Mortise and tenon joint and bolt hybrid assembling type steel structure beam-column joint

A technology of beam-column joints and mixed assembly, which is applied in the direction of building construction and construction, can solve the problems of complex installation process of self-locking unilateral bolts, inability to realize rigid connection of beams and columns, and large amount of steel used for end plates, etc. Excellent anti-seismic performance, improved installation accuracy and engineering quality, and easy loading and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The embedded tenon is trapezoidal:

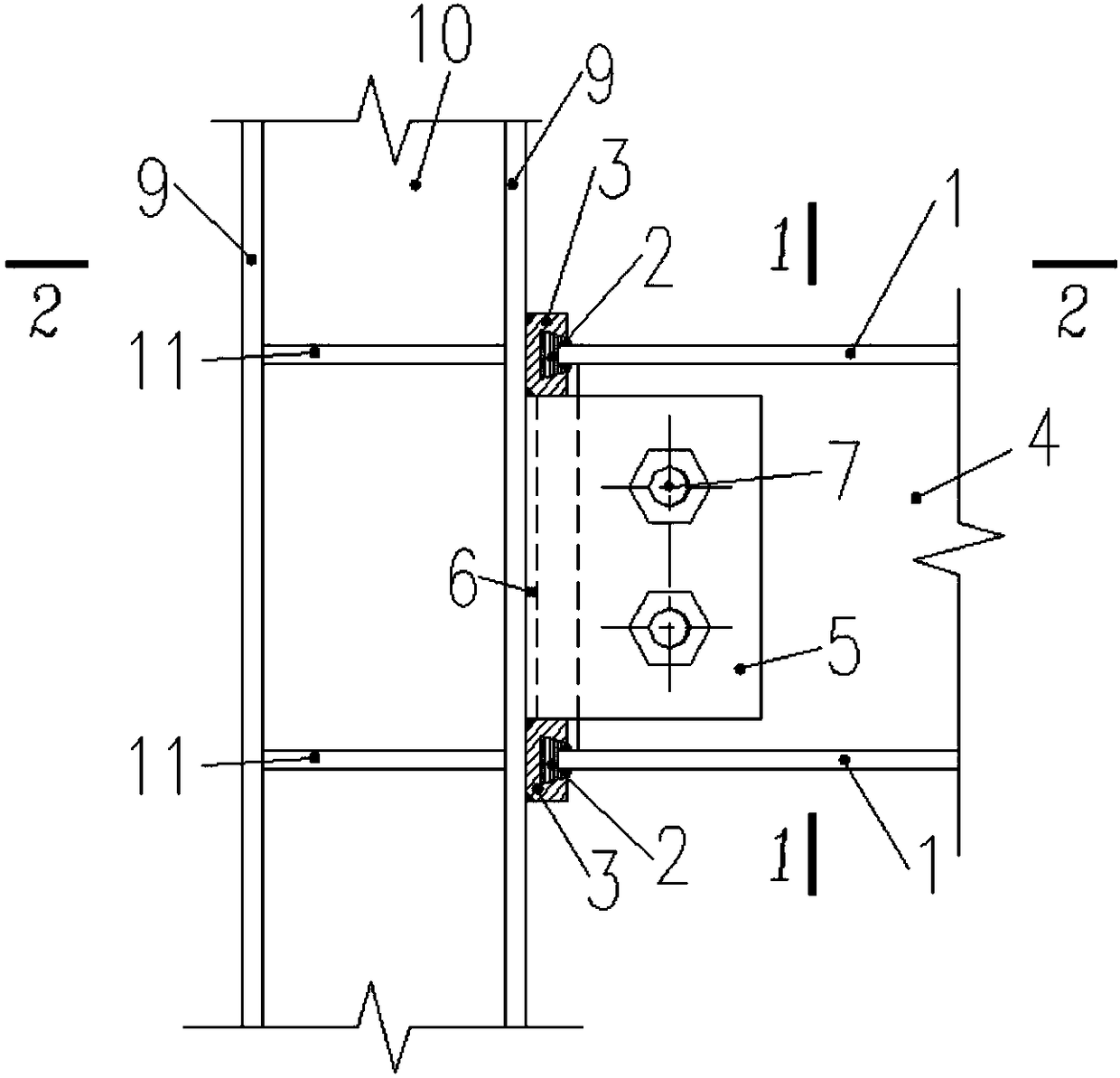

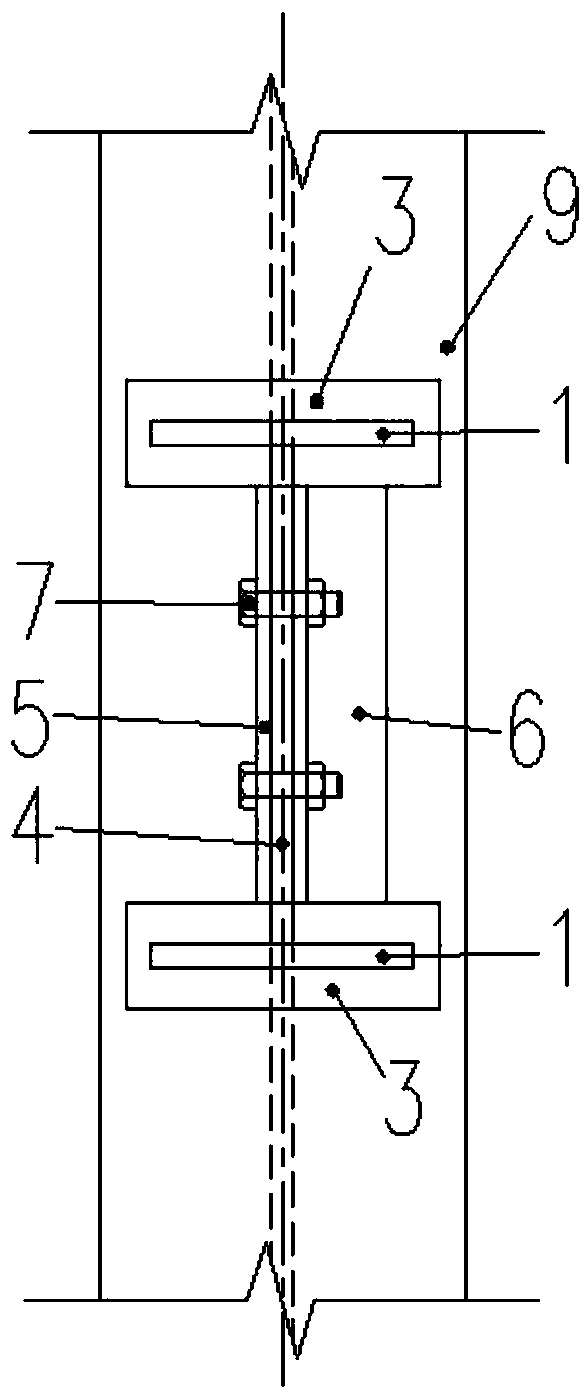

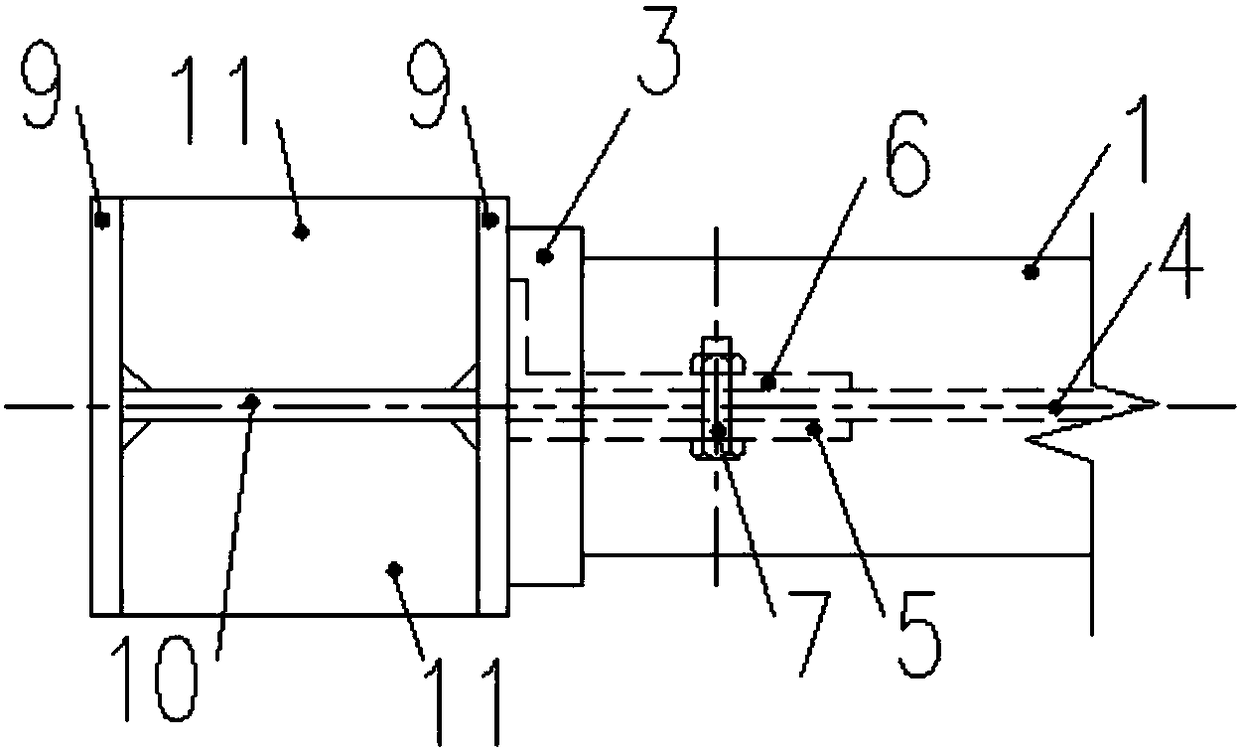

[0032] Such as Figure 1 to Figure 7 A mortise and tenon and bolt mixed-assembled steel structure beam-column joint is shown, including a steel structure beam, a steel structure column, and a beam-column joint. The two beam flanges 1 of the steel structure beam are connected together by a beam web 4 , The two column flanges 9 of the steel structure column are connected together through the column web 10, and the steel structure beam and the steel structure column are connected together through the beam-column joint, and the beam-column joint includes the end of the beam flange 1 Embedding tenon 2, embedding groove body 3 fixedly arranged on the surface of the steel structure column, web connecting plate 5, and additional connecting plate 6, the embedding tenon 2 and the embedding groove body 3 are connected together by mortise and tenon, and the web connecting plate 5 Placed on the side of the beam web 4, one end of the web connecti...

Embodiment 2

[0039] The embedded tenons are round:

[0040] Such as Figure 7 to Figure 10 A mortise and tenon and bolt mixed-assembled steel structure beam-column joint is shown, including a steel structure beam, a steel structure column, and a beam-column joint. The two beam flanges 1 of the steel structure beam are connected together by a beam web 4 , The two column flanges 9 of the steel structure column are connected together through the column web 10, and the steel structure beam and the steel structure column are connected together through the beam-column joint, and the beam-column joint includes the end of the beam flange 1 Embedding tenon 2, embedding groove body 3 fixedly arranged on the surface of the steel structure column, web connecting plate 5, and additional connecting plate 6, the embedding tenon 2 and the embedding groove body 3 are connected together by mortise and tenon, and the web connecting plate 5 Placed on the side of the beam web 4, one end of the web connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com