Patents

Literature

46results about How to "Excavation face stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

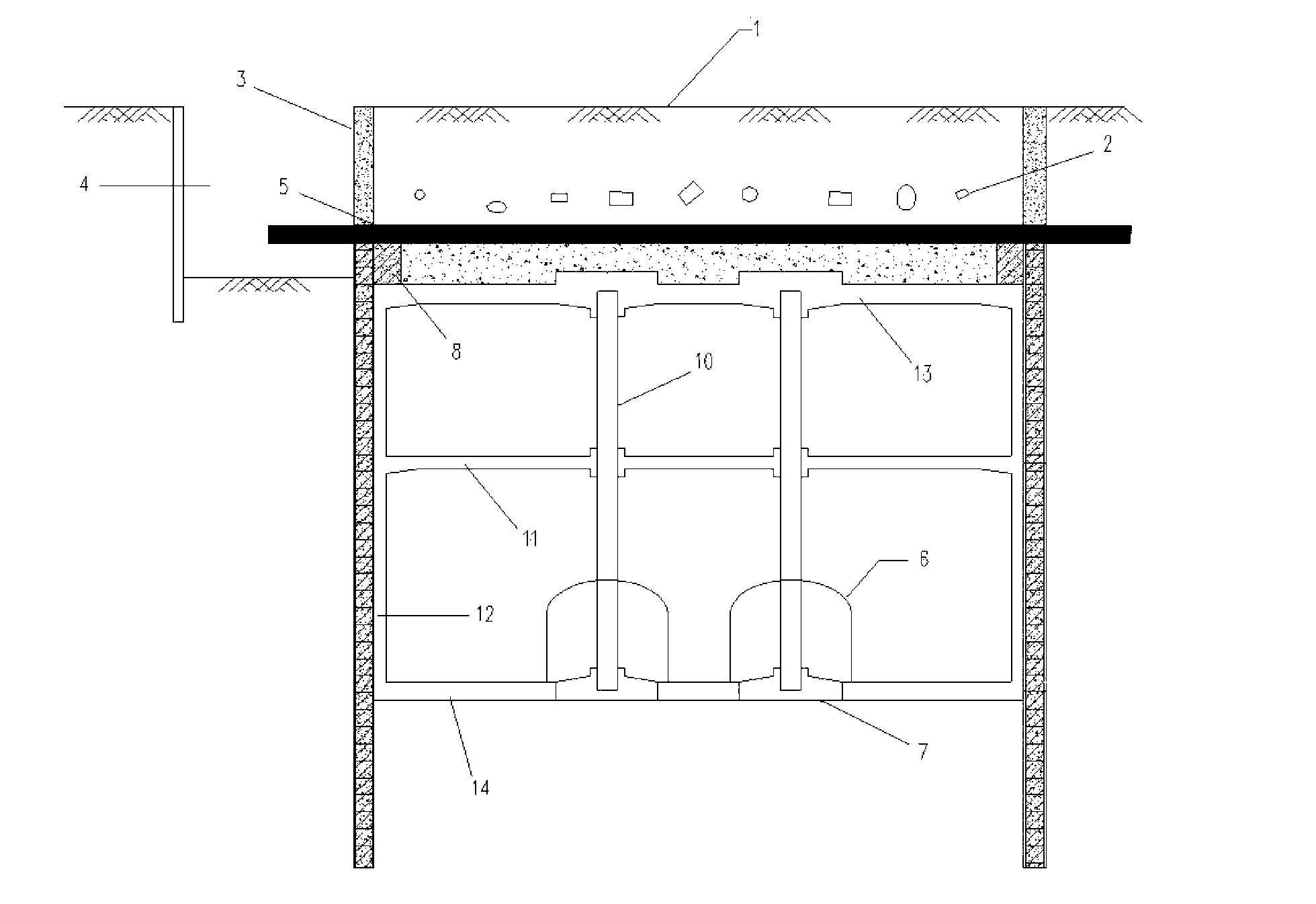

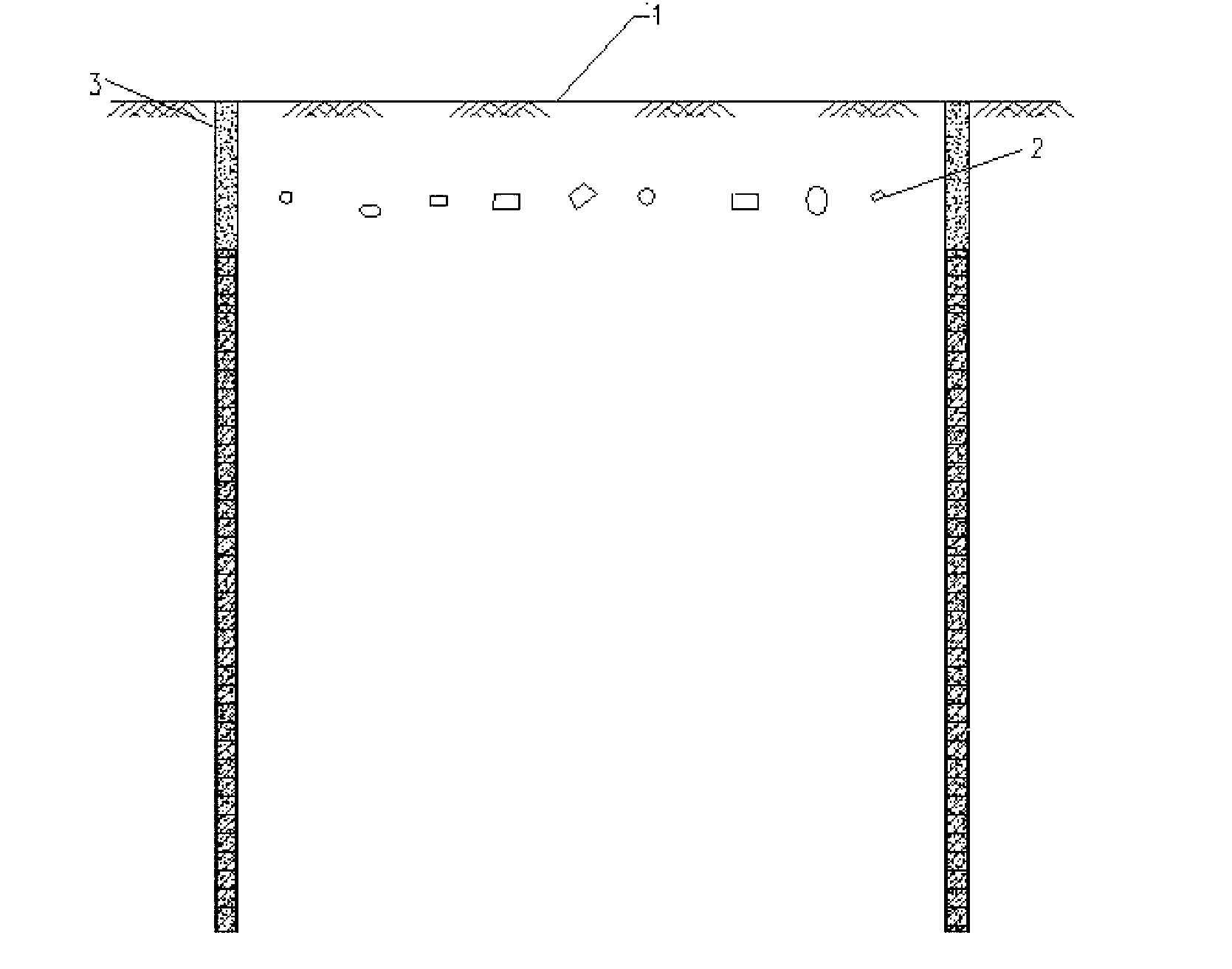

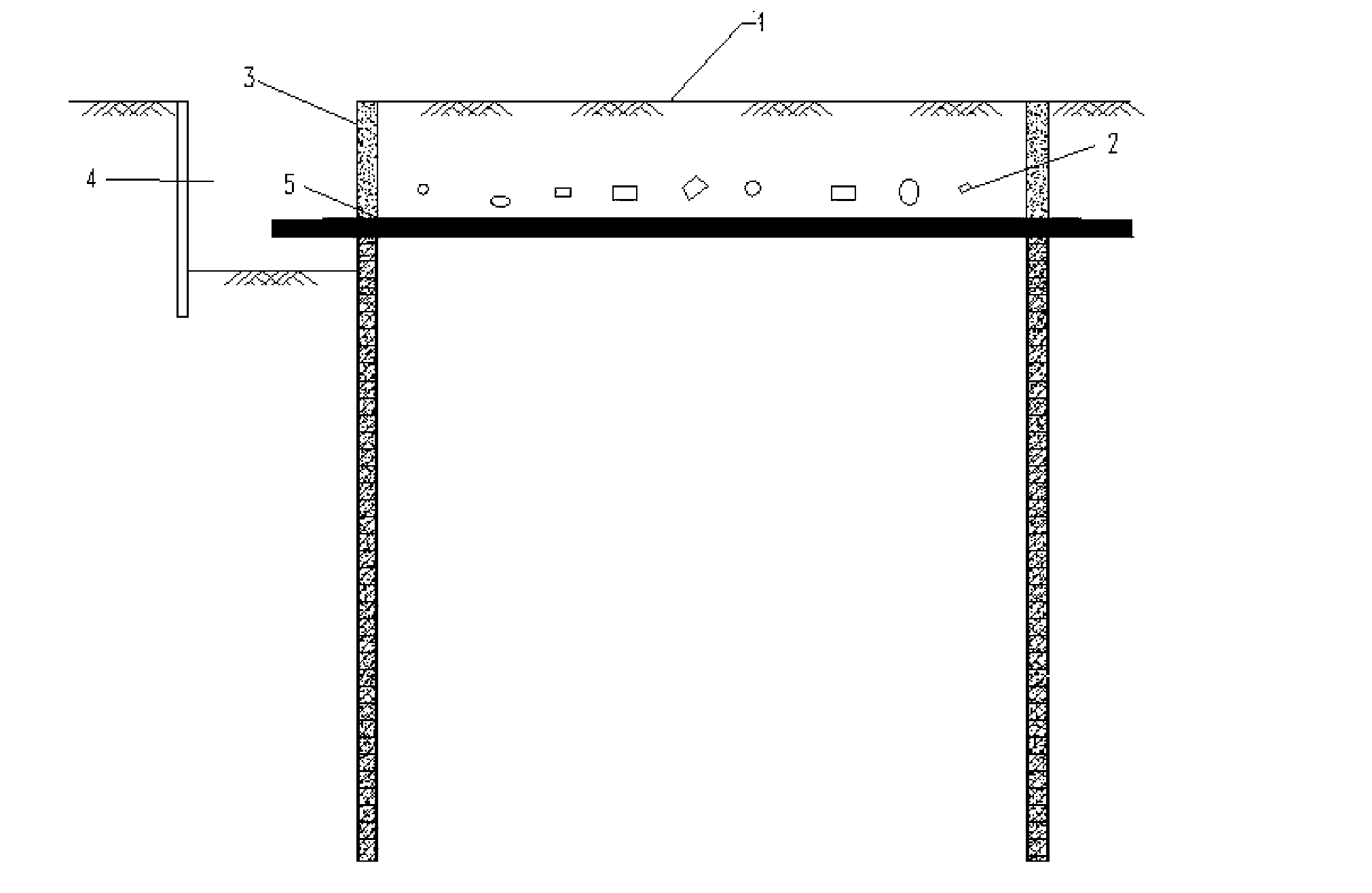

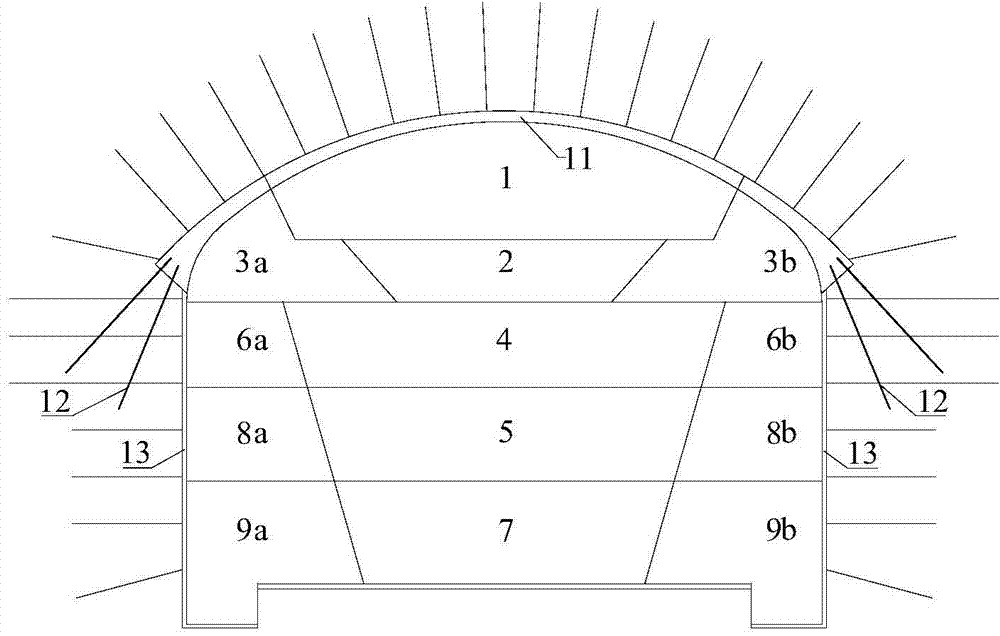

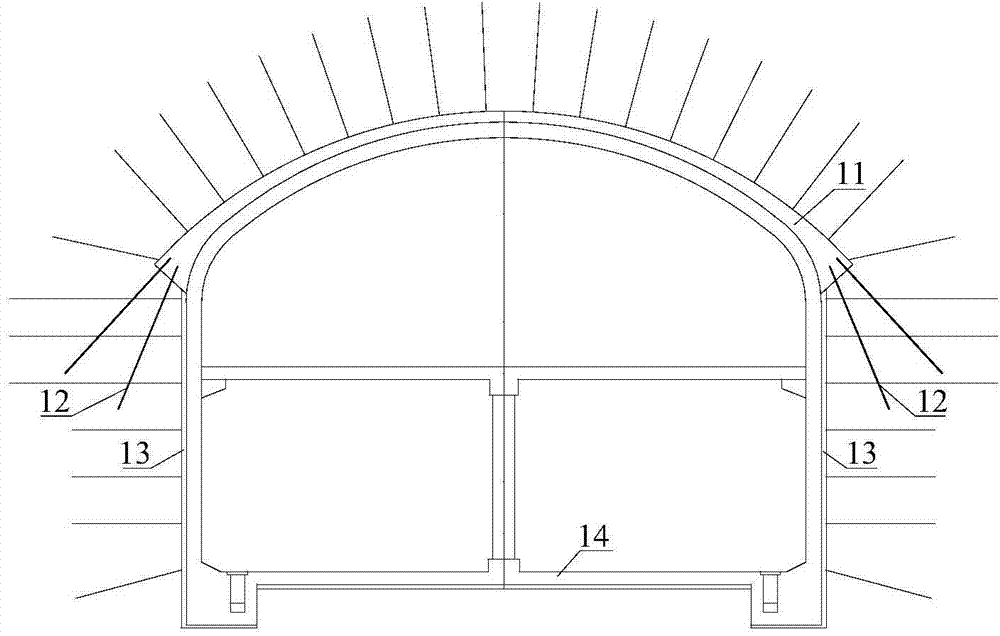

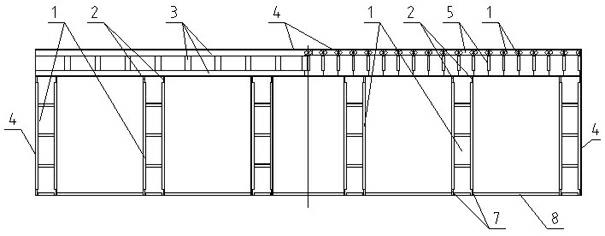

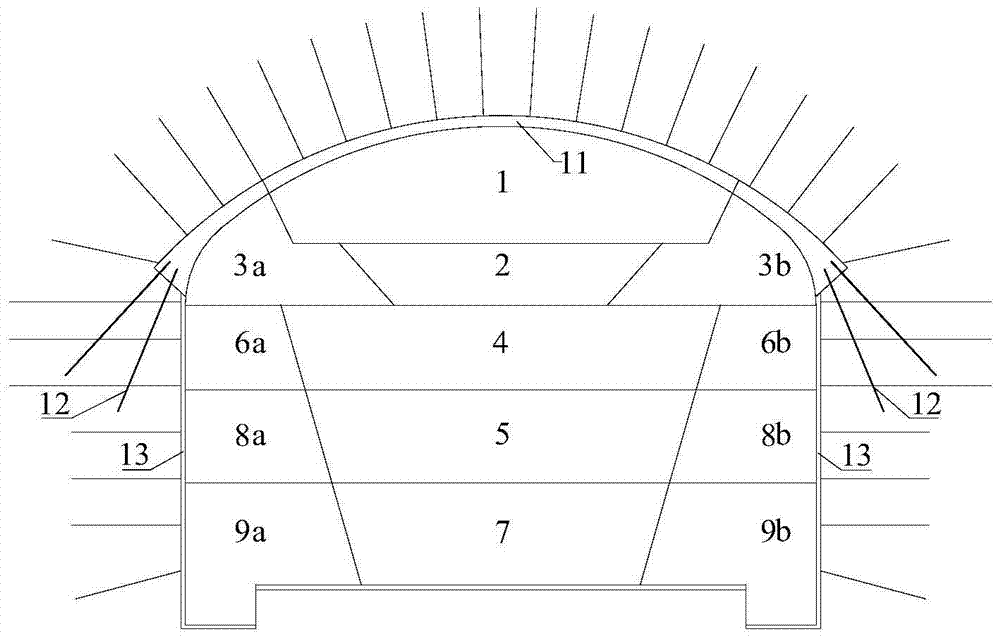

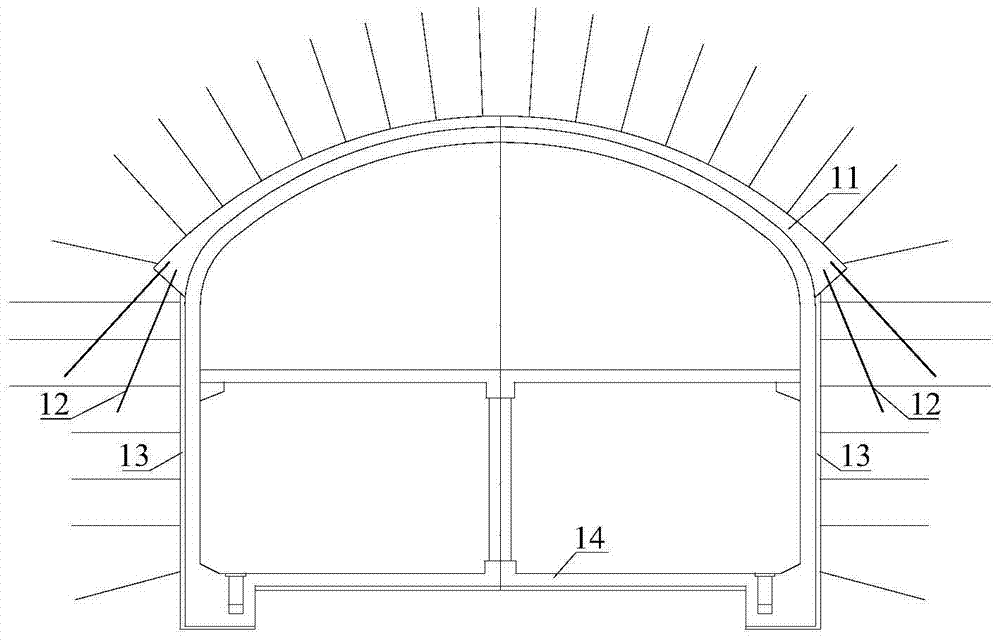

Shed-frame method for shallowly burying large-sized underground structure construction

InactiveCN102704957AGuaranteed lateral stabilityIncrease stiffnessUnderground chambersSupporting systemRoad surface

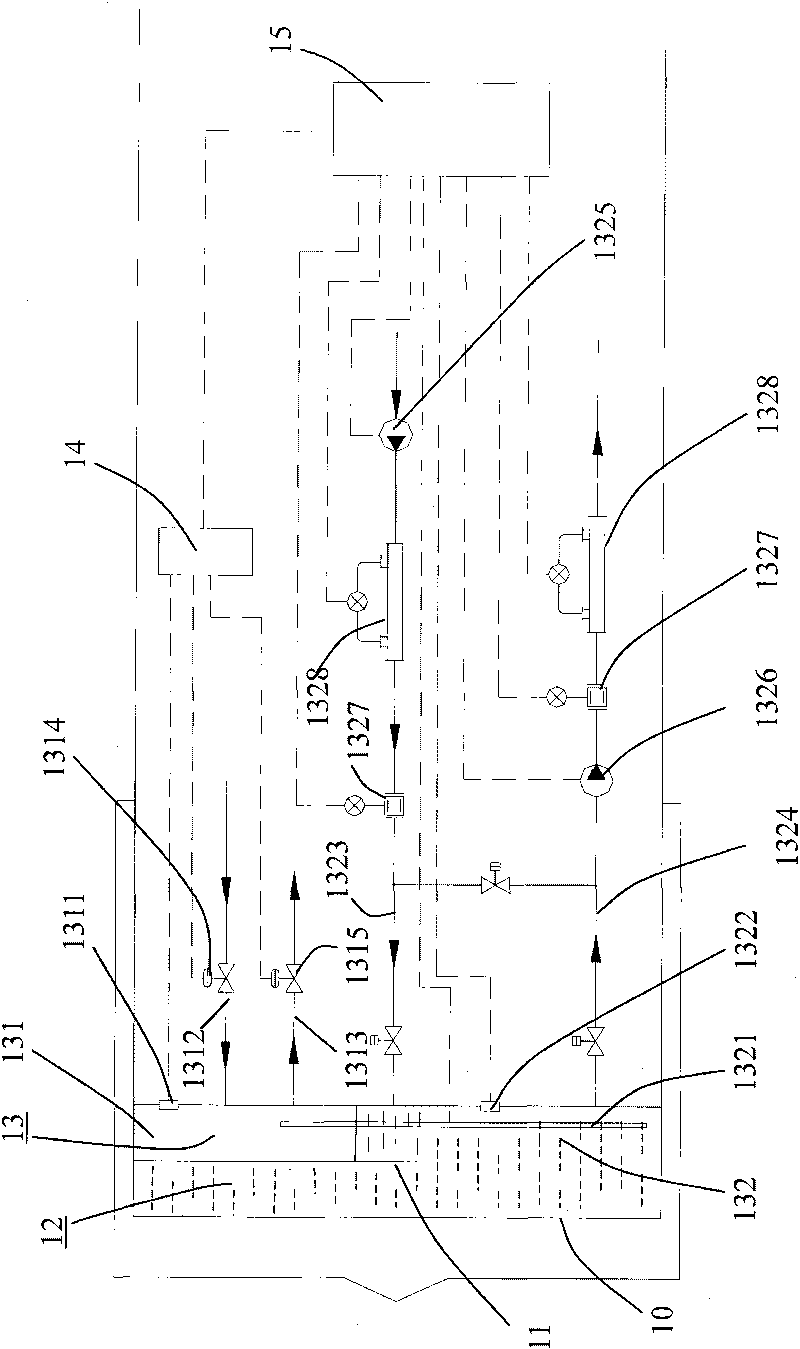

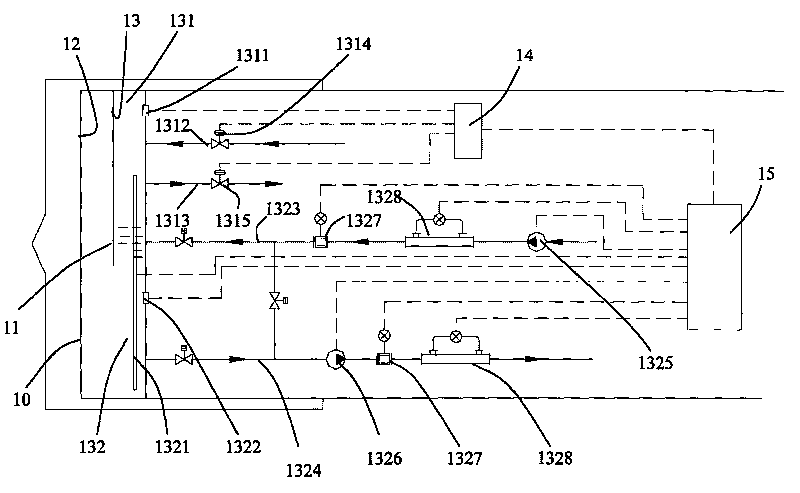

The invention relates to a shed-frame method for shallowly burying a large-sized underground structure construction. A construction principle is as follows: an envelope enclosure is adopted for retaining soil and water and resisting lateral deformation; a large-diameter pipe shed is arranged to bear the load of road surfaces and stratums and protecting underground pipelines; strip foundation construction of a center pillar in a main structure is carried out in a small pilot tunnel which is excavated with a subsurface excavation method; and under the protection of a top pipe shed frame, main structure construction is carried out with a cover-and-excavation half-top-town half-bottom-up method, and the center pillar, side walls, a center plate and a top plate which are pre-constructed well are utilized for providing vertical and horizontal support systems in an excavation space. The invention aims at providing a new method for shallowly burying the large-sized underground structure construction under an urban road; and the method is reasonable and feasible in technique and strong in operability, the quality of the main structure is guaranteed easily, construction is safe and rapid, the influences on ground transportation and the dismantlement and change to underground pipelines are reduced, and the comprehensive benefits are remarkable, therefore the shed-frame method has an important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

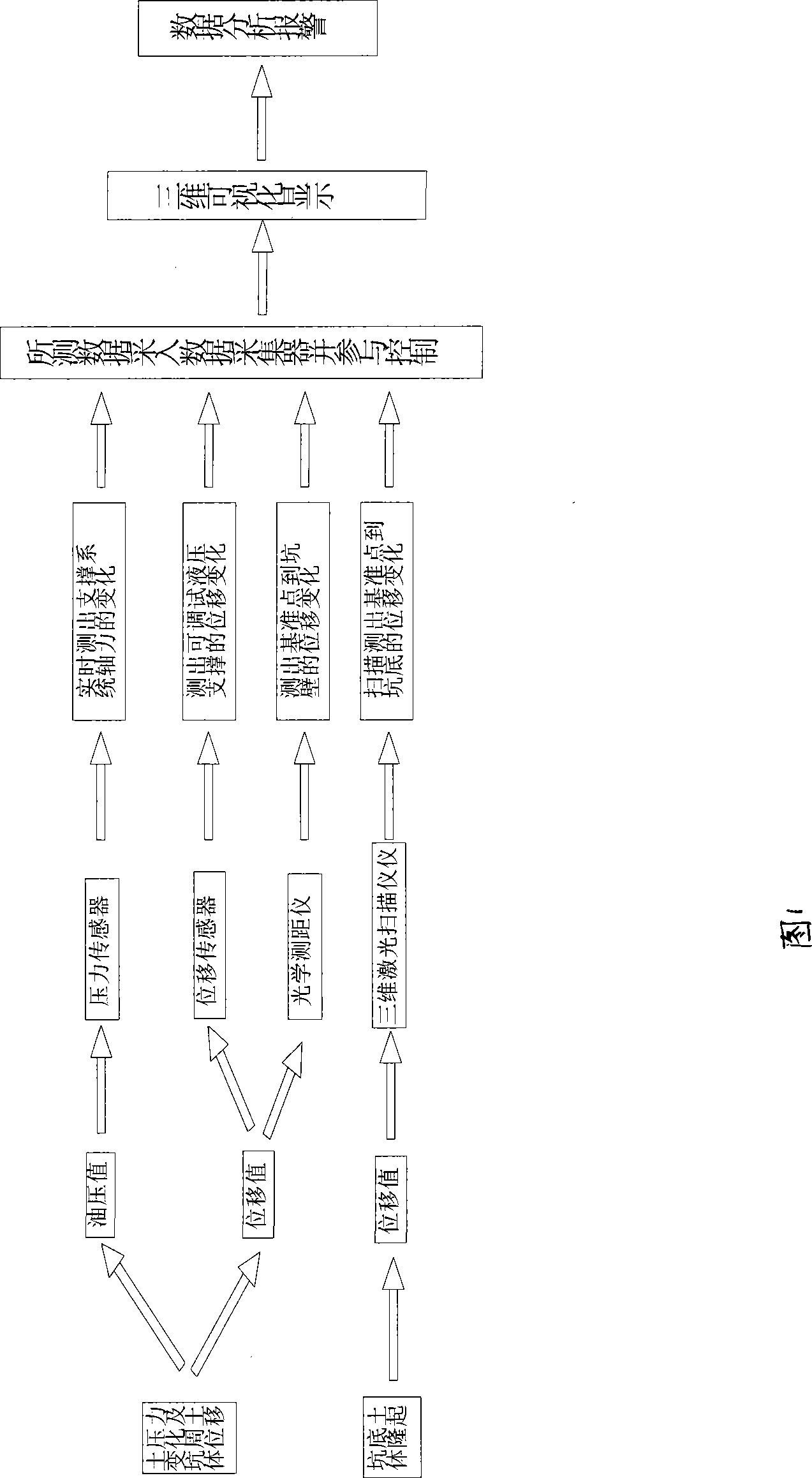

Foundation ditch digging real-time detection method

InactiveCN101457533AReal-time monitoring of pressure changesReal-time monitoring of displacementFoundation testingExcavationsVisual monitoringAxial force

The invention relates to a real-time detection method of excavation of a foundation pit, which is used for detecting the displacement change of the peripheral soil body of the pit in the excavation process of the foundation pit, the change of the pressure of the peripheral soil body of the pit and the change of raised soil body of the bottom of the pit and belongs to the construction engineering field. The invention utilizes a pressure sensor and a displacement sensor to detect the axial force change of a steel support device of an internal hydraulic oil cylinder in real time; an optical distance meter is used for detecting the horizontal distance and longitudinal distance of the periphery of the foundation pit, then a three-dimensional laser scanner is used for monitoring the change of raised or concave surface of the foundation pit in real time and visual monitoring and operation are carried out by a computer. Compared with the existing detection method of the foundation pit, the invention realizes the supporting monitoring of the foundation pit with automatic collection, can greatly improve the degree of automation and the safety of the construction, saves the labor, simultaneously realizes the purpose of construction with high efficiency and can be widely applied to the field of construction of the foundation pit.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Muddy water balance push bench

ActiveCN103398214AReduce land subsidenceGood working environmentPipe laying and repairInstrument controlWater balance

The invention relates to a muddy water balance push bench. The muddy water balance push bench comprises a steel cylindrical housing, a cutting blade disc arranged at the front end of the steel cylindrical housing as well as a cutting disc driving unit, a hinged unit, an electrical instrument control unit and a mud conveying and circulating unit which are accommodated and supported in the steel cylindrical housing, wherein the cutting blade disc is used for cutting a soil body during excavation; the cutting disc driving unit is used for driving forward and reverse rotation of the cutting blade disc; the hinged unit is used for fitting an excavation curve, and especially suitable for the advance of a curve with the small radius; the electrical instrument control unit is used for controlling corresponding actions of all parts; the mud conveying and circulating unit is used for conveying mud and establishing balance of an excavation plane. The push bench provided by the invention adopts a muddy water balanced type, when the excavation plane in an unstable stratum is blocked, the muddy water can be used for pressurizing so as to enable the excavation plane to keep stable, and disturbance on the soil body around a jacked pipe is smaller, so that the land subsidence is smaller. The push bench can pass through transmission pipeline projects of roads, rivers, buildings and the like, and is simple to operate, high in speed and low in cost.

Owner:SHANGHAI LIXING ENG TECH DEV

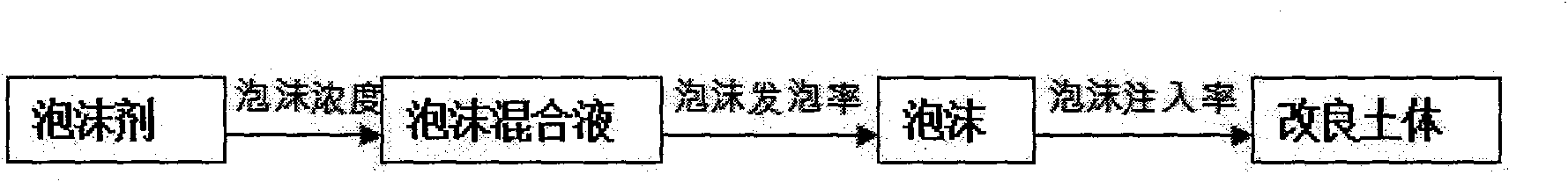

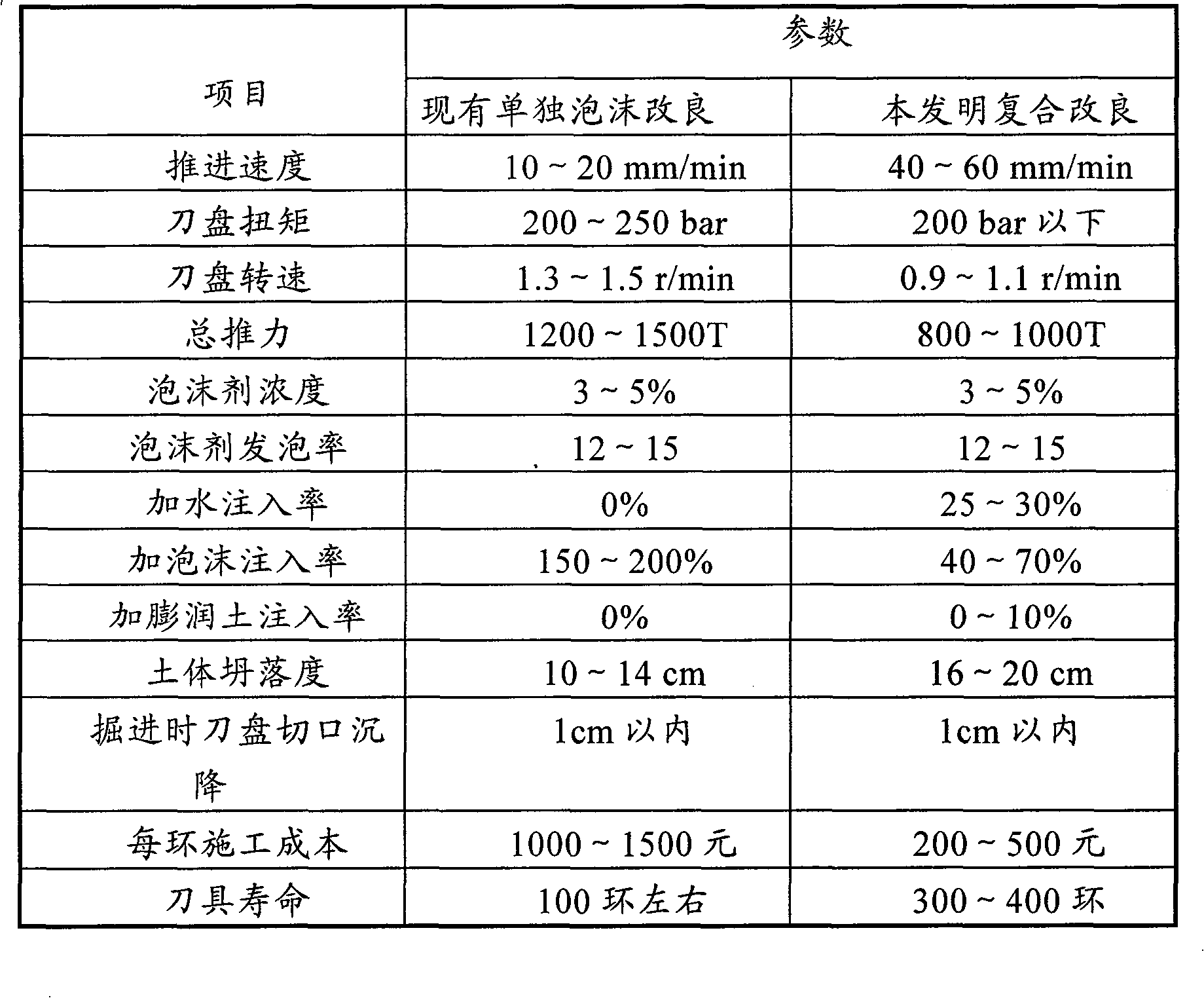

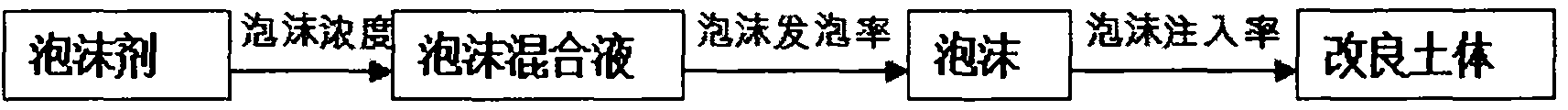

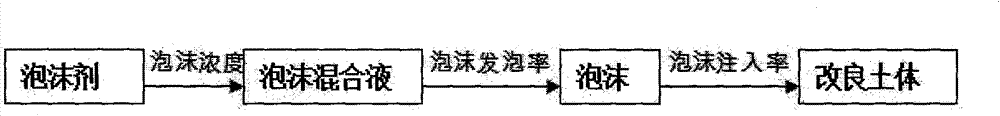

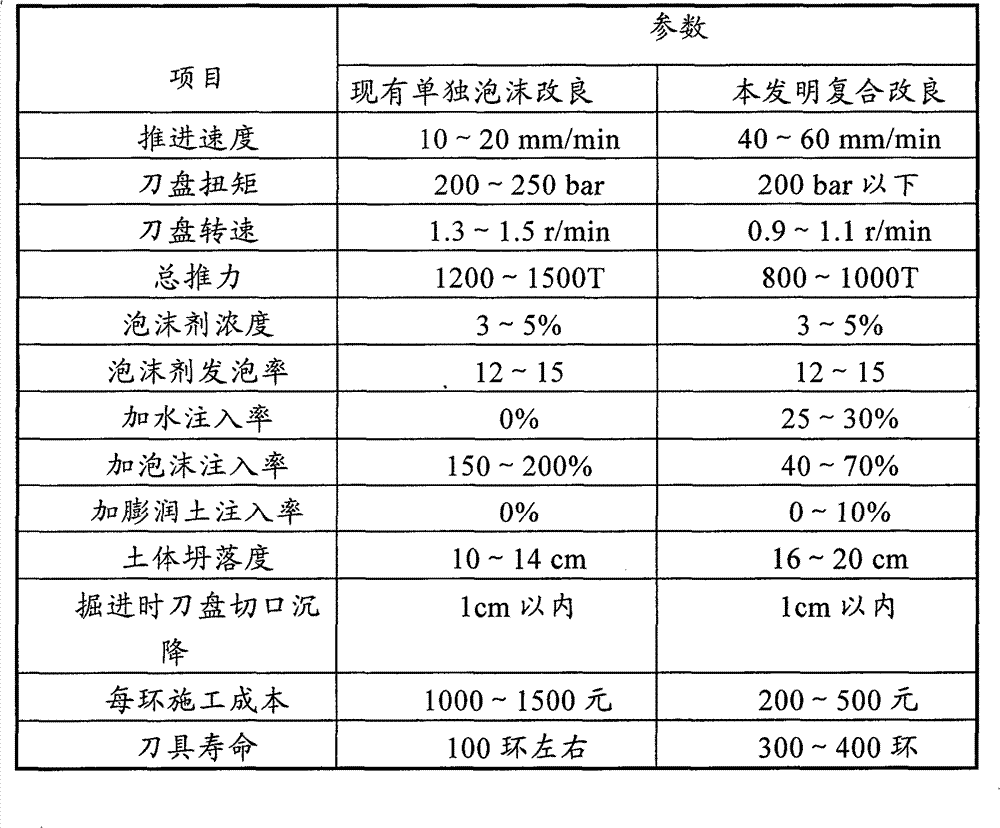

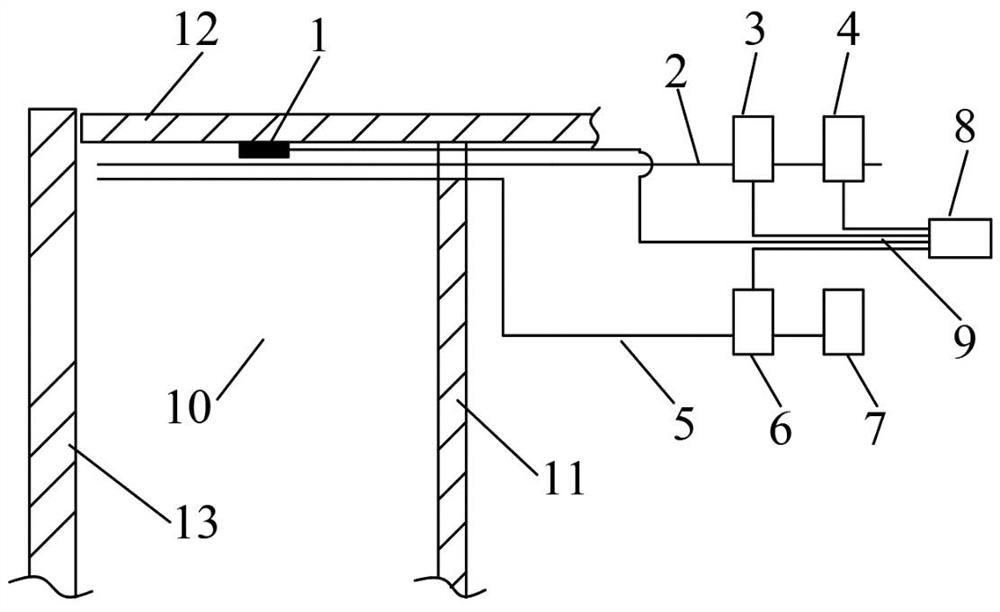

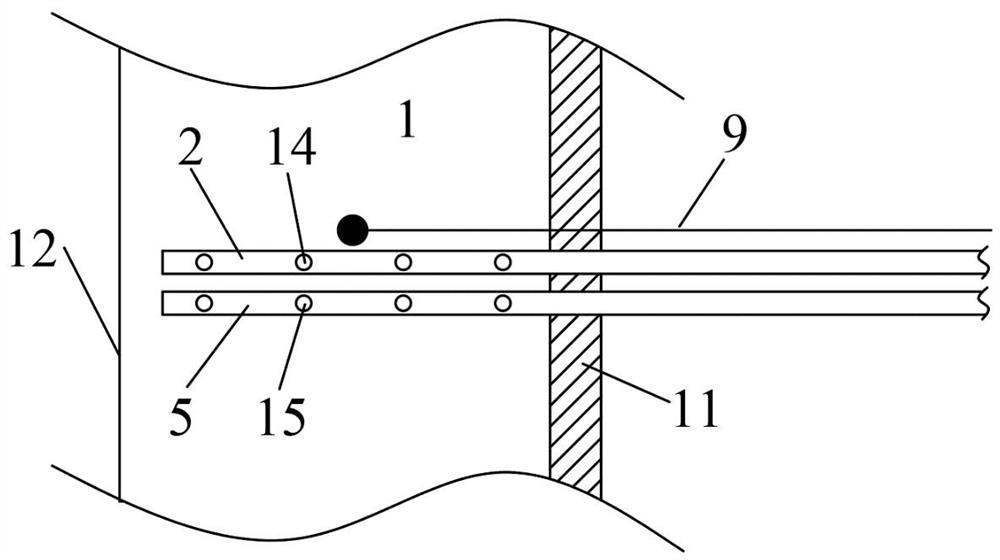

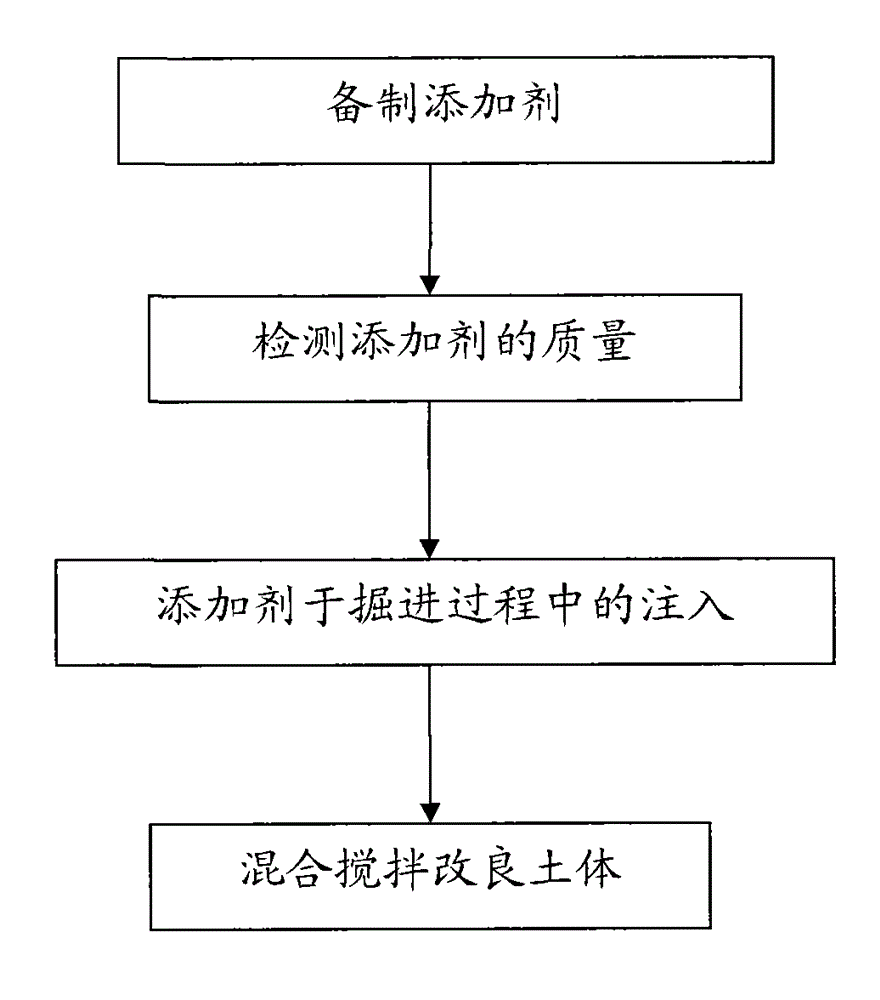

Construction method for improving shield soil in composite sand gravel stratum

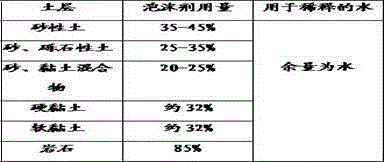

The invention provides a construction method for improving shield soil in a composite sand gravel stratum. Water, foam and bentonite slurry are used as composite improvement additives; and different additives are selectively injected to the front of a cutter head, the inside of a soil barn or a screw conveyor according to the actual working condition during shield driving with the aid of special improvement equipment and processes so as to play a role in improving the plastic fluidity of the soil, reducing the torque of the cutter head, stabilizing the excavation face and improving the driving efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD

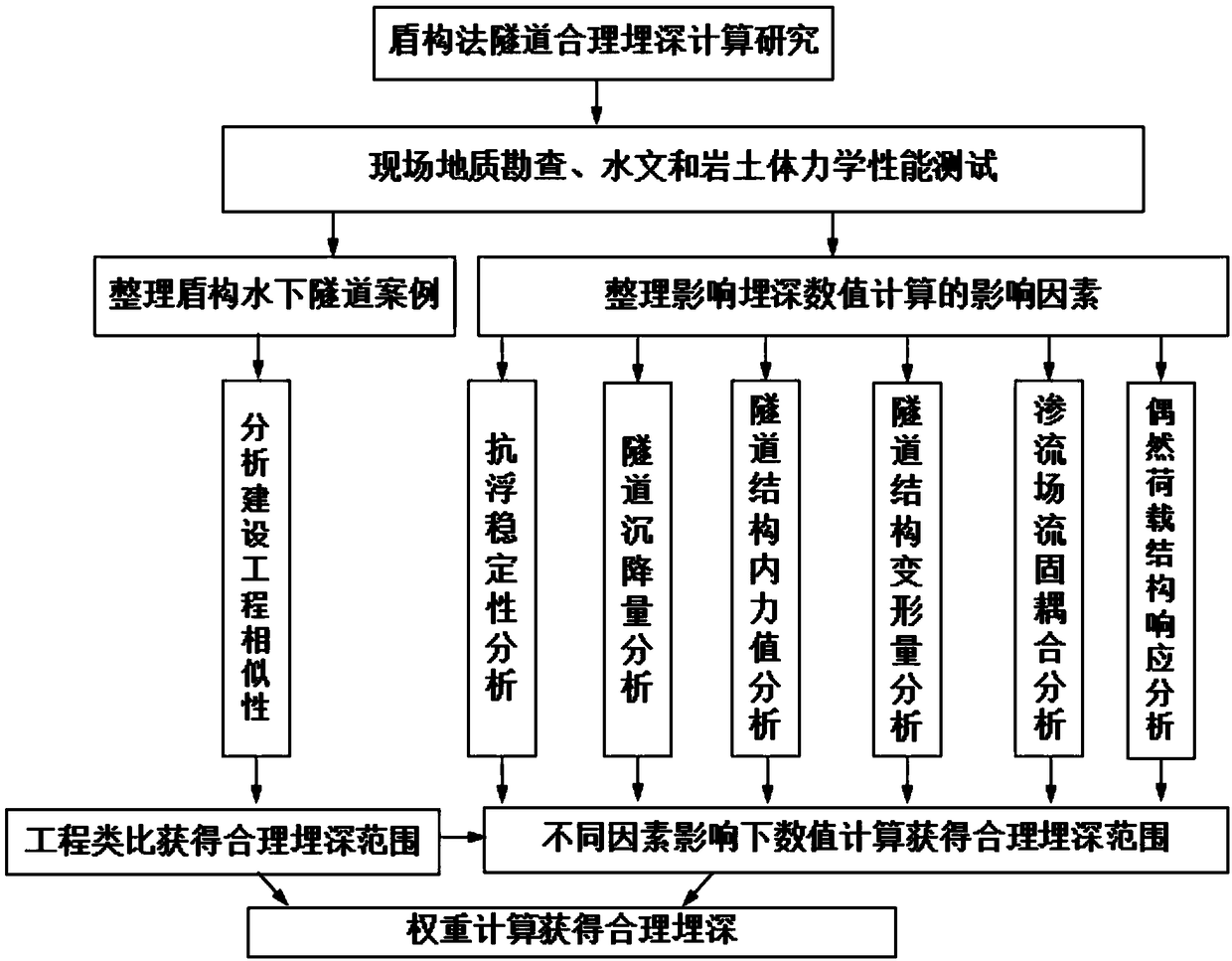

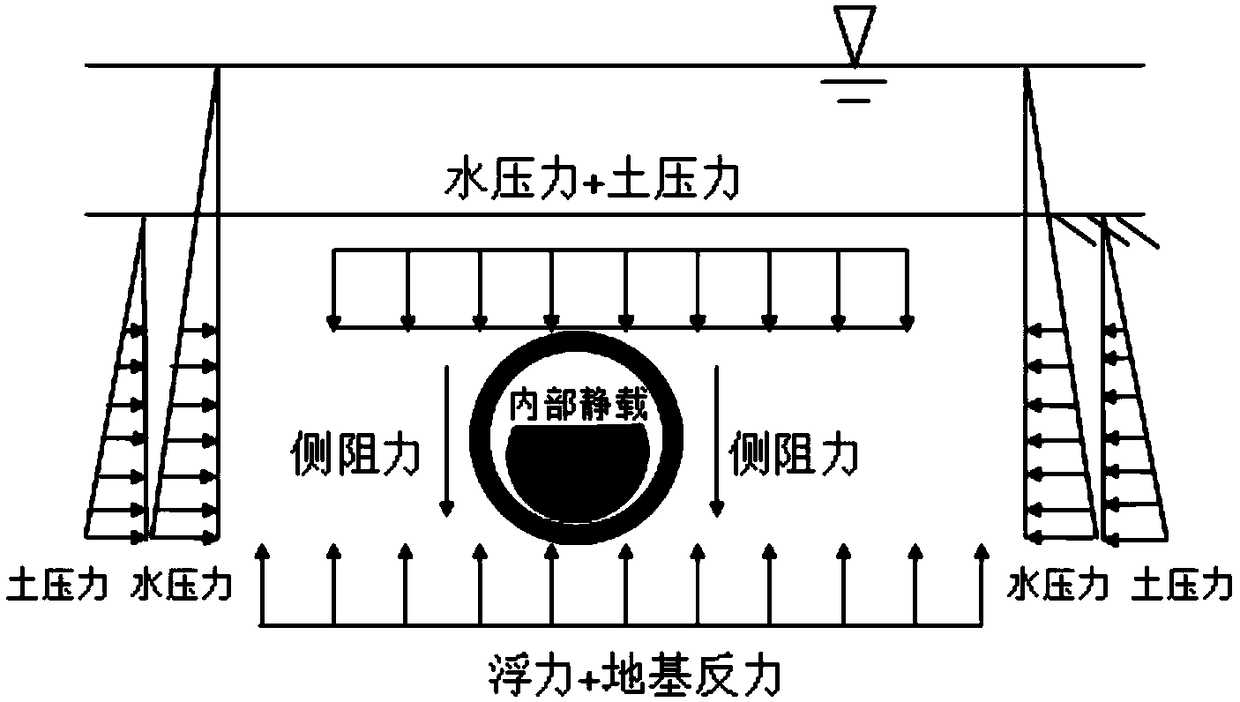

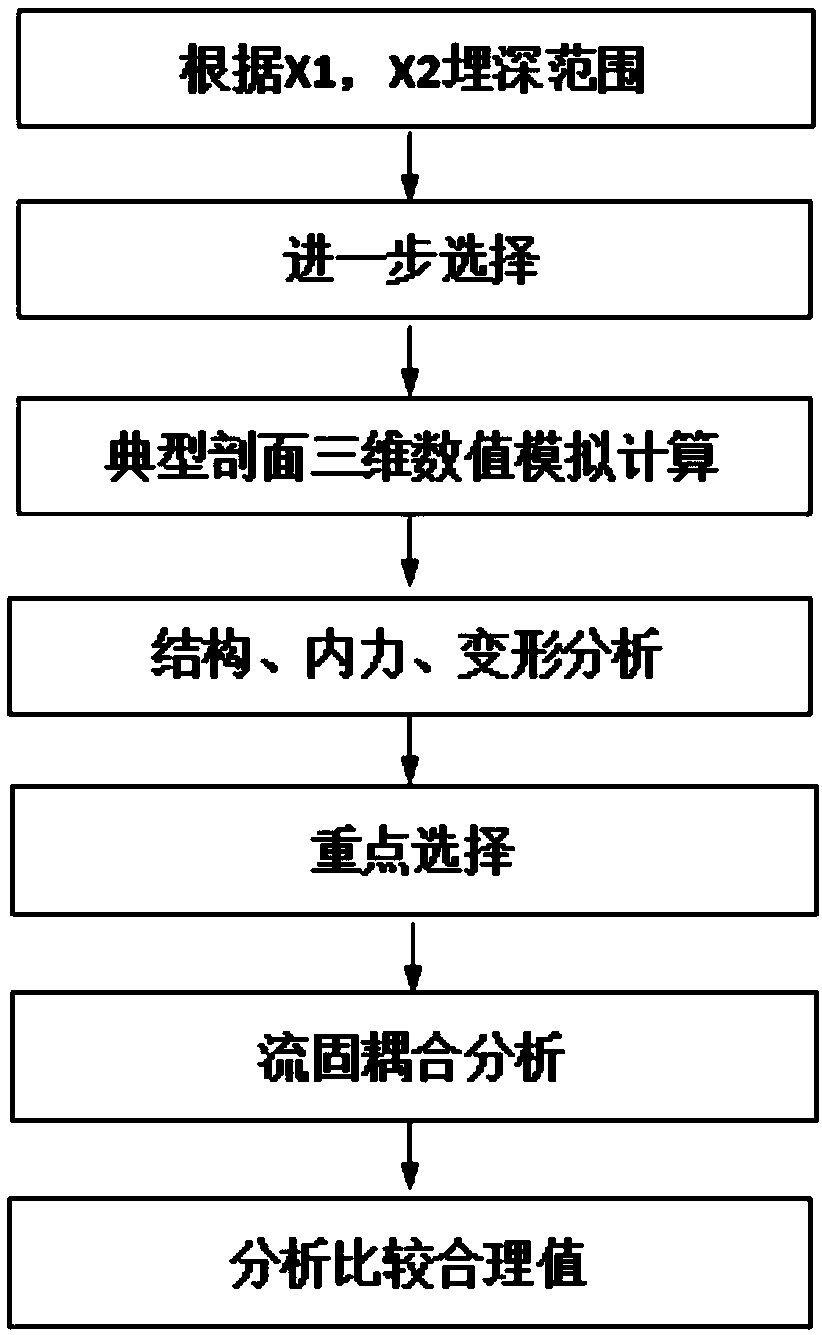

Rational burying depth calculation method for constructing subsea tunnel by shield method

PendingCN108647473AExcavation face stabilityGeometric CADSpecial data processing applicationsSingle holeGeomorphology

The invention discloses a rational burying depth calculation method for constructing a subsea tunnel by a shield method. The method comprises the steps of determining meteorological, hydrological andgeological environment conditions of a to-be-constructed subsea tunnel region, and obtaining hydraulics parameter values and physical mechanics parameters of a rock-soil body; obtaining previous subsea tunnel cases, performing arrangement on construction information of single-hole / multi-hole tunnels with different geological conditions and diameters, and analyzing existent factors, influencing theburying depth, of the to-be-constructed subsea tunnel region; by an engineering analogy method and a numerical calculation method, determining different burying depth values under the influence of the factors; and by a weight analysis method, calculating out weight values of judgment factors to obtain a final burying depth value.

Owner:SHANDONG UNIV +1

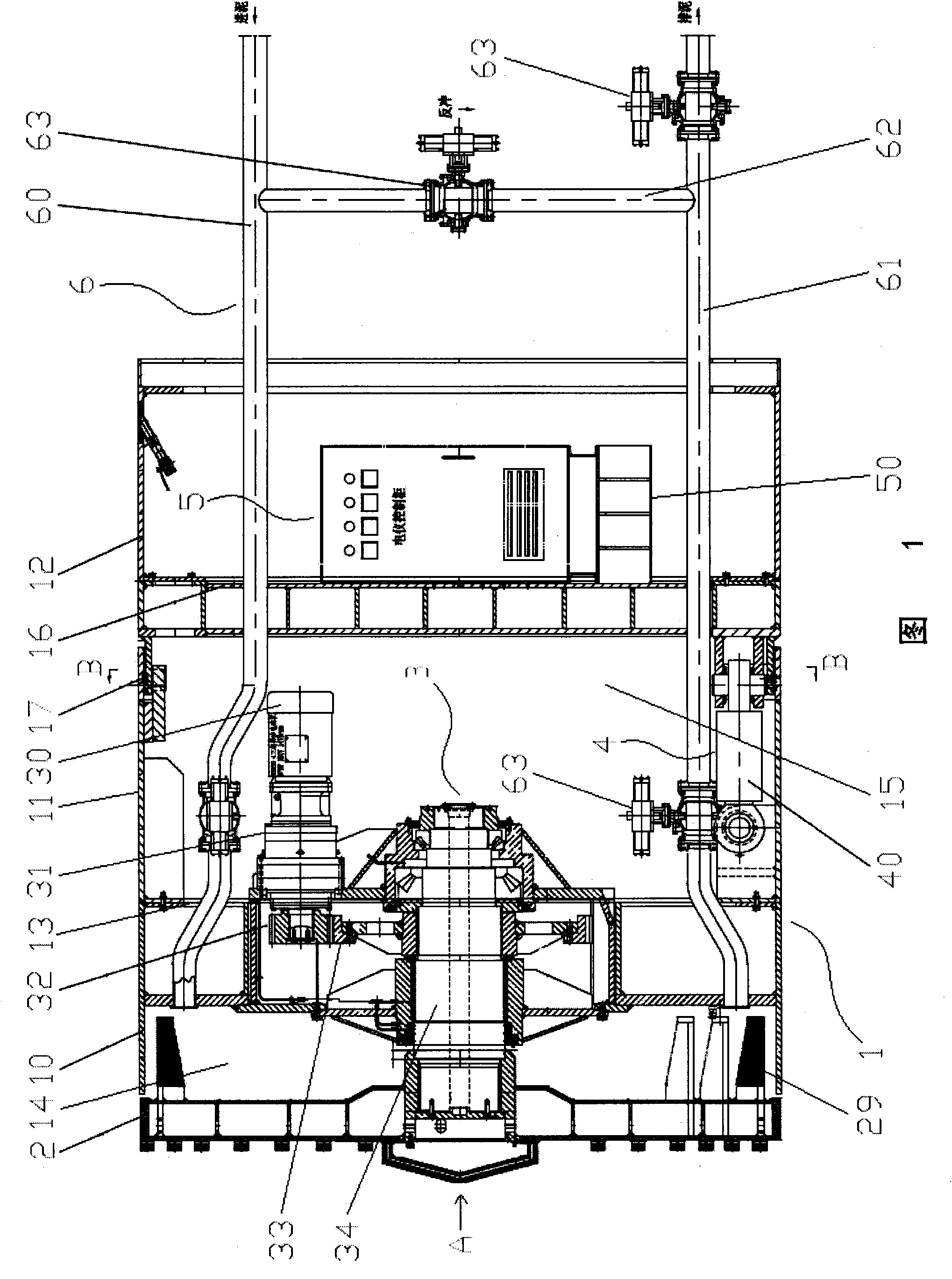

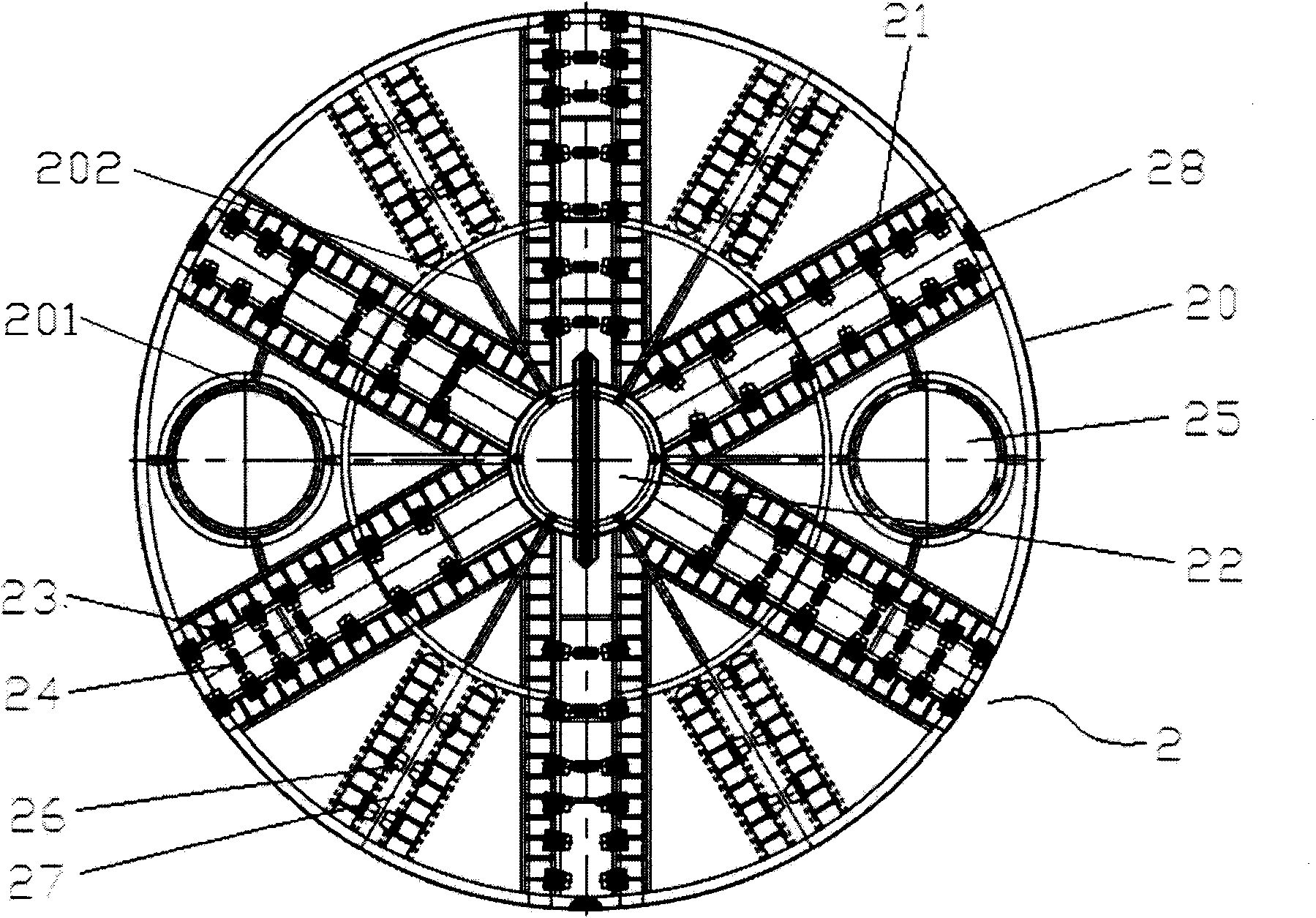

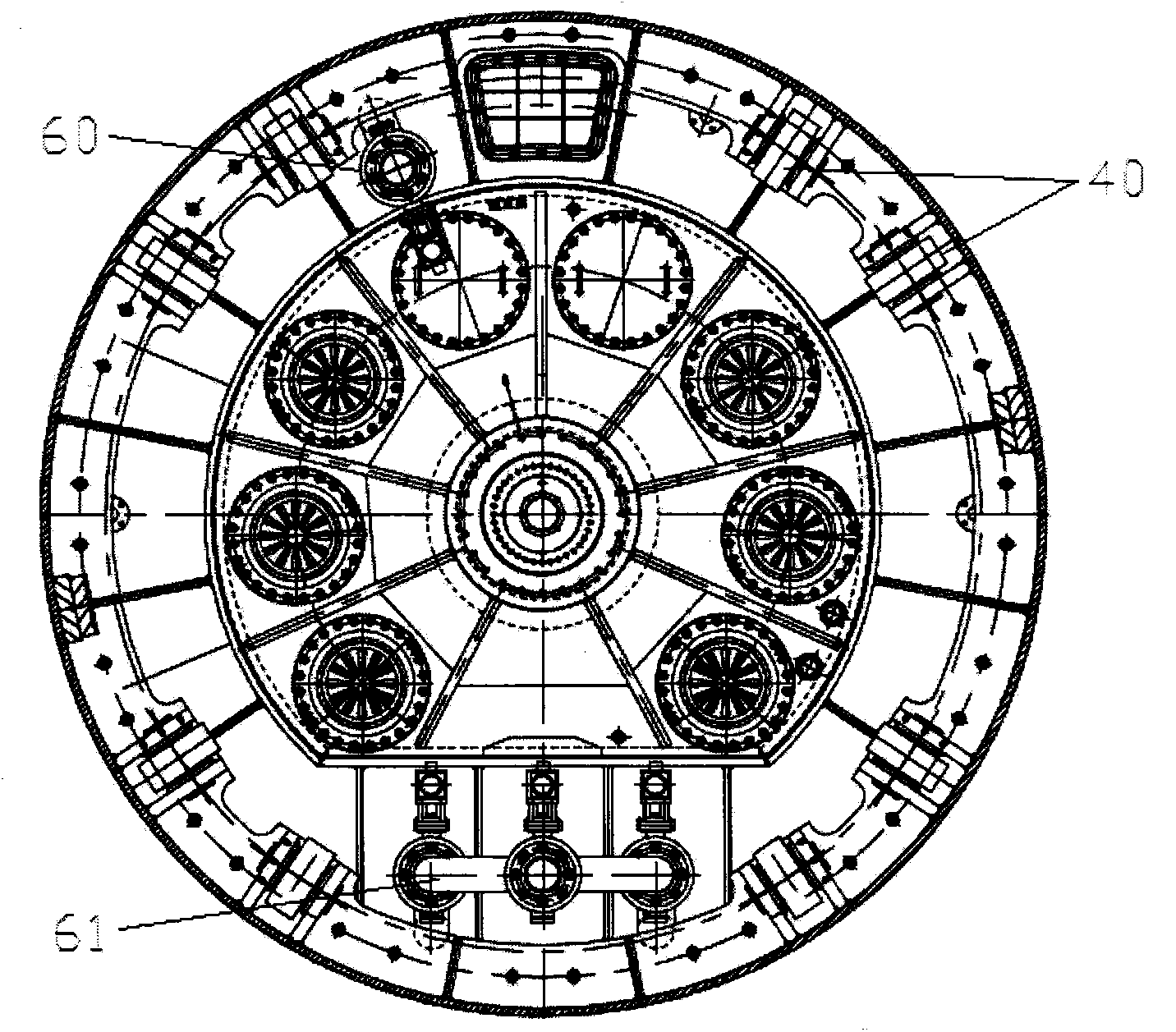

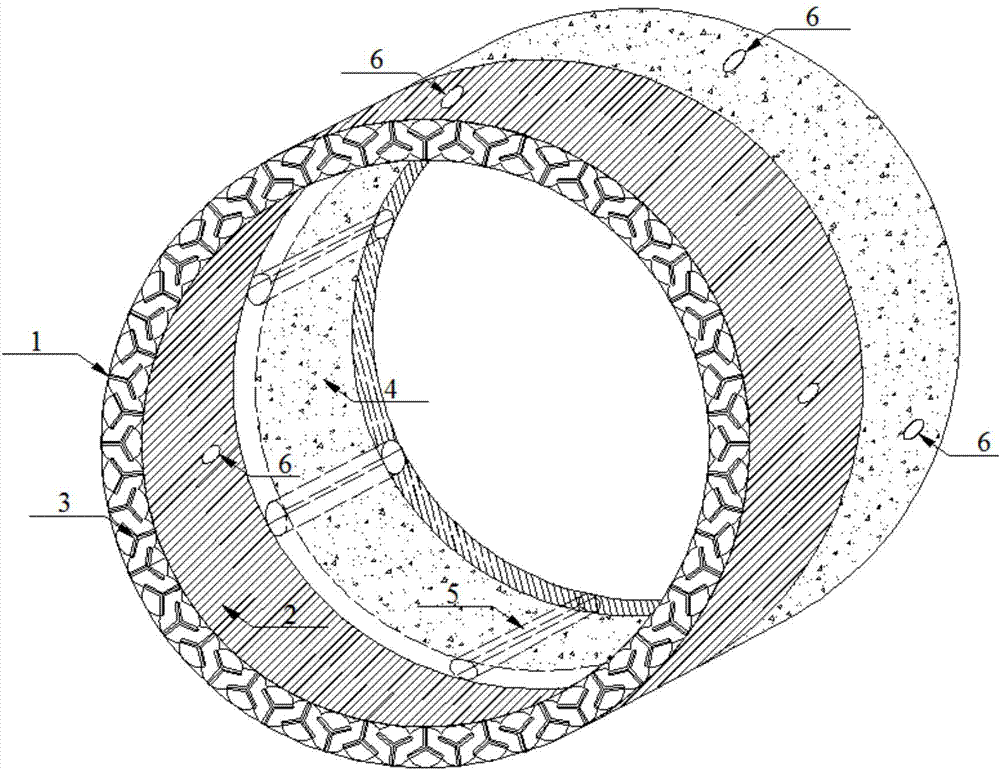

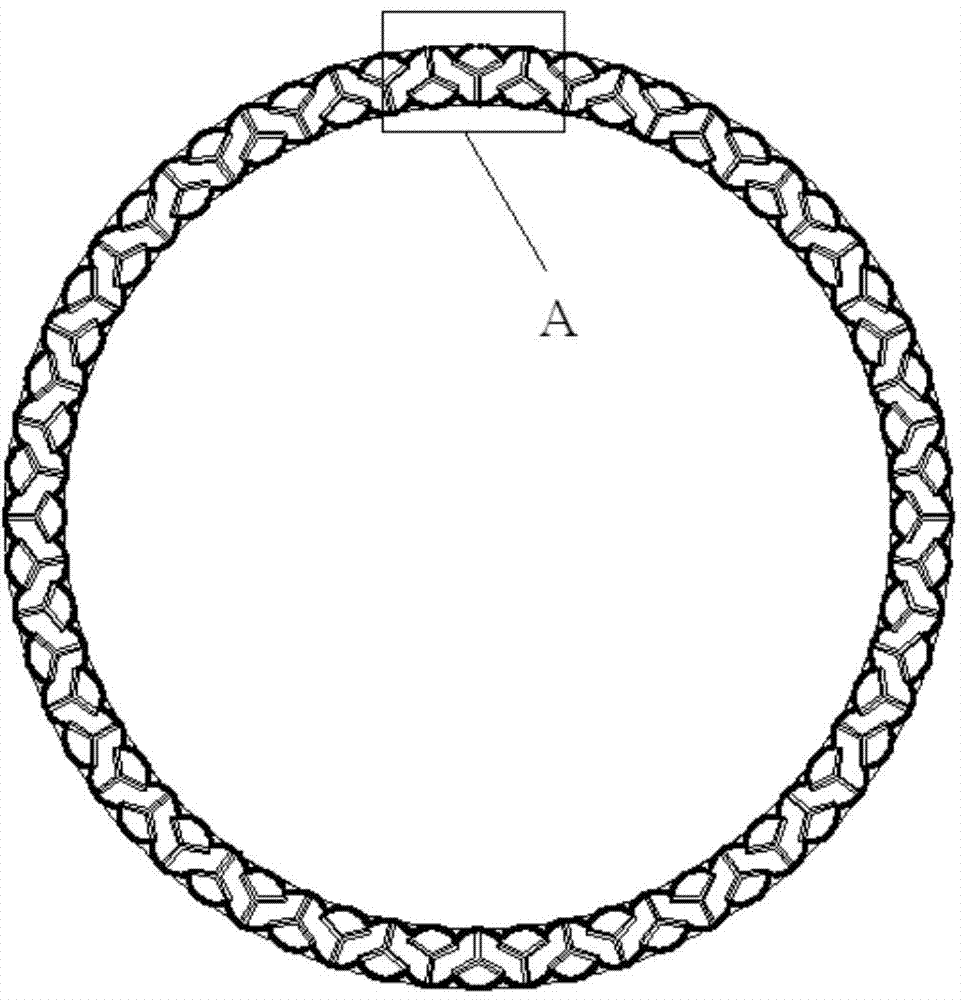

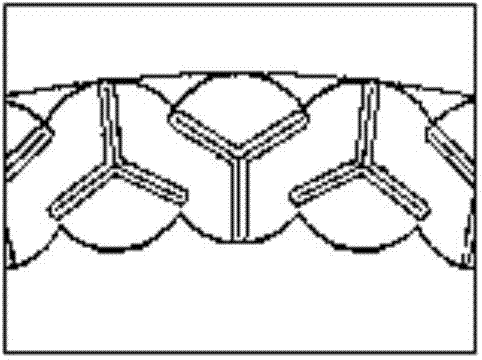

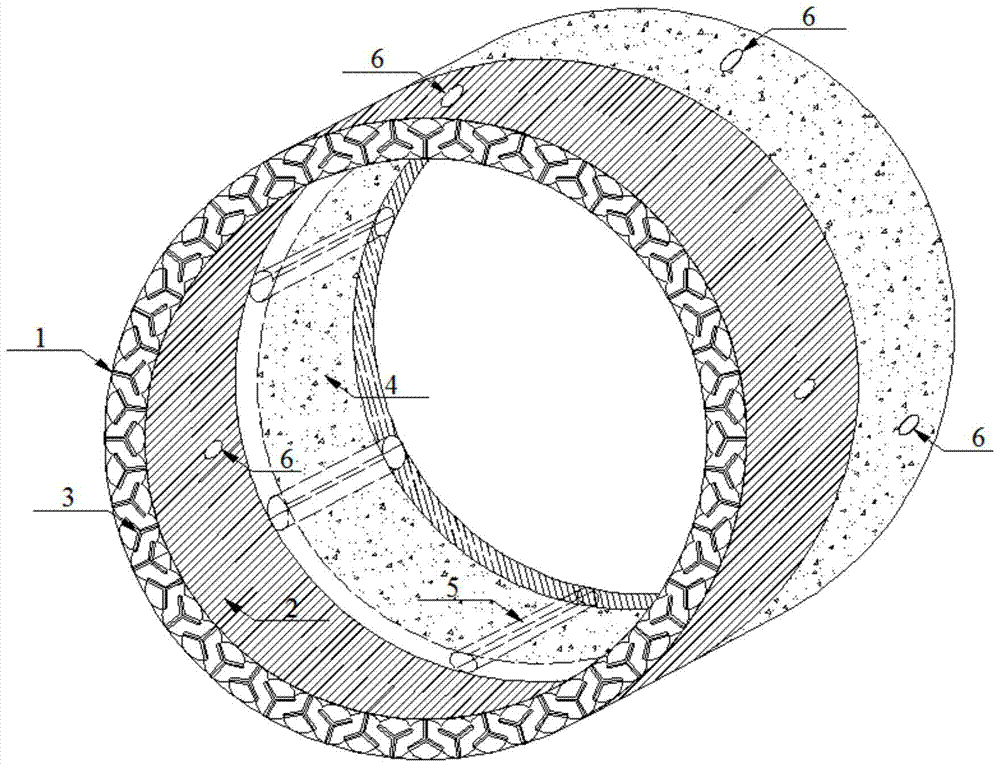

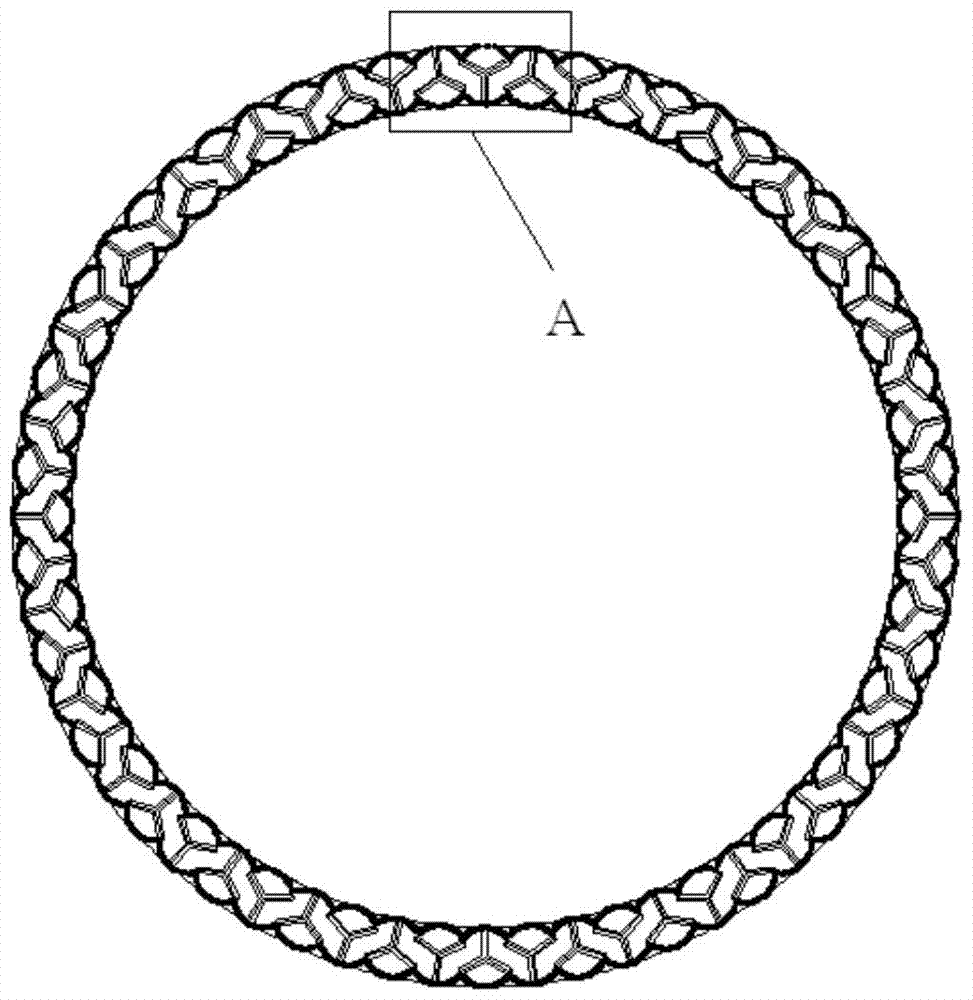

Annular pipe jacking machine

InactiveCN104712339ASolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

The invention relates to an annular pipe jacking machine which comprises an annular shell, a cutter head, a muddy water system, a synchronous grouting system, a jacking mechanism, a guide system and a control system. The annular shell comprises an outer-layer shell body and an inner-layer shell body, the cutter head is arranged in the annular shell, the muddy water system comprises a mud inlet and outlet pipeline and a mud and water separation treatment device, the mud and water separation treatment device is arranged on the ground, grouting pipes of the synchronous grouting system are arranged in the annular shell and sections of a jacking pipe respectively, thixotropic slurry is injected through a grouting hole, the jacking mechanism is arranged in a jacking pipe work well and used for jacking the sections of the jacking pipe, the guide system comprises a gyroscope, a tilt meter and a height gauge which are used for determining the posture of the annular pipe jacking machine and tunneling precision, and the control system is arranged on the ground and used for performing cooperative control on the cutter head, the muddy water system, the synchronous grouting system, the jacking mechanism and the guide system. Compared with the prior art, an excavated section is small, the shape of the section is flexible, and the annular pipe jacking machine is suitable for building tunnels with large sections and extra-large sections.

Owner:TONGJI UNIV

Muddy water and air balance shield pressure control method and device

The invention discloses a method for realizing the balance of a shield excavated surface by regulating muddy water and air, comprising the following steps: a semi-clapboard is arranged in a muddy water bin to divide the muddy water bin into a front muddy water bin and a rear muddy water bin; the lower parts of the front muddy water bin and the rear muddy water bin are communicated; the muddy water is filled in the front muddy water, the compressed air is injected at the upper part of the rear muddy water; the muddy water height in the rear muddy water bin is monitored by a liquid level sensor; when fluctuating, the muddy water height is adjusted to a preset height by adjusting the rotation speed of a mud entering pump or a mud discharging pump; the pressure of the compressed air in the rear muddy water bin is monitored by an air pressure sensor while the muddy water height is fluctuated; and the pressure of the compressed air is kept at the preset value by adjusting an air inlet valve and an air exhaust valve, thus realizing the stability of the excavated surface in the process of the whole shield driving.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

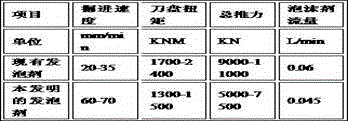

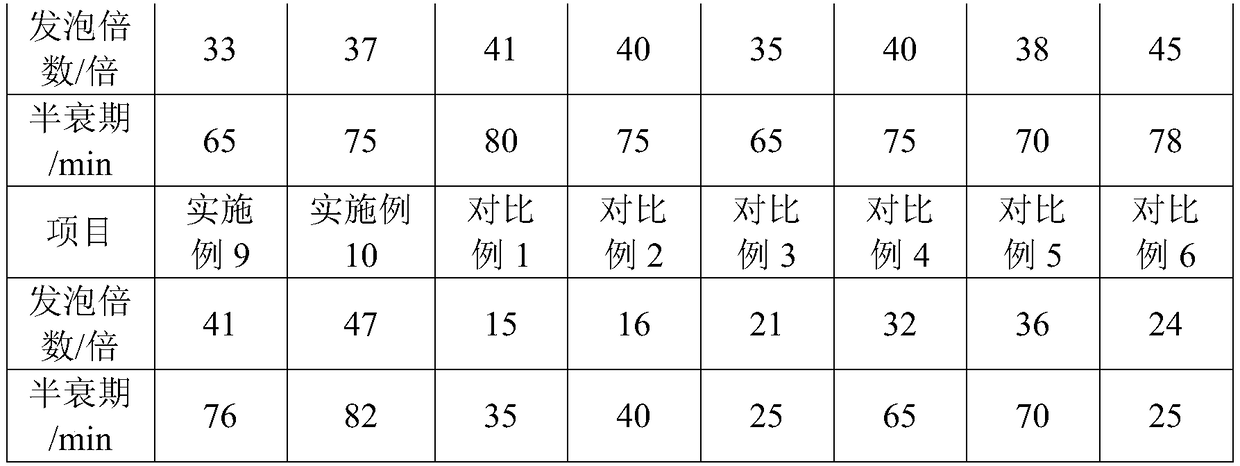

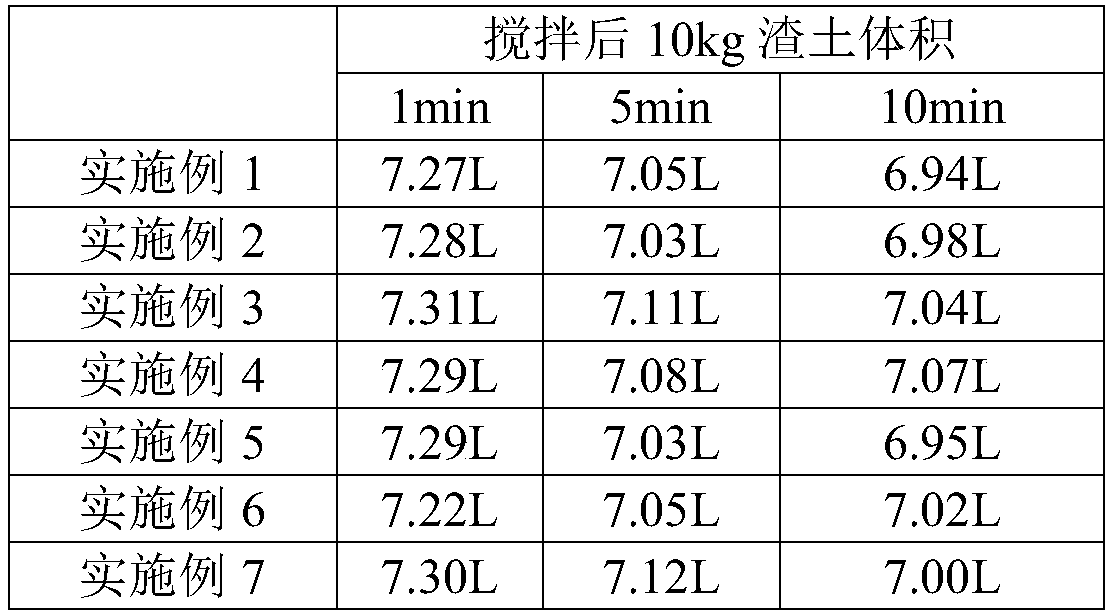

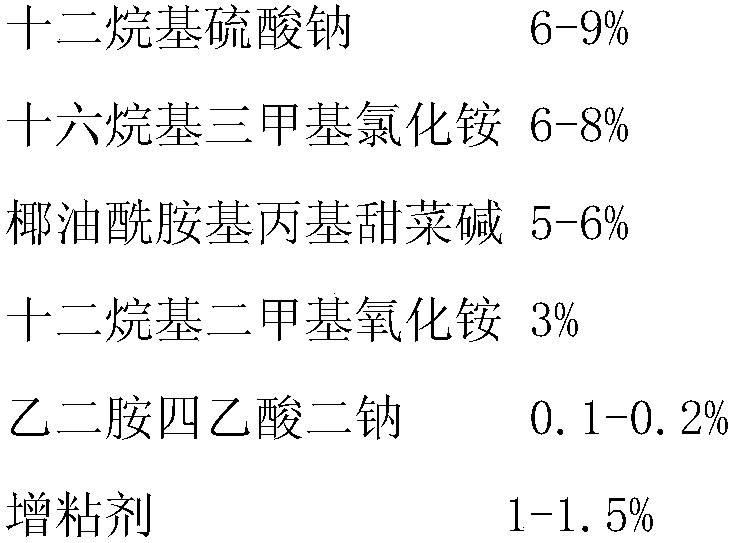

Earth pressure balance shield foaming agent

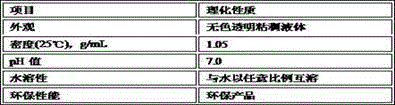

ActiveCN104946263AImprove plasticityImprove liquidityBuilding constructionsOrganic fertilisersBetaineCocamidopropyl betaine

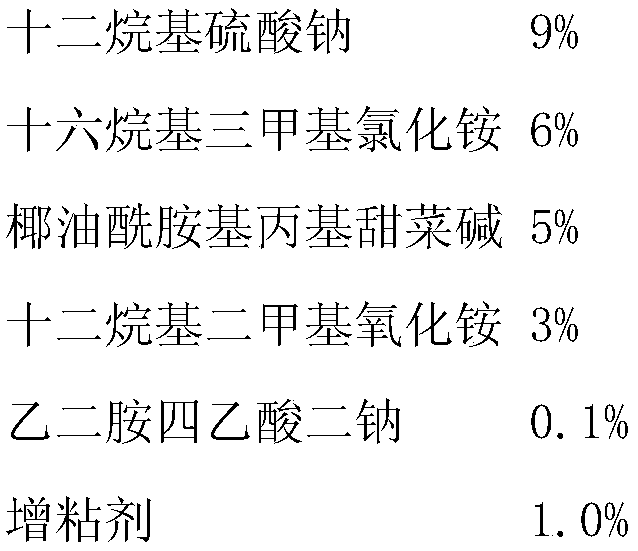

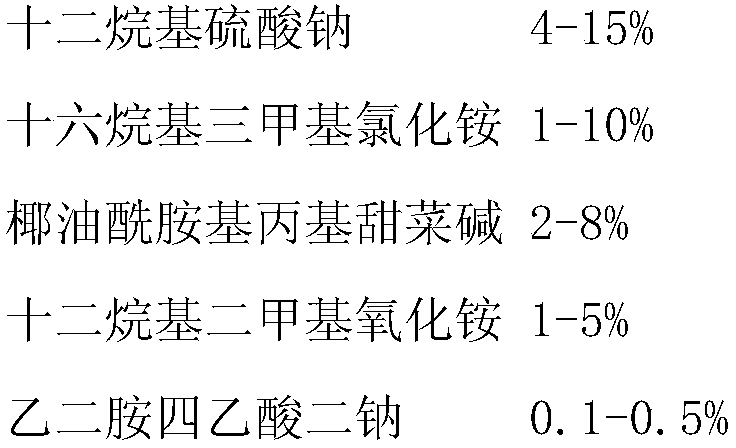

The invention relates to an earth pressure balance shield foaming agent and a preparation technology thereof. The earth pressure balance shield foaming agent is prepared from 4-15% by weight of sodium dodecyl sulfate, 1-10% by weight of cetyltrimethylammonium chloride, 2-8% by weight of cocamidopropyl betaine, 1-5% by weight of dodecyldimethylamine oxide, 0.1-0.5% by weight of disodium ethylene diamine tetraacetate, 0.1-2.0% by weight of a tackifier and the balance water. The earth pressure balance shield foaming agent has a simple formula and high effects, and utilizes cetyltrimethylammonium chloride with excellent permeability, flexibility, emulsification effects and sterilization performances as a cationic surfactant which can be mixed with other surfactants. The earth pressure balance shield foaming agent is environmentally friendly, has excellent permeability and lubricity and can effectively improve excavated soil fluidity and watertightness.

Owner:XIAMEN NORNS TECH

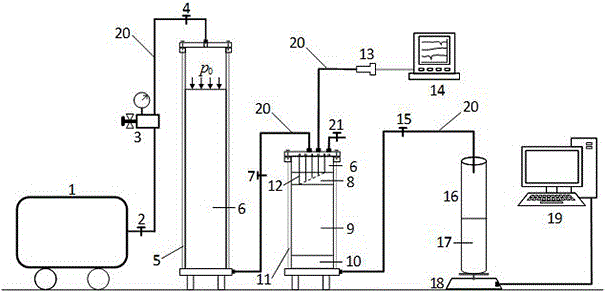

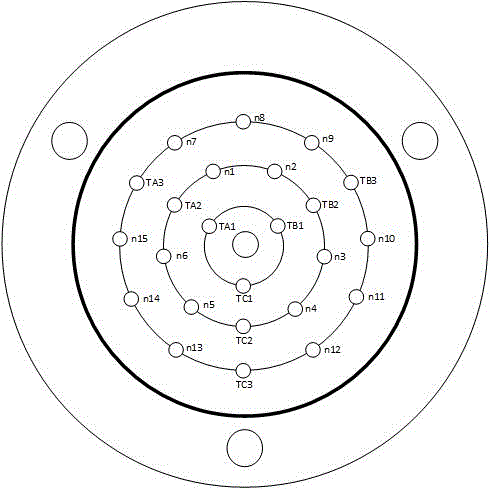

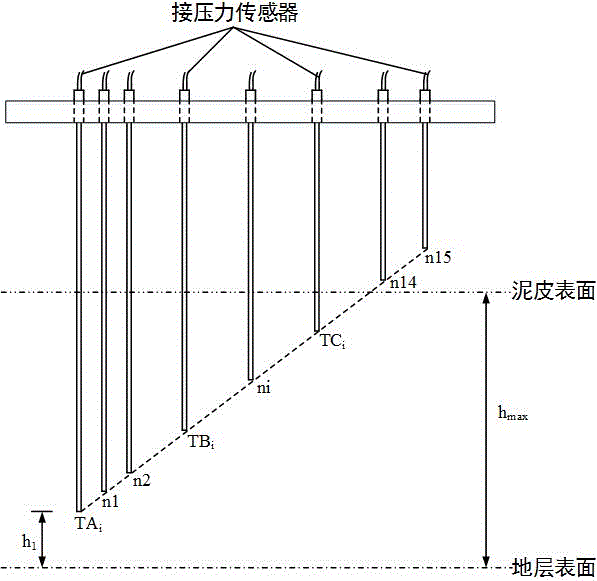

Slurry shield model test mud cake thickness real-time measurement device and measurement method

ActiveCN106153862ASolve Thickness ProblemsSolve real-timePreparing sample for investigationEarth material testingMeasurement deviceGraduated cylinder

The invention provides a slurry shield model test mud cake thickness real-time measurement device which structurally comprises an air compressor, a valve A, a pressure regulating valve, a valve B, a sludge barrel, sludge, a valve C, a glass barrel, a valve D, a measuring cylinder, filtrate, an electronic balance, a computer, hoses and a valve E, wherein the air compressor is connected with the sludge barrel through the hoses, the valve A, the pressure regulating valve and the valve B, the sludge barrel is connected with the glass barrel through the hoses and the valve C, the glass barrel is connected with the measuring cylinder containing the filtrate through the hoses and the valve D, the measuring cylinder is placed on the electronic balance, the electronic balance is connected with the computer through a serial data cable, the valve E is connected with the glass barrel, and the sludge is placed in the sludge barrel. A real-time measurement method includes the steps: (1) preparing the sludge, a stratum layer and a filter layer; (2) measuring the thickness of a mud cake in real time. The device has the advantage that the thickness of the mud cake can be measured by probe pressure in real time conveniently and accurately.

Owner:NANJING FORESTRY UNIV

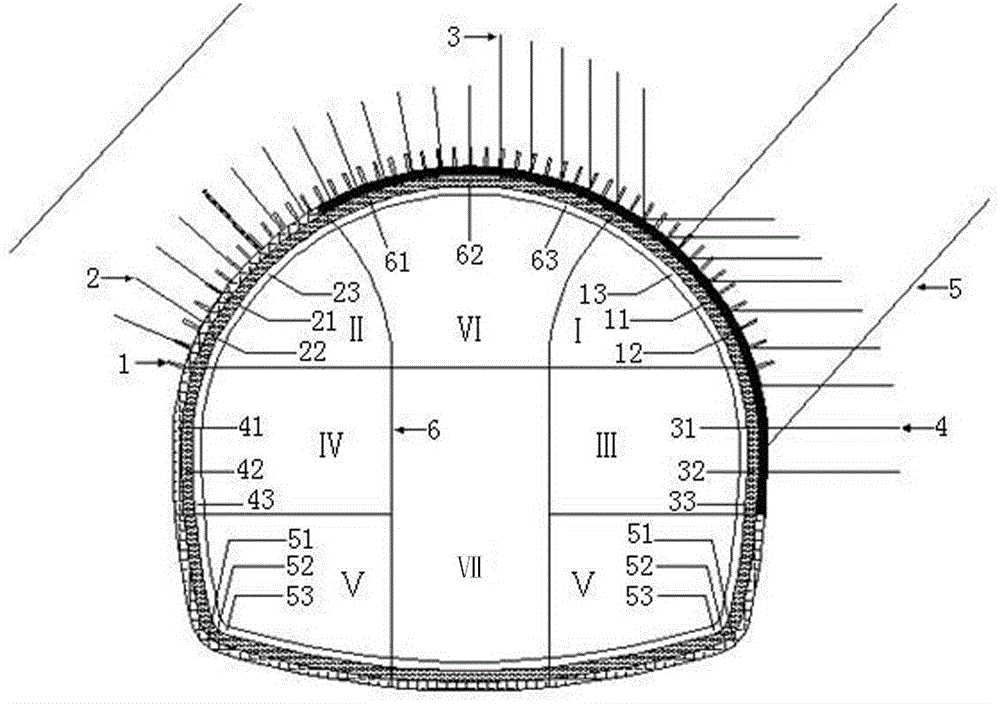

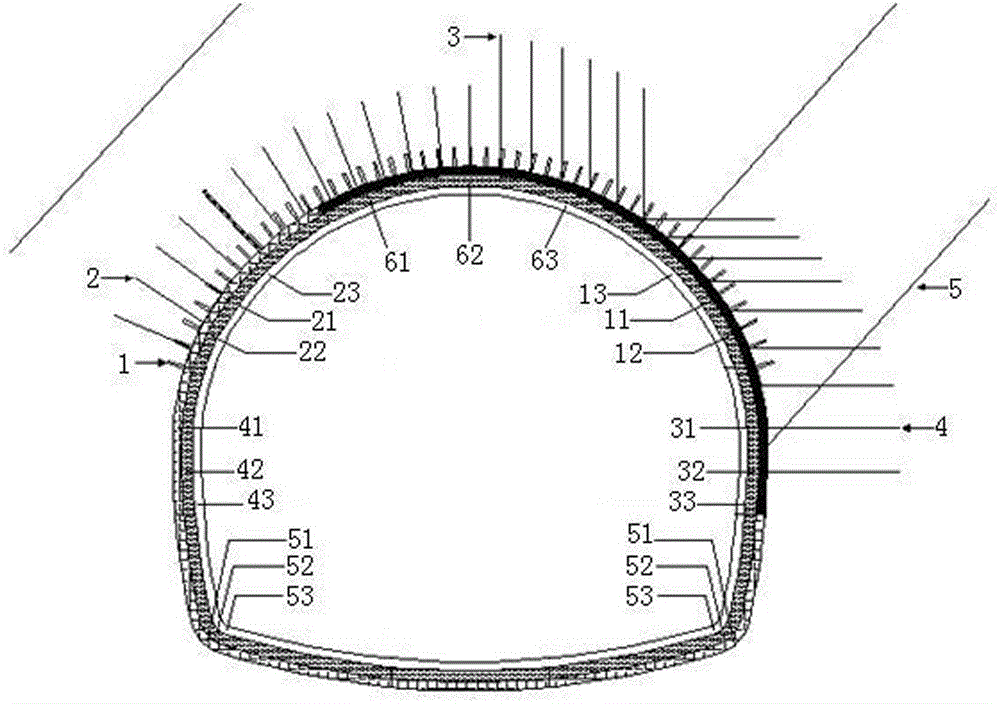

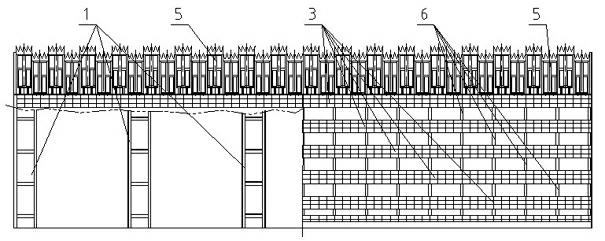

Large-span subway station underground excavation construction method for hard rock stratum

ActiveCN104847362AGood for subsidence controlAvoid impact damageUnderground chambersTunnel liningClerestoryGeomorphology

Disclosed is a large-span subway station underground excavation construction method for a hard rock stratum. The large-span subway station underground excavation construction method for the hard rock stratum is used for effectively reducing the excavation construction risk and improving the excavation construction efficiency. The large-span subway station underground excavation construction method for the hard rock stratum comprises the following steps that the arch portion middle of a station is divided into two steps to be excavated, a tunnel arch portion middle upper step is excavated, and an initial support arch cover of the tunnel arch portion middle is constructed; a tunnel arch portion middle lower step is excavated; a tunnel arch portion left side portion and a tunnel arch portion right side portion are excavated, feet-lock bolts are constructed at the arch foot positions, the initial support arch cover on the arch top is lengthened through connection, and construction of the initial support arch cover is accomplished; a rock mass arranged below the station is excavated in a slot broaching mode under the protection action of the initial support arch cover, nine portions including upper steps on the left portion, the middle portion and the right portion, middle steps on the left portion, the middle portion and the right portion and lower steps on the left portion, the middle portion and the right portion are excavated, and side wall initial supports of corresponding sections are constructed until the rock mass is excavated to the bottom; and a station body structure is sequentially constructed from bottom to top, and station construction is accomplished.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction method for reducing disturbance of slurry shield passing through foundation-free residential area

ActiveCN109736842AExcavation face stabilityReduce disturbanceUnderground chambersHeight/levelling measurementArchitectural engineeringEngineering

The invention discloses a construction method for reducing the disturbance of a slurry shield passing through a foundation-free residential area. The construction method comprises the steps of performing house detection and evaluation; performing ground tracking grouting reinforcement on the seriously damaged house; doing pre-traversing preparation work; setting various parameters in the traversing process; and performing in-tunnel grouting reinforcement; and performing monitoring measurement control. According to the construction method, disturbance to a building when the slurry shield passesthrough the foundation-free residential area is reduced, normal construction of the slurry shield is guaranteed, facility safety of the foundation-free residential area is guaranteed, and the construction method has wide guiding significance for construction in the field.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

Foaming agent specially used for soil pressure balance shield tunneling machine and preparation method thereof

InactiveCN107502358AIncreased foam stabilityReduce surface tensionBuilding constructionsOrganic fertilisersChemistryChloride sodium

The invention provides a foaming agent specially used for a soil pressure balance shield tunneling machine and a preparation method thereof, and relates to the field of shield construction buildings. The foaming agent is prepared from the following raw materials, in parts by weight: 6-10 parts of sodium dodecyl sulfate, 9-15 parts of dodecyl betaine, 3-5 parts of sodium chloride, 6-8 parts of n-butyl alcohol, 4-6 parts of dodecyl dimethyl amine oxide, 2-3 parts of sodium lauryl alcohol polyoxyethylene ether sulfate, 5-7 parts of sodium alginate, 3-7 parts of sodium dodecyl polyoxyethylene ether sulfate, 3-5 parts of hexadecyl trimethyl ammonium chloride, 2-3 parts of fluoranthene, 2-4 parts of ethylenediamine tetraacetic acid disodium salt, 3-5 parts of a cinnamon bark extractive, 3-5 parts of polyethylene glycol, 5-7 parts of a tackifier, and 70-100 parts of water, and the preparation method comprises three steps. According to the invention, the foaming agent can improve soil plasticity, fluidity and impermeability, can improve residual soil fluidity in seal earth cabins, protects cutting tools, reduces cutter head torque, can make soil bodies formed soil plugs in a screw conveyer, and effectively prevents spewing, and the foaming agent has no toxicity, no corrosion, good bubble stability, and long duration time.

Owner:合肥卓立雅工程材料科技有限公司

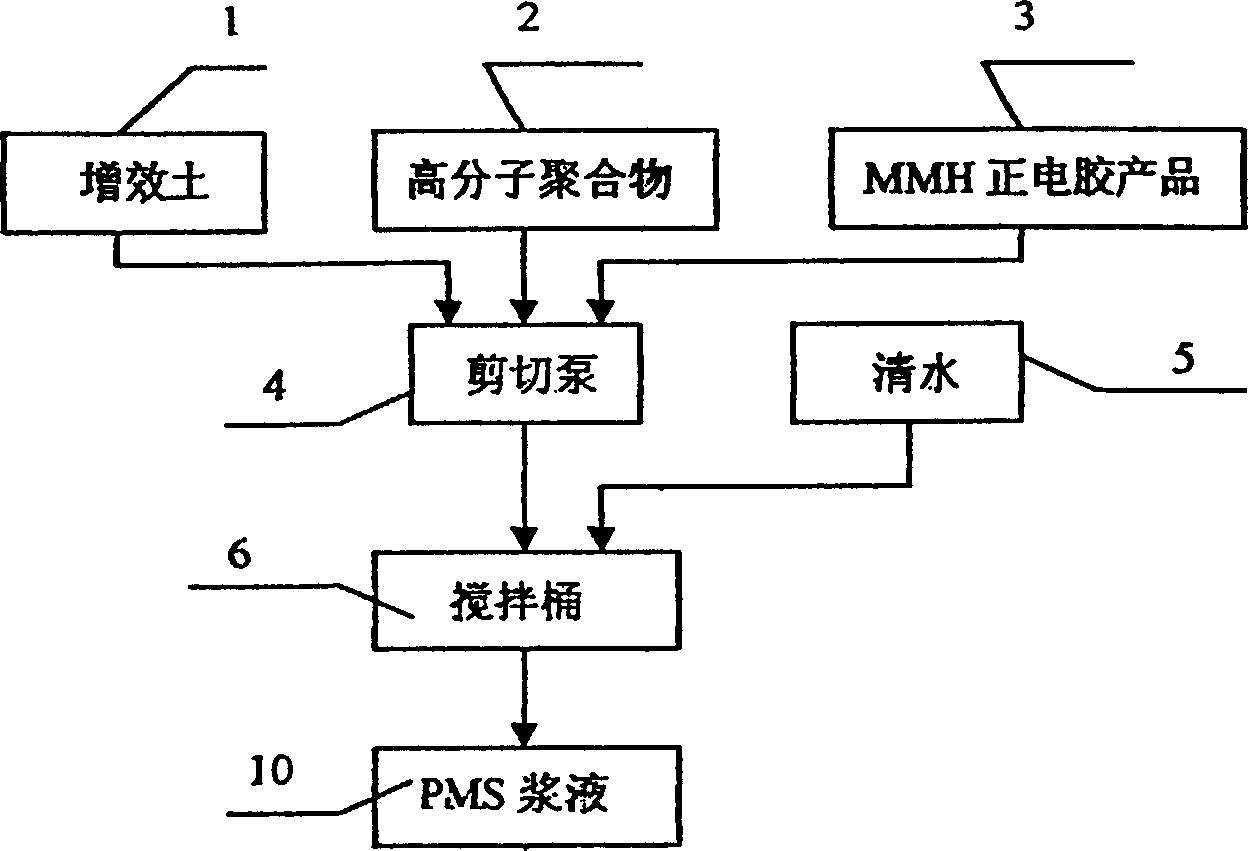

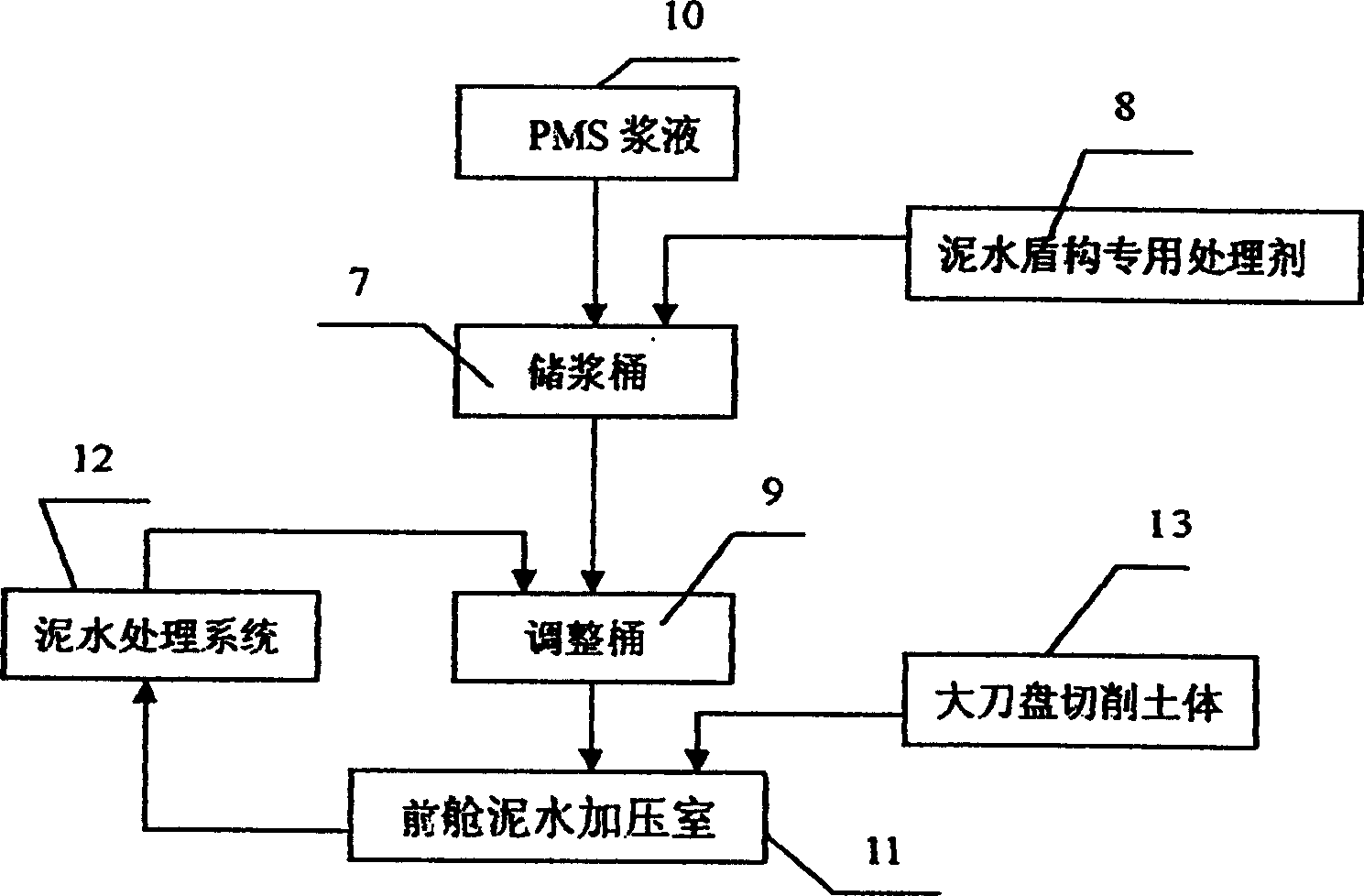

PMS sludge prepn. method and its application in construction of sludge balance shield and pipe-jacking

This is a preparing method of PMS mud and water paste and its application on the working of supporting pipe. Its features are: Use high polymer and positron glue to prepare PMS mud and water paste liquid. During this procession, to use soil mortar liquid separated grade by grade, in the mud paste mix PMS paste liquid and its assistant materials in proper time, and advance the six steps on the application.

Owner:上海第二市政工程有限公司

Large cross-section tunnel supporting system construction method applicable to steep dip layered rock mass

ActiveCN105065032AEnsure stabilityHigh strengthUnderground chambersTunnel liningSupporting systemRailway tunnel

The invention relates to the field of highway tunnel and railway tunnel surrounding rock supporting, in particular to a large cross-section tunnel supporting system construction method applicable to steep dip layered rock mass. The method is characterized in that when a forward inclination layer pilot tunnel and an upper part middle pilot tunnel are dug, a temporary support and first and second layer linings positioned in the positions of the forward inclination layer pilot tunnel and the upper part middle pilot tunnel are made; and when a backward inclination layer pilot tunnel and a lower part pilot tunnel are dug, a temporary support and a first layer lining positioned at the backward inclination layer pilot tunnel and the lower part pilot tunnel are made. The method has the advantages that by aiming at the steep dip layered rock mass tunnel digging damage features, the strength and the rigidity of top and arch part supporting structures are mainly reinforced; the strength and deformation characteristics of surrounding rock of tunnel top and layer exposure parts can be effectively enhanced; the deformation and the instability of the surrounding rock in the two weak positions are controlled; and the stability of the rock mass in the arch part or layer exposure parts is ensured.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

Foaming agent for improvement of slag oil of soil pressure balance shield and preparation method thereof

ActiveCN109054842AGood foaming effectEnhanced surface forceBuilding constructionsOrganic fertilisersPolyethylene oxideSlag

The invention provides a foaming agent for improvement of slag oil of a soil pressure balance shield and a preparation method thereof. The foaming agent for the improvement of the slag oil of the soilpressure balance shield is prepared from the following components in percentage by weight: 4% to 8% of alpha-alkenyl sodium sulfonate, 8% to 12% of lauryl sodium sulfate, 3% to 5% of alkylphenol polyoxyethylene, 0.05% to 0.2% of xanthan gum, 1% to 4% of coconut oil fatty acid diethanolamide, 1% to 3% of sodium gluconate, 0.5% to 2% of polyethylene oxide, 1% to 2% of polyaspartic acid, and the balance of water. The foaming agent has the advantages that by adopting the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene to prepare the foaming agent, thefoaming ability is enhanced under the compounding and cooperation function of the alpha-alkenyl sodium sulfonate, the lauryl sodium sulfate and the alkylphenol polyoxyethylene; the foaming time is greater than 30 times; by adopting the coconut oil fatty acid diethanolamide to enhance the surface action force of the air foam through cooperation, the stability of the foam under the high-speed shearing function of a knife disc is improved; the pressure fluctuation of a soil bin is reduced; the stability of the excavated surface of the shield is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

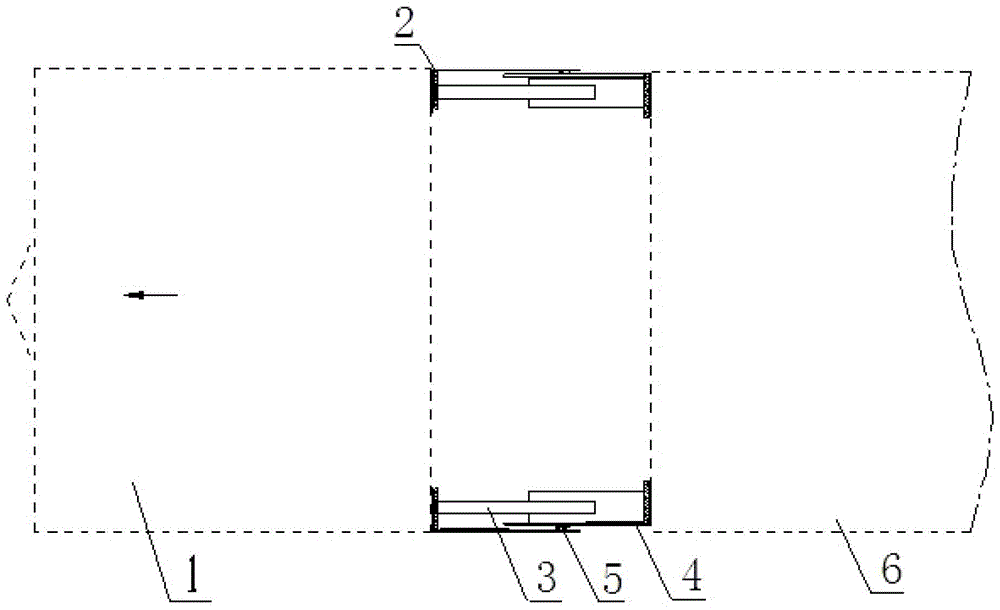

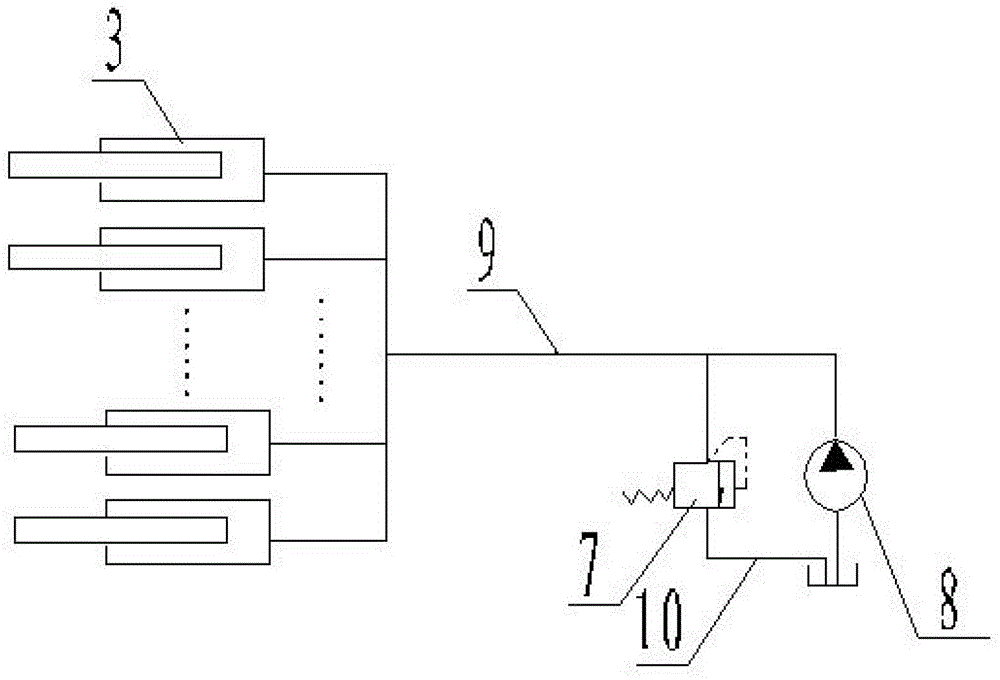

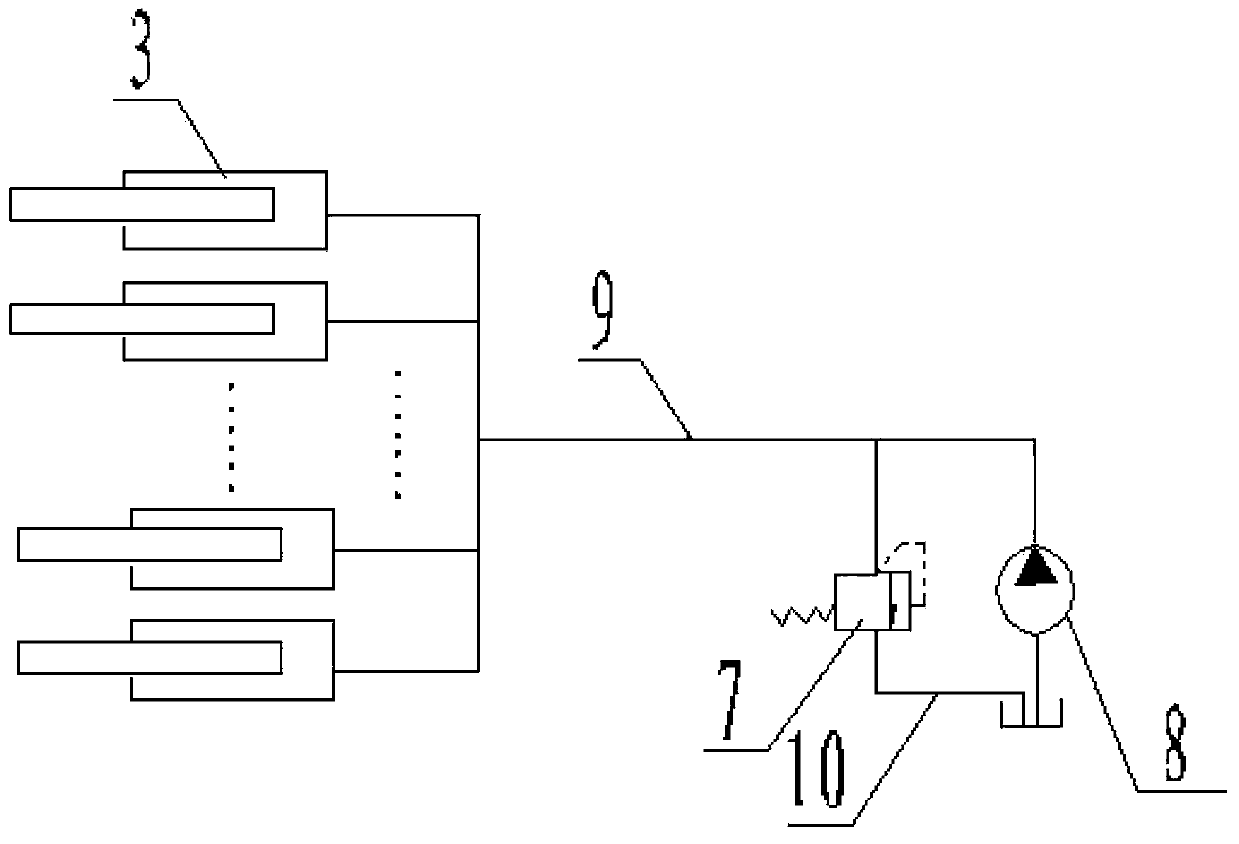

Automatic control device and method for head-on earth pressure in mechanical tube jacking construction

ActiveCN102748533AControl bulgeSettlement controlPipe laying and repairServomotorsAutomatic controlControl engineering

The invention relates to the technical field of mechanical control of building construction and mainly discloses an automatic control device and an automatic control method for the head-earth pressure in mechanical tube jacking construction. The automatic control device comprises a tube jacking machine, a front shell, hydraulic oil cylinders, a rear shell, a sealing device, a jacking-in tube section, an overflow valve, a hydraulic pump station, a hydraulic pipeline and a hydraulic oil loop, and is characterized in that the tube jacking machine is arranged at the front end of jacking-in direction in the mechanical jacking, the front shell and the rear shell are arranged at the rear part of the tube jacking machine, and are connected by a plurality of hydraulic oil cylinders, sealing devices are arranged outside the hydraulic oil cylinders, the plurality of hydraulic oil cylinders are respectively connected in parallel by the hydraulic pipeline and are respectively connected with the hydraulic pump station, and the hydraulic pump station is provided with the hydraulic oil loop which is provided with the overflow valve. The automatic control device disclosed by the invention can respond to the head-on earth pressure of the tube jacking machine in real time, then the control device automatically adjusts the jacking force of a head of the tube jacking machine, the control oil supply can be realized by the adjustable overflow valve on an oil path, so that the tube jacking machine can respond to the pressure of the head-on earth pressure in real time, the effect of earth pressure balance is realized, and the method is simple and effective.

Owner:中铁市政环境建设有限公司

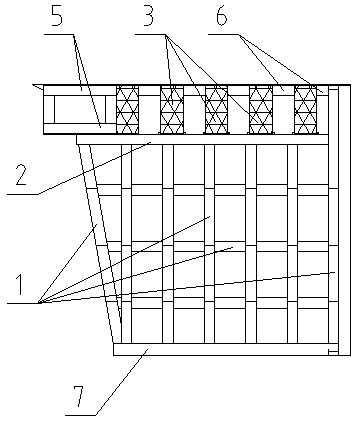

Combined framework steel structure of jacked subway bridge and method for jacking subway bridge

InactiveCN102108679AReduce or remove speed limitsReduce the impactBridge erection/assemblyReinforced concreteArchitectural engineering

The invention discloses a combined framework steel structure of a jacked subway bridge. The combined framework steel structure comprises a square main frame structure and sub frame structures, wherein the main frame structure consists of vertical oblong frameworks, a longitudinal upper supporting beam at the top, a transverse top cross beam, a spacing beam, a longitudinal lower supporting beam at the bottom and a transverse bottom cross beam, which are fixedly connected into a whole through bolts; and the sub frame structures are positioned at the upper part of the front end of the main frame structure. The method for tunneling a subway bridge comprises the following steps: jacking the sub frame structures at intervals to reduce resistance during jacking and disturbance to the soil, and jacking the square main frame structure; digging soil under the support and shield of the sub frame structures and the main frame structure, and delivering out the soil of a dug surface; and repeatedly and circularly jacking till the reinforced concrete subway bridge is jacked to a designed position, and detaching the combined framework steel structure at the front end. The combined framework steel structure can be assembled for jacking the subway bridges or culverts of different sections, and can greatly save steels and construction cost by repeated use; and the method can ensure soil holding pressure balance, stable excavating surface and safe operation, reduce speed limit of lines and reduce the influence on transportation.

Owner:李家稳

SCAP type cabin opening method with pressure based on earth pressure balance shield machine

ActiveCN110439577AHigh osmotic pressureOvercome the difficulty of opening the cabinTunnelsAir tightnessEarth pressure balance

The invention discloses a SCAP type cabin opening method with pressure based on an earth pressure balance shield machine. Grain composition of a stratum where the shield machine is located is collected, and a suitable mud material is selected. A gap between the shield machine and the stratum where the shield machine is located, and pores of a soil body of an excavation surface are injected with mud to be blocked, and the soil body around the shield machine is reinforced; a part of muck in a soil cabin is discharged, mud is injected into the soil cabin, and the excavation surface is kept stable; then a cutter disc is retracted, seepage pressure of the mud in the soil cabin is improved to conduct mud seepage, and an integral air tight mud film is formed on the excavation surface; and finally, the muck and the mud are discharged to prepare cabin opening operation. The mud film is effectively formed, stability and the airtight property of the excavation surface are ensured, the problems ofdifficulty of cabin opening with the pressure in a high-permeable stratum, and poor air tightness are solved, and preparation time of the cabin opening operation with the pressureis saved. Accordingto the SCAP type cabin opening method, the technological process of mud film formation is easy and simple to do, other equipment does not need to be added, andthe simple and practicable, quicker and more economic method of earth pressure shield cabin opening with the pressure is provided.

Owner:HOHAI UNIV

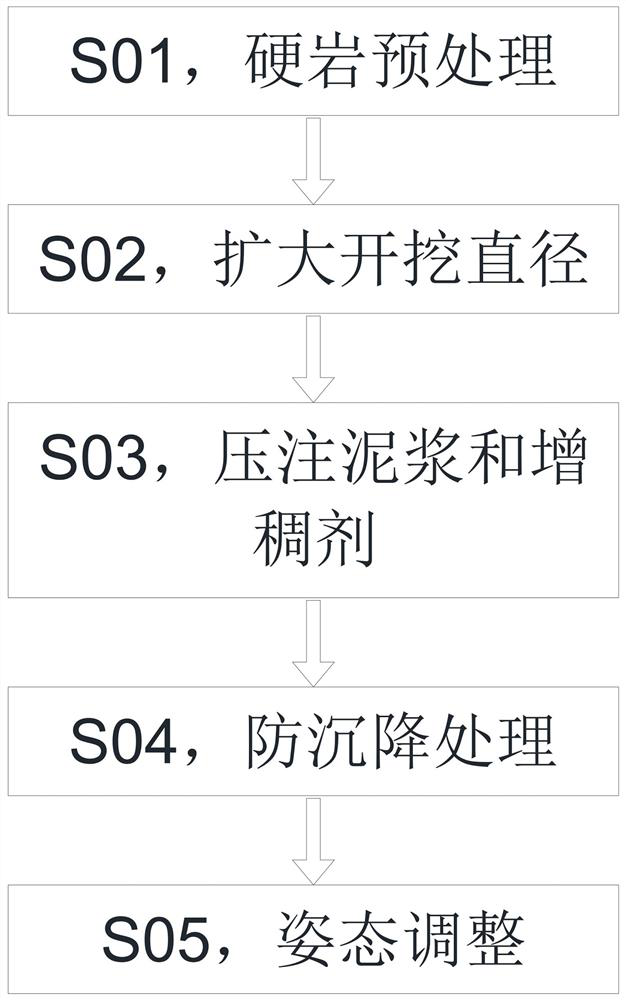

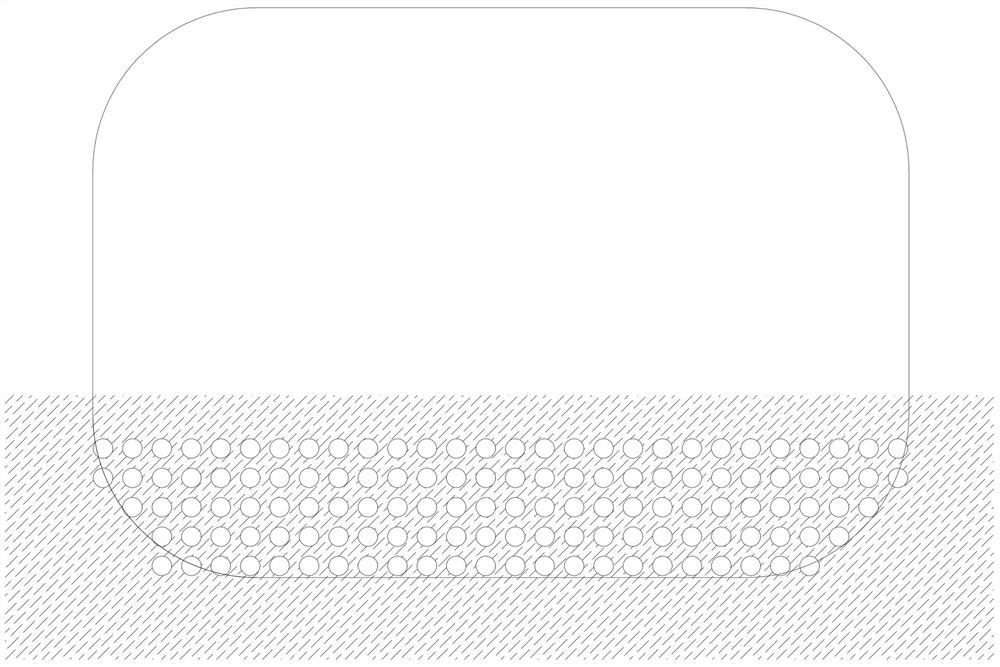

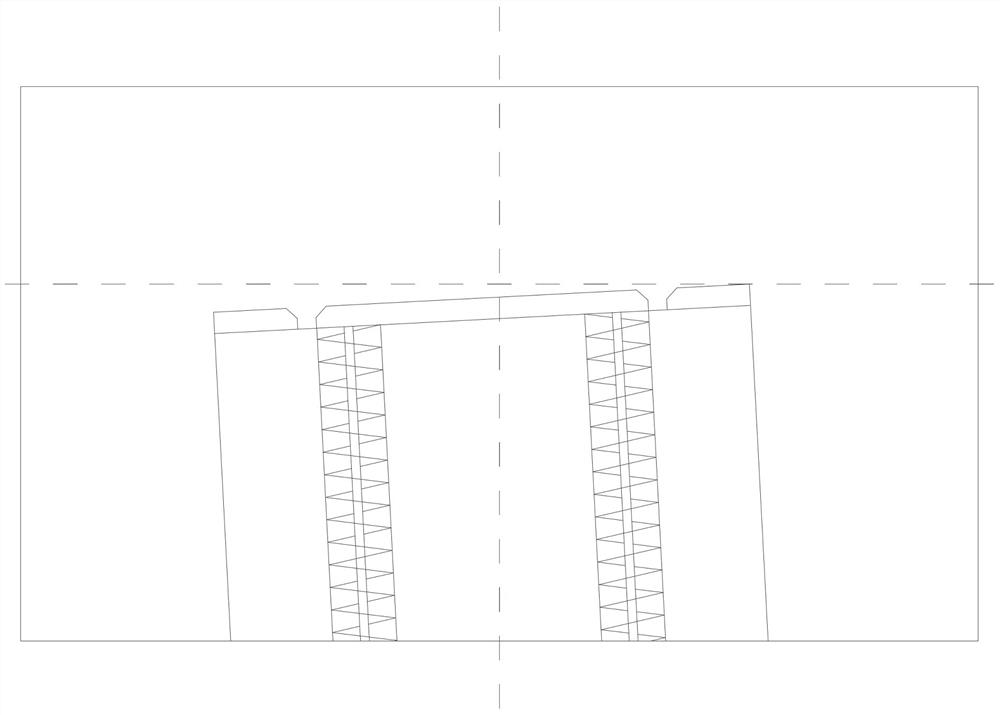

Large-size rectangular pipe jacking construction method for upper-soft lower-hard stratum

PendingCN113944475AImprove construction safetyReduce construction costsTunnelsPre treatmentPressure injection

The invention discloses a large-size rectangular pipe jacking construction method for an upper-soft lower-hard stratum, and belongs to the technical field of pipe jacking construction. The large-size rectangular pipe jacking construction method for the upper-soft lower-hard stratum comprises the following steps that S01, hard rock pretreatment is conducted, specifically, hard rock invading a pipe jacking tunnel is subjected to pre-crushing treatment; S02, the excavation diameter is enlarged, specifically, a cutter head is adjusted, and the excavation diameter of the bottom of a pipe jacking machine is enlarged; S03, pressure injection of slurry and a thickening agent is conducted, specifically, the slurry and the thickening agent are pressure-injected in front of the cutter head, so that the workability of a soil body is improved, the pressure of the soil body is balanced, and the excavation surface of a sand layer is kept stable; S04, anti-sedimentation treatment is conducted, specifically, high-consistency bentonite is injected into the periphery of the duct piece for filling; and S05, posture adjustment is conducted, in the jacking process, axis deviation correction and posture roll correction are conducted on the pipe jacking machine, and jacking accuracy is guaranteed. The technical problems that in upper-soft lower-hard complex geological large-size rectangular pipe jacking construction, the pipe jacking machine floats upwards and rolls left and right are effectively solved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

A kind of earth pressure balance shield foaming agent

ActiveCN104946263BImprove plasticityImprove liquidityBuilding constructionsOrganic fertilisersCocamidopropyl betaineEarth pressure balance

The invention relates to an earth pressure balance shield foaming agent and a preparation technology thereof. The earth pressure balance shield foaming agent is prepared from 4-15% by weight of sodium dodecyl sulfate, 1-10% by weight of cetyltrimethylammonium chloride, 2-8% by weight of cocamidopropyl betaine, 1-5% by weight of dodecyldimethylamine oxide, 0.1-0.5% by weight of disodium ethylene diamine tetraacetate, 0.1-2.0% by weight of a tackifier and the balance water. The earth pressure balance shield foaming agent has a simple formula and high effects, and utilizes cetyltrimethylammonium chloride with excellent permeability, flexibility, emulsification effects and sterilization performances as a cationic surfactant which can be mixed with other surfactants. The earth pressure balance shield foaming agent is environmentally friendly, has excellent permeability and lubricity and can effectively improve excavated soil fluidity and watertightness.

Owner:XIAMEN NORNS TECH

A ring pipe jacking machine

InactiveCN104712339BSolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

Owner:TONGJI UNIV

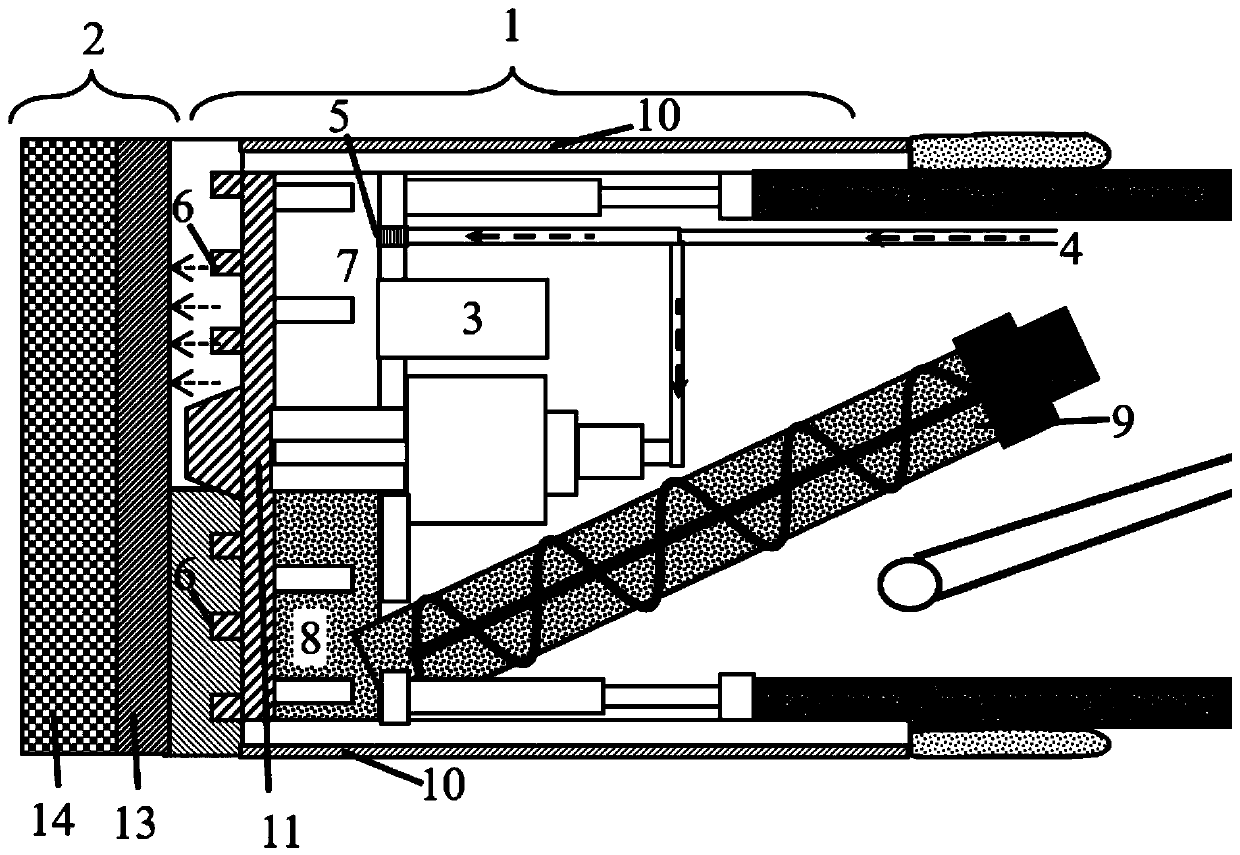

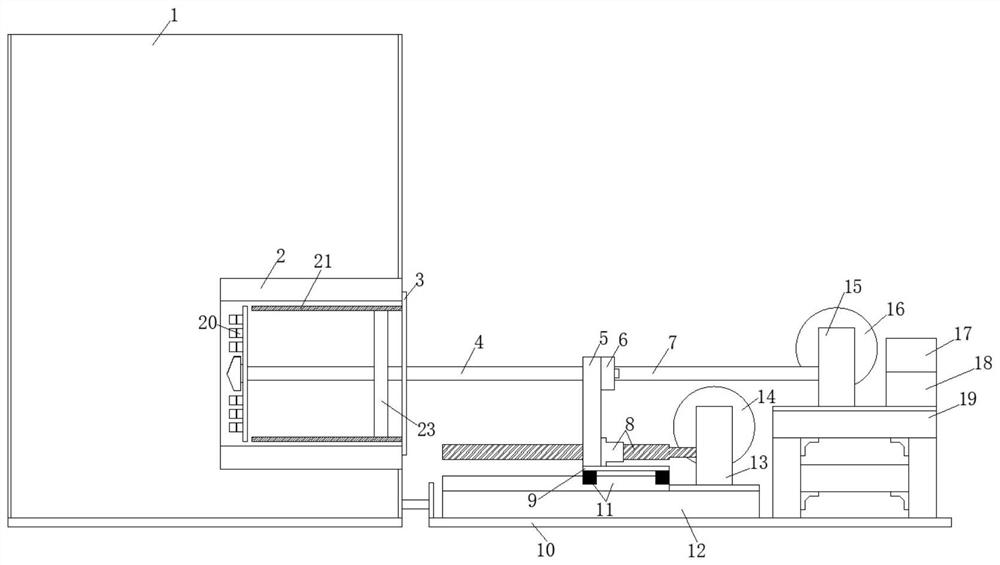

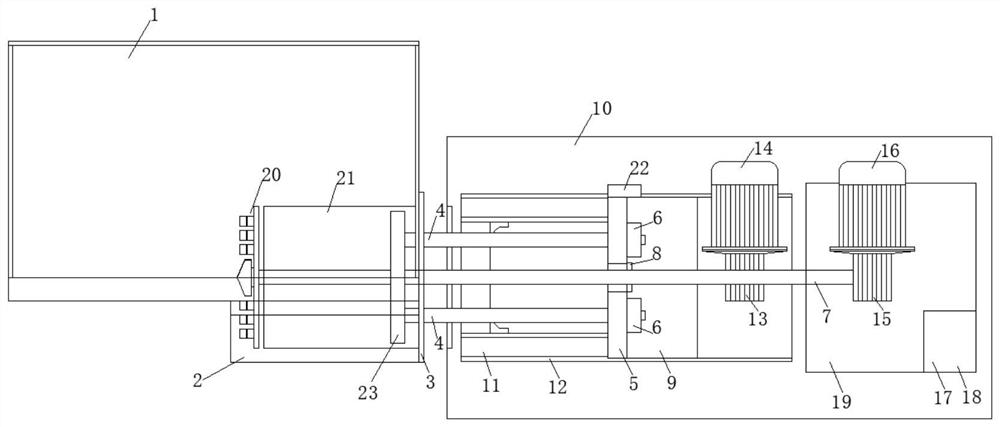

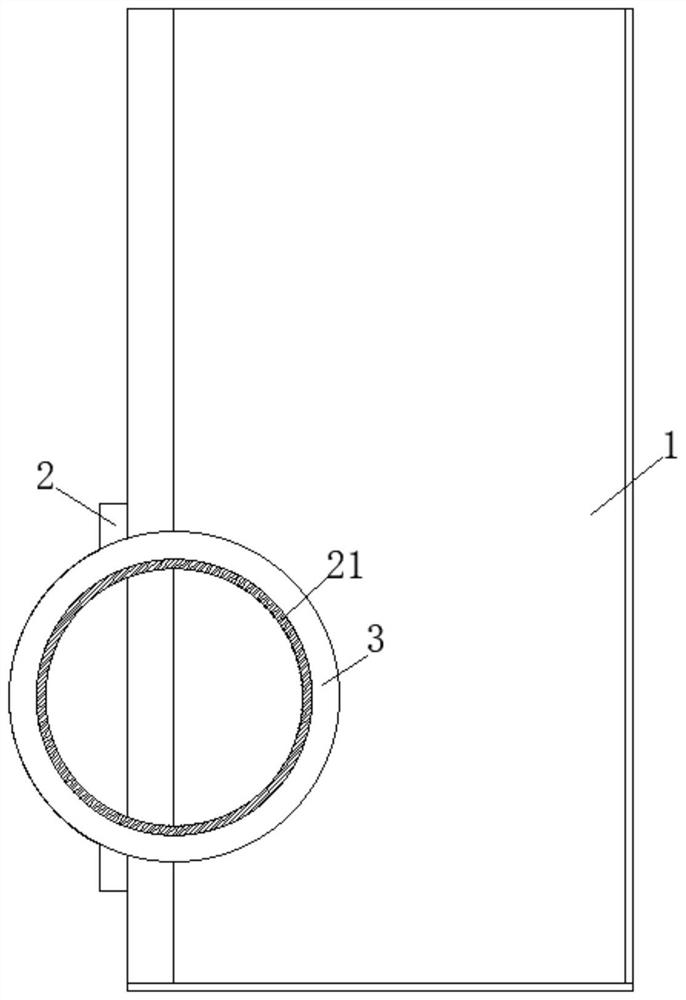

Tunnel excavation face stability experiment equipment and method considering shield cutter head influence

ActiveCN114236092AExcavation face stabilityEarth material testingStructural/machines measurementFrequency changerPower control system

The invention provides a tunnel excavation face stability experiment device and method considering shield cutterhead influence, the tunnel excavation face stability experiment device comprises an integral frame part, a shield system, a cutterhead power control system, a soil bin plate power control system and a monitoring system.The integral frame part comprises a test box, a protective cover, a working face, a workbench I and a workbench II; the shield system comprises a cutterhead, a tunnel, a flange and a soil bin plate, the cutterhead power system comprises a transmission shaft, a speed reducer II, a motor II and a frequency converter II, the soil bin plate power control system comprises a push rod, a reaction frame, a bearing platform, a ball screw, a guide rail, a speed reducer I, a motor I and a frequency converter I, and the monitoring system comprises a laser ranging device and a spoke type force sensor. The equipment can analyze the stability of the excavation face under the action of a shield dynamic cutterhead and determine the limit support pressure required for maintaining the stability of the excavation face, so that the stability of the excavation face during shield tunneling construction can be guaranteed.

Owner:BEIJING JIAOTONG UNIV

Construction method of underground excavation for large-span subway station in hard rock formation

ActiveCN104847362BGood for subsidence controlAvoid impact damageUnderground chambersTunnel liningSubway stationClerestory

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Scap type earth pressure balance shield opening mud and its preparation method

ActiveCN110436836BReduce outbound volumeAlleviate the problem of outbound transportationTunnelsSlagSlurry

The invention discloses a SCAP-type soil pressure balance shield mud for opening a cabin, which comprises the following components according to the mass parts: 50-80 parts of silt, 400-600 parts of clear water, 100-150 parts of calcium-based bentonite, and a modifier 2~6 parts and 0~2 parts of tackifier. It also discloses the preparation method of mud for SCAP-type earth pressure balance shield opening: the waste silt produced when the shield tunnels into the silt or silty clay layer is dried, passed through a mesh screen, and stored near the muck pit. When the shield machine needs to be opened under pressure, add stored silt, clear water, calcium-based bentonite, modifier and viscosifier to the mud truck, and stir continuously to prepare a product that meets the mud density and viscosity requirements. Utilizing the discarded dregs during the excavation process can save bentonite resources and opening costs, and reduce the environmental pollution caused by the amount of muck transported abroad, and prepare mud for opening that meets the requirements of density, viscosity, physical and chemical stability, etc. .

Owner:HOHAI UNIV

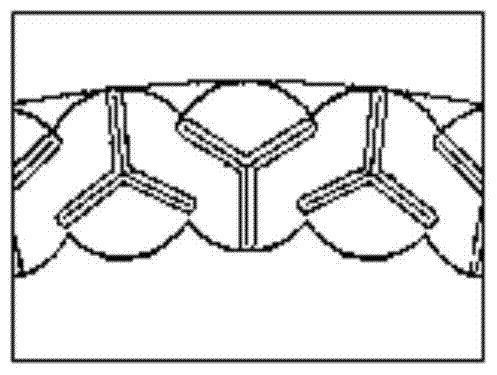

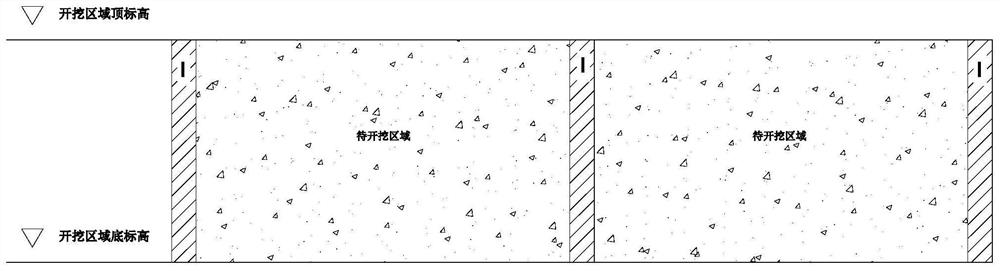

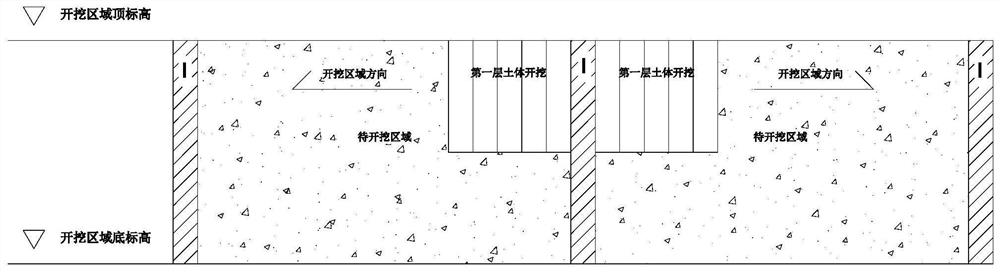

Method and device for pile sinking type excavation of foundation pit

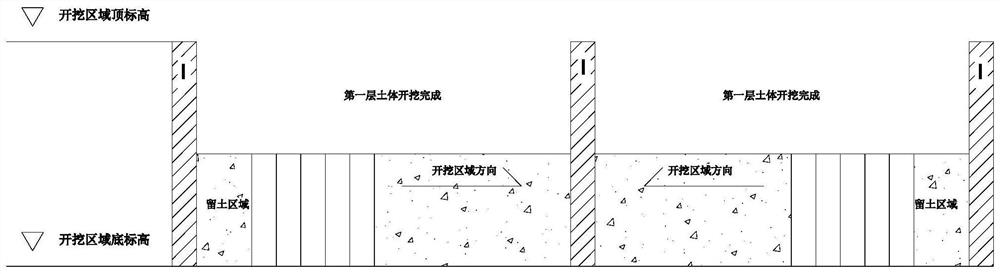

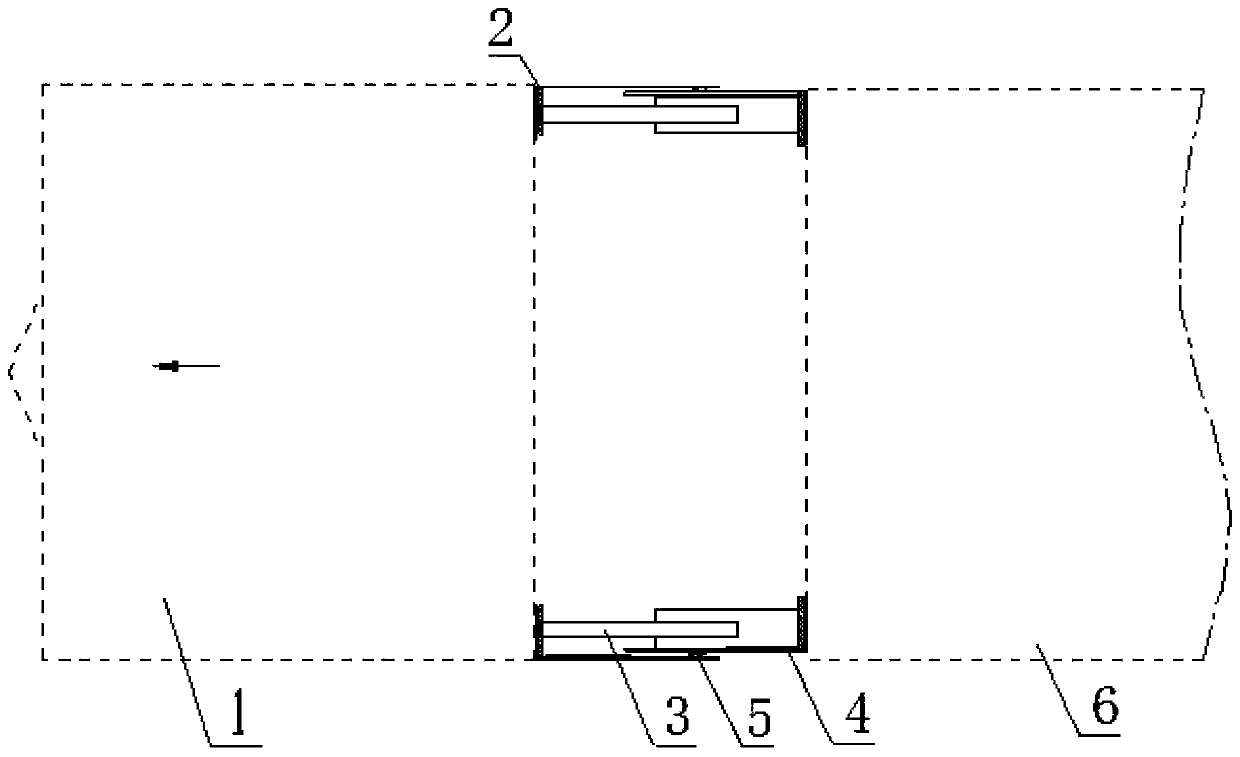

The invention belongs to the technical field of civil engineering construction, and in particular relates to a method and device for excavating foundation pits by sinking piles, the purpose of which is to provide an earthwork honeycomb array excavation method for foundation pits, which reduces earthwork barging and on-site earthwork piles The field occupies. In this method, the excavation array of the foundation pit is firstly divided into regions to form several partitioned soil layers, and type I soil-borrowing tool pipes are driven into the boundary to form boundaries; Excavation, after the excavation of the first layer of soil is completed, excavate the soil of the second layer of soil, and repeat until the remaining soil area is left; finally, insert the type II soil extraction tool tube, and move the soil extraction tools in sequence Pipe, complete the excavation of foundation pit earthwork. The device is a soil-borrowing tool tube, including a hollow tube body and a one-way check mechanism at the bottom. The one-way check mechanism includes two soil retaining plates spliced and connected, and the sides of the two soil retaining plates that are close to each other are respectively hinged with the positioning rod Connection, also includes three limit bar.

Owner:SHANGHAI CONSTRUCTION GROUP

Automatic control device and method for head-on earth pressure in mechanical tube jacking construction

ActiveCN102748533BSettlement controlEffective settlementPipe laying and repairServomotorsAutomatic controlControl engineering

The invention relates to the technical field of mechanical control of building construction and mainly discloses an automatic control device and an automatic control method for the head-earth pressure in mechanical tube jacking construction. The automatic control device comprises a tube jacking machine, a front shell, hydraulic oil cylinders, a rear shell, a sealing device, a jacking-in tube section, an overflow valve, a hydraulic pump station, a hydraulic pipeline and a hydraulic oil loop, and is characterized in that the tube jacking machine is arranged at the front end of jacking-in direction in the mechanical jacking, the front shell and the rear shell are arranged at the rear part of the tube jacking machine, and are connected by a plurality of hydraulic oil cylinders, sealing devices are arranged outside the hydraulic oil cylinders, the plurality of hydraulic oil cylinders are respectively connected in parallel by the hydraulic pipeline and are respectively connected with the hydraulic pump station, and the hydraulic pump station is provided with the hydraulic oil loop which is provided with the overflow valve. The automatic control device disclosed by the invention can respond to the head-on earth pressure of the tube jacking machine in real time, then the control device automatically adjusts the jacking force of a head of the tube jacking machine, the control oil supply can be realized by the adjustable overflow valve on an oil path, so that the tube jacking machine can respond to the pressure of the head-on earth pressure in real time, the effect of earth pressure balance is realized, and the method is simple and effective.

Owner:中铁市政环境建设有限公司

Construction method for improving shield soil in composite sand gravel stratum

The invention provides a construction method for improving shield soil in a composite sand gravel stratum. Water, foam and bentonite slurry are used as composite improvement additives; and different additives are selectively injected to the front of a cutter head, the inside of a soil barn or a screw conveyor according to the actual working condition during shield driving with the aid of special improvement equipment and processes so as to play a role in improving the plastic fluidity of the soil, reducing the torque of the cutter head, stabilizing the excavation face and improving the driving efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD

Device and method for improving supporting effect of excavation face of earth pressure balance type tunnel boring machine

PendingCN113202488AExcavation face stabilityReduce land subsidenceUnderground chambersTunnel liningExhaust gasEarth pressure balance

The invention relates to a device and method for improving the supporting effect of an excavation face of an earth pressure balance type tunnel boring machine. The device comprises an exhaust system, a grouting system and an industrial personal computer; the method comprises the following steps that during a shutdown period of a shield tunneling machine, gas pressure P1 in a soil bin is measured through a pressure sensor, meanwhile, the industrial personal computer obtains underground water pressure P2 at the same height, and if P1 is larger than or equal to P2, exhaust and grouting operation does not need to be conducted; if P1 is smaller than P2, the exhaust system is controlled by the industrial personal computer to exhaust gas until gas in the soil bin is completely exhausted; after exhaust is stopped, the grouting system is started through the industrial personal computer, the grouting pressure is set to be P2, the change of the monitored value P1 is observed during grouting, and when the monitored value P1 of the pressure sensor is equal to P2, the grouting system is closed; and after shutdown, P1 and P2 are compared once every 1 h, and when P1 is smaller than P2, the steps S2-S3 are repeated. According to the device and the method, the exhaust system and the grouting system are additionally arranged, operation is convenient, and the construction quality and safety can be effectively improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

Improved construction method of soil mass of extra-large-diameter soil pressure balancing shield on soft soil stratum

The invention relates to an improved construction method of a soil mass of an extra-large-diameter soil pressure balancing shield on a soft soil stratum, which particularly solves the construction travelling problem of the extra-large-diameter soil pressure balancing shield. The improved construction method of the soil mass of the extra-large-diameter soil pressure balancing shield on the soft soil stratum comprises the following steps: adopting foam and bentonite slurry as additives in the tunneling construction process, injecting the additives to different positions of an excavation surfaceof a cutter, focusing on the foam and controlling the stability of soil pressure, causing bentonite slurry to play a subsidiary role and reducing the excavation strength of the soil mass, simultaneously adopting a central agitator in a soil warehouse to agitate and mix the soil mass and the additives entering into the soil warehouse and further stabilizing the excavation surface, improving the plastic fluidity, reducing the torque of the cutter and improving the tunneling efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD

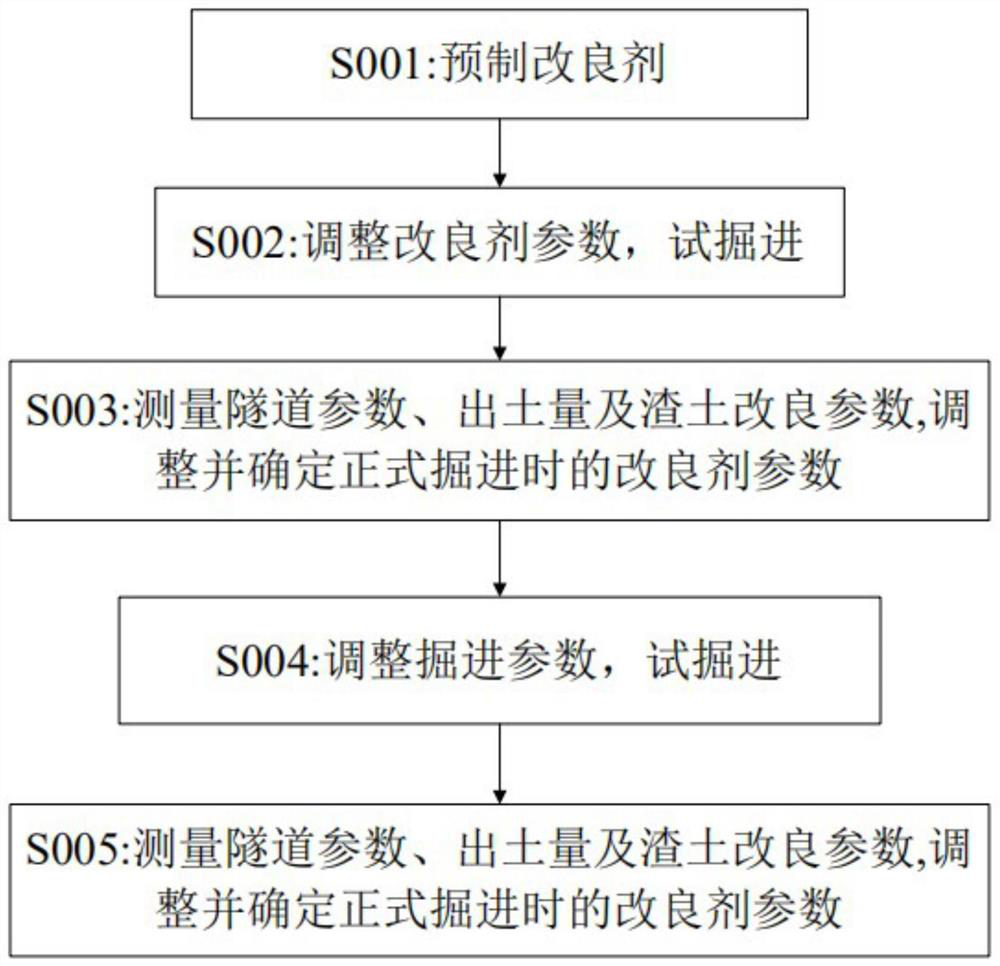

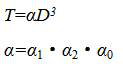

A construction test method for improving the slag soil of shield tunneling with water-rich sand layer

A water-rich sand layer shield tunneling slag improvement construction test method includes the following steps: 1. Adding prefabricated modifiers to the shield machine cutter head, soil bin and screw conveyor respectively. 2. Determine the modifier parameters: Select the first 100m of the shield as the test section, set the same excavation parameters, and set different modifier parameters, and test the excavation in the test section. 3. Measure the parameters of the tunnel, the amount of unearthed soil and the improvement parameters of the slag after the excavation, and adjust the parameters of the modifier to determine the parameters of the modifier during the formal excavation. 4. Determine the excavation parameters: the parameters of the modifier are the same, and the shield machine will try to excavate in the test section under different excavation parameters. 5. Measure the tunnel parameters, excavation volume and slag improvement parameters after excavation and adjust the excavation parameters to determine the formal excavation parameters of the shield machine. The method solves the problem that in the prior art, due to the unreasonable setting of the modifier parameters and the tunneling parameters, the slag soil improvement effect is not good, the tunneling speed is reduced, and the wear of the shield machine is increased.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com