Measuring apparatus for moisture transmission performance of wadding fiber assembly

A fiber aggregate and measuring device technology, which is applied in the field of measuring device for moisture transfer performance of flocculent fiber aggregates and measuring device for moisture conductivity, can solve the problems of inability to change, difficult to diffuse upward, and unable to transmit, etc., and achieve structural and the effects of using simplification, changing bulk density, and speeding up flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

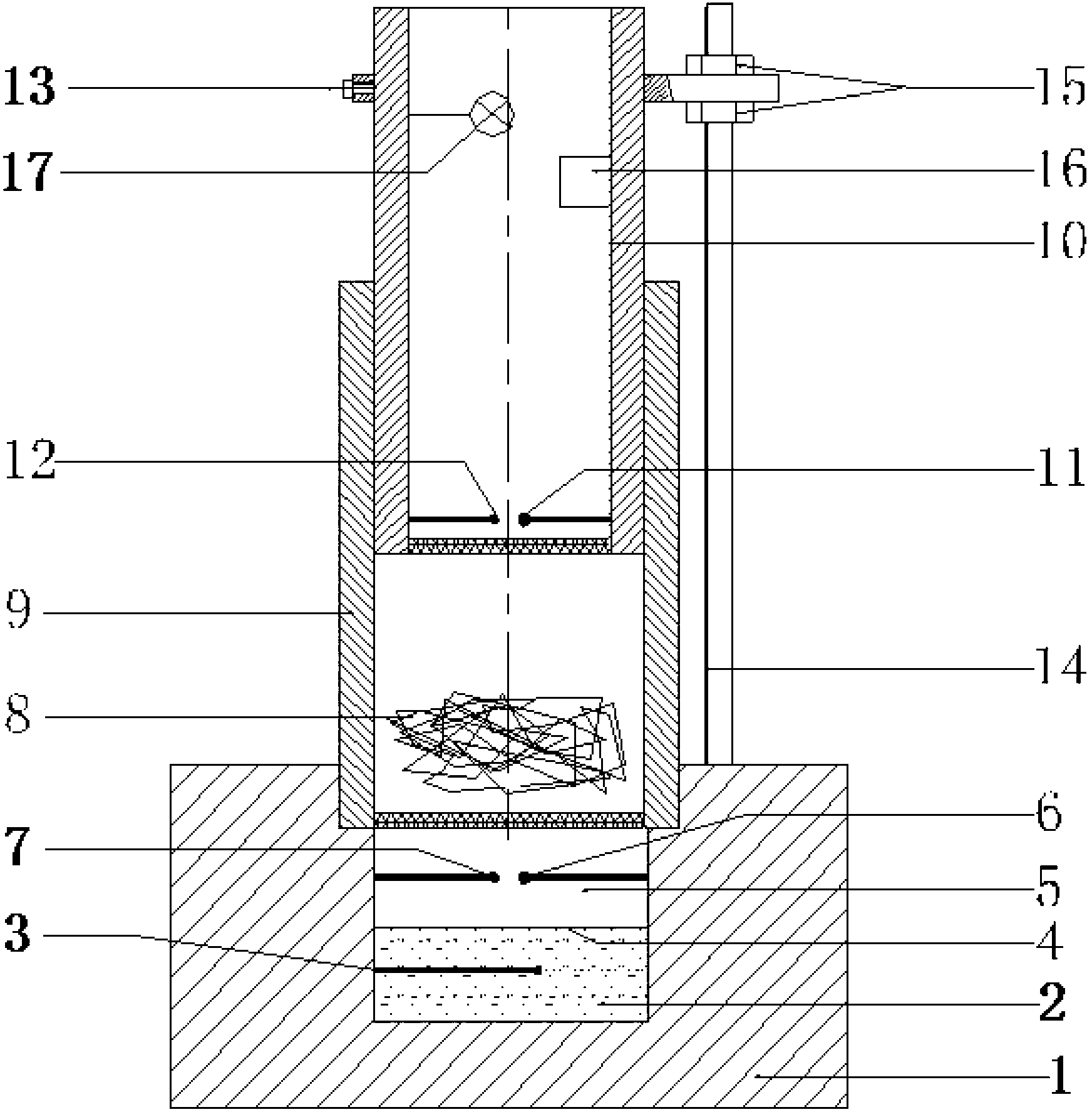

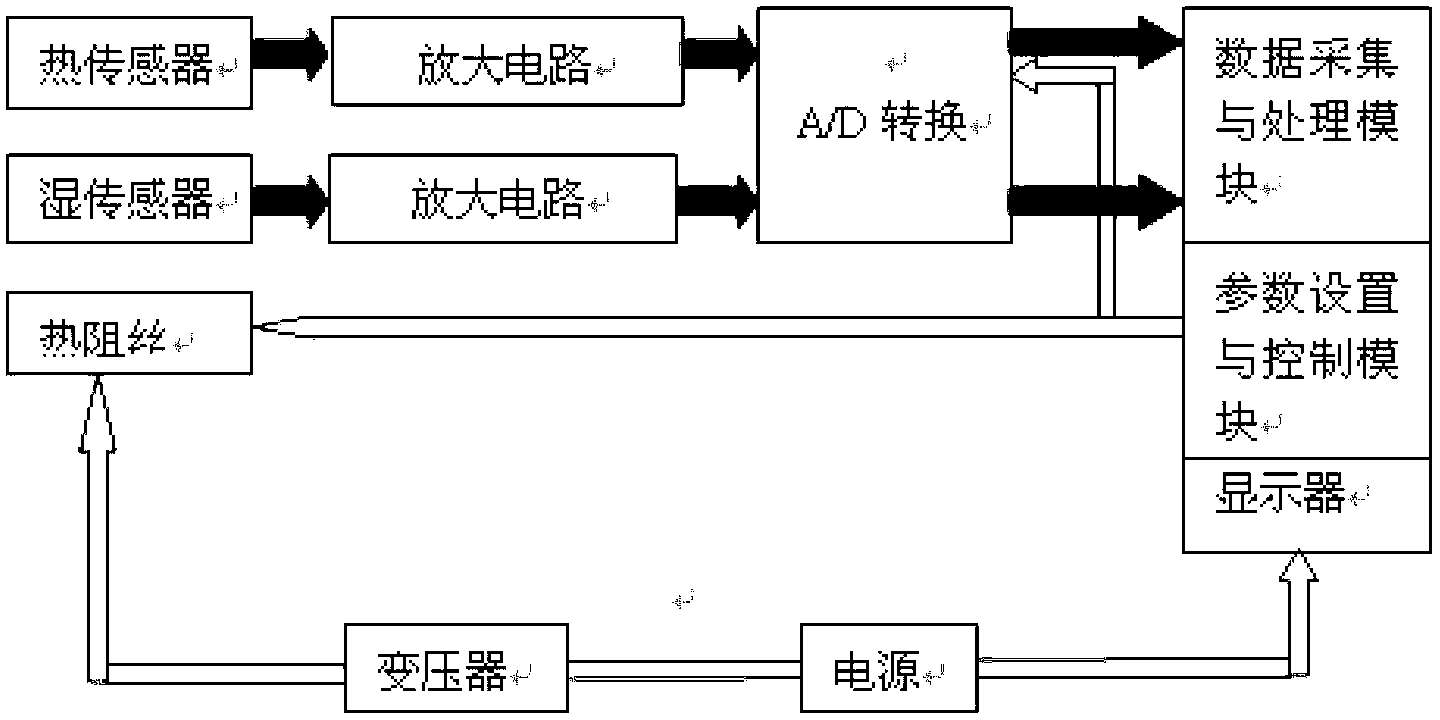

[0040] The measuring device is mainly composed of four parts, namely: humidity production area, microclimate area, sample cylinder, push cylinder, control circuit and signal acquisition part.

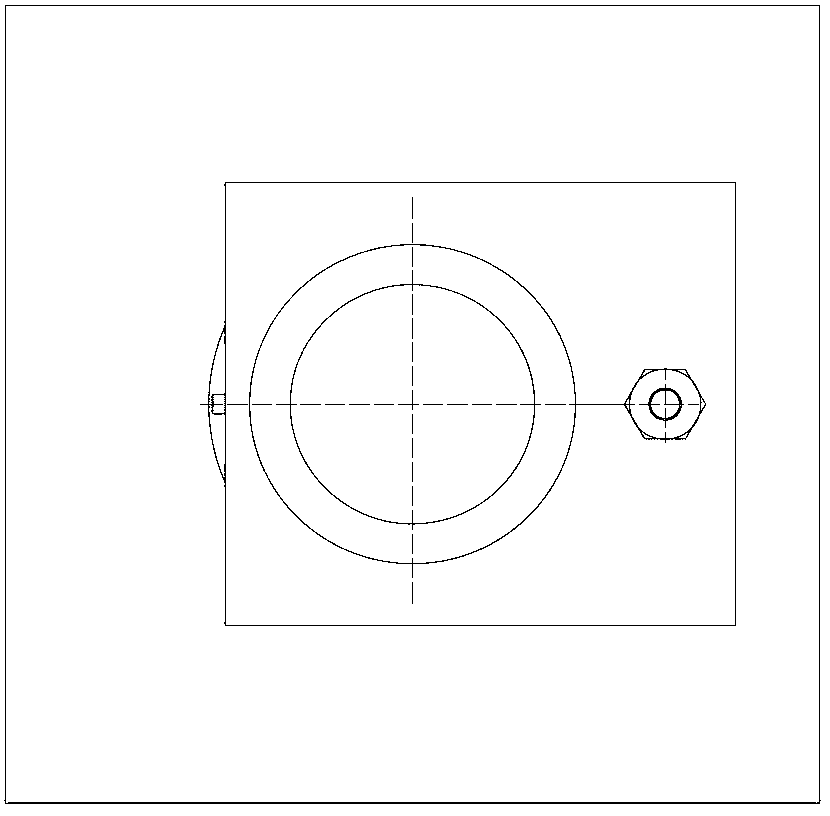

[0041] a. In the humidity production area, the heat insulation protection seat 1 is a cuboid with a cylindrical groove. The cylindrical groove is a two-stage groove. The lower part of the groove is equipped with a constant temperature water bath 2 with a diameter of 20cm. The constant temperature water bath 2 The thermal resistance wire 3 is fixedly installed in the middle, and the thermal resistance wire 3 is a ring-shaped copper ring to ensure uniform and stable heating. The simulated skin 4 is close to the upper liquid surface of the constant temperature water bath 2 and adheres to the upper heat insulation protection seat 1 of the liquid surface. On the inner wall of the skin, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com