Preparing method of block amorphous ring type magnetic core

A ring-shaped, amorphous technology, applied in the direction of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve the problem that the surface quality of the strip is not easy to control, affect the transformer core space factor, The effects of working magnetic performance and other issues are easy to implement, with few surface defects and improved space factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the present invention is specifically as follows:

[0012] (1) Weigh each element

[0013] Calculate the weight of each element related to it according to the number of atoms required;

[0014] (2) Melting master alloy

[0015] Put the required raw materials weighed in step (1) into the vacuum high-frequency induction smelting furnace, and adjust the vacuum degree to 1~8×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.01-0.08MPa; the current is adjusted to 15-25A, the induction temperature is 1000-1600°C; the melting time is 5-10min, and the master alloy is taken out after cooling with the furnace;

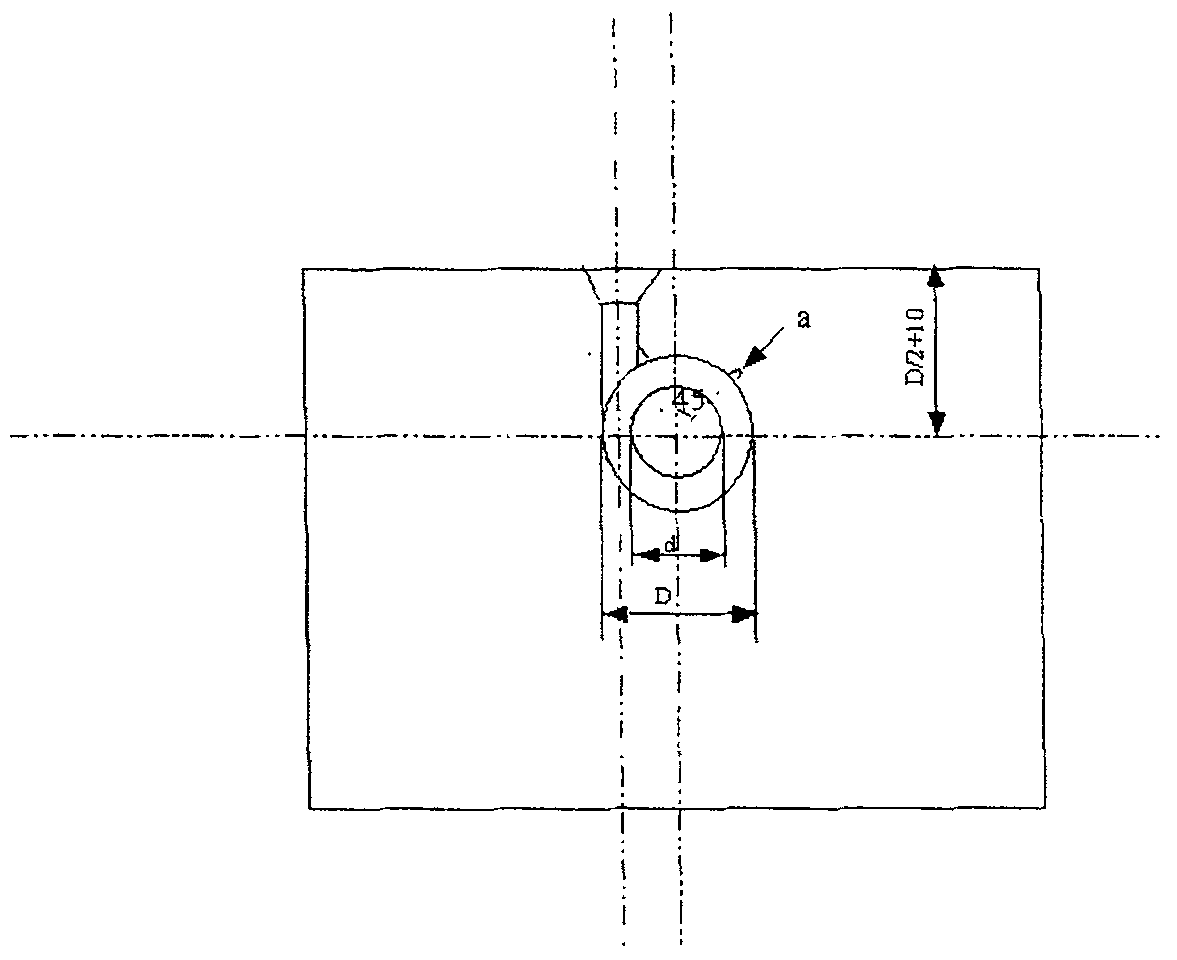

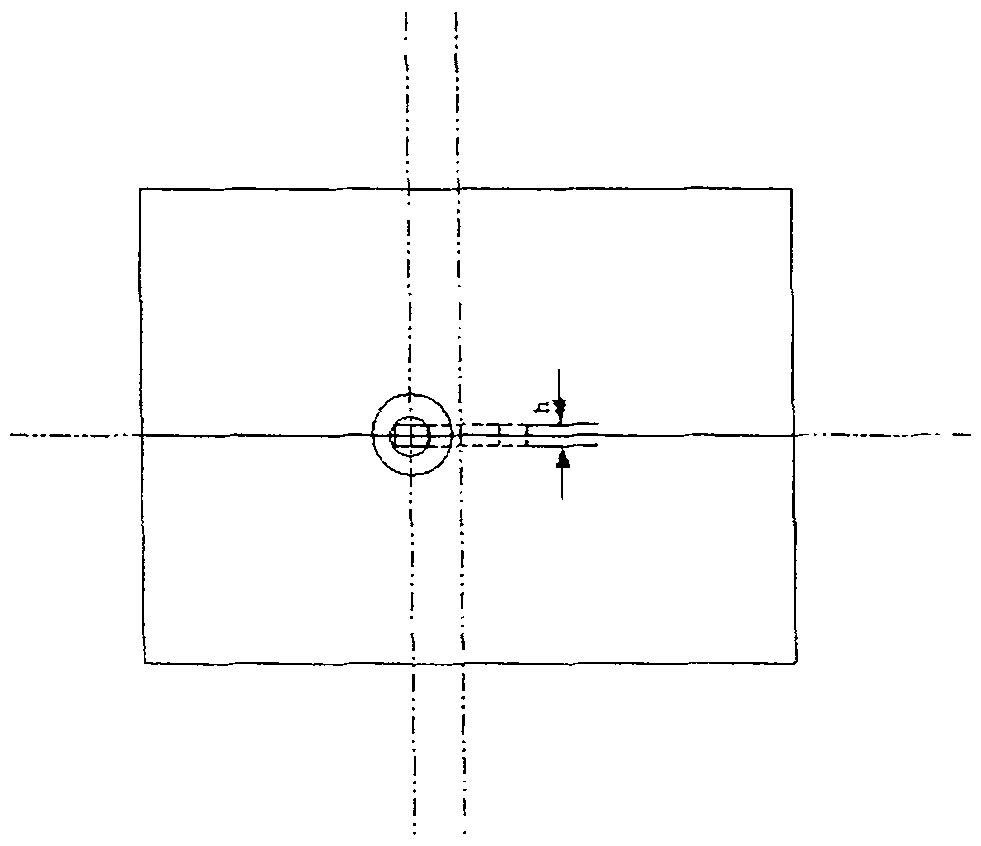

[0016] (3) Ring-shaped bulk amorphous alloy

[0017] Put the master alloy prepared in step (2) into the induction furnace of the rapid solidification device, and adjust the vacuum degree to 1~8×10 -3 Pa, filled with argon protective gas, the pressure of argon is 0.01-0.08MPa; the current is adjusted to 2-10A, the induction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com