A stator winding frame and a method for measuring the number of turns of a sub-coil

A technology of stator winding and coil turns, applied in measuring devices, measuring electrical variables, instruments, etc., can solve problems such as leakage, high hardness of thick copper wires, and scratches of copper wires, so as to improve motor performance and save skeleton materials , the effect of improving the duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

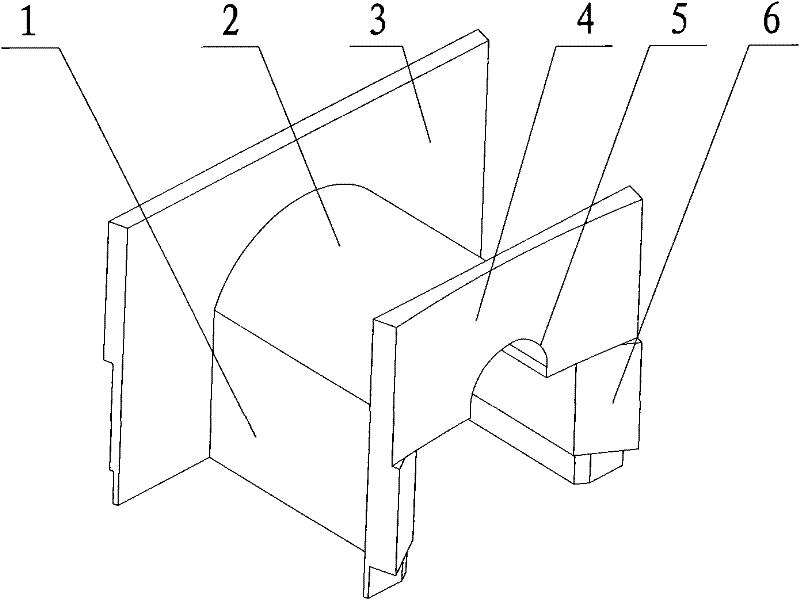

[0022] Such as Figure 1-3 Shown: 1 is the clamp arm, 2 is the winding ridge, 3 is the outer baffle, 4 is the inner baffle, 5 is the through groove, and 6 is the slope of the inner baffle.

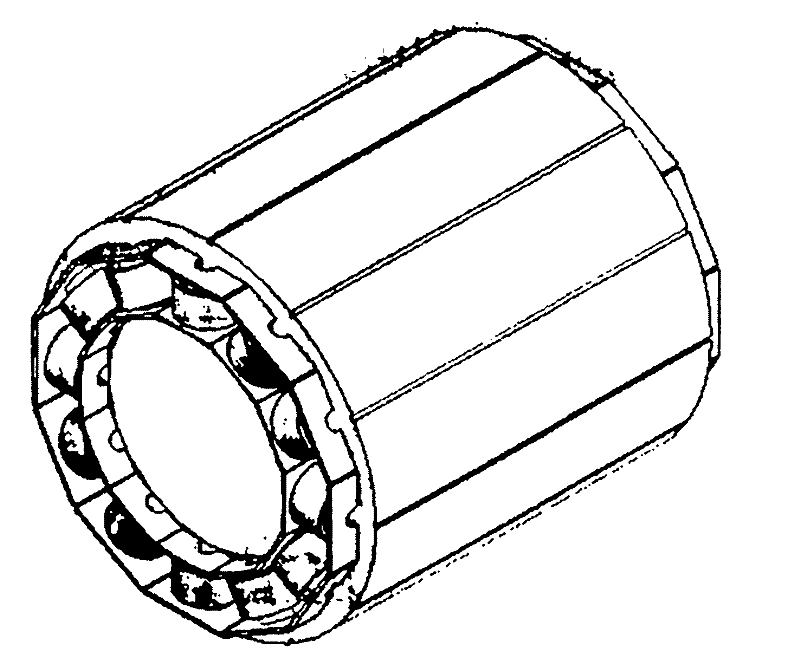

[0023] The stator winding skeleton of the present invention includes an arc-shaped winding ridge 2 and clamp arms 1 on both sides. The winding surface of the winding ridge 2 is but not limited to an arc surface, and the distance between the clamp arms 1 on both sides depends on the width of the stator teeth. Set, just enough to buckle the stator teeth. There are inner baffles 4 and outer baffles 3 at both ends of the winding ridge 2 and the clamping wall 1, and the height of the baffles in the winding direction of the clamping arm 1 and the winding ridge 2 depends on the required winding line type and winding It depends on the number of turns, and generally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com