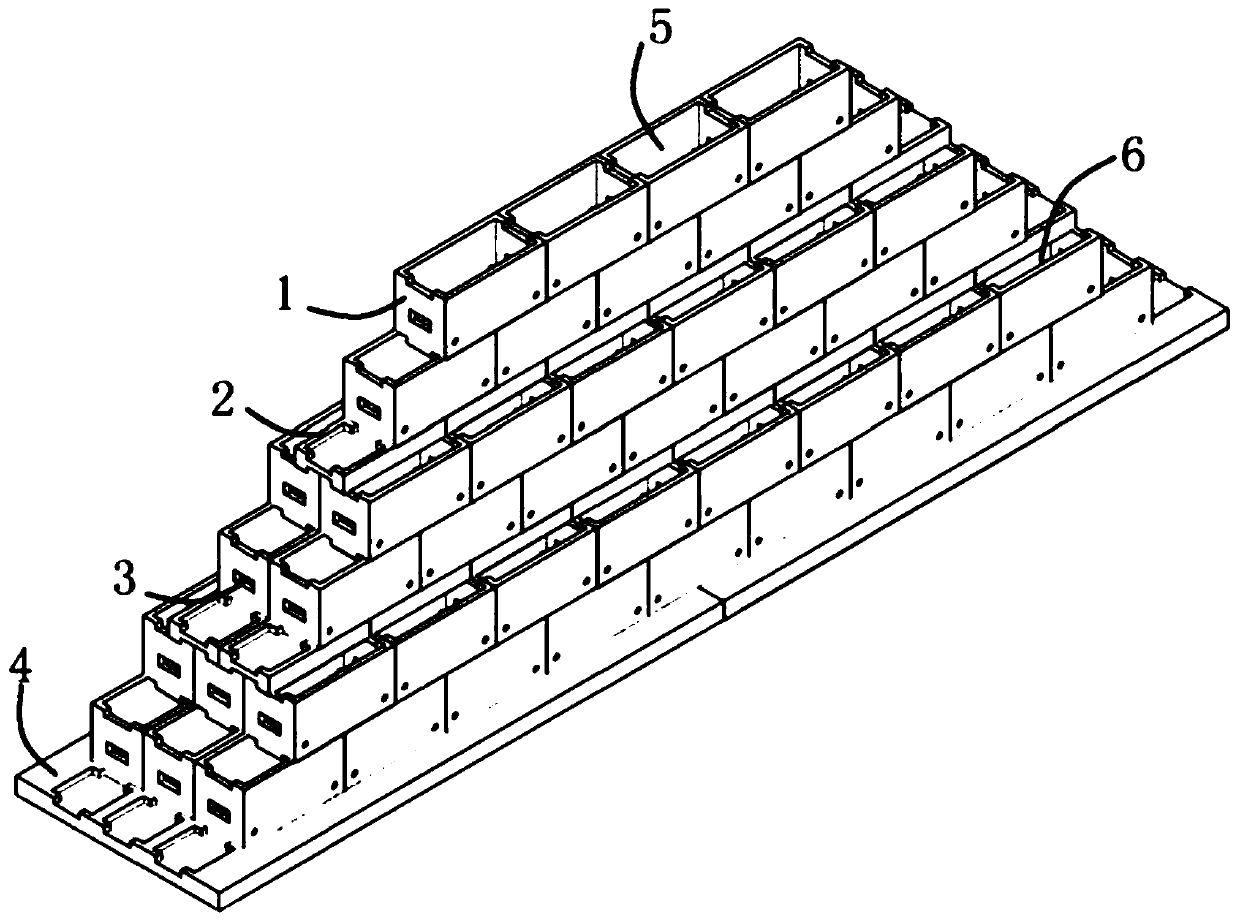

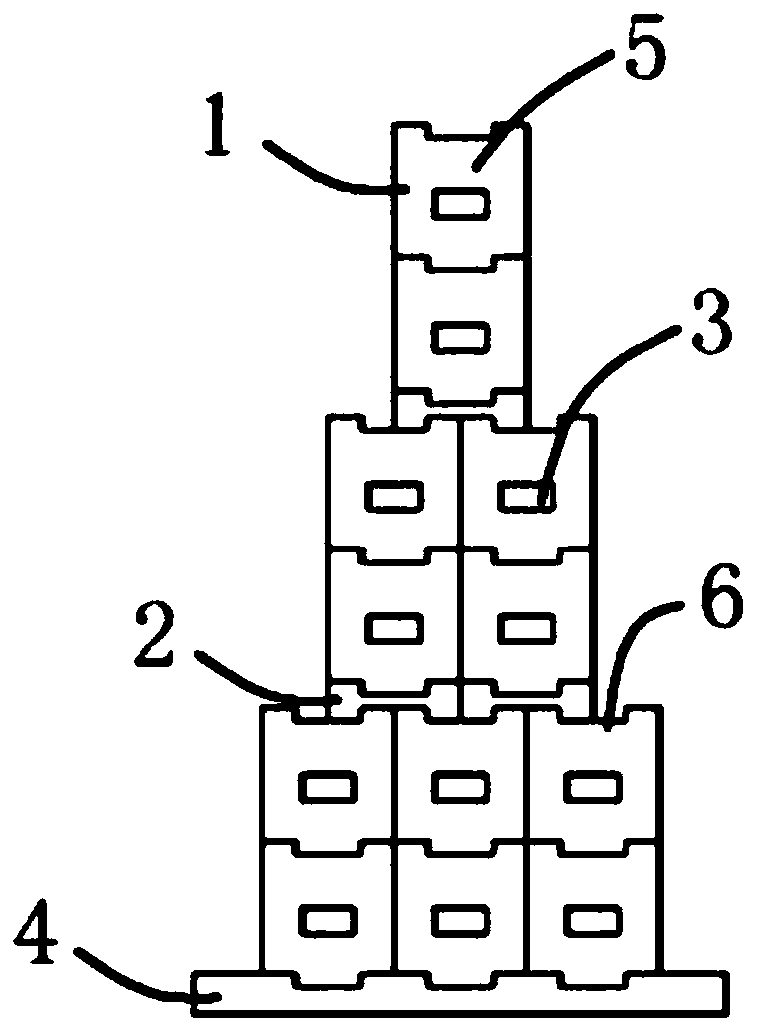

Fabricated concrete box retaining wall and construction method thereof

PendingCN110241849AReduce abandonmentLow costArtificial islandsUnderwater structuresRetaining wallMultiple layer

The invention discloses a fabricated concrete box retaining wall and construction method thereof. The fabricated concrete box retaining wall comprises a cast-in-situ foundation and a wall body arranged on the cast-in-situ foundation, concave string-shaped grooves are formed in the upper surface of the cast-in-situ foundation, the wall body is of a multiple-layer structure, each layer of the wall body comprises a plurality of prefabricated concrete box single bodies, the end parts of the two adjacent prefabricated concrete box single bodies in a single layer wall body are connected through side wall clamping blocks, compared with a traditional gravity retaining wall, according to the fabricated concrete box retaining wall, hollow concrete boxes are filled with waste soil stone materials, masonry or concrete cubic amount is reduced about 40 %, the cubic meter of earth and stone waste in engineering is utilized reasonably, the waste cubic of engineering is reduced, the engineering cost can be reduced over 15 %, the smallest assembling unit of the fabricated concrete box retaining wall is the prefabricated concrete box single bodies, all the prefabricated concrete box single bodies are the same in size, standardized production is facilitated, assembling construction is convenient, and the field construction period can be lowered over 30 %.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

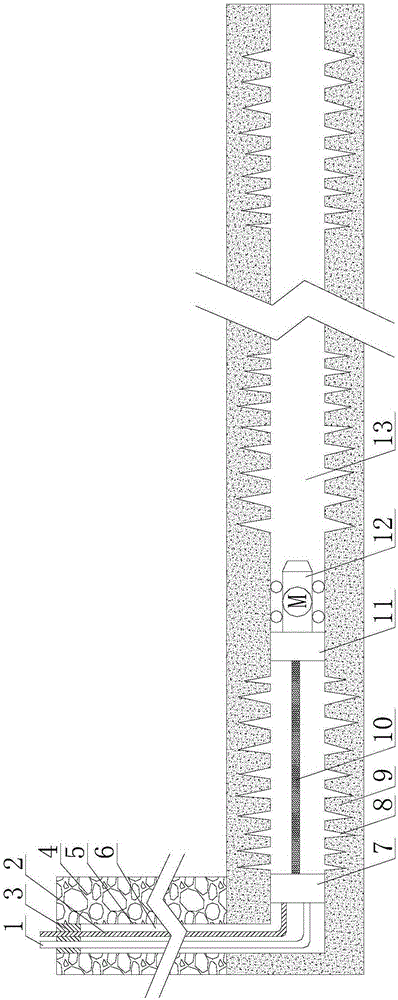

Environment-friendly downhole stratum fracturing method

InactiveCN105201483AImprove permeabilityAvoid damageFluid removalExplosivesHorizontal wellsDesorption

The invention discloses an environment-friendly downhole stratum fracturing method, and belongs to the technical field of anti-reflection fracturing of horizontal wells, inclined shafts, vertical wells and the like. The method is achieved through an environment-friendly downhole stratum fracturing device. The environment-friendly downhole stratum fracturing device structurally comprises a well mouth plugging device, a downhole dragging device, well inside packers, a high-pressure hose, a well inside armor cable, a high-strength cable, an operating and control mechanism and a sensor assembly. Through the operating and control mechanism of the device, the downhole dragging device drags the two well inside packers to a set layer position, a set downhole stratum fracturing space is formed, the high-pressure hose is controlled to inject separation liquid, liquid powder, primary powder and the like into a to-be-fractured downhole space according to a formula proportion, the well inside cable is further controlled to carry out electronic ignition, high-energy and high-pressure gas stratum fracturing work is carried out, and multi-repeating or non-repeating stratum fracturing work of different stratum spaces and different stratum conditions is achieved. According to the method, the efficient, economical and environment-friendly stratum fracturing method and device are provided for coalbed methane / shale gas extraction, the fracturing effect is good, a large-range crack system is formed, the permeability of a reservoir stratum is improved, the desorption speed of the reservoir stratum is increased, and the aim of increasing production is achieved. The method and device are worthy of adoption and popularization.

Owner:ZHONGBEI UNIV

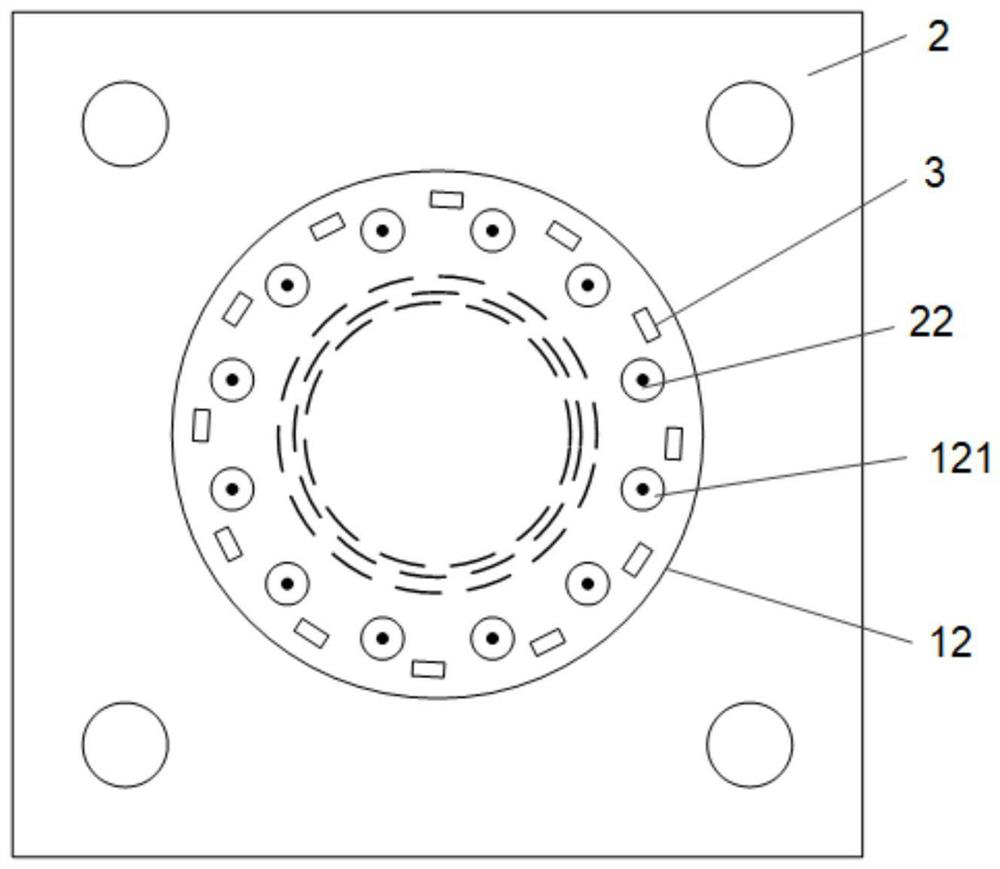

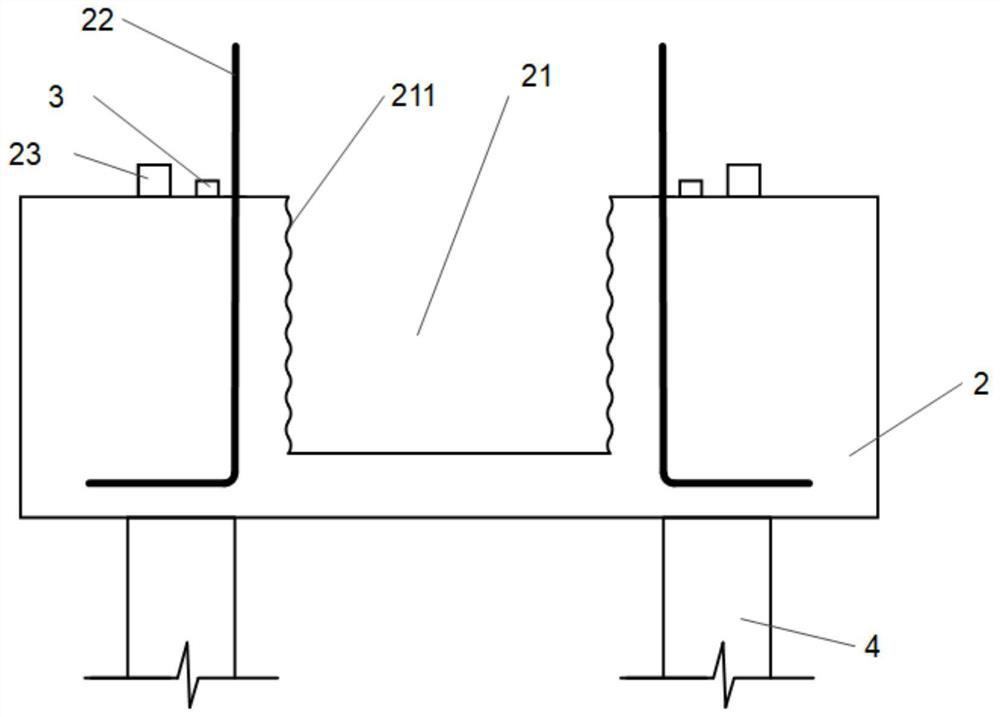

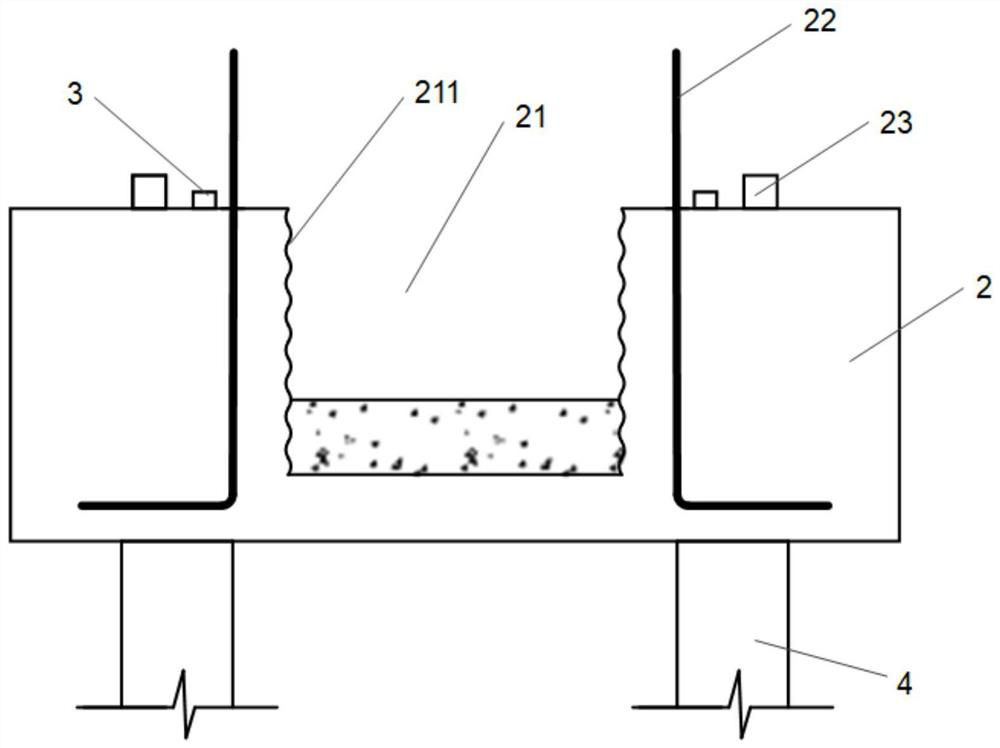

Bearing-socket type prefabricated pier connecting structure and construction method thereof

PendingCN111809510AIncrease the gapNo lack of fullnessBridge structural detailsFoundation engineeringArchitectural engineeringRebar

The invention discloses a bearing-socket type prefabricated pier connecting structure. The structure comprises a prefabricated pier body and a bearing platform, a bearing platform groove is formed inthe bearing platform; a plurality of bearing platform reserved steel bars arranged in the vertical direction are pre-buried in the bearing platform. The prefabricated pier body sequentially comprisesan exposed end, a bearer and an embedding end from top to bottom. The bearer is provided with a plurality of steel bar inserting grooves matched with reserved steel bars of the bearing platform in thecircumferential direction. The free ends of the plurality of bearing platform reserved steel bars are respectively inserted into the steel bar inserting grooves; the outer wall of the embedded end isprovided with a plurality of annularly-protruding stand column shear keys. The embedded end is embedded into the groove of the bearing platform; the lower surface of the bearer is placed on the uppersurface of the bearing platform; grouting materials are poured into the steel bar inserting grooves and the bearing platform grooves. The volume of the grouting material can be adopted to calculate the pouring amount of the grouting material, a gap between the bearing platform and the prefabricated pier body is large, the phenomenon of non-fullness does not exist, splicing construction is easy, the construction error-tolerant rate is high, and the defects that in the prior art, potential safety hazards exist, and the grouting fullness degree is not easy to check can be overcome.

Owner:SHANGHAI INST OF TECH

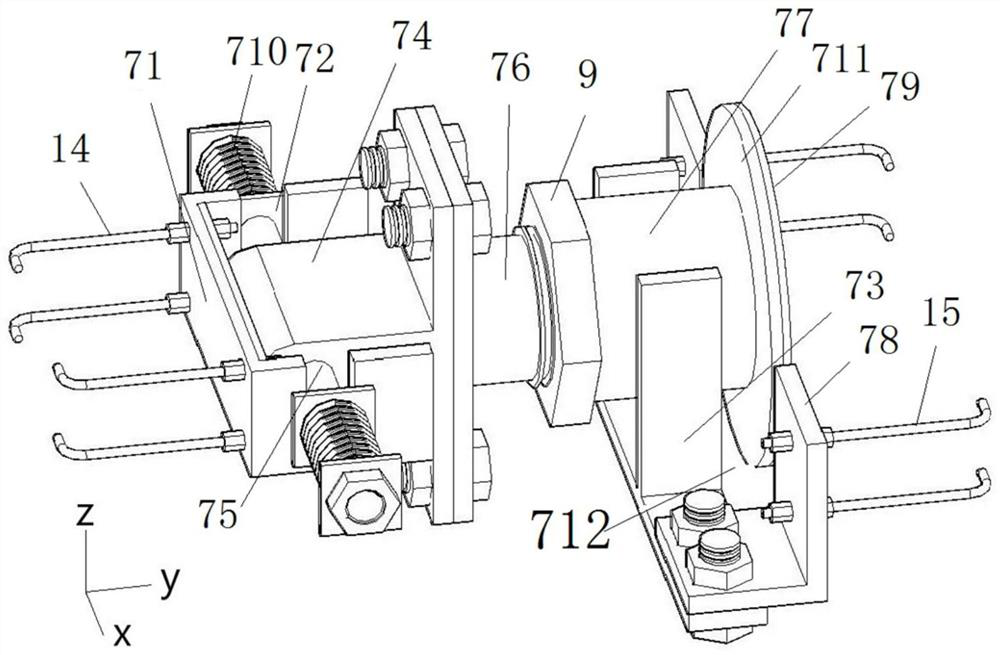

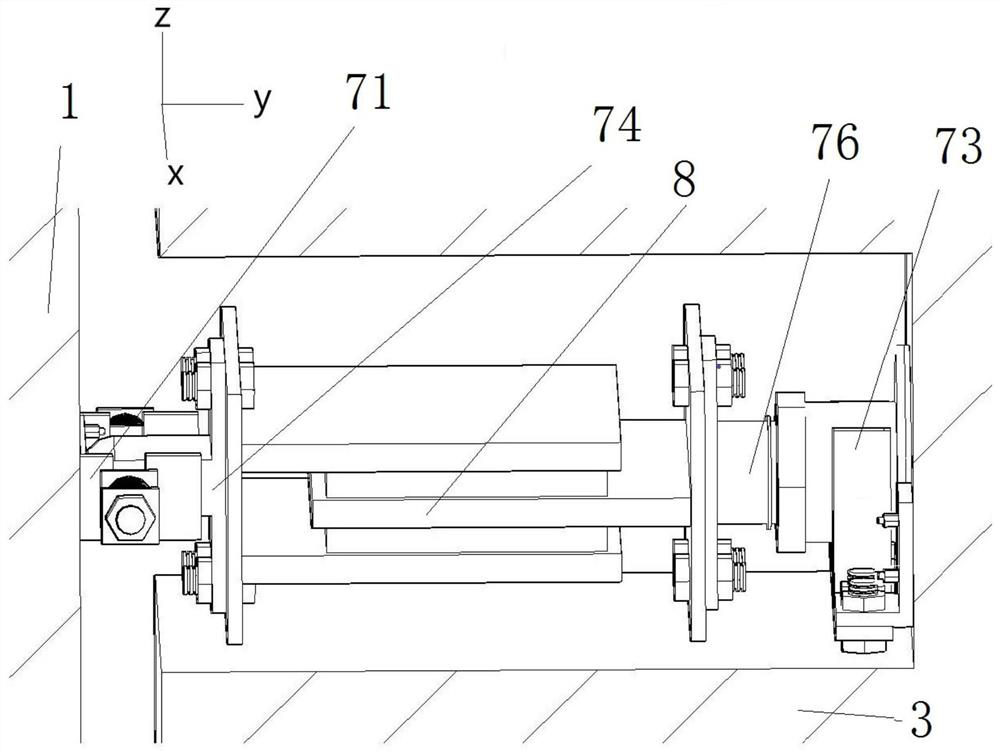

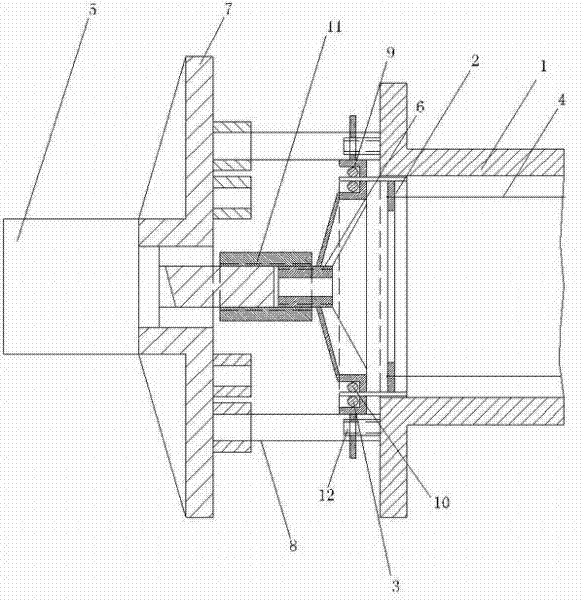

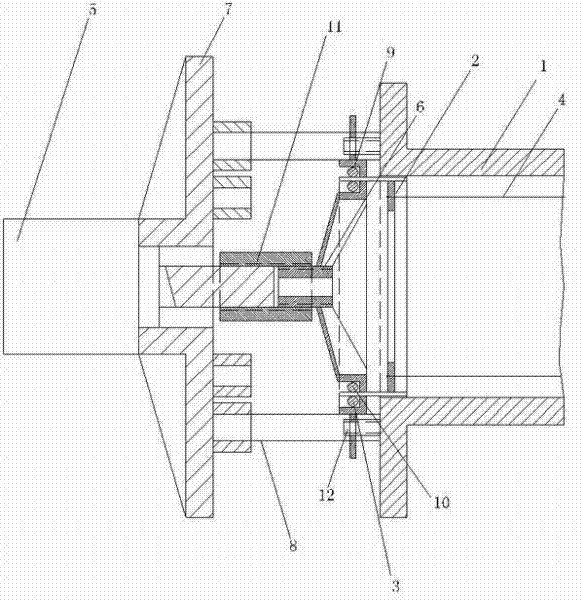

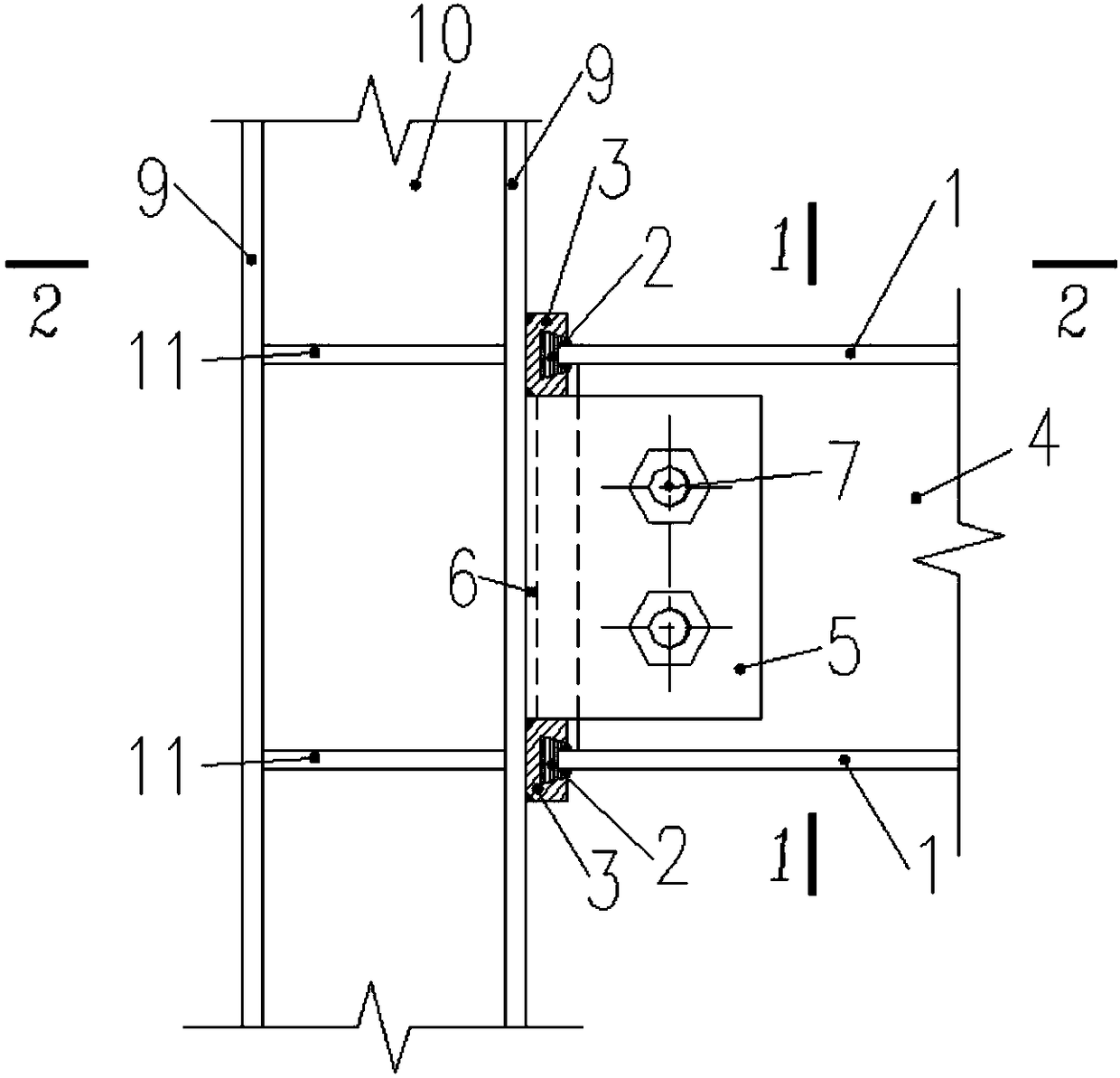

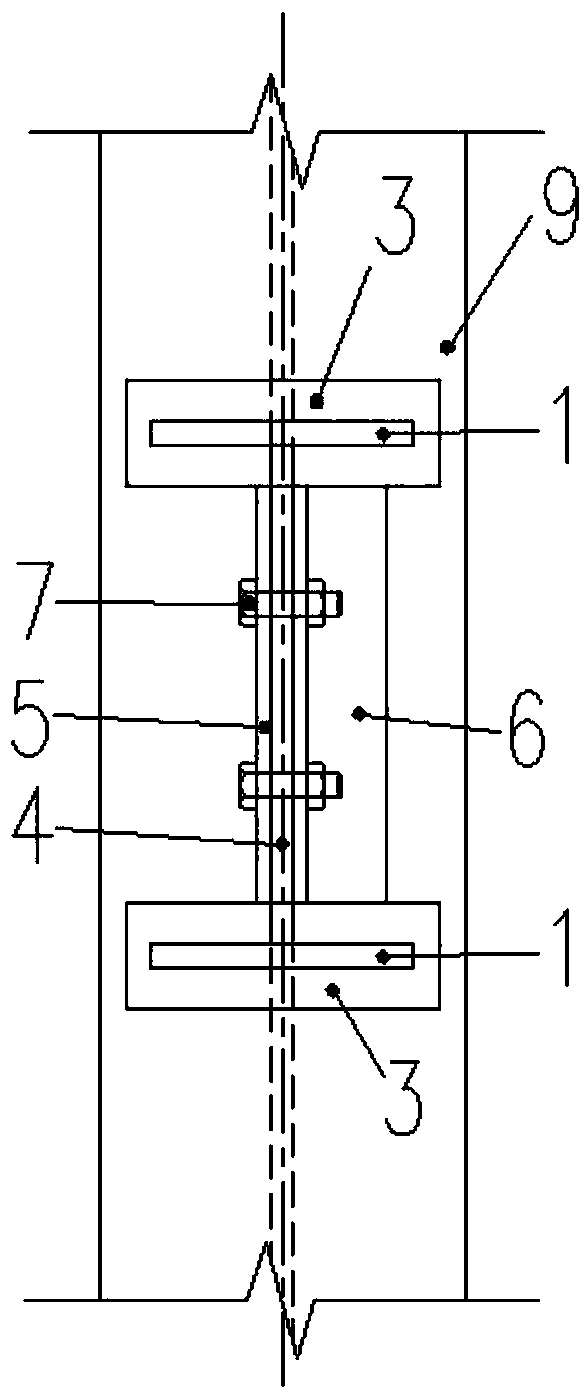

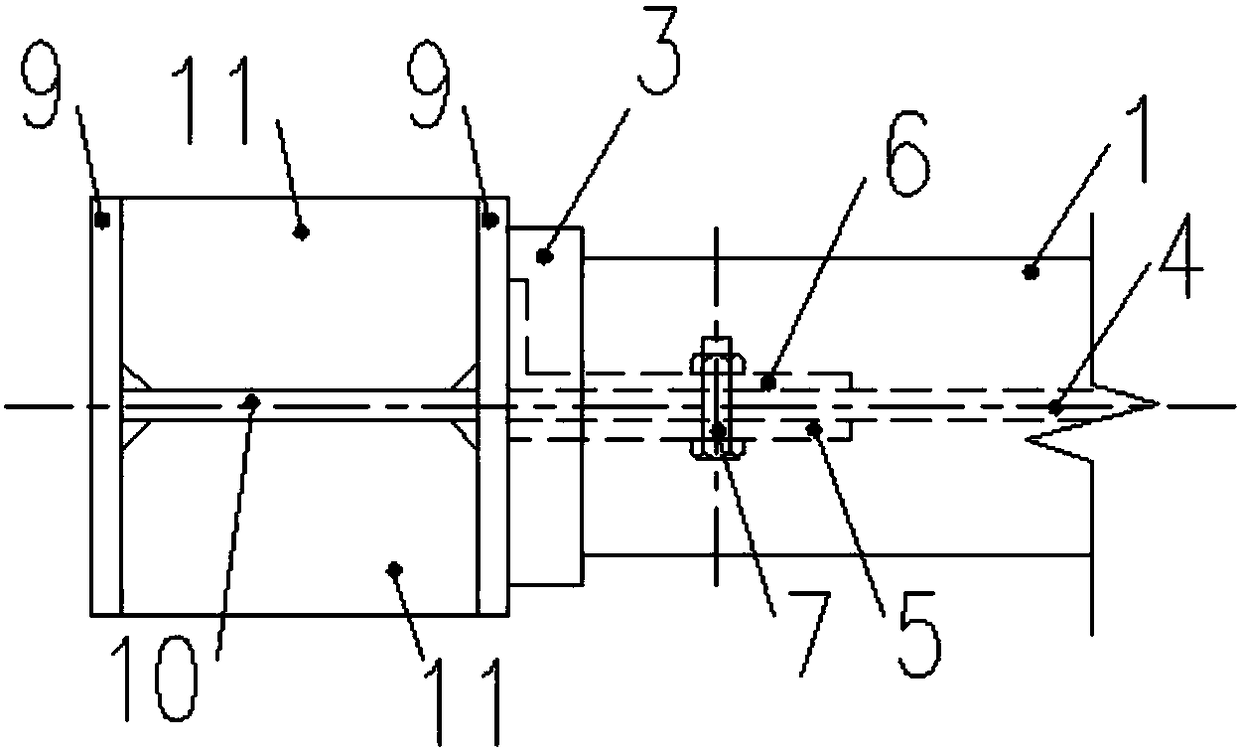

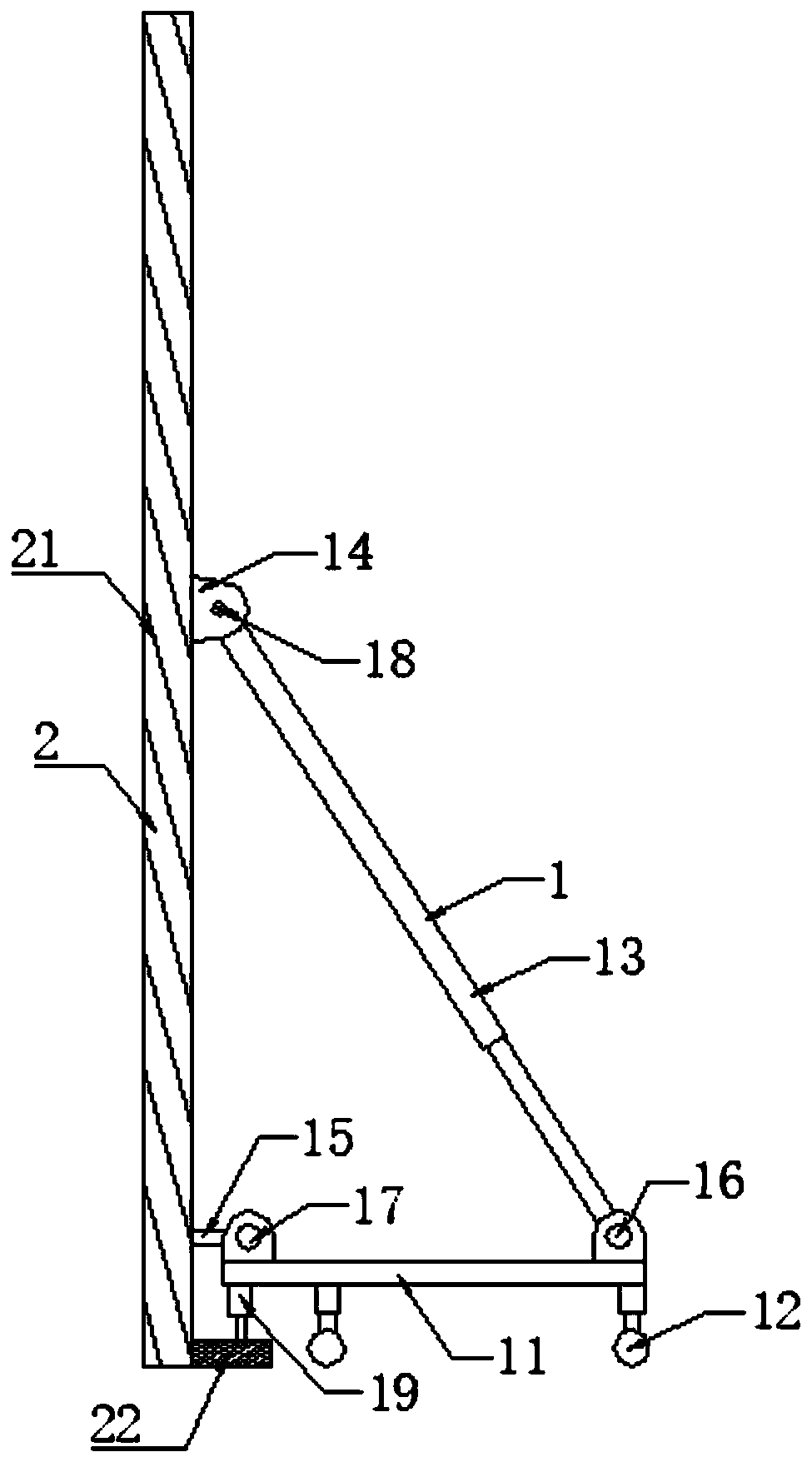

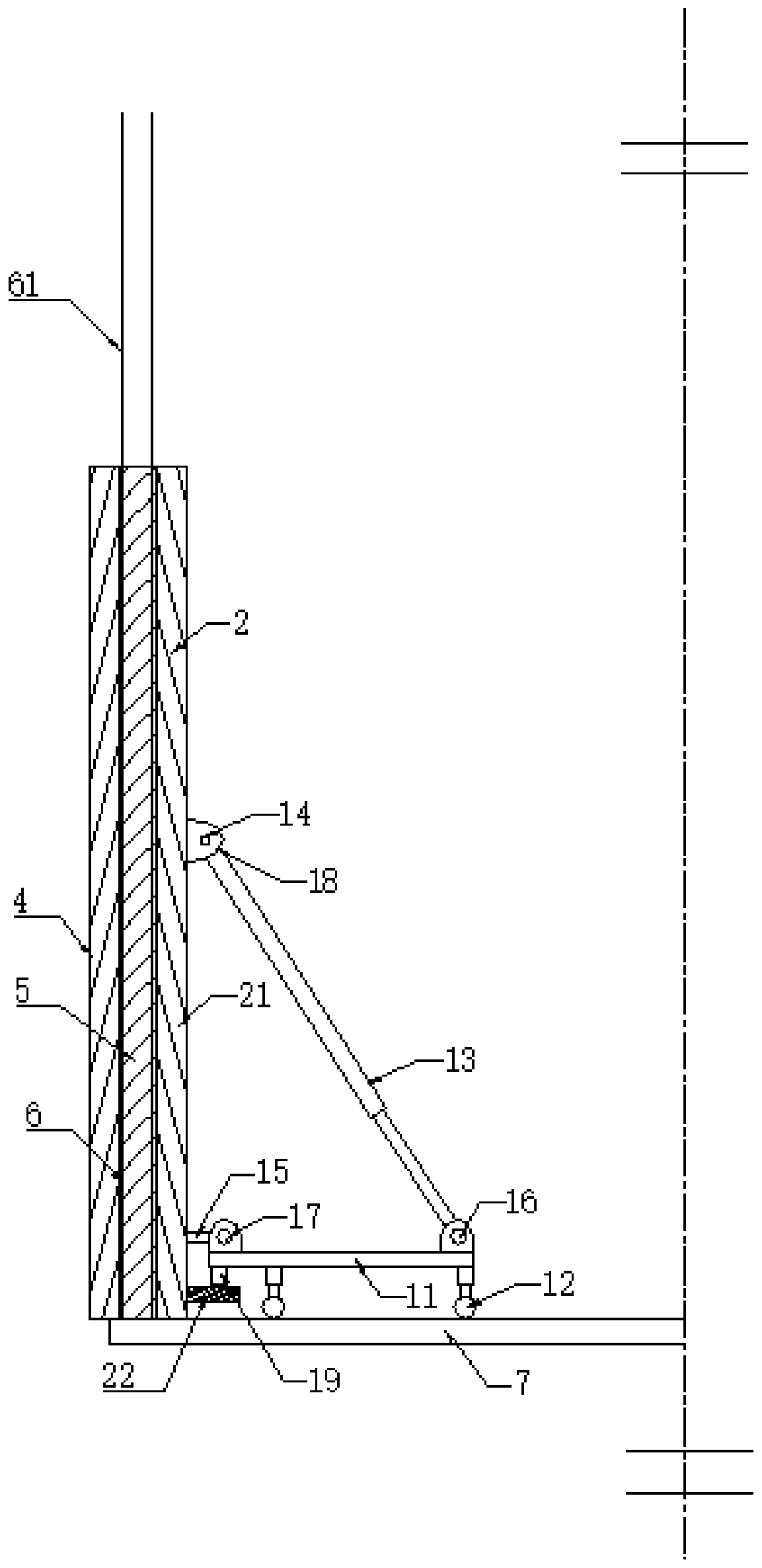

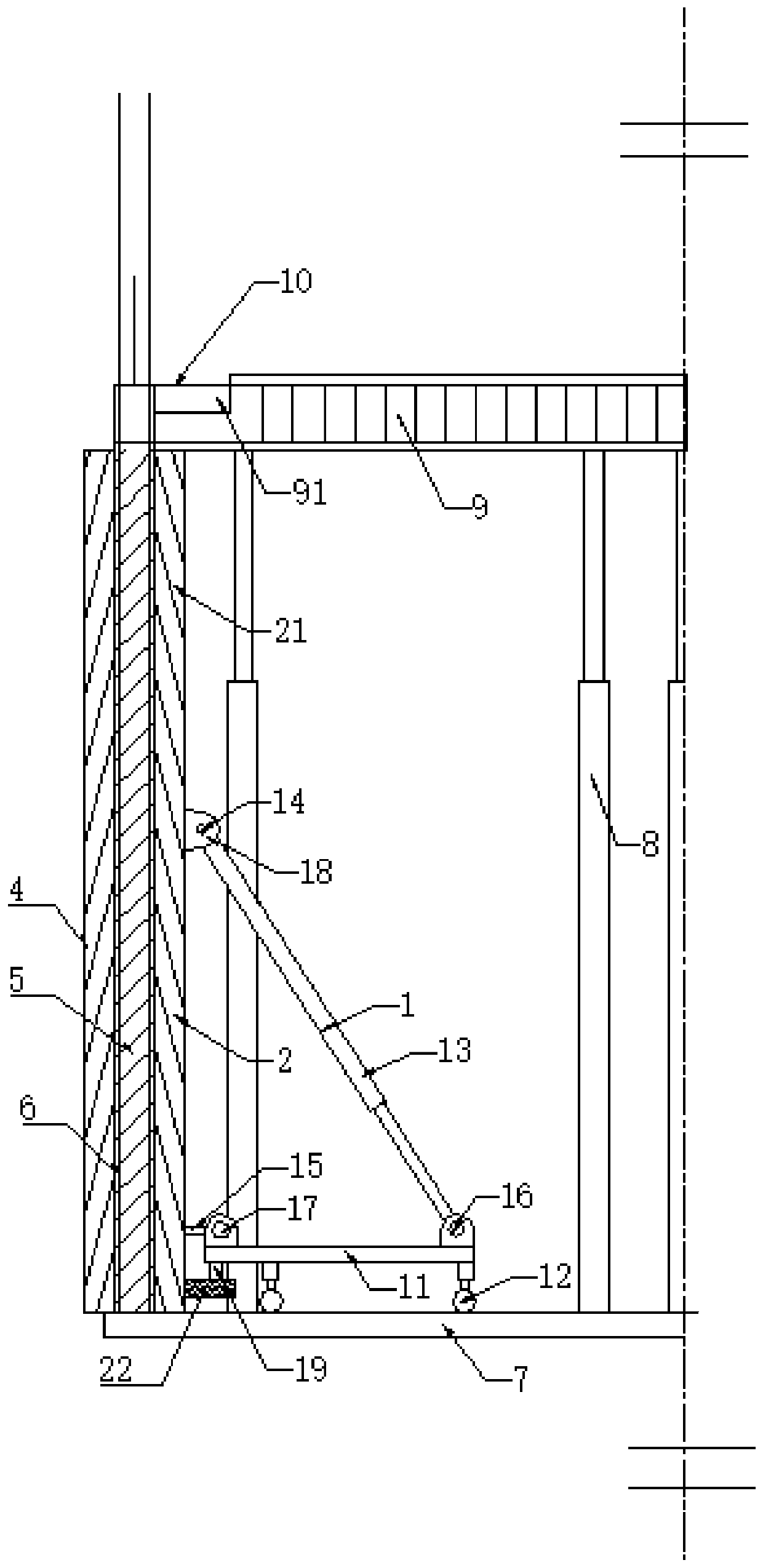

Tensioning device and method for applying prestressing force on high bending moment prestressed concrete electric pole

The invention discloses a tensioning device and method for applying a prestressing force to a high bending moment prestressed concrete electric pole. A pull shaft of a jack is connected with a tensioning claw by virtue of a tensioning nut in a screwing way, the claw hook of the tensioning claw is inserted into a steel plate coil to hook an inner arc rib, a steel bar anchored on the steel plate coil is tensioned, and the tension stress of prestressed steel is maintained by adopting an external fixation method that an adjusting screw rod of a fixed disk is screwed down to be against the end part of a steel mould. The invention has the technical effects that: the tensioning claw is adopted to hook the inner arc rib in the steel plate coil, thus tensioning is realized; the moment arm between the tensioning claw and the prestressed steel is small, thus the produced bending moment is low; and the steel plate coil does not deform under a tensile force of large tonnage, and the tensioning nutis adopted to connect the tensioning claw and the pull shaft of the jack in the screwing way, thus the technical problem that a bolt can not bear a shear force of large tonnage when the original boltis used for fixing is solved. The screw rod of the fixed disk is adopted for carrying out external fixation, thus the process is simple and convenient. The supporting lug of a supporting frame is of movable type, thus being applicable to production of various high bending moment electric holes in different specifications.

Owner:CHANGSHA SHENGFENG POLE MFG

Mortise and tenon joint and bolt hybrid assembling type steel structure beam-column joint

PendingCN108517962ARealize a rigid connectionReasonable node structureBuilding constructionsMortise and tenonEmbedment

The invention relates to a mortise and tenon joint and bolt hybrid assembling type steel structure beam-column joint which comprises a steel structure beam, a steel structure column and a beam-columnjoint body. The steel structure beam and the steel structure column are connected together through the beam-column joint. The beam-column joint comprises an embedment mortise arranged at the flange end of the beam, an embedment groove body fixedly formed in the surface of the steel structure column, a web connecting plate and an additional connecting plate. The embedment mortise and the embedmentgroove body are in mortise and tenon joint connection. The web connecting plate, a beam web and the additional connecting plate are fixedly connected together through bolts. The beam-column joint is reasonable in structure, definite in force transmission, simple in installation process, safe, reliable, free of welding on site, free of damage to paint coatings, free for paint supplementing on site,high in speed and capable of saving materials and labor cost, the beam-column rigid connection is realized, and the construction period can be shortened by 15-25% compared with a site welding steel structure beam-column joint; no outward-extending cantilever beam sections are arranged on the column, loading and transporting are facilitated, the transport cost can be reduced by 20-30%; the construction cost is lower after standardized production is adopted.

Owner:王士奇

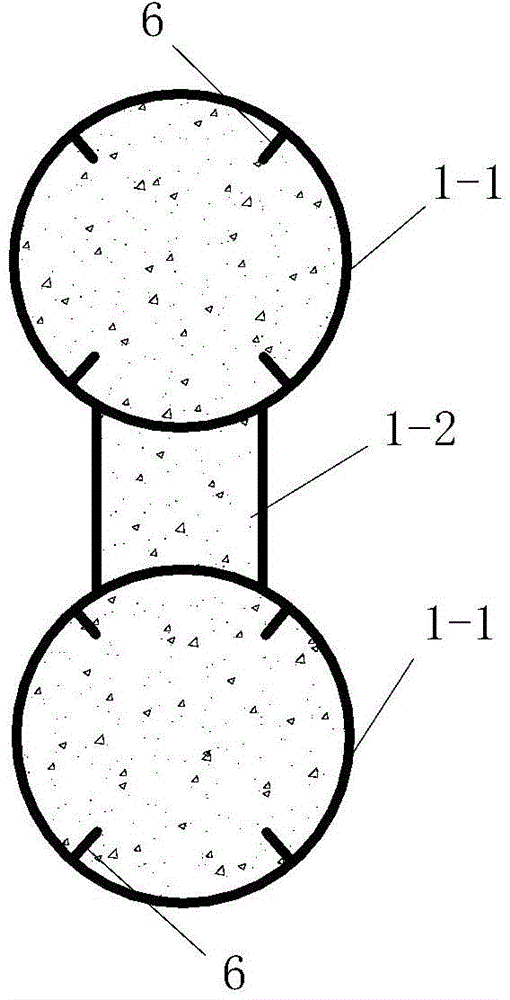

Assembling light steel pipe-constraint small-diameter wood combined bearing column and manufacturing method

The invention discloses an assembling light steel pipe-constraint small-diameter wood combined bearing column and a manufacturing method and belongs to the technical field of structural engineering. The assembling light steel pipe-constraint small-diameter wood combined bearing column is suitable for the development of low multilayer assembling type buildings in towns. An external assembling template is formed after the concrete is poured onto the light steel pipes and embedded connecting reinforcements, the bearing capacity of small-diameter wood under the enclosure constraint of FRP carbon fiber sheets is greatly increased, the bearing capacity of the column structure can be increased by 30%, and meanwhile, the assembling construction is simple and the small-diameter wood is effectively utilized and developed so that the green environmental protection and low carbon are realized.

Owner:BEIJING UNIV OF TECH

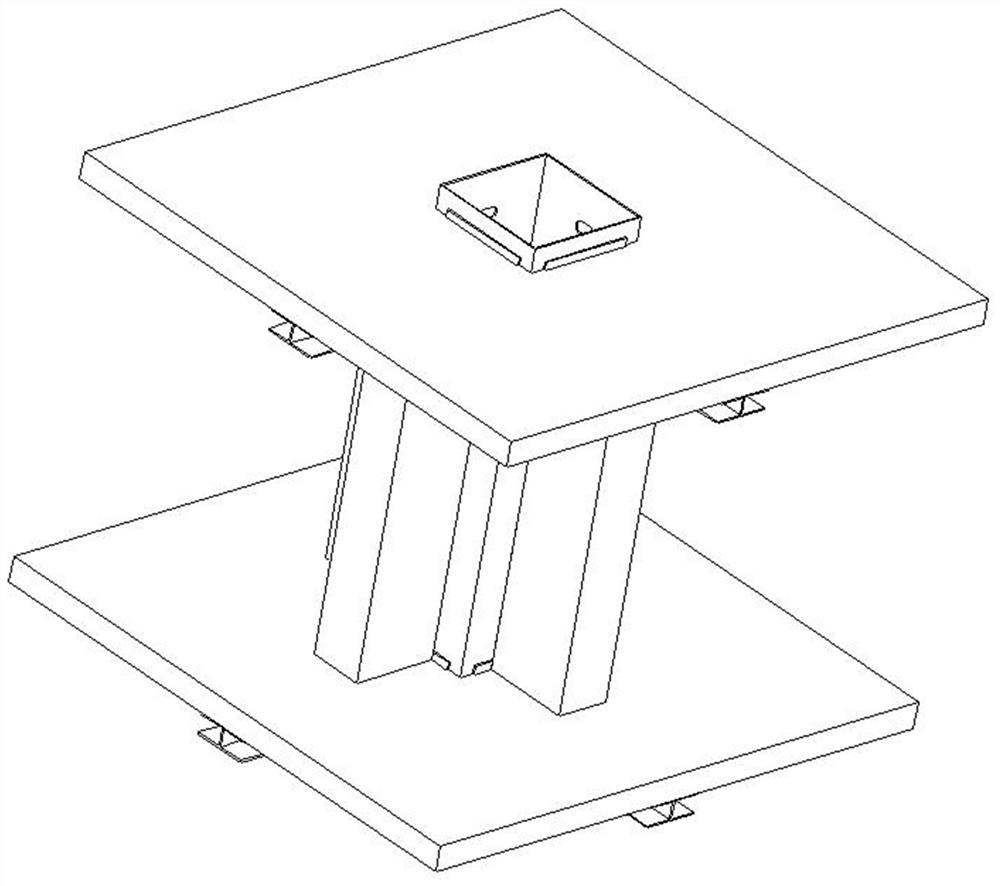

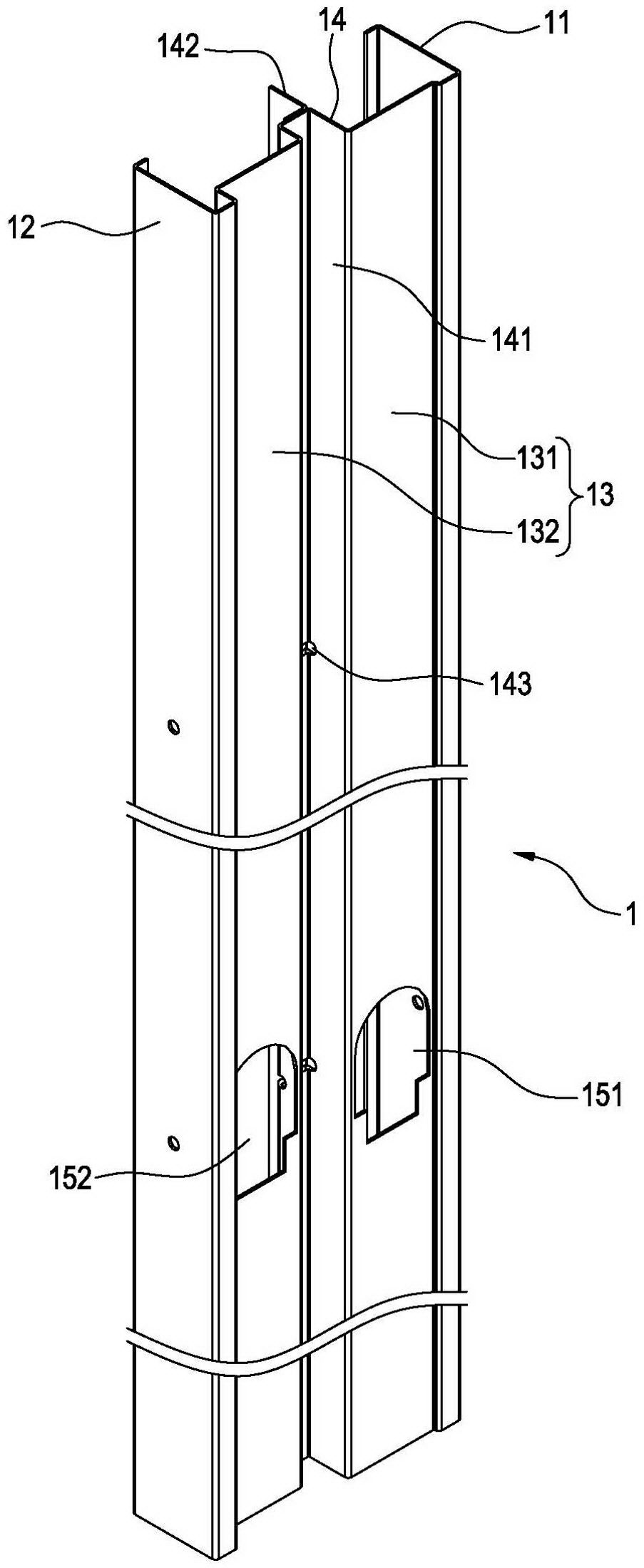

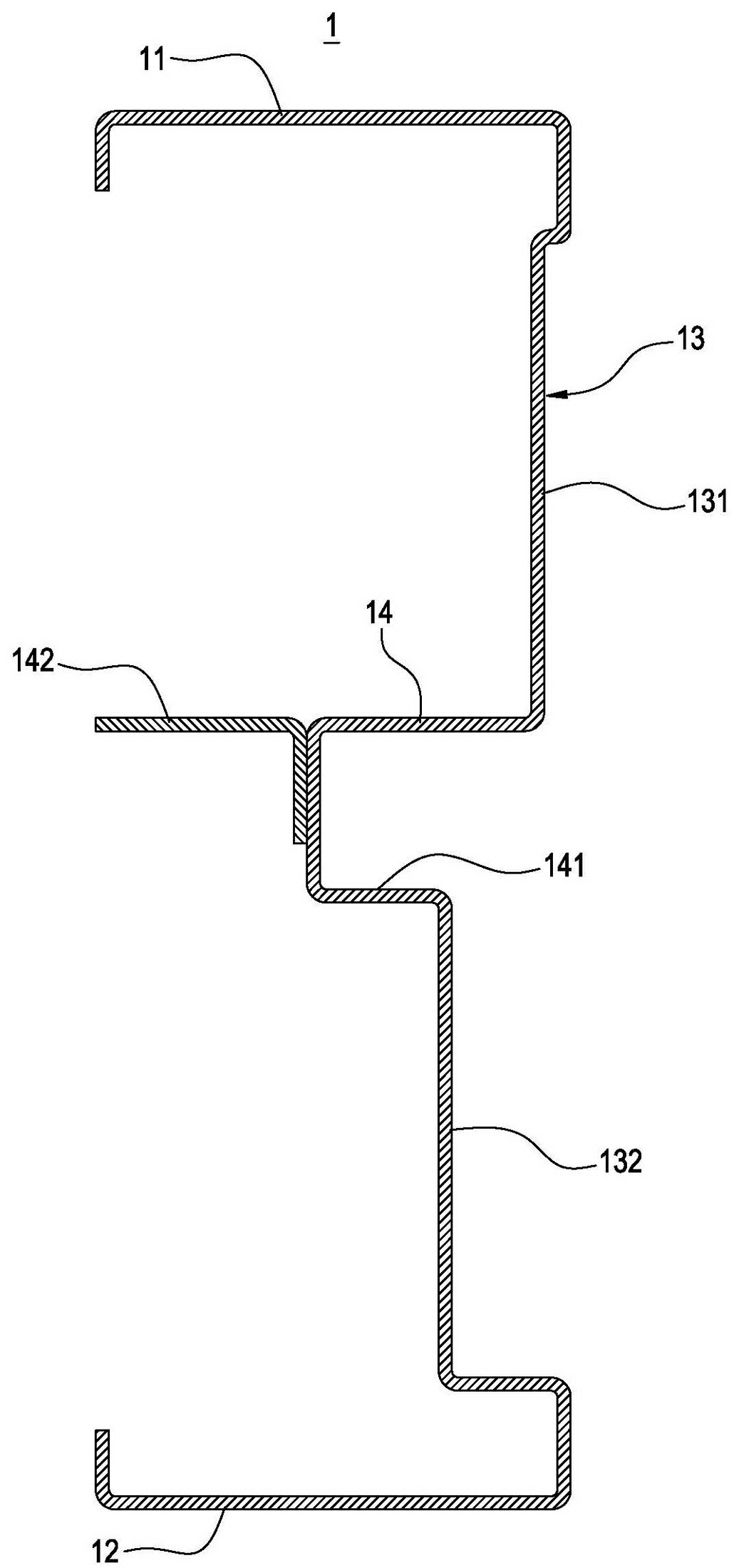

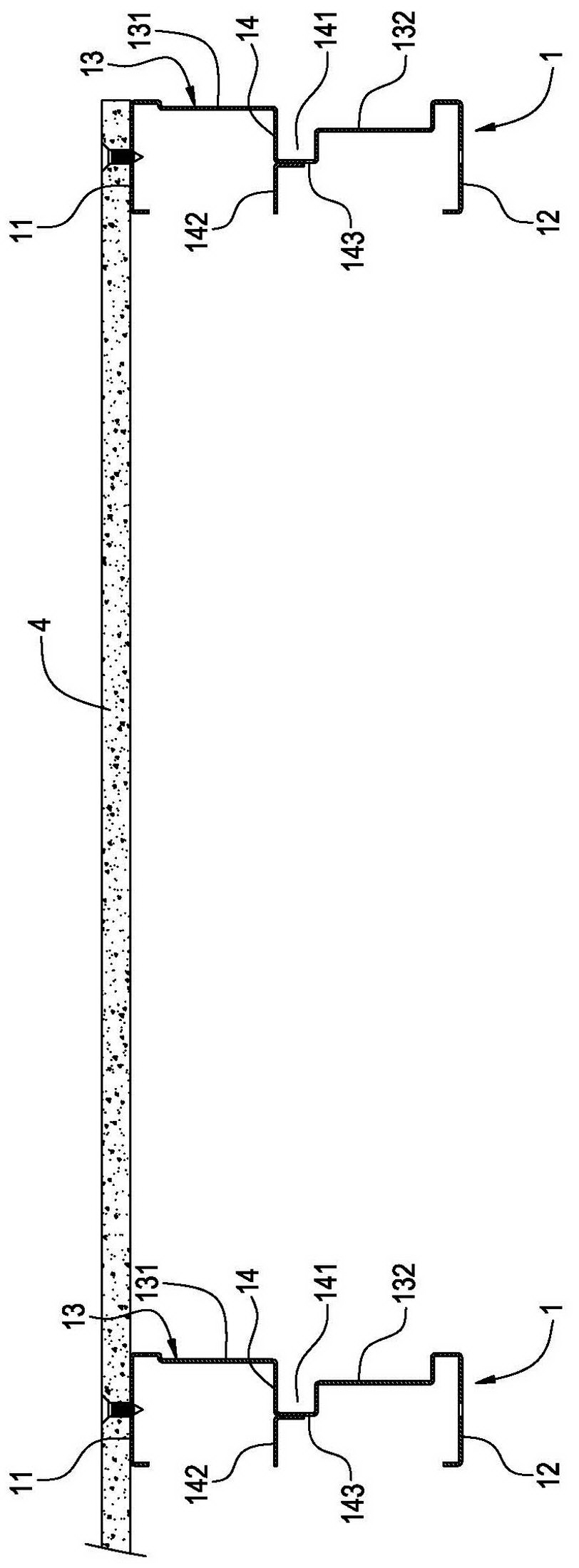

Steel structure platform frame units and assembled and constructed steel structure platform

Disclosed are steel structure platform frame units and an assembled and constructed steel structure platform. Each steel structure platform frame unit is constructed by assembling of column bases, vertical columns, main bearing beams, auxiliary bearing beams, a platform face plate and pulling bearing guardrails. The multiple steel structure platform frame units are assembled, leveled and fixed on site to form the steel structure platform. The invention relates to urban road traffic. By utilizing the steel structure platform, traffic congestion is relieved; the solution is worked out according to the fact that in recent years, whole line traffic congestion caused by street markets and street parks; roads, squares and parks in a city are changed from ground single-layer plane operation into a three-dimensional mode of two layers or multiple layers of a steel structure to be complementary with original traffic facilities, so that a complete traffic system is formed; and overpass bridge building and land acquisition are not needed, the construction cost is low, the influence on the environment is low, and the problems of driving and parking difficulties are solved effectively. According to the steel structure platform frame units and the assembled and constructed steel structure platform, industrialized production is achieved, expanding mounting and dismantling can be conducted at any time, and the steel structure platform frame units and the assembled and constructed steel structure platform are a good method for solving traffic congestion.

Owner:王圣玉

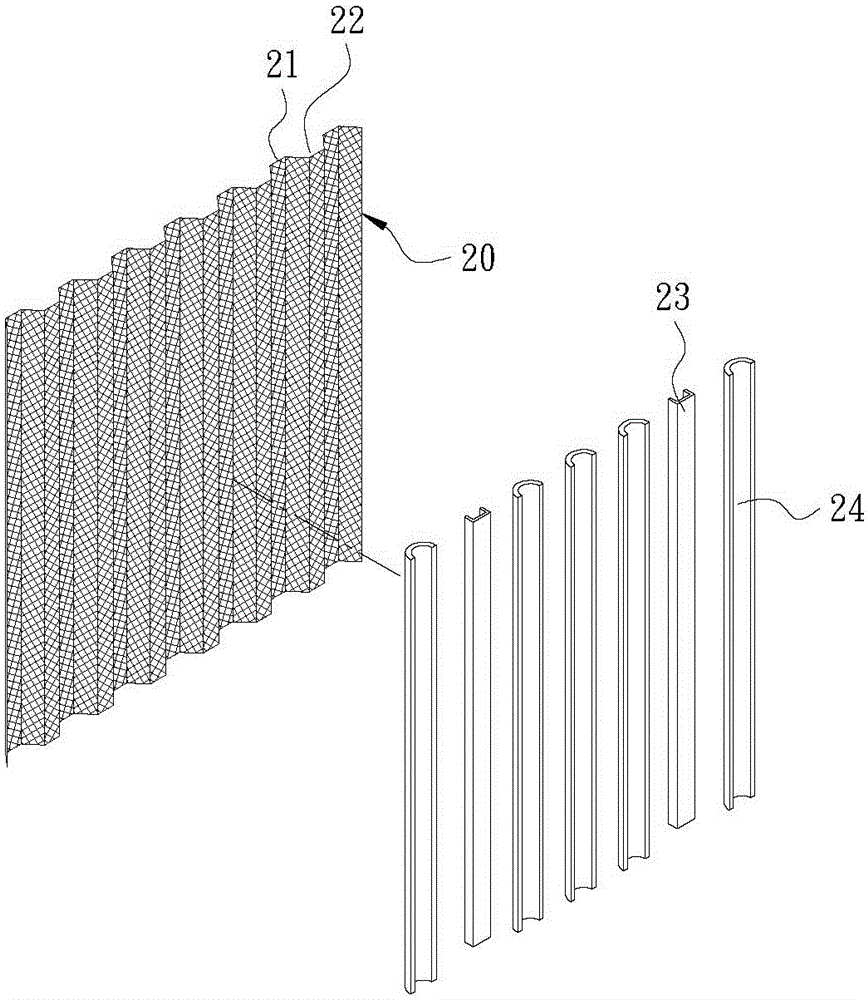

Integrated curtain wall and construction method of thermal-insulating wall system

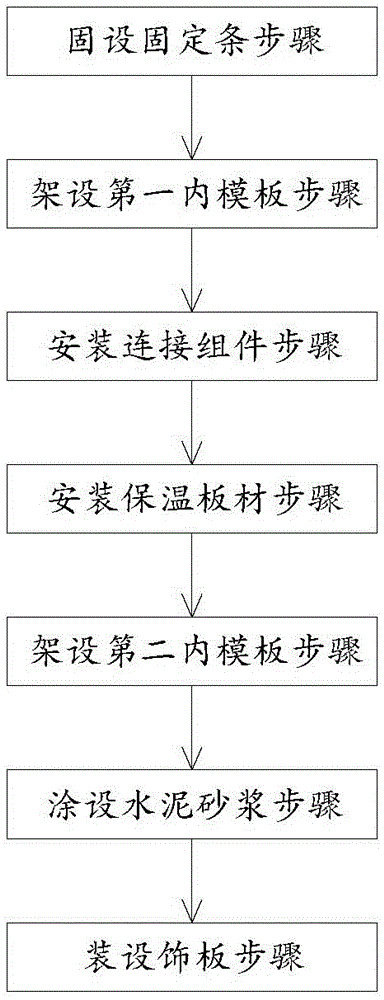

InactiveCN106468081AEasy to assembleShort construction periodWallsBuilding material handlingThermal insulationWave shape

The invention discloses an integrated curtain wall and a construction method of a thermal-insulating wall system. The method comprises following steps: fixedly arranging fixing strips, erecting a first inner template, installing connection assemblies, installing thermal insulation plates, erecting a second inner template, coating cement mortar and decorating plaques. Wave-shaped metal screen plates are utilized to form a first inner template and a second inner template. A thermal insulation plate and multiple thermal insulation pipes are clamped between the first inner template and the second inner template. The cement mortar is coated outside the metal screen plates through a mortar spraying or smearing mode so that a thermal insulation wall with a hollow inner template is formed. Multiple connection assemblies are arranged on one side of the thermal insulation wall in an outwardly extending mode. The connection assemblies are connected fixedly with the multiple plaques so that the integrated thermal insulation wall and a curtain wall are formed. The integrated curtain wall and construction method of the thermal-insulating wall system have following beneficial effects: advantages such as thermal insulation, energy conservation, flame resistance, heat insulation, sound insulation, and water prevention are obtained; and the method is simple in formation, quick in construction, and is capable of shortening a construction period and protecting the environment.

Owner:庄继昌

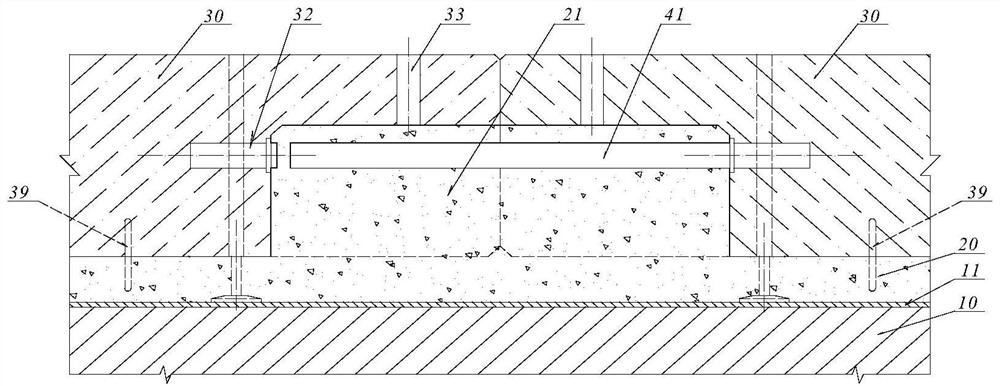

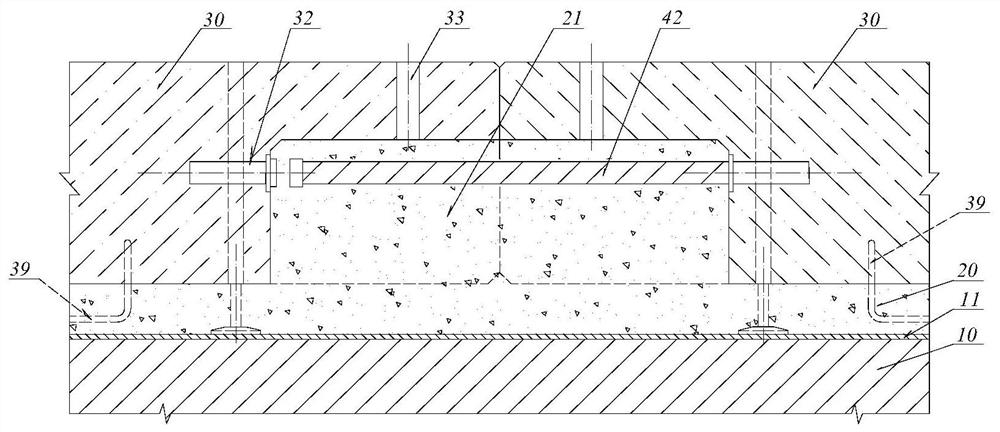

Shear wall construction process based on fully prefabricated floor slab

ActiveCN110984427AReduce difficultyEasy assembly and constructionWallsForms/shuttering/falseworksSupporting systemFloor slab

The invention discloses a shear wall construction process based on a fully prefabricated floor slab. The shear wall construction process comprises the following steps: (1) binding shear wall steel bars at the bottom layer after the construction of a standard layer is finished; (2) respectively installing a shear wall inner template and a shear wall outer template on two sides of the shear wall steel bars; (3) pouring concrete; (4) installing a supporting system of the prefabricated floor slab; (5) hoisting the prefabricated floor slab close to one end of a shear wall to serve as a constructionplatform; (6) dismantling the shear wall inner template and the shear wall outer template to lift the shear wall inner template and the shear wall outer template to the construction platform; (7) hoisting prefabricated floor slabs which are not installed in the step (5); (8) binding shear wall steel bars, beam steel bars, column steel bars and floor steel bars on the upper layer; (9) respectivelyinstalling a shear wall inner template and a shear wall outer template on two sides of the shear wall steel bars; (10) pouring concrete; and (11) repeating the steps (4) to (10) to finish the shear wall construction layer by layer. The process can reduce the difficulty of cross-layer transportation of a shear wall template system and reduce the construction cost.

Owner:CCCC FIRST HARBOR ENG +1

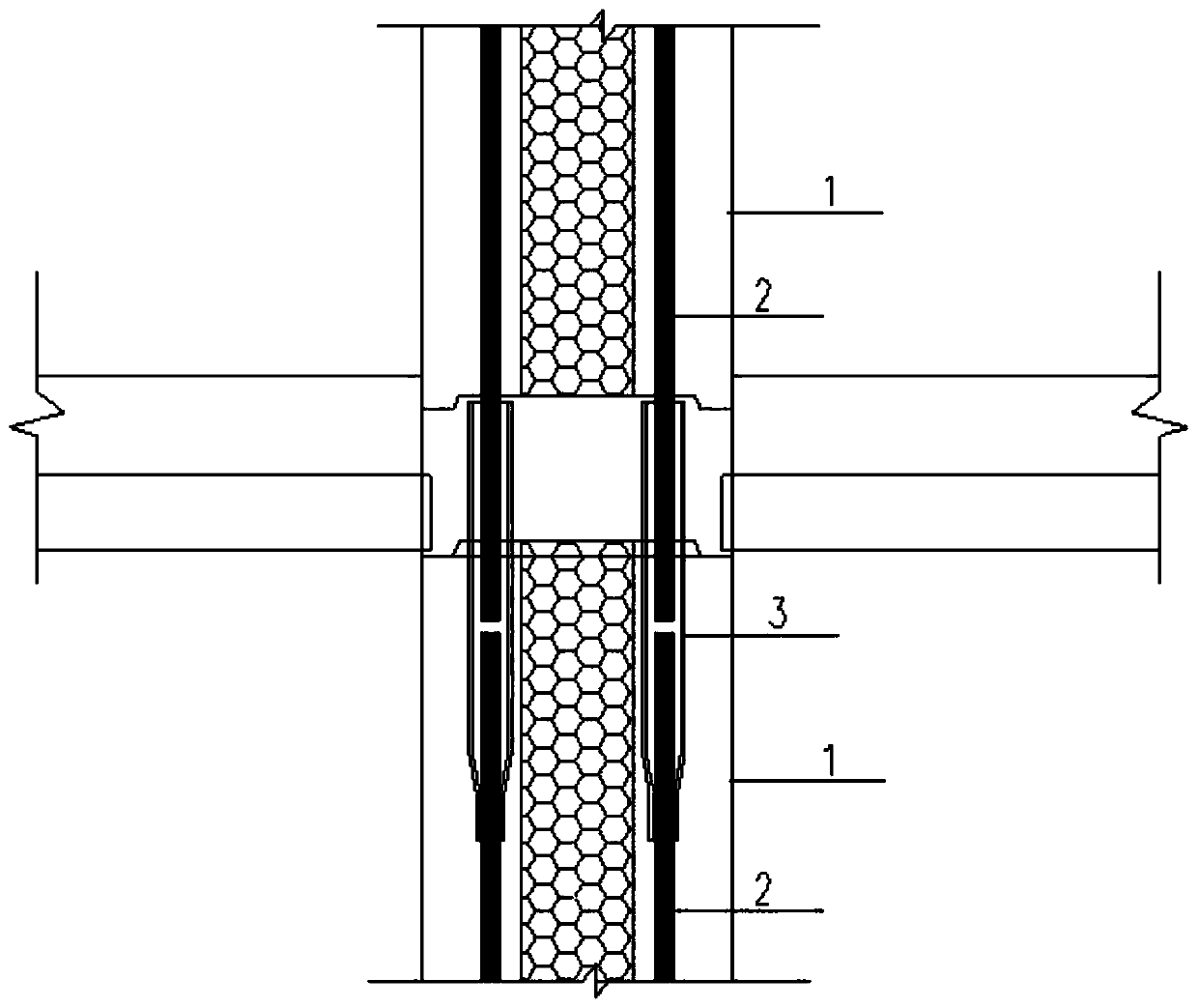

Construction method for connecting wallboards by reversely inserting single-end cold rolling head grouting sleeve

PendingCN110656713AMeet the connection requirements of prefabricated building structuresEasy assembly and constructionWallsBuilding reinforcementsConstruction engineeringSlurry

The invention discloses a construction method for connecting wallboards by reversely inserting a single-end cold rolling head grouting sleeve. The construction method changes a traditional wallboard connecting construction method. The method comprises the steps of firstly respectively cold rolling a single-end cold rolling head at the bottom end of a grouting sleeve on a stressed rib at the upperend part of a plane truss of a lower wallboard by adopting a hydraulic machine, respectively installing an upper wallboard in place, then grouting the grouting sleeve with ready-mixed slurry from theupper opening of the grouting sleeve into the sleeve, inserting the stressed connecting rib head exposed and extending out of the bottom of the upper wallboard into the grouting sleeve after the grouting is full, and correcting the fixed position of the upper wallboard until the bottom of the upper wallboard is placed at the upper opening of the grouting sleeve at the top of the lower wallboard. According to the method, the grouting sleeve is prefabricated in the lower wallboard and fixed on the stressed steel bar head at the top of the plane truss by cold rolling to ensure that the stressed steel bars at the upper layer and the lower layer are communicated and reliable through the stress connection of the grouting sleeve, and the connection requirement of an assembled building structure is met; the method is convenient to assemble and construct, and the quality is visual and reliable.

Owner:南通联泷装配式建筑科技有限公司

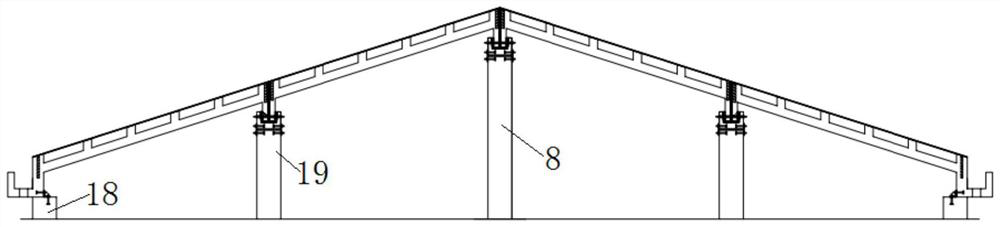

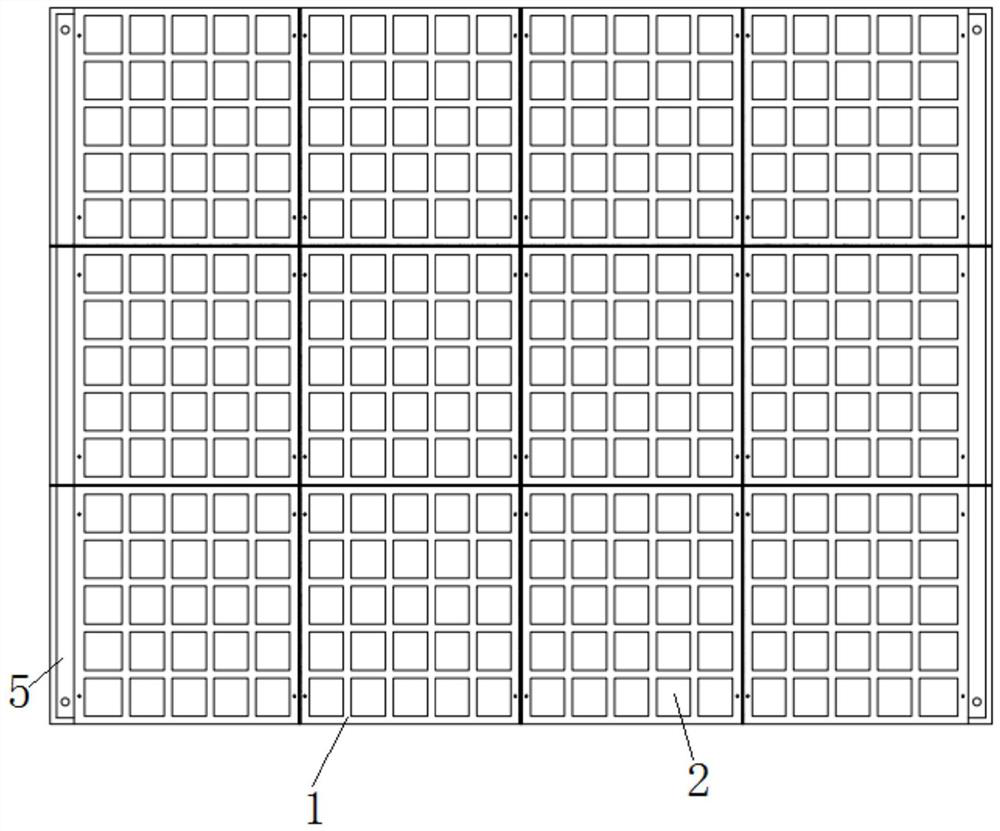

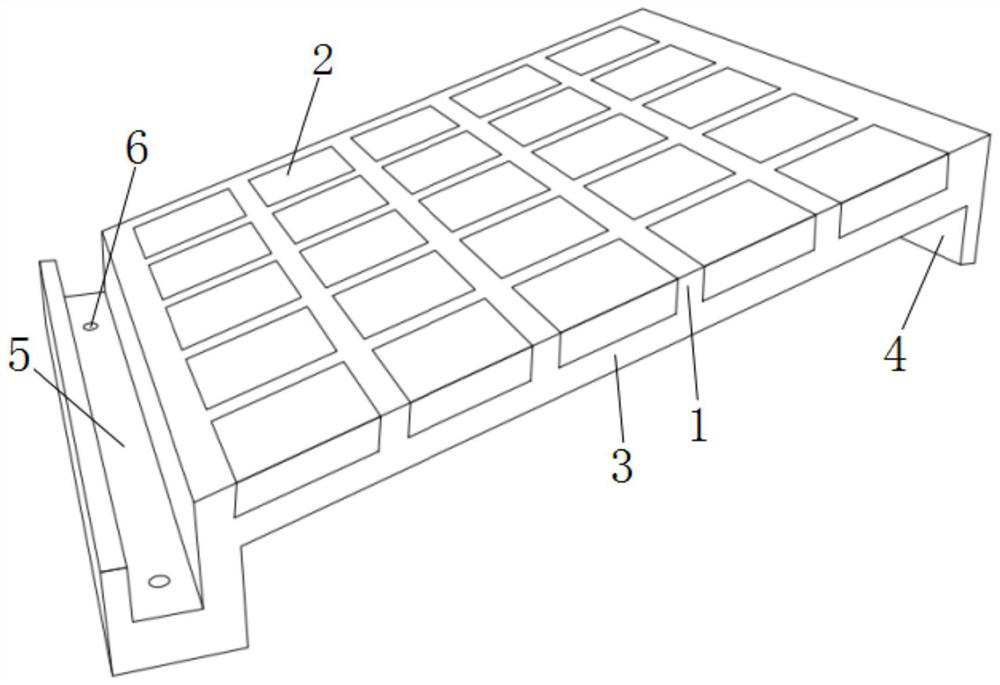

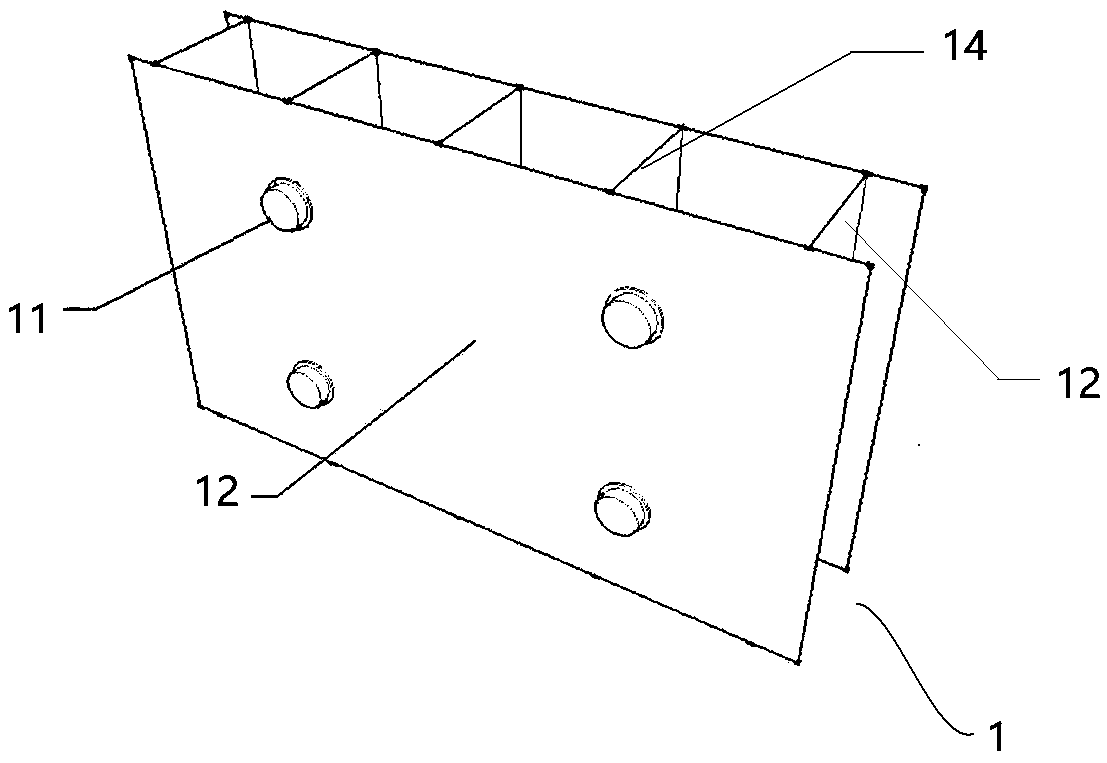

Fabricated pitched roof structure and construction method thereof

PendingCN113293907ASimple structureEasy assembly and constructionBuilding roofsRoof coveringShaped beamButt joint

The invention discloses a fabricated pitched roof structure and a construction method thereof. The fabricated pitched roof structure comprises two pitched roof bodies, and the top ends of the two pitched roof bodies are in butt joint to form a ridge; L-shaped beams are arranged at the upper end and the lower end of the pitched roof bodies correspondingly, the upper ends of the L-shaped beams are fixed to the ends of the pitched roof bodies, and the lower ends of the L-shaped beams vertically extend to be fixedly connected with stand columns, wherein the L-shaped beams at the top ends of the two pitched roof bodies are spliced to form a ridge beam, and the lower end of the ridge beam is fixedly connected with a first stand column through a prefabricated groove beam; the L-shaped beams at the lower ends of the pitched roof bodies are fixedly connected with a second stand column. According to the fabricated pitched roof structure, the L-shaped beams are arranged at the two ends of the pitched roof bodies, the L-shaped beams at the two ends of the two pitched roof bodies with the tops in butt joint are spliced to form the ridge beam, the ridge beam is fixed to the stand columns through the prefabricated groove beam, and the L-shaped beam at the lower end is fixedly connected with the stand column; block prefabricated structural members are adopted, the requirement for factory prefabrication is met, construction efficiency is high, on-site formwork erecting is not needed, energy is saved, environment friendliness is achieved, and structural integrity is good.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

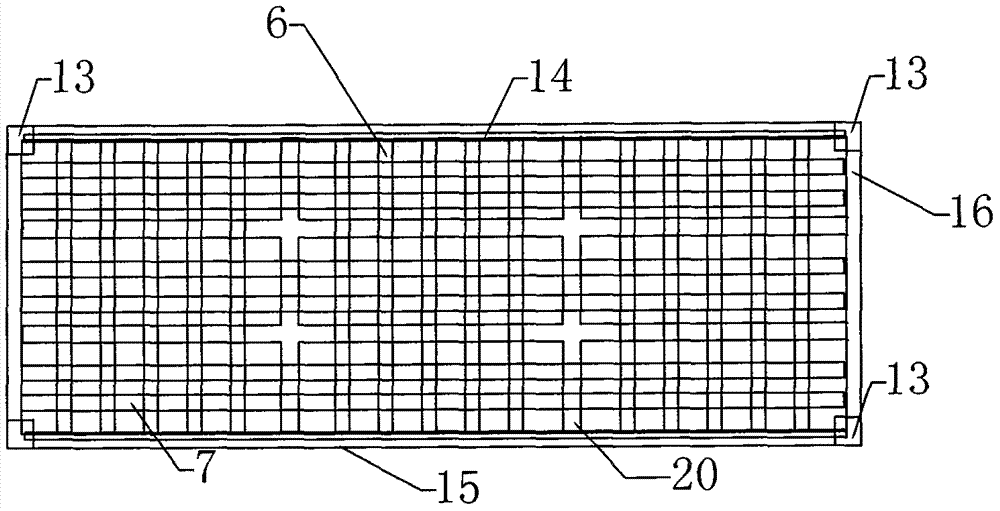

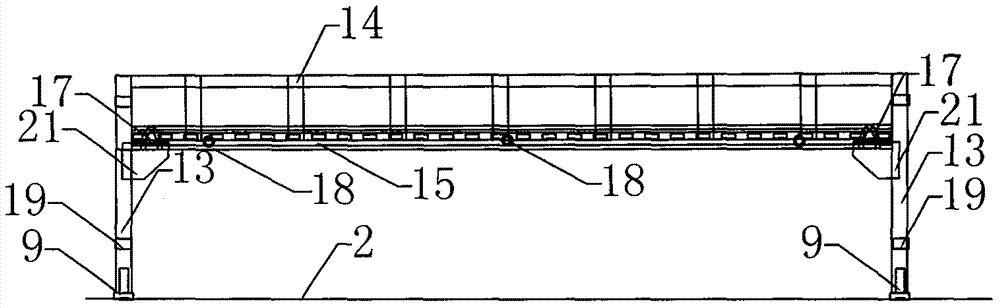

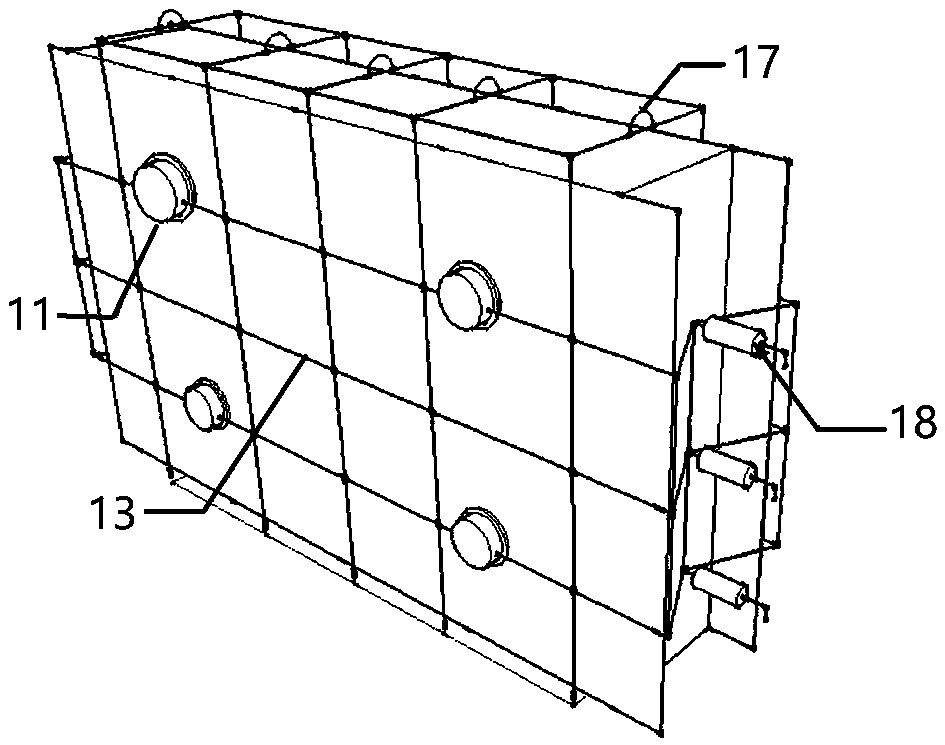

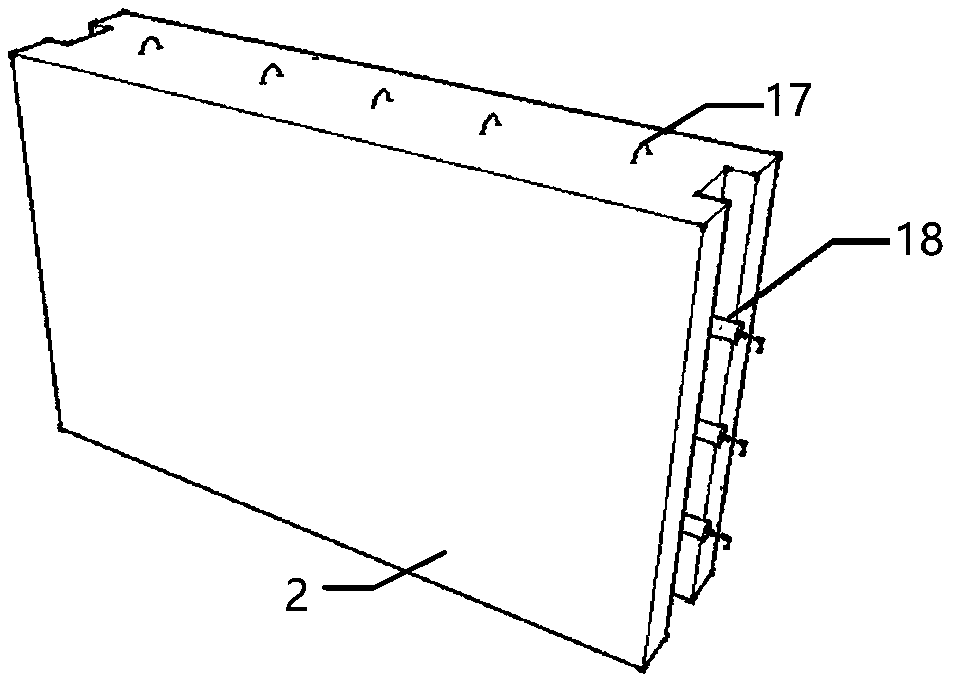

Prefabricated filling wall system with hollow thermal insulation structure and construction method thereof

The invention discloses a prefabricated filling wall system with a hollow thermal insulation structure and a construction method thereof. The prefabricated filling wall comprises a hollow cavity box structure and a concrete shell layer, wherein the concrete shell layer is poured on the outer side surface of the hollow cavity box structure. The hollow cavity box structure comprises cushion blocks,a steel bar mesh frame, a hollow box body and partition boards, wherein the hollow box body is formed by surrounding of box wall plates; and the partition boards are arranged in a hollow box body in parallel and at intervals. At least four cushion blocks are arranged on the front and rear box wall plates of the hollow box body. The steel bar mesh frame is formed by tie tying of a transverse steelbar and a vertical steel bar, and is laid on the hollow box body. Holes are arranged on the cushion blocks, wherein the transverse steel bar can penetrate through the hoes. A groove is formed by the left and right side box wall plates of the hollow box body and the front and rear side box wall plates of the hollow box body. The prefabricated filling wall has simple structure, convenient construction, good thermal insulation and sound insulation performance, and little influence of human factors on the construction. Flexible connection is used for effectively suppressing cracks in the filling wall.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

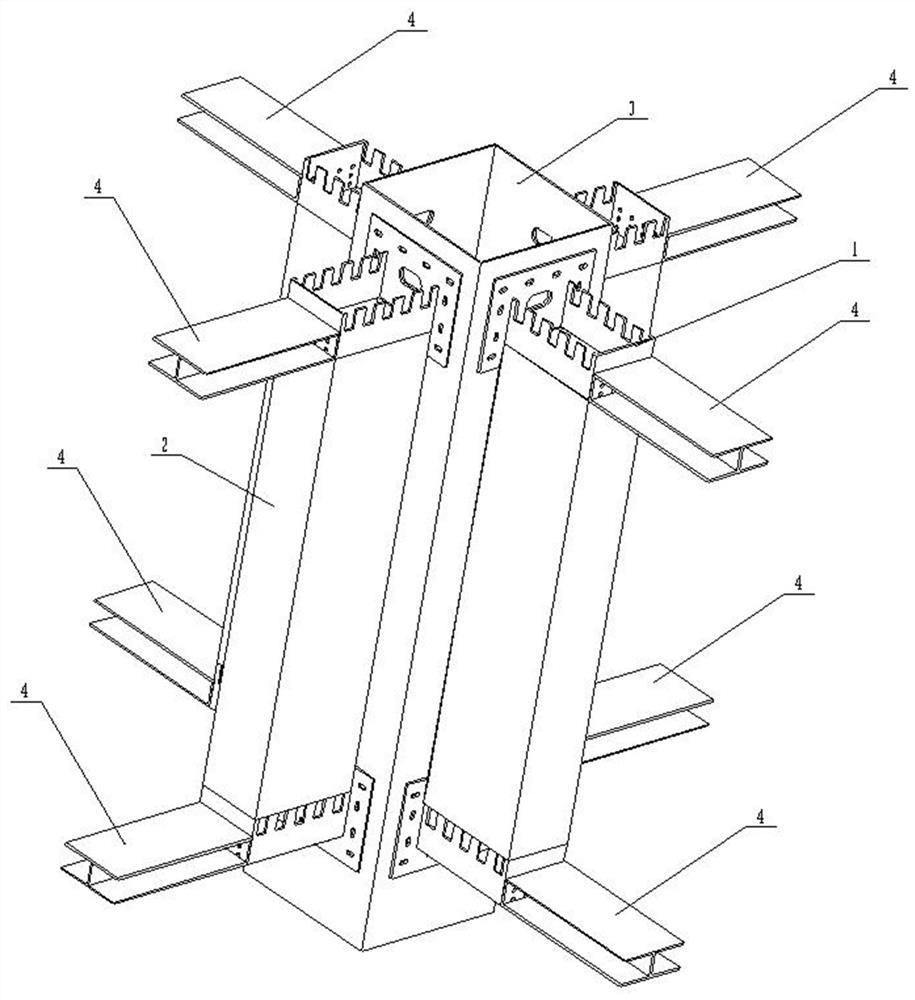

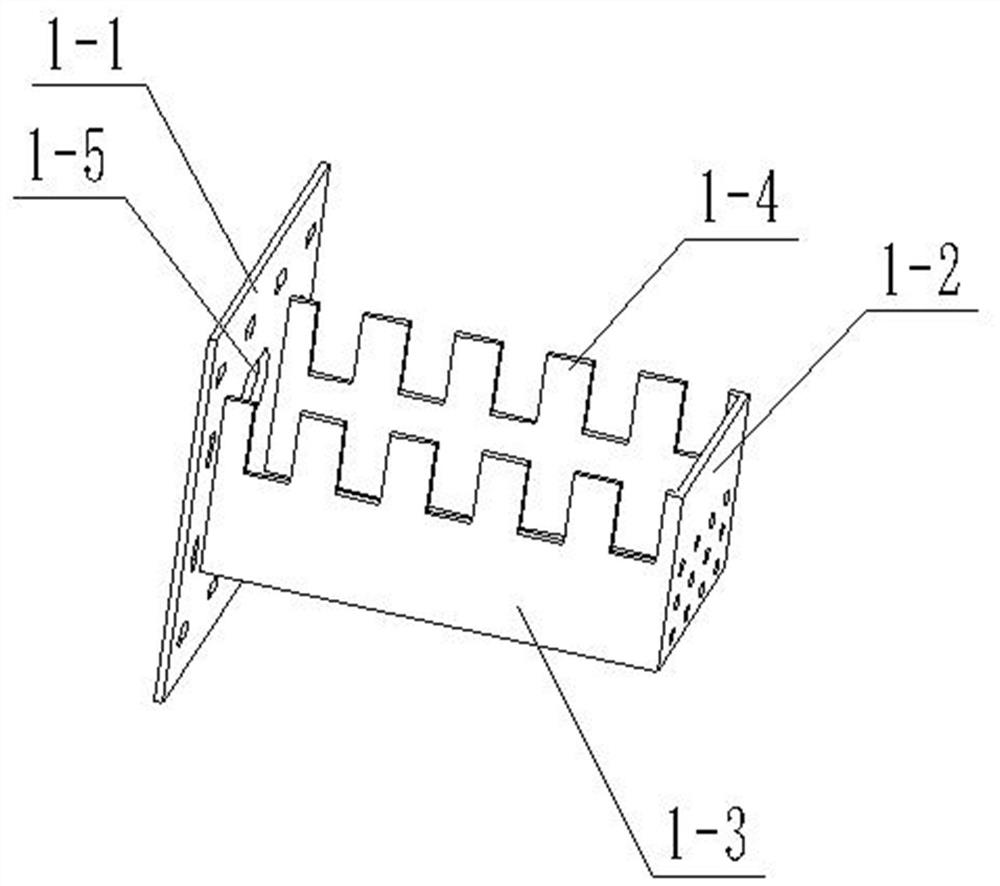

Steel and concrete shear wall mixed structure and manufacturing method thereof

ActiveCN112302209AHigh strengthImprove seismic performanceWallsForms/shuttering/falseworksUltimate tensile strengthBearing surface

The invention relates to the technical field of building tempered structures, in particular to a steel and concrete shear wall mixed structure and a manufacturing method thereof. The steel and concrete shear wall mixed structure comprises a vertically-through stand column, a plurality of beam supports are arranged on the outer edge of the stand column in the length direction at intervals, each beam support is a vertically-through steel structure body, a fixing plate, a connecting plate and a side sealing plate are arranged on the side face of each steel structure body, the fixing plate is fixedly connected with the stand column, and the connecting plate is fixedly connected with a connecting plate at the end of a cross beam; the upper part of the side sealing plate is connected with a tooth plate; the upper edges of the fixing plate, the connecting plate and the side sealing plate form an upper bearing surface, the lower edges form a lower bearing surface, and the upper bearing surfaceand the lower bearing surface are matched with the lower end surface and the upper end surface of a cast-in-place wallboard template respectively; and the beam supports and the cast-in-place wallboard template are sequentially matched and connected. Concrete connecting layers are poured into cavities formed after the stand column, the wall body and a connecting beam are connected, and the shear wall is integrally formed through pouring, so that the overall strength of the shear wall is improved.

Owner:日照大象房屋建设有限公司

Partition and construction method thereof

InactiveCN104343200AImprove sound insulationEasy to assemble and constructCovering/liningsWallsClassical mechanicsStructural engineering

Owner:郭恒盛 +1

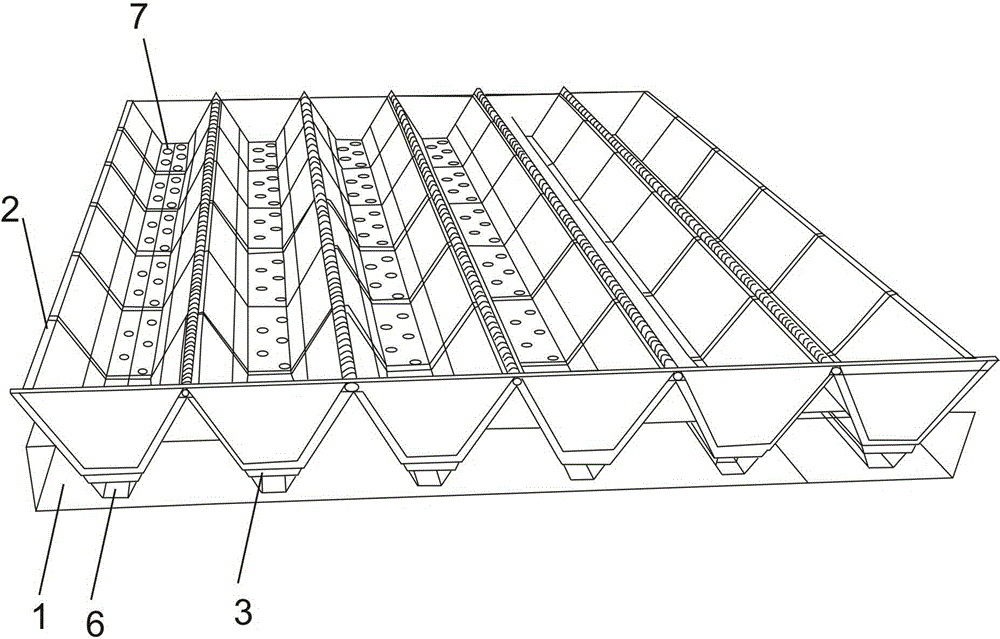

Rolling and spreading type roof greening structure and greening method thereof

ActiveCN105145165AEasy to storeEasy to transportCultivating equipmentsReceptacle cultivationIsosceles trapezoidWhole body

The invention provides a rolling and spreading type roof greening structure comprising a supporting base plate, a planting base groove and a root isolating plate, which are capable of being rolled and spread, wherein the supporting base plate consists of five base plate units and connecting units which are respectively positioned at two sides of a whole body composed of the five base plates; each base plate unit and each connecting unit are strip-shaped; the cross section of each base plate unit is in the shape of an isosceles trapezoid; the cross section of each connecting unit is in the shape of a right angle trapezoid; after right-angle sides of two connecting units are spliced, the cross section is consistent with that of each base plate unit; each base plate unit and each connecting unit are connected with each other to form a foldable whole body; and multiple vacancy grooves are formed between the five base plate units and the two connecting units. By adopting the rolling and spreading type roof greening structure and a greening method thereof provided by the invention, the problems of large occupied space and complex construction process can be solved, the structure is small in occupied space, is convenient to transport, and is convenient in assembly construction; and the roof greening construction efficiency and the greening effect are greatly improved.

Owner:CHINA THREE GORGES UNIV +2

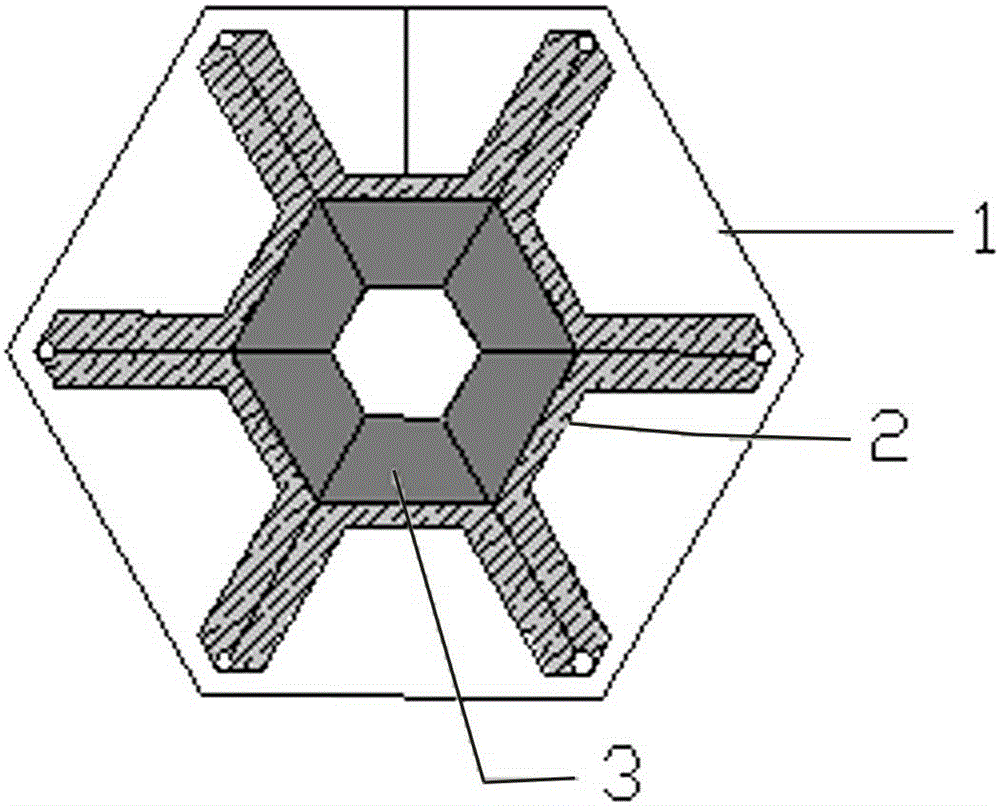

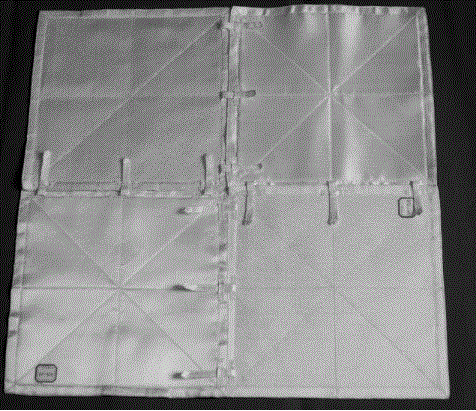

Isomerization reactor component made from sealing fabric and preparation method of isomerization reactor component

ActiveCN105879787ALess catalystIncrease the effective filling volumeChemical/physical processesMetal foilManufacturing engineering

The invention provides an isomerization reactor component made from sealing fabric. The isomerization reactor component is of a multilayer fabric sewn structure and comprises an upper laying layer, a middle layer and a lower laying layer. The upper laying layer and the lower laying layer are each of a ceramic fiber fabric structure. Each fabric structure is formed by stacking and laying a single layer or multiple layers of ceramic fiber cloth. The middle layer is made of stainless steel metal foil. The reactor component can be formed by combining and splicing multiple fabric units. Fabric unit blocks are each of a multilayer fabric sewn structure, and the fabric unit blocks are combined and spliced through connecting pieces. A preparation method of the reactor component includes the steps that the sizes of the fabric unit blocks are designed firstly, and the upper laying layer, the middle layer and the lower laying layer are cut; then laying is conducted layer by layer according to the scheme; stacked sewing is conducted, and the fabric unit blocks are obtained; finally, the fabric unit blocks are combined and spliced into a whole through the connecting pieces. The product is good in high temperature resistance, low in cost and convenient to manufacture, and the use effect of an isomerization reactor catalyst can be remarkably improved.

Owner:CHANGSHA JINGYOU NEW MATERIAL TECH CO LTD

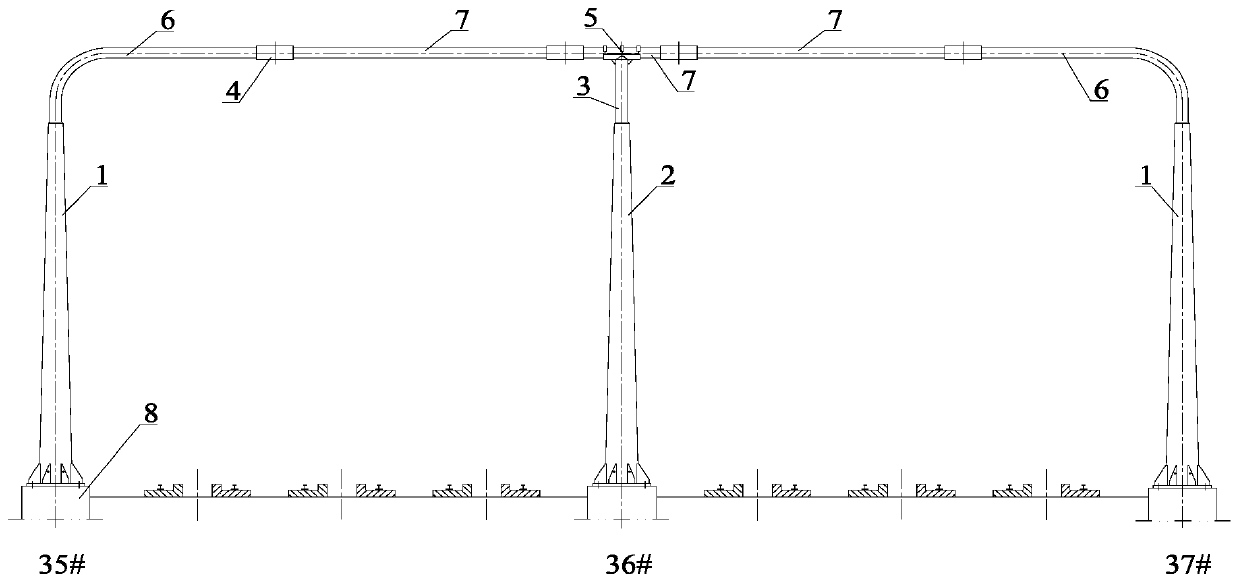

Overhead line system hard cross beam connected in welded manner and construction method thereof

PendingCN110145159AGuaranteed construction accuracyAvoid reworkTrolley linesTowersVertical loadSteel columns

The invention discloses an overhead line system hard cross beam connected in a welded manner and a construction method thereof. A hard cross beam comprises a plurality of steel columns. A cross beam is connected between every two steel columns. The steel columns and the cross beams are prefabricated components. The height of the steel columns is determined according to the basis elevation measuredand obtained. The length of the cross beams is determined according to the center distance of two bases measured and obtained. The negative spread degree of the cross beams is determined by the vertical load borne by the cross beams under the working condition of normal use. The construction method comprises the steps that base pouring is carried out; the negative spreading degree needed by the cross beams is calculated; the height of each steel column of the hard cross beam is determined, and the steel columns are prefabricated; the length of each cross beam of the hard cross beam is determined, and the cross beams are prefabricated according to the needed negative spreading degree; the steel columns are fixedly installed on the base; the cross beams are transferred in place, and the length of the cross beams is checked again; the cross beams are hoisted, the cross beams and the steel columns are connected temporarily in a bolt manner, then a hoisting vehicle is utilized for carryingout second-time bolt connecting after adjusting the cross beams to the needed negative spread degree, and finally, welding connection is carried out on the connecting portion.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

Integral type building construction assembly technique

InactiveCN105587117AAccelerateControl construction qualityFloorsForms/shuttering/falseworksRebarSteel columns

The invention discloses an integral type building construction assembly technique. The integral type building construction assembly technique is characterized in that: a base is arranged on the bottom of a column template; an adjustable support pillar is arranged at one side of the column template; angle steel is arranged on the upper part of the support pillar; a superposed beam is arranged on the angle steel; a hole is formed in the superposed beam; a steel column is inserted into the hole; a square timber is arranged on the steel column; a prefabricated ribbed prestressed concrete superposed plate are arranged on the square timber; the columns, the beam, and plate steel bars are lapped according to a design demand; a prefabricated concrete superposed beam template is arranged; and then the columns, the beam, and the plates are poured into a whole. The integral type building construction assembly technique can increase the whole speed of building assembly and construction, facilitates construction quality control, and can ensure construction safety.

Owner:HARBIN TAOYI ADVERTISING DECORATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com