Automatic printing device

A technology of automatic printing and printing device, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of low efficiency and single function, and achieve the effect of changing height and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

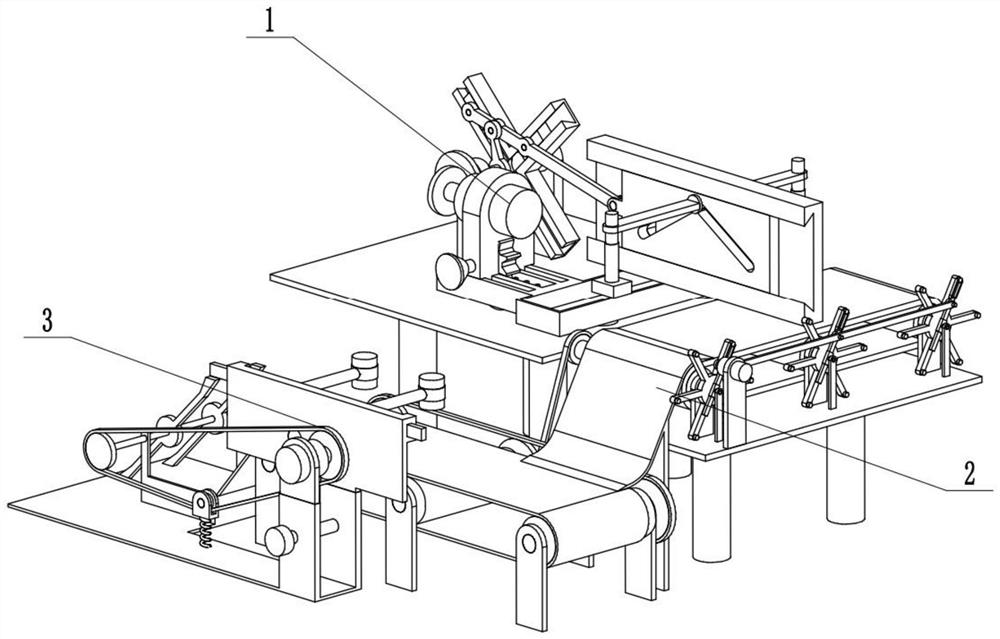

[0029] Combine below Figure 1-13 In this embodiment, an automatic printing device includes a reciprocating printing device 1 , a conveying device 2 , and a drying device 3 . The reprinting device 1 is connected to the conveying device 2 , and the conveying device 2 is connected to the drying device 3 .

specific Embodiment approach 2

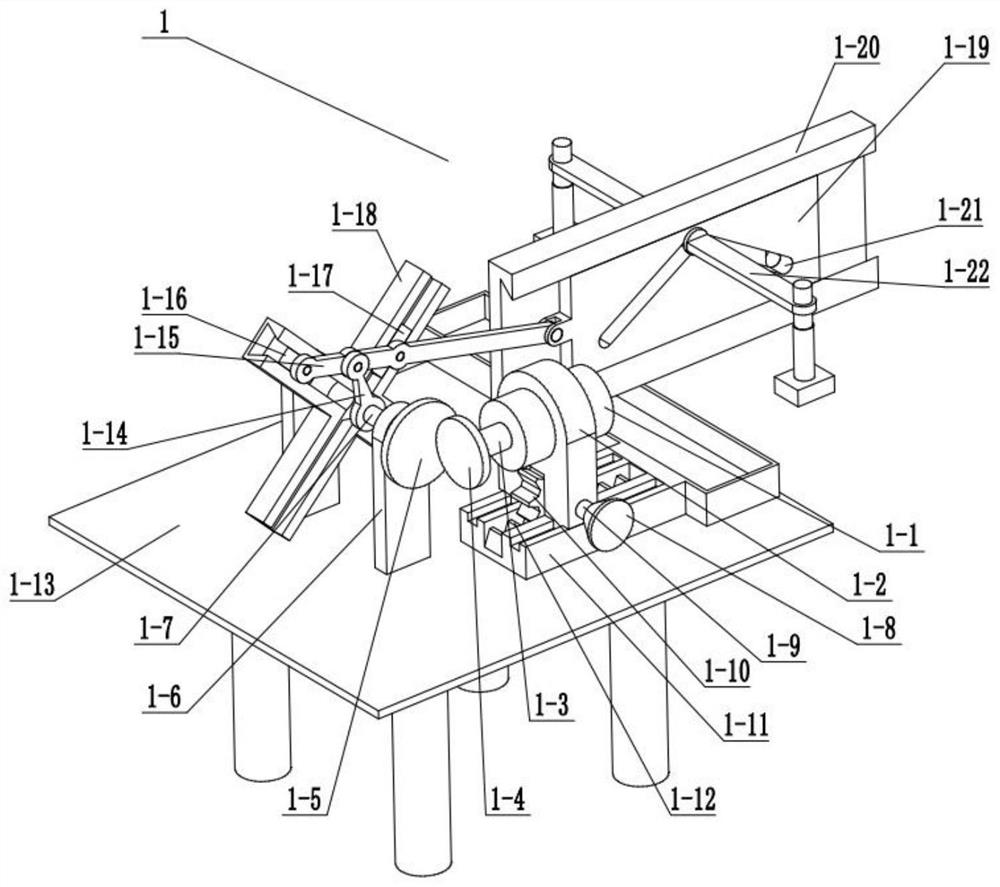

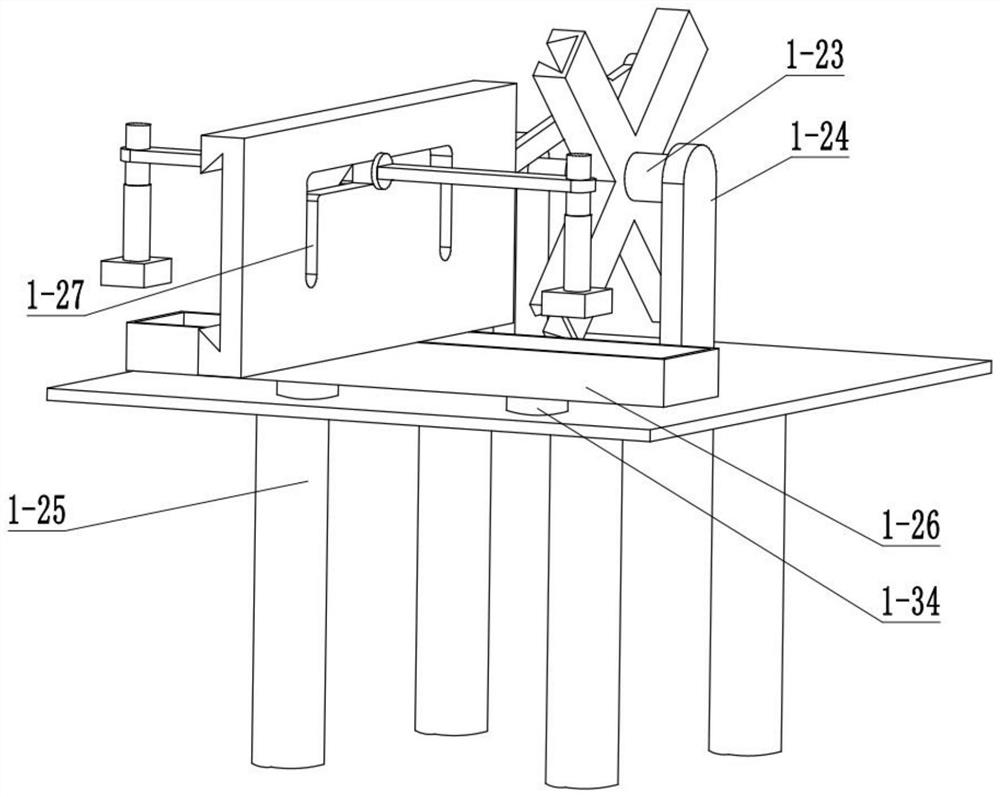

[0031] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1, the reciprocating printing device 1 includes a motor 1-1, a bracket 1-2, a connecting column 1-3, a runner 1-4, a rotary Wheel 2 1-5, Bracket 2 1-6, Connecting Column 2 1-7, Knob 1 1-8, Connecting Column 3 1-9, Gear 1 1-10, Base 1 1-11, Straight Teeth 1-12 , Base two 1-13, connecting rod one 1-14, connecting rod two 1-15, slider one 1-16, slider two 1-17, cross 1-18, inner slider 1-19, outer frame 1 -20, curved groove one 1-21, long rod 1-22, connecting column four 1-23, bracket four 1-24, leg frame 1-25, ink tank 1-26, curved groove two 1-27, square column 1-28, cylinder 1-29, fixed column 1-30, spring 1-31, external fixed column 1-32, printed board 1-33, pillar 1-34, motor one 1-1 and bracket one 1-2 are fixed Connection, motor one 1-1 is fixedly connected with connection column one 1-3, connection column one 1-3 is fixedly connected with runner one 1-4, runner on...

specific Embodiment approach 3

[0034] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the transmission device 2 includes motor two 2-1, bracket five 2-2, connecting column five 2-3, connecting rod five 2-4, hinged column One 2-5, functional rod 2-6, functional slot 2-7, bracket six 2-8, transfer column two 2-9, fixed block 2-10, hexagonal wheel 2-11, small cylinder 2-12, connecting column Six 2-13, bracket seven 2-14, round roll one 2-15, transmission rod 2-16, transmission surface one 2-17, bottom plate 2-18, bracket eight 2-19, connecting column eight 2-20, pillar Two 2-21, connecting column nine 2-22, runner five 2-23, belt one 2-24, support nine 2-25, connecting column ten 2-26, runner six 2-27, runner seven 2- 28. Belt two 2-29, slope one 2-30, bracket eleven 2-31, transmission surface two 2-32, connecting column eleven 2-33, round roller two 2-34, bracket twelve 2-35 , support 13 2-36, motor two 2-1 is fixedly connected with support fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com