Patents

Literature

204results about How to "Simple winding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

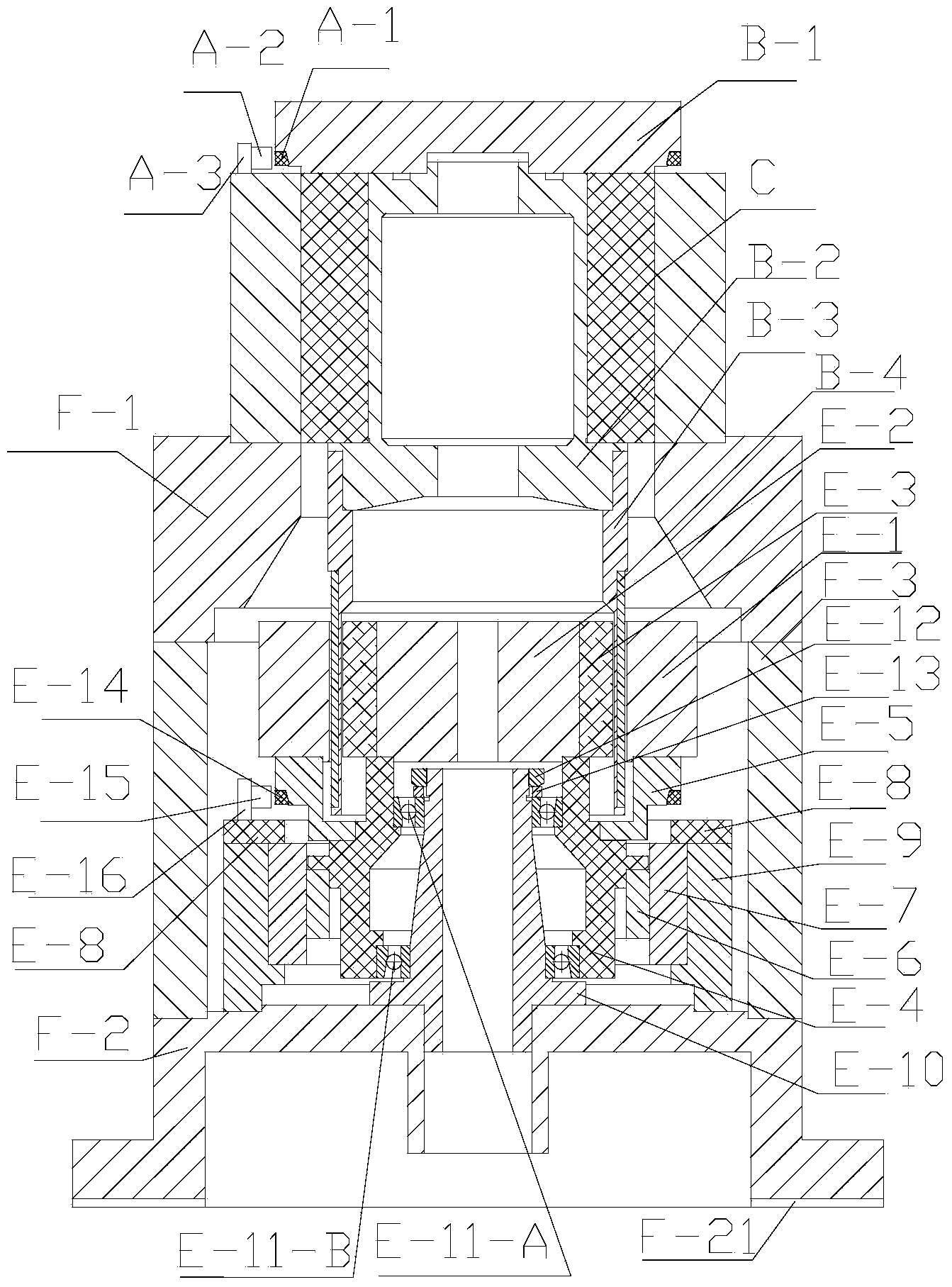

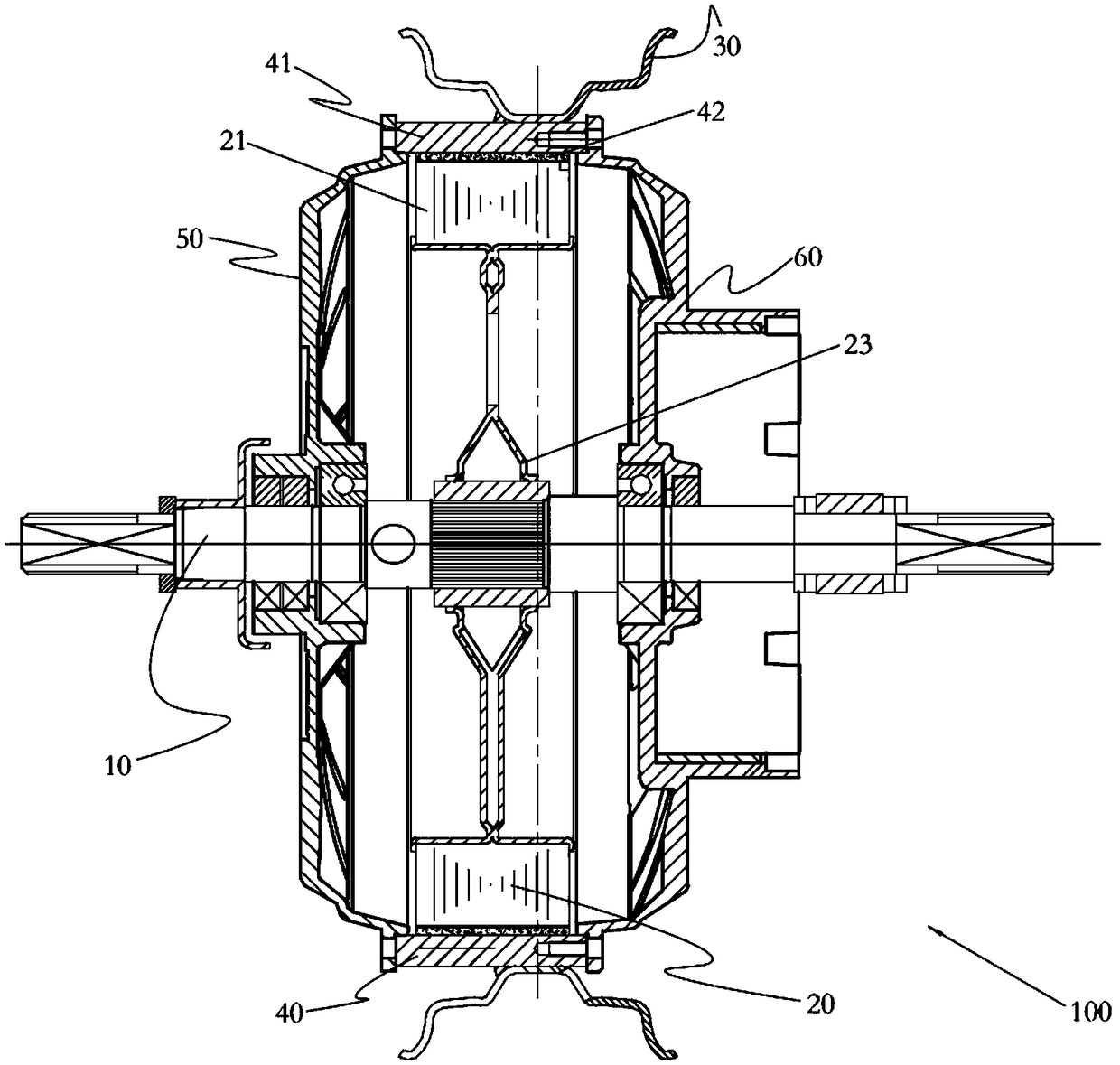

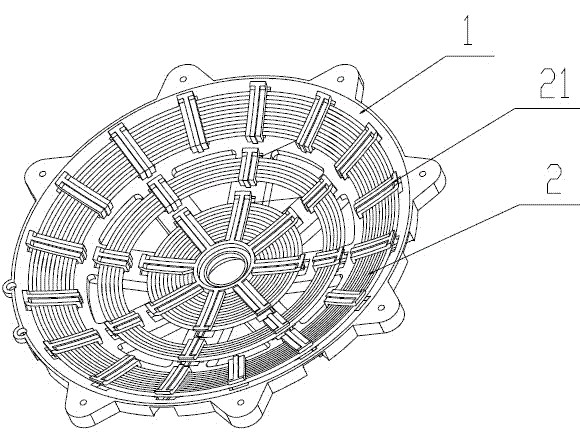

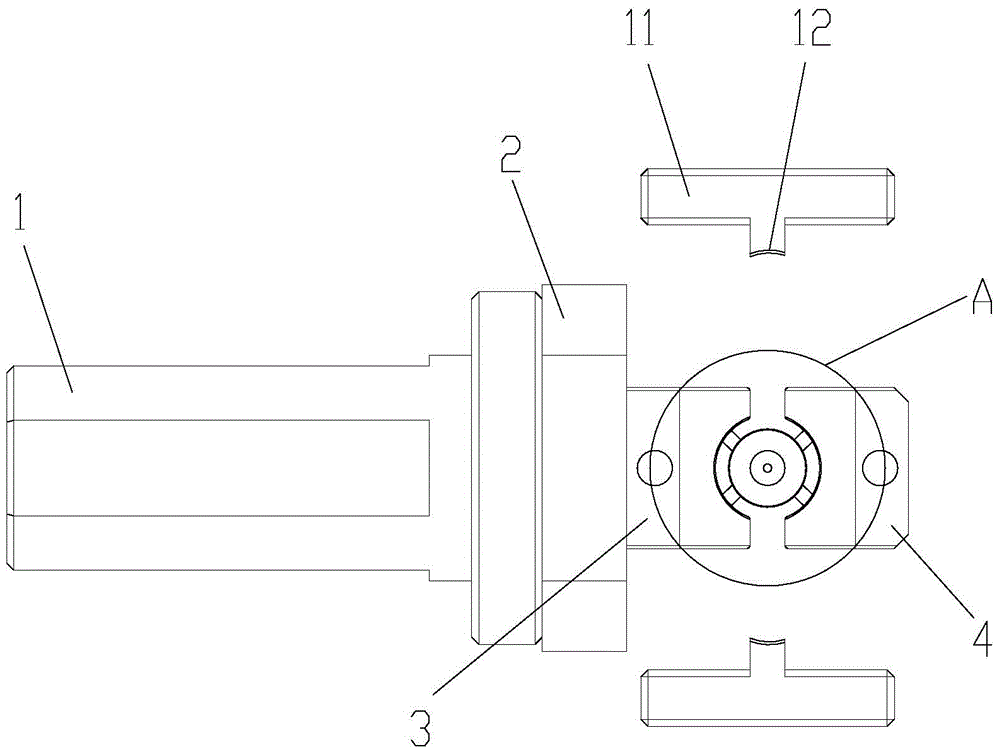

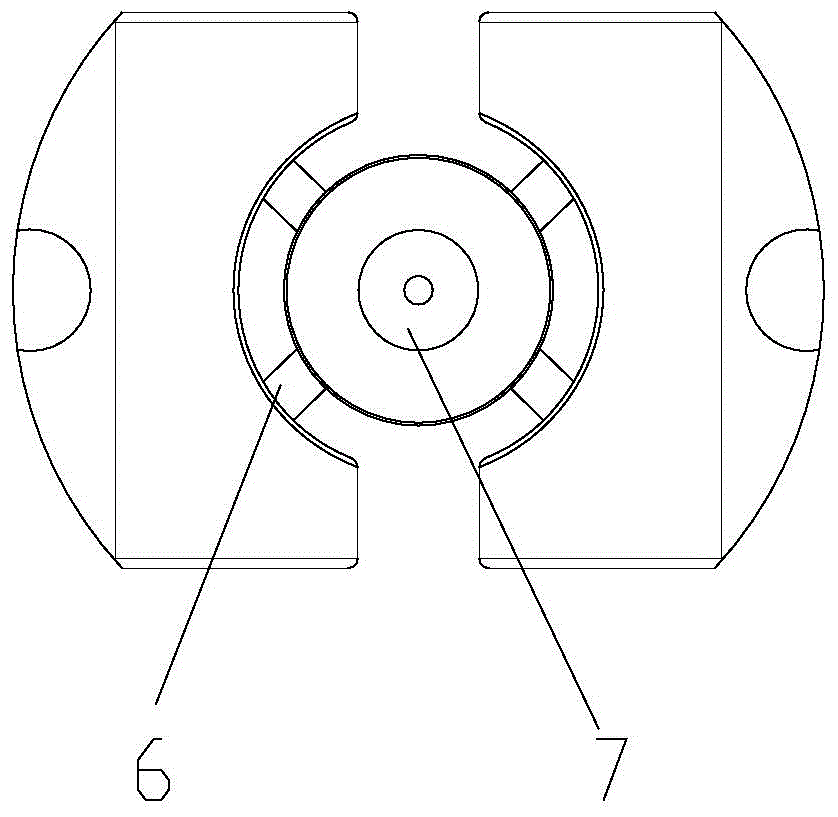

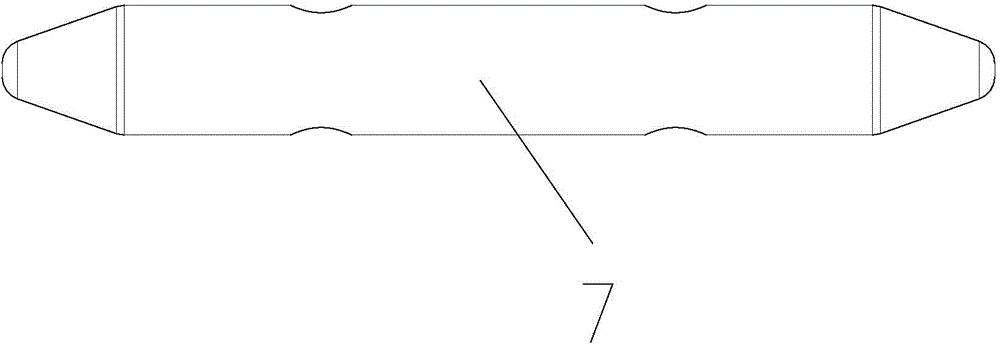

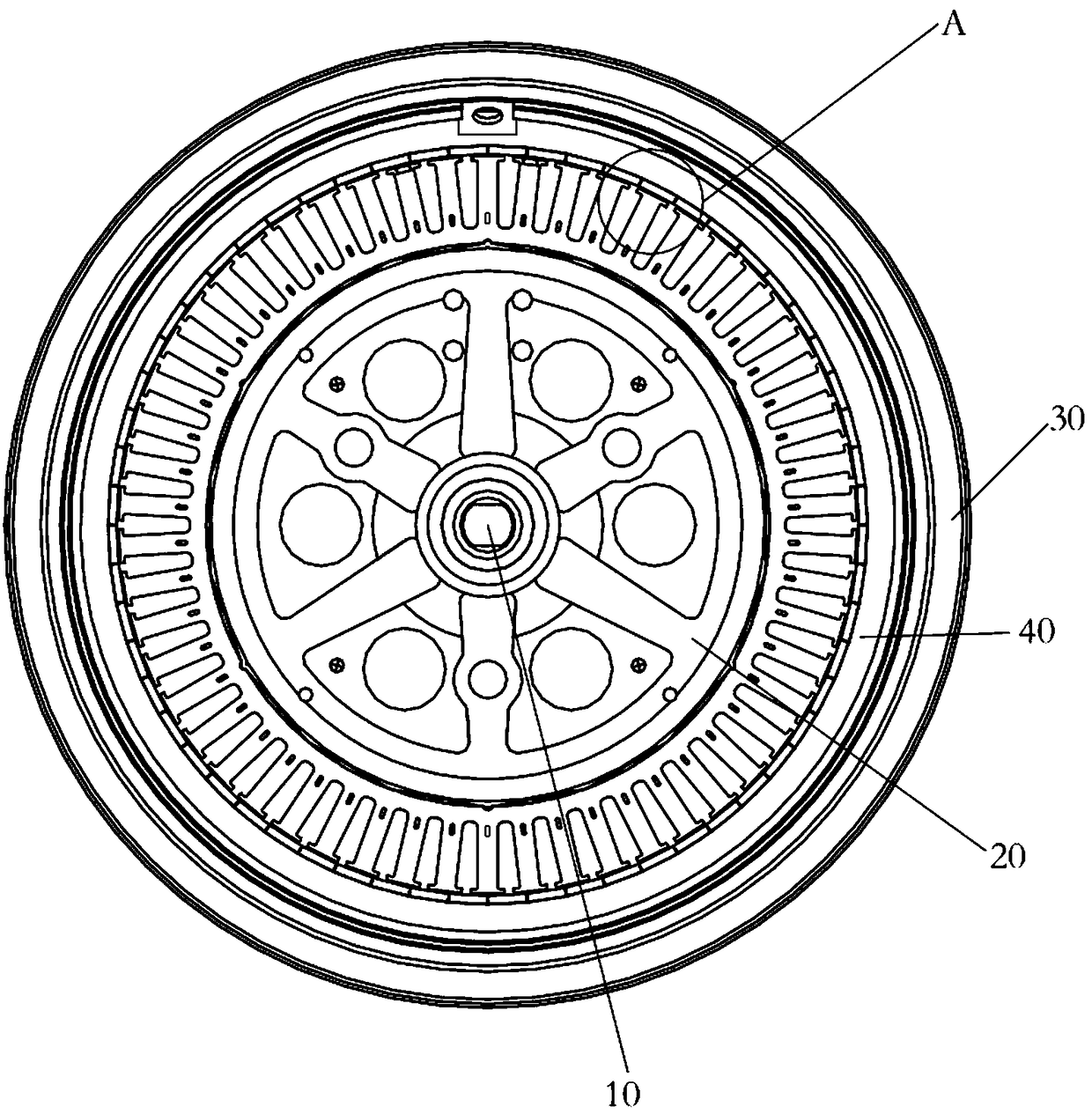

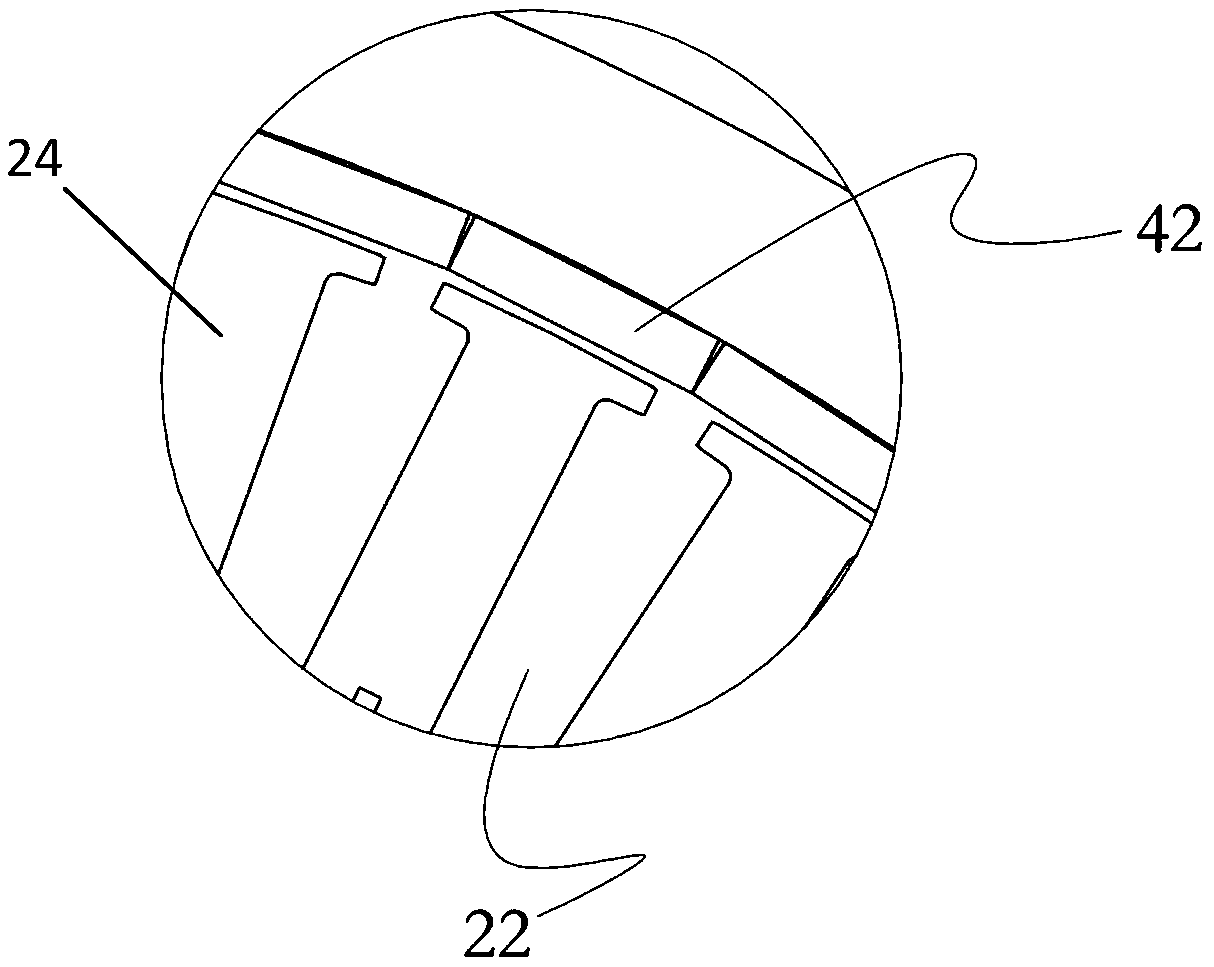

Driving device for electric toothbrush

ActiveCN101554342ASimple winding processEasy to controlMagnetic circuitSupports/enclosures/casingsMagnetic reluctanceEngineering

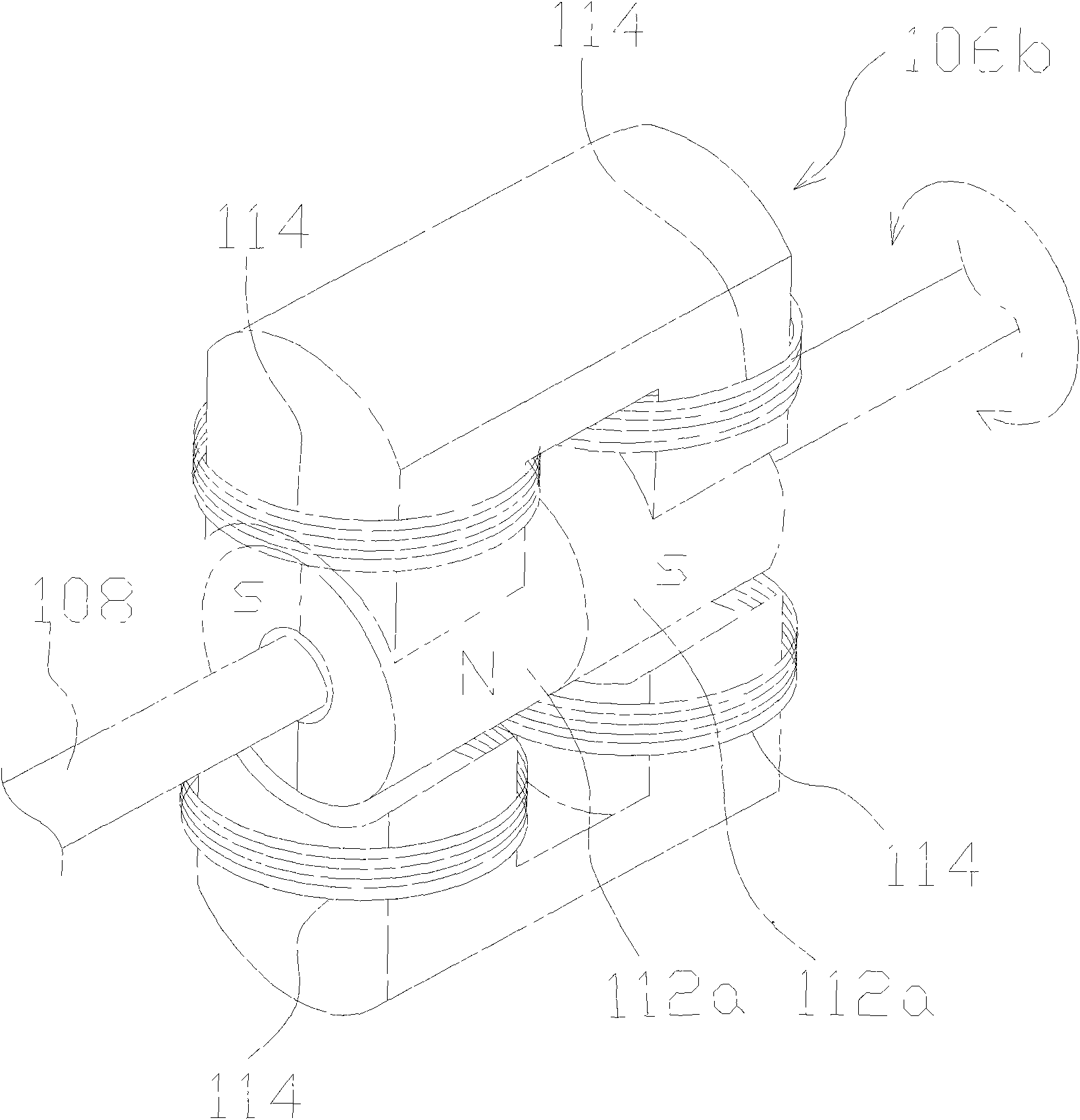

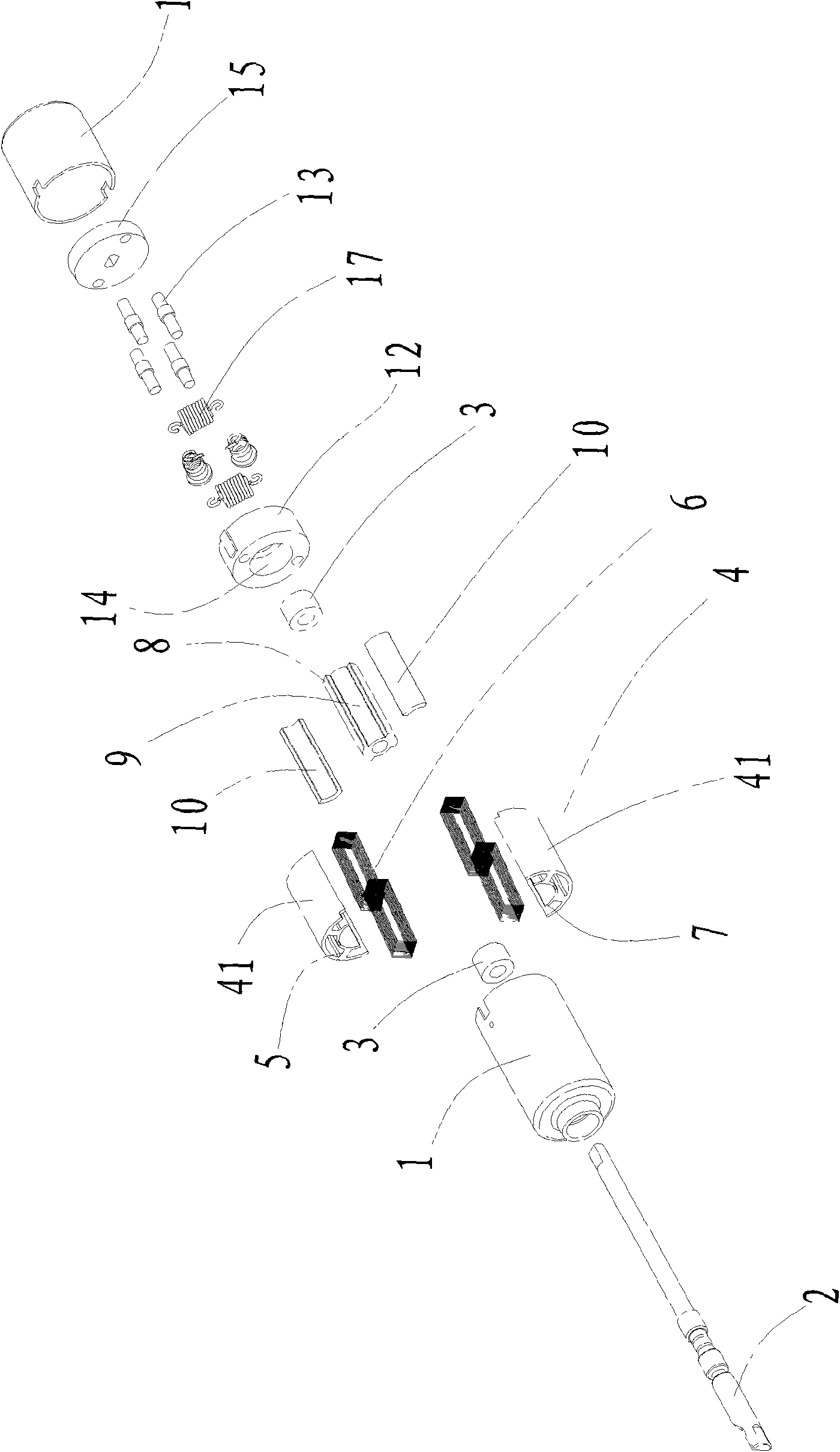

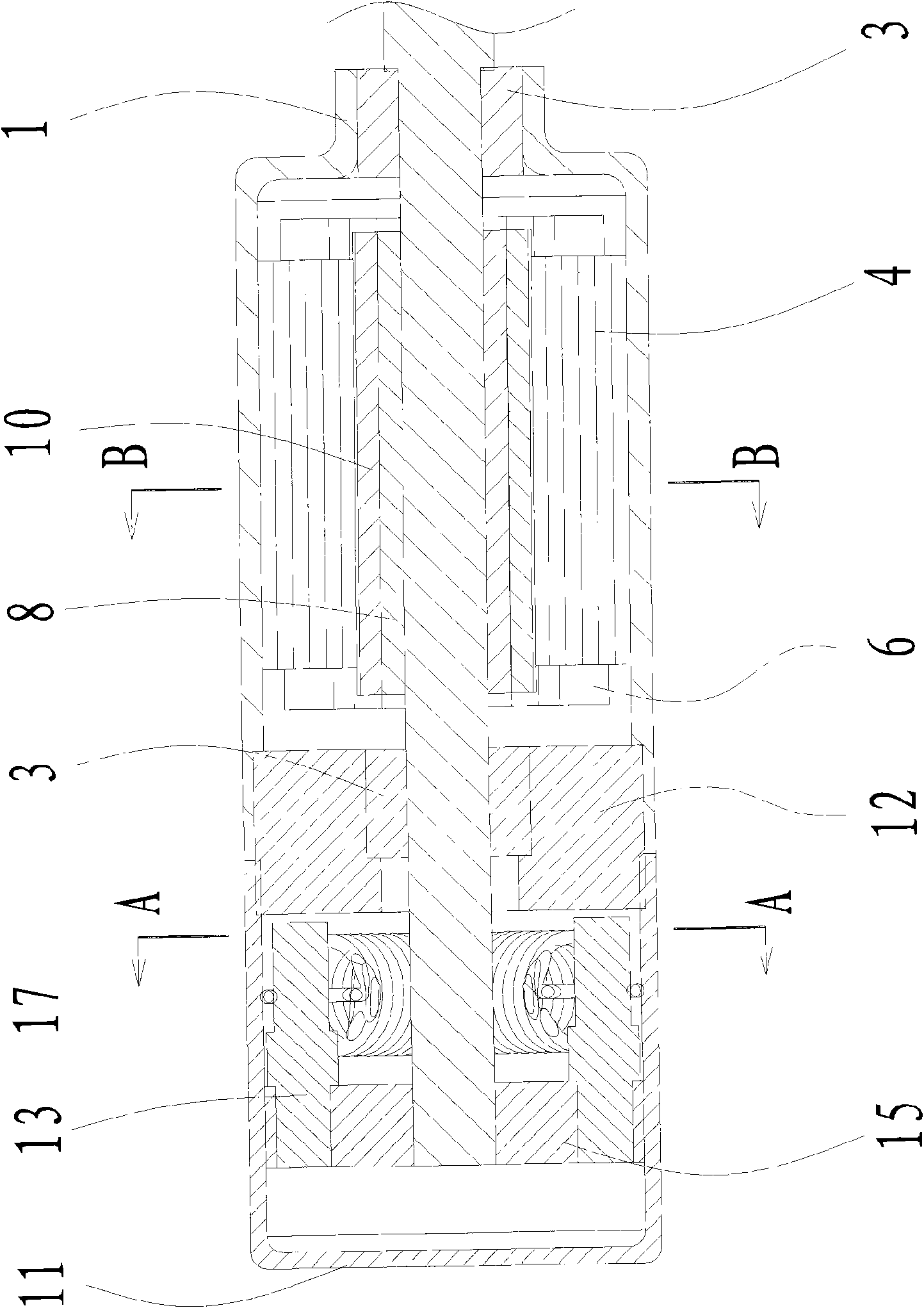

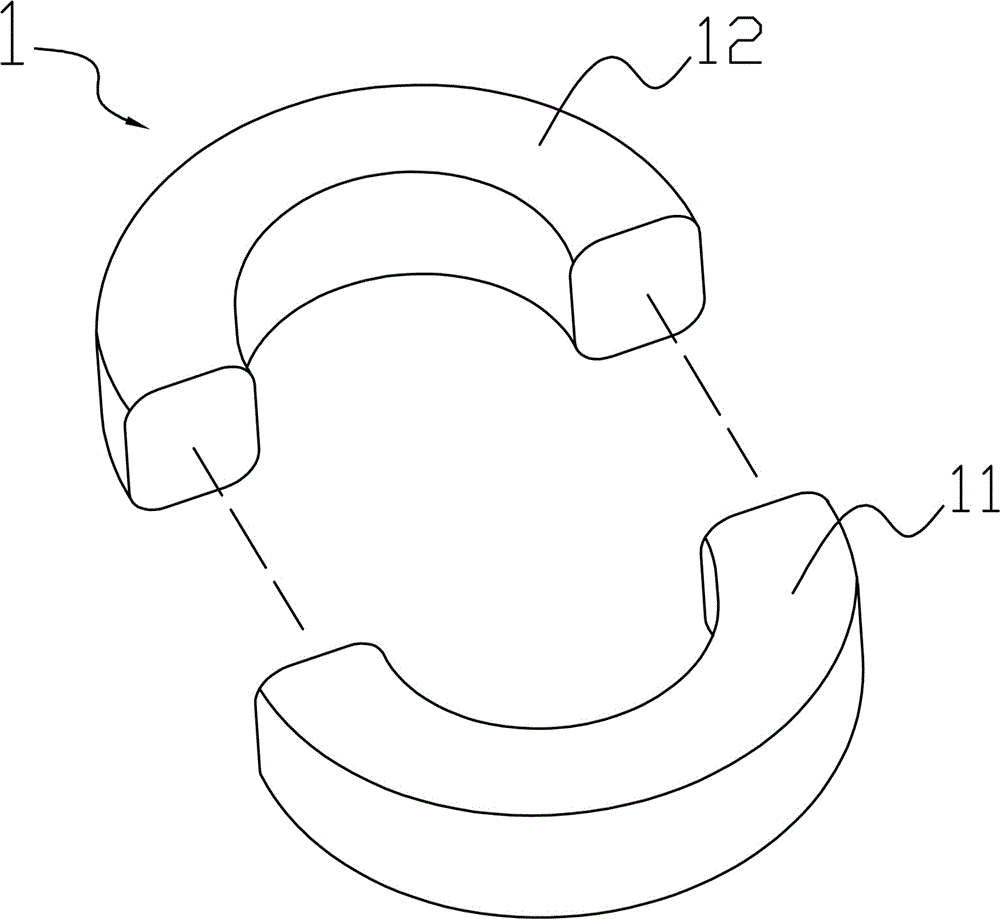

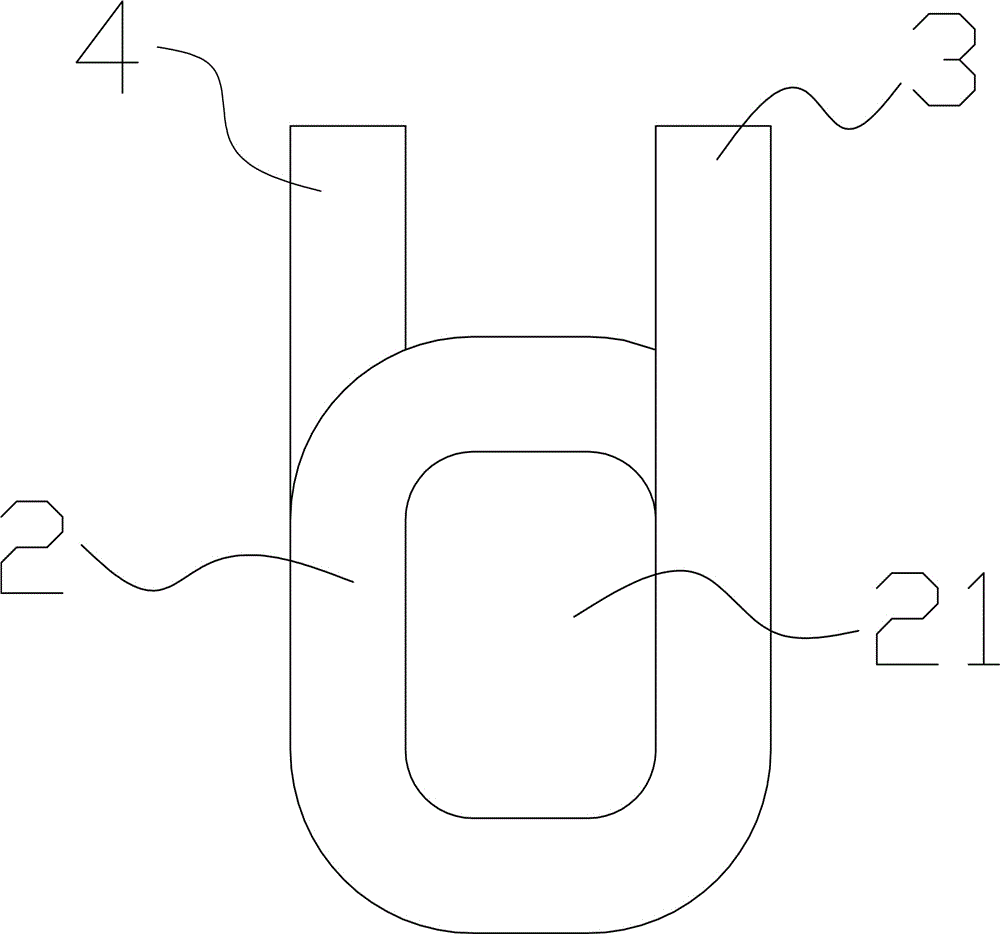

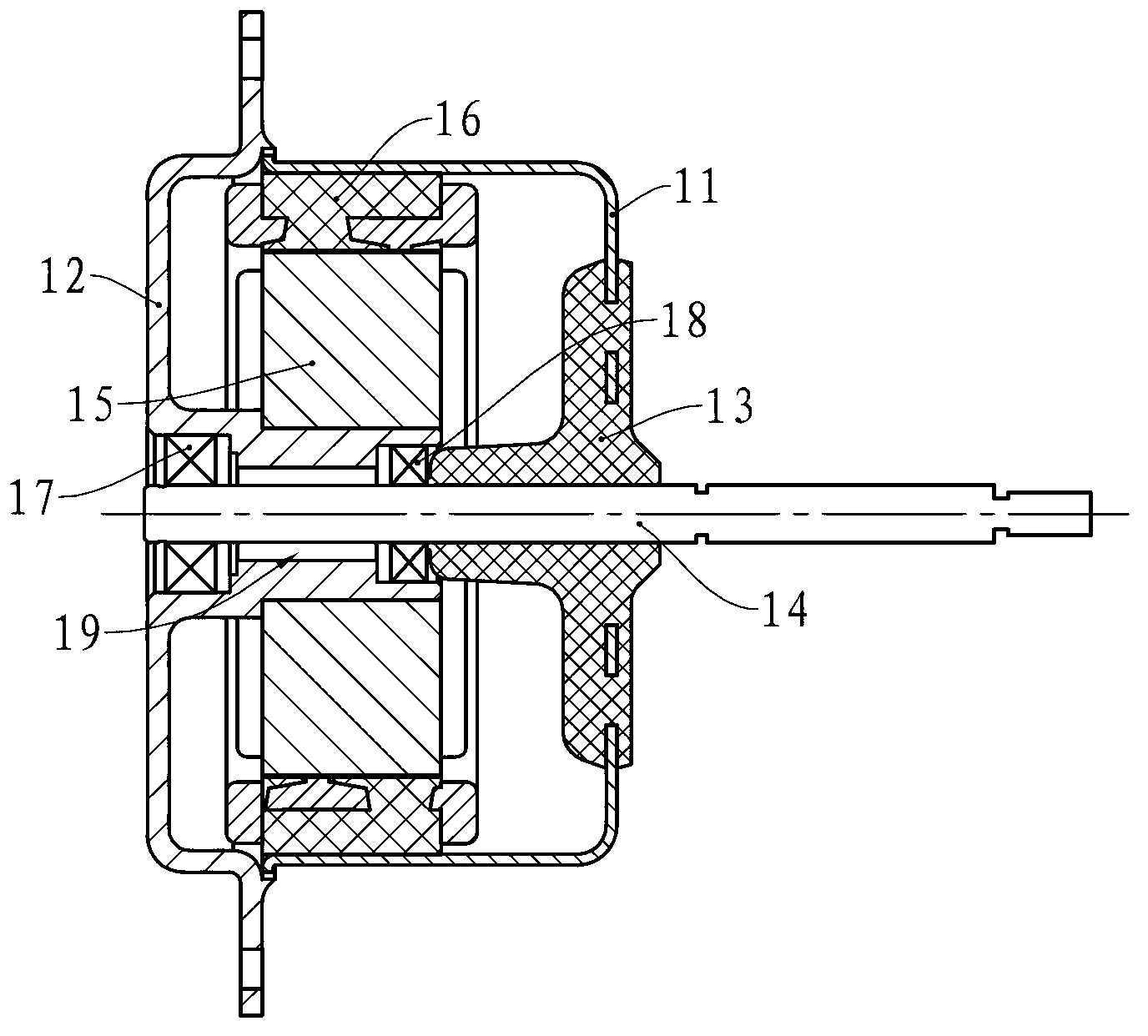

The invention discloses a driving device for an electric toothbrush, which comprises a driving circuit, an external shell, a revolving shaft, a bearing, a coil fixing bracket, a boot shape pole yolk, a driving coil, a magnet positioning post, a permanent magnet, an end cover and a damping device which is used for assisting the revolving shaft to do reciprocating movement; a common rotor and a common stator are adopted to control the current direction of the coil in the rotor in a matching manner so as to change the direction of the magnetic field and cause the rotor to rotate with high frequency in a reciprocating way; the alternating magnetic field in the stator is generated by adopting alternating rectangular wave current; the setting of the driving circuit is simpler and is beneficial to control; the coil fixing bracket is formed by the abutment joint of two semi-circular iron cores, which causes the winding process of the coil to become simpler; in addition, the fixing bracket is formed by overlying of multiple lays of magnetic conducting elements, which ensures that the magneto resistance and the eddy current of a middle magnetic loop are relatively decreased, reduces the lossof the magnetic field, improves the efficiency and has simple structure; the revolving shaft is also provided with the damping device for assisting the movement of the alternating magnetic field, thus causing the reciprocating movement of the revolving shaft to be smoother and greatly improving the system efficiency.

Owner:DONGGUAN LEBOND ELECTRONICS TECH CO LTD

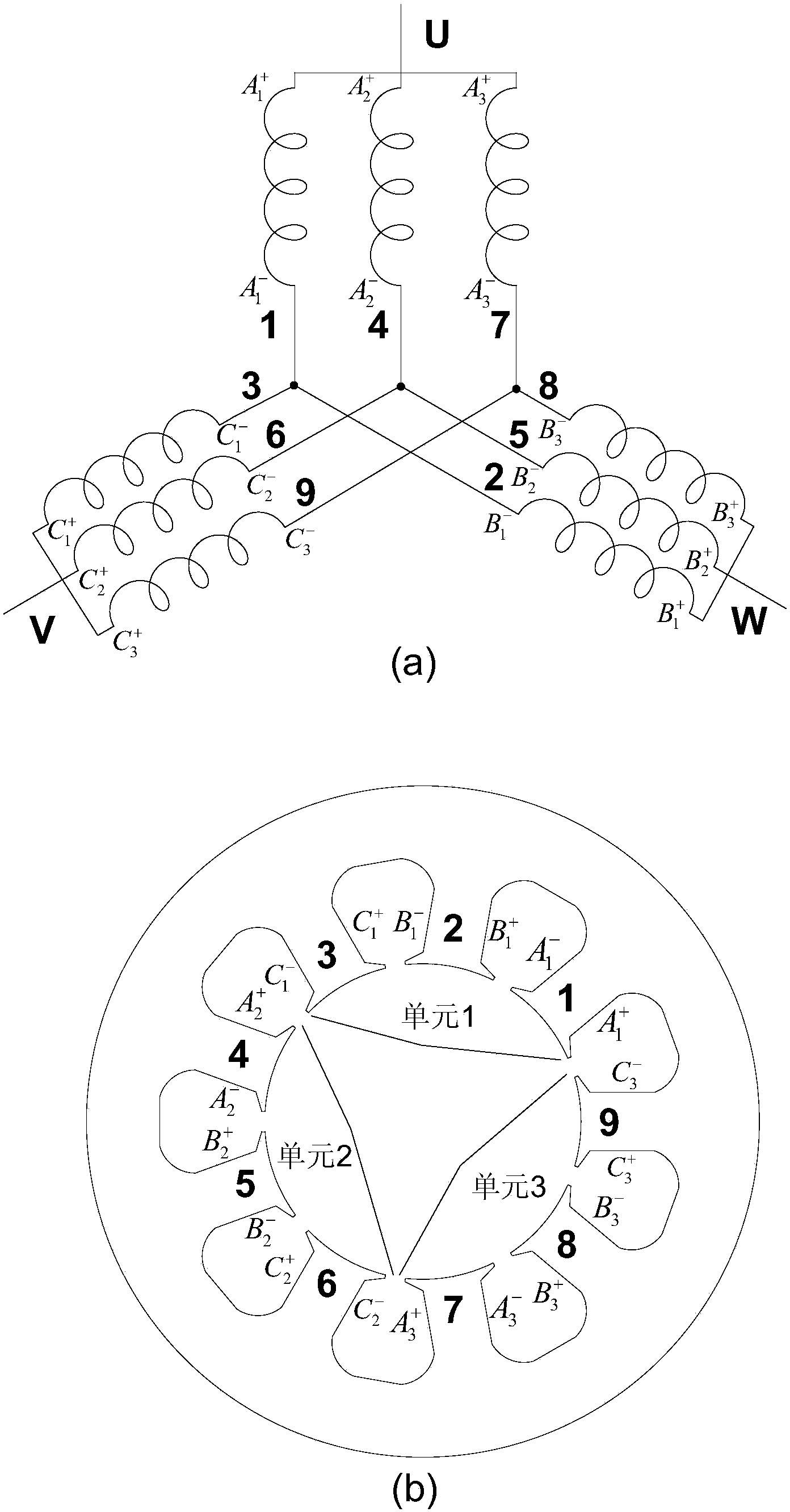

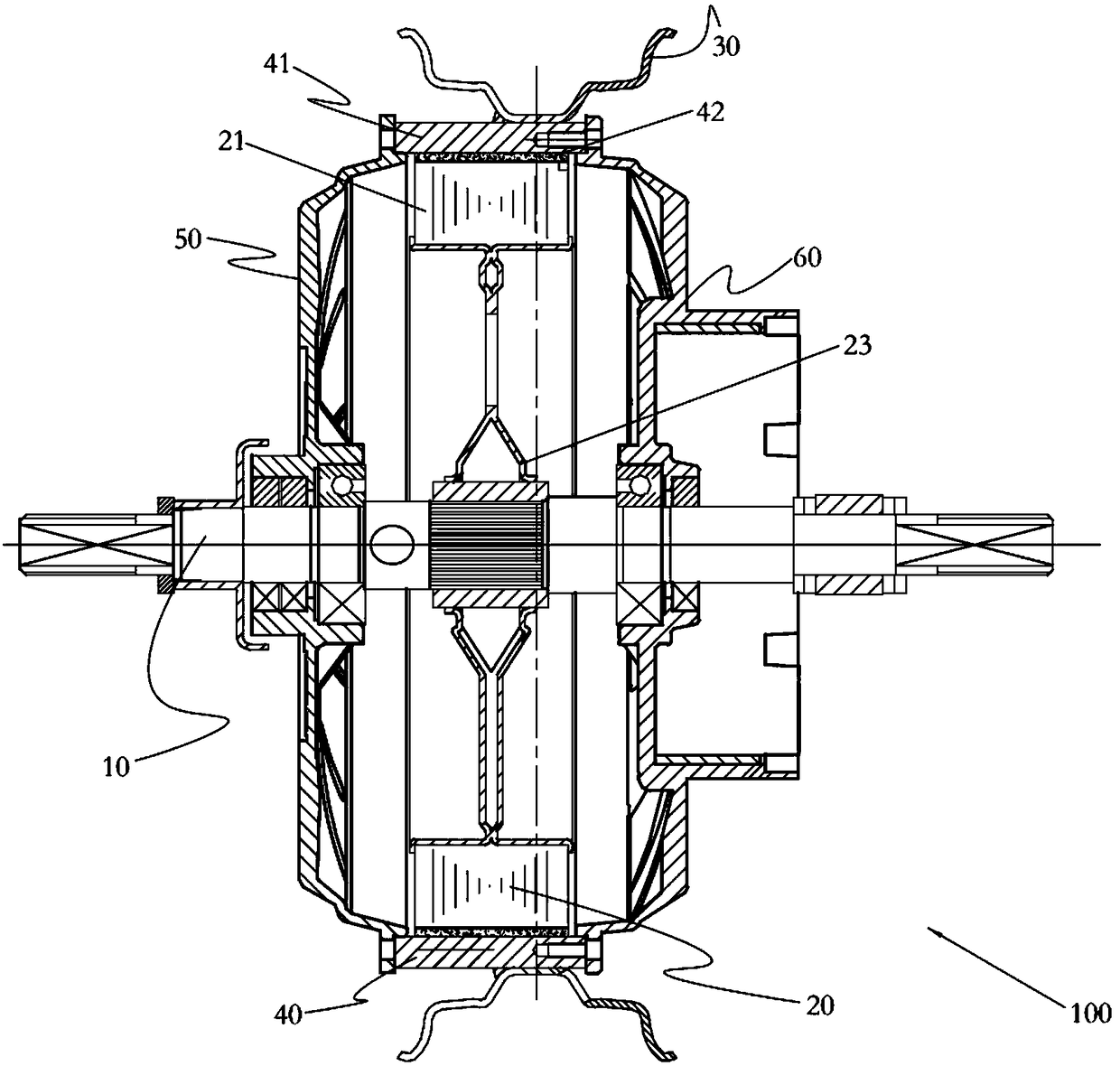

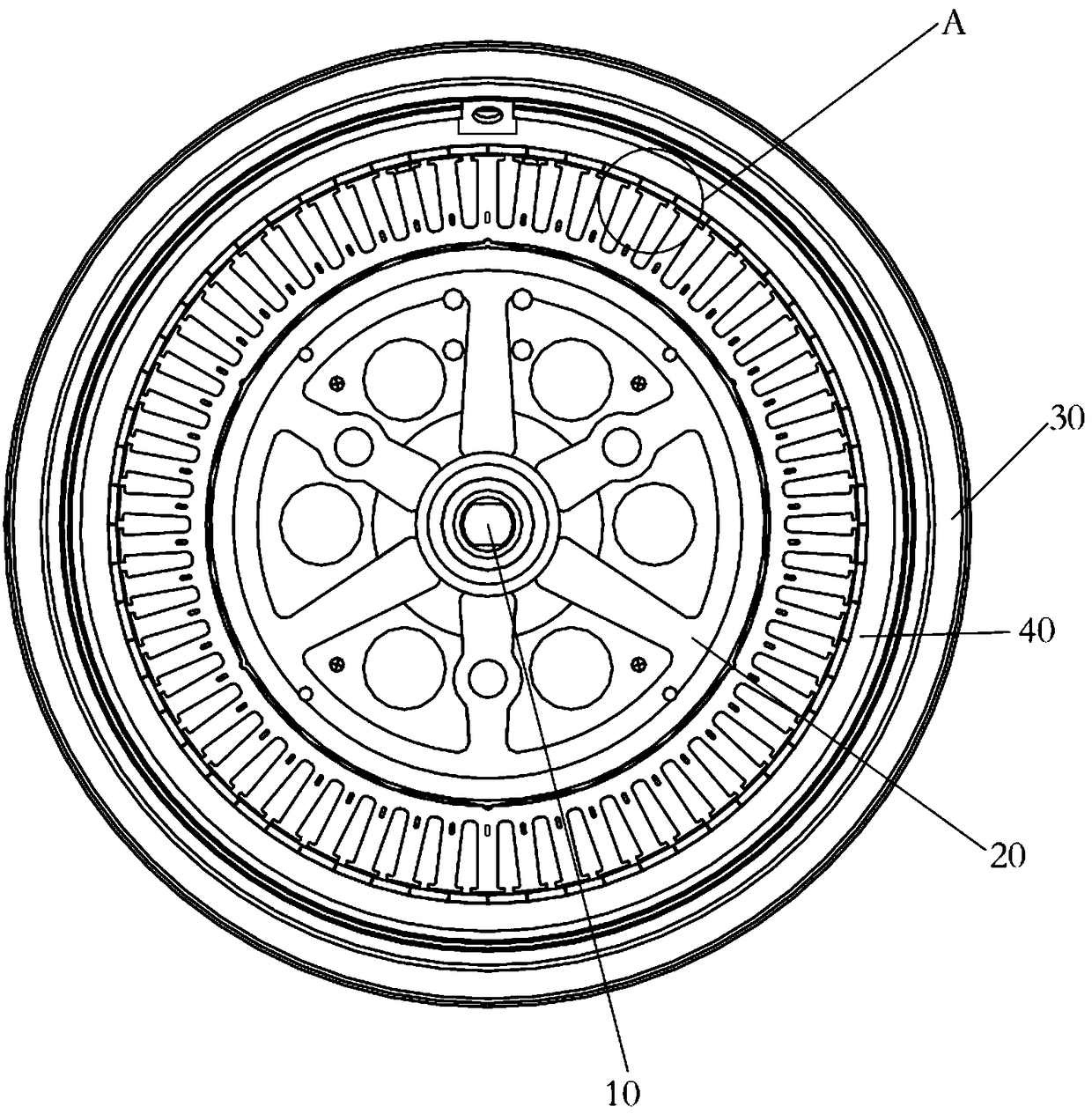

A motor driving system for an electric vehicle and an electric vehicle

ActiveCN109245343AImprove fault toleranceDoes not increase insulation performance requirementsAssociation with control/drive circuitsAC motor controlElectricityMotor drive

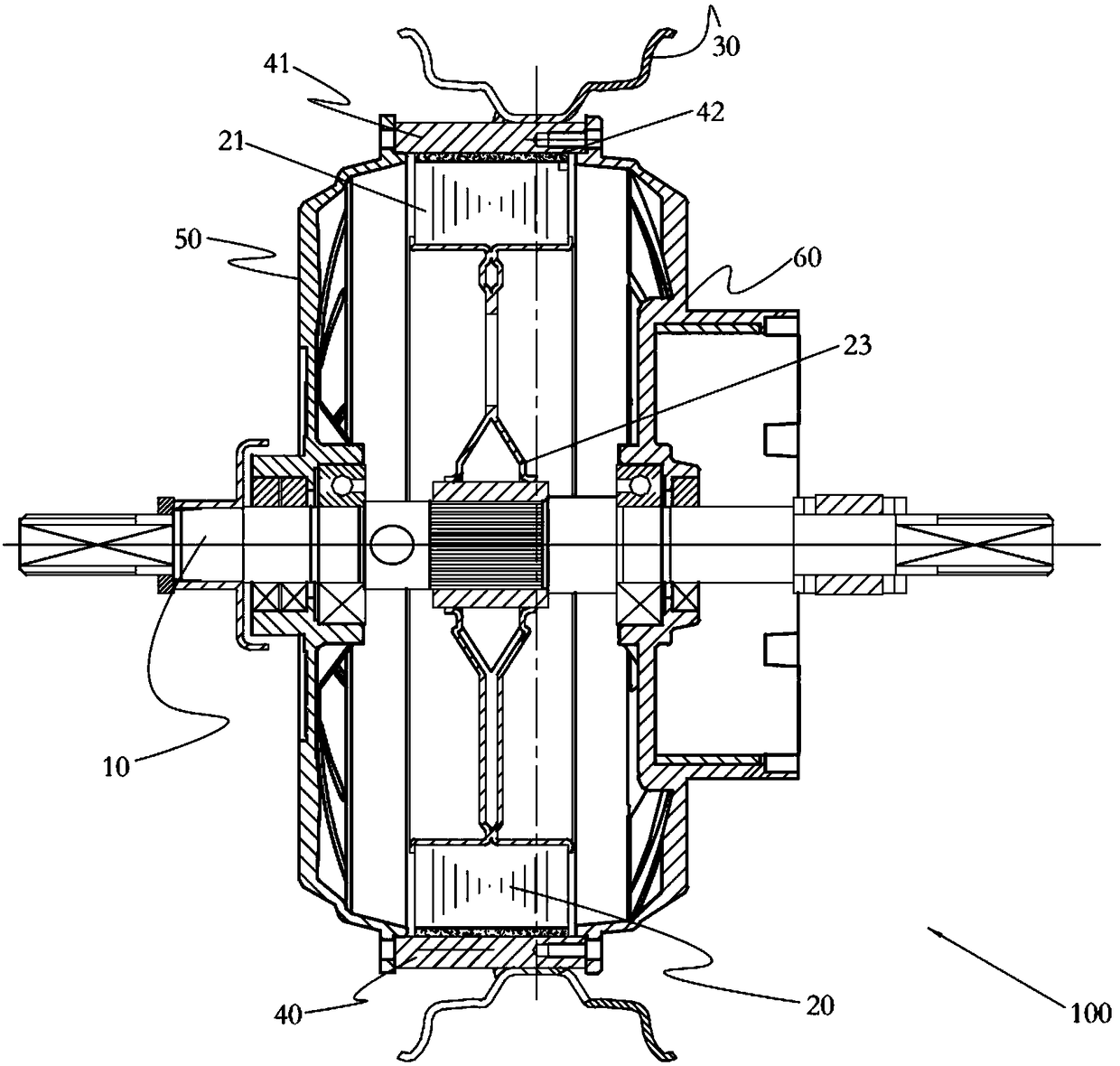

The invention discloses a motor driving system for an electric vehicle and an electric vehicle. The motor driving system comprises a three-phase alternating current motor and a controller group for controlling the three-phase alternating current motor. The stator of the three-phase alternating current motor adopts two or more winding units, and the three-phase alternating current motor is a permanent magnet motor. The controller group includes motor driver units electrically connected with each winding unit, and each motor driver unit is used for controlling the operation of the correspondingwinding unit. Wherein, the controller group performs centralized coordinated management control on the running state of each motor driver unit; Each motor driver unit includes an electrically connected battery and a controller, respectively. The invention effectively improves the technical bottleneck of unreliable performance and low cost of the electric vehicle in the medium and high power marketat present, and can effectively promote the development process of the future electric vehicle market to realize higher power and high performance on the premise of medium and low cost.

Owner:WUXI SINE POWER TECH CO LTD

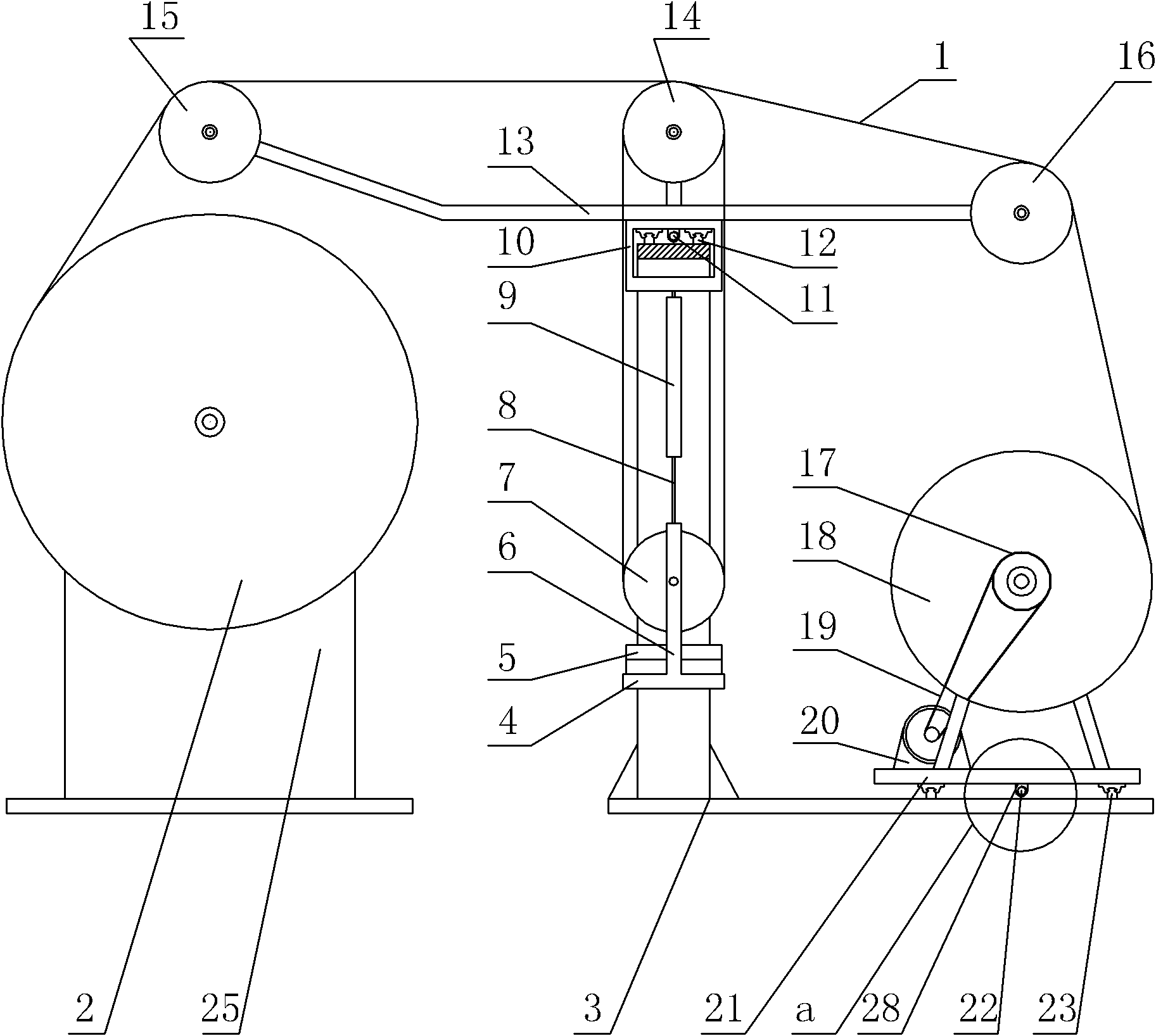

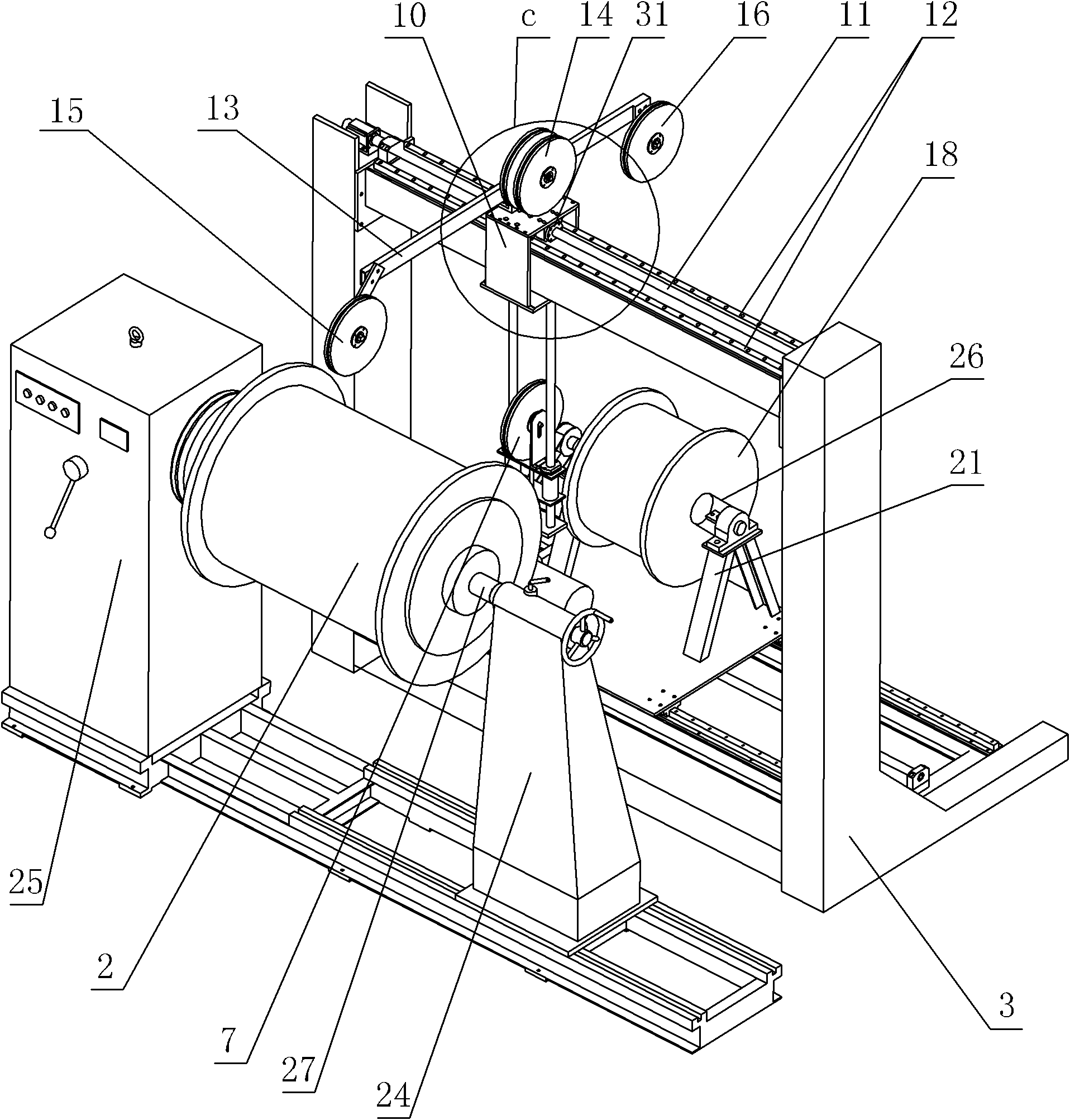

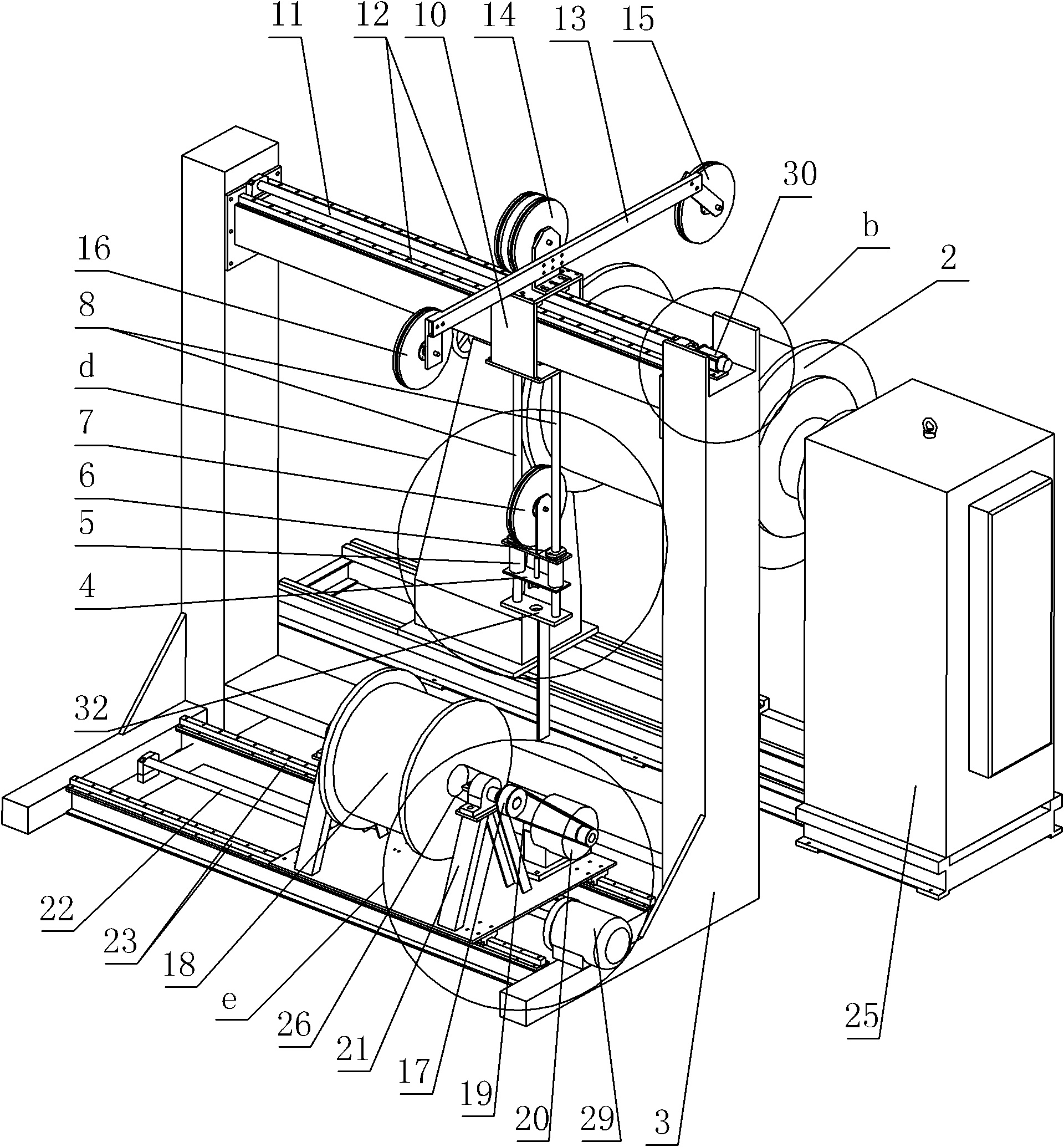

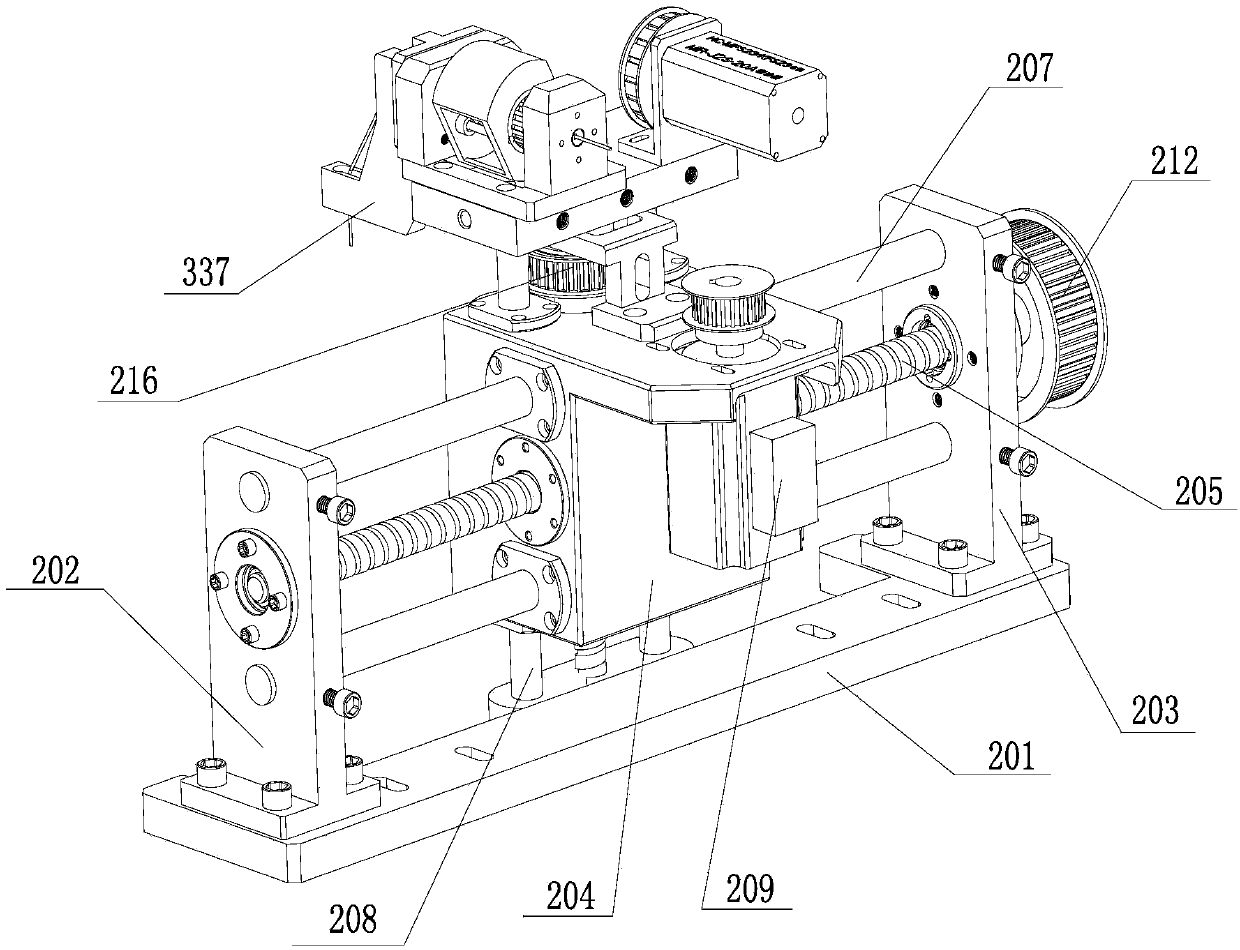

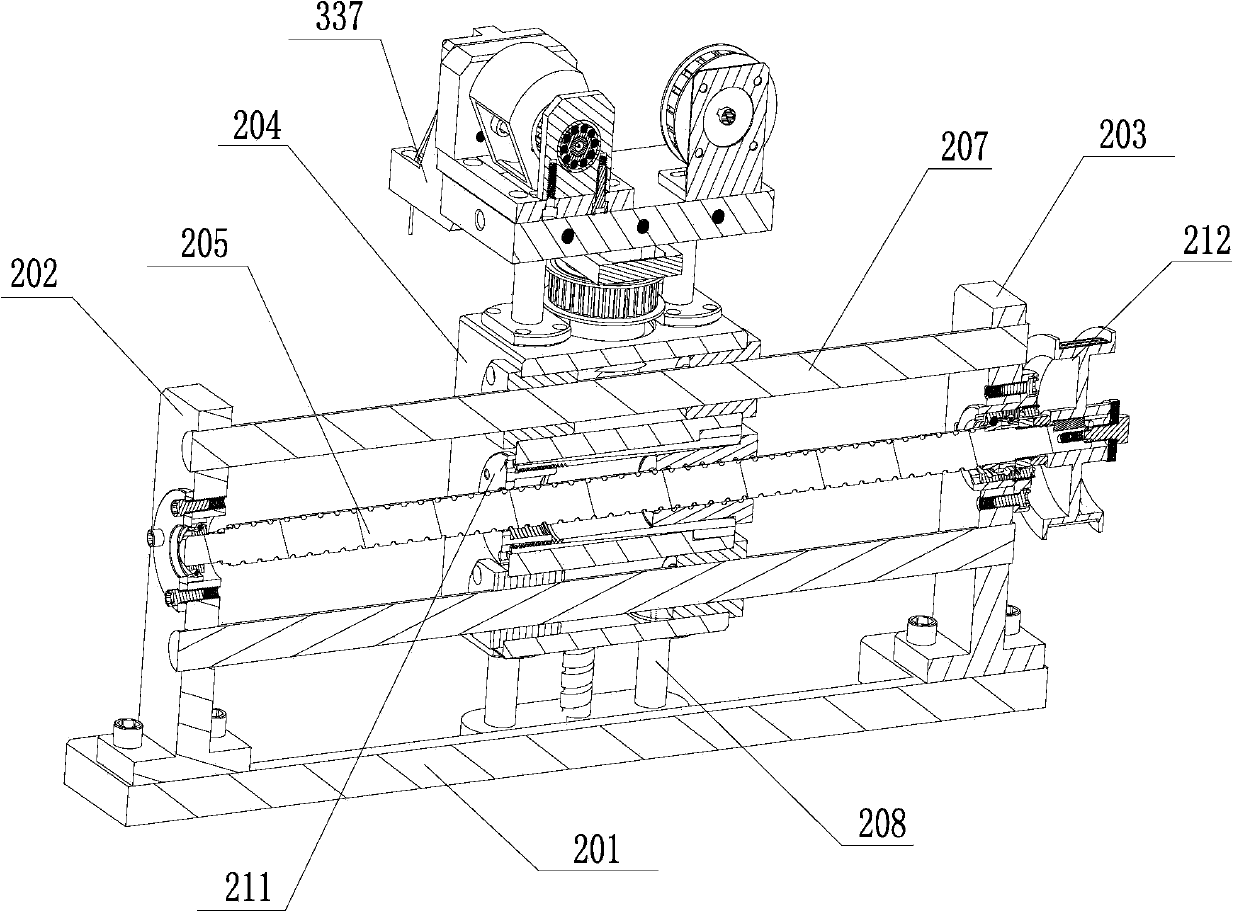

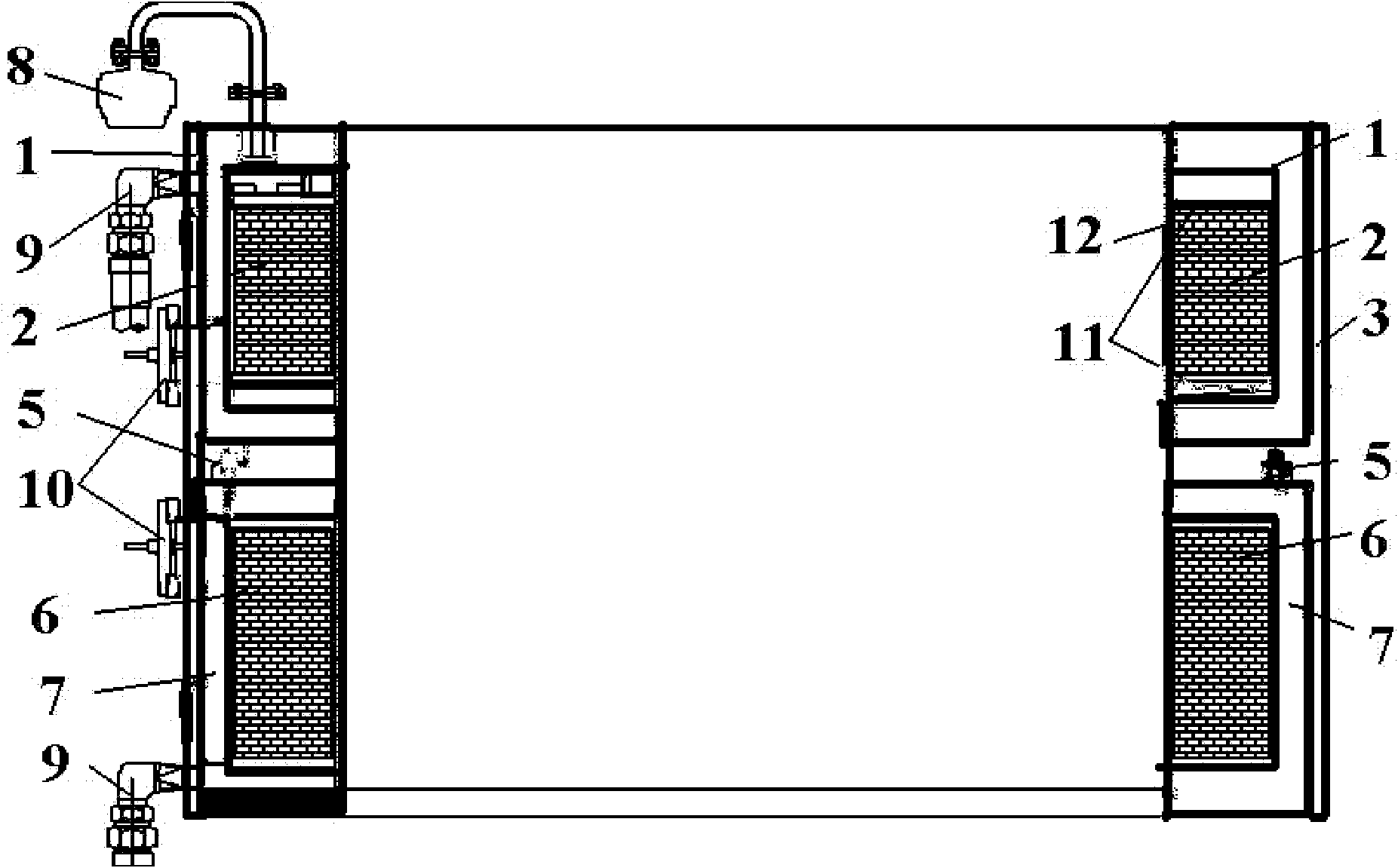

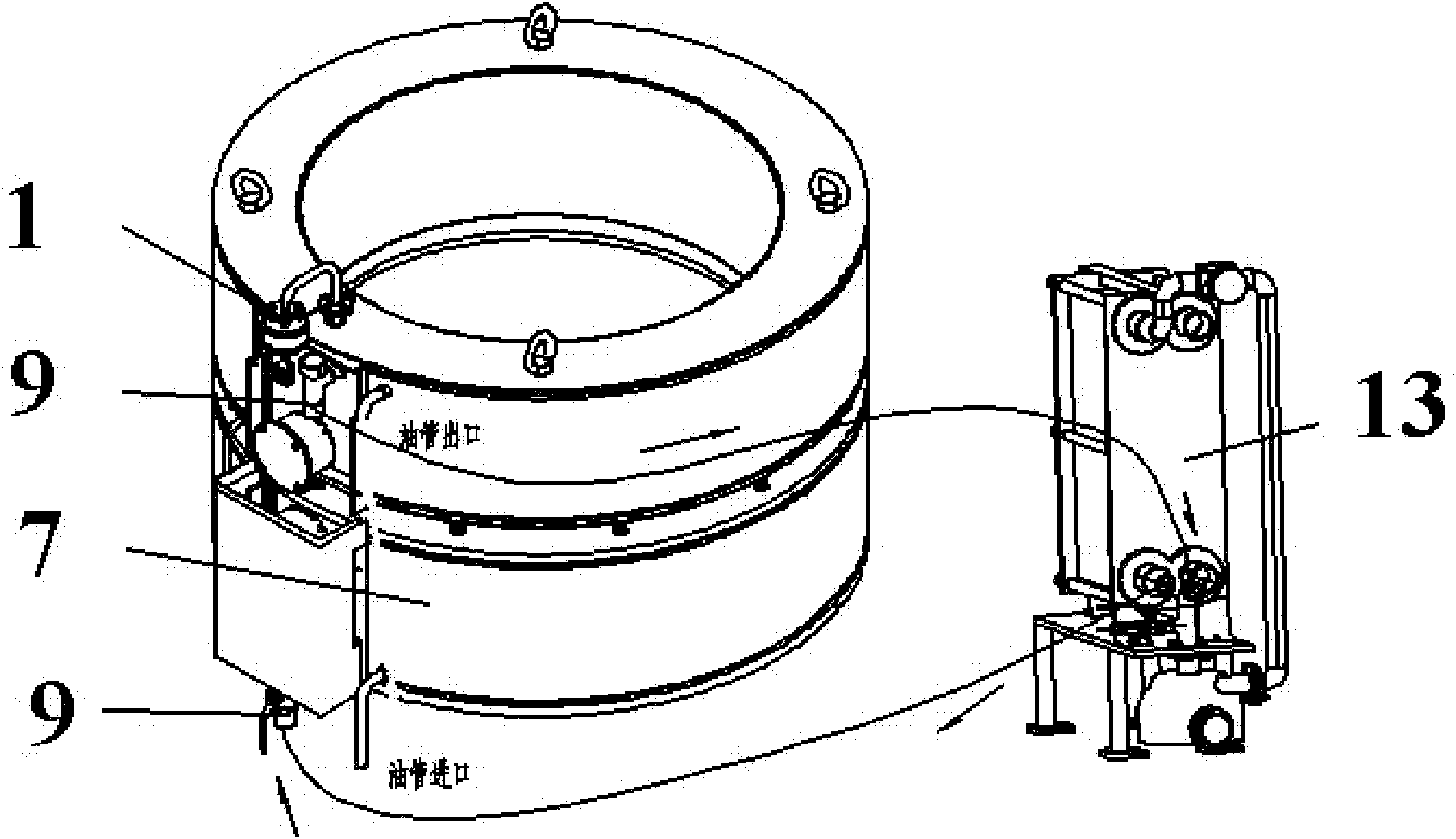

Constant-tension winding machine for niobium titanium-copper superconducting solenoid coils

InactiveCN102030223ACompact space arrangementSmall footprintFilament handlingCoils manufactureWinding machineSuperconducting solenoid

The invention provides a constant-tension winding machine for niobium titanium-copper superconducting solenoid coils, relating to a winding machine for superconducting solenoid coils. The invention solves the problems of complex winding process, high labor intensity of operators and low use ratio of equipment space of the current winding machine for superconducting solenoid coils. In the invention, an L-shaped portal frame is provided with two first slider linear guide rails and a first ball screw, and a double-track pulley is installed on a wiring arm. A wiring support arm of the wiring arm is provided with a wiring pulley, and a wire loading support arm of the wiring arm is provided with a wire loading pulley. A movable pulley is installed on a movable pulley axis support, and a wire loading tray is rotatably installed on a wire loading support. A superconducting solenoid coil to be wound is rotatably installed on a winding support, and a lead wire is led out through the wire loading tray and wound on the superconducting solenoid coil to be wound after moving round the wire loading pulley, one slideway of the double-track pulley, the movable pulley, the other slideway of the double-track pulley and the wiring pulley. The constant-tension winding machine is suitable for winding niobium titanium-copper superconducting solenoid coils.

Owner:HARBIN INST OF TECH

Transformer production process

The invention discloses a transformer production process and belongs to the technical field of transformer processing. The transformer production process includes (A) a preparation process (B) coiling I, (C) coiling II, (D) encapsulation, (E) reshaping encapsulation, (F) wire cutting and paint peeling, (G) iron core assembly, (H) inductance high voltage measurement, (I) steel strip binding and inductance high voltage measurement, (J) appearance inspection and vacuum paint dipping, (K) wire cutting, paint peeling and tin plating, (L) lead stranding, (M) lead welding and encapsulation, (N) wire folding, heat-shrinkable sleeving and wire binding, (O) QC electrical testing, (P) model mark sticking, (Q) appearance inspection and (R) packaging. The transformer production process has the advantages of being simple, efficient and high-qualified. Manufactured transformers are attractive in appearance, reliable and safe in insulating treatment, small in flux leakage, high in efficiency and particularly suitable for mass production.

Owner:XUZHOU GLORIA TECH

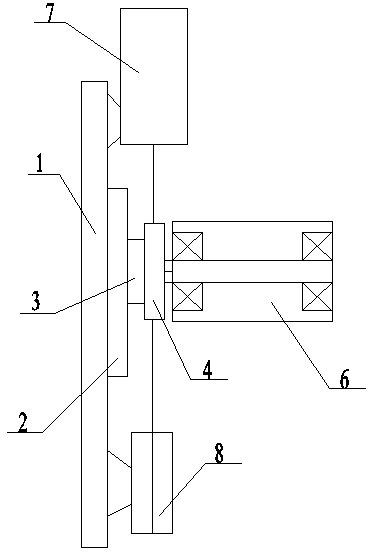

Linear guide track functional pulley group for bundle-like winding machine

A linear guide track functional pulley group for a bundle-like winding machine comprises a movable pulley used for guiding materials to be wound, and fixed pulleys which are arranged at two sides of the movable pulley; the movable pulley is arranged on a linear guide track and can reciprocate along the linear guide track; the movable pulley is connected with a displacement sensor connected with a control system; the control system controls the winding speed of the winding machine according to the displacement measured by the displacement sensor. The movable pulley is also connected with a forcing mechanism adopting any one from a spring, a cylinder or an oil cylinder, and the cylinder or the oil cylinder is connected with the control system. The linear guide track functional pulley group for the bundle-like winding machine is simple in structure, high in automation degree, safe and reliable in use, wide in application range, capable of fully meeting the demands of a production line and suitable for being promoted and used.

Owner:LUOYANG MINGWEI MACHINERY TECH

Method for manufacturing optical fiber current sensor sensitivity coil

ActiveCN101303373ASimple winding processEnsure stabilityCurrent/voltage measurementVoltage/current isolationEngineeringCurrent sensor

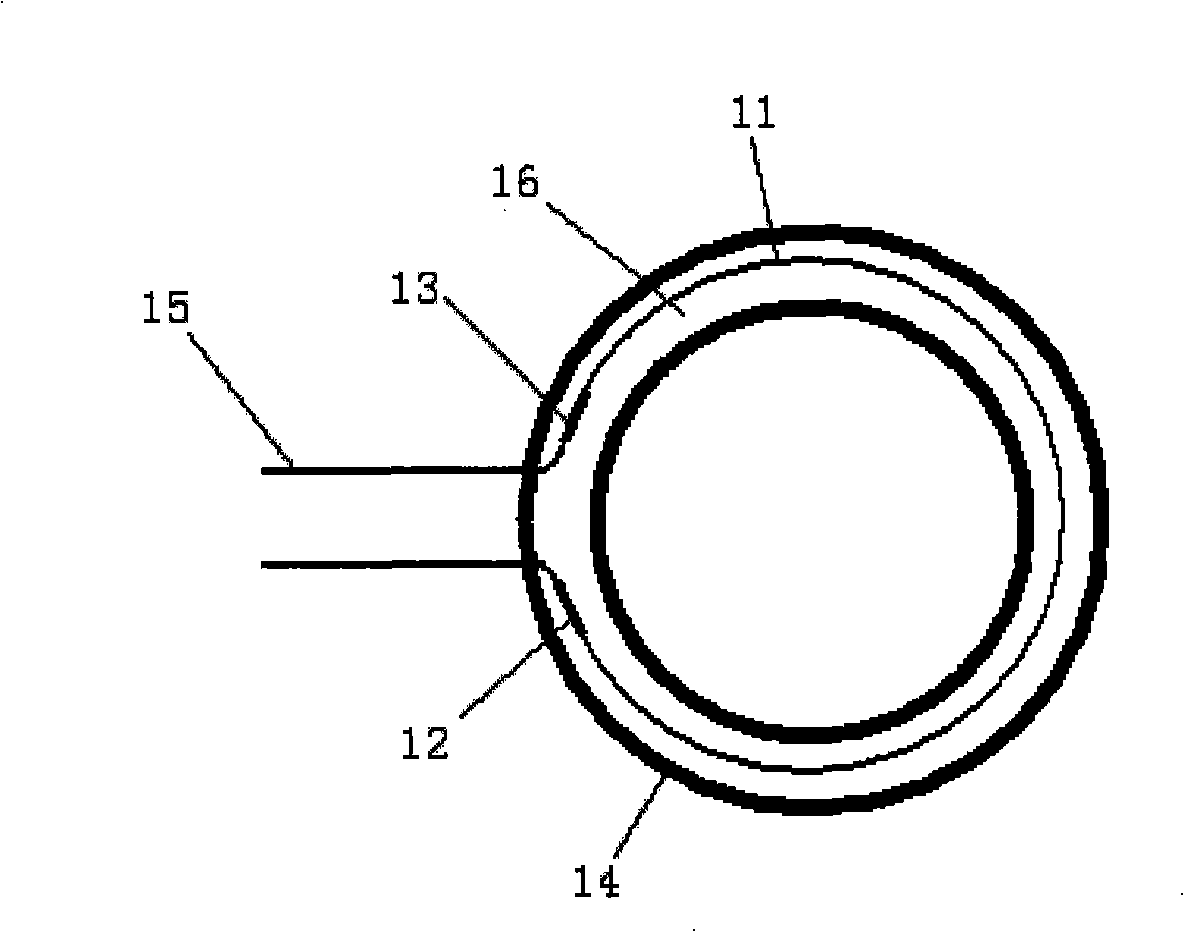

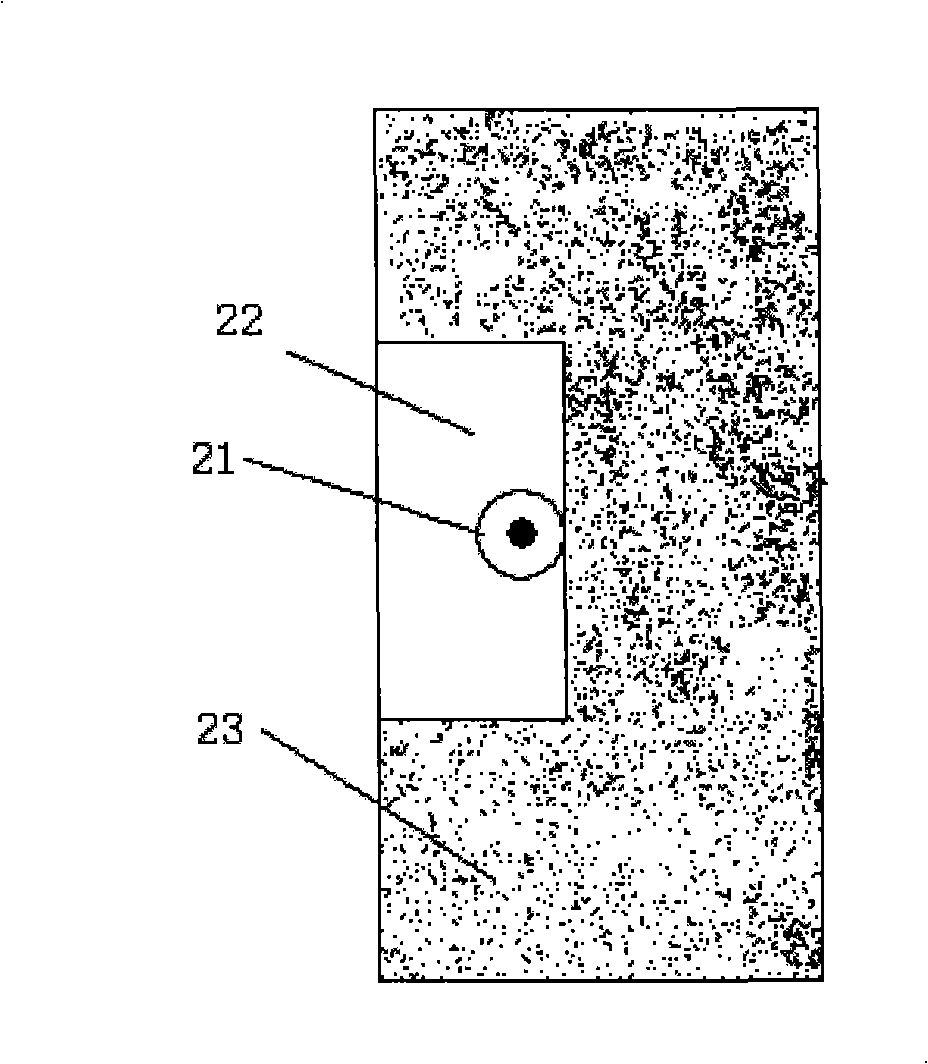

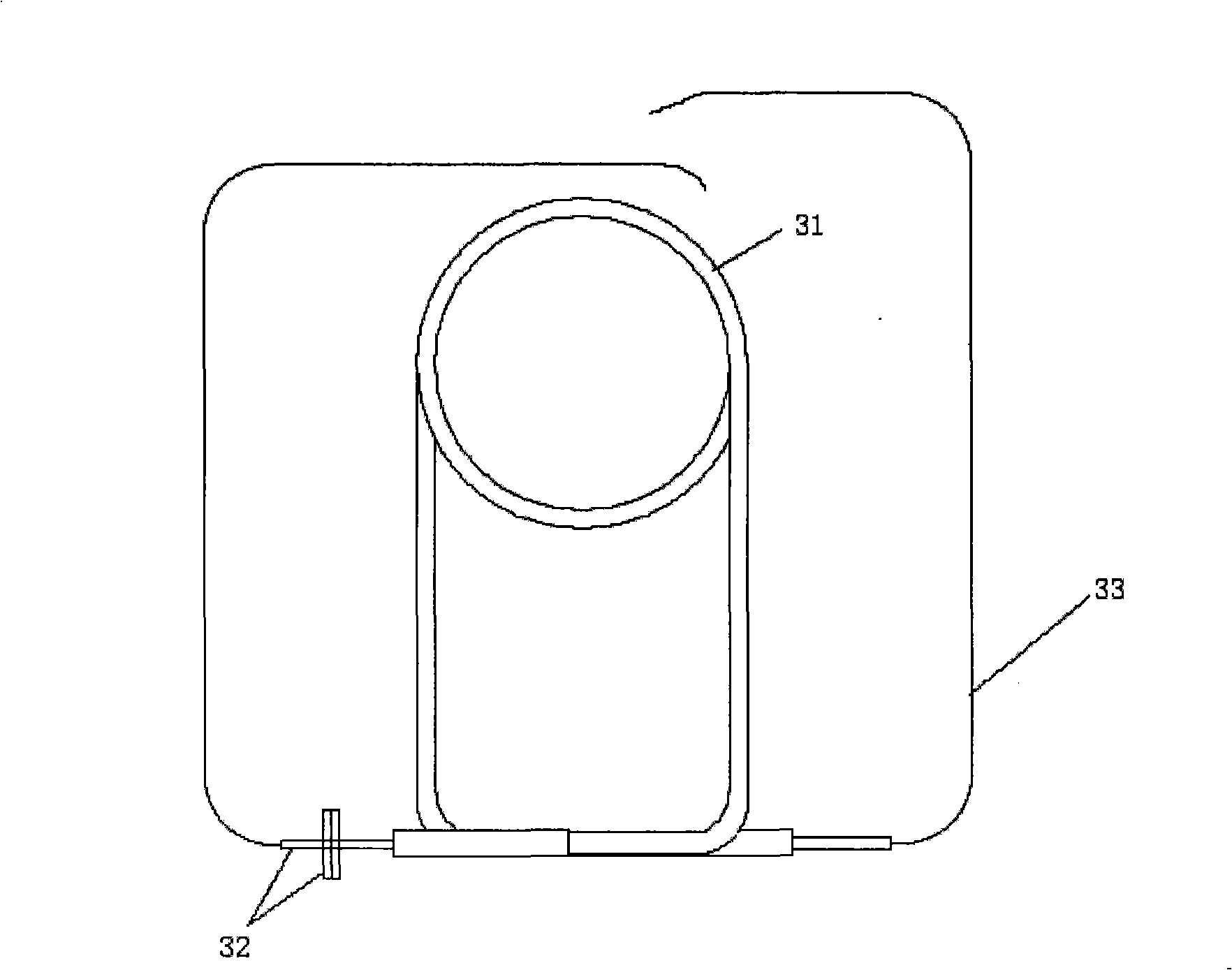

The invention discloses a method for preparing a sensor coil for an optical fiber current sensor, which comprises the steps that: (1) an annular coil frame is prepared with a relatively rough outer side surface, and an angle bracket is arranged on the outer side surface and the two sides of the angle bracket are both tangent with the coil frame; (2) the torsion of an optical fiber is removed to release stress; (3) the coil frame is fixed on the horizontal axis to ensure that the normal of the coil frame and the axes of the horizontal axis coincide and the horizontal axis of the coil frame is evenly rotated and fixed to fix the optical fiber on the coil frame; (4) symmetrical distributed points are chosen along the circumference direction of the coil frame to fix the optical fiber; (5) the two ends of the optical fiber are respectively provided with 1 / 4 wave plate and reflector and fixed on a bracket, the projection of the 1 / 4 wave plate and the reflector on the normal of the coil frame coincide and the end of the optical fiber provided with the 1 / 4 wave plate is connected with a polarization maintaining optical cable; (6) the coil is put into an incubator to remove stress introduced during the fixing process of the optical fiber; (7) the coil is fixed in a closed annular outer shell and sealed.

Owner:中国航天时代光电科技有限公司

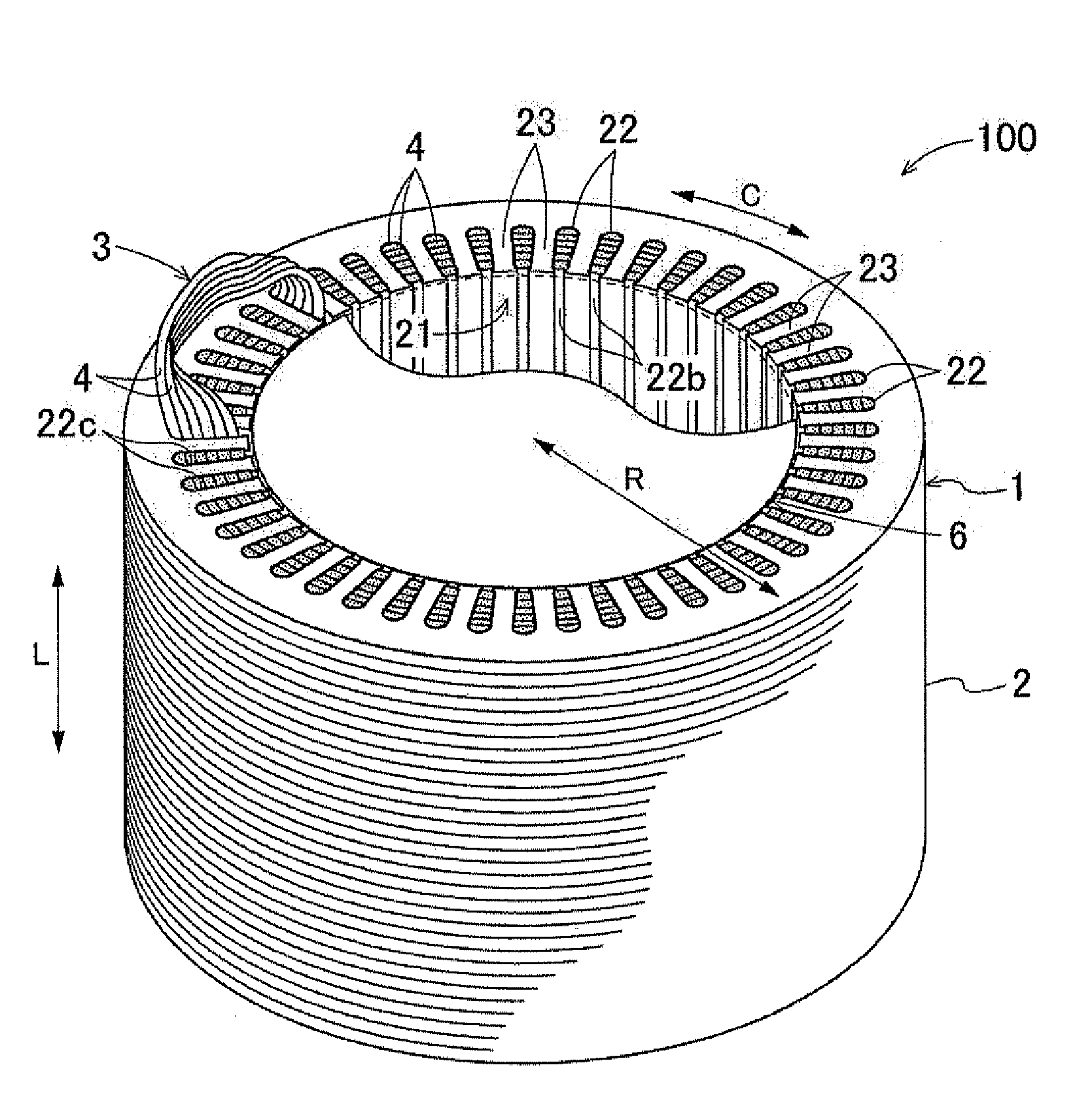

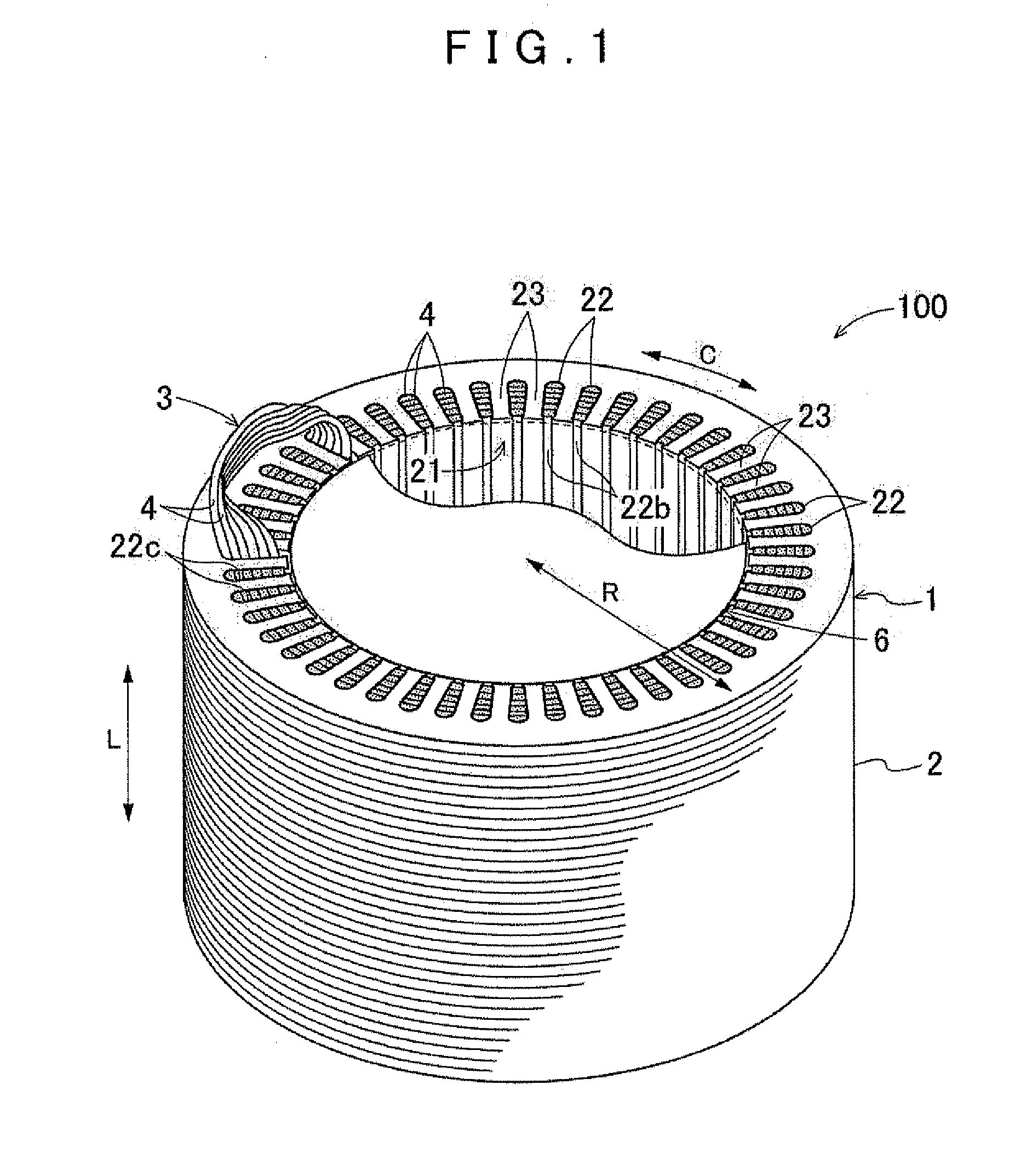

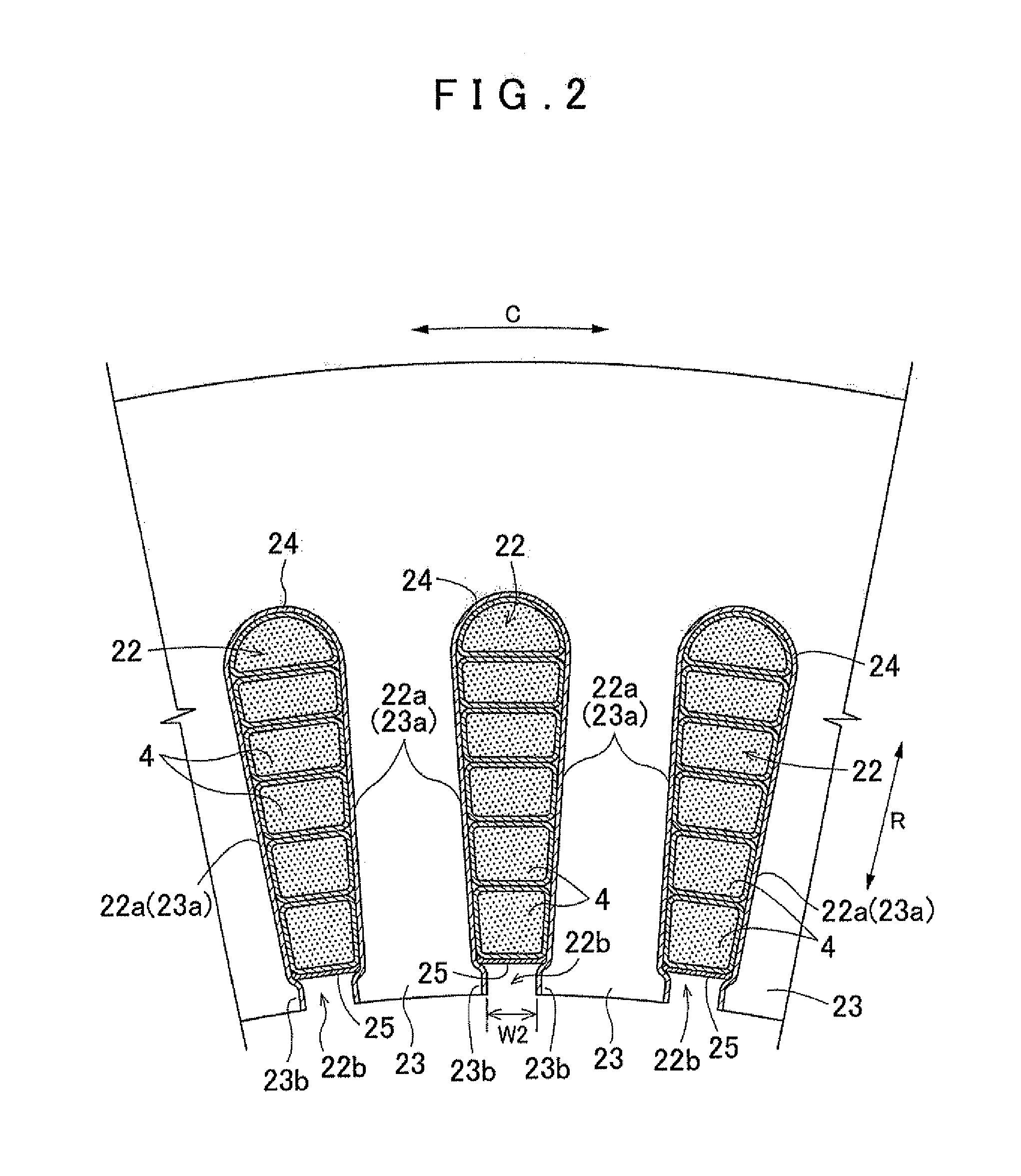

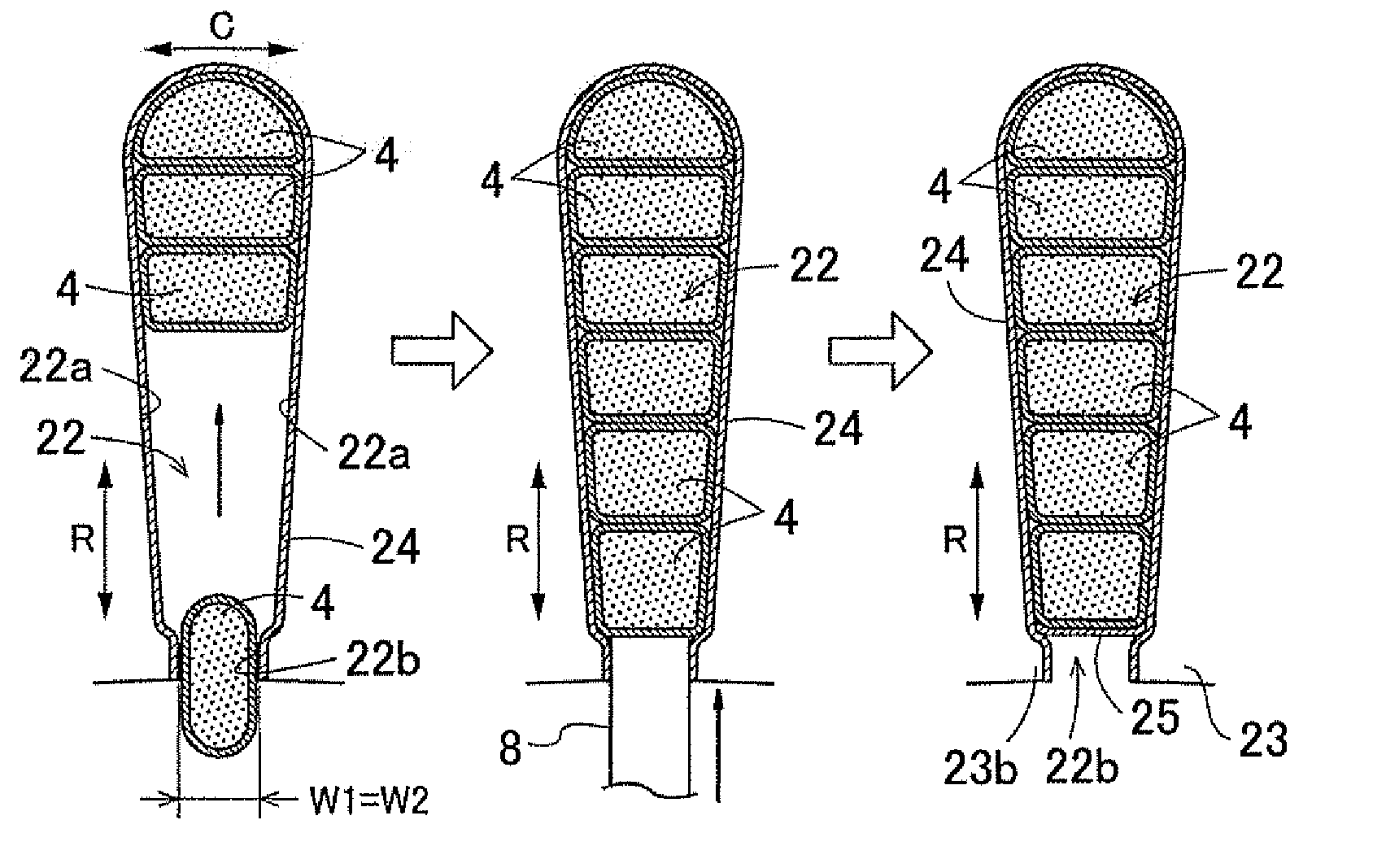

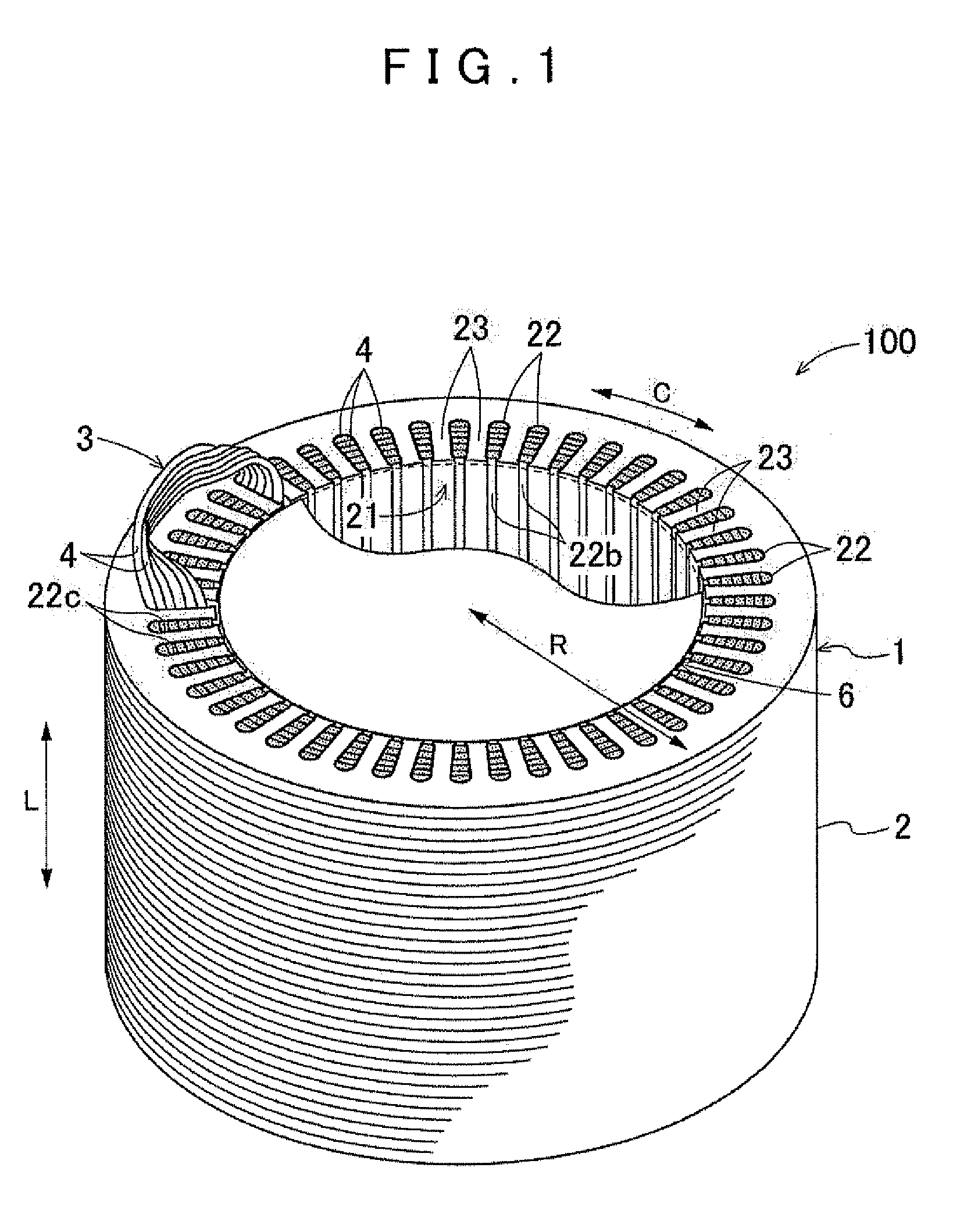

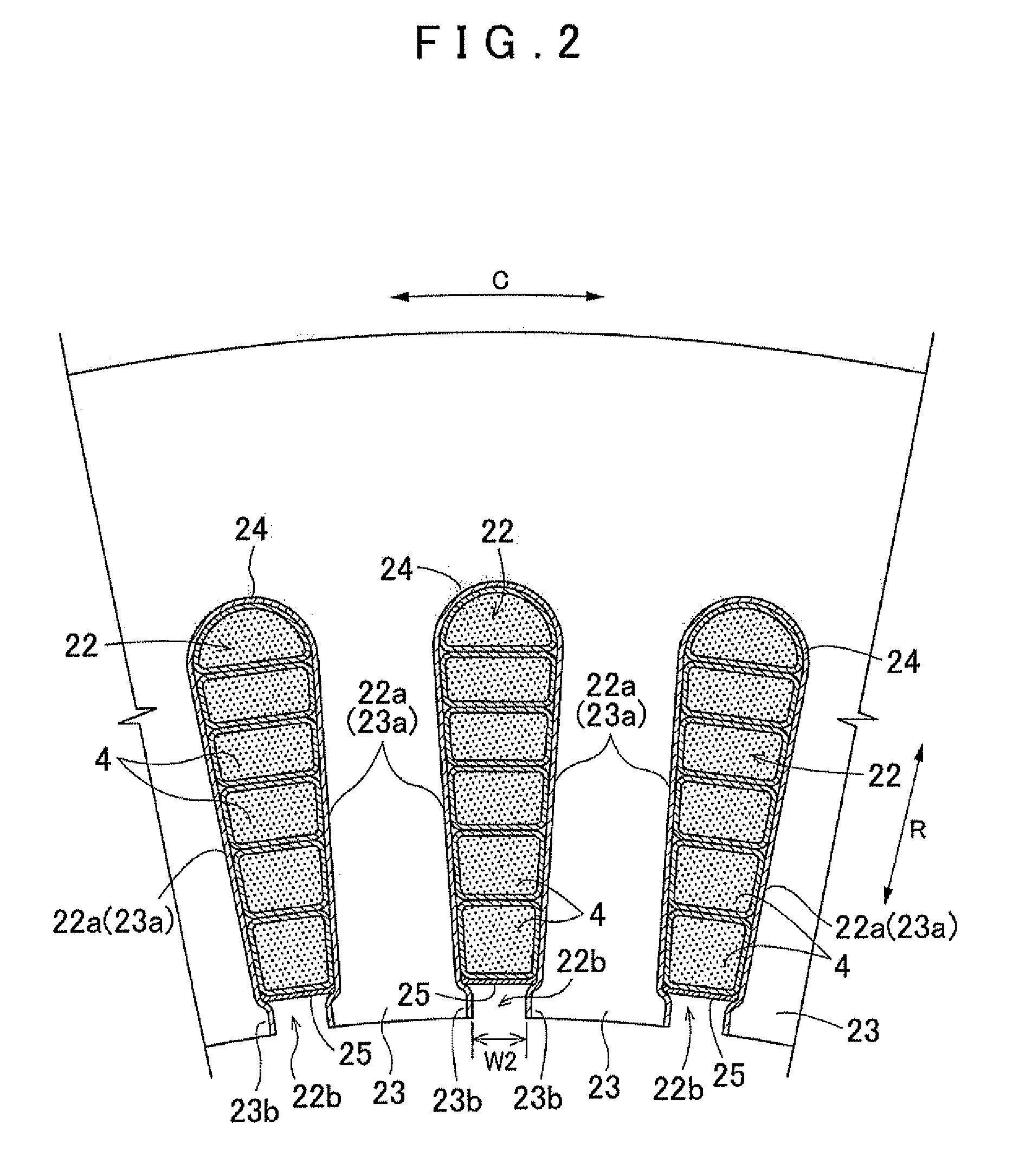

Conductor and rotating electrical machine

ActiveUS20130127289A1Simple processRaise the ratioWindings insulation shape/form/constructionSynchronous machinesElectrical conductorElectric machine

A conductor for a coil of a rotating electrical machine that includes a conductor wire bundle formed by gathering a plurality of conductor wires and a flexible insulating covering material that covers a periphery of the conductor wire bundle. The conductor has an intra-covering gap formed inward of the insulating covering material in a radial direction so that the conductor wires can move relative to each other in the intra-covering gap, and a cross-sectional shape of the insulating covering material along a perpendicular plane that is perpendicular to an extending direction in which the conductor wire bundle extends can be deformed.

Owner:AISIN AW CO LTD

Conductor and rotating electrical machine with a covering material

ActiveUS9172280B2Simple winding processRaise the ratioWindings insulation shape/form/constructionSynchronous machinesElectrical conductorMechanical engineering

A conductor for a coil of a rotating electrical machine that includes a conductor wire bundle formed by gathering a plurality of conductor wires and a flexible insulating covering material that covers a periphery of the conductor wire bundle. The conductor has an intra-covering gap formed inward of the insulating covering material in a radial direction so that the conductor wires can move relative to each other in the intra-covering gap, and a cross-sectional shape of the insulating covering material along a perpendicular plane that is perpendicular to an extending direction in which the conductor wire bundle extends can be deformed.

Owner:AISIN AW CO LTD

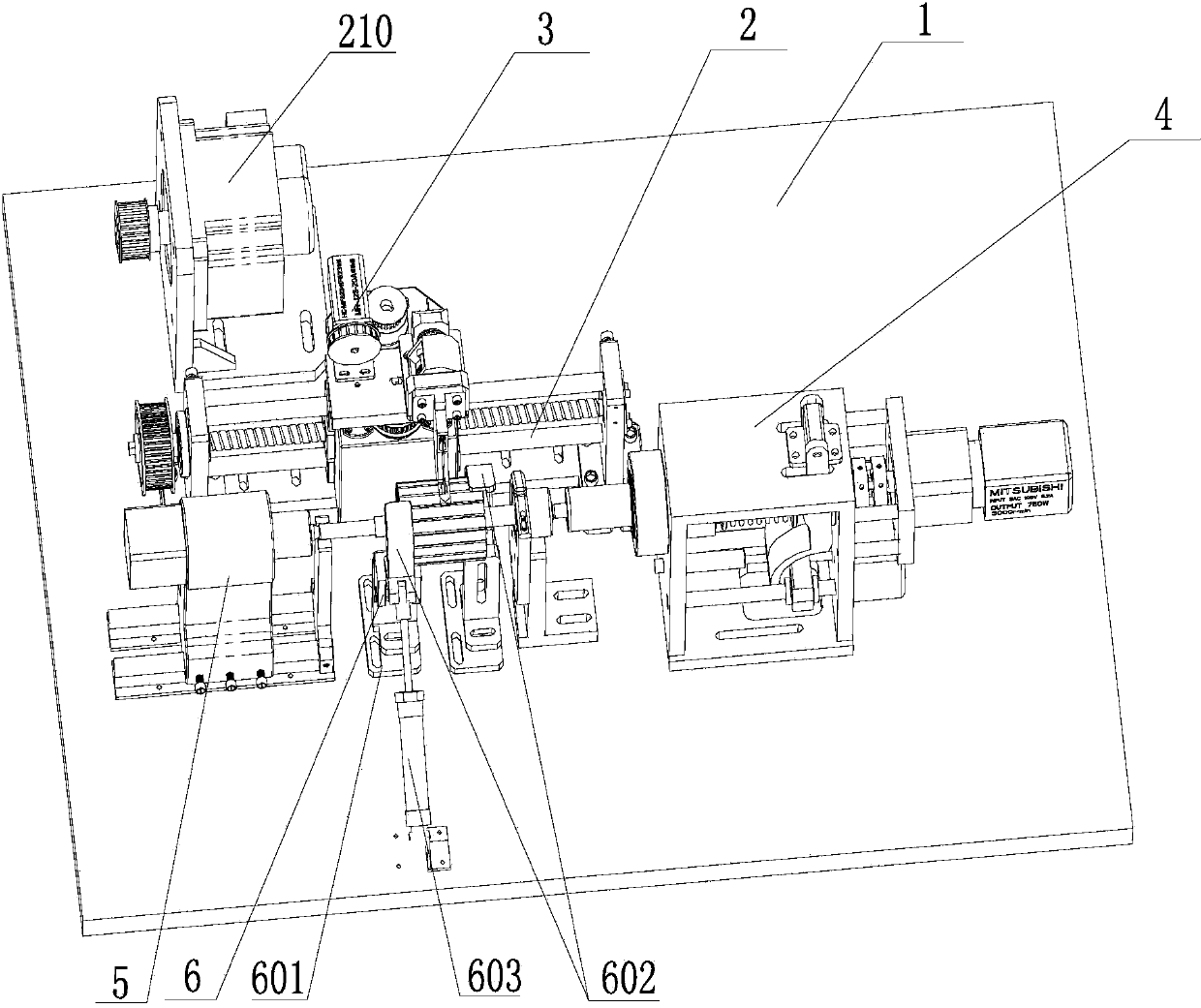

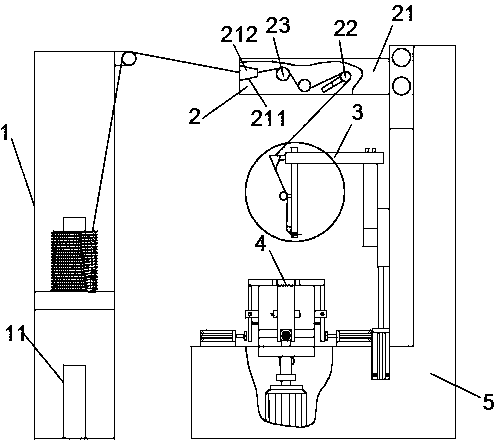

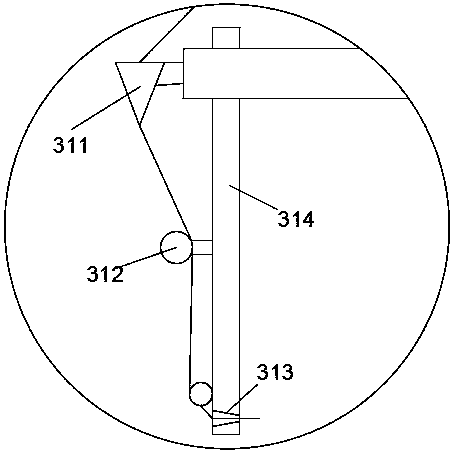

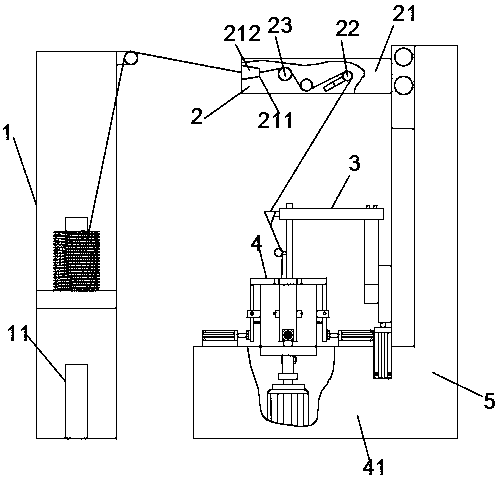

Winding mechanism of direct-current motor rotor

ActiveCN104184277AEasy to remove paintSimple winding processManufacturing dynamo-electric machinesConductor CoilTailstock

The invention discloses a winding mechanism of a direct-current motor rotor. The winding mechanism comprises a working table, a main winding mechanism, a depainting mechanism, a clamping mechanism used for clamping the motor rotor and a tailstock. The depainting mechanism is arranged at the top of the main winding mechanism, and the clamping mechanism, the tailstock and the main winding mechanism are all arranged on the working platform. The main winding mechanism comprises a first base, a first vertical plate, a second vertical plate, a block, a first lead screw, a second lead screw, one or more first guide rails, one or more second guide rails, a second motor and a first motor, wherein the first vertical plate and the second vertical plate are arranged at the two ends of the first base, the first lead screw is arranged horizontally, the second lead screw is arranged vertically, the first guide rails are arranged horizontally, the second guide rails are arranged vertically, and the first motor is used for driving the first lead screw to rotate. The second lead screw is perpendicular to the first lead screw in different surfaces. The depainting mechanism is arranged on an upper end plate, and the connecting line of the clamping mechanism and the tailstock is parallel to the first lead screw. The winding mechanism has the advantages that the motor rotor does not move axially when the motor rotor conducts winding, the winding process of the motor rotor is simple, and the motor rotor does not need to be positioned repeatedly.

Owner:NANJING COLLEGE OF INFORMATION TECH

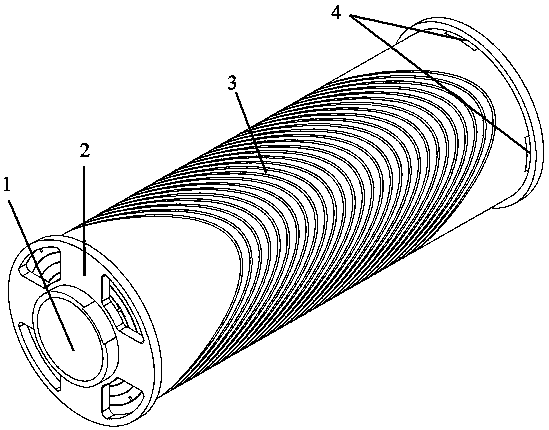

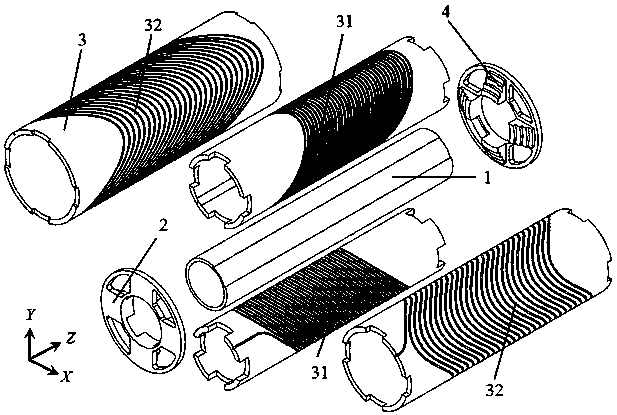

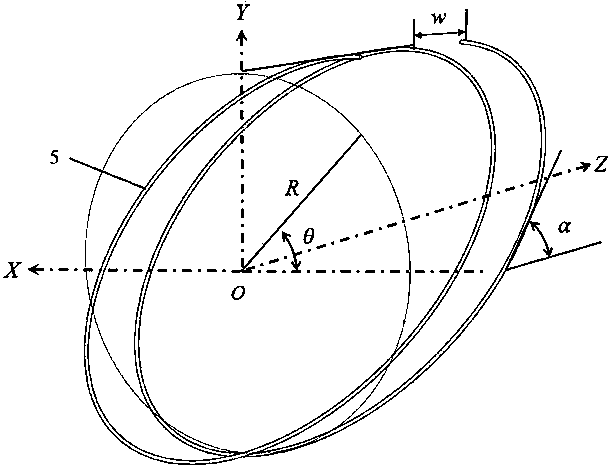

Inclined solenoid for Gantry magnet

ActiveCN107670181ASmall sizeReduce weightX-ray/gamma-ray/particle-irradiation therapyEngineeringMedical treatment

The invention relates to an inclined solenoid for a Gantry magnet. The inclined solenoid herein includes a support cylinder and a multilayer skeleton which has a rectangular wire duct and is coaxiallyin sleeving connection to the support cylinder. Two ends of the multilayer skeleton are separately provided with an end plate. Each end plate is provided with a position guide boss on the internal side thereof. The inclined solenoid herein is characterized in that: the rectangular wire duct is provided with a multi-turn superconducting wire which can generate multi-polar magnetic fields, and themulti-turn superconducting wire forms coins of internal layer combination and external layer combination, wherein at least two layers of both internal layer combination and external layer combinationare provided, and the coils appear in pair in a direction opposite to the inclining direction; each turn of the coils is in periodic arrangement in the axial direction Z and has a shape which is controlled by a space curve equation. According to the invention, the inclined solenoid herein uses a yoke-free magnet, which can effectively reduce the size and weight of the magnet, reduces manufacturing, and operation and maintenance cost, and makes medical treatment apparatuses more energy-saving and small in size.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

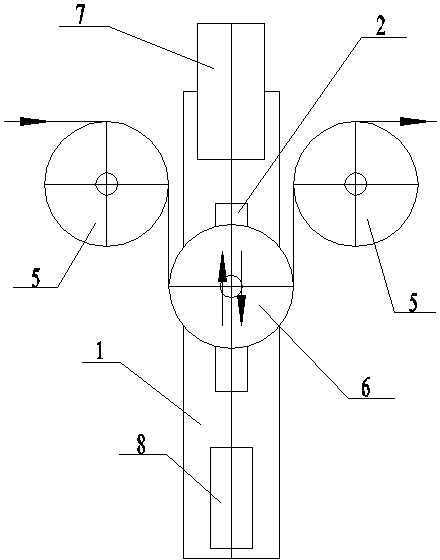

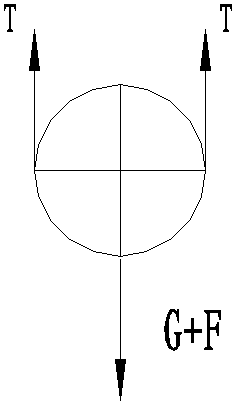

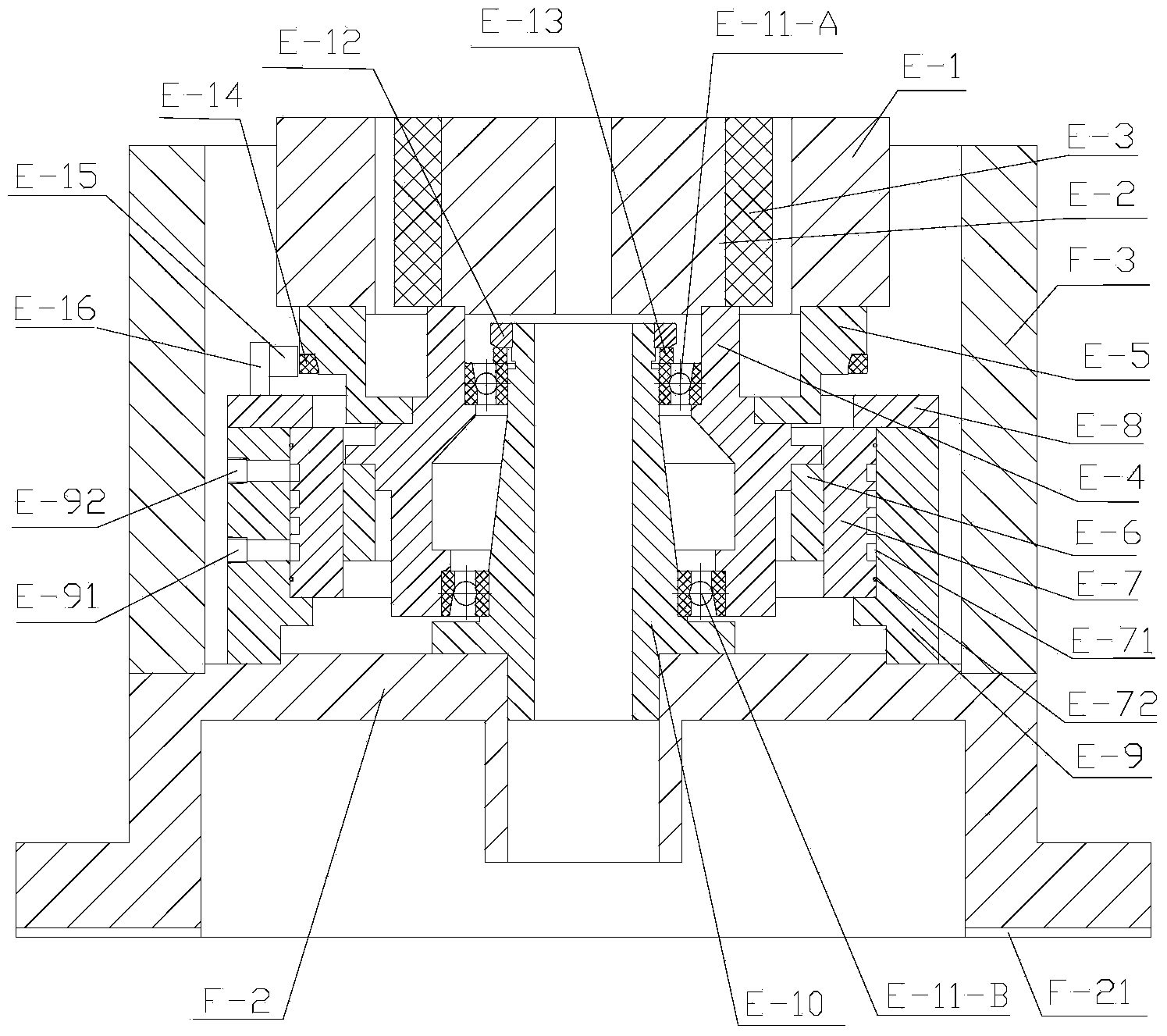

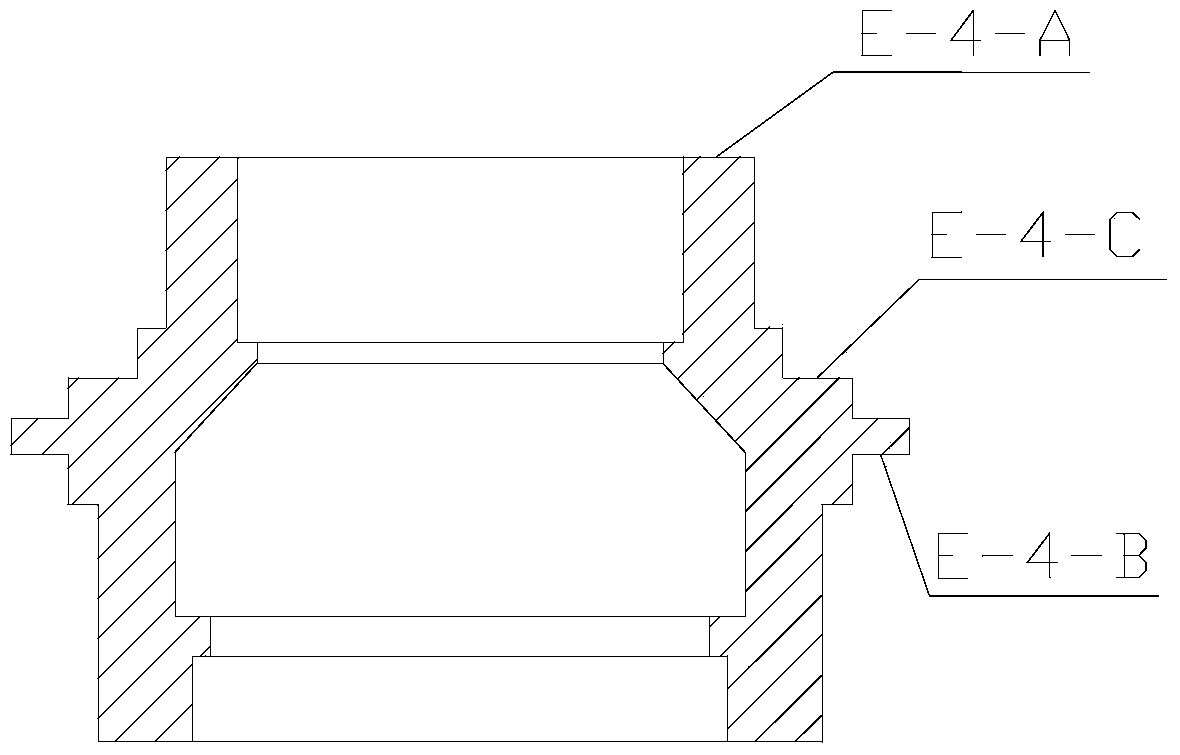

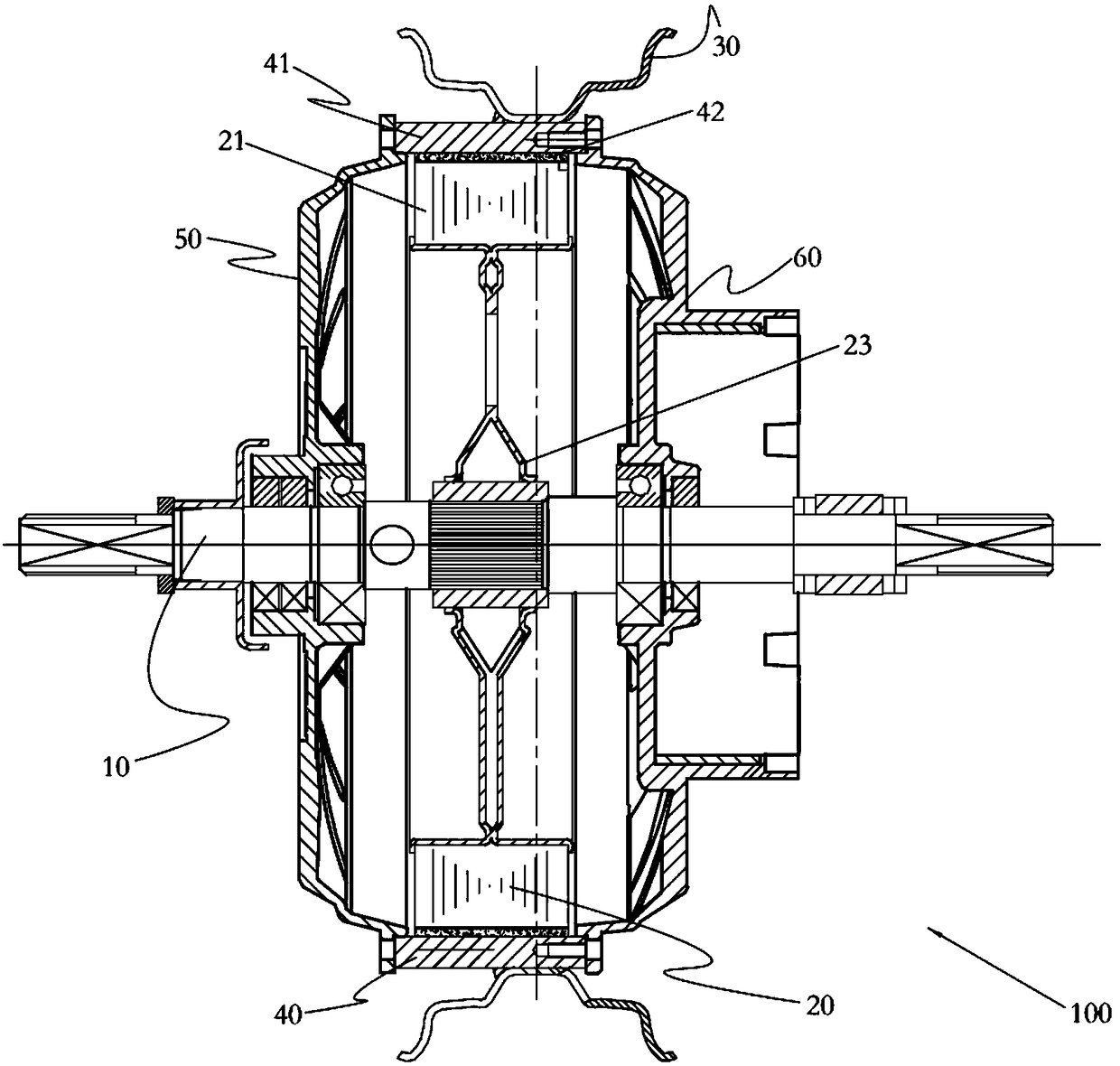

Low-frequency and large-displacement angular vibration table

A low-frequency and large-displacement angular vibration table comprises a case, a work tabletop, a main shaft driving the work tabletop to rotate, a moving coil assembly, a magnetic circuit assembly, a motor driving the magnetic circuit assembly to rotate, a closed-loop control assembly of the motor, an electric viscoelastic feedback control assembly, an air bearing and an angular displacement sensor. The main shaft is fixedly connected with the moving coil assembly, and the magnetic circuit assembly is fixedly connected with a rotor of the motor through a connector. The moving coil assembly comprises a moving coil base body and coils, wherein the moving coil base body is fixedly connected with the main shaft. The magnetic circuit assembly comprises a magnetism guide ring, a central magnetic pole and magnetic steel, wherein the magnetism guide ring, the central magnetic pole, the magnetic steel and an air gap form a closed magnetic loop. The central magnetic pole is located in the magnetism guide ring, the magnetism guide ring is coaxial with the central magnetic pole, and the magnetic steel is located between the magnetism guide ring and the central magnetic pole and attracted to the central magnetic pole. The moving coil assembly is located between the magnetic steel and the magnetism guide ring and is coaxial with the magnetism guide ring. The low-frequency and large-displacement angular vibration table has the advantages that the distortion factor of output wave forms is small, and the output angular displacement is large.

Owner:ZHEJIANG UNIV

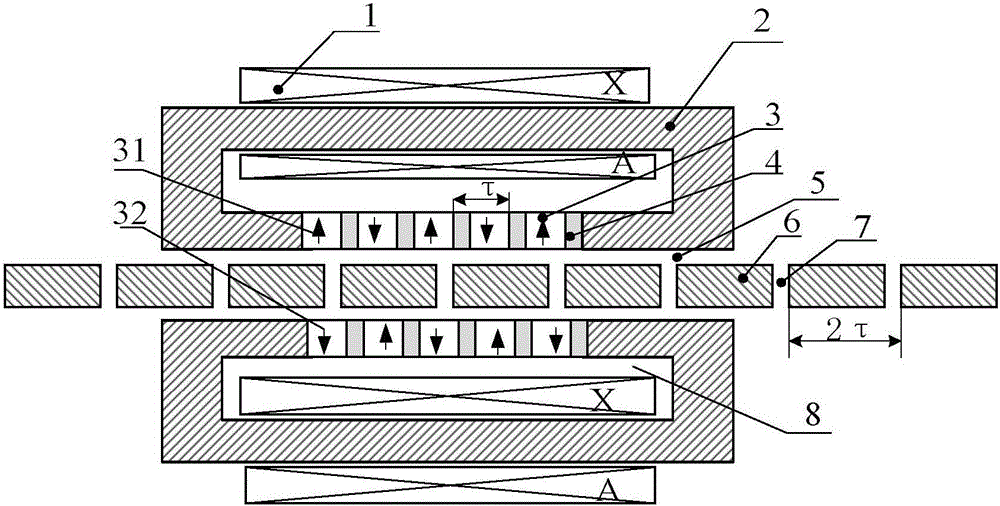

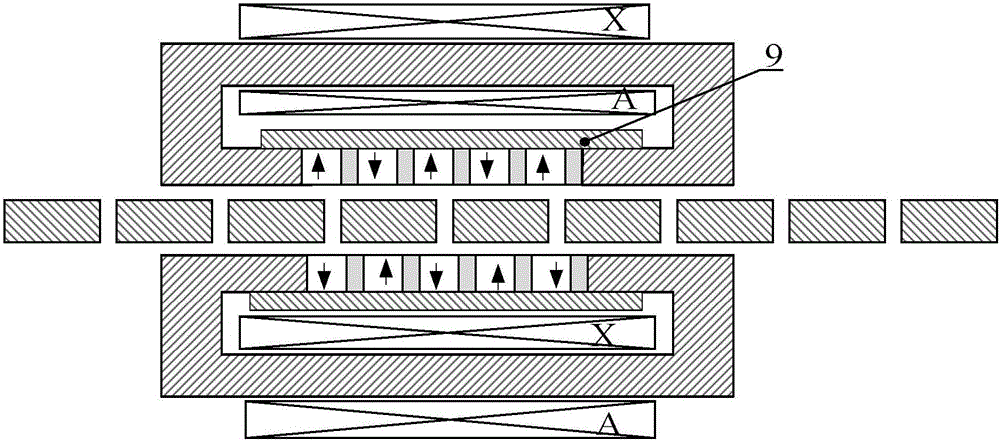

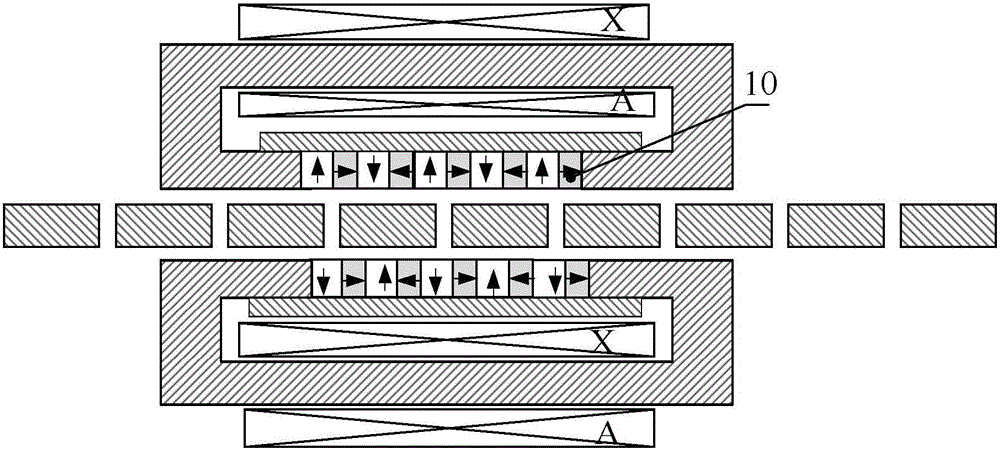

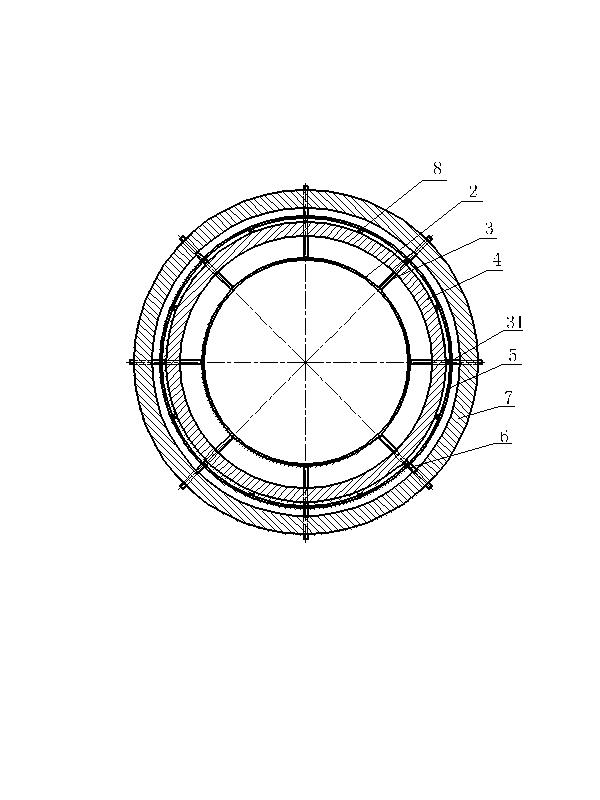

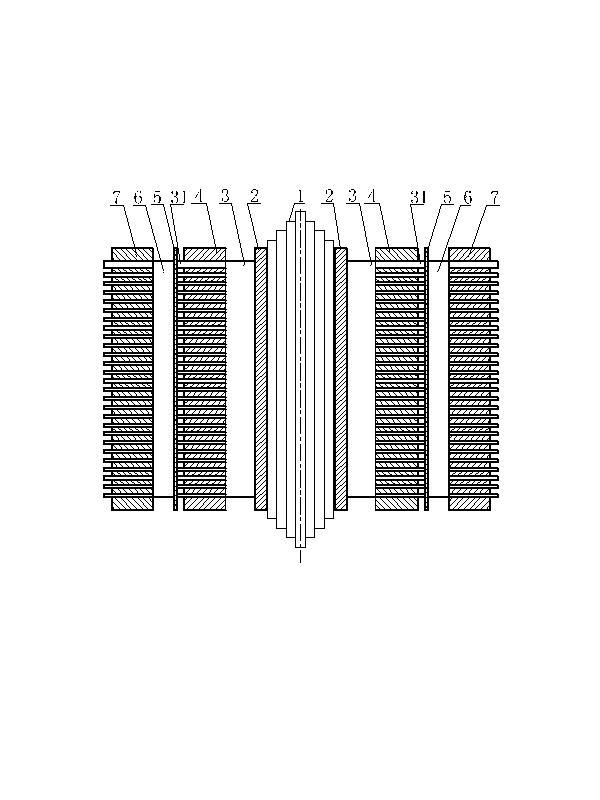

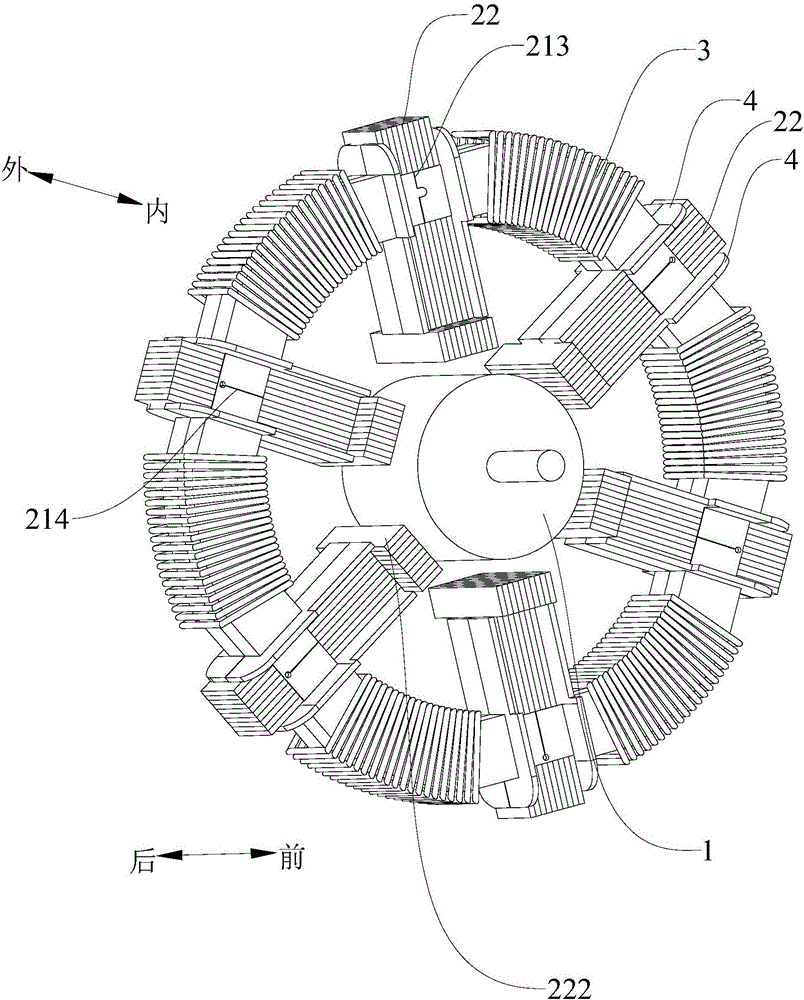

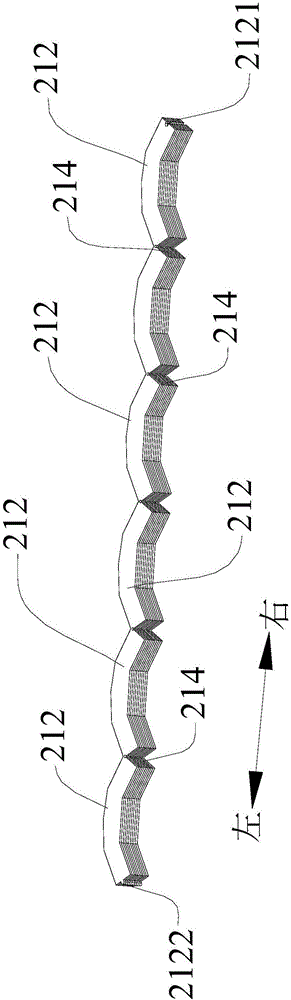

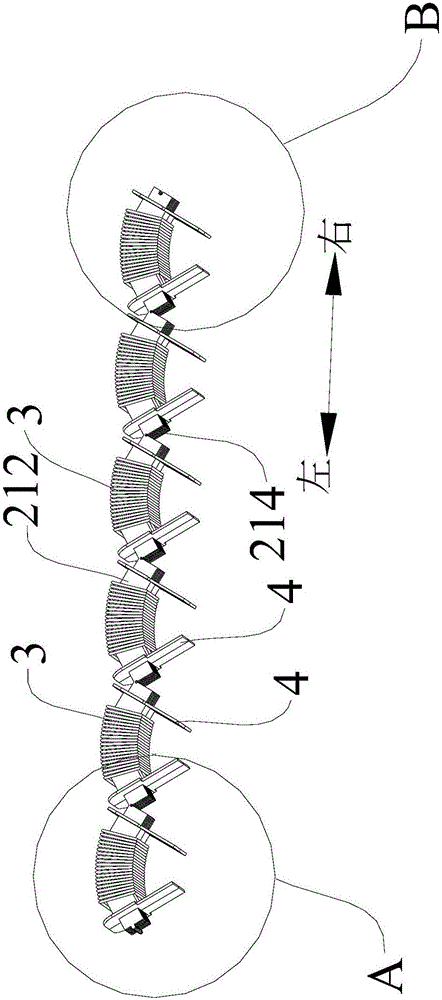

Independent-winding double-side plate permanent magnet linear motor

ActiveCN106100283ASimple winding processEasy to achieve coolingPropulsion systemsModular compositionElectricity

The invention discloses an independent-winding double-side plate permanent magnet linear motor, which comprises primary sides, a secondary side and air gaps. Each primary side comprises an armature winding, a primary magnetic-conductive iron core and a permanent magnet array. The two primary side assemblies are arranged at the two sides of the secondary side respectively to form a double-side structure. The primary magnetic-conductive iron core forms a big open slot structure, and the permanent magnet array is arranged in the slot mouth. One side, opposite to the corresponding open slot, of each primary magnetic-conductive iron core is provided with the armature winding; and the armature windings of the two primary sides at the two sides of the secondary side are same-phase windings, but electrical angle difference is 180 degrees. The secondary side is formed by magnetic-conductive iron cores having a salient pole structure, and gaps. The two air gaps are formed between the two primary sides and the secondary side respectively. The motor is a single-phase motor or a multi-phase motor, wherein the multi-phase motor is modular combination of the single-phase motors. Permanent magnets and the armature windings of the permanent magnet linear motor are arranged at the primary sides; through the big open slot structure design, winding heat dissipation is realized helpfully, and through the design of a large electrical load, thrust is improved; and meanwhile, the secondary side is simple in structure and light in weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

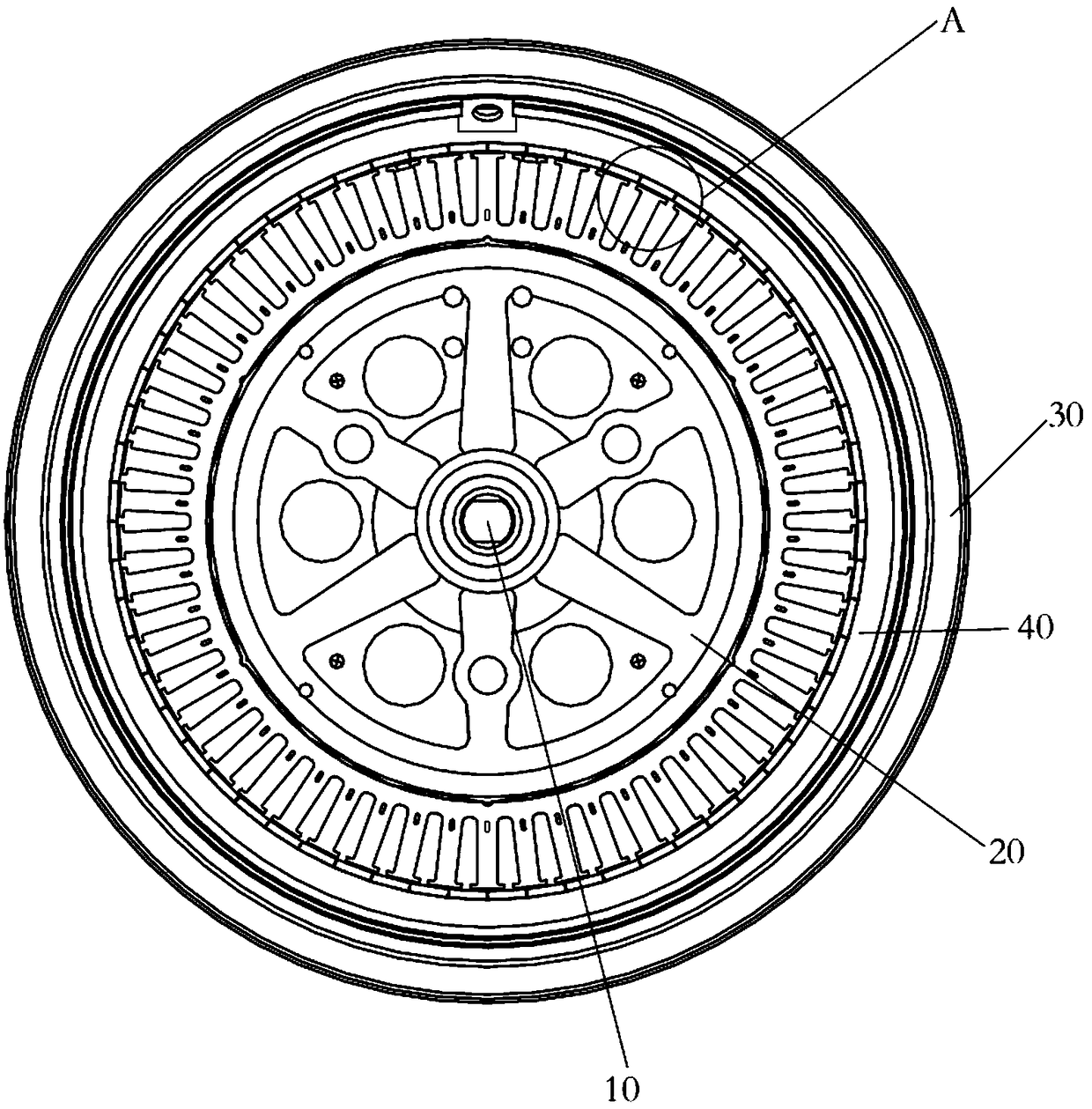

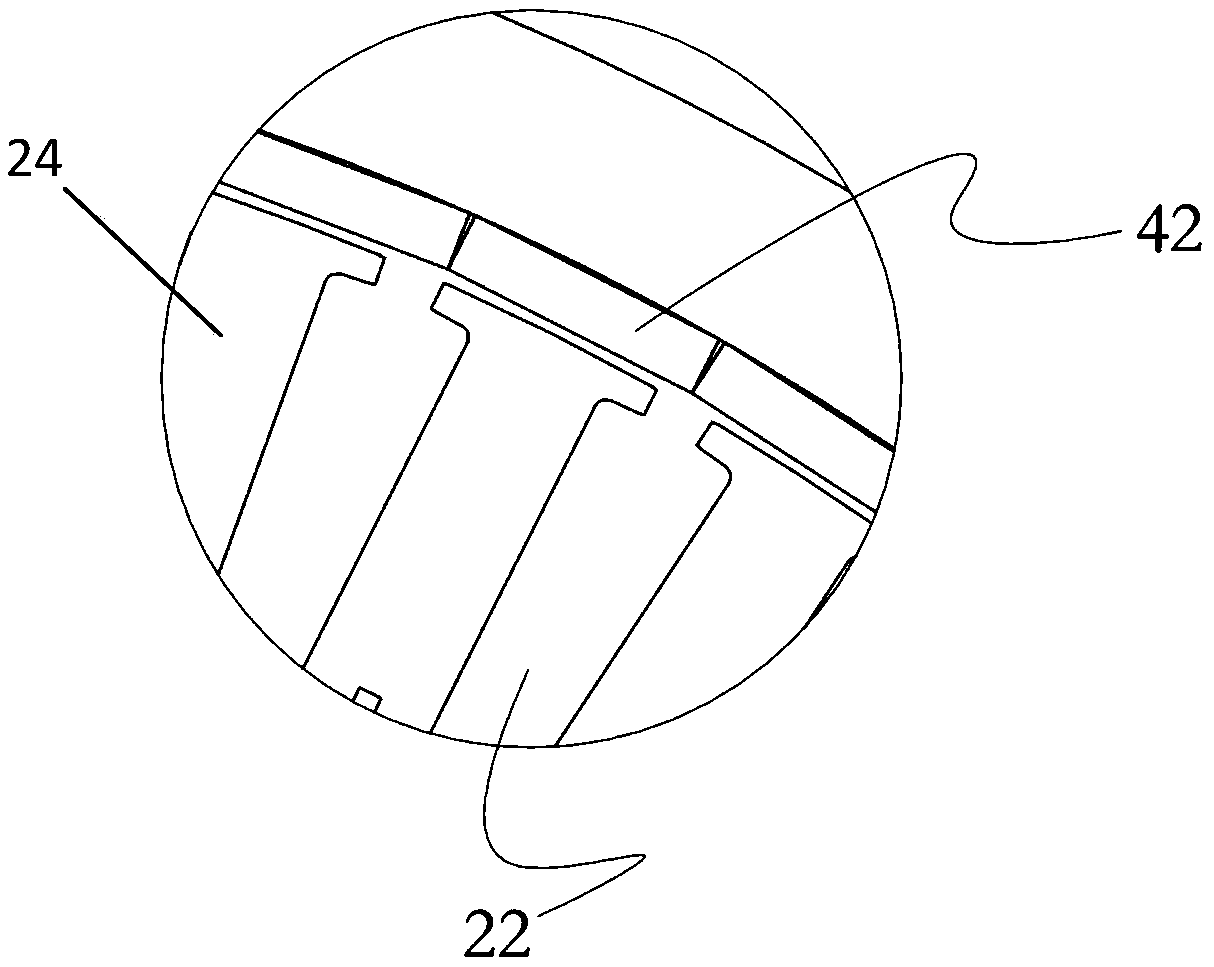

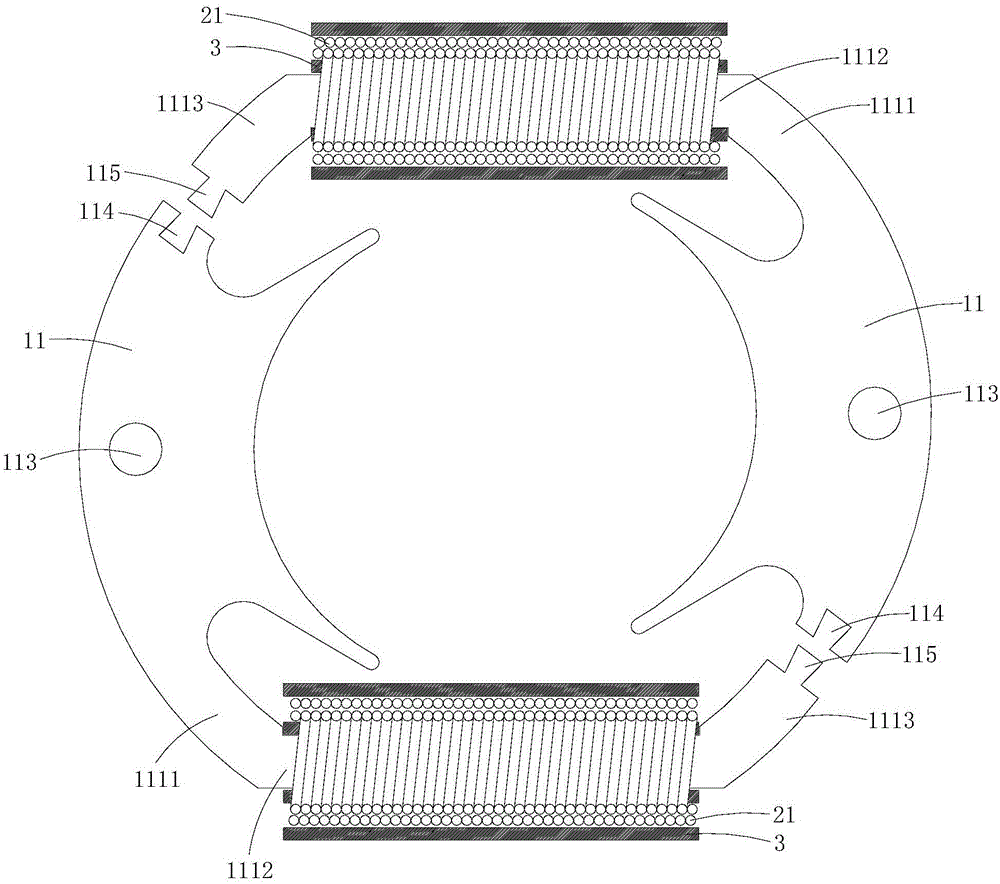

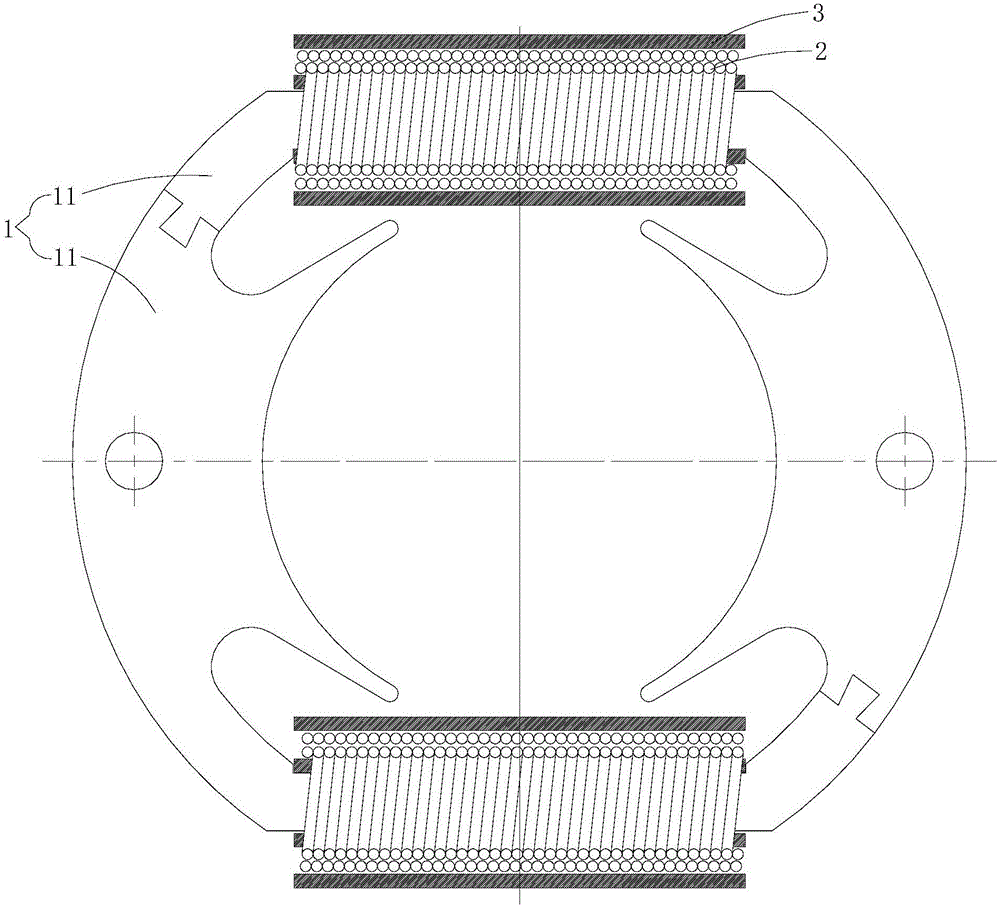

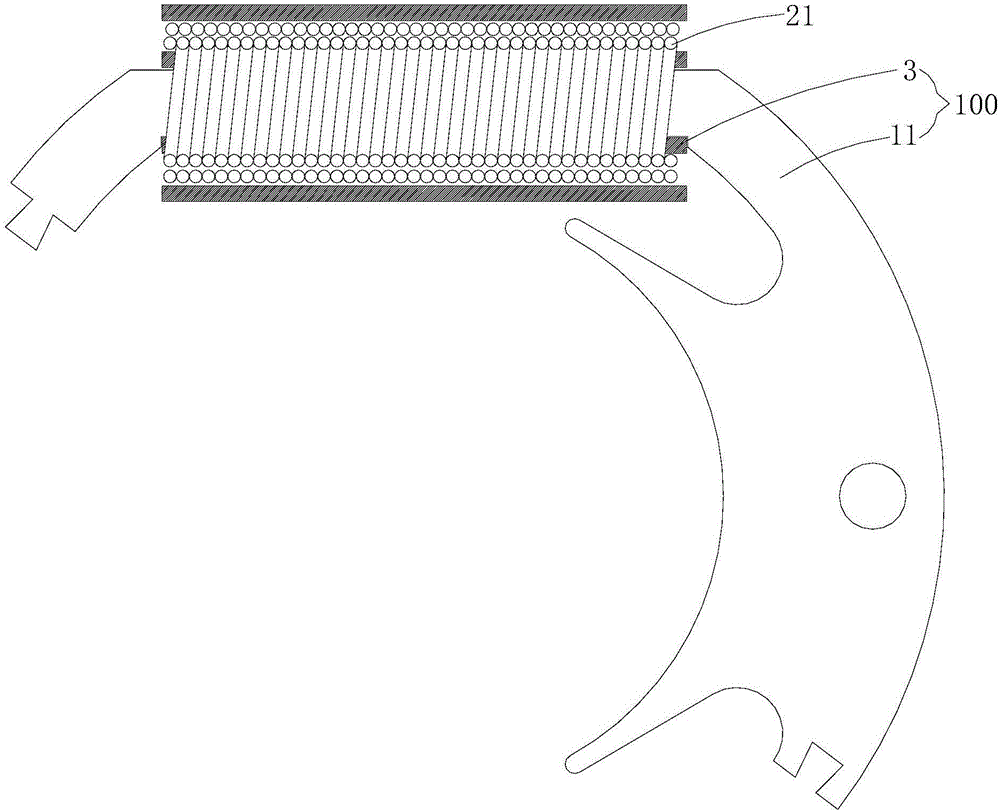

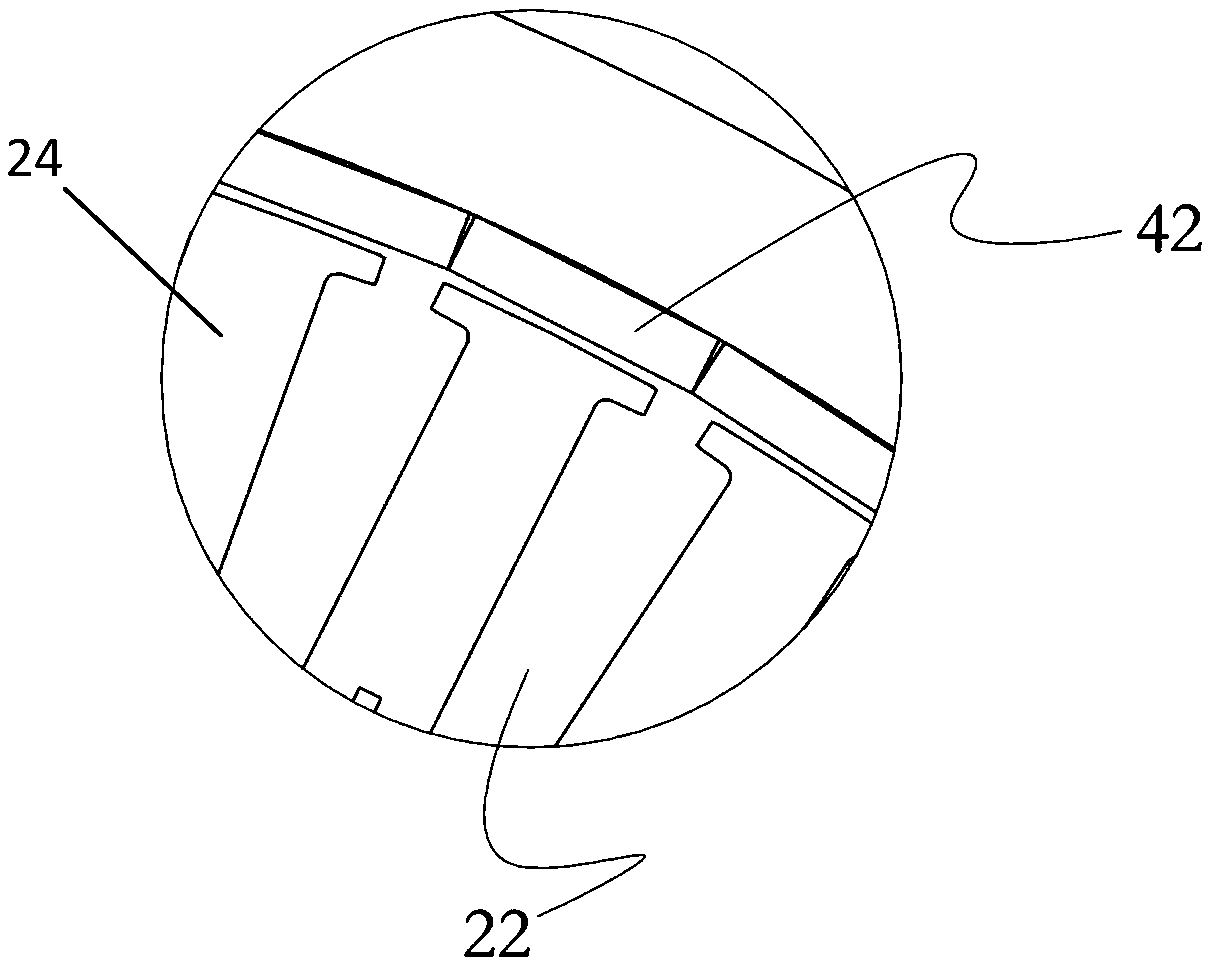

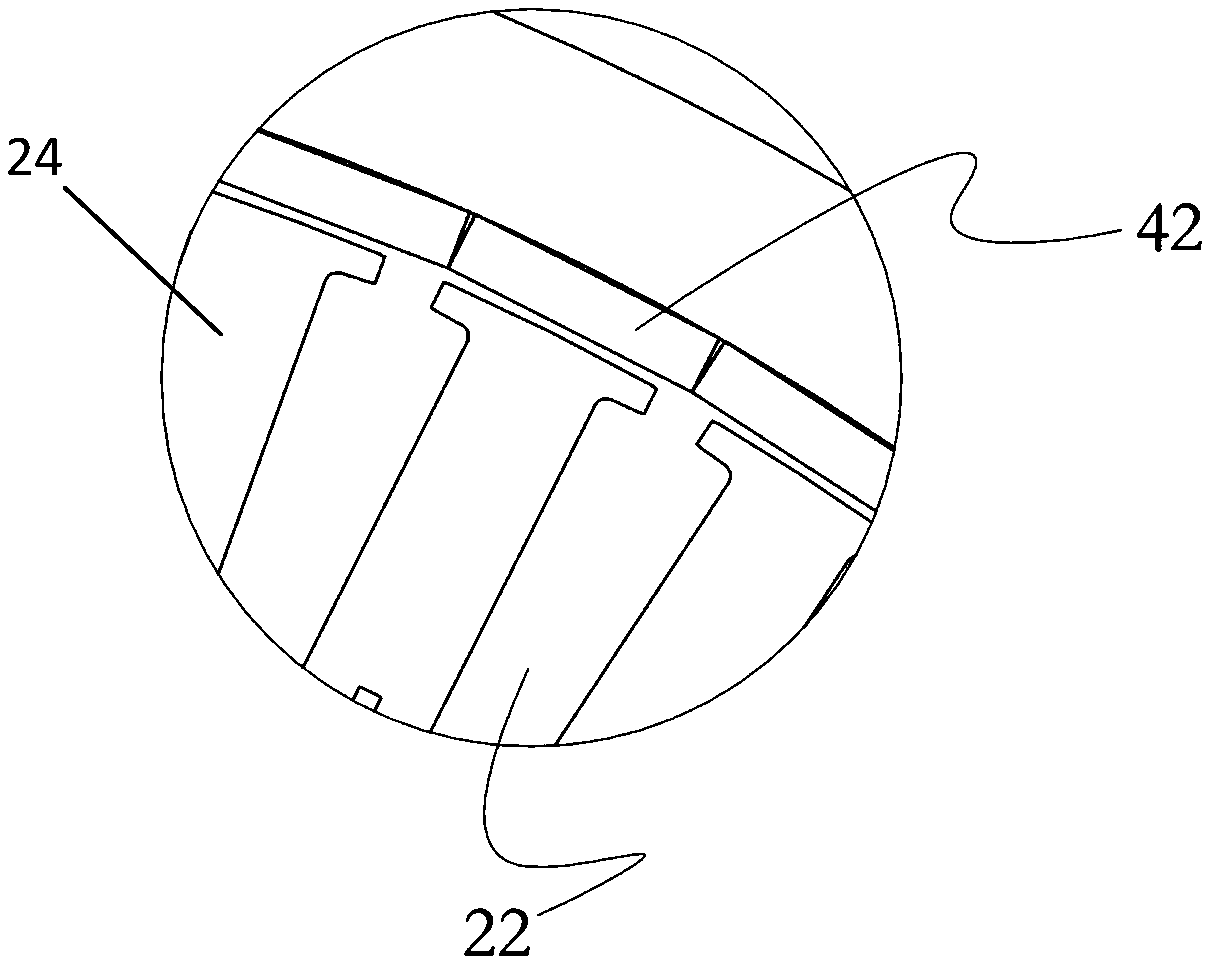

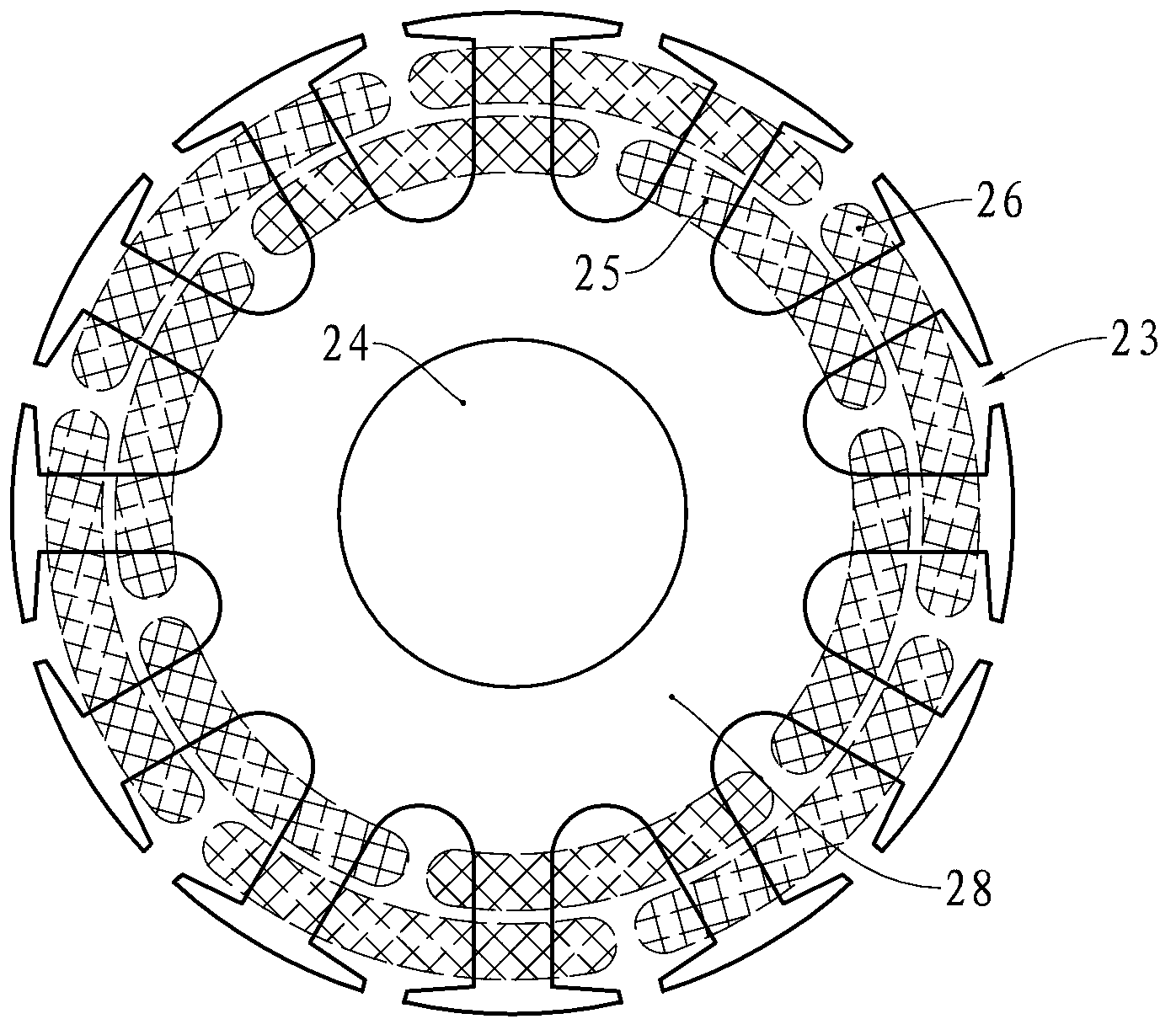

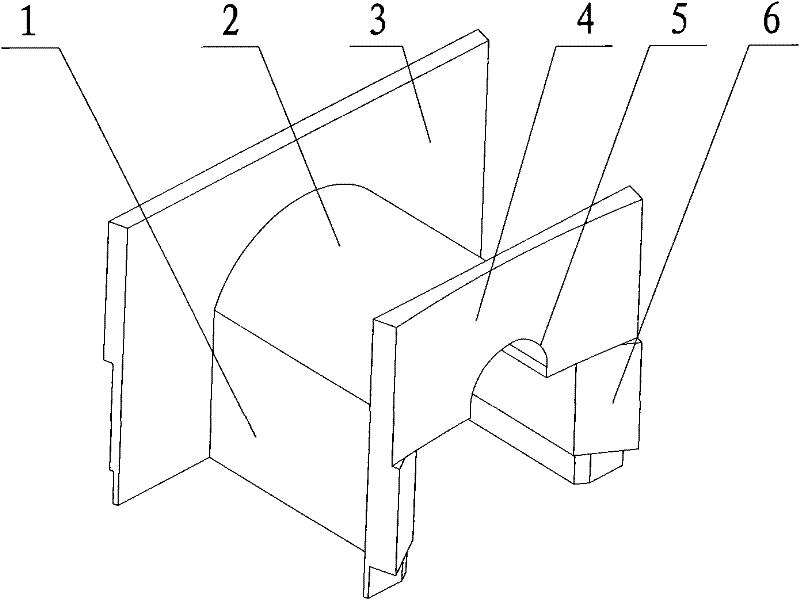

Series motor, stator iron core and stator thereof, and manufacturing method of stator

ActiveCN105024464AIncrease productivityReduce sizeWindings insulation shape/form/constructionMagnetic circuit stationary partsConductor CoilPhysics

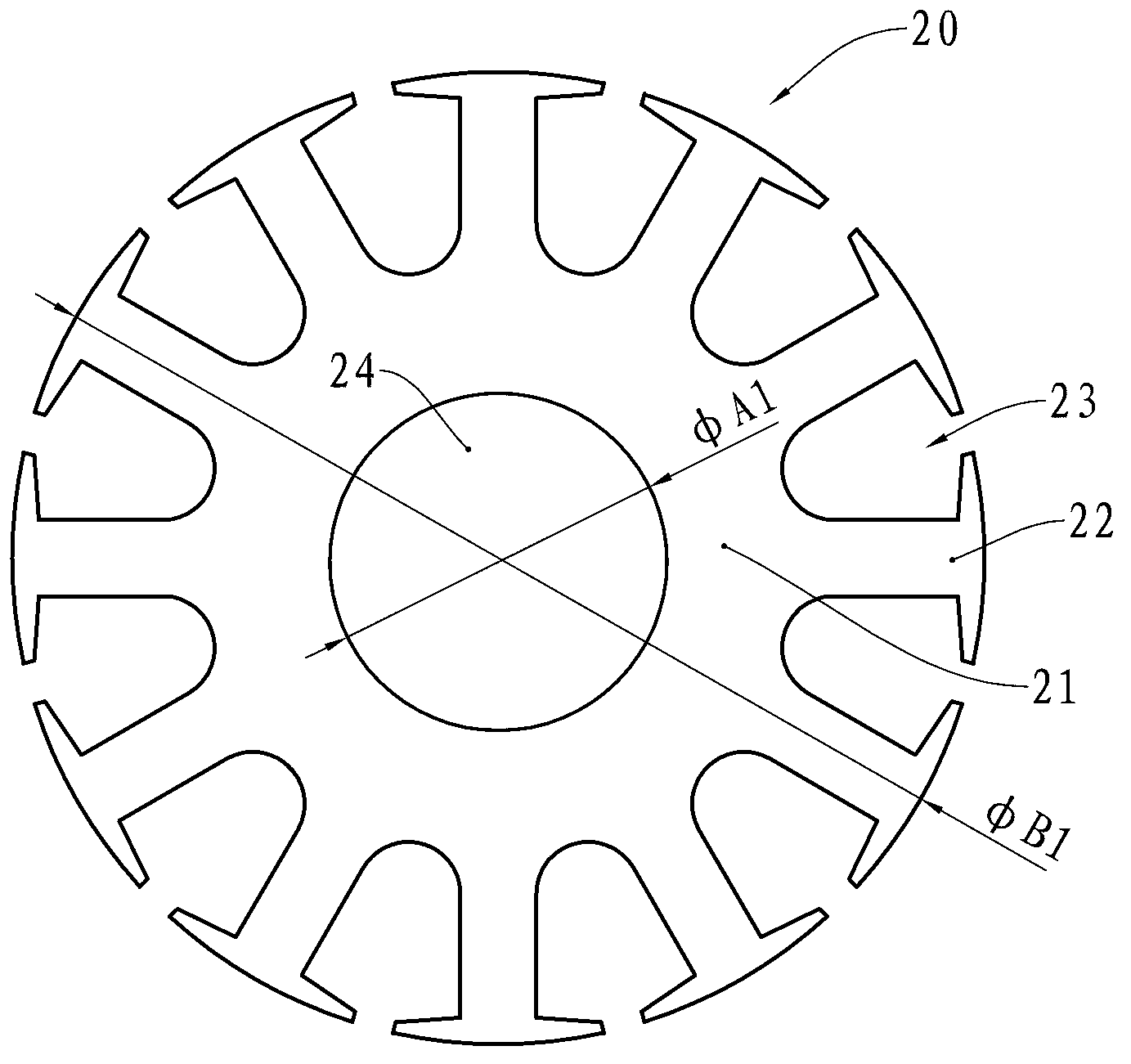

The invention is suitable for the field of motors and provides a series motor stator iron core, a series motor stator, a manufacturing method of the series motor stator, and a series motor, wherein two iron core parts are spliced along the circumferential direction along the series motor stator iron core, each iron core part comprises a sub stator yoke and a stator tooth arranged on the sub stator yoke in a projected manner. The sub stator yoke comprises a first arc-shaped yoke part, a straight yoke part whose one end is connected with one end of the first arc-shaped yoke part, and a second arc-shaped yoke part whose one end is connected with the other end of the straight yoke part. The stator tooth is arranged on the first arc-shaped yoke part in a projected manner. The first arc-shaped yoke part and the second arc-shaped yoke part of one iron core part are respectively connected with the second arc-shaped yoke part and the first arc-shaped yoke part of the other iron core part. According to the invention, the winding efficiency of a stator winding is improved; sizes of end parts, projected from two ends of the stator iron core along the axial direction of the stator iron core, of the stator winding are reduced; the coil perimeter of the stator winding is reduced, the utilization rate of the stator winding is improved, and the cost of the series motor is lowered.

Owner:FOSHAN WEILING WASHER MOTOR MFG

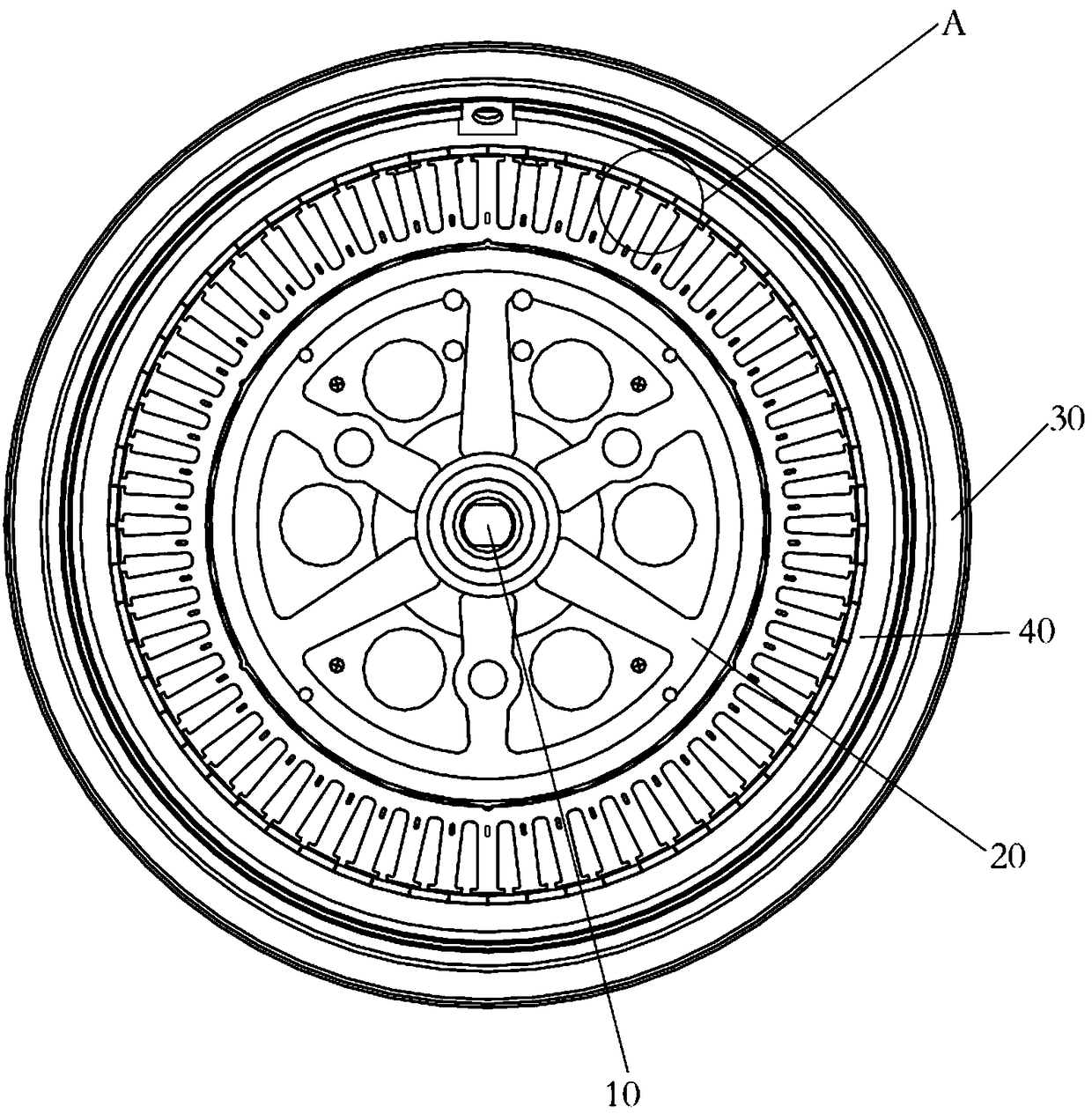

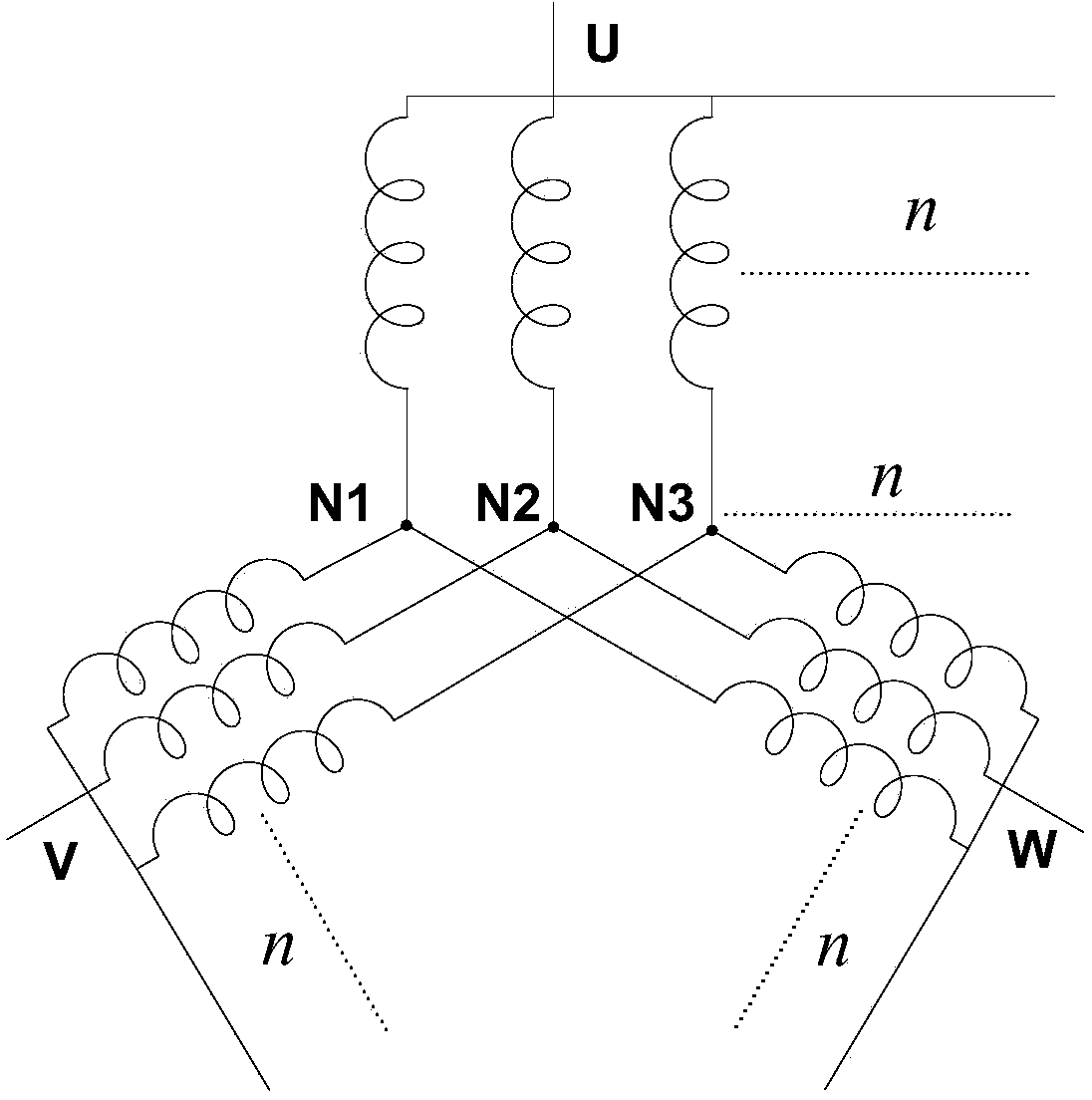

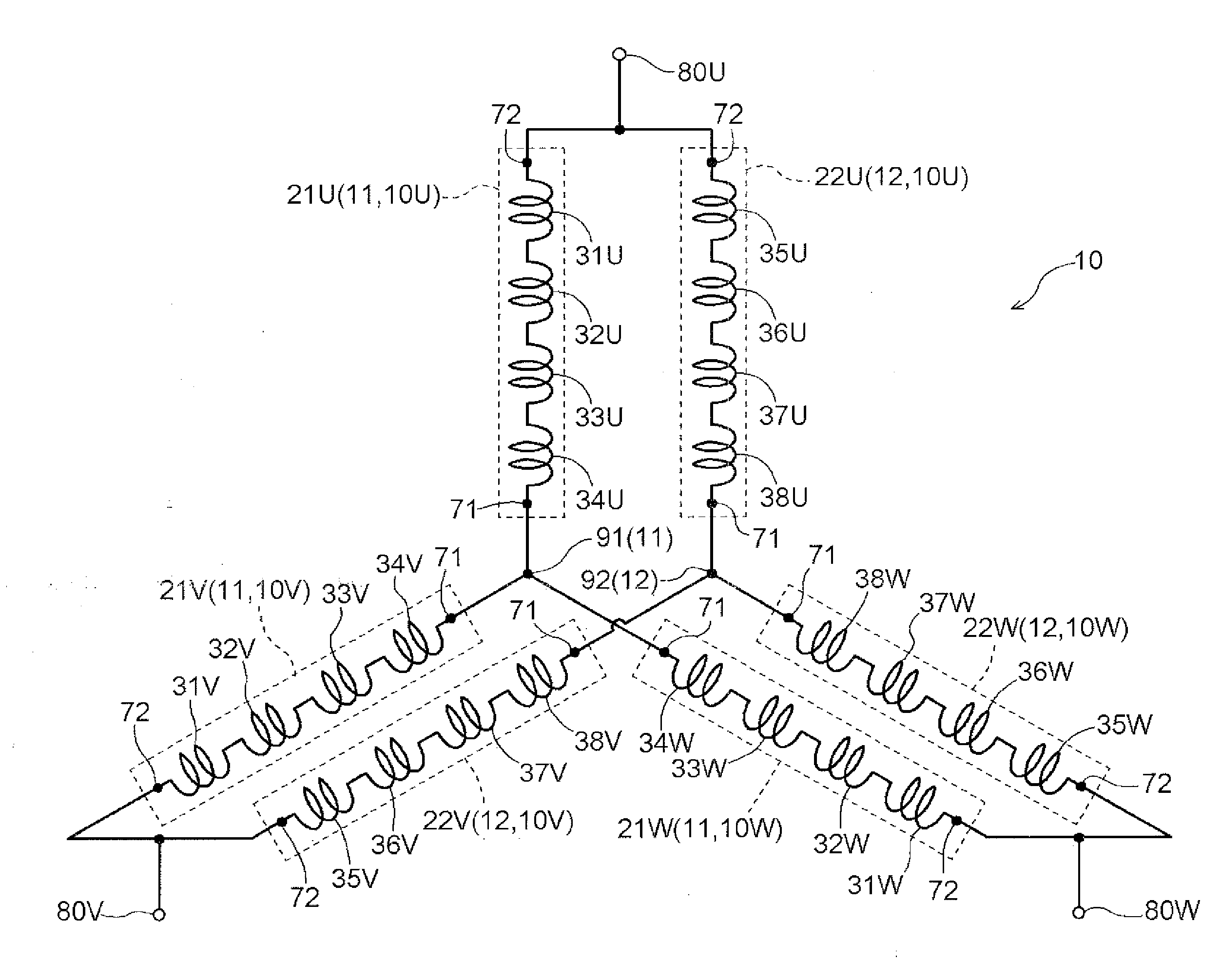

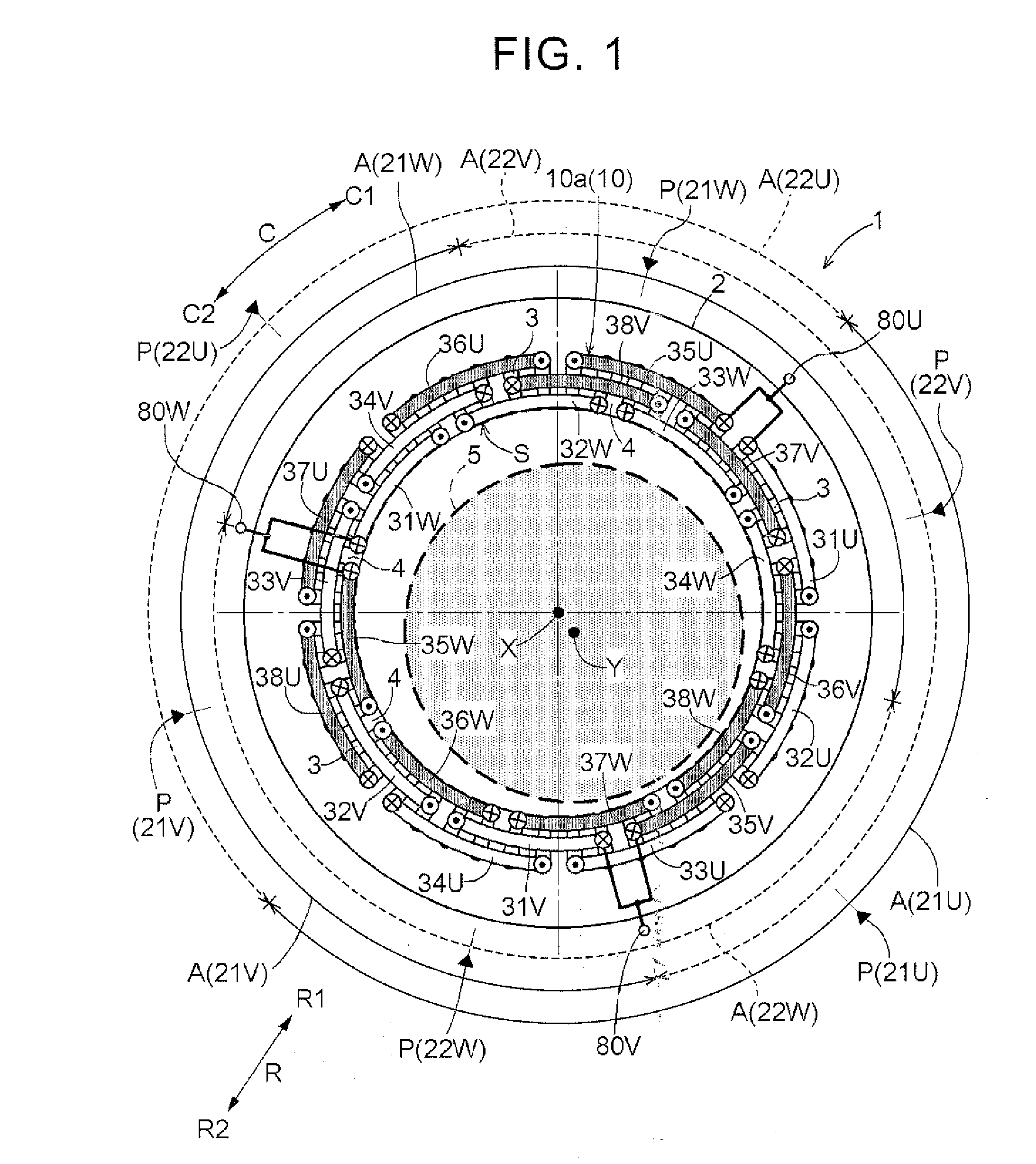

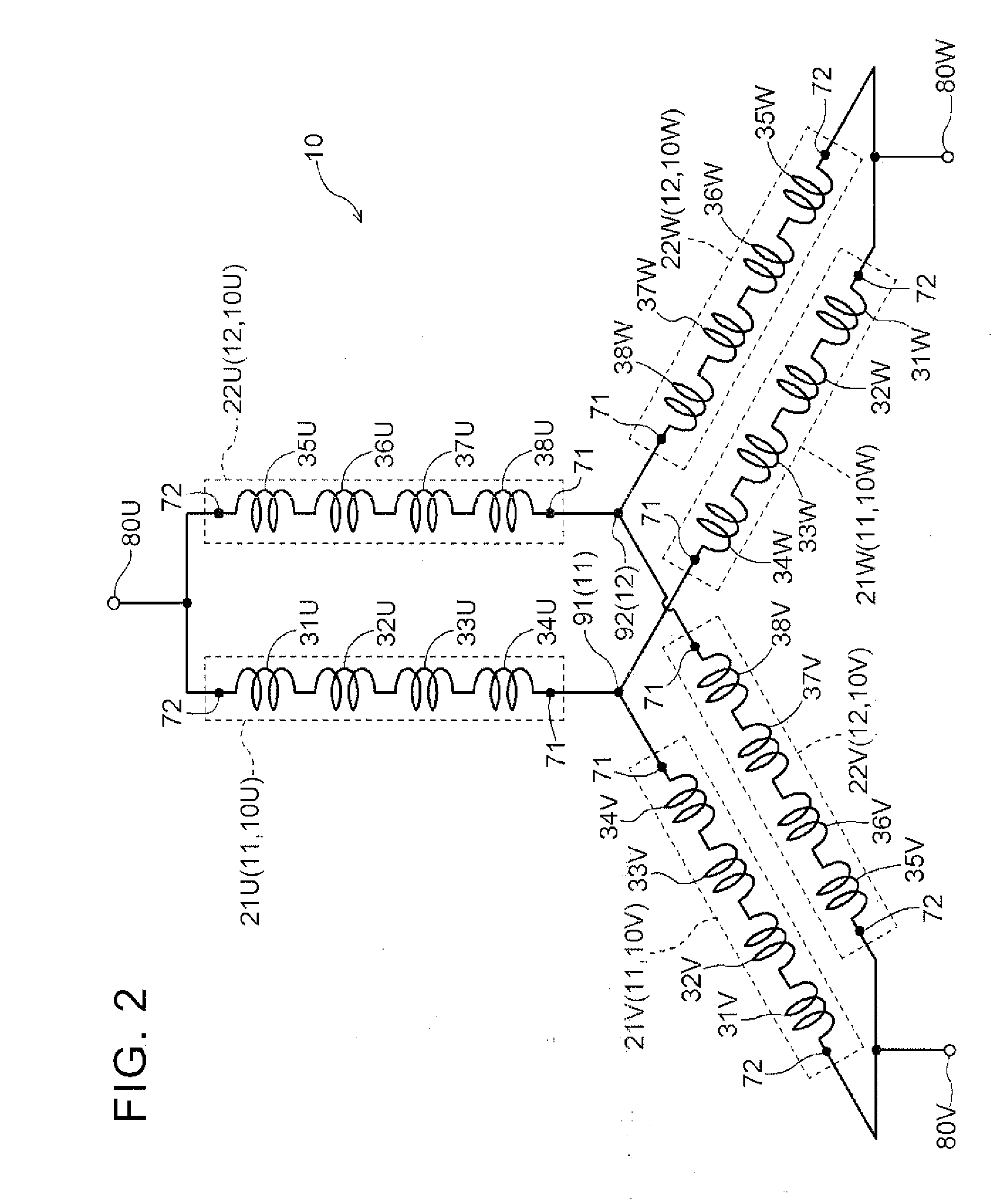

A three-phase alternating current motor for a medium-high power device and a medium-high power device

ActiveCN109167444AImprove fault toleranceDoes not increase insulation performance requirementsElectric motor controlMultiple ac dynamo-electric motors controlFault toleranceElectricity

The invention discloses a three-phase alternating current motor for medium and high power device and a medium and high power device, wherein the stator of the three-phase alternating current motor hasa stator slot of the multiples of 3 * n, n is a positive integer greater than 0 and not 1; The stator groove is formed by every two adjacent stator teeth; Wherein the stator comprises two or more winding units, each winding unit is respectively wound on different stator teeth; Each of the winding units is electrically connected with a motor driver unit corresponding to the winding units, and themotor driver units are used for controlling the operation of the winding units electrically connected with the winding units corresponding to the winding units; The input power of the medium and highpower device is not less than 1KW; The invention effectively solves the problems of unreliable performance, high cost and poor fault tolerance of a single large-capacity driver, and the winding process is simple, and the stator insulation performance requirement standard is not increased.

Owner:WUXI SINE POWER TECH CO LTD

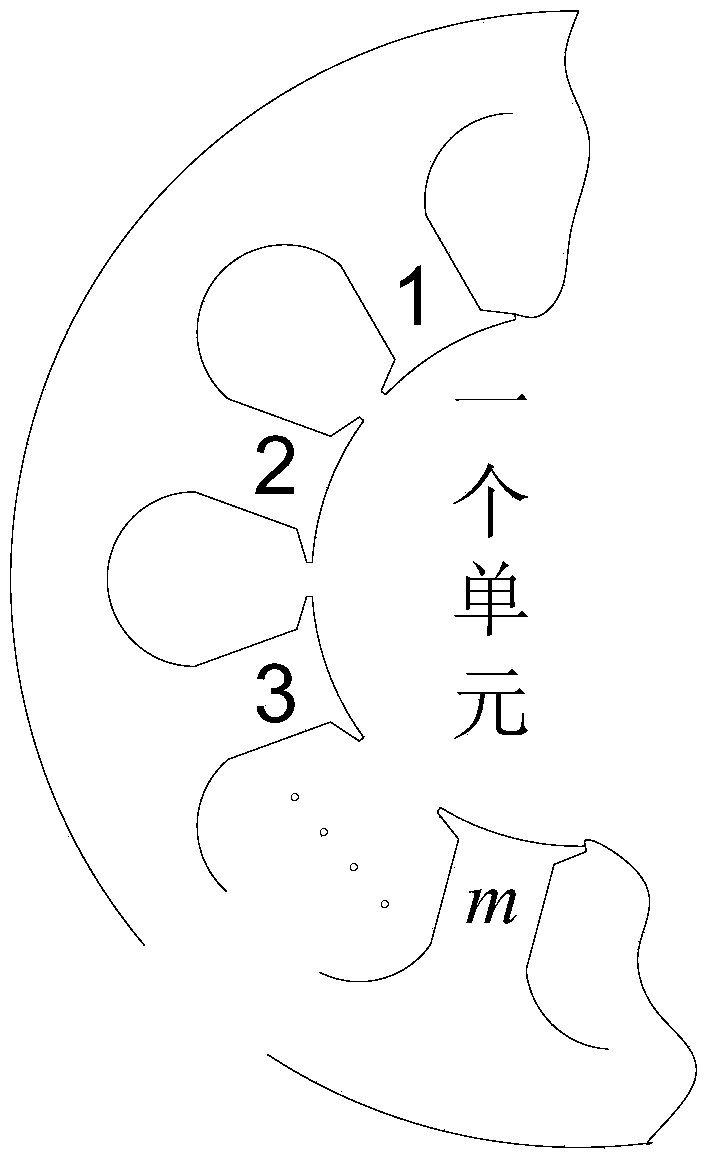

Winding unitized parallel winding structure of alternating current motor stator winding

InactiveCN104393699AShorten connection lengthReduce dosageWindings conductor shape/form/constructionCurrent meterAlternating current

The invention provides a winding unitized parallel winding structure of an alternating current motor stator. The alternating current motor stator adopts a concentrated winding structure to be connected with a phase winding branch, with independent neutral points, in parallel in a star connection mode; the number of phases of an alternating current motor is m; the number of stator slots is Z; the number of pole-pairs is P; Z can evenly divide m; the stator slots of the alternating current motor are divided into Z / m units; in each unit, a parallel branch of a corresponding phase is wound on each tooth; tail ends of the parallel branches on each the unit are connected with one another, so as to form a neutral point of star connection; the Z / m units form Z / m independent disconnected neutral points. The winding unitized parallel winding structure reduces the length of a connecting lead at the end part of the motor, reduces copper use level and copper consumption, improves the motor efficiency, power density and slot utilization, and simplifies the winding technology; in addition, the fluctuation of cogging torque is correspondingly restrained, and the counter electromotive force sine of windings is improved.

Owner:SOUTHEAST UNIV

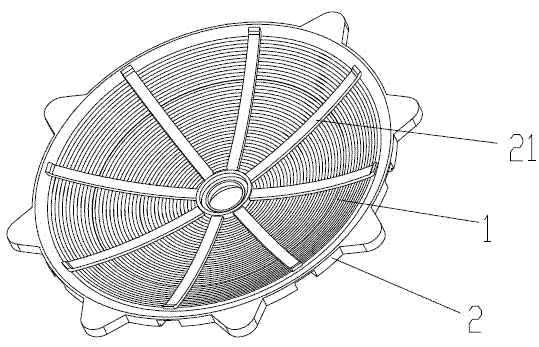

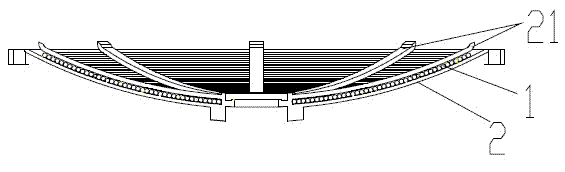

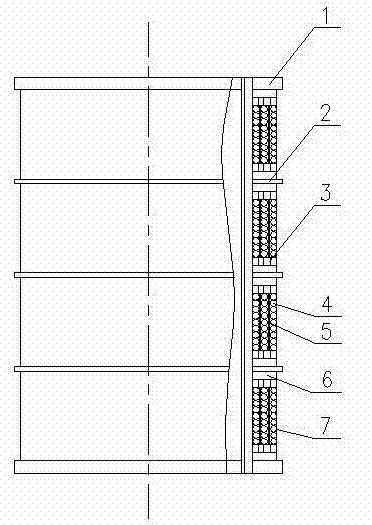

Coil disc of electromagnetic oven

ActiveCN102523643AGuaranteed performance and stabilityImprove performanceCoil arrangementsCoil procedureEngineering

The invention discloses a coil disc of an electromagnetic oven, comprising a coiling bracket and coil windings arranged on the coiling bracket, wherein the coiling bracket is provided with a plurality of wire buckles which are distributed in a ring shape and are convenient for winding fixed enamelled wires; and the coil windings are formed by winding of the enamelled wires which penetrate through the wire buckles distributed in a ring shape. The coil disc is characterized in that due to adoption of the structure with wire buckles, adhesive-less winding on the coiling bracket can be realized, and no matching of a coiling mold is needed, so that the coiling procedure is greatly simplified, the safe and convenient effects are achieved, the production efficiency is improved and the manufacturing cost is saved. Especially for multiple circles of windings, the coil disc can realize accurate coiling of multiple windings and ensures that the distance among wire rings is constant all the time, thus ensuring the performance stability of the coil disc in batch production. According to the coil disc, not only can the manual fast and accurate coiling be realized and is the operation simple and convenient, but also the high-speed coiling also can be realized by matching of simple mechanical equipment, and the requirement for corresponding equipment is lower, the production efficiency is greatly improved and the manufacturing cost is reduced. The coil disc is ingenious in design and is convenient and practical.

Owner:MIDEA GRP CO LTD

Novel high tension coil for dry transformer and manufacturing method for novel high tension coil

InactiveCN102360821ASimple structureLow costTransformers/inductances coils/windings/connectionsCoils manufactureTransformerHigh pressure

The invention discloses a high tension coil for a transformer. The high tension coil has a multi-section cylinder structure and is wound on support strips which are uniformly distributed on an insulation cylinder. All sections of the coil are isolated from one another by annular insulation plates and air; an insulation grid plate is wrapped outside each section of the coil; and the upper and lower ends of the coil are provided with insulation end rings and positioned by the support strips and gaskets which are sleeved on the support strips. The annular insulation plates are clamped and positioned by the support strips and the gaskets which are sleeved on the support strips so as to form radial air channels. The cross section of the cylinder coil is circular, rectangular or oblong. The high tension coil has the advantages of a cake coil, namely the high tension coil radiates heat well, and has strong overload capacity, and materials can be recycled; and the high tension coil also has the advantages of simple structure and mould and short production cycle, can be easily obtained through winding without casting, and has a flat appearance and insulation protection layers of an encapsulated coil, integrates the advantages of the encapsulated coil and a non-encapsulated coil, and is very suitable for the dry transformer.

Owner:丁钰莹

Swing motor coil winding apparatus and coil winding method

ActiveCN104967263ASimple winding processImprove pass rateManufacturing dynamo-electric machinesCooking & bakingEngineering

Owner:深圳市欧亚激光智能科技有限公司

Three-phase alternating current motor

PendingCN108923594AImprove fault toleranceDoes not increase insulation performance requirementsAssociation with control/drive circuitsMultiple ac dynamo-electric motors controlFault toleranceCurrent meter

The invention discloses a three-phase alternating current motor. A stator of the three-phase alternating current motor is provided with stator grooves with the number of 3*n, wherein n is a positive integer which is larger than 0 and is not 1; each stator groove is formed by every two adjacent stator teeth, wherein the stator comprises two or more than two winding units, and the winding units arewound on different stator teeth respectively; the winding units are electrically connected with corresponding motor driver units respectively; the motor driver units are used for carrying out operation control on the winding units which are electrically connected with the motor driver units; the problems that a single large-capacity driver is unreliable in performance, high in cost and poor in fault tolerance are effectively solved; and meanwhile, the winding process is simple, and the requirement for the insulation performance requirement of the stator is not increased.

Owner:WUXI SINE POWER TECH CO LTD

Co-wound high-voltage and low-voltage coil of transformer and winding method of co-wound high-voltage and low-voltage coil

ActiveCN102568772AReduce process stepsSimple winding processTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringHigh pressure

The invention discloses a co-wound high-voltage and low-voltage coil. The co-wound high-voltage and low-voltage coil comprises an iron core and a high-voltage insulating barrel, wherein the high-voltage insulating barrel is arranged at the outer part of the iron core, a high-voltage coil supporting bar is arranged on an outer surface of the high-voltage insulating barrel, and a high-voltage coil is wound at the outer part of the high-voltage coil supporting bar. The co-wound high-voltage and low-voltage coil is characterized in that the high-voltage coil supporting bar is provided with a protruding end relative to the high-voltage coil, a low-voltage soft paper barrel is arranged at the outer part of the protruding end of the high-voltage coil supporting bar, a low-voltage coil supporting bar is arranged at the outer circumference of the low-voltage soft paper barrel, and a low-voltage coil is wound at the outer part of the low-voltage coil supporting bar. According to the invention, the problems of complex winding process and much tooling equipment of the high-voltage and low-voltage coil in the prior art are solved. The co-wound high-voltage and low-voltage coil has the advantages of simple structure, simple winding process, high production efficiency and low cost.

Owner:NEWONDER SPECIAL ELECTRIC

A control method of a motor driving system

ActiveCN109245344AImprove fault toleranceDoes not increase insulation performance requirementsAssociation with control/drive circuitsAC motor controlElectricityThree-phase

The invention discloses a control method of a motor driving system. The motor driving system comprises a three-phase alternating current motor and a controller group for controlling the three-phase alternating current motor. The stator of the three-phase alternating current motor adopts two or more winding units; The controller group includes motor driver units electrically connected to each of the winding units, and the motor driver units are used for controlling the operation of the winding units corresponding to the motor driver units. Wherein the controller group performs centralized coordinated management control on the operation states of each of the motor driver units, wherein, after the centralized coordinated management control performs communication aggregation on the operation states of each motor driver unit, the controller group determines control instructions according to the operation state aggregation information and executes the control instructions to meet the controlrequirements of the motor driving system.

Owner:WUXI SINE POWER TECH CO LTD

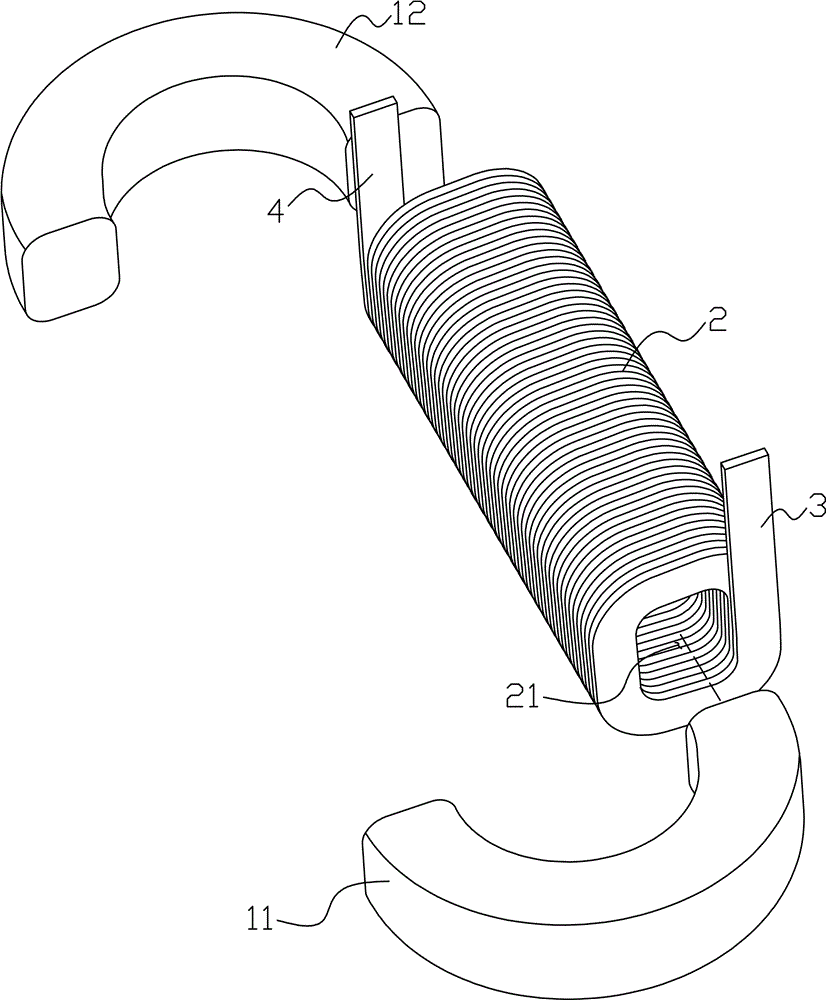

coil

ActiveUS20150061450A1Inhibit productionReduce componentsMagnetic circuitSynchronous machinesThree-phaseEngineering

A coil that is wound around a core having a plurality of slots arranged so as to be distributed in a circumferential direction of a cylindrical core reference plane, and that has N (where N is an integer of 2 or more) star connections. Each of the N star connections includes three phase coil portions corresponding to respective three phases, and first ends of the three phase coil portions are connected together at a neutral point that is formed independently for each of the star connections, second ends of the N phase coil portions of the same phase which are included in the different star connections are connected to each other, a phase coil placement region where the phase coil portion is placed is designed to be continuous in the circumferential direction.

Owner:AISIN AW CO LTD

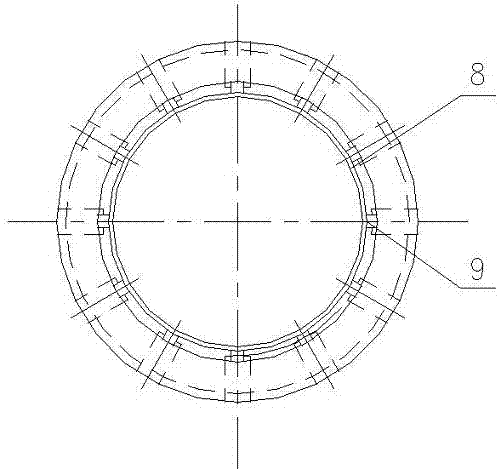

Annular differential-mode inductor and production method thereof

InactiveCN105825998AReduce labor intensityAvoid damageTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresElectricityWinding machine

The present invention relates to the field of magnetoelectric technology, in particular to a ring-shaped differential-mode inductor and a production method thereof. The ring-shaped differential-mode inductor includes a ring-shaped magnetic core and a coil, and the ring-shaped magnetic core is connected by a first magnetic core and a second magnetic core. In combination, the window in the middle of each turn coil forms a magnetic core channel, and the first and second magnetic cores are inserted into the magnetic core channel and then docked. The production method of the annular differential mode inductor comprises the following steps: winding the coil by a winding machine, respectively passing the first and second magnetic cores through the coil, while the second magnetic core is passed through the other end of the coil core channel, and the The starting and tail wires are stripped and soldered. In the present invention, the coil passes through the magnetic core after being wound by a winding machine. The winding process is simple, which solves the problem that the wire diameter is too large and cannot be wound. At the same time, it reduces the labor intensity of workers and improves production efficiency; The copper wire will be damaged or have pinholes during the process, which improves the yield.

Owner:湖口健诚电子电器有限公司

Stator stamping and motor

InactiveCN103078423AReduced insulation requirementsReduce manufacturing costMagnetic circuit stationary partsWindings conductor shape/form/constructionEngineeringOuter coil

The invention provides a stator stamping and a motor. The stator stamping is provided with an annular yoke and a plurality of teeth, the teeth are outwardly extended from the yoke along the radial direction of the stator stamping, a notch is formed between each two neighboring teeth, moreover, the middle of the stator stamping is provided with an inner round hole, wherein the notches are shallow notches and deep notches, which are arranged alternately, and the opening height of the deep notch is greater than the total height of the shallow notch. The motor is provided with a stator and a rotor, the stator is provided with a stator core made of the laminated stator stampings and coils wound on the stator core, the coils are a plurality of inner coils and a plurality of outer coils, each inner coil is wound between two deep notches, and each outer coil is wound between two shallow notches. The invention can decrease the difficulty of the coil-winding process; moreover, the coils are not overlapped spatially, so that the requirement on the insulation of the coils is decreased, and thereby the production cost of the motor is reduced; moreover, when the motor operates, the magnetic density is more uniform, and operation is more stable.

Owner:GREE ELECTRIC APPLIANCES INC +4

Motor and water pump provided with same

ActiveCN106712329AIncrease slot fill rateImprove performanceMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingPhysics

The invention discloses a motor and a water pump provided with the same. The motor comprises a rotor, a stator and a plurality of coils, and is characterized in that the stator is arranged outside the rotor, the stator comprises an annular stator yoke portion which is formed by bending a plurality of bar-shaped yoke portion punching sheets superimposed along the axial direction and a plurality of stator teeth which are arranged at intervals along the circumferential direction of the stator yoke portion, the stator teeth are formed by superimposing a plurality of tooth portion punching sheets along the circumferential direction of the stator yoke portion, the superimposing direction of the plurality of yoke portion punching sheets is perpendicular to the superimposing direction of the plurality of tooth portion punching sheets, one end of each bar-shaped punching sheet is provided with a protruding portion, and the other end of each bar-shaped punching sheet is provided with a sinking portion matched with the corresponding protruding portion; and the plurality of coils are wound on the stator yoke portion, each two adjacent stator teeth are provided with a coil therebetween, and an insulating piece is arranged between each coil and the stator yoke portion. According to the motor disclosed by the invention, the production efficiency of the stator yoke portion is improved, materials of the stator yoke portion are saved, and the material cost is reduced. In addition, the slot fullness rate of the stator is further effectively improved, and the performance of the motor is improved.

Owner:MIDEA WELLING MOTOR TECH SHANGHAI +1

Automatic winding equipment and winding method for motor coil

ActiveCN109687660AFast windingPrecise windingManufacturing dynamo-electric machinesCopper wireLocking mechanism

The invention relates to automatic winding equipment and a winding method for a motor coil, which are mainly used for winding the motor coil and aim to solve the problems of low winding efficiency andeasy error in the prior art. The invention provides a technical scheme that the automatic winding equipment and the winding method for the motor coil. The automatic winding equipment for the motor coil comprises a coil frame, a wire feeding mechanism, a frame, a clamping and breaking mechanism and a winding mechanism; the winding mechanism comprises a winding device for clamping and winding copper wires, and a winding die fixing device for clamping and rotating the winding die; the winding device comprises a winding mechanical arm, a rotating wheel, a lifting module and a translation module;the winding die fixing device comprises a rotating motor, a bearing, a second rotating connecting component, a coil sleeve and a locking mechanism. According to the automatic winding equipment and thewinding method for the motor coil, winding is carried out by utilizing the lifting of the winding mechanical arm in the winding device and the rotary reciprocating of the winding die fixing device, so that the winding step is simplified into two single reciprocating processes, and the production efficiency is effectively improved.

Owner:ZHEJIANG JEAMO MOTOR

A stator winding frame and a method for measuring the number of turns of a sub-coil

InactiveCN102280980ASimplify the winding processImproved duty cycleManufacturing dynamo-electric machinesElectrical measurementsStatorBobbin

The invention discloses a winding skeleton which is sleeved on the stator iron core of a motor, and a method for detecting the number of coil turns of the stator winding by using the skeleton. The winding frame includes an arc-shaped winding ridge and clamp arms on both sides, and a through hole or a through groove parallel to the clamp arm is opened on the back side of the winding surface of the winding ridge. When the frame is buckled on the stator teeth, the The through holes or slots are still open, and there are baffles at the two ends of the winding ridge and the clamping wall. The stator winding frames are used in pairs, and are respectively buckled on the stator teeth at both ends of the stator core block, and are positioned against the stator tooth tips. The fastening surface between the inner baffle plate at one end and the tooth tip of the stator is an inclined plane, and its inclination coincides with the inclined plane of the tooth tip of the stator. The winding skeleton is made of synthetic material of nylon and glass fiber. The use of the winding frame can effectively improve the space factor and winding quality of the stator winding, improve the performance of the motor, and can detect the number of coil turns of a single stator winding.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

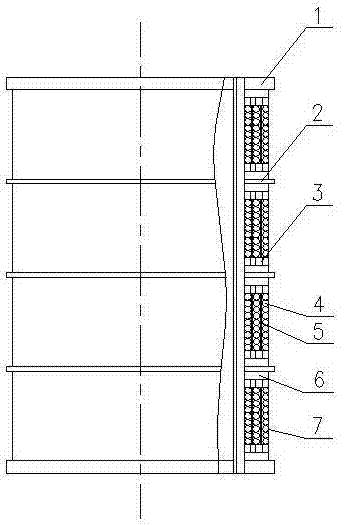

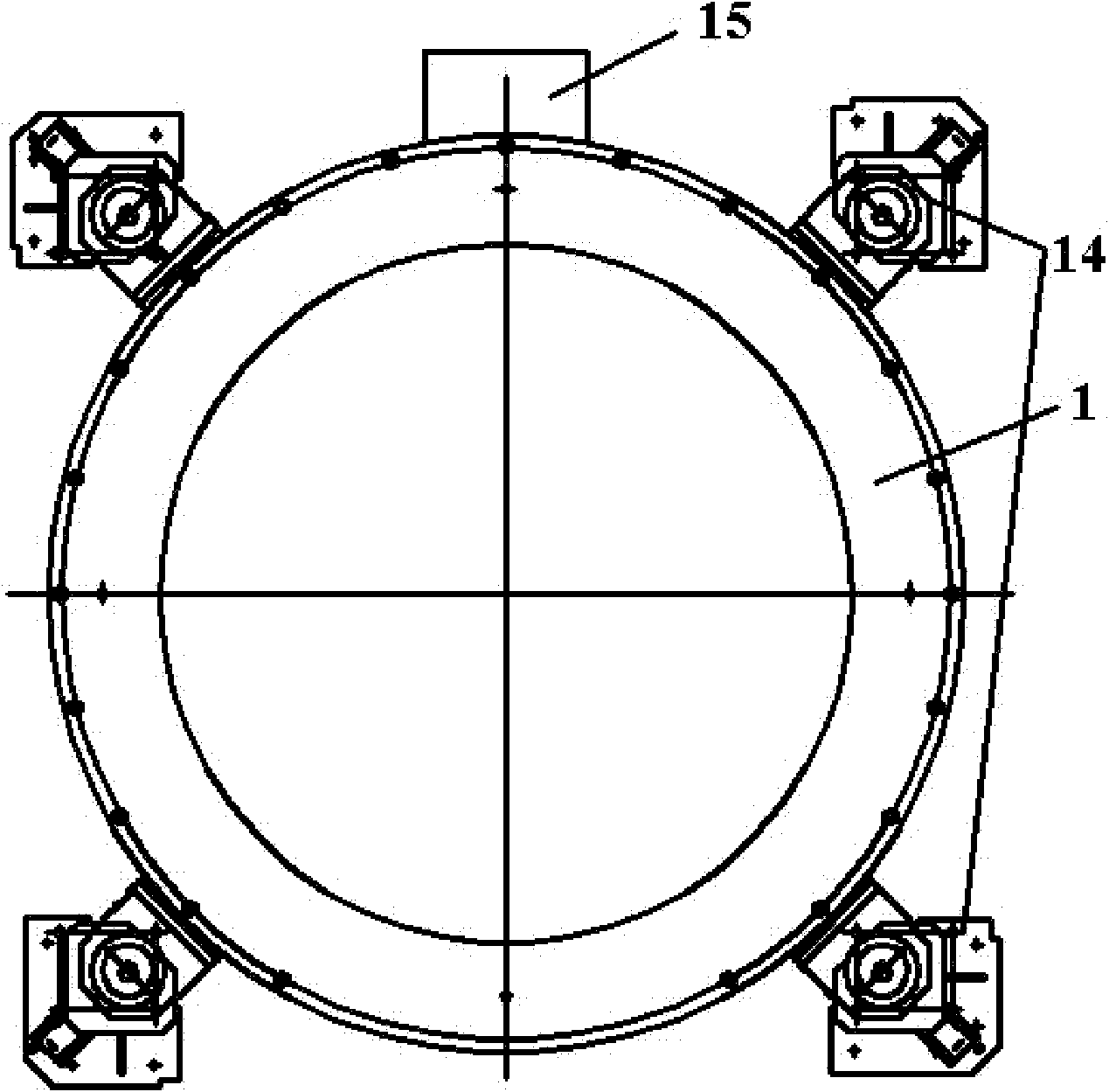

Hook-type electromagnetic field device of full-diameter single crystal furnace

ActiveCN102154687AGuaranteed axial and radial uniformityDoes not affect evaporationAfter-treatment apparatusBy pulling from meltEngineeringSingle crystal

The invention relates to silicon single crystal material processing equipment, aiming at providing a hook-type electromagnetic field device of a full-diameter single crystal furnace. The hook-type electromagnetic field device comprises direct current coils for generating hook-type electromagnetic fields and at least two annular sealed containers filled with cooling oil, wherein the annular sealed containers are vertically overlaid to form a hollow cylinder shape; each sealed container is formed by mutually connecting a semi-enclosed shield located on the outer side, an inner cylinder located on the inner side and two yoke plates through welding, and the sealed containers as well as an oil pump and an oil cooler jointly form a forcible oil cooling system through pipelines; and the sealed containers are respectively and internally provided with one group of direct current coils formed by winding solid copper pipes. In the invention, because the two upper and lower coils are arranged in parallel, generated magnetic force lines are in axial symmetry distribution, meanwhile, the magnetic field intensity is continuously adjustable, and the axial and radial uniformity of a crystal bar is guaranteed so that the effect of controlling the content of oxygen in a single crystal is good. As bolts are used for connecting a bisectional structure, the transportation, dismounting, installation and debugging of the device provided by the invention are simpler and more convenient.

Owner:杭州慧翔电液技术开发有限公司 +1

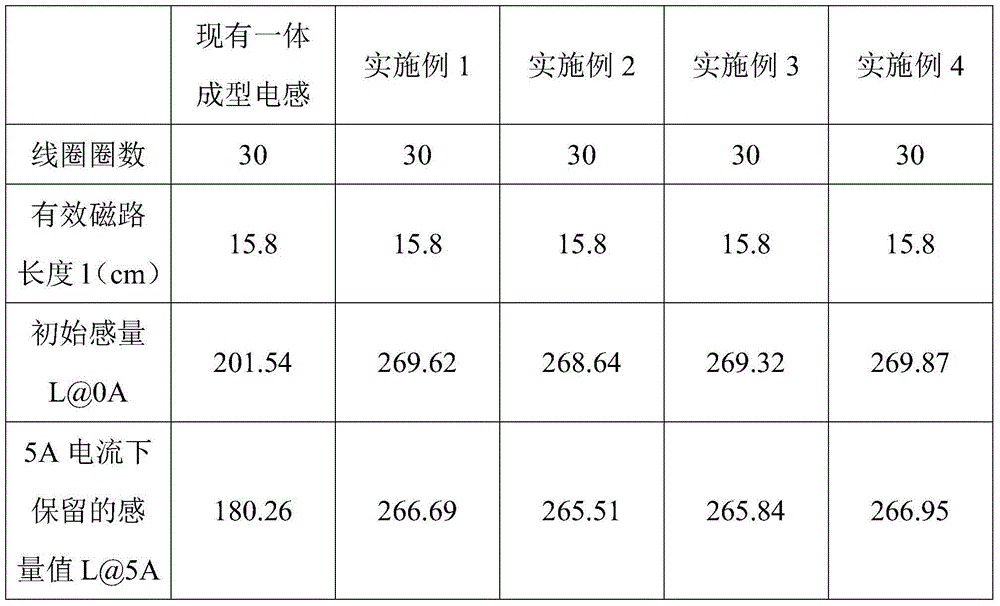

Novel high density integrated electric inductance manufacturing method

ActiveCN104900390ASimplify the winding processRealize automated productionInductances/transformers/magnets manufactureMagnetic materialsMagnetic coreElectrical and Electronics engineering

The invention discloses a novel high density integrated electric inductance manufacturing method, which comprises: (1) winding an varnished wire coil into a spiral shape; (2) making first iron magnetic powers into a magnetic core through mechanical pressing; (3) packing the magnetic core into a hollow cavity of the varnished wire coil; (4) packing the varnished wire coil packed with the magnetic core into an injection mold; (5) uniformly mixing and blending resin adhesive, coupling agent and accelerant to obtain high temperature resin adhesive; (6) uniformly mixing and blending the second iron magnetic powers and the high temperature resin adhesive to obtain magnetism composite material; (7) injecting the magnetism composite material into a mold cavity of the injection mold to mold, and solidifying to obtain external magnetic body; and (8) cooling and stripping to obtain molded electric inductance. According to the invention, the volume of the electric inductance manufactured with the method provided herein is small; the density is high; the relative magnetic conductivity is high; the cooling performance is good; the service life is long; the electric inductance is molded as a whole; and the manufacturing method of the electric inductance is simple, thus reducing the production cost.

Owner:POCO HLDG CO LTD +2

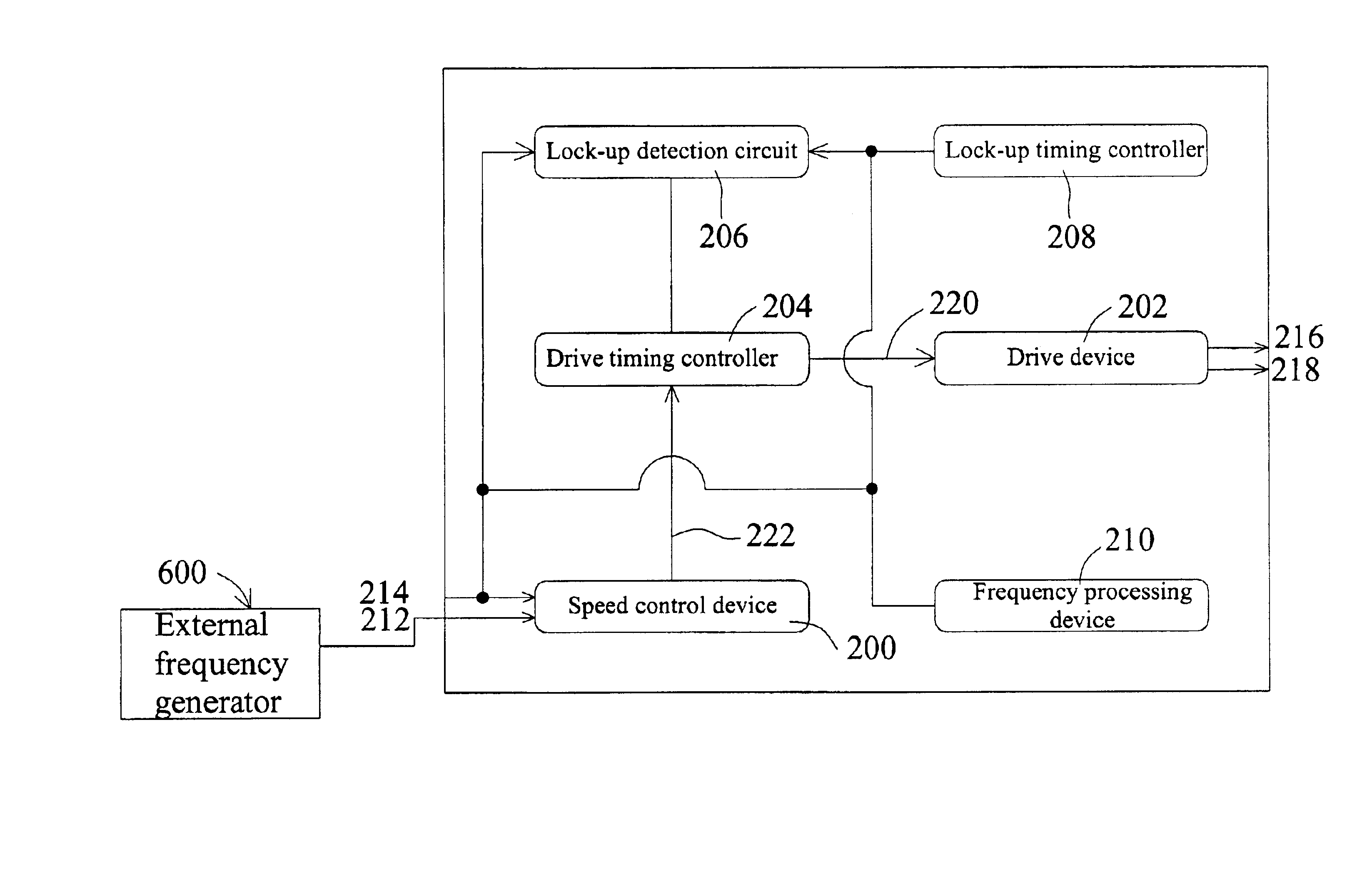

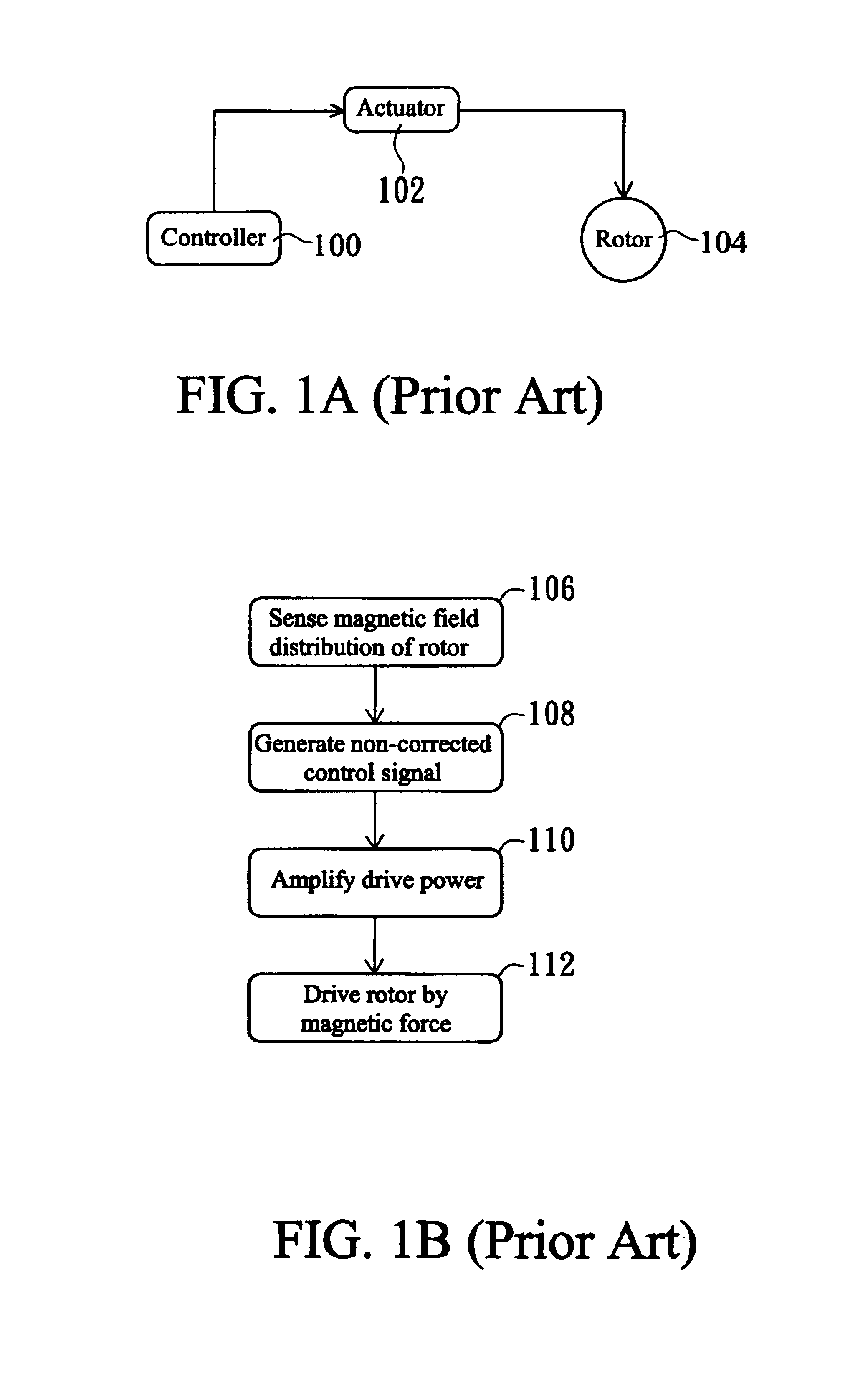

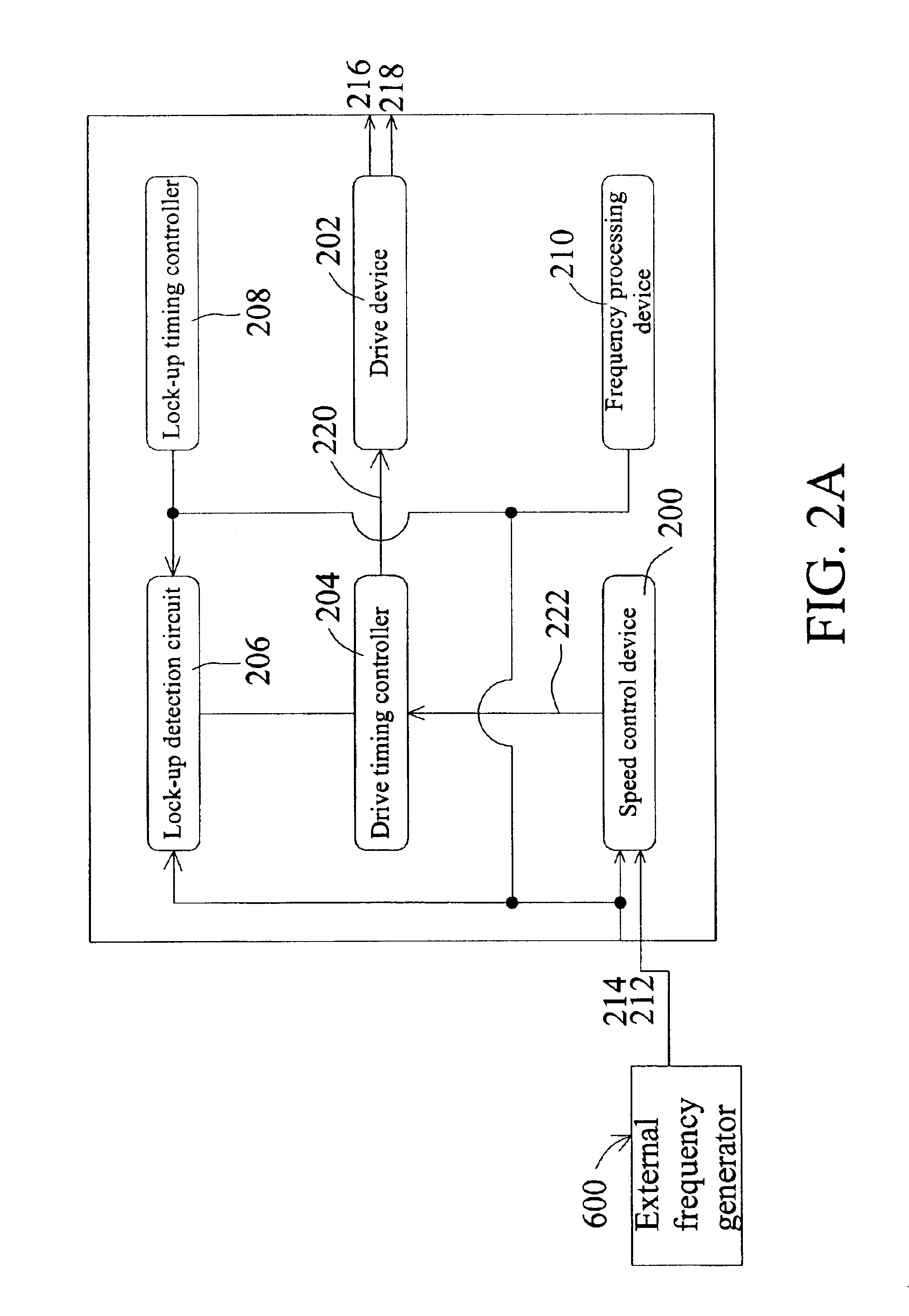

Motor drive circuit and method with frequency setting and correcting functions

ActiveUS6933699B2Increase manufacturing yieldAvoid vibration and noiseSingle-phase induction motor startersMotor/generator/converter stoppersMotor drivePulse-width modulation

A motor drive circuit and method with frequency setting and correcting functions. The drive circuit includes a speed control device, which simultaneously receives a sense signal and a rotation frequency signal. A pulse width modulation signal capable of modulating a duty ratio may be generated by a pulse width modulation method. The pulse width modulation signal is then transferred to a drive timing controller that generates a timing control signal to control output timing of a power drive signal for the drive circuit. Meanwhile, a sensor is used to detect a motor and to generate a correction sense signal, which is immediately fed back to the speed control device to form a closed loop control, so that the rotation frequency of the motor may be automatically corrected and set.

Owner:PROLIFIC TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com