Apparatus for measuring film thickness and refractive index in medium

A film thickness, internal measurement technology, applied in the field of optical measurement, to achieve the effect of improving measurement accuracy, strong practical value, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

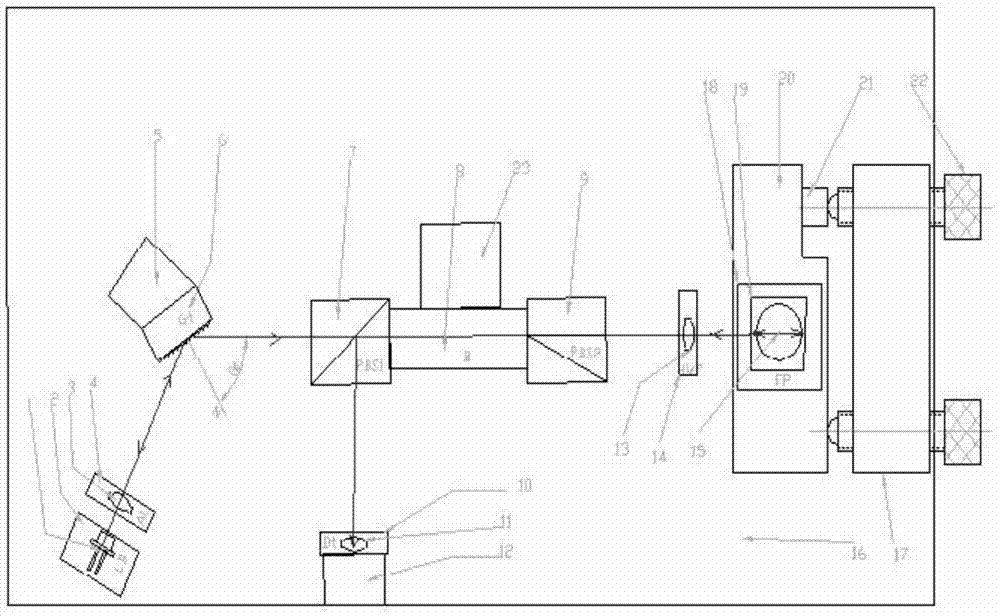

[0019] In order to further illustrate the advantages and purposes of the present invention, the content of the present invention will be further described below in conjunction with examples.

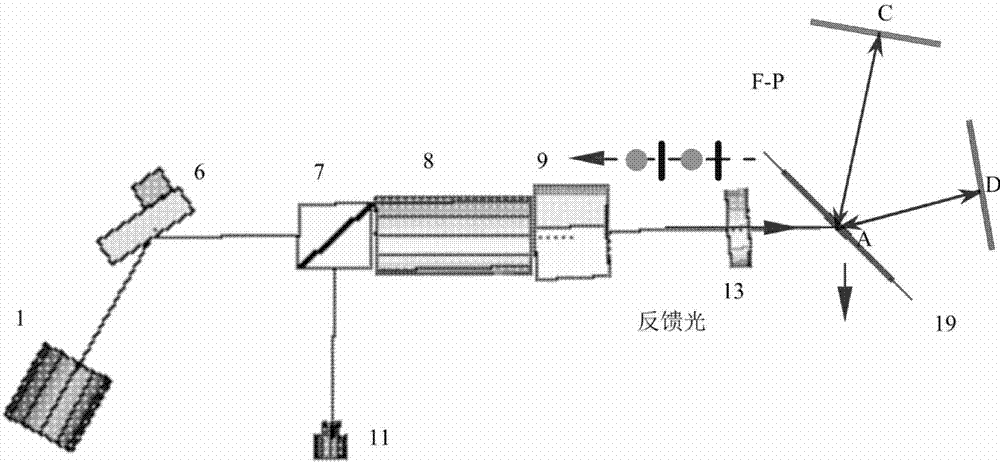

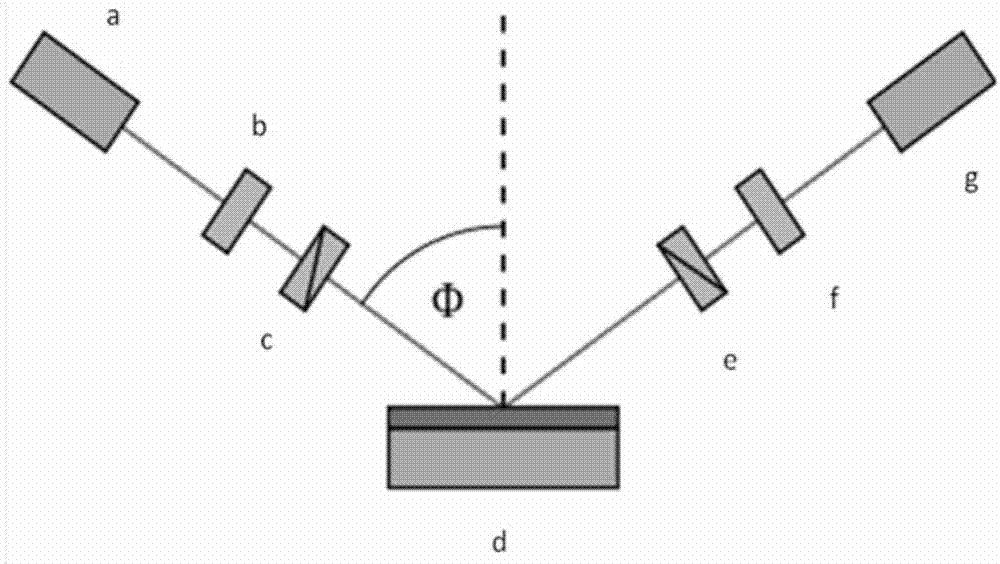

[0020] The device used for measuring the relative phase difference in the optically dense medium of the present invention is as figure 2 shown. image 3 An embodiment of this device for measuring relative phase difference in an optically dense medium is given.

[0021] In this embodiment, the first high-reflection film and the second high-reflection film plane are made of optical quartz glass with low transmission loss. figure 2 Among the three optical surfaces, the surface where point A is located is the folding surface and the input-output coupling surface, and the reflectivity of p-polarization and s-polarization is both 93%. The surfaces where points C and D are located constitute the reflective surfaces at both ends of the equivalent confocal F-P cavity, and its reflectivity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com