PMS sludge prepn. method and its application in construction of sludge balance shield and pipe-jacking

A mud-water balance and mud-water shield technology, which is used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of unfavorable and complex geological conditions, the advancing speed, the inability of the shield or pipe jacking machine to advance, and the poor strain capacity. The effect of mud loss, simultaneous grouting reduction, and low solids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

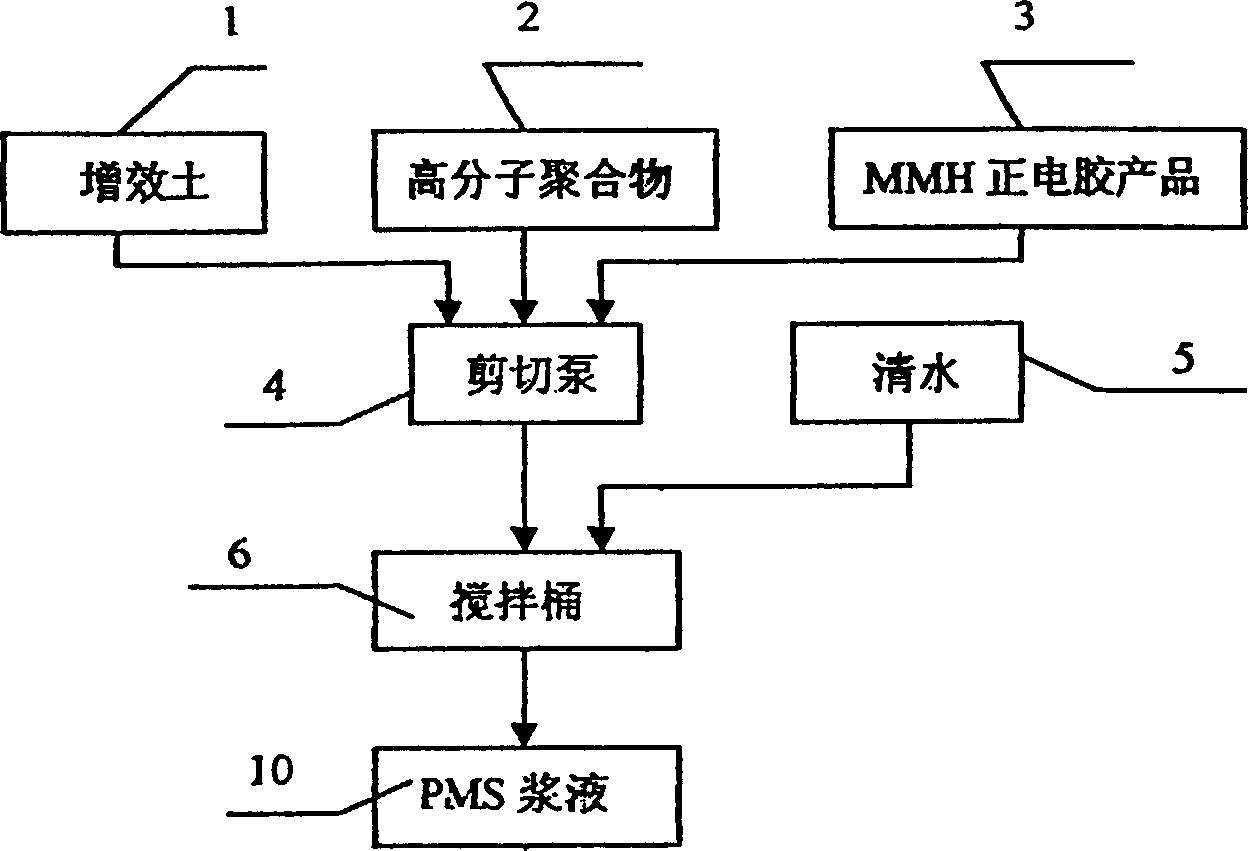

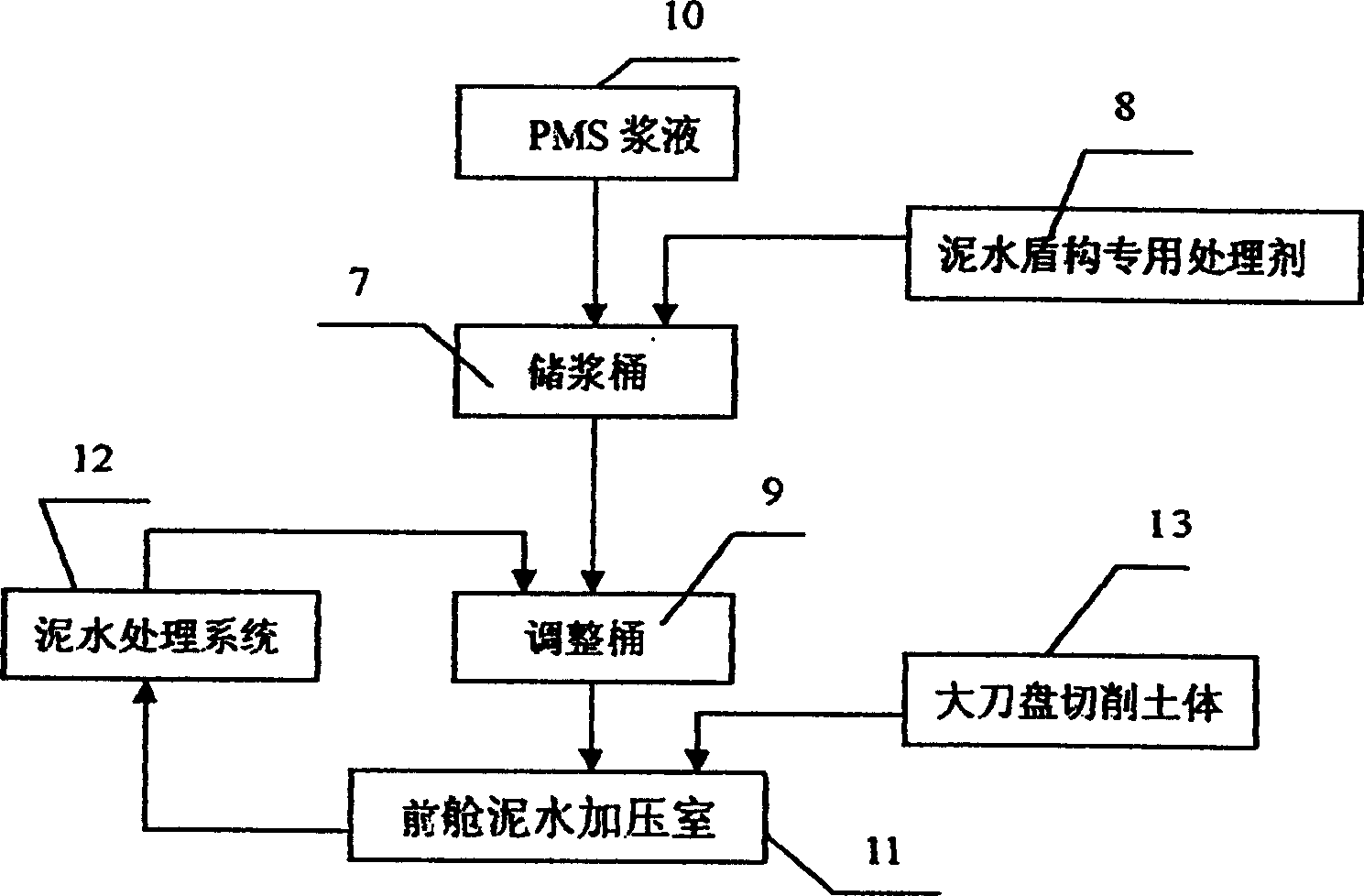

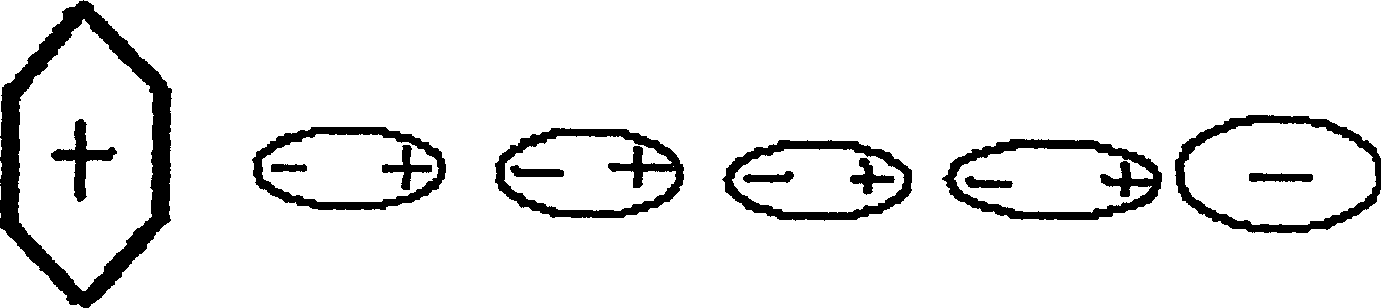

[0029] PMS (full name: Polymer-MMH Shield buriedtunneling Slurry System), the mud-water slurry preparation method is: add clear water 5 into the mixing tank 6, and start the shear pump 4, and the shear pump Add synergistic clay 1 or activated sodium bentonite to the feeding funnel, add large, medium and small polymers 2, and positively charged MMH positive gel product 3, and the shear pump circulates for 5 to 10 minutes to make ready for use . See figure 1 , the high molecular polymer is a high molecular polyacrylic acid salt, including polyacrylic acid (amide) amide (see the structural formula Figure 7 ), strong covering agent, compound ionic polyacrylic acid (acyl) salt. MMH positive gel is a mixed metal hydroxide solution (Mixed Metal Hydroxide).

[0030] The application of MPS mud-water slurry in mud-water balance shield tunneling and pipe jacking construction is carried out according to the following steps: the mud water is sent into the mud-water pressure chamber 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com