Method for preparing functionally graded material through pressure filtration forming in motional magnetic field

A technology of moving magnetic field and filter press molding, which is applied to ceramic molding machines, manufacturing tools, etc., to achieve the effects of process simplification and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

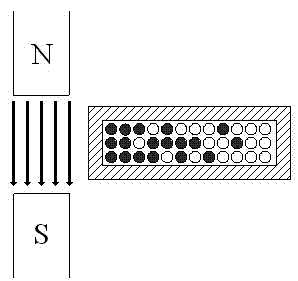

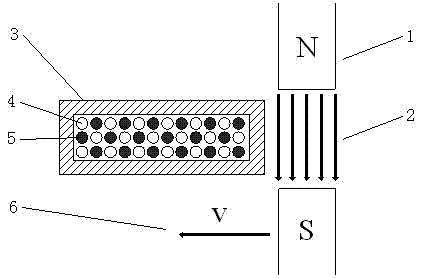

[0031] The preparation method of pressure filtration molding of gradient material in moving magnetic field, its steps are as follows:

[0032] 1) Plaster mold preparation

[0033] α-gypsum and β-gypsum are mixed with water at 15-25°C, stirred for 3-8 minutes and then poured. 30% saved in the environment. Since the filter press is shaped by filtering out part of the liquid medium through a porous mold, the porous mold is extremely important. The filter press mold must not only meet the requirements of the filter press process for porous filter materials, but also meet the requirements for the mold structure. On the one hand, porous materials for press filtration must have ideal filtration performance, that is, have sufficiently small pores, narrow pore size distribution, moderate porosity and permeability coefficient; on the other hand, in order to ensure the size and shape of the molded body, these Porous materials must have sufficient rigidity and strength, and easy contro...

Embodiment 1

[0044] 1) Mix α-gypsum and β-gypsum with pure tap water at 20°C, add phenolic resin, the content of which is 10% of the mass of the gypsum, pour after stirring for 4 minutes, and solidify and harden the gypsum slurry. After drying, the inner cavity of the mold is a cuboid of 30mm×10mm×5mm;

[0045] 2) Select SmCo with strong magnetic properties with an average particle size of 4 μm 5 Powder and ZrO with an average particle size of 2.2 μm 2 The powder is composed of a mixed powder in a ratio of 1:10, and the mixed powder is continuously added to deionized solvent water, and hydrochloric acid is added to adjust the pH value to 5, until the solid phase content reaches 45vol%, stirred in a ball mill for 4 hours, and ultrasonically Dispersion treatment. The humidity of the pouring slurry obtained is 35%, the temperature is 40°C, and the viscosity is 68mPa·s;

[0046] 3) The mold temperature during grouting is 28°C. Fill the slurry into the plaster mold, wipe the mold with 3% sod...

Embodiment 2

[0050] 1) Mix α-gypsum and β-gypsum with pure tap water, add polyvinyl fluoride, the content of which is 10% of the mass of the gypsum, stir for 4 minutes and pour. After the plaster mold made by solidifying and hardening the gypsum slurry is dried, the inner cavity of the mold is a cuboid of 30mm×10mm×5mm;

[0051] 2) Select 50 μm aluminum powder and Al with an average particle size of 2.2 μm 2 o 3 The powder is composed of a mixed powder in a ratio of 1:1, and the mixed powder is continuously added to deionized solvent water, and hydrochloric acid is added to adjust the pH value to 3.8, until the solid phase content reaches 45vol%, stirred in a ball mill for 6 hours, and dispersed by ultrasonic waves processing. The humidity of the obtained pouring slurry is 40%, the temperature is 35°C, and the viscosity is 30mPa·s;

[0052] 3) The mold temperature is 27°C during grouting, the mold is wiped with 3% soda solution, the slurry is filled into the plaster mold, and a moving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com