Slurry shield model test mud cake thickness real-time measurement device and measurement method

A mud-water shield and model test technology, which is applied in the measurement of mud film formation process, and in the field of real-time measurement device for mud skin thickness in mud-water shield model test, can solve reading errors, can only be obtained, and mud skin thickness is difficult to read accurately, etc. problem, to achieve the effect of accurate measurement and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

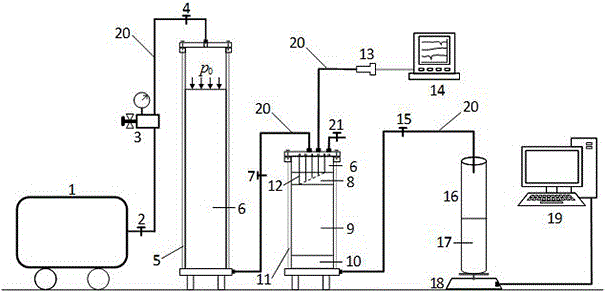

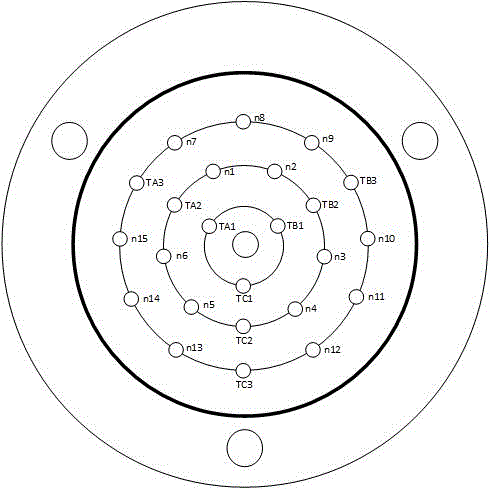

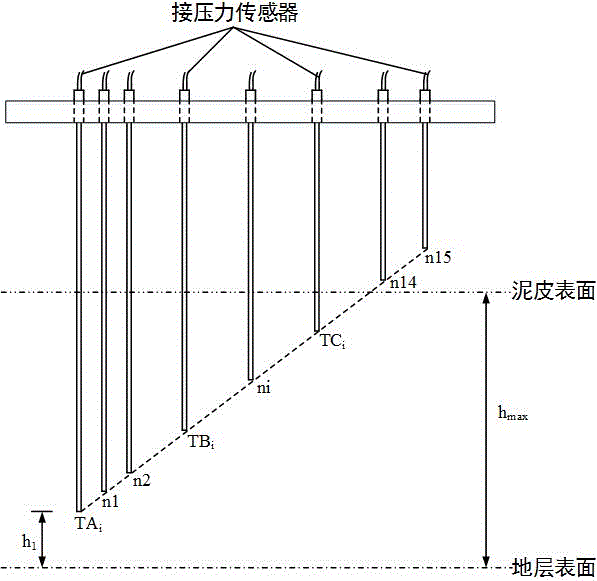

Method used

Image

Examples

Embodiment 1

[0056] A method for real-time measurement of mud skin thickness in mud-water shield model test:

[0057] ①According to the practice of mud-water shield engineering, select the mud proportion plan suitable for the model test formation, weigh 8800ml of clear water according to the proportion and pour it into the mixing tank, slowly pour in 1200g of bentonite, 25g of sodium carbonate, carboxymethyl Sodium cellulose (CMC) solution 200ml (CMC8g + hot water 192g fully stirred), fully stirred evenly and then let stand for 24 hours to allow the mud to fully react, and measure the pH value of the mud, funnel viscosity, specific gravity, sand content rate and water separation rate and other properties, before the test, the mud is packed in the mud barrel 5;

[0058] ② Clean and sieve the sand, and prepare sand filter material and sand formation material;

[0059] ③ Select the appropriate sand filter layer gradation according to the sand layer gradation, weigh the sand filter layer mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com