Driving device for electric toothbrush

A driving device and electric toothbrush technology, applied in electromechanical devices, electric components, dentistry, etc., can solve the problems of reduced efficiency, large magnetic field energy loss, complex process, etc., achieve smooth reciprocating motion, reduce magnetic field loss, and simple winding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, specific embodiment is described:

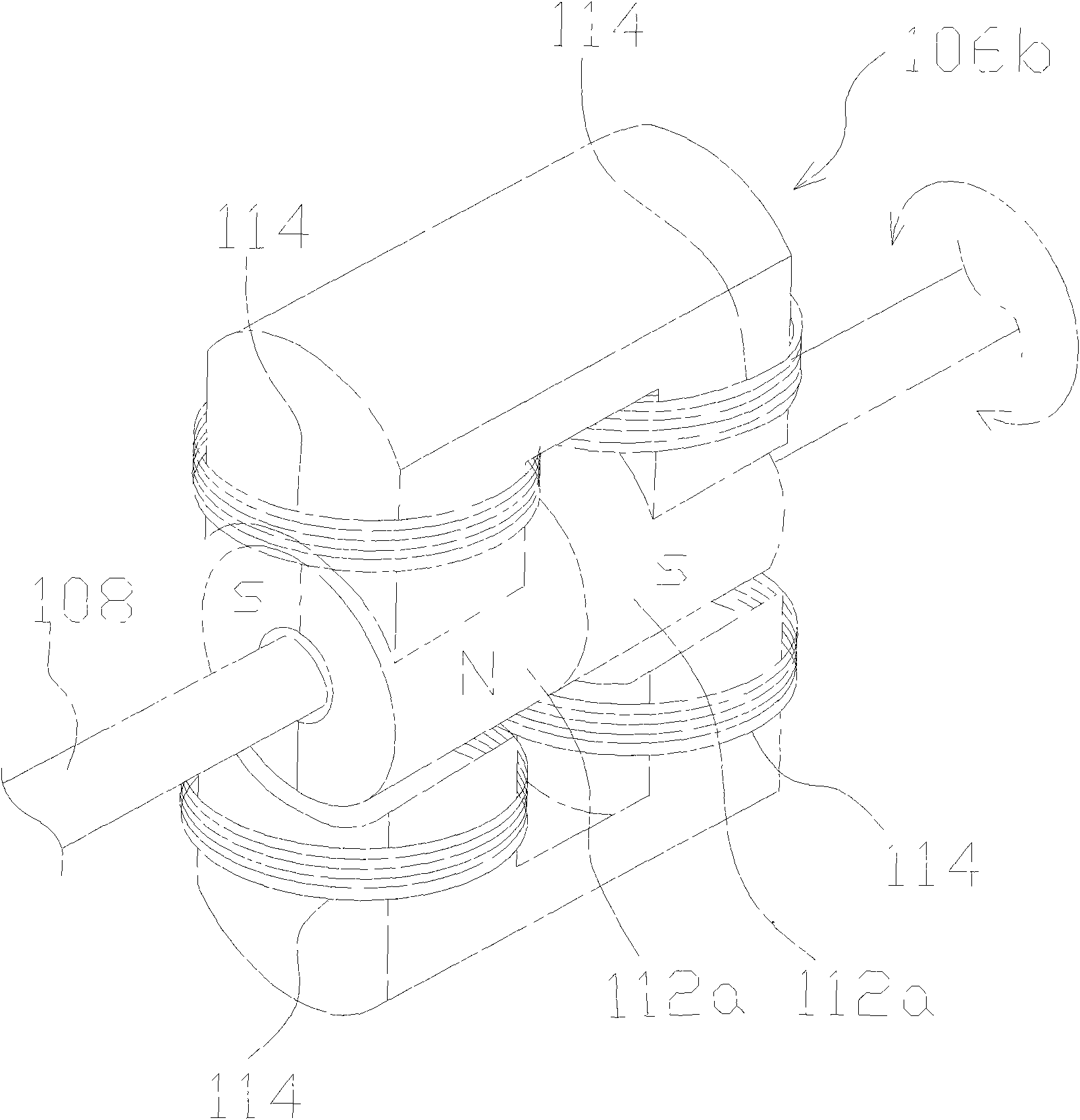

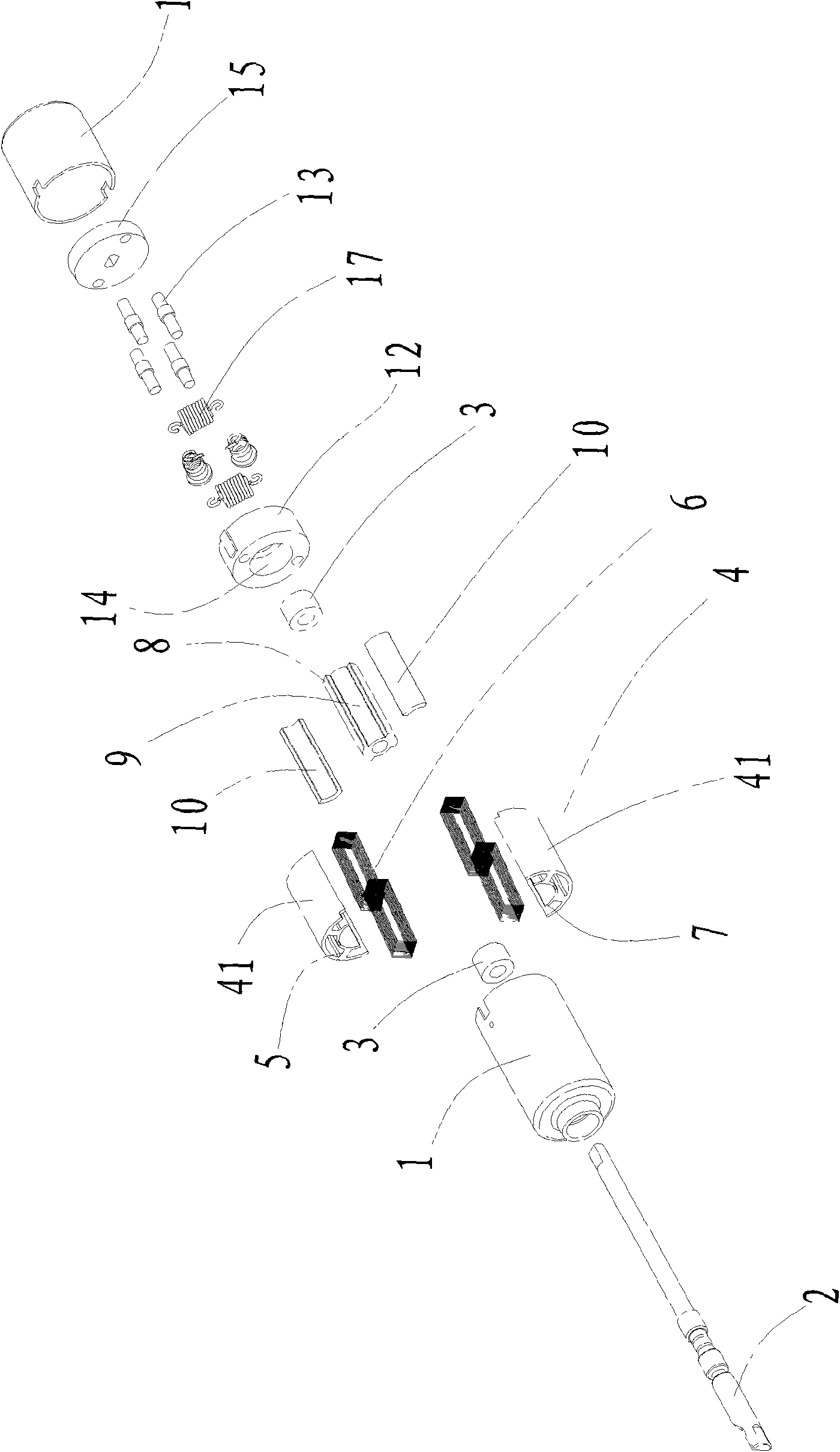

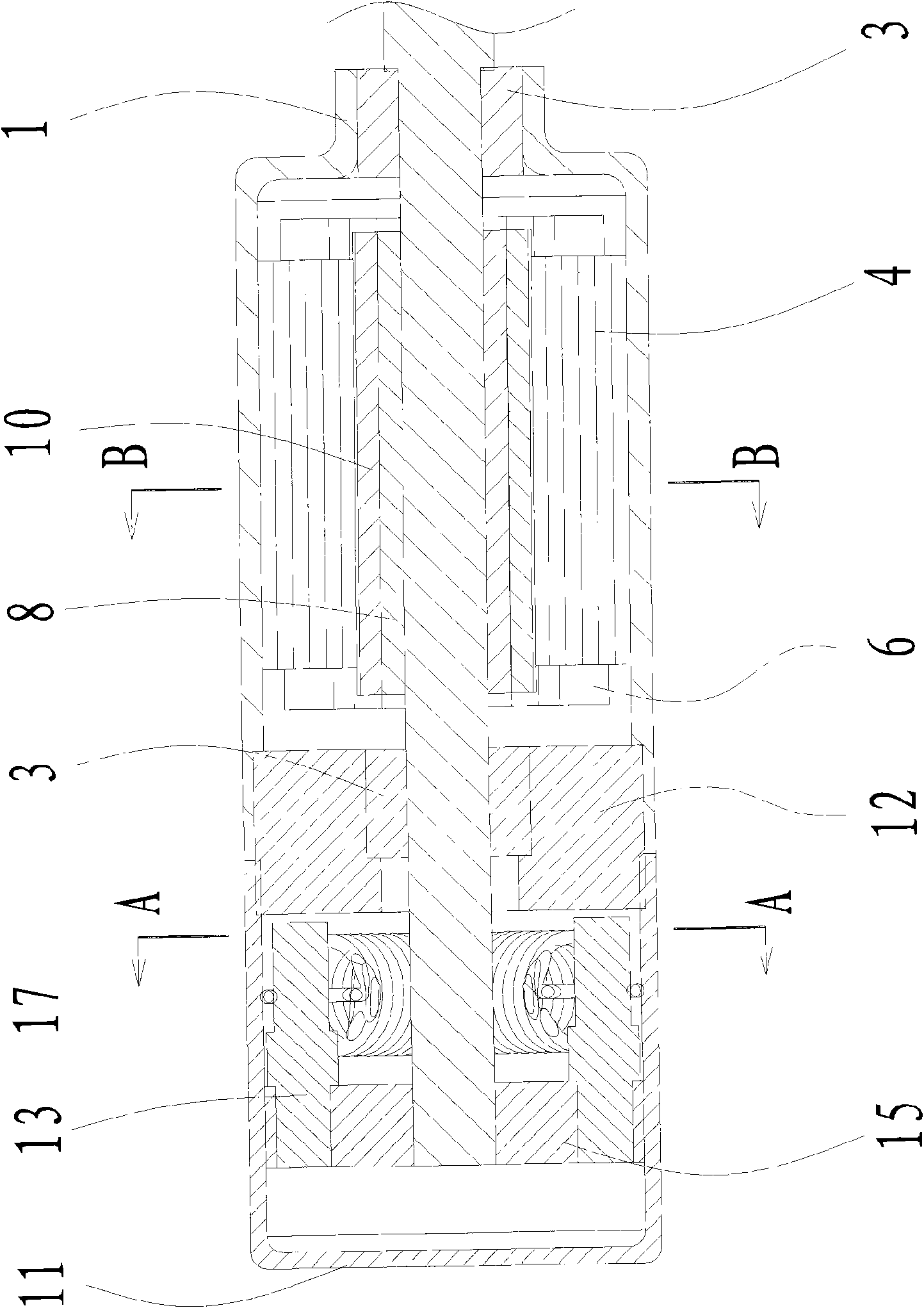

[0036] Specific embodiment one of the present invention, such as figure 2 , image 3 , shown in Fig. 4 and Fig. 5, a kind of electric toothbrush drive device, comprises a drive circuit and the housing 1 of sealing dust-proof and supporting function together, also comprises a drive rotating shaft 2, and the two ends necks of rotating shaft 2 are respectively equipped with a Bearing 3, the bearing 3 is fixedly installed in the inner cavity of the housing 1; a coil fixing frame 4 is sleeved in the inner cavity of the housing 1, and the inner surface of the coil fixing frame 4 evenly protrudes inwards to have four shoe-shaped pole yokes 5. Each shoe-shaped pole yoke 5 is wound with a drive coil 6, and the drive coil 6 is connected to the electrodes of the drive circuit. The end of each shoe-shaped pole yoke 5 is also connected to an arc-shaped pole yoke 7, four arcs The pole yoke 7 forms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com