Patents

Literature

99 results about "Pipe bursting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipe bursting is a trenchless method of replacing buried pipelines (such as sewer, water, or natural gas pipes) without the need for a traditional construction trench. "Launching and receiving pits" replace the trench needed by conventional pipe-laying.

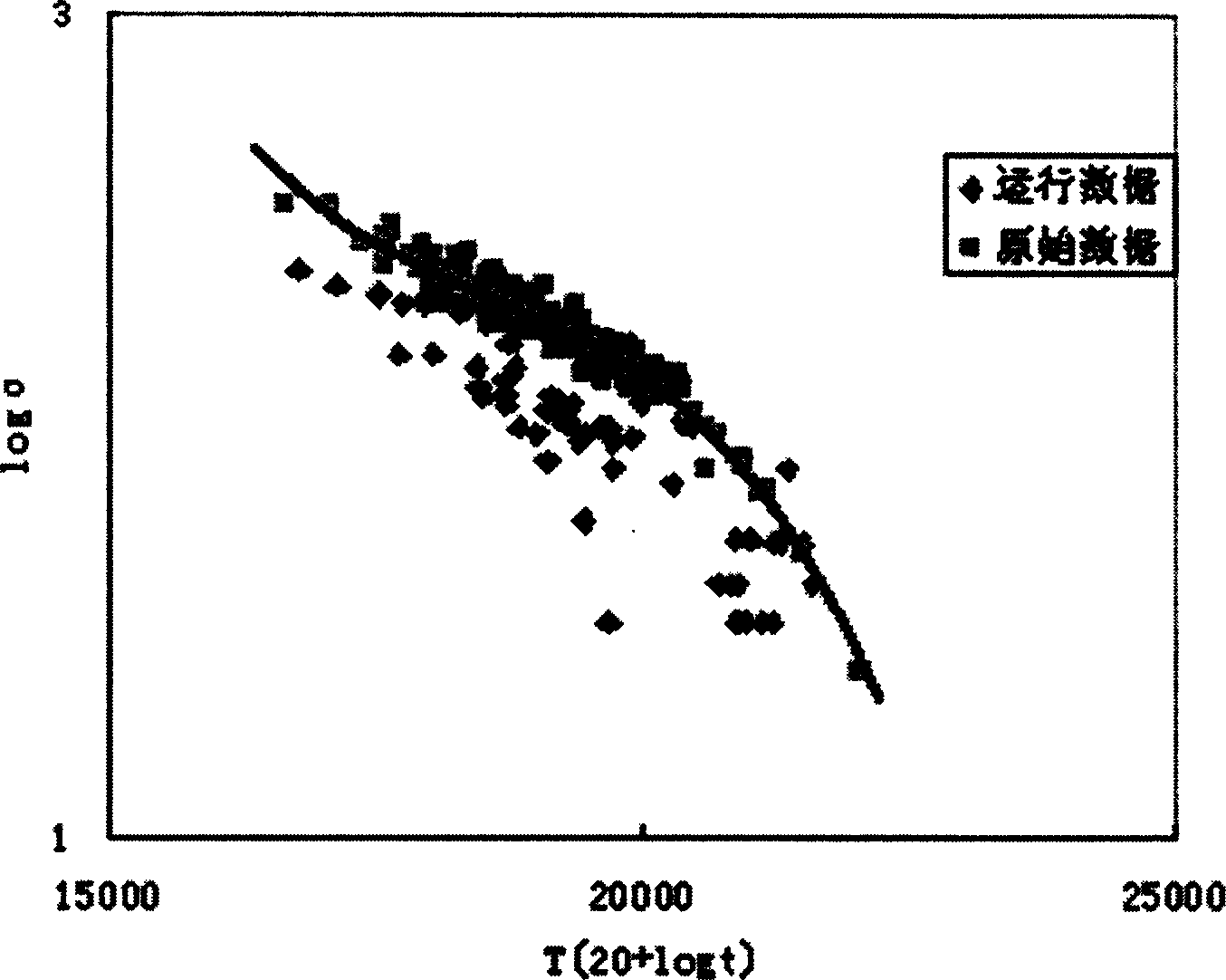

Test method of high-temp, component creep life

The testing method of high-temp. component creep life adopts the simulation pipe-bursting test machine or durable strength testing machine to make creep rupture acceleration simulation test of new materials which have different ageing extents and are not aged under the condition of a series of temp. and stresses. It adopts polynomical regressive analysis method to process data, and obtain the relationship formula of non-aged material between ageing factor, temp. and life time. By utilizing test, data processing and formula operation the material creep service life can be obtained.

Owner:XIAN THERMAL POWER RES INST CO LTD

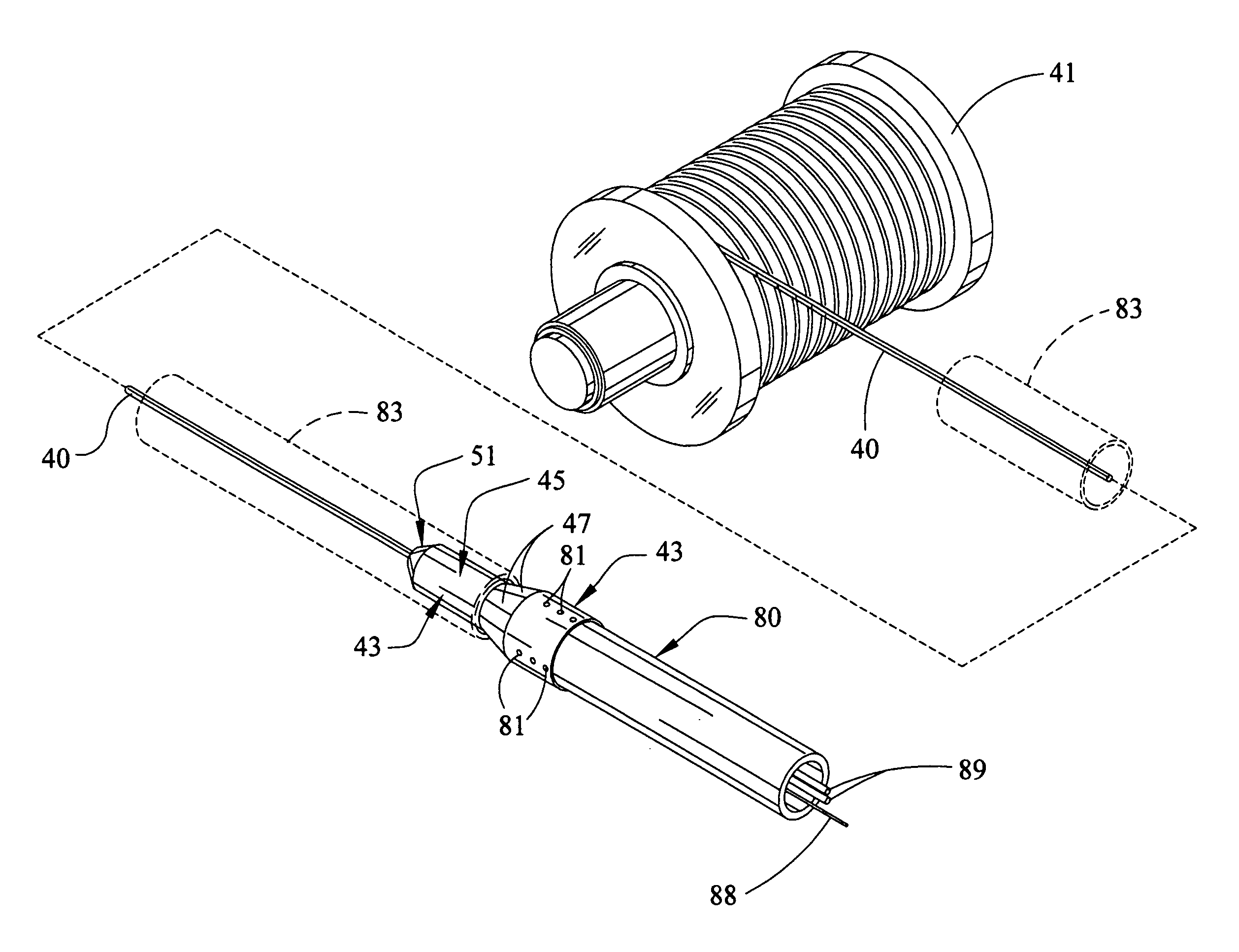

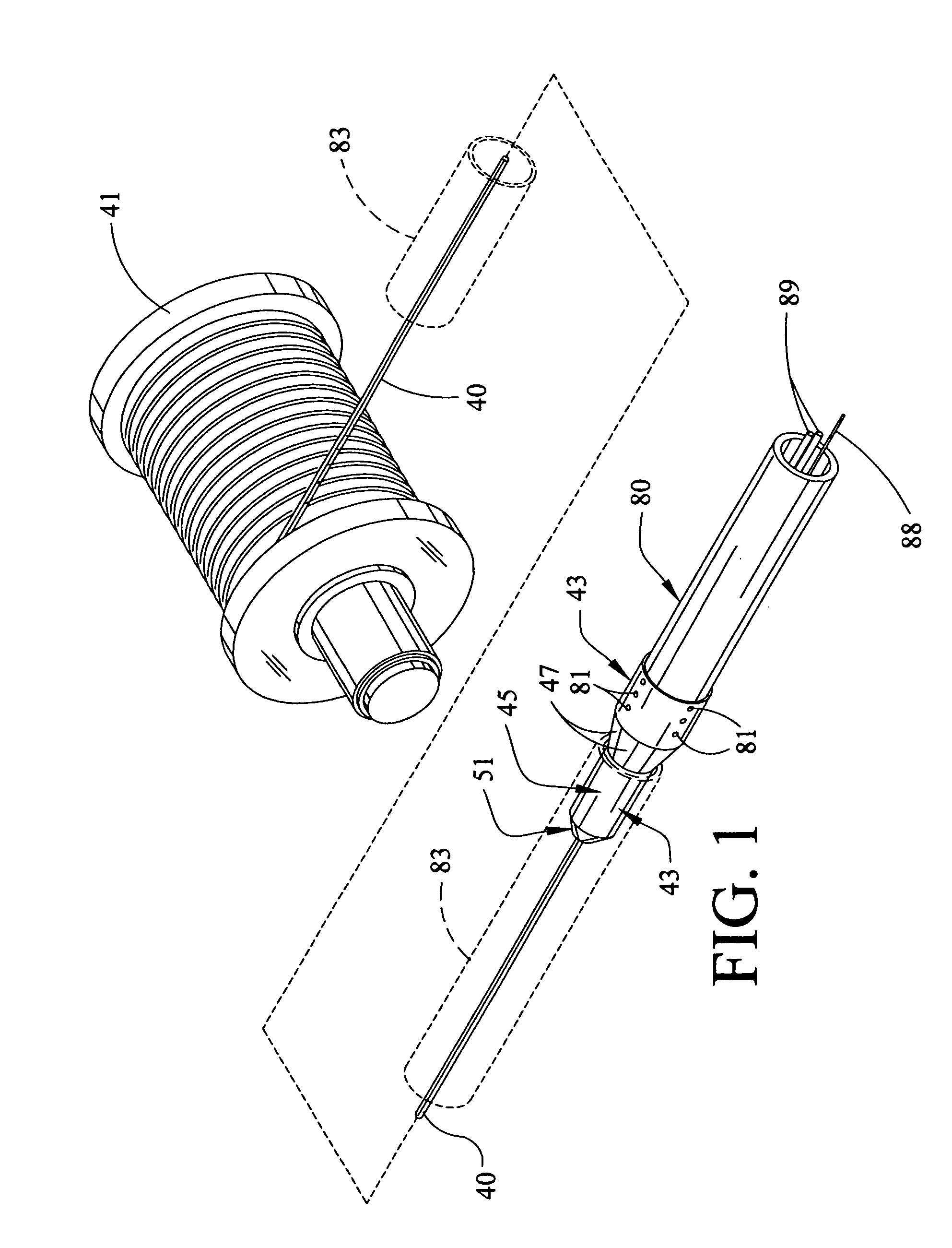

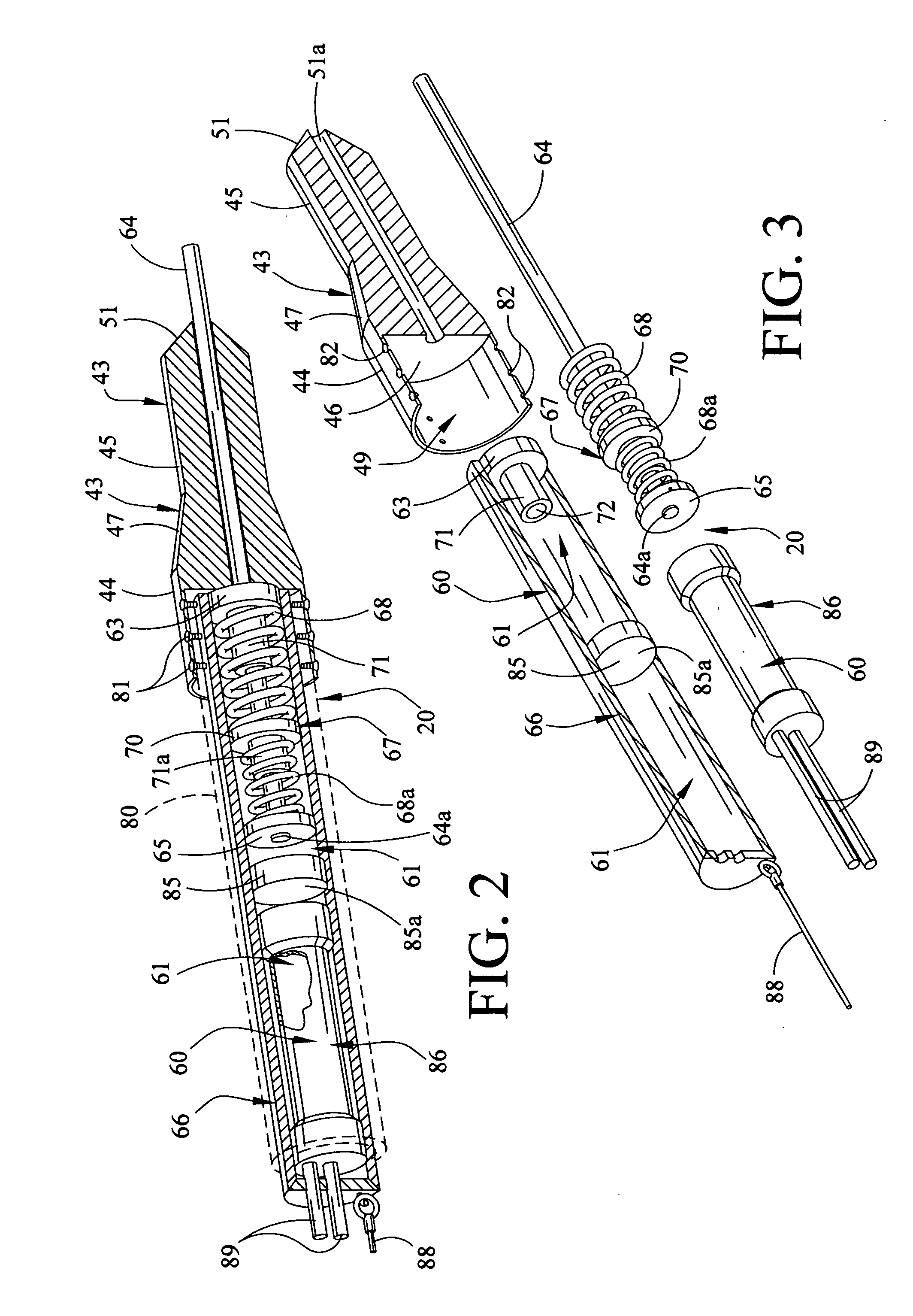

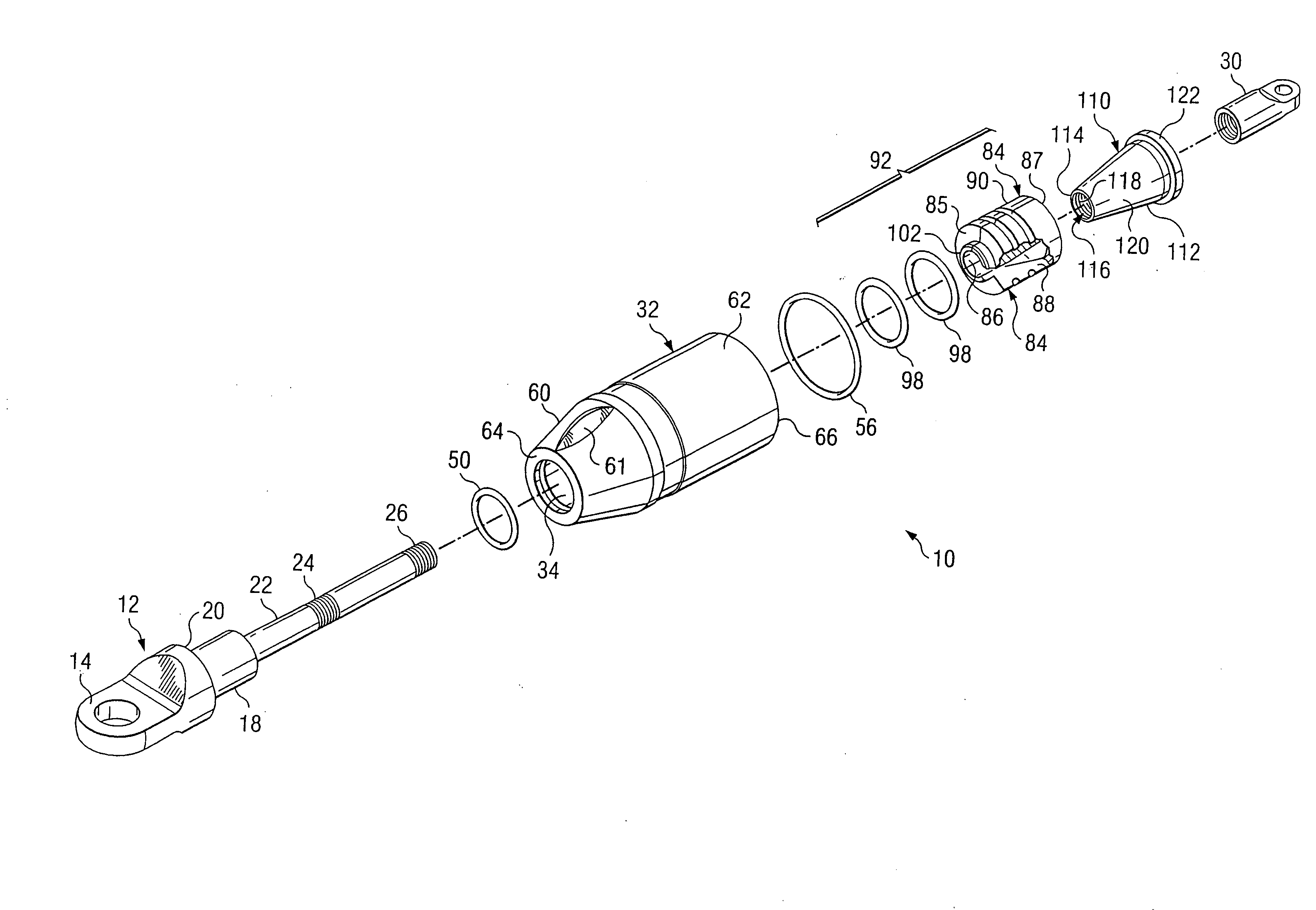

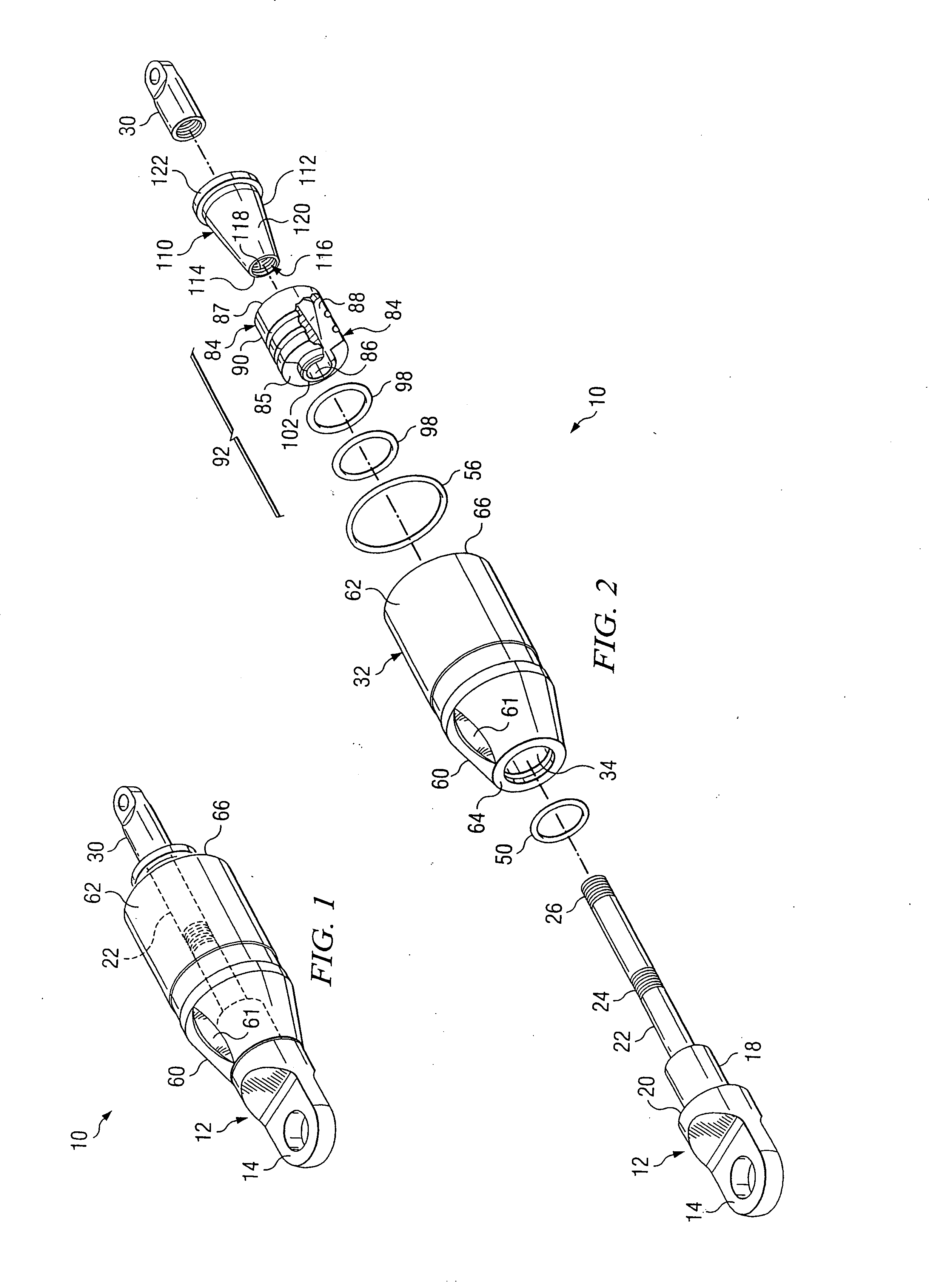

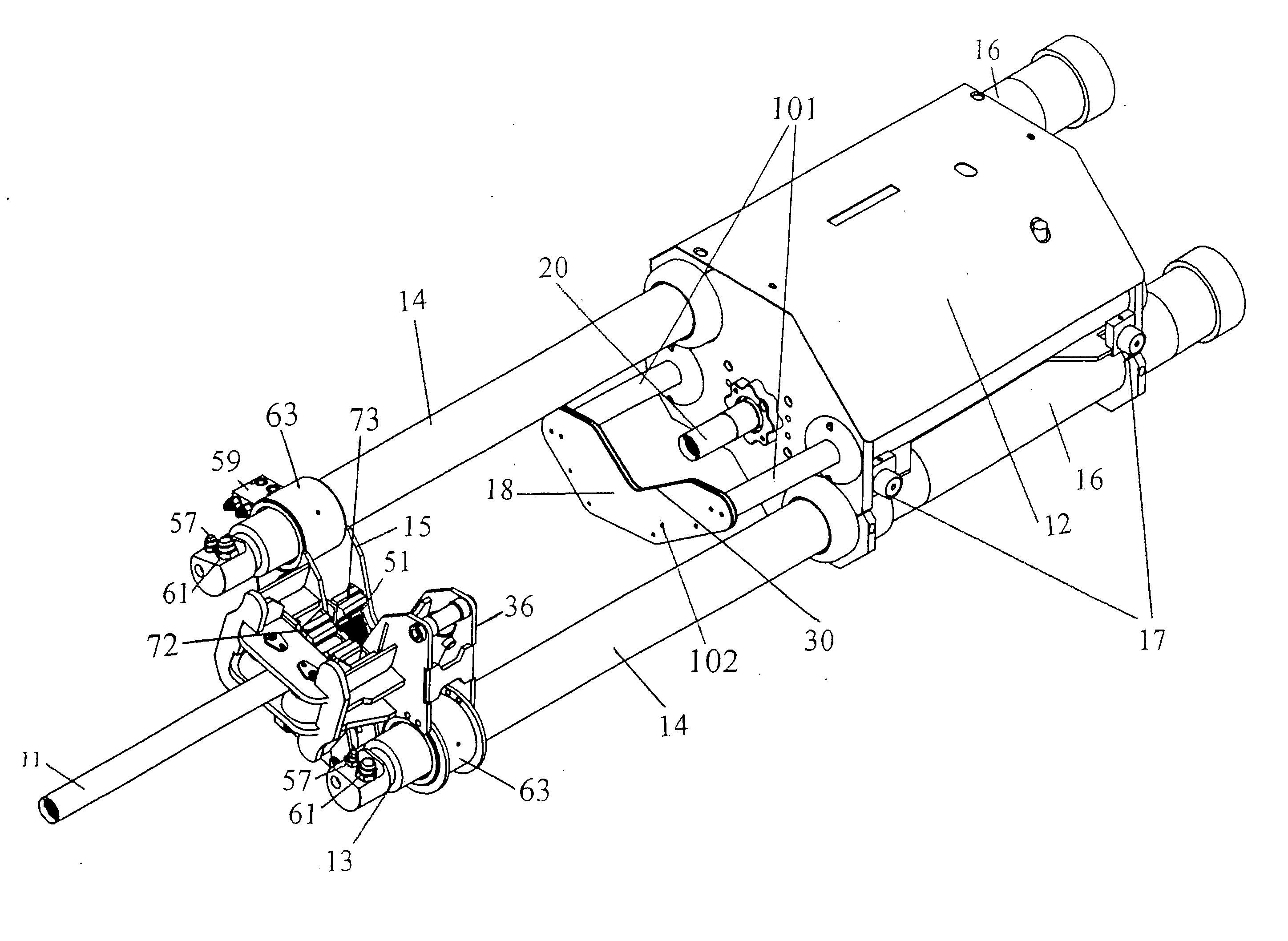

Stored energy coupling and pipe bursting apparatus

A stored energy coupling and pipe bursting apparatus which is designed to increase the efficiency of pipe-bursting by enhancing the effect of a pneumatic or hydraulic hammer used while moving the pipe-bursting head. In one embodiment the stored energy coupling has one or more internal springs and operates to improve the energy output of a hammer as the pipe-bursting head traverses the length of the pipe to be broken responsive to the pulling action of a single hydraulic cylinder having dual rod or cable gripping elements. In another embodiment the stored energy coupling has no spring and is designed to prevent damage to the static pulling device when the hammer is implemented. The stored energy coupling of this invention can be installed in front or behind the bursting head, or even in the bursting head and is always positioned in front of the hammer. The stored energy coupling can also be utilized in a common housing with the hammer and with a cable or rod pulling apparatus of any design, including a hydraulic cylinder which uses a rod or cable connection and dual gripping elements for immobilizing the rod or cable between pulling sequences.

Owner:PUTNAM SAMUEL W

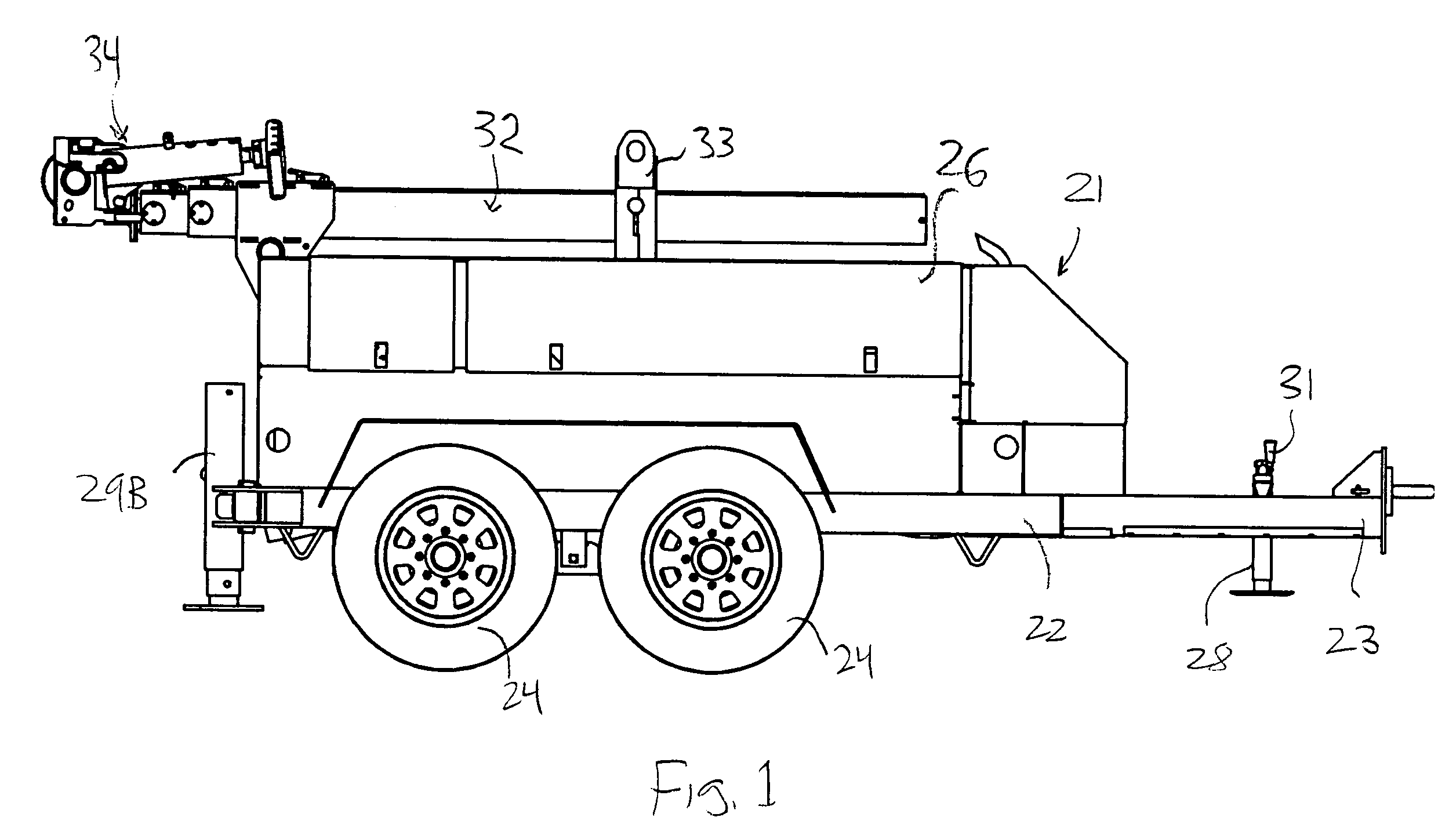

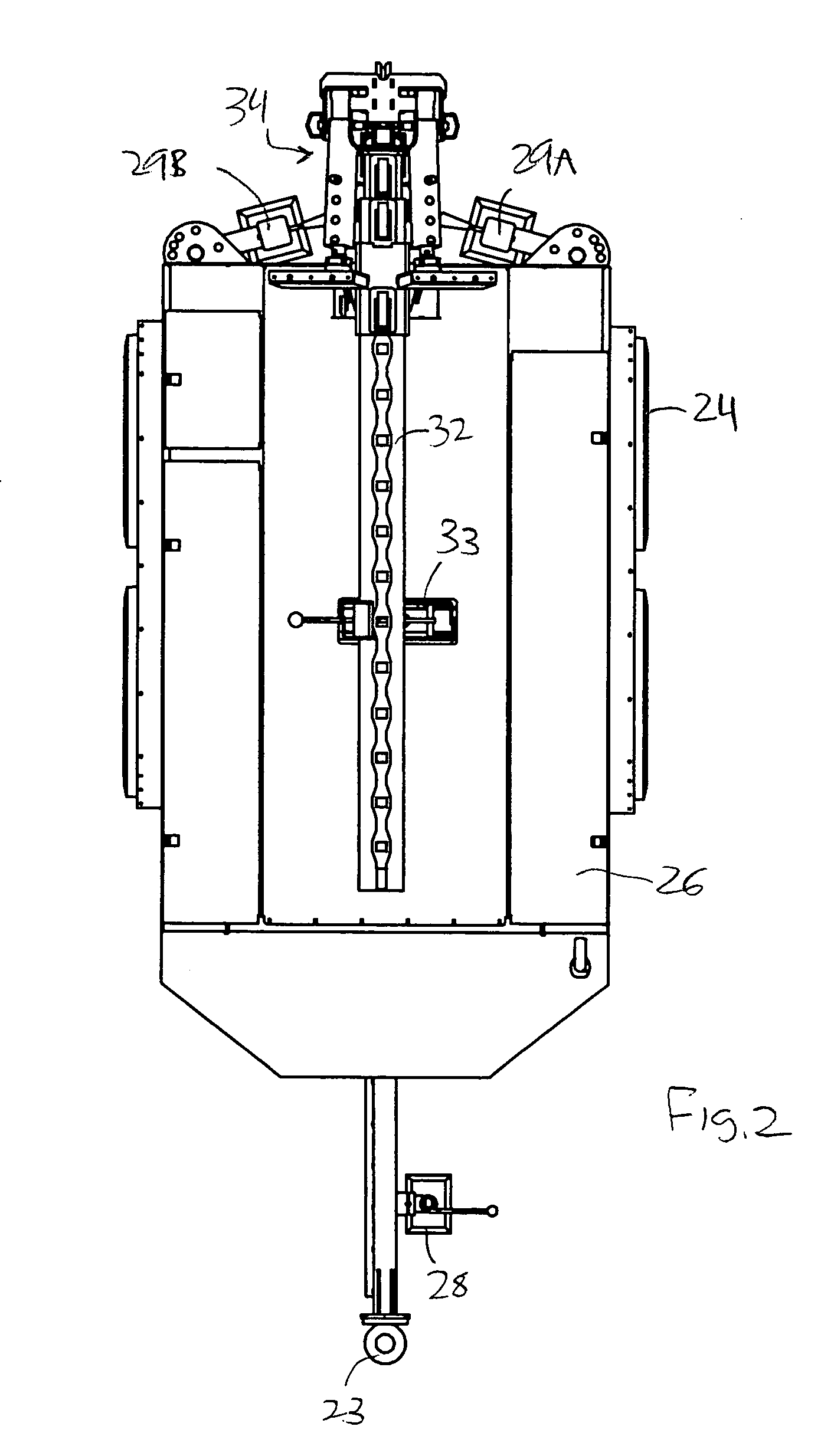

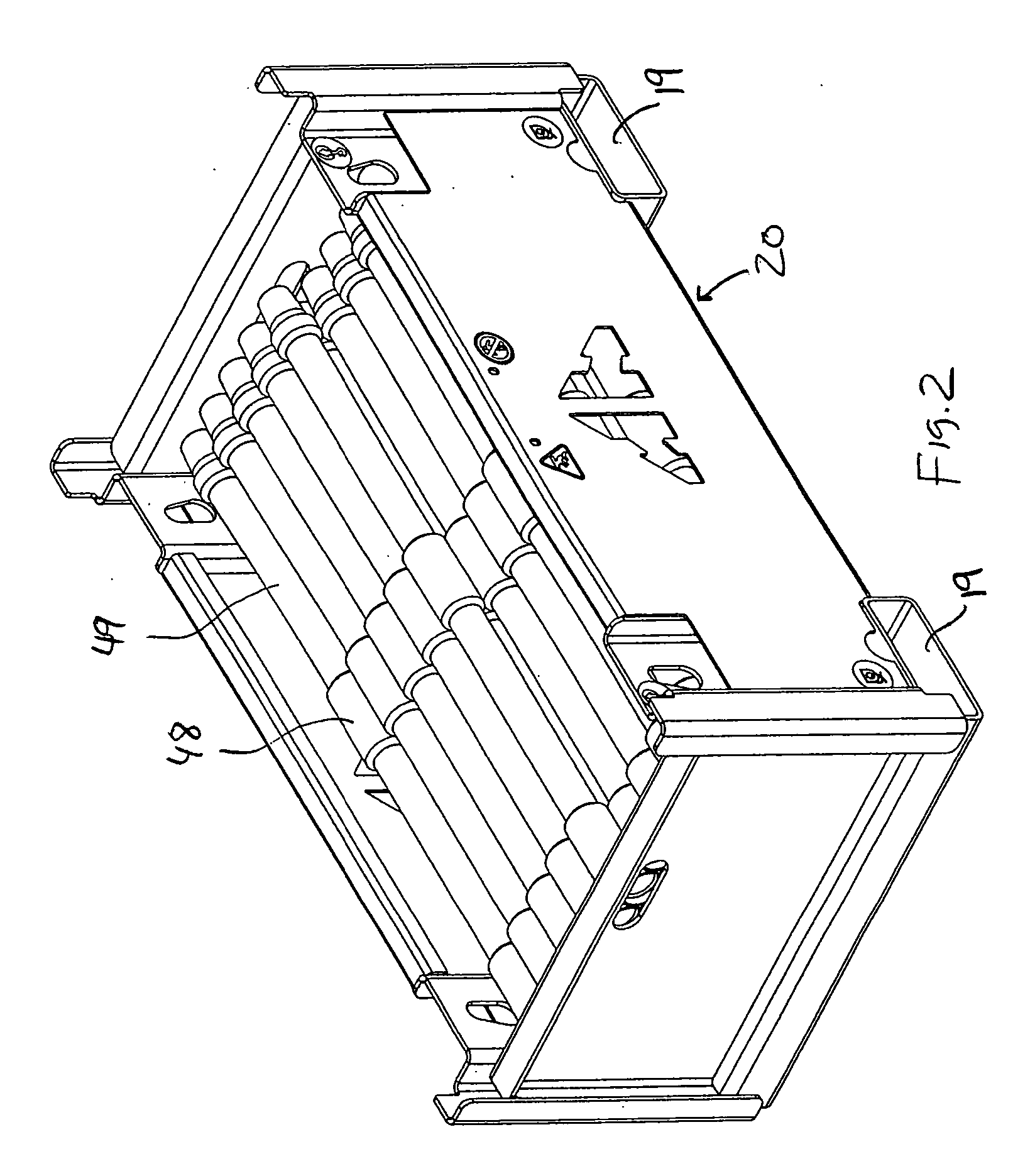

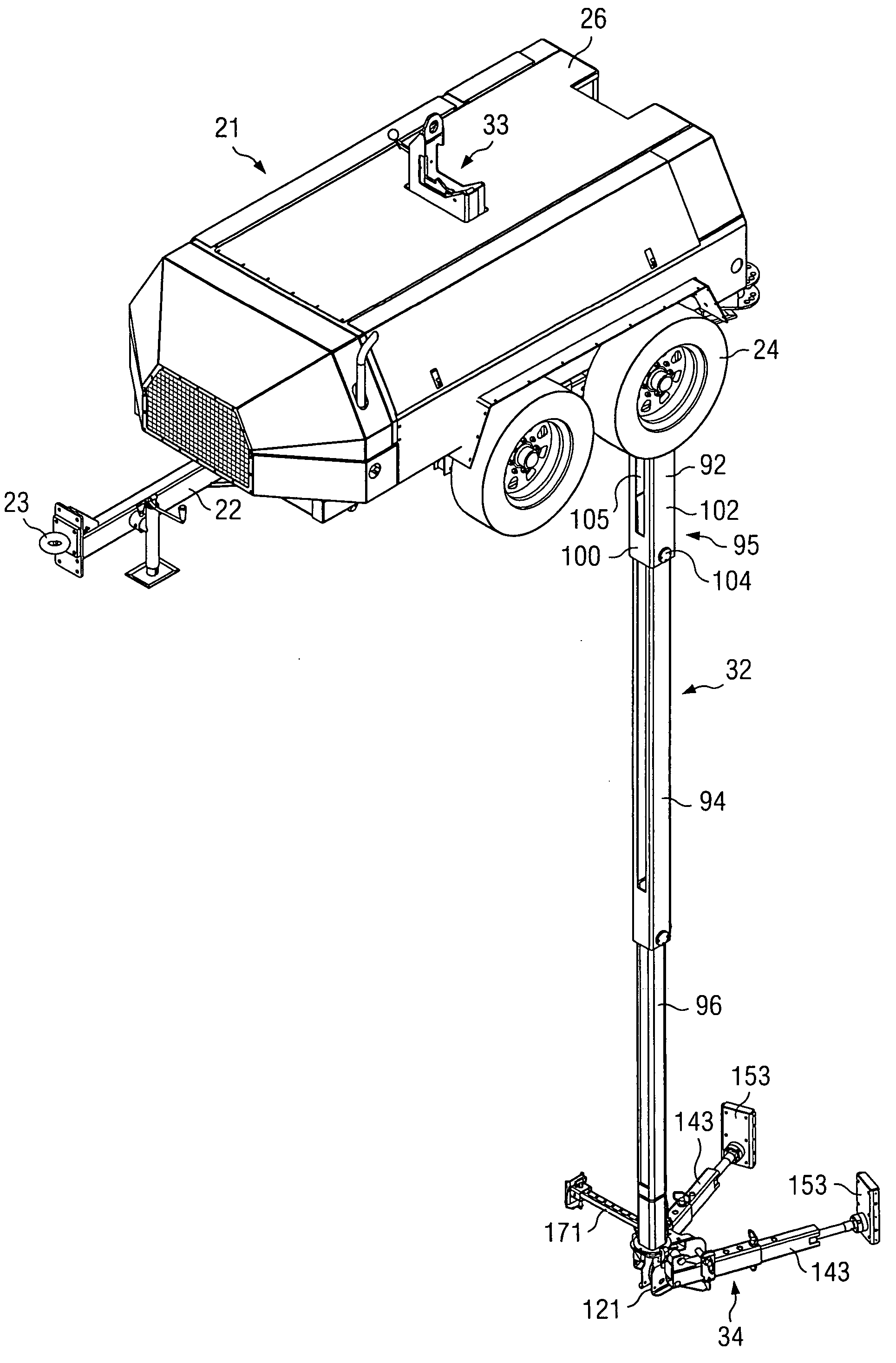

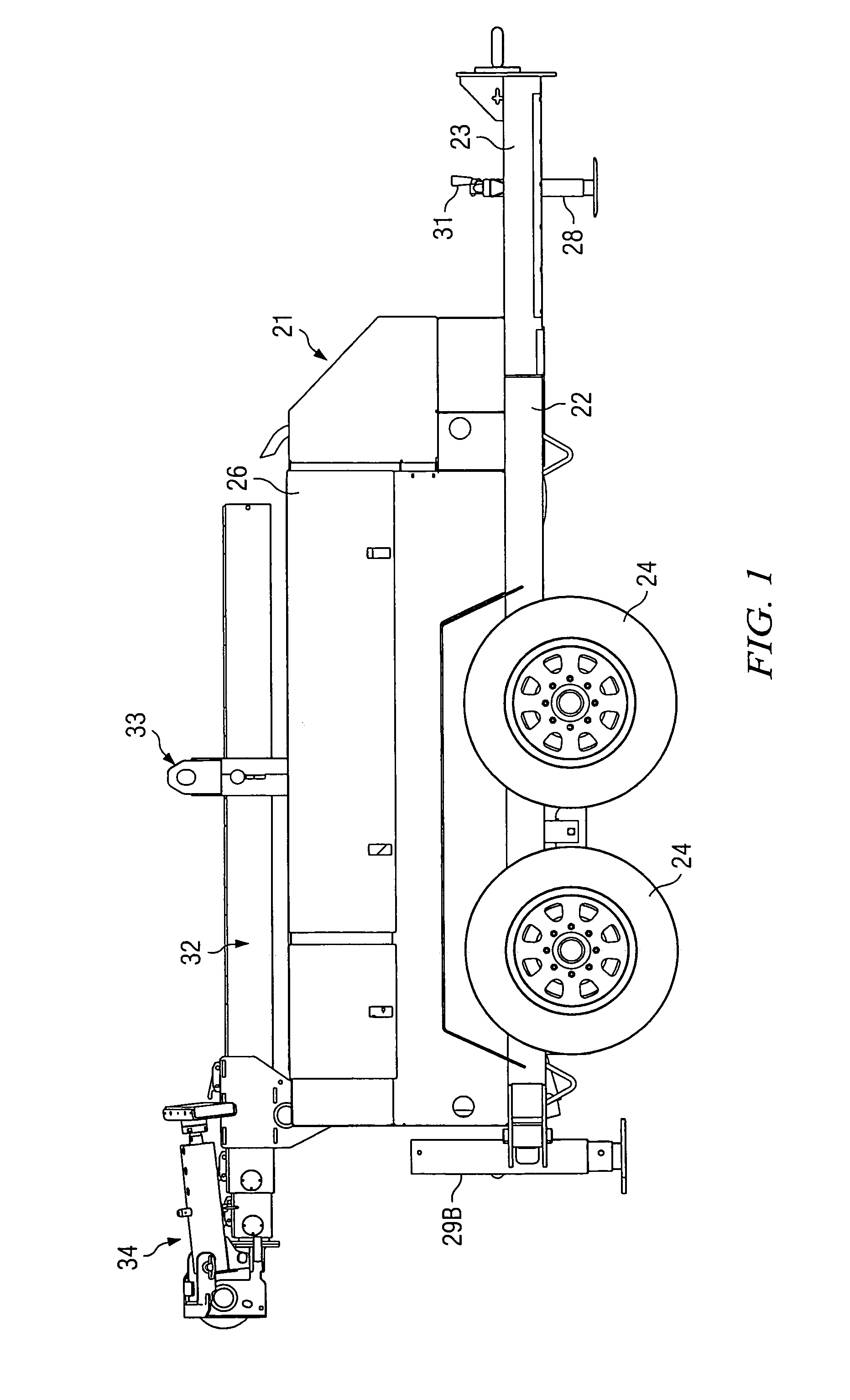

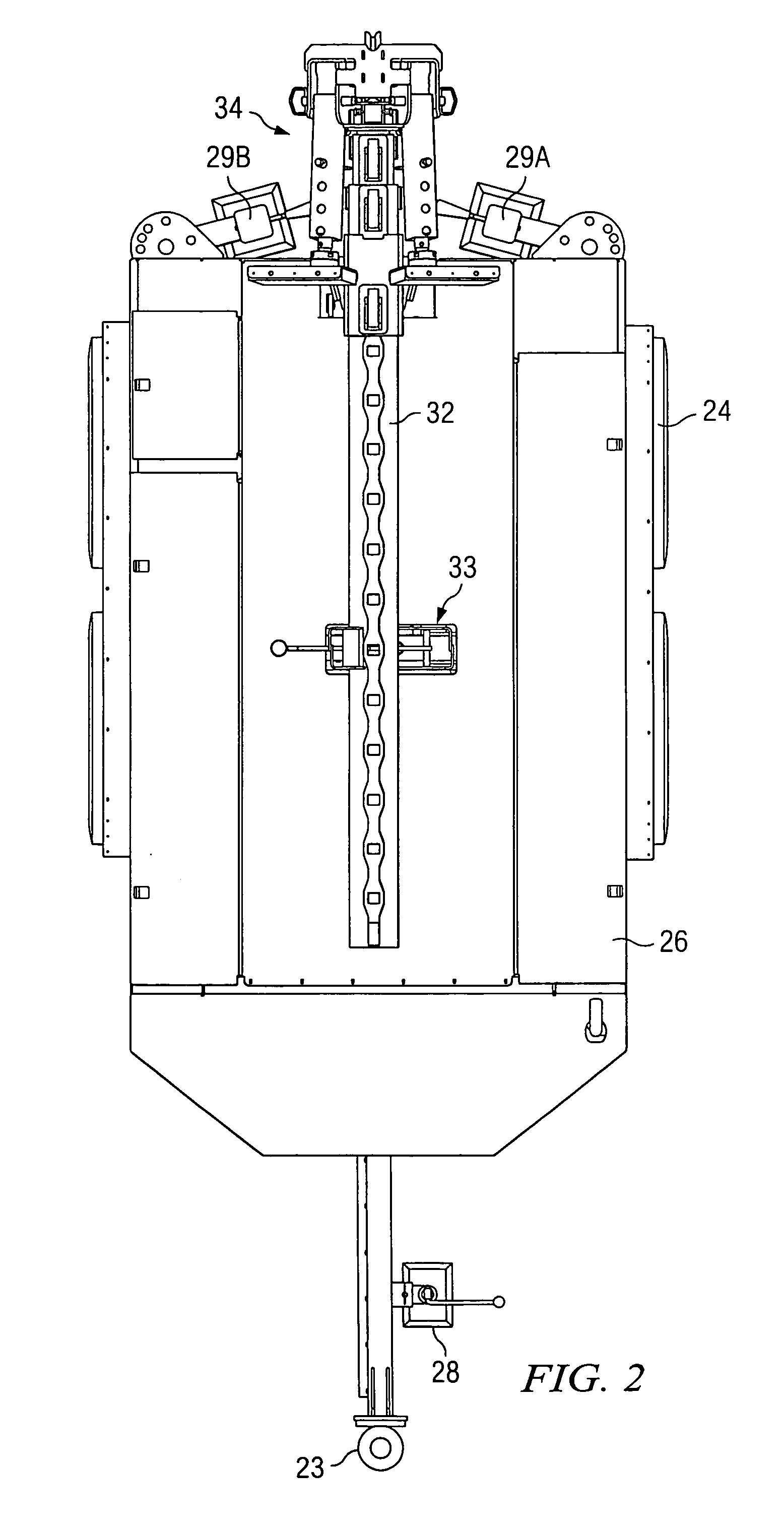

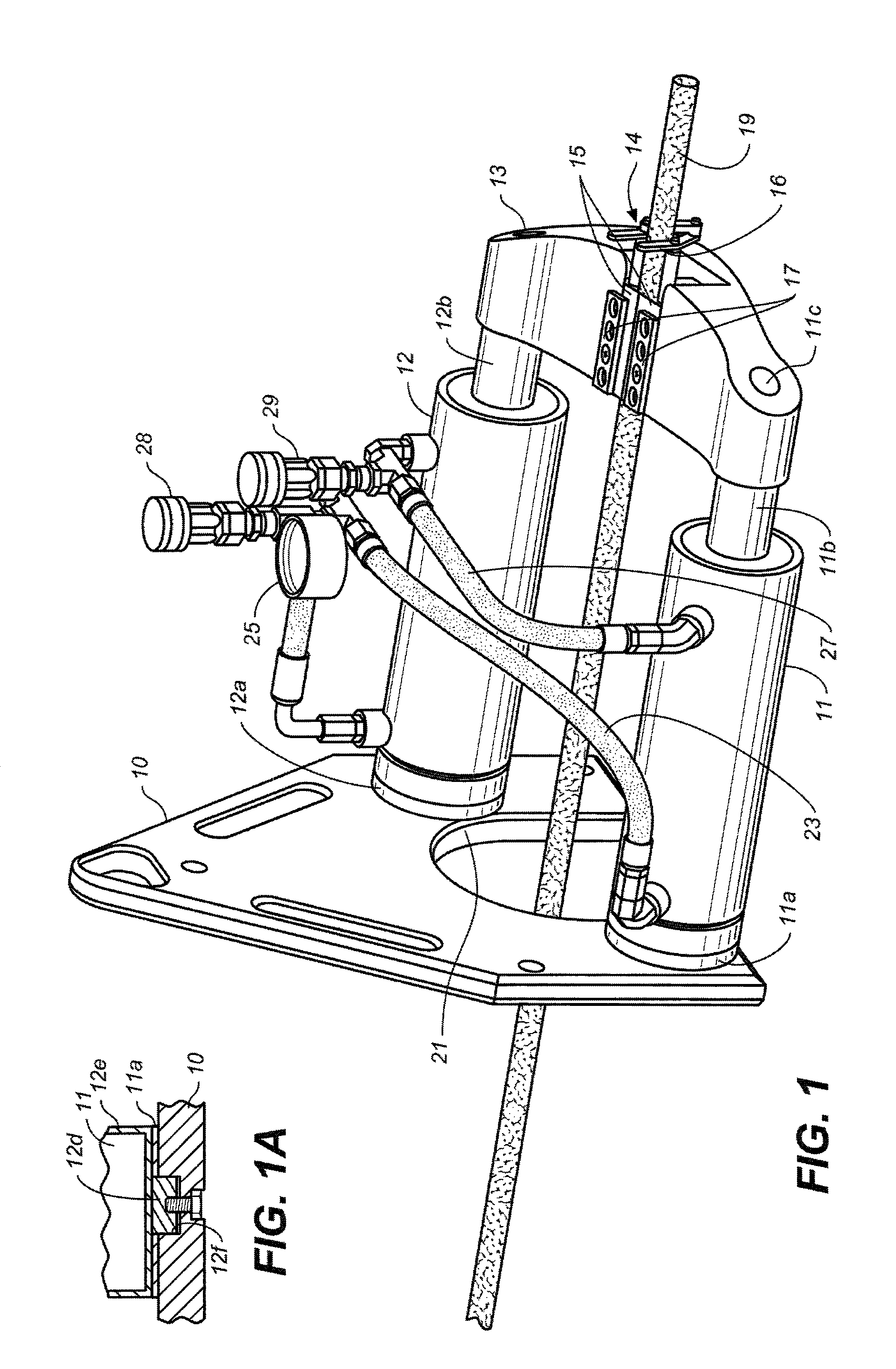

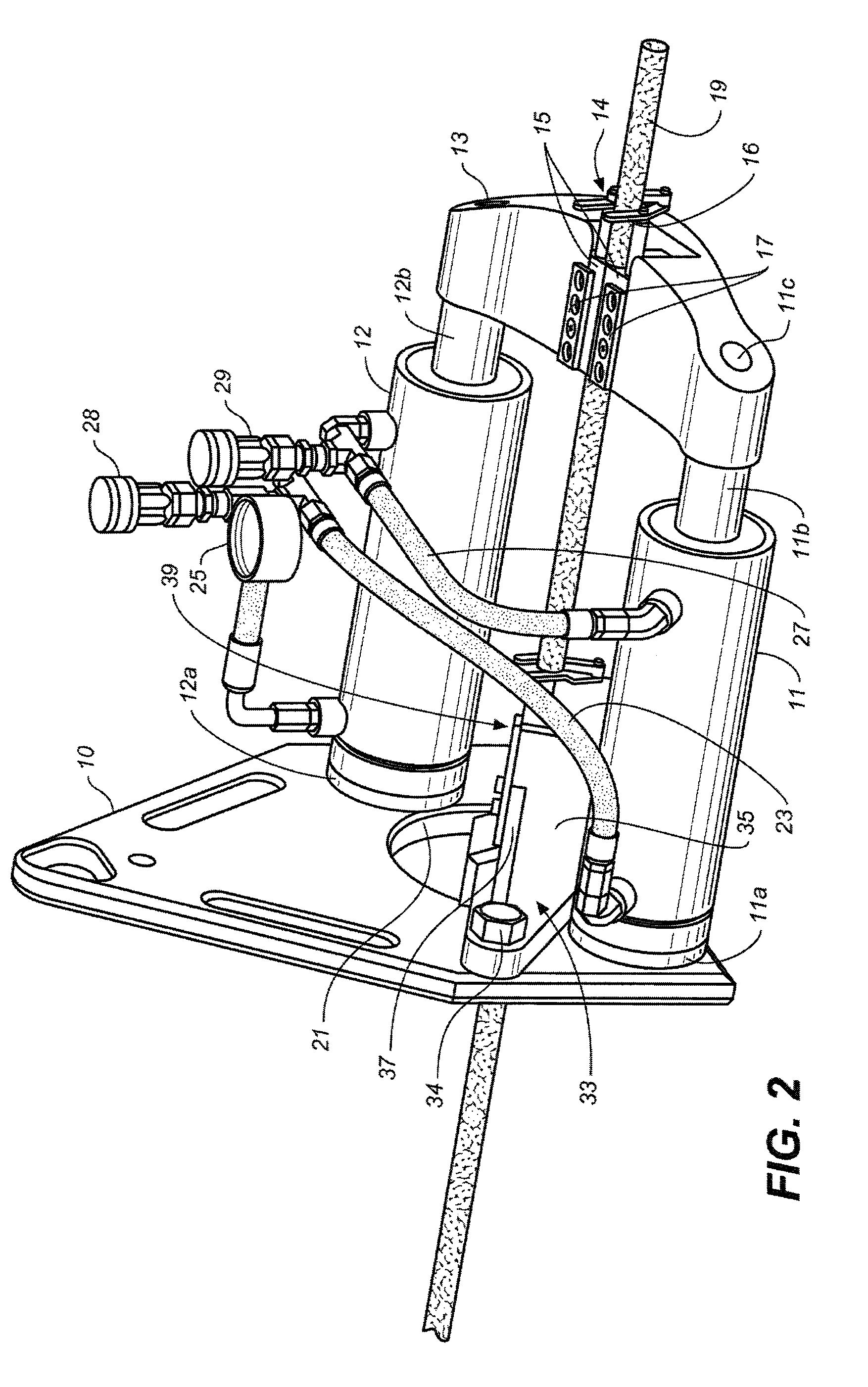

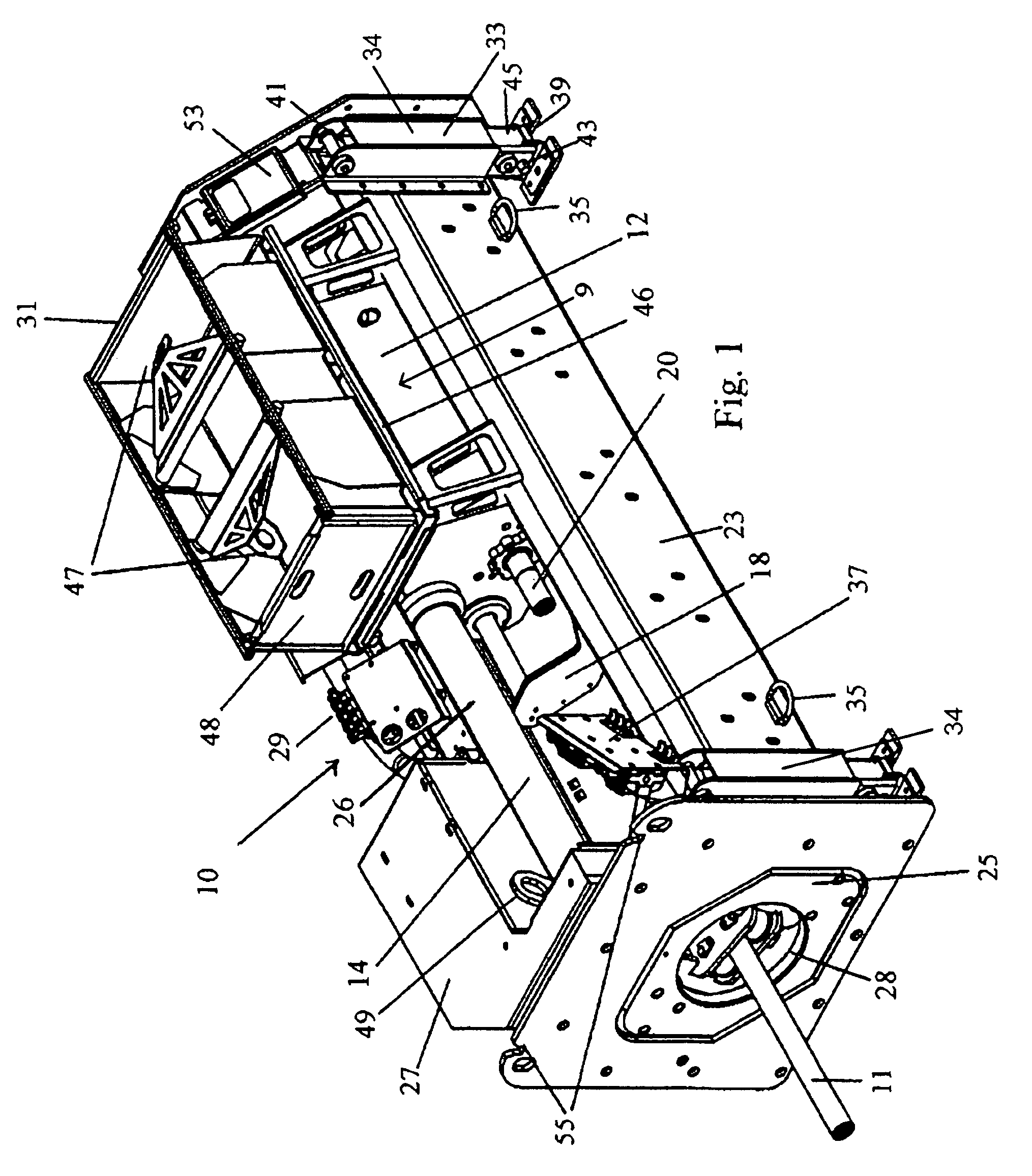

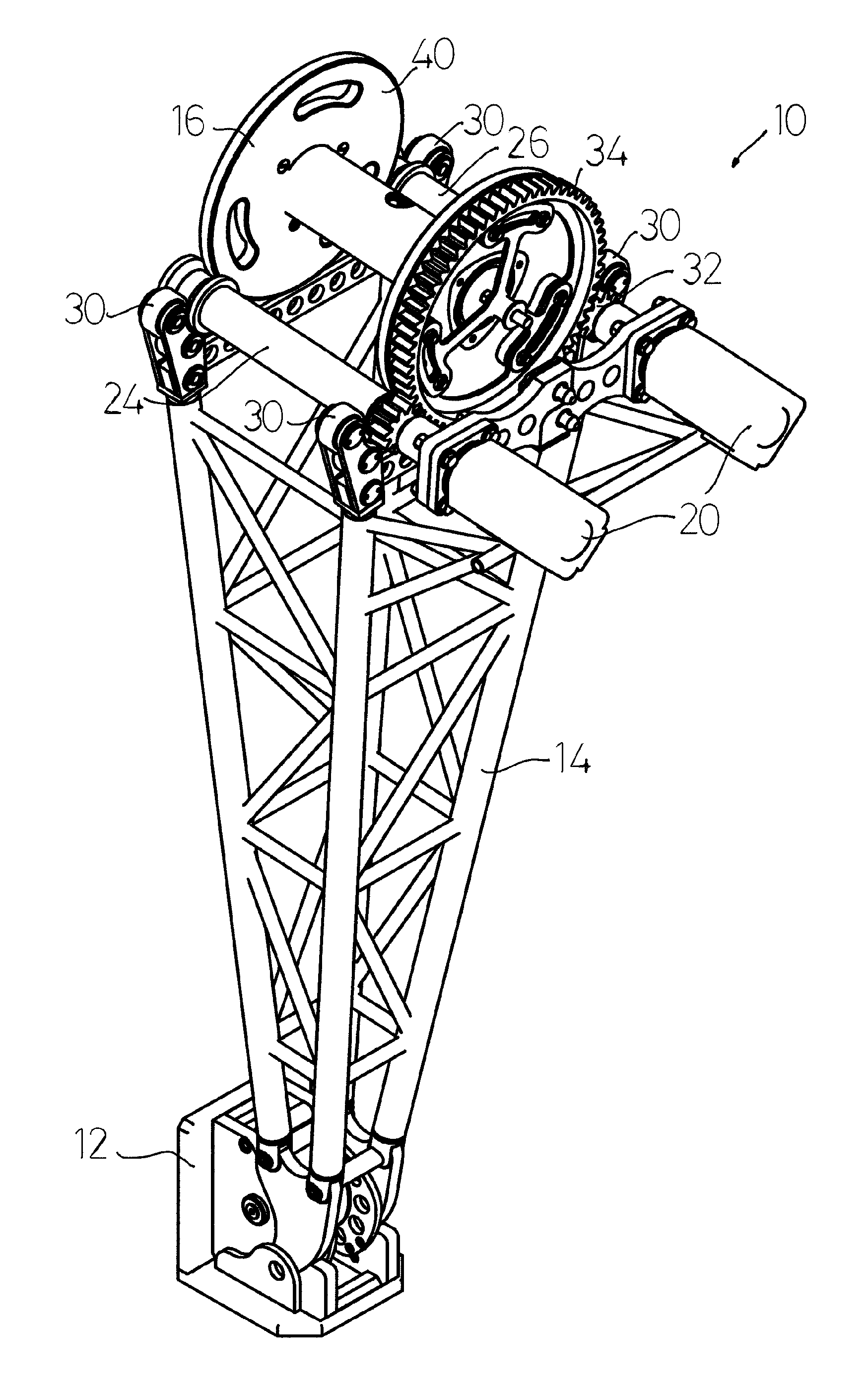

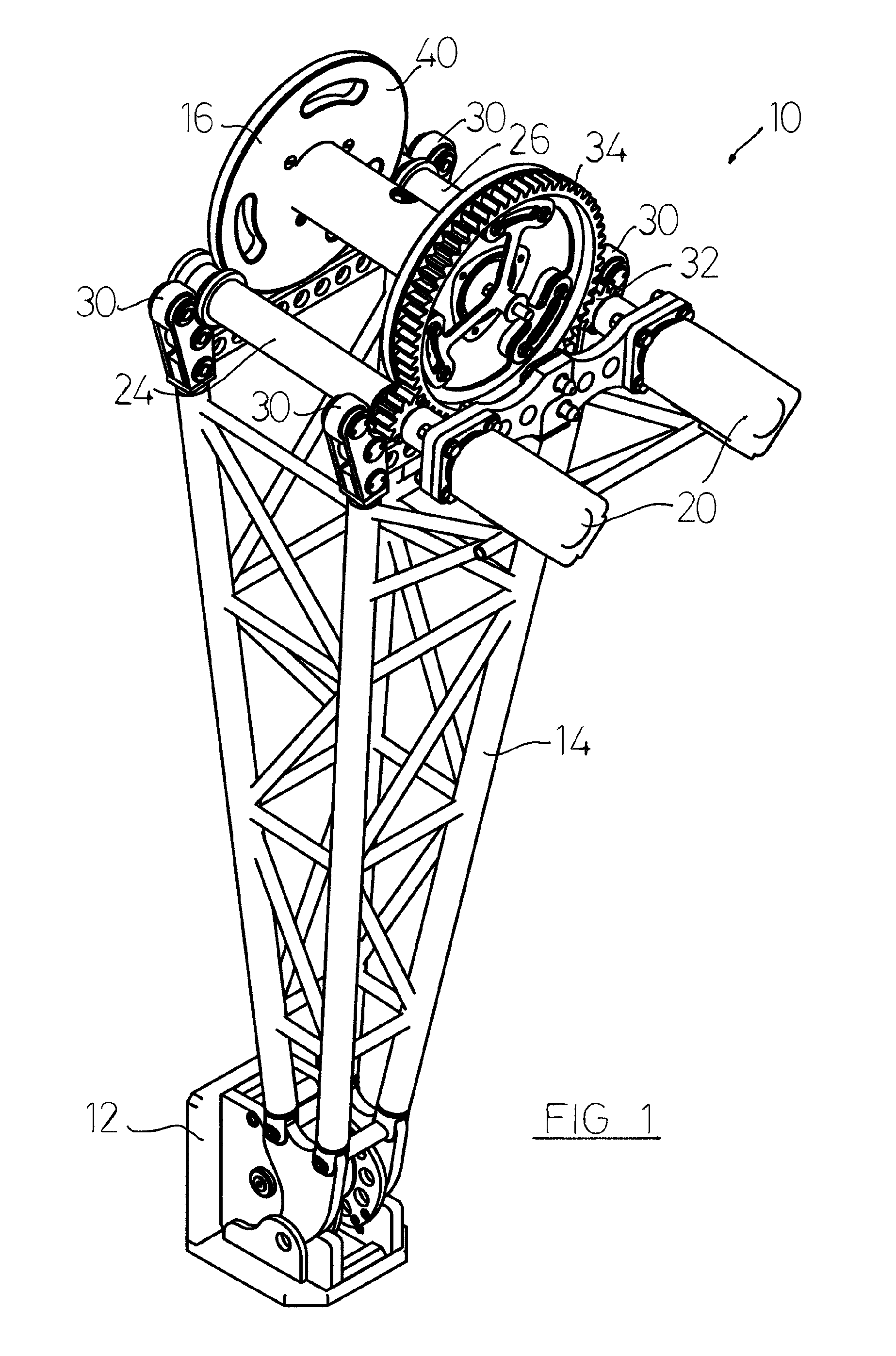

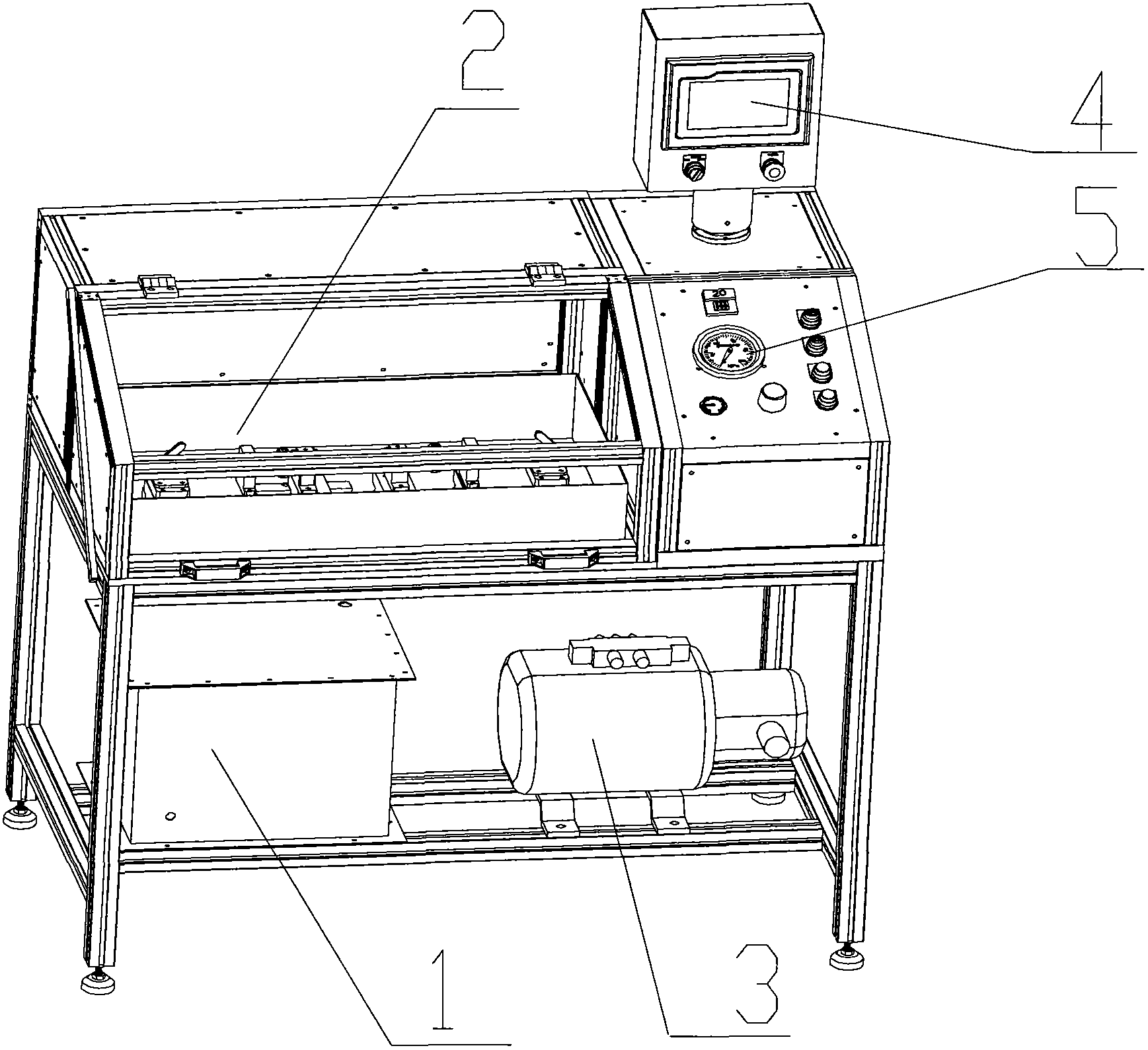

Winch with telescoping mast

ActiveUS20050062030A1Suitable for useDrilling rodsArrangements using take-up reel/drumPipe burstingWinch

A portable winch suitable for use in underground pipe bursting and replacement includes a mounting frame positionable at a top opening of a hole such as a receiving pit or manhole. A telescoping mast having a series of nested, top and bottom mast sections is mounted on the frame. A powered winch unit, also mounted on the frame, includes a drive unit and a cable. A guide assembly includes a sheave that guides the cable from the drive unit to the bottom mast section. Suitable means are connected to the frame for mechanically raising and lowering the mast into and out of the hole. As such, the mast according to the invention does not require assembly or disassembly at the beginning and end of each job. The mechanical means for raising and lowering the mast is preferably the powered winch unit.

Owner:CHARLES MACHINE WORKS

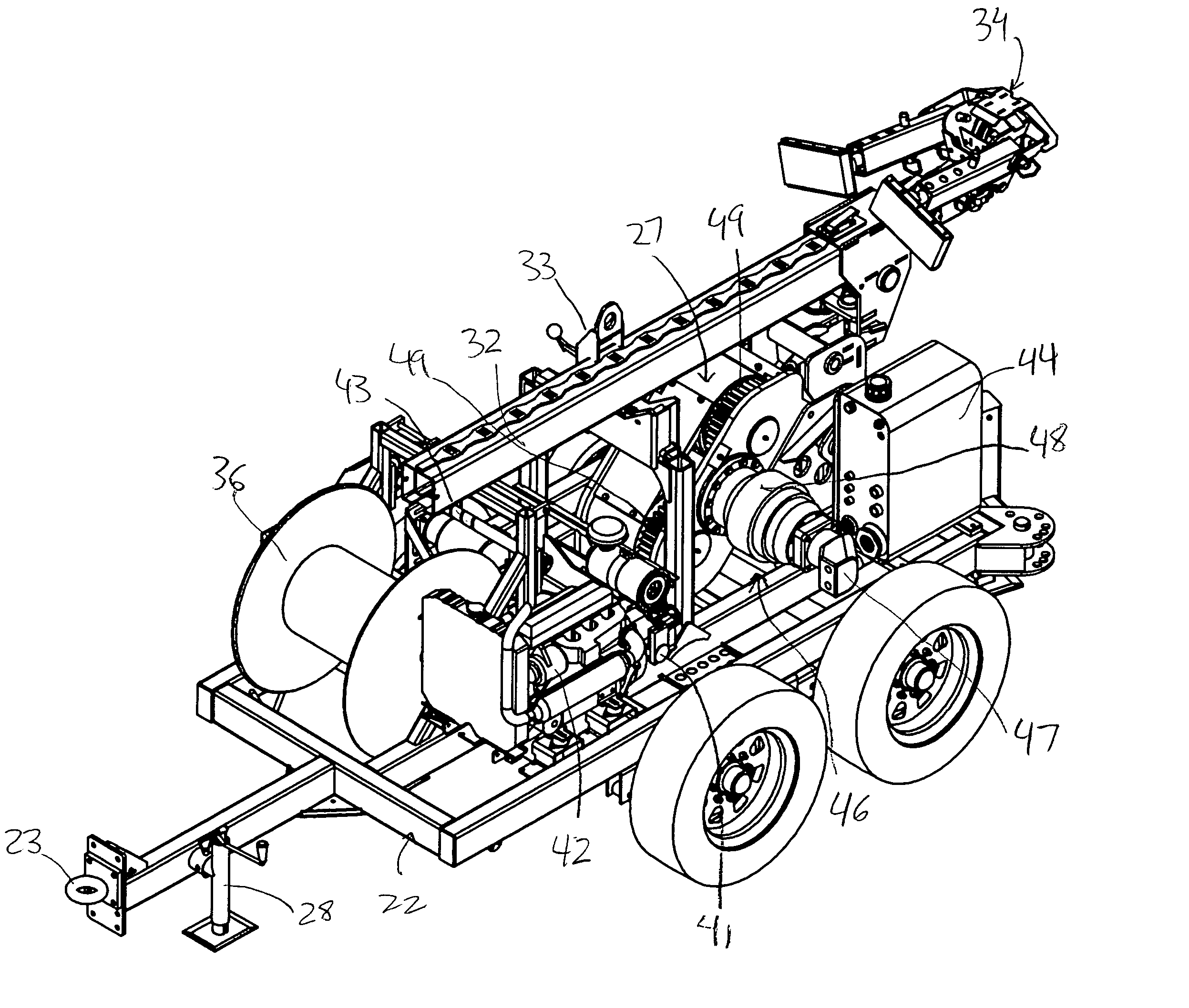

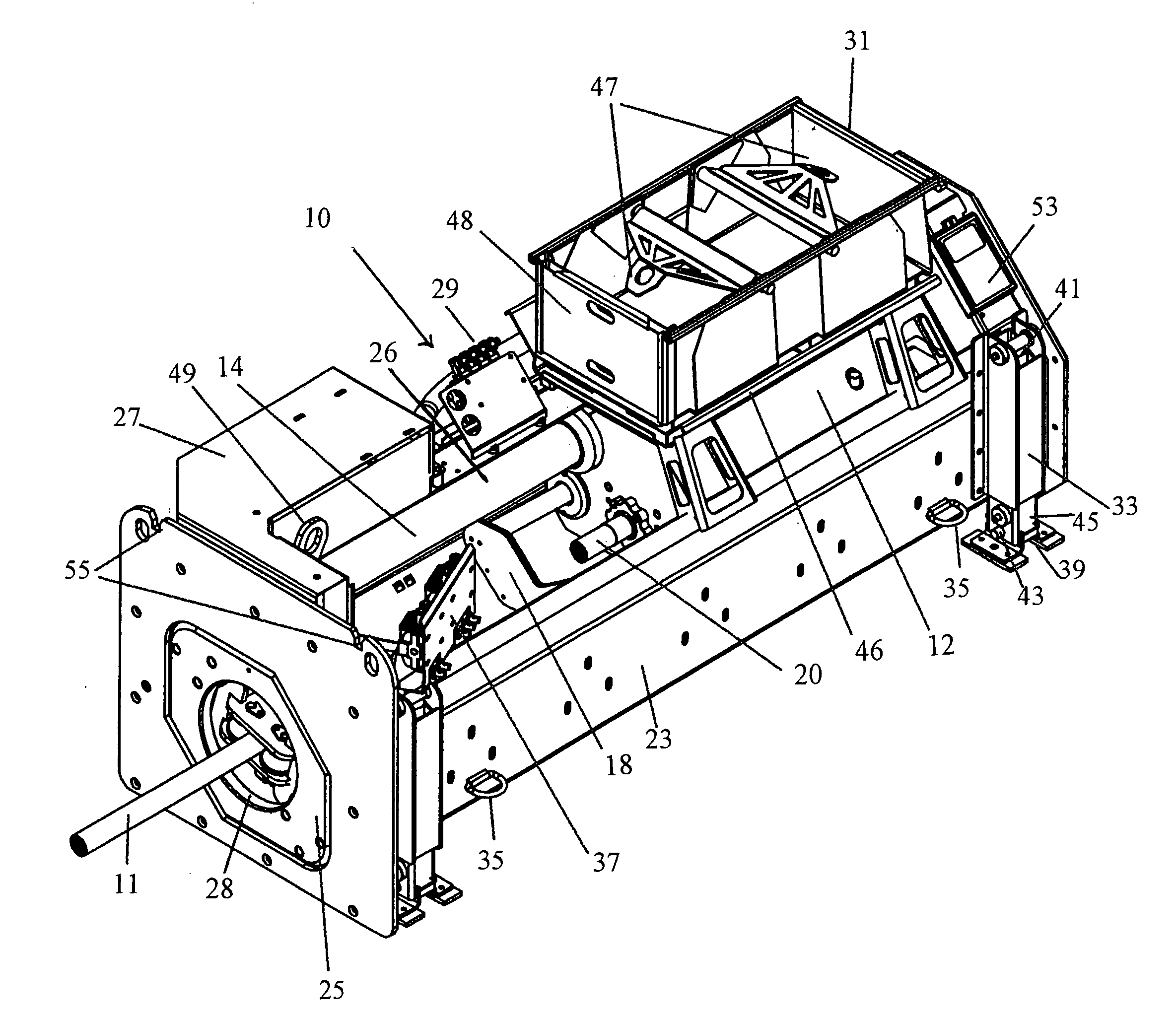

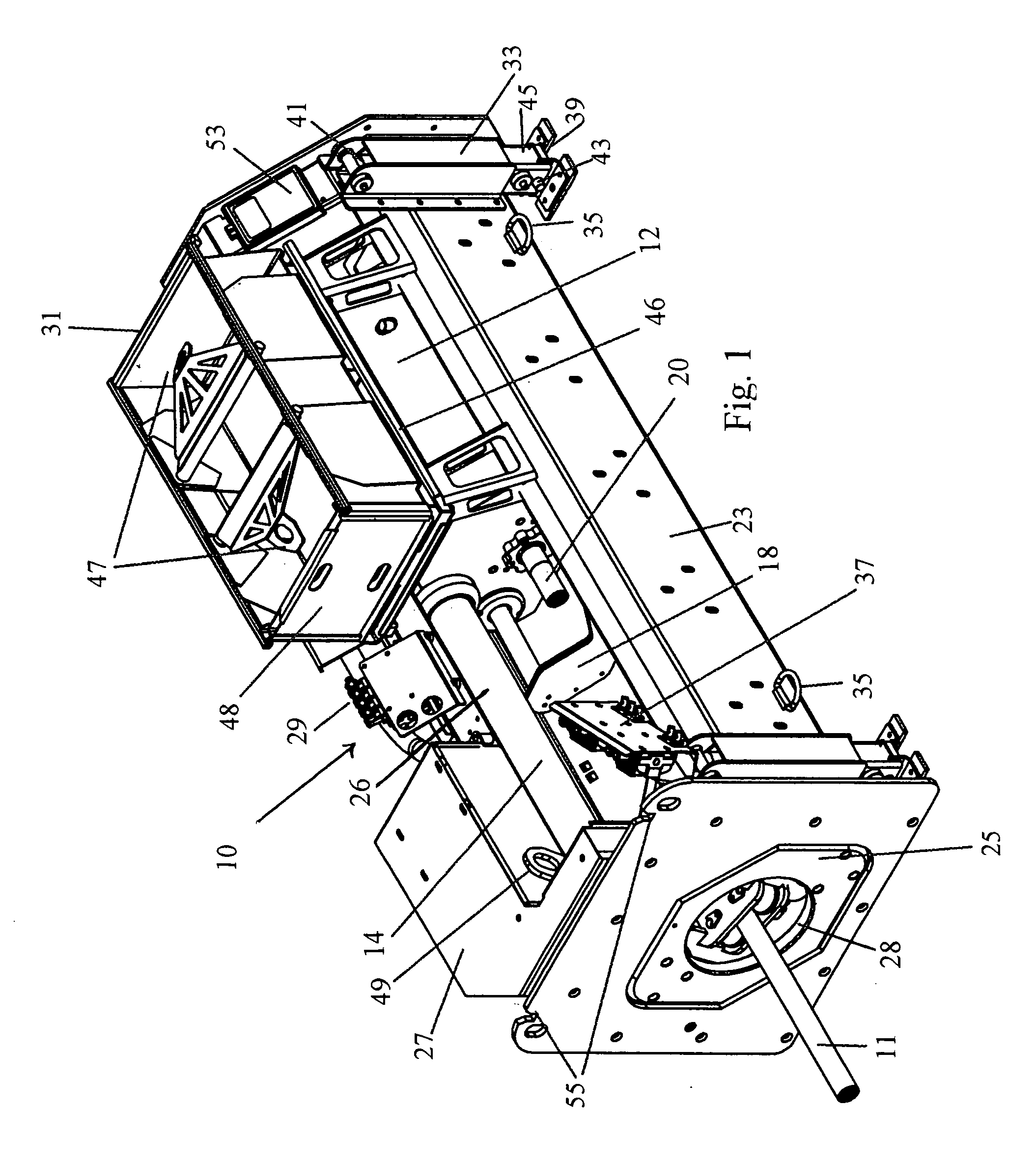

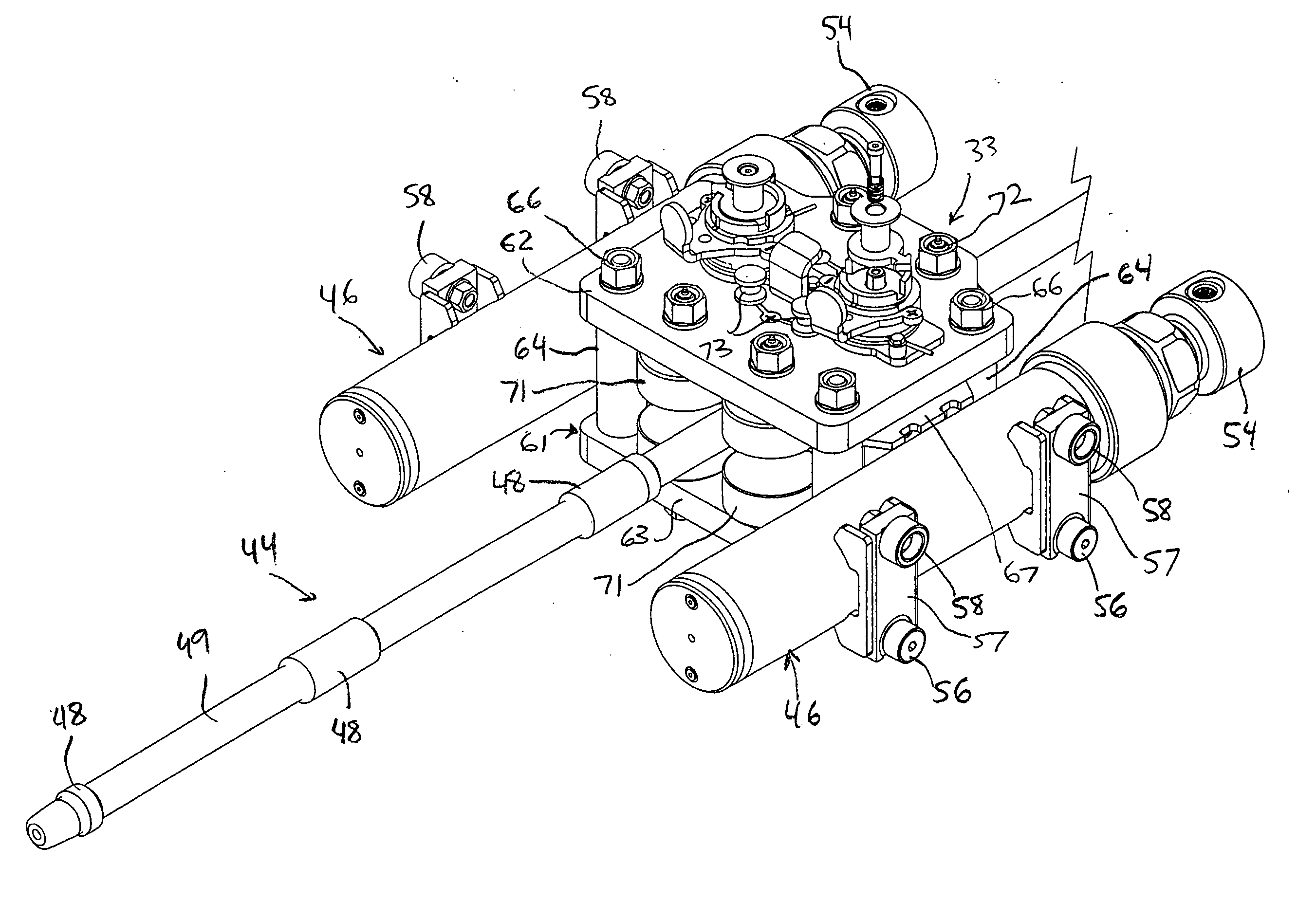

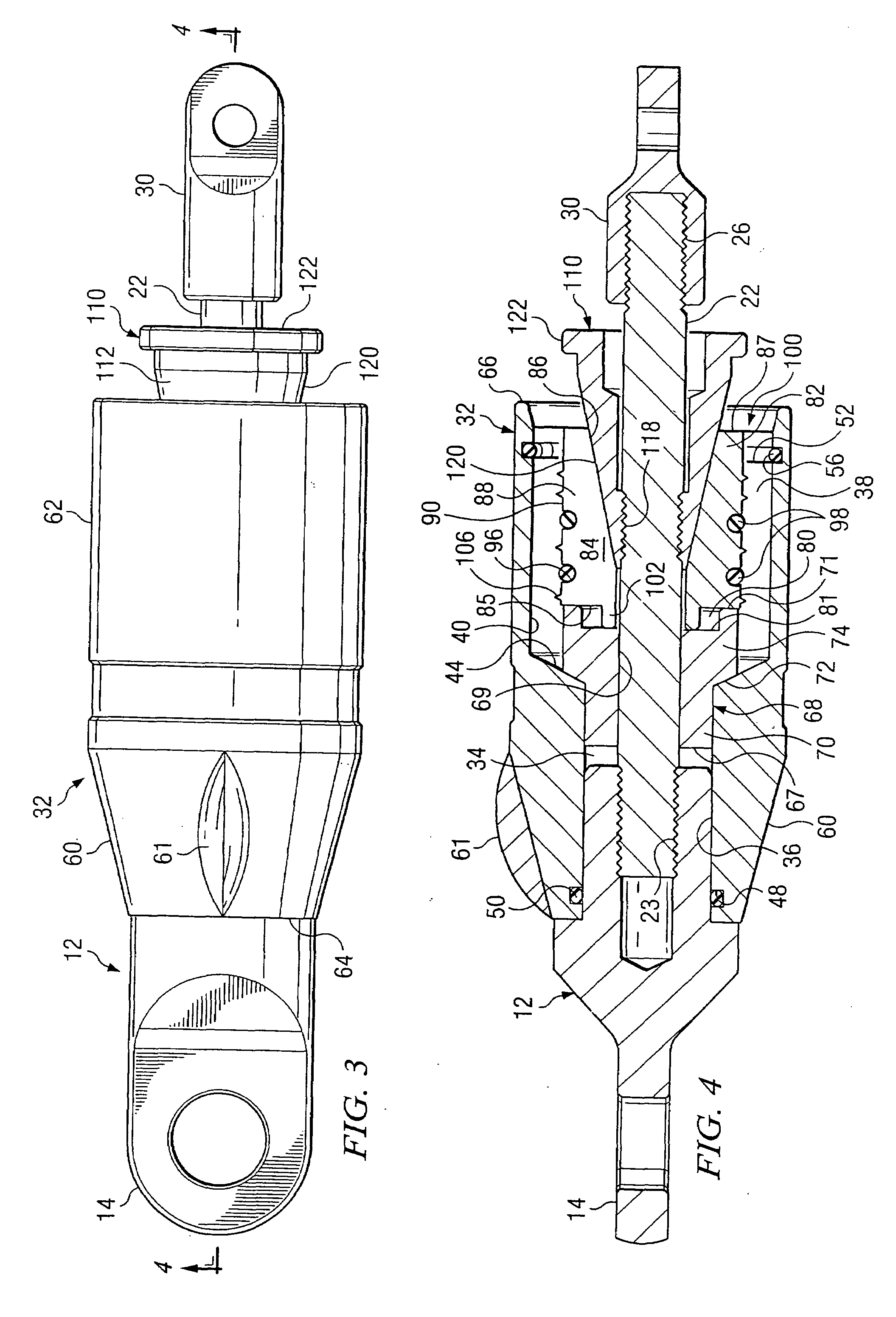

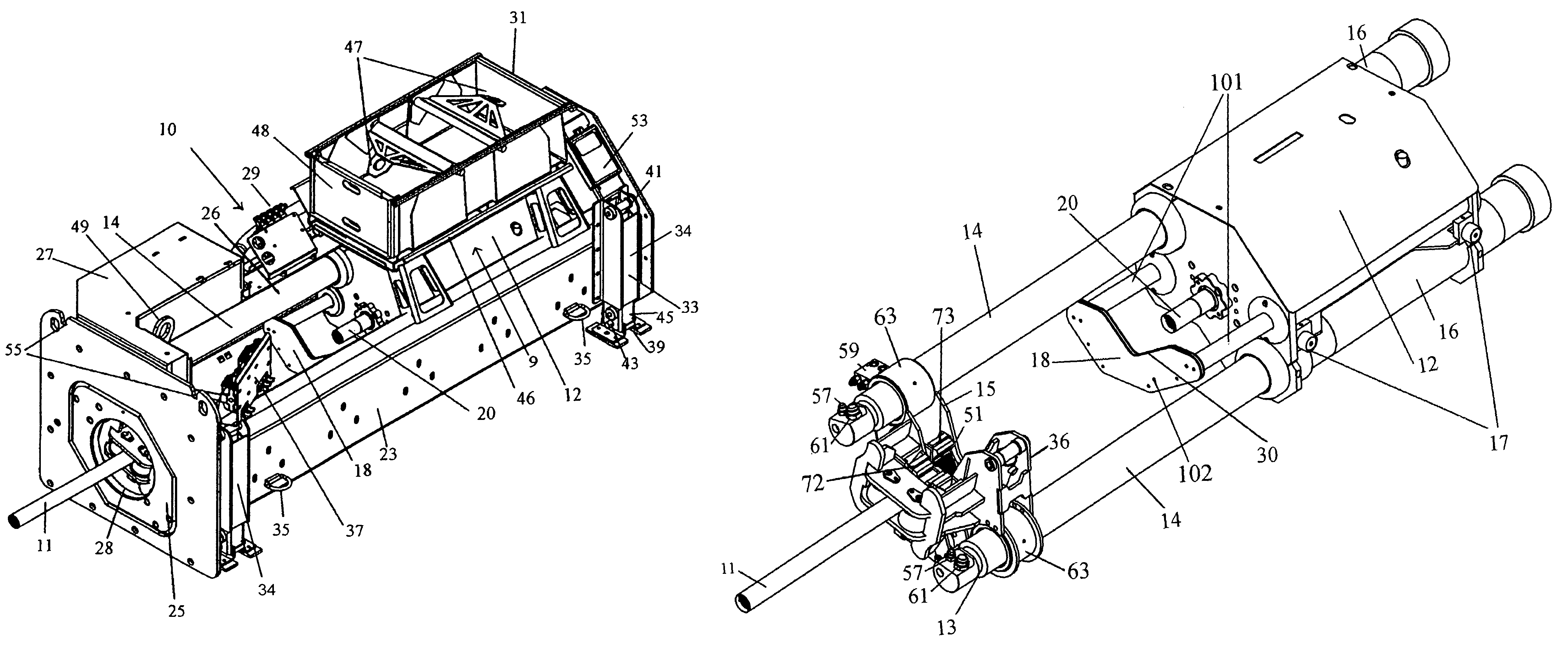

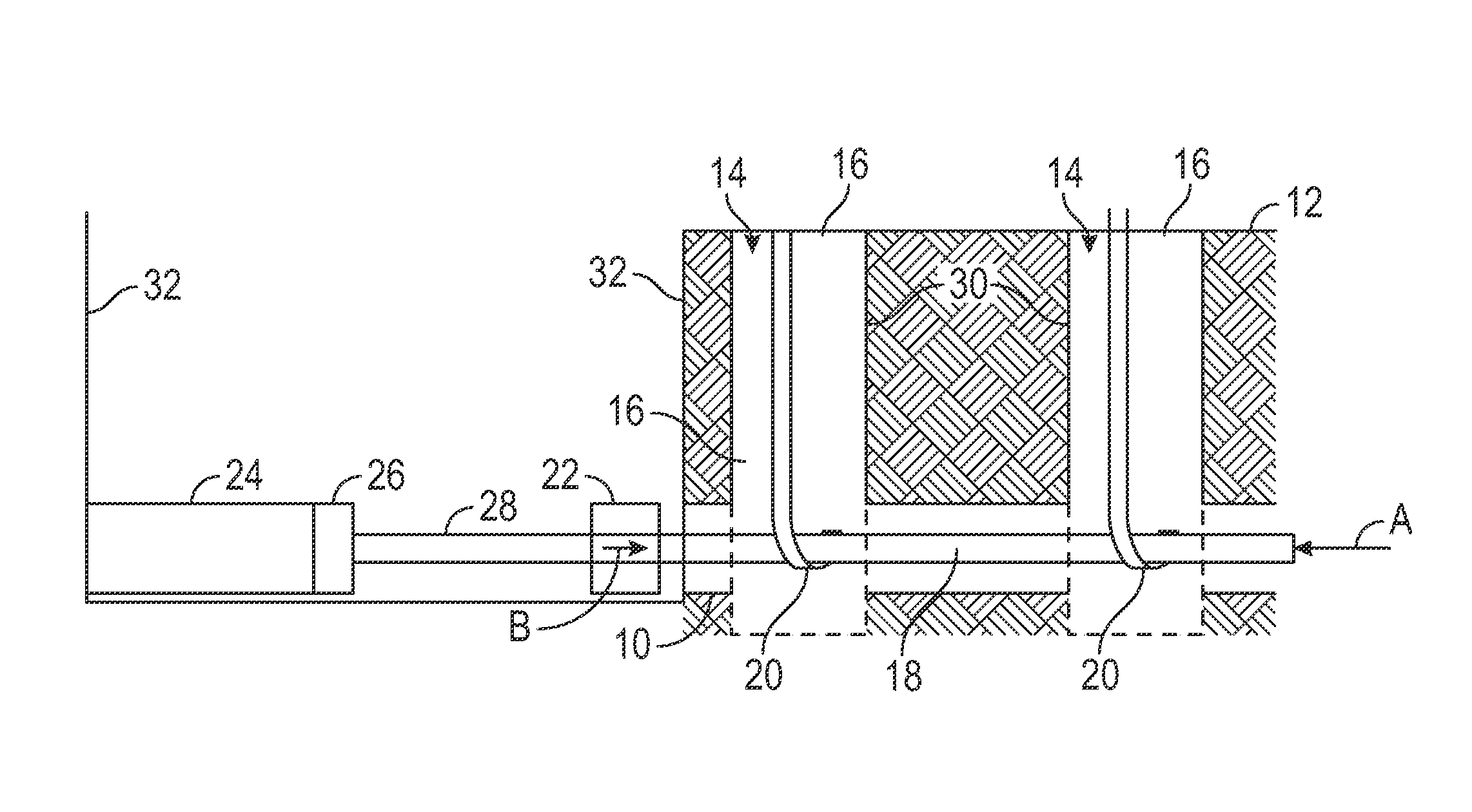

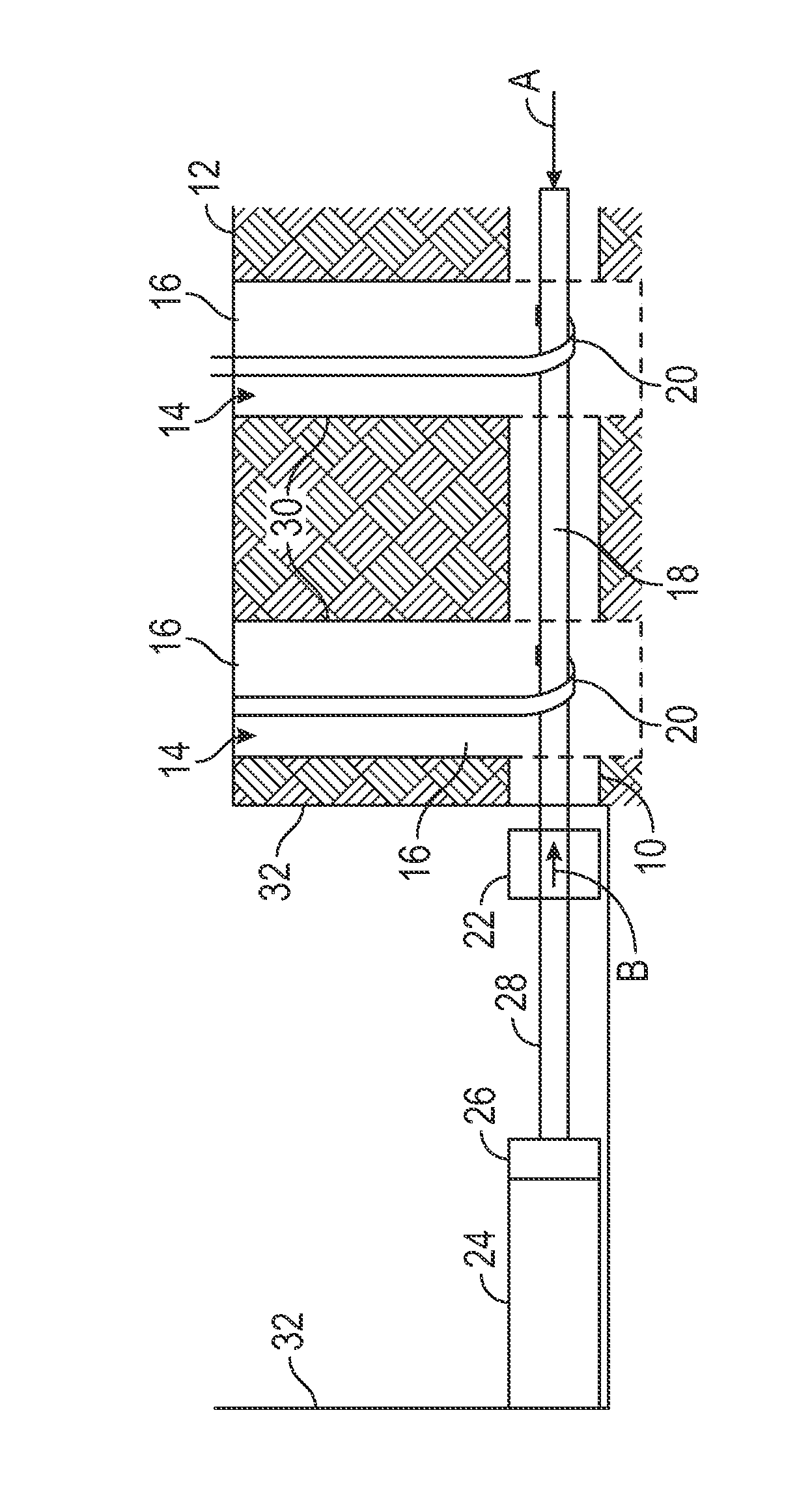

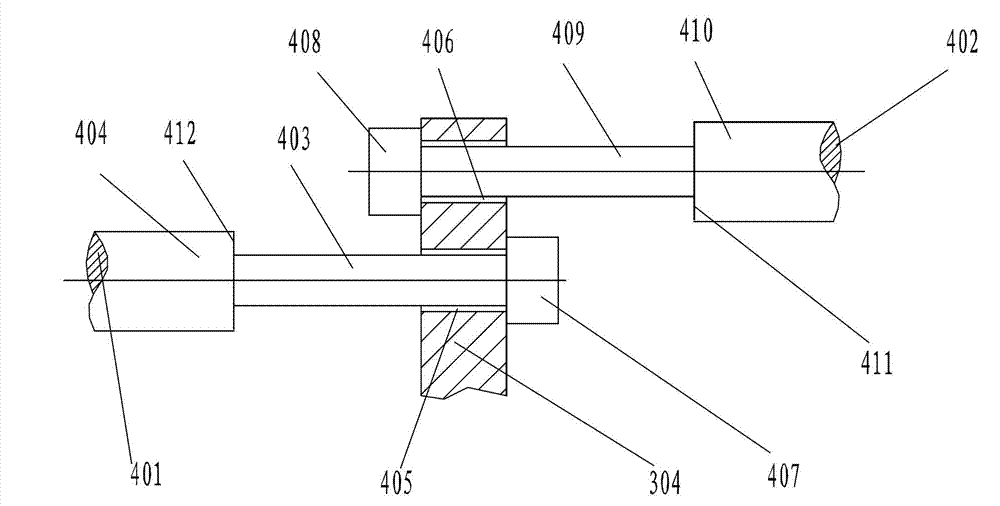

Rod pulling and pushing machine for pipe bursting

ActiveUS20060034666A1Control damagePipe laying and repairSoil-shifting machines/dredgersHydraulic cylinderPush and pull

A rod pushing and pulling machine includes at least one hydraulic cylinder having a front end thereof engagable with a reaction surface at an entry opening of a existing pipeline or borehole, a spindle assembly, and a dual vise assembly. The spindle assembly includes a frame, a spindle shaft rotatably mounted in the frame, a distal end of the spindle shaft being threaded for engagement with a mating thread of a rod, a drive system for rotating the spindle shaft in threading and unthreading directions, the spindle frame being secured to a rear end of the hydraulic cylinder for pushing or pulling of a rod string engaged to the spindle shaft upon extension or retraction of the hydraulic cylinder, and a support assembly for the spindle shaft. The support assembly includes a set of roller bearings rotatably supporting the spindle shaft, a radial flange on the spindle shaft, and a load flange secured to the spindle frame positioned to engage the radial flange, whereby the radial flange comes into engagement with the load flange during pulling operation to prevent rotation of the spindle shaft during pulling operation, and leaves engagement with the load flange during pushing operation so that the spindle shaft may rotate during pushing operation supported by the roller bearings. The dual vise assembly has two pairs of separately actuable jaws positioned to grip a rod nearest the spindle shaft and a rod adjacent the rod nearest the spindle shaft.

Owner:CHARLES MACHINE WORKS

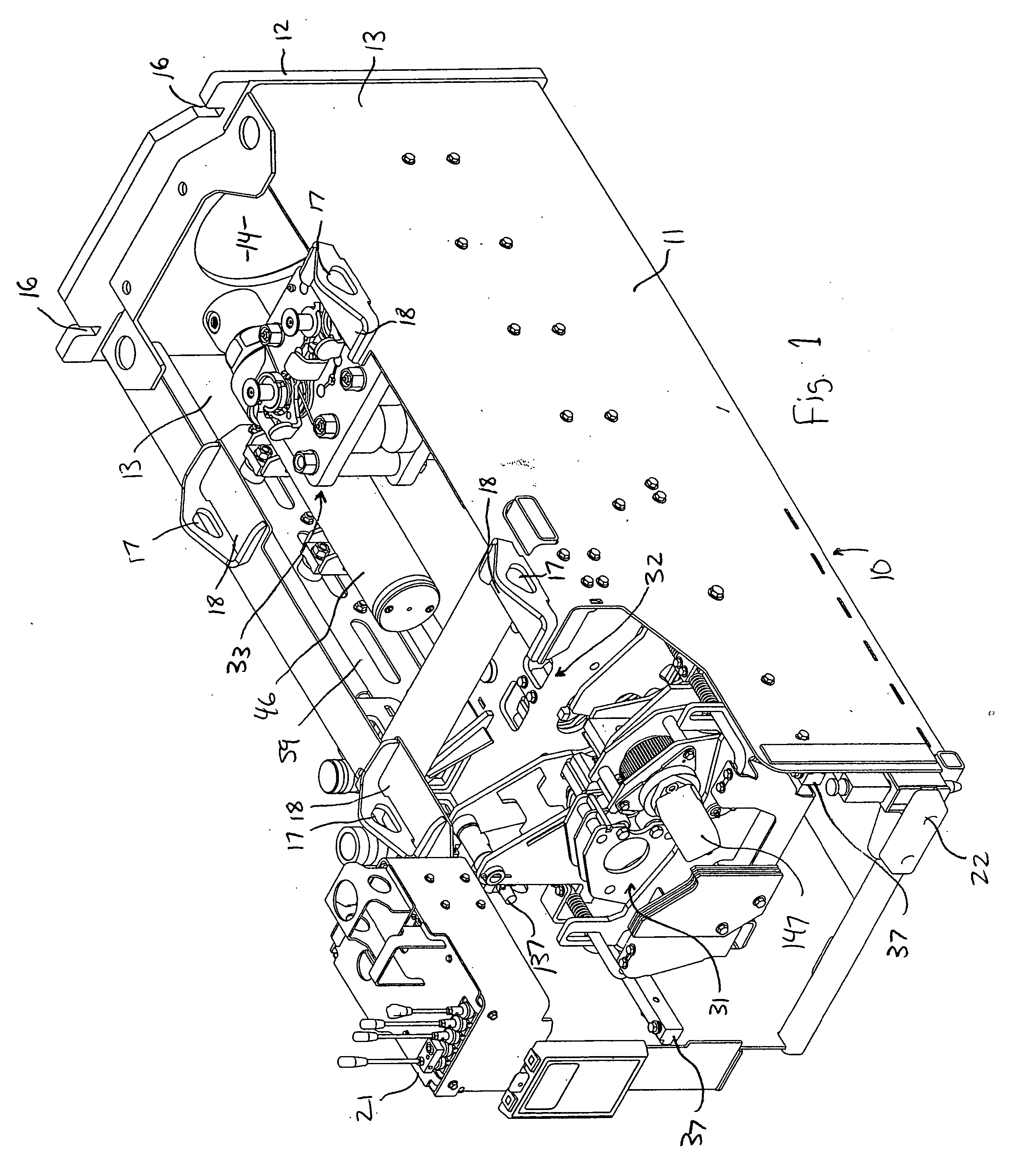

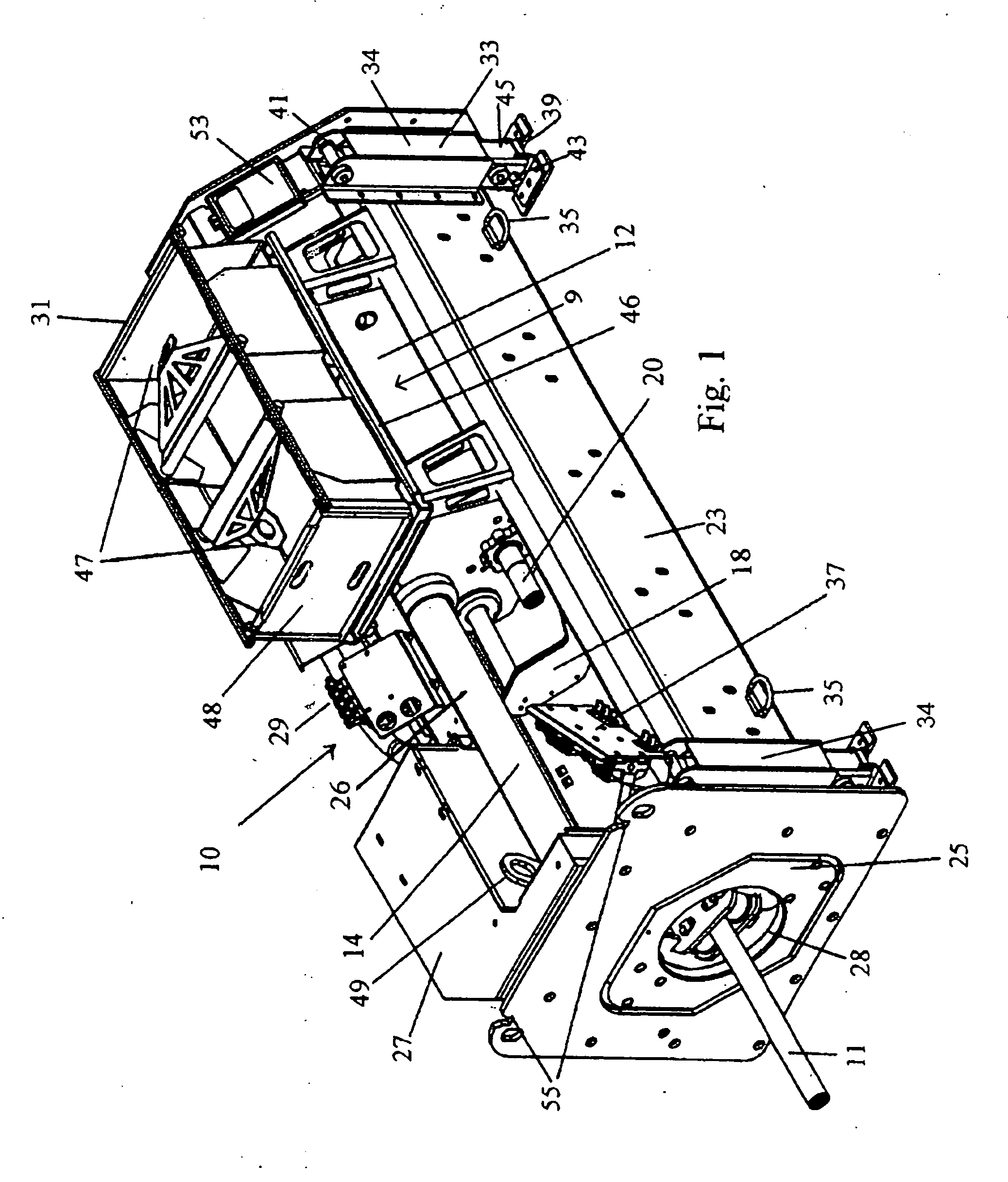

Rod pushing and pulling machine

ActiveUS20060193697A1Small sizeLow costPipe laying and repairSoil-shifting machines/dredgersPush and pullPipe bursting

The invention relates to an improved rod pushing and pulling machine suited for use in underground pipe bursting and replacement with a rod string wherein each rod has at least one radially enlarged upset thereon. The machine includes a housing or frame having a front wall with an access opening therein through which a rod string can extend. At least one main thrust cylinder is mounted on the housing. A movable carriage connected to the thrust cylinder engages the rod, drives it in a pushing or pulling direction, and then releases it for another stroke. Between strokes, a “bungee” vise holds the rod string so that it does not slip back in the opposite direction.

Owner:CHARLES MACHINE WORKS

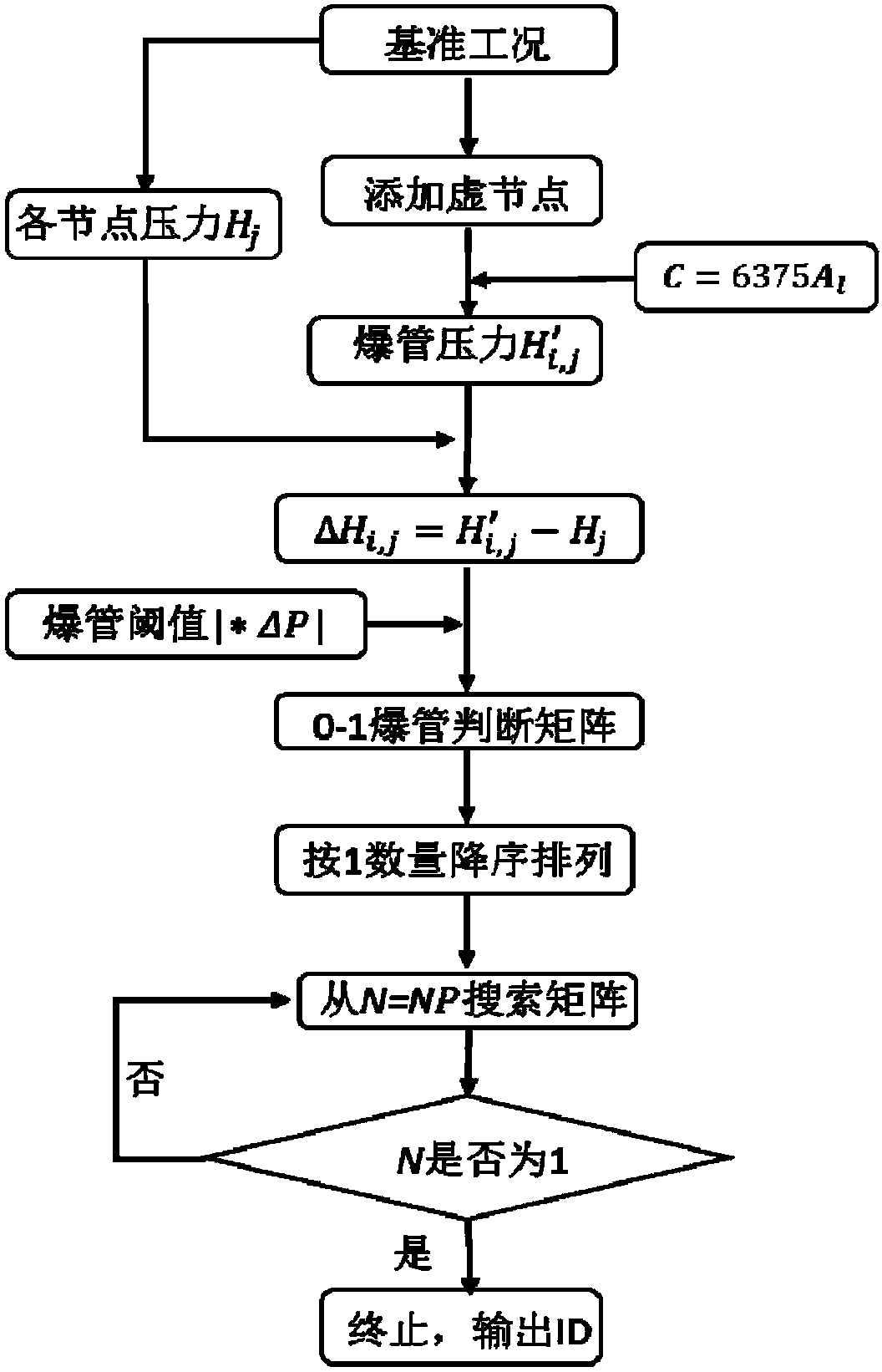

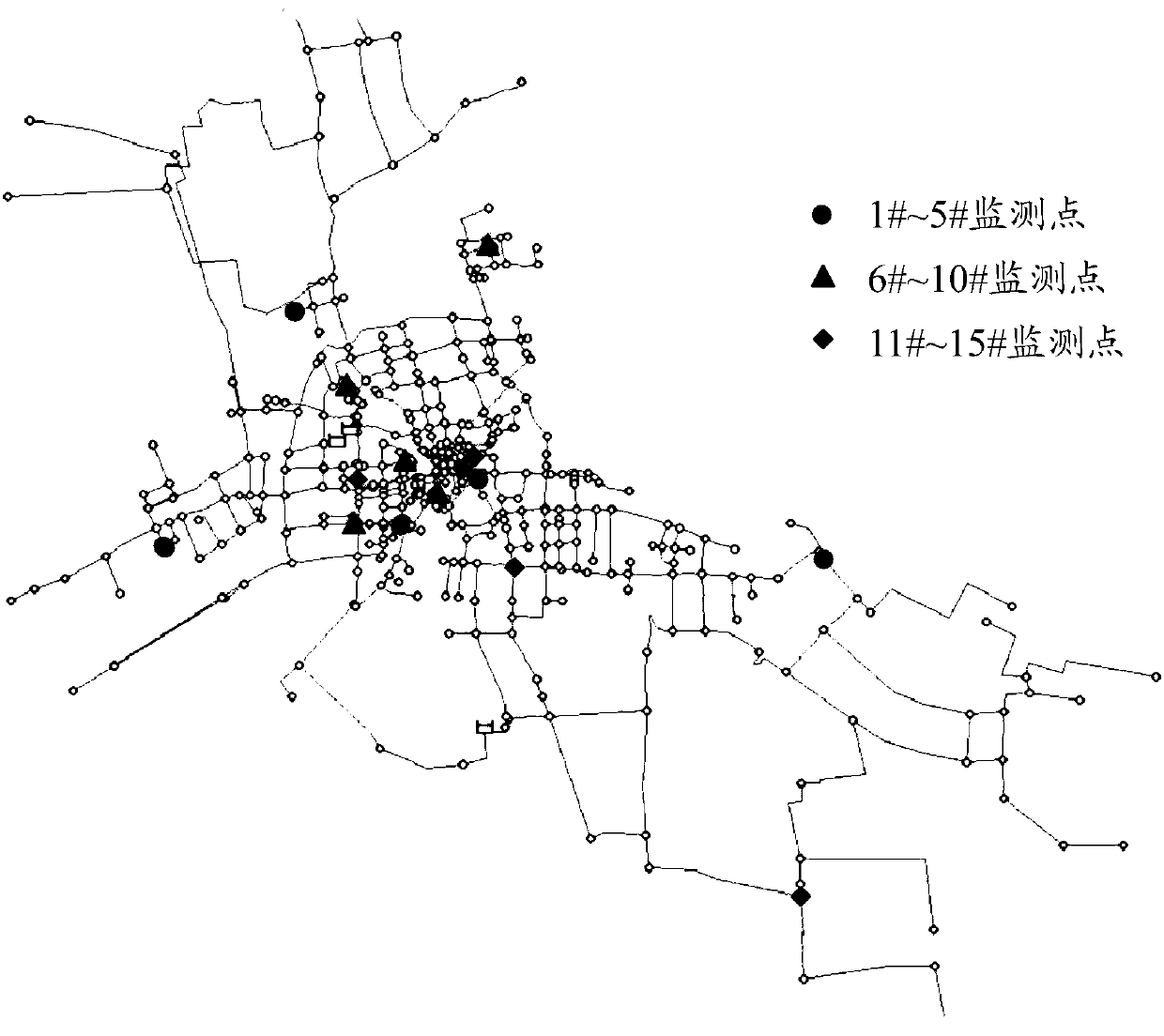

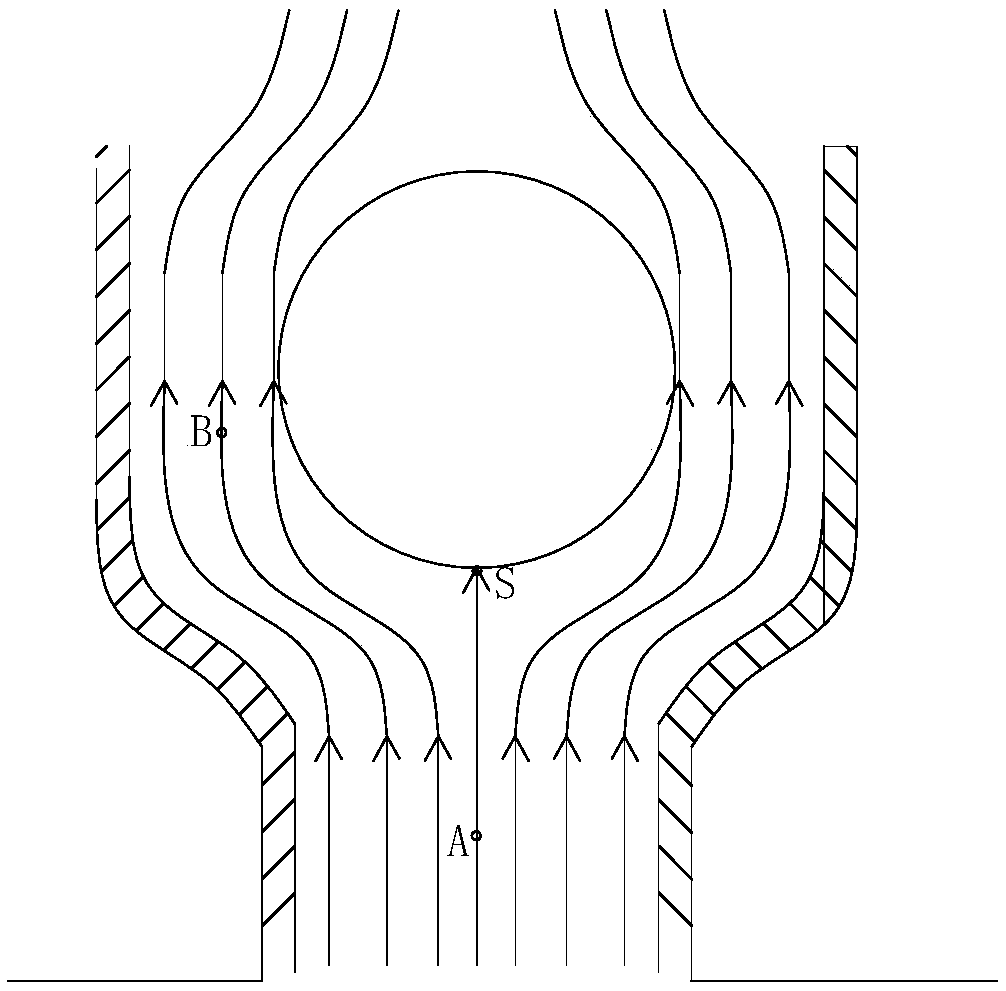

Pressure-measuring point optimizing and arranging method serving water supply pipe network pipe-bursting monitoring

ActiveCN108332059AOptimize layout methodImprove accuracyForecastingPipeline systemsPipe burstingJet flow

The invention discloses a pressure-measuring point optimizing and arranging method serving water supply pipe network pipe-bursting monitoring. The pressure-measuring point optimizing and arranging method comprises the steps that (1) a datum working condition is selected, and the pressure values of all nodes are calculated based on monitoring data; (2) a pipe bursting model is established, virtualnodes are sequentially added in the middles of all pipe sections, pipe bursting is simulated by adopting a jet flow mode, the jet flow coefficient C value is input, and the pressure values of the corresponding nodes are sequentially calculated after pipe bursting occurs on all the pipe sections; (3) the pressure change value is calculated, a pressure change matrix is obtained, a 0-1 pipe burstingjudging matrix is obtained by comparing the pressure change matrix with the pipe bursting threshold, and the 0-1 pipe bursting judging matrix is subjected to order descending according to rows and sorting to obtain an order descending matrix; (4) the order descending matrix is retrieved from large to small according to a set principle, if the condition is met, a pressure monitoring point is newlyadded; and (5) when the situation that the monitoring point only can monitor a newly-added pipe bursting pipe section is searched, calculation is terminated, the pressure monitoring point ID is output, otherwise, returning to (4) for continuing to calculate is executed, and a new monitoring point is searched.

Owner:ZHEJIANG UNIV

Winch with telescoping mast

A portable winch suitable for use in underground pipe bursting and replacement includes a mounting frame positionable at a top opening of a hole such as a receiving pit or manhole. A telescoping mast having a series of nested, top and bottom mast sections is mounted on the frame. A powered winch unit, also mounted on the frame, includes a drive unit and a cable. A guide assembly includes a sheave that guides the cable from the drive unit to the bottom mast section. Suitable means are connected to the frame for mechanically raising and lowering the mast into and out of the hole. As such, the mast according to the invention does not require assembly or disassembly at the beginning and end of each job. The mechanical means for raising and lowering the mast is preferably the powered winch unit.

Owner:CHARLES MACHINE WORKS

Pipe bursting and replacement apparatus and method

InactiveUS20080181728A1Limit magnitudeTensile strength is not compromisedPipe elementsDrilling machines and methodsPipe burstingEngineering

A pipe bursting and pulling apparatus for use in replacing horizontal underground pipes including a cylindrical body with a tapered forward section including means for attaching one of a cable, rod, rope or chain, the cylindrical body including an annular inner wall defining a longitudinally extending, rearwardly opening recess, a shaft passing through the recess, a plurality of gripping jaws, at least one of the jaws including a pipe gripping tooth extending radially outward relative to a longitudinal axis of the shaft, a tapered expander connected to the shaft and configured to fit between the jaws, the expander forcing the jaws outward to clamp a replacement pipe inserted into the cylindrical body between the jaws and the inner wall when pulled by the shaft, a stop, the stop limiting the forward travel of the expander and preventing outward radial travel of the jaws after the tooth has been engaged in the wall of the replacement pipe whereby the tooth penetrates to a depth of no more than 35% of the thickness of the wall of the replacement pipe.

Owner:EARTH TOOL L L C

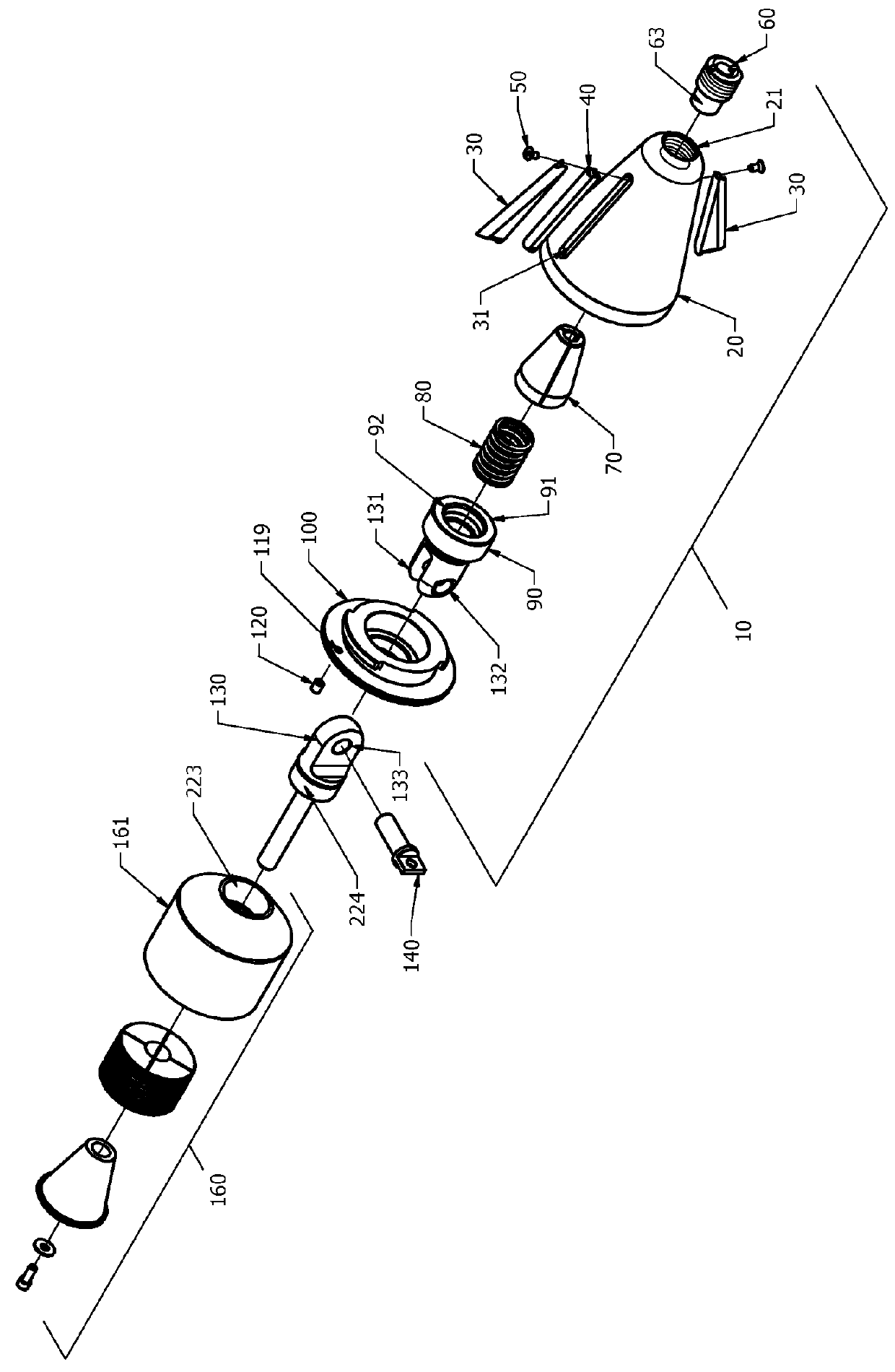

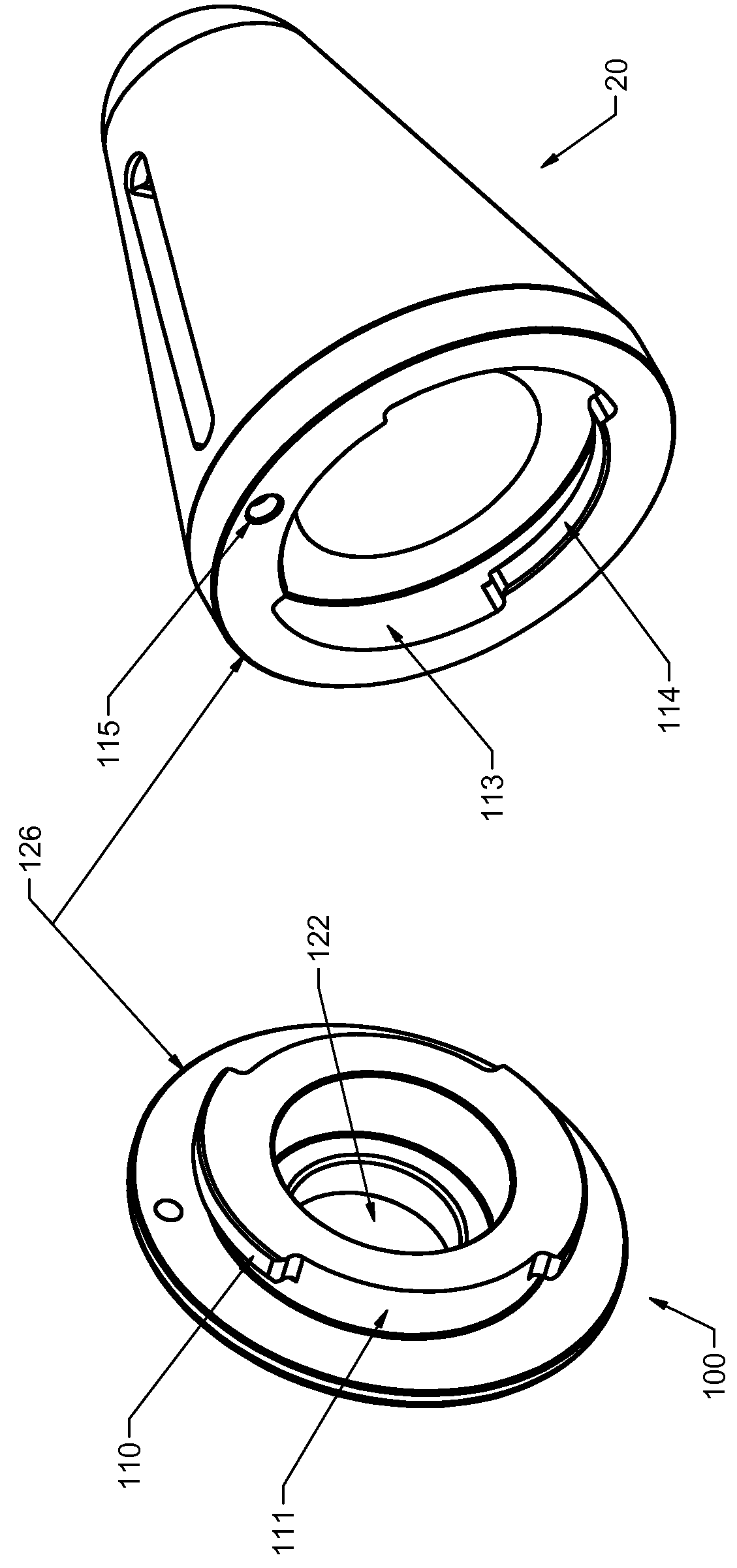

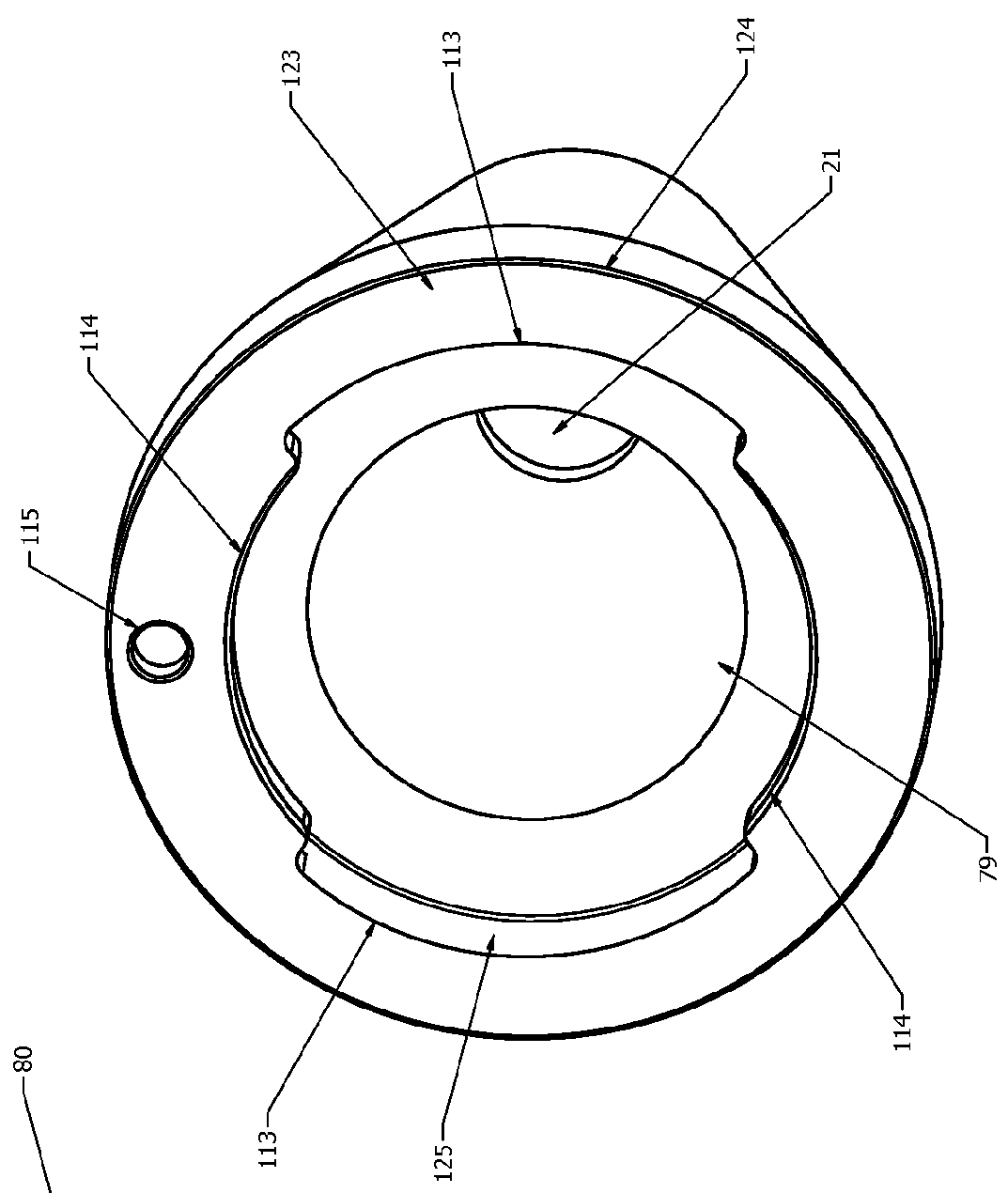

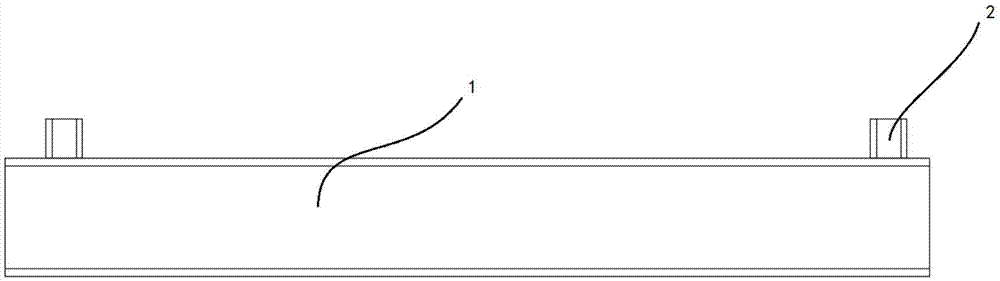

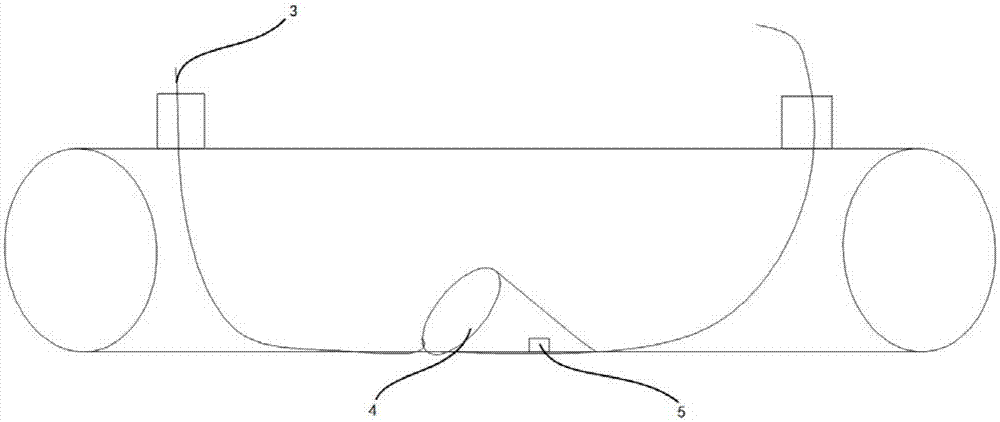

Pipe bursting apparatus

ActiveUS8702349B2Light weightLow costPipe laying and repairSoil-shifting machines/dredgersHydraulic cylinderPipe bursting

Owner:TRIC TOOLS INC

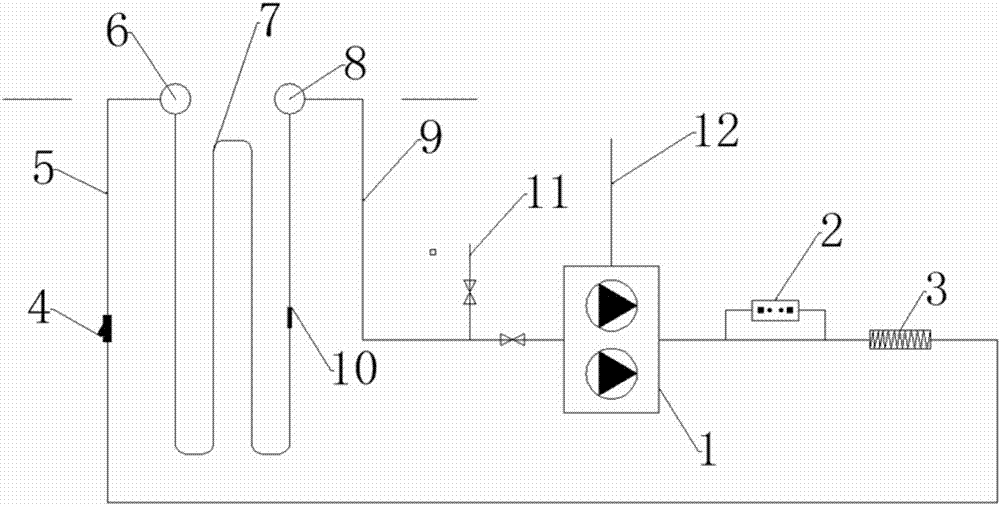

Chemical cleaning system and method for oxide skin of power station superheater or reheater

The invention relates to a chemical cleaning system and method for the oxide skin of a power station superheater or reheater. The system comprises a cleaning power platform, wherein the cleaning power platform is connected with the system inlet of the power station superheater or reheater through a liquid inlet pipeline, and is connected with the system outlet of the power station superheater or reheater through a liquid returning pipeline, so that circular cleaning is realized for the power station superheater or reheater; corrosion on-line monitoring equipment and a heater are arranged on the liquid inlet pipeline; the corrosion on-line monitoring equipment is used for monitoring the corrosion rate of the superheater or reheater in real time during a chemical cleaning period, so that excessive corrosion of the superheater or reheater is prevented; the heater is used for heating cleaning liquid; dead-end pipe on-line monitoring equipment which is used for monitoring the pipe flowing state of the superheater or reheater in real time is arranged in the pipe of the power station superheater or reheater; and the invention further discloses the cleaning method. By using the system and method disclosed by the invention, the oxide skin of the power station superheater or reheater is completely removed; pipe bursting risk is lowered during the operation period of the power station superheater or reheater is lowered; and meanwhile, the heat conduction efficiency of the power station superheater or reheater is improved, so that safe and economical operation of a power station is ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

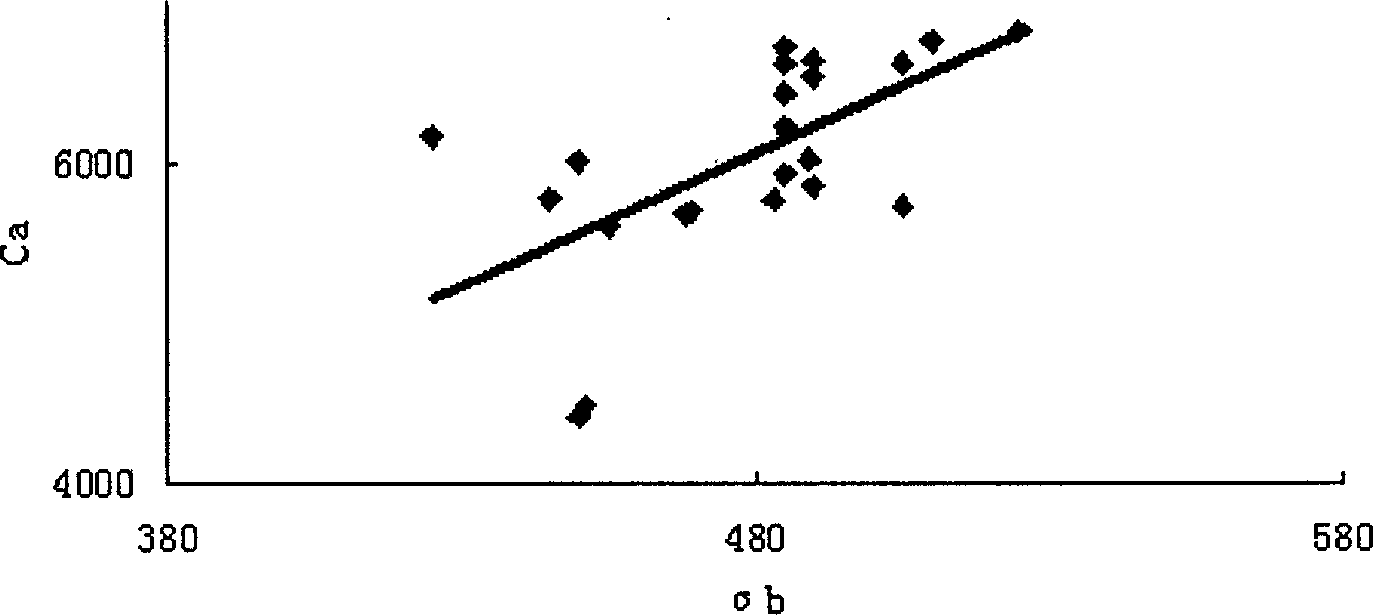

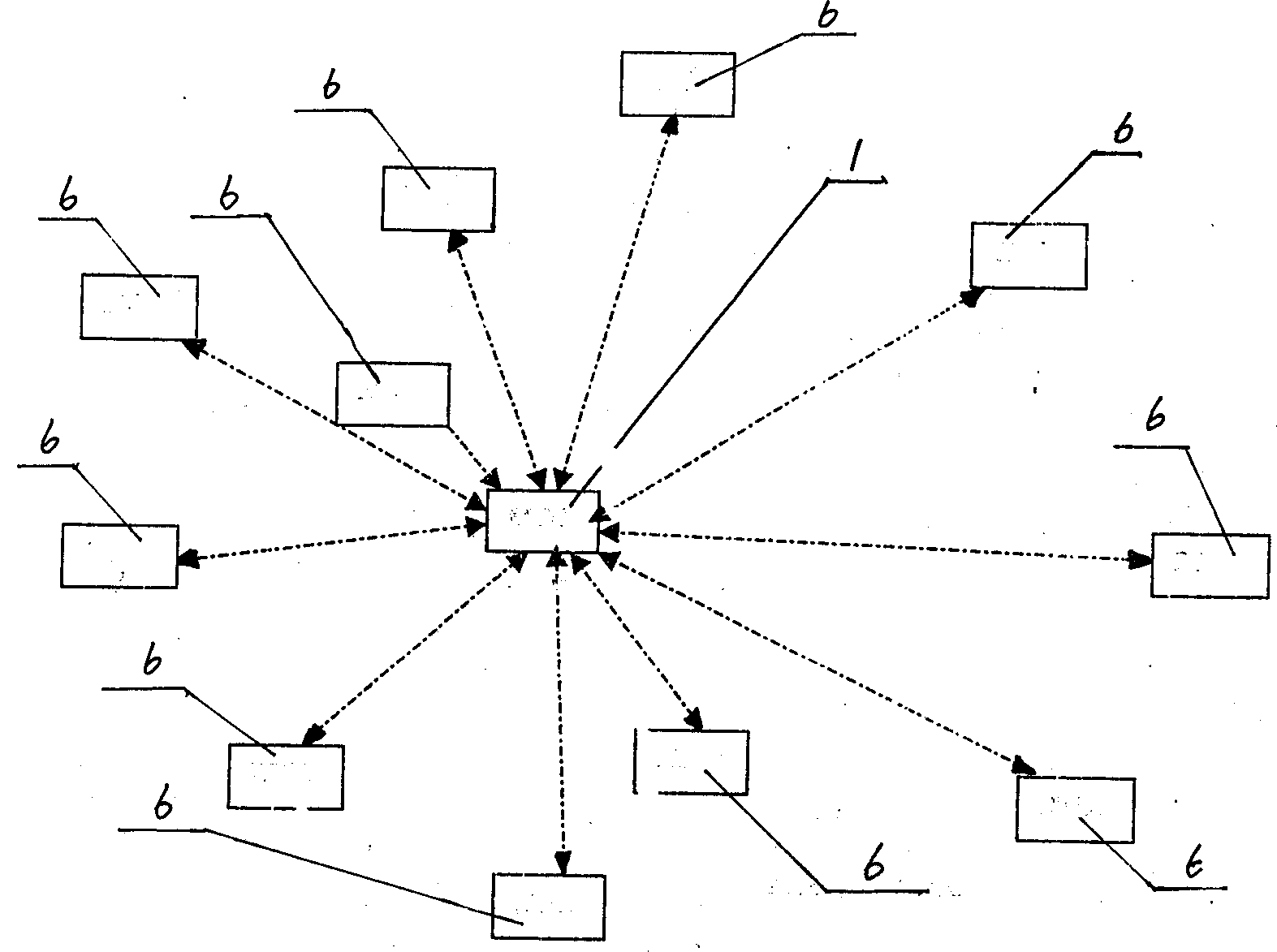

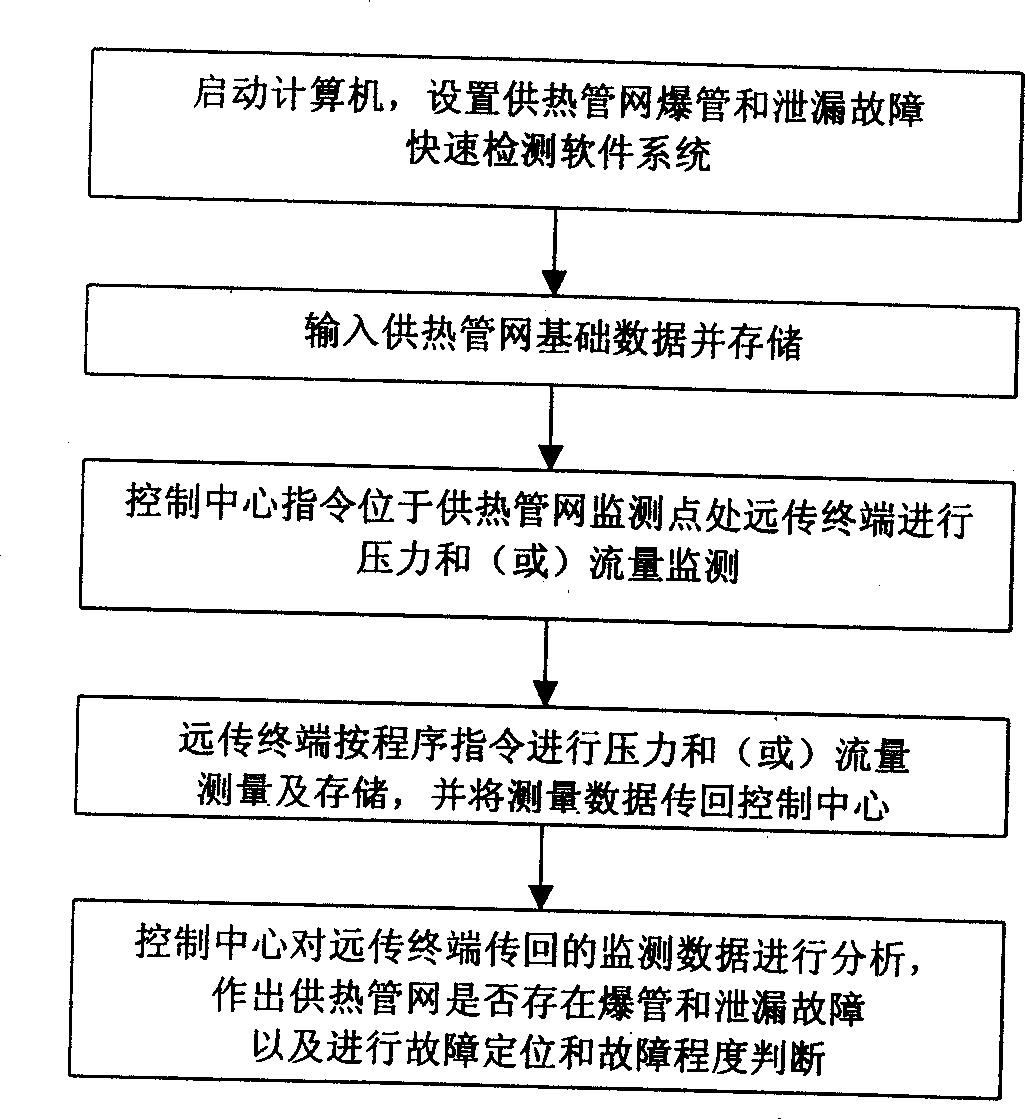

Heat-supply network failure quick detection system

InactiveCN1367374APrecise positioningFast and accurate online detectionFluid-tightness measurement using fluid/vacuumModem deviceData set

The heat-supplying pipe network fault quick detecting system is characterized by that it is composed of a control centre formed from computer, multichannel drive receive, modem and data-set which areconnected sequentially and a remote transmission terminal formed from terminal data-set, terminal dmodem, terminal multichannel drive receiver, microprocessor and terminal A / D converter which are sequentially connected, in which the terminal A / D converter is respectively connected with heat supplying pressure sensor and heat-supplying flow rate sensor. Said computer memory contains software program system of pipe-bursting and leakage fault of heat-supplying pipe network. Said ivnention utilizes the correspondent relationship of heat-supplying pressure change between monitoring point and non-monitoring point to detect fault.

Owner:TIANJIN UNIV

Pressure resistance valve for nuclear grade air passage

ActiveCN102359603ASo as not to damageSimple structureOperating means/releasing devices for valvesLift valveNuclear gradeElectricity

Owner:SHIJIAZHUANG NO 1 VALVE FACTORY

Realizing method for improving exhaust capacity of air inlet and exhaust valves

InactiveCN109163101AImprove intake and exhaust performanceExtended service lifeValve members for absorbing fluid energyDesign optimisation/simulationPipe burstingViewpoints

The invention discloses a realizing method for improving the exhaust capacity of air inlet and exhaust valves. On the basis of establishment of streamline mathematical models of the air inlet and exhaust valves, as for a water supplying system, the theoretical exhaust quantity is calculated, the types and specifications of the conventional air inlet and exhaust valves are determined, and the exhaust flow coefficients are calculated; and the same specification of the section-variable air inlet and exhaust valves with exhaust flow channels being in a streamline shape are designed, the actual exhaust quantity and the actual exhaust flow coefficients are tested, recorded and calculated on an exhaust performance test platform. Experiments prove that the exhaust capacity of the section-variableair inlet and exhaust valves is obviously improved, thus under the premise of meeting the exhaust requirements, the diameter and the number of the air inlet and exhaust valves can be decreased, investment is lowered, the anti-cavitation performance of inner components is improved, the service life is prolonged, and the pipe-bursting accident caused by improper type selection of the air inlet and exhaust valves is avoided; and the viewpoint that the internal and external pressure differences of the air inlet and exhaust valves are different, and thus the exhaust flow coefficients of the air inlet and exhaust valves are also different is put forward and verified for the first time, the basis is provided for improvement of type selection standards and formulation of production technical standards in the water supply industry in China, and the realizing method is of great significance to ensure safe operation of pipelines.

Owner:TAIYUAN UNIV OF TECH

Rod pulling and pushing machine for pipe bursting

ActiveUS7140806B2Control damagePipe laying and repairSoil-shifting machines/dredgersPush and pullHydraulic cylinder

A rod pushing and pulling machine includes at least one hydraulic cylinder having a front end thereof engagable with a reaction surface at an entry opening of a existing pipeline or borehole, a spindle assembly, and a dual vise assembly. The spindle assembly includes a frame, a spindle shaft rotatably mounted in the frame, a distal end of the spindle shaft being threaded for engagement with a mating thread of a rod, a drive system for rotating the spindle shaft in threading and unthreading directions, the spindle frame being secured to a rear end of the hydraulic cylinder for pushing or pulling of a rod string engaged to the spindle shaft upon extension or retraction of the hydraulic cylinder, and a support assembly for the spindle shaft. The support assembly includes a set of roller bearings rotatably supporting the spindle shaft, a radial flange on the spindle shaft, and a load flange secured to the spindle frame positioned to engage the radial flange, whereby the radial flange comes into engagement with the load flange during pulling operation to prevent rotation of the spindle shaft during pulling operation, and leaves engagement with the load flange during pushing operation so that the spindle shaft may rotate during pushing operation supported by the roller bearings. The dual vise assembly has two pairs of separately actuable jaws positioned to grip a rod nearest the spindle shaft and a rod adjacent the rod nearest the spindle shaft.

Owner:CHARLES MACHINE WORKS

Production apparatus and oxidative combustion method of organic tritium carbon sample

InactiveCN106969953ALow oxygen content in the combustion zonePrevent open flames from burningChemical analysis using combustionPreparing sample for investigationPipe burstingCombustion

The present invention discloses a preparation apparatus and an oxidative combustion method of an organic tritium carbon sample. The preparation apparatus comprises a reaction working pipe, an oxidative combustion furnace and an absorption device, wherein the reaction working pipe comprises a pipe body, a first gas inlet hole, a second gas inlet hole and a gas outlet hole, a heating zone is arranged in the oxidative combustion furnace and is sequentially divided into a catalytic reaction zone, a sample stacking zone and a sample recovery zone, the lower portions are respectively provided with a temperature controller, the reaction working pipe is horizontally arranged in the oxidative combustion furnace, the pipe body penetrates through the heating zone, the gas outlet hole is connected to the absorption device, the absorption device comprises a collection bottle and a low temperature cold trap, the collection bottle is arranged in the low temperature cold trap, and the gas outlet hole is connected to the collection bottle. According to the present invention, the structure is simple, the problems of open fire production caused by combustion, quartz pipe bursting, incomplete sample combustion and the like during the sample treatment process are effectively prevented, the generated water has the clear color, the sample treatment capacity is high, the sample absorption rate of the combustible materials such as tritium and carbon-14 is substantially improved, and the sample measurement requirements in the modern industry are met.

Owner:SHANGHAI HAPSTAR MECHANICAL & ELECTRICAL EQUIP

Rod pulling and pushing machine for pipe bursting

ActiveUS20070071558A1Control damagePipe laying and repairSoil-shifting machines/dredgersHydraulic cylinderPush and pull

A rod pushing and pulling machine includes at least one hydraulic cylinder having a front end thereof engagable with a reaction surface at an entry opening of a existing pipeline or borehole, a spindle assembly, and a dual vise assembly. The spindle assembly includes a frame, a spindle shaft rotatably mounted in the frame, a distal end of the spindle shaft being threaded for engagement with a mating thread of a rod, a drive system for rotating the spindle shaft in threading and unthreading directions, the spindle frame being secured to a rear end of the hydraulic cylinder for pushing or pulling of a rod string engaged to the spindle shaft upon extension or retraction of the hydraulic cylinder, and a support assembly for the spindle shaft. The support assembly includes a set of roller bearings rotatably supporting the spindle shaft, a radial flange on the spindle shaft, and a load flange secured to the spindle frame positioned to engage the radial flange, whereby the radial flange comes into engagement with the load flange during pulling operation to prevent rotation of the spindle shaft during pulling operation, and leaves engagement with the load flange during pushing operation so that the spindle shaft may rotate during pushing operation supported by the roller bearings. The dual vise assembly has two pairs of separately actuable jaws positioned to grip a rod nearest the spindle shaft and a rod adjacent the rod nearest the spindle shaft.

Owner:CHARLES MACHINE WORKS

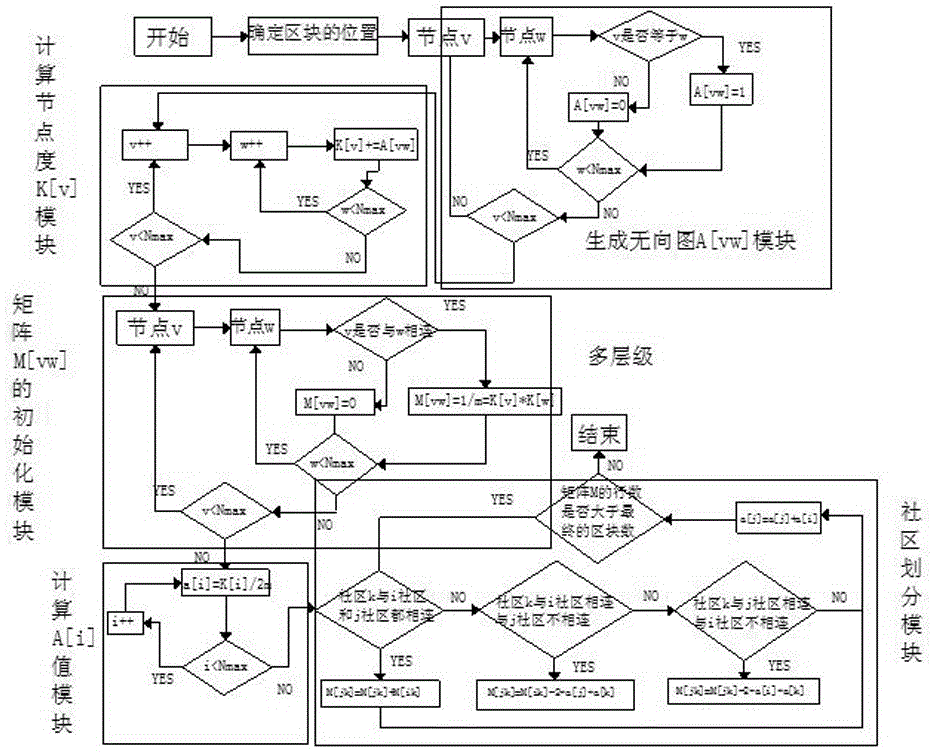

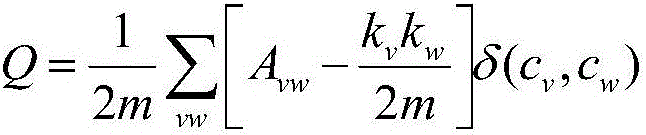

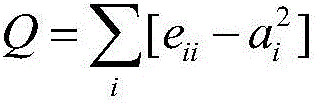

Automatic multi-level zoning method for water supply pipe network

InactiveCN106088212ABalance water supply pressureReduce squibWater supply installationPipe burstingWater quality

The invention discloses an automatic multi-level zoning method for a water supply pipe network. The method comprises the steps: firstly, partitioning a subzone system, wherein a water supply system is composed of a plurality of units, a zone which is directly connected with water tanks and water pumps is called a first-level subzone system, multi-level subzone systems are partitioned based on the first-level subzone system, and each subzone serves as a node; carrying out calculation by an evaluation function of an automatic multi-level zoning algorithm, and gradually merging the quantity of the subzones from more to less, wherein an N-level zone appears when a certain stage is merged, and a larger-scale N-1-level zone appears when a certain stage is merged again until a first-level zone is completed. According to the method, the pipe network is subjected to multi-level zoned water supply, the water supply pressure of the pipe network can be balanced, pipe bursting can be reduced, and leakage loss can be lowered; meanwhile, water quality can be improved, water supply enterprises can conveniently manage each zone, and the level of service of water supply is increased.

Owner:GUANGZHOU JINGWEI INTELLIGENT TECH

Method of replacing an underground pipe

An improved method for replacing existing underground sewer pipe is accomplished without excavation, pipe bursting, or pipe reaming. First, vertical sight holes are drilled into the ground and through the existing pipe. Slurry material from the vertical hole drilling fills the old pipe. Then, a pilot hole is drilled in a first direction through the old pipe. Then, a reaming tool is pulled in the opposite direction so as to enlarge the pilot hole and grind out the old pipe, while simultaneously pulling the new pipe into position behind the reaming tool. The broken old pipe and slurry are vacuumed out of the vertical relief holes.

Owner:DIMITROFF TED R

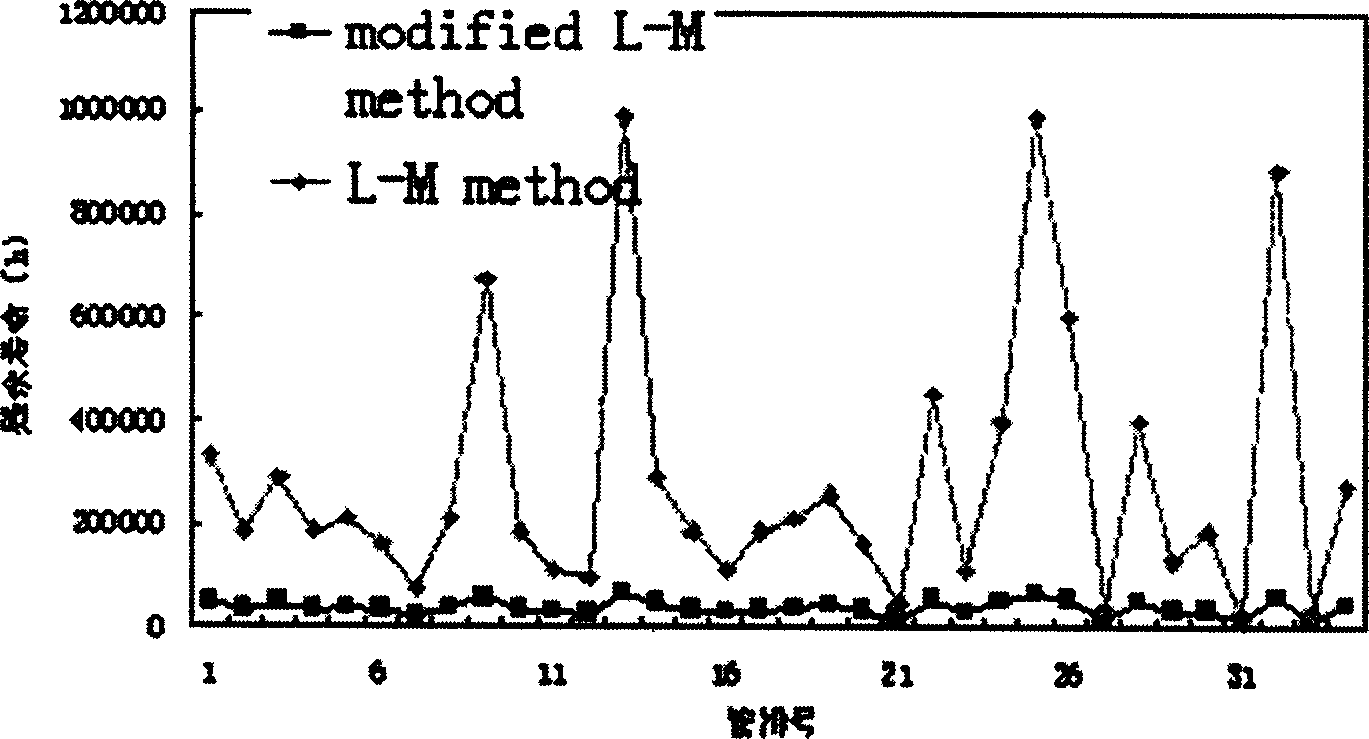

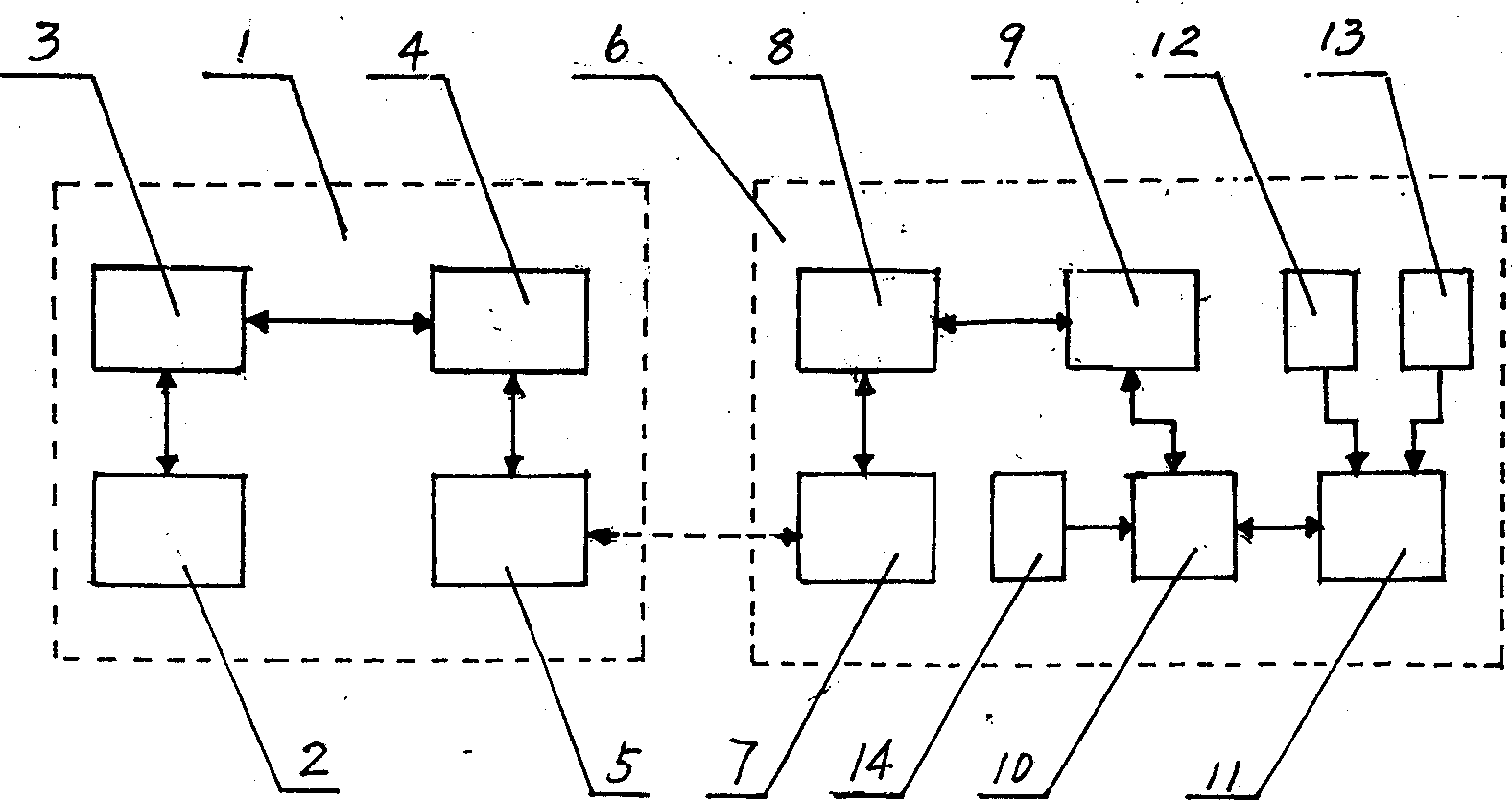

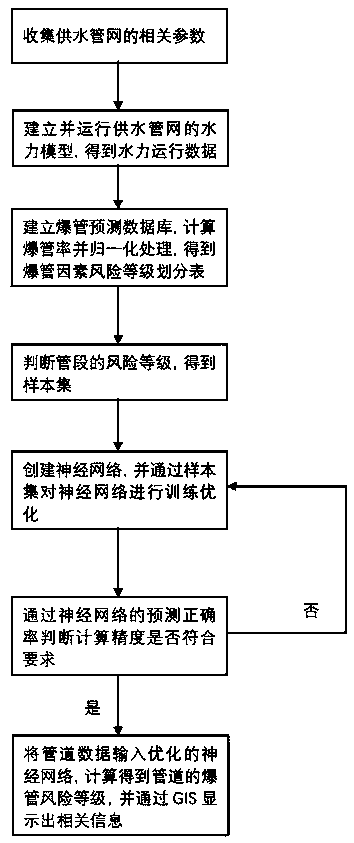

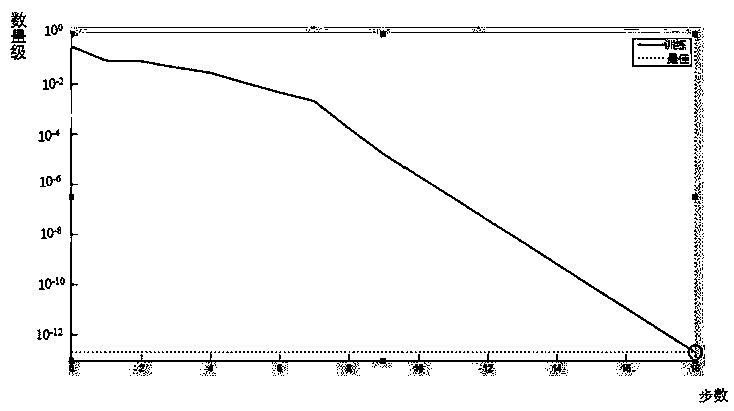

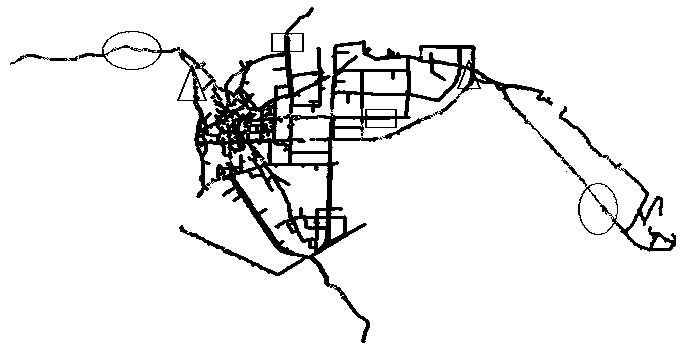

A water supply network pipe explosion risk analysis method

ActiveCN109886506AImprove analysis efficiencyImprove analytical accuracyForecastingResourcesRisk levelPipe bursting

The invention relates to a pipe bursting risk analysis method for a water supply pipe network. The pipe bursting rate of different pipe bursting factors is analyzed by establishing a pipe bursting prediction database, and normalization processing is carried out. According to the pipe bursting rate, pipe bursting risk grade division is carried out on different pipe bursting factors, a pipe burstingfactor risk grade division table is obtained and used for judging the risk grade of each pipe bursting factor of all pipe sections in the pipe bursting prediction database, and if at least R-1 (R isthe number of all the pipe explosion factors) pipe explosion factor belongs to the same risk level, the pipe explosion risk of the pipe section belongs to the risk level, and pipelines at different pipe explosion risk levels are divided, so that the efficiency and accuracy of pipe explosion risk analysis are improved. And for the pipelines which cannot be divided and analyzed through the definitions, analyzing the pipelines through a neural network. Sample set data obtained through statistical analysis of the pipeline is used for training the neural network, and the accuracy of the neural network is improved.

Owner:CHONGQING UNIV

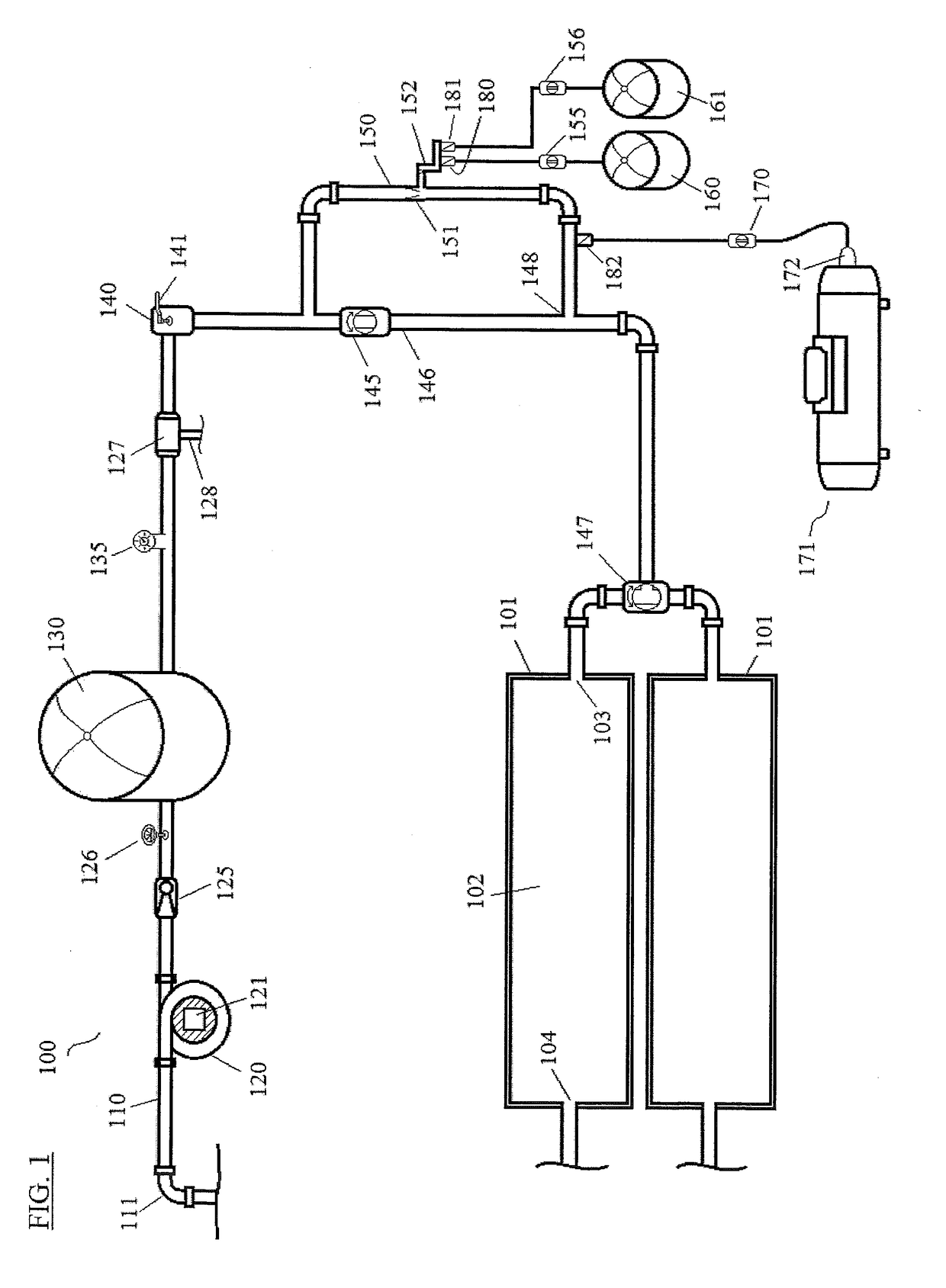

Systems And Methods for Filling and Flushing Animal Footbaths

ActiveUS20190045744A1Saving down timeSave labor timeVeterinary washing devicesAnimal shoeingPipe burstingWater source

The present invention provides improved systems and methods for flushing out animal footbaths at remote locations which do not have a reliable or high pressure water supply. Embodiments of the flushing systems of the present invention preferably include at least one fluid pressurizing pump and one or more large fluid storage tanks which receive water from a source and place it under pressure for use in the system. Embodiments of the flushing systems of the present invention are capable of automatically: taking in water from a low pressure water source; pumping the water into one or more storage tanks to place it under pressure; preventing backflow of the pressurized water; storing the pressurized water until one or more footbaths requires flushing; performing a flushing operation by opening a master valve or a series of valves in parallel; controlling whether the pressurized water remains untreated by flowing through a flush tube or becomes treated with one or more cleaning or disinfecting compounds by flowing through a mixing pipe in communication with one or more chemical tanks, the pressurized water flowing into and flushing out the one or more fouled footbaths; filling the footbaths with fresh disinfecting solution; refilling and re-pressurizing the one or more storage tanks for the next flushing operation; and blowing out any remaining moisture from the system of pipes to reduce bacterial growth and prevent pipe-bursting in freezing weather.

Owner:SPECIALTY SALES LLC

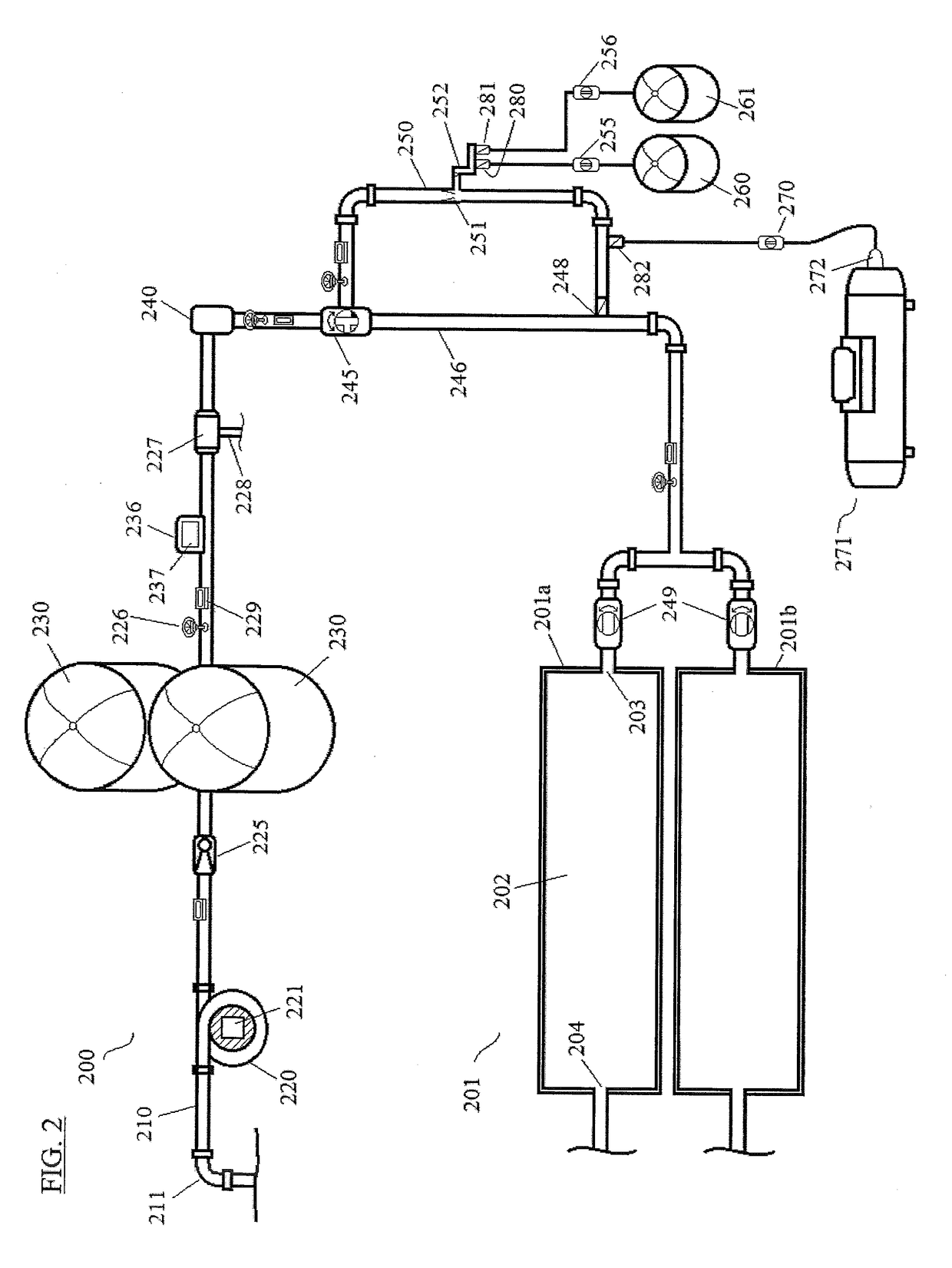

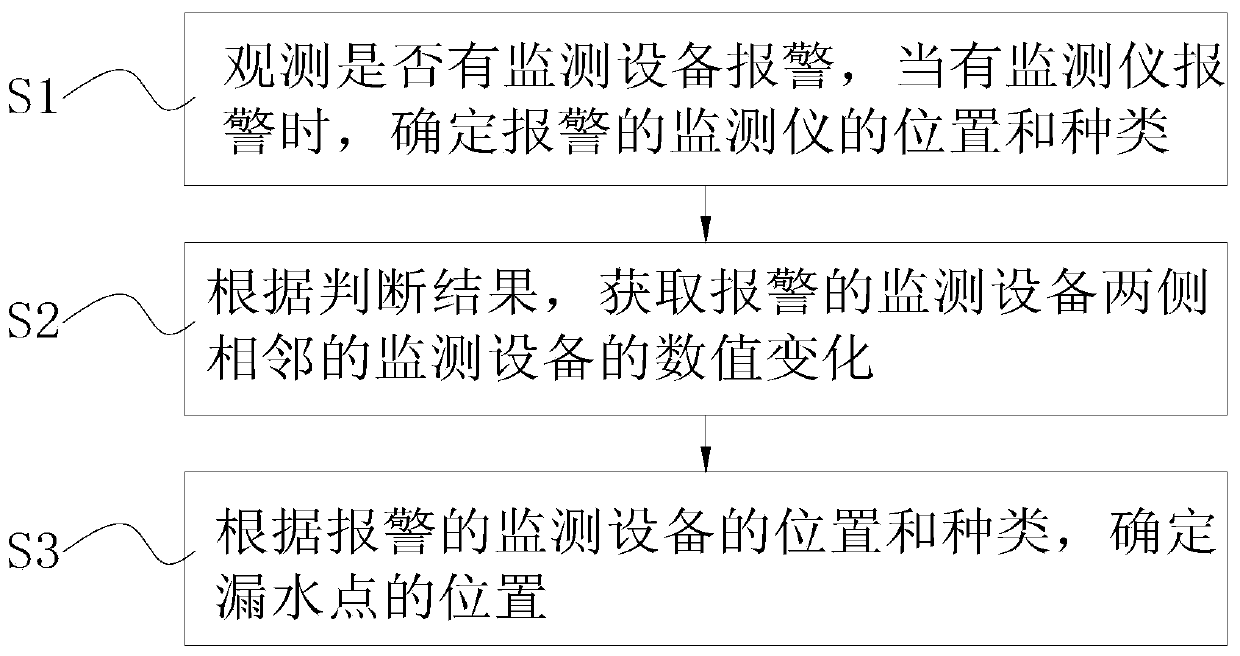

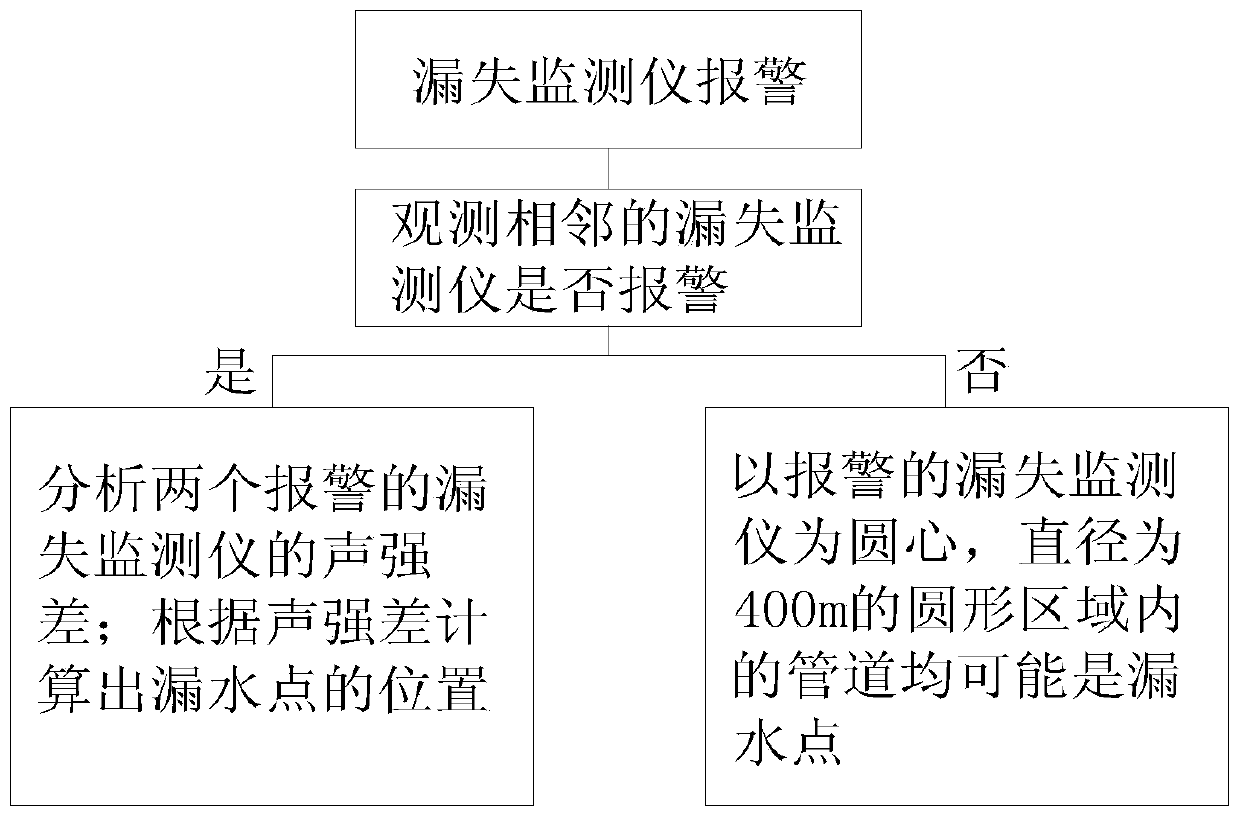

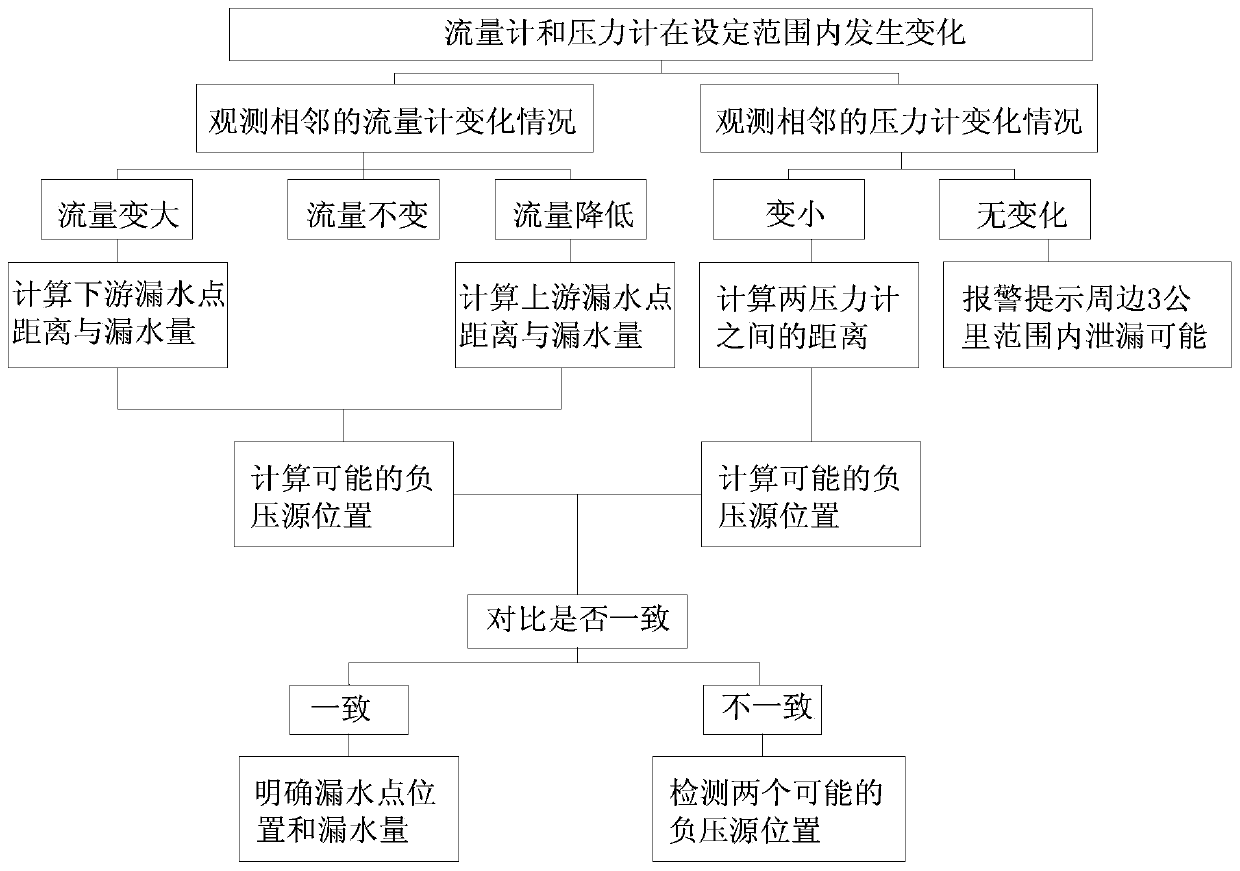

Device and method for positioning different water leakage quantities of water supply pipeline

ActiveCN109708009AImprove accuracyImprove judgment efficiencyPipeline systemsWater leakagePipe bursting

The invention relates to the field of pipe networks, in particular to a device and method for positioning different water leakage quantities of a water supply pipeline. The device comprises a plurality of sets of monitoring devices which are arranged in the length direction of the water supply pipeline in an arrayed mode, each set of monitoring device comprises a flow meter, a pressure meter, a leakage monitor and a pipeline pavement video, and the flow meters and the pressure meters are mounted in the same position. The device and the method have the advantages that as for a system, through matched using of the flow meters, the pressure meters, the leakage monitors and the pipeline pavement videos, the three conditions of leakage, pipeline hidden leakage and pipe bursting can be monitoredwell, especially leakage and pipeline hidden leakage. According to the method, by using the system, a comprehensive identification and judgment technique for leakage, hidden leakage and pipe burstingof the water supply pipeline is formed.

Owner:ANHUI ZEZHONG SAFETY TECH +1

Bursting head device

ActiveUS9360148B2Secure couplingQuick releaseRopes and cables for vehicles/pulleyPipe elementsPipe burstingCoupling

Owner:RODDIE

Impact-resistant modified polyvinyl chloride (PVC-M) pipe material for coal mine

The invention provides an impact-resistant modified polyvinyl chloride (PVC-M) pipe material for a coal mine. The pipe material is prepared by adding a nanoscale antistatic reinforcing and tougheningmaterial and a flame-resistant material. The impact-resistant modified polyvinyl chloride (PVC-M) pipe material for the coal mine has the advantages that by fully utilizing the advantages of high strength, low cost, convenient material taking and easy processing, the electrical conductivity of nanoscale conductive carbon black and the synergistic flame-retardant smoke suppression effect of tricresyl phosphate or aluminum hydroxide and cooperating with the toughening and reinforcing material, the pipe material achieves the purpose of the safe use in the field of coal mine medium conveying and has an antistatic function, and the antistatic capacity of a pipeline is improved, so that the pipeline is suitable for the application of an underground system of the coal mine; the pipe material hasantistatic, flame-resistant, inner pressure-resistant and impact-resistant properties, compared with a traditional plastic pipeline, the pipeline is more durable and safer, and especially suitable forthe work environment, flame retardance, impact resistance and other fields which have requirements for the anti-static electricity, the use safety can be effectively improved, and the possibility ofthe safety accident injury caused by pipe bursting and air leakage due to accidental damage is reduced.

Owner:宁夏青龙塑料管材有限公司

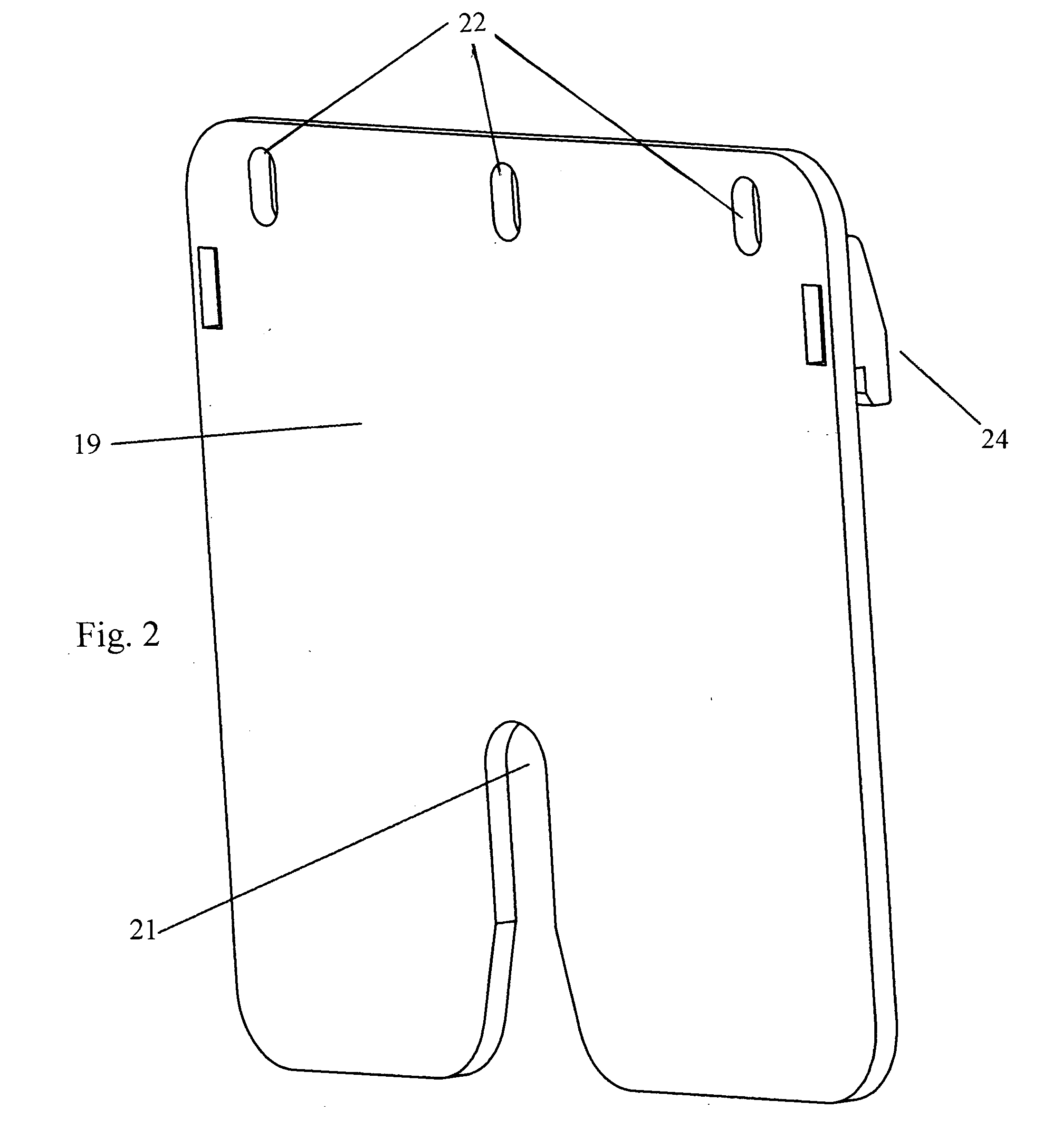

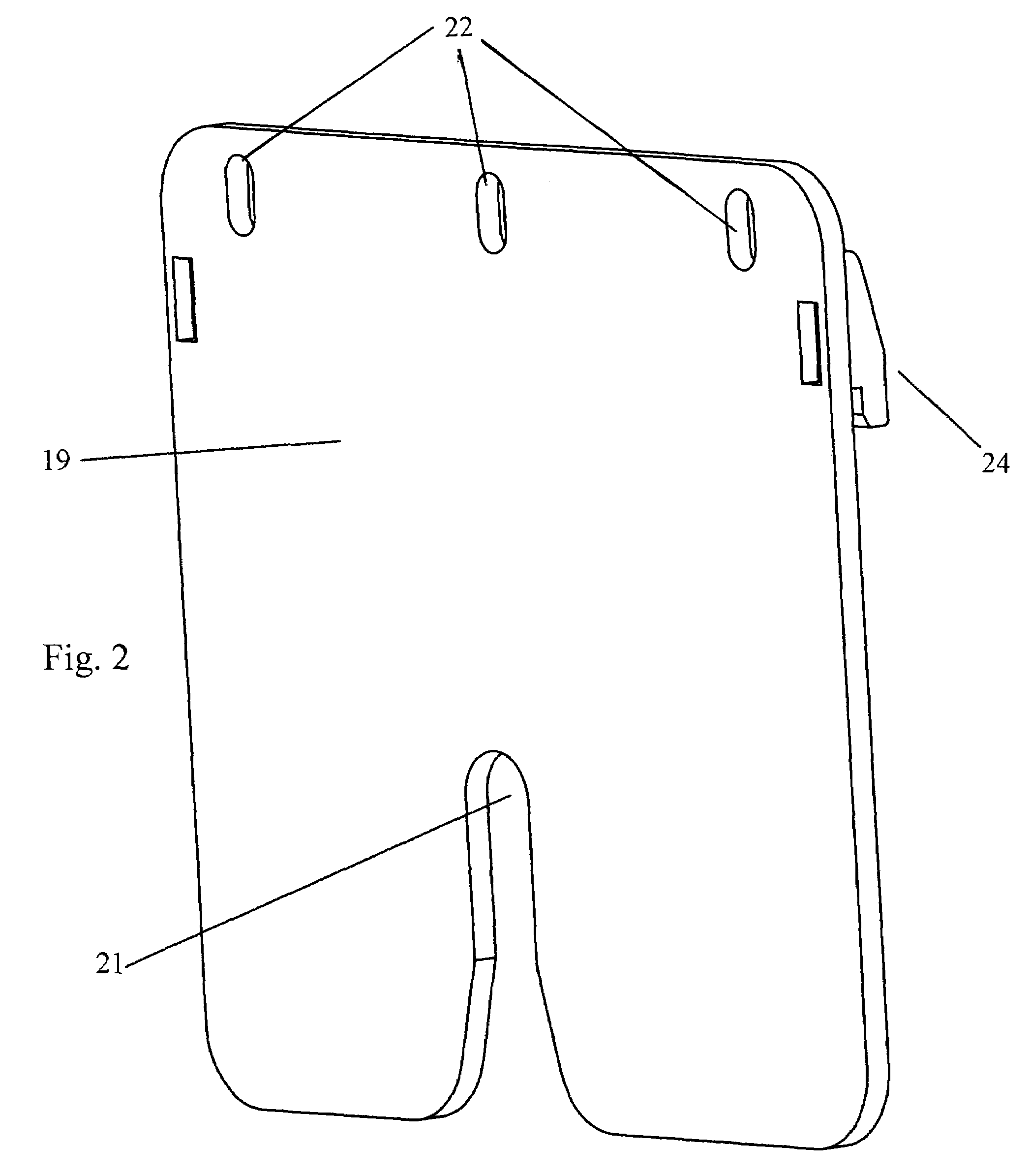

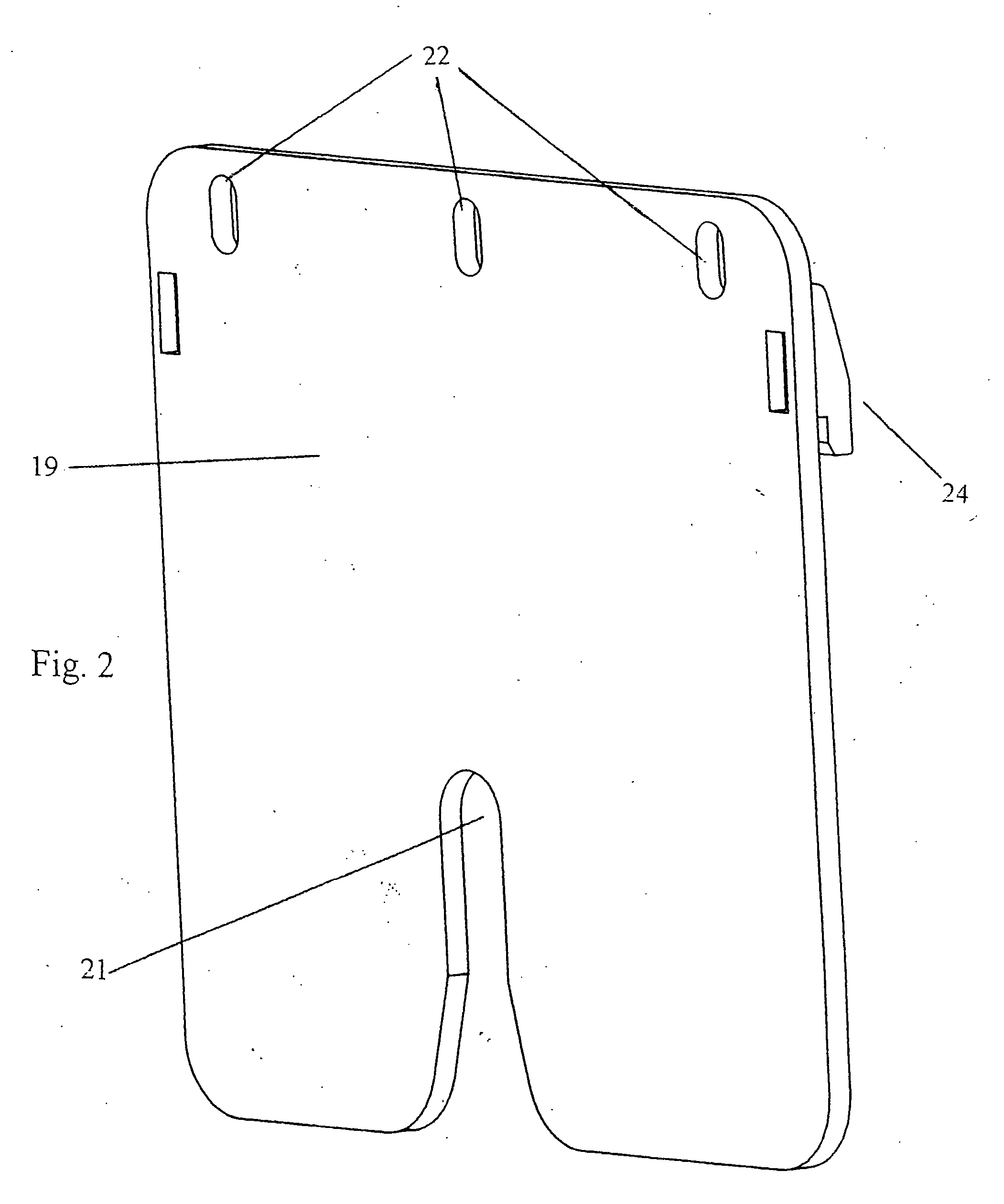

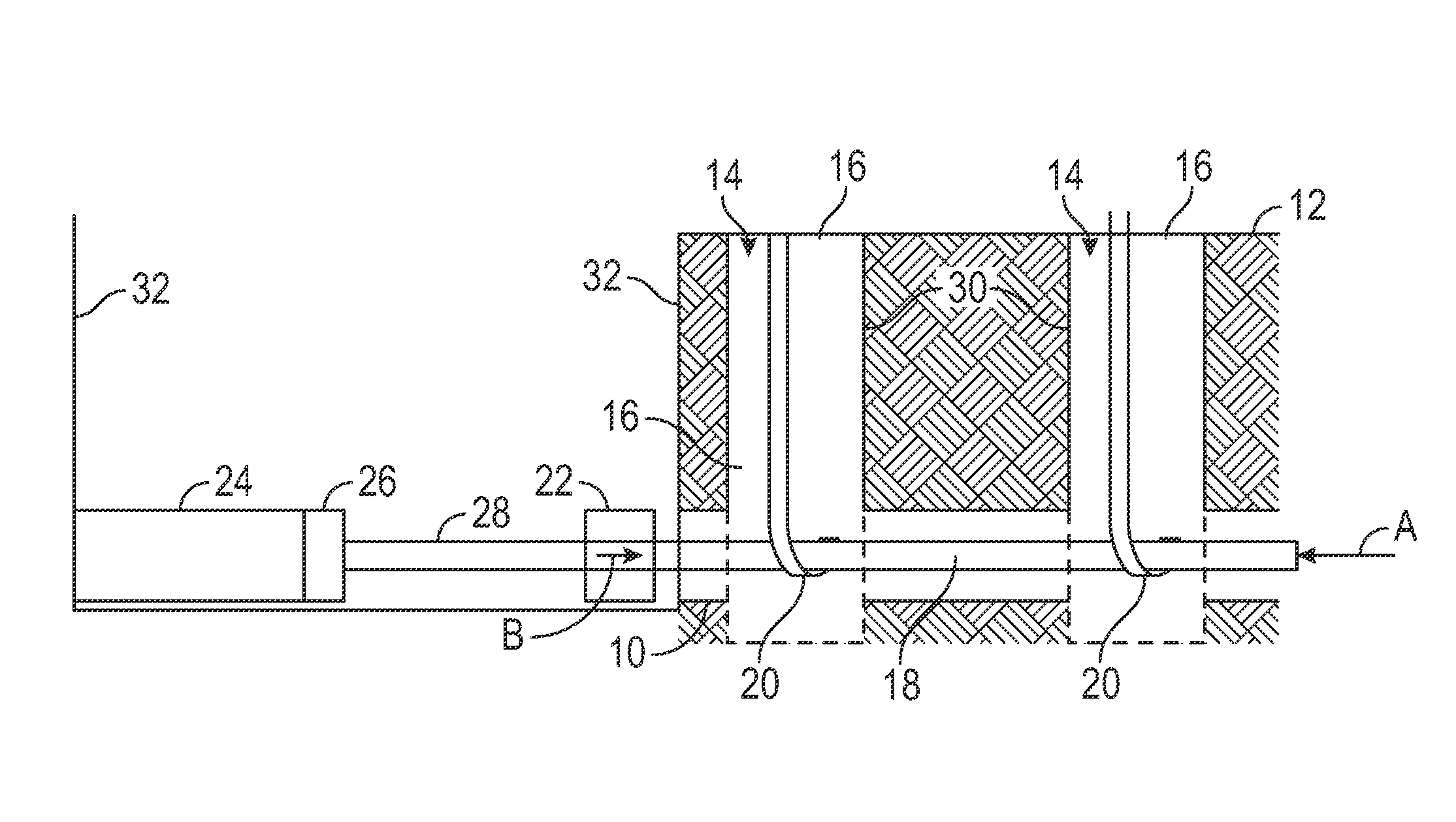

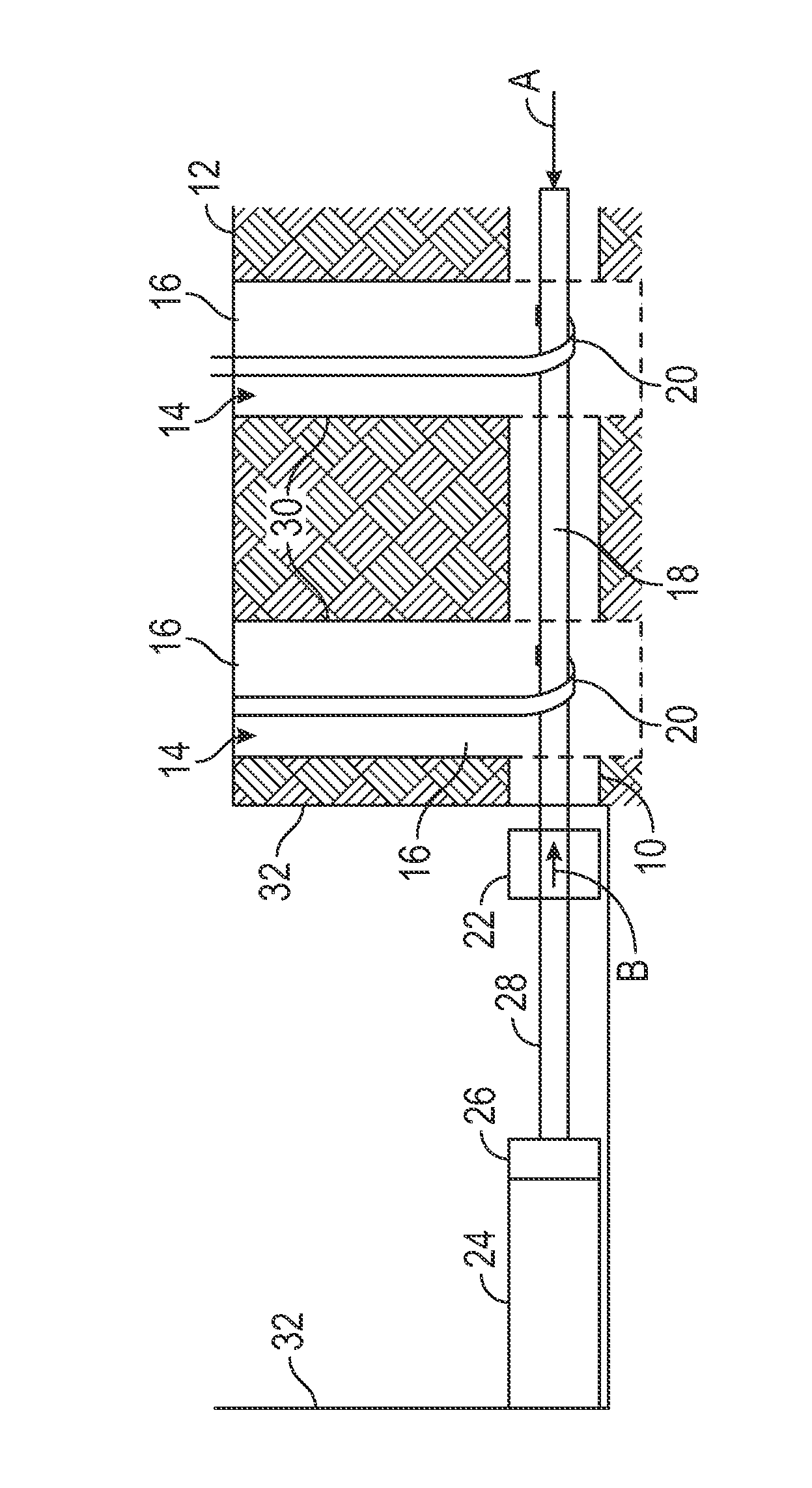

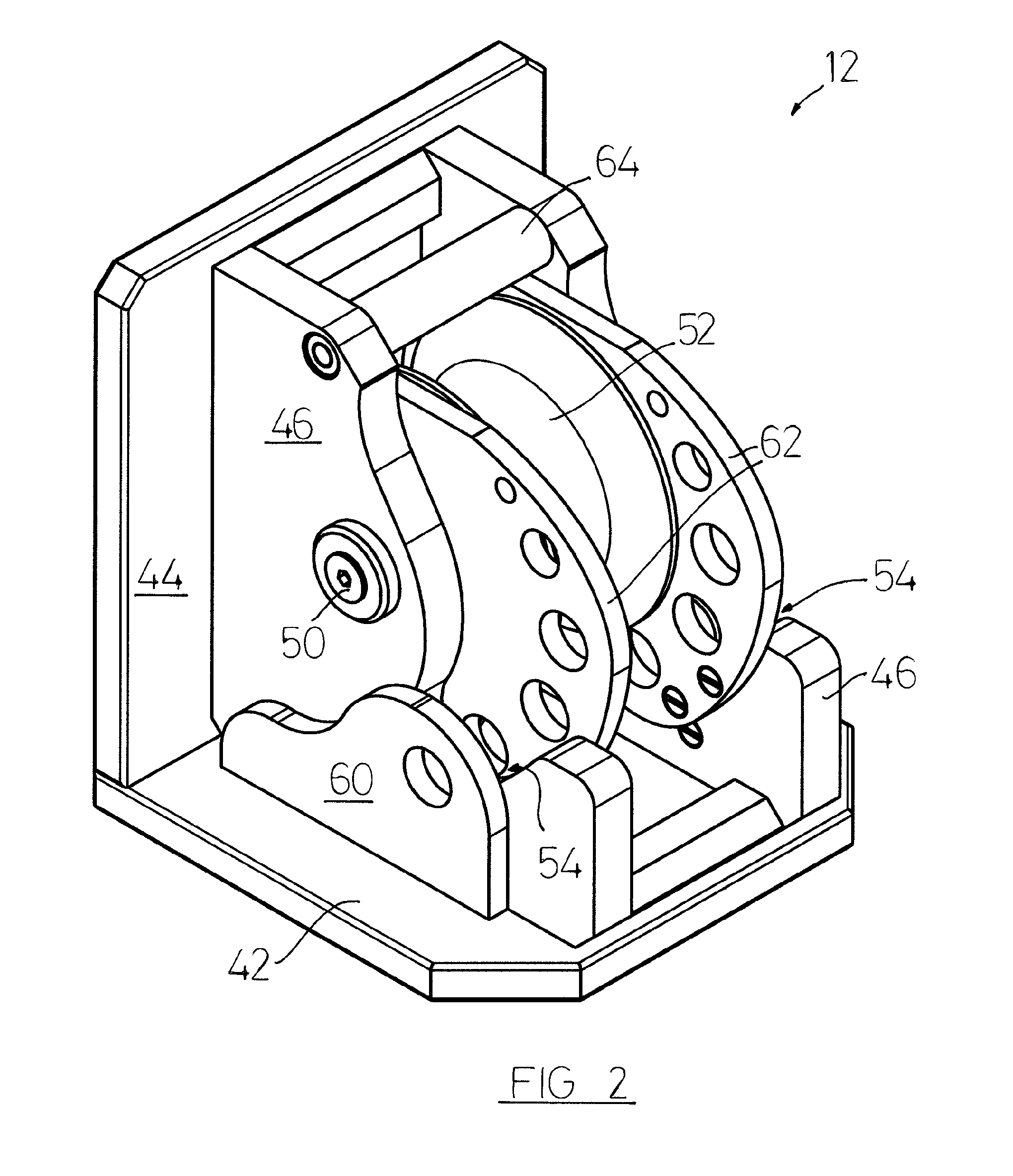

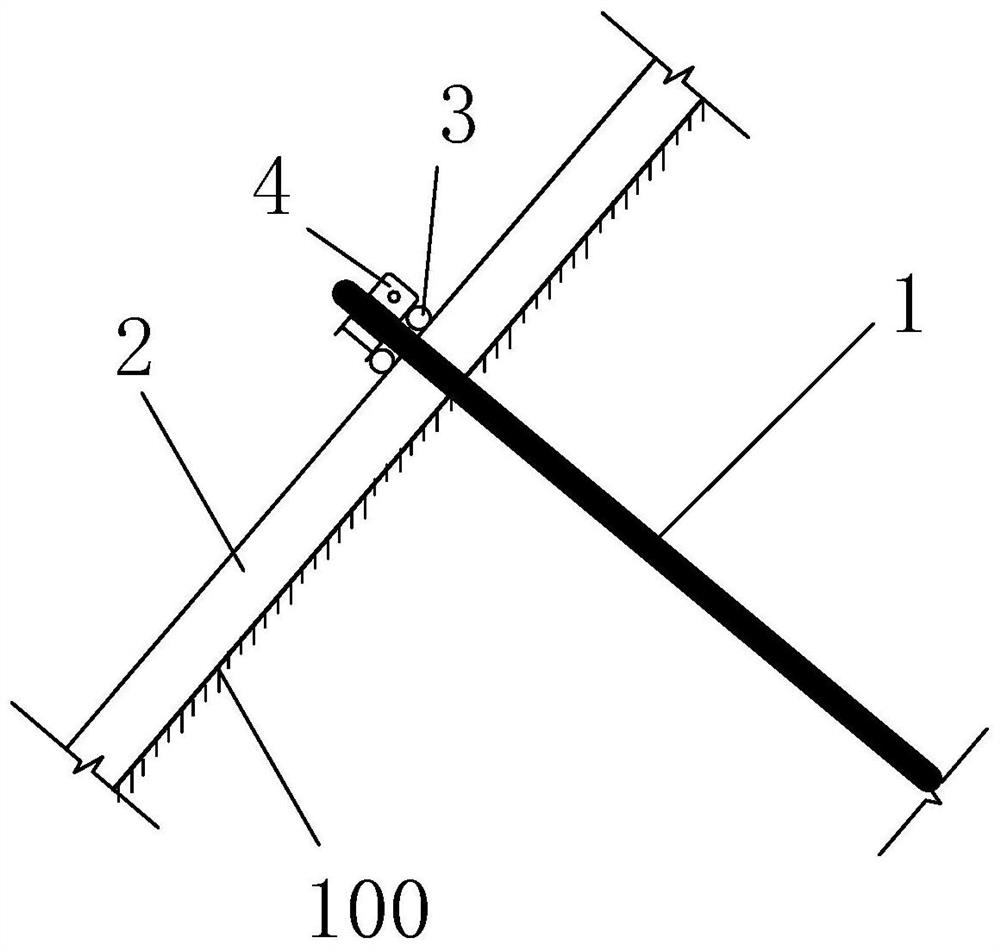

Portable winch assembly

This invention relates to a portable winch assembly (10; 210) comprising a footplate (12; 212), a support frame (14; 214) which is locatable upon the footplate, a magazine (16; 216) which is locatable upon the support frame, and a drive mechanism (22; 222) which is connectable to the magazine to drive the magazine to rotate. The foot plate, support frame, magazine and drive mechanism comprise separable components which may be transported separately to a site of use and assembled into the winch at the site of use. The invention can provide a portable winch assembly capable of generating a tensile force of up to 10 tonnes, and is therefore suitable for pipe pulling and pipe bursting applications for example, and yet is made up of parts which can readily be carried to the site of use, which site of use may be inaccessible for vehicles.

Owner:KOBUS SERVICES

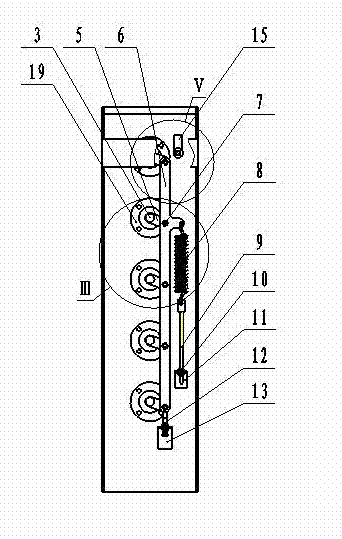

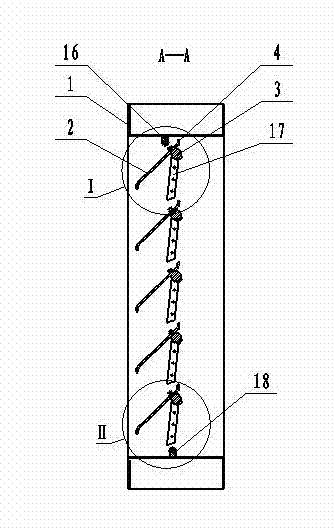

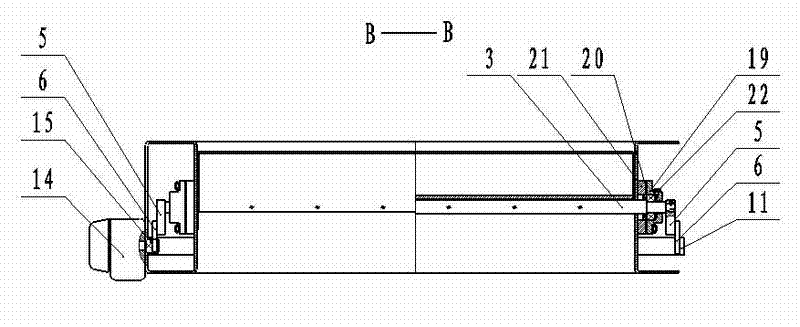

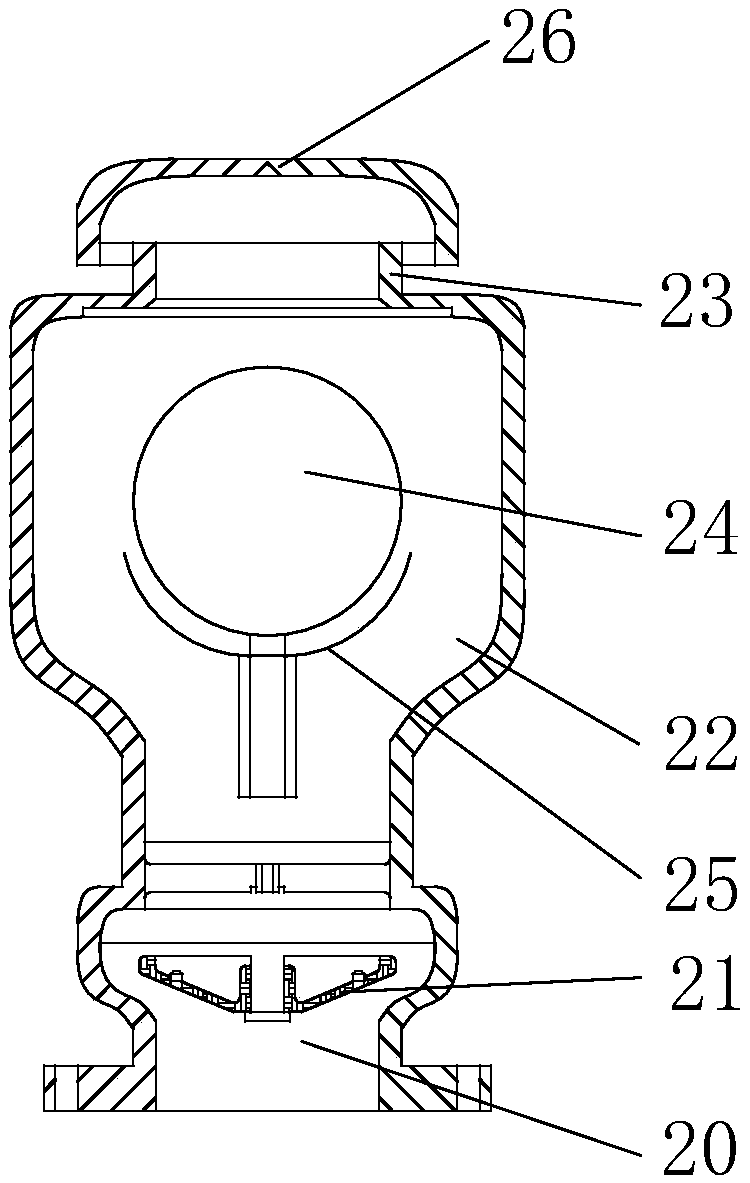

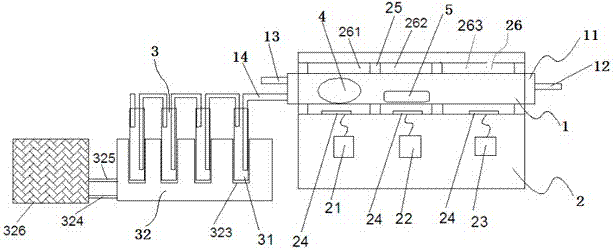

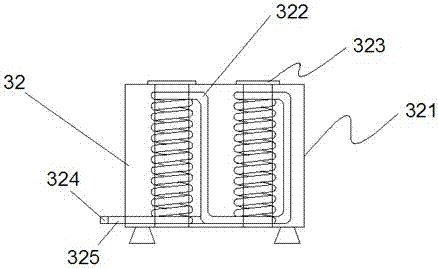

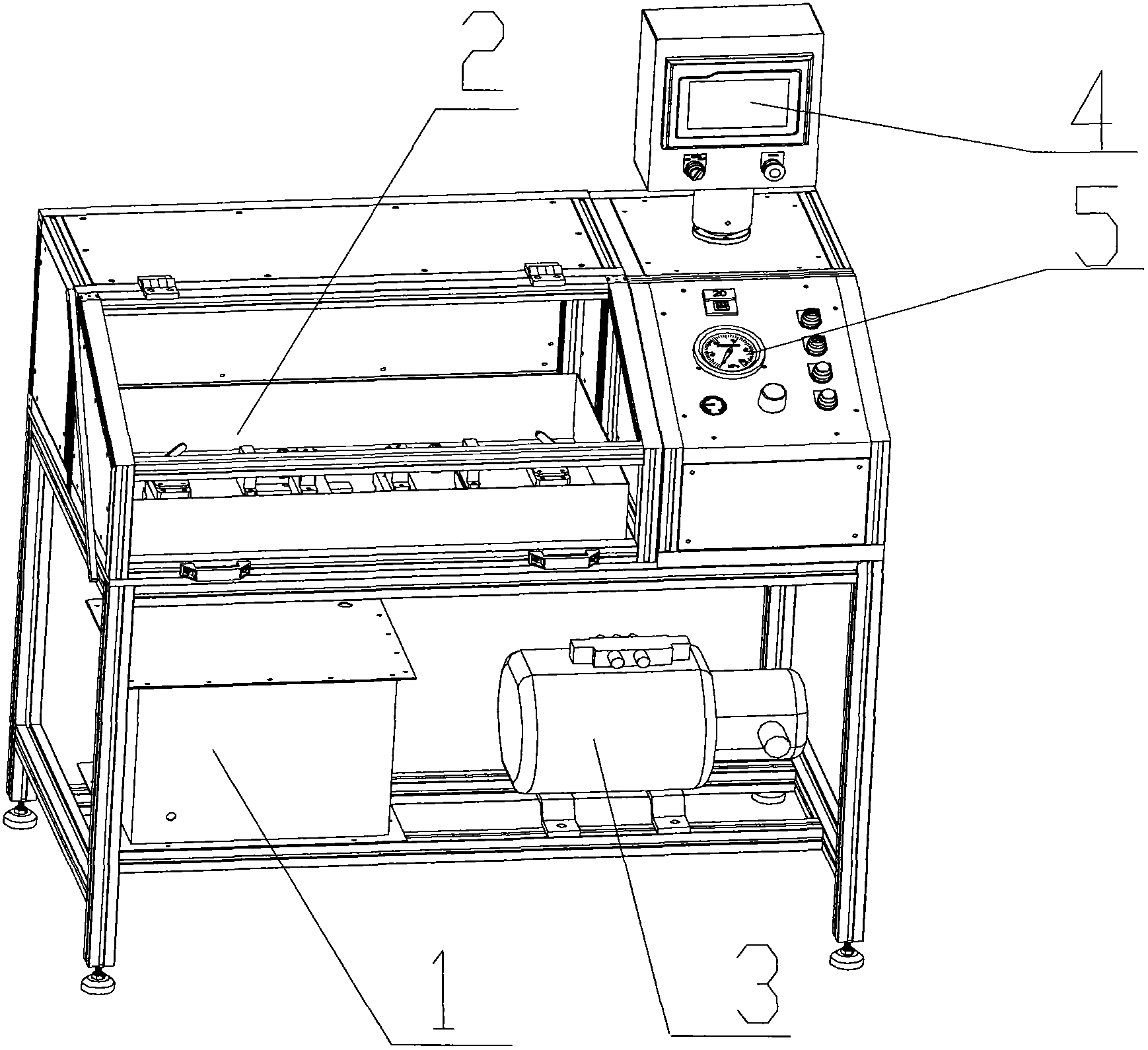

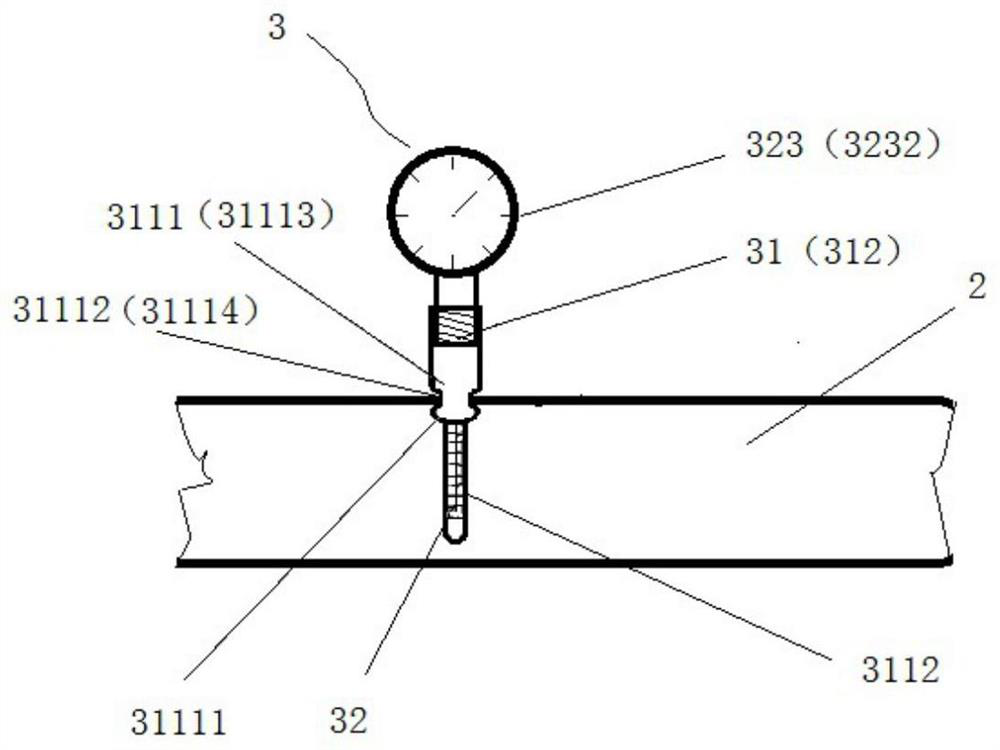

Oil pipe bursting test device

InactiveCN102645376APrevent splashIncrease profitMaterial strength using tensile/compressive forcesPipe burstingControl system

The invention discloses an oil pipe bursting test device which comprises a containing box, a test tank, a pipeline system and a central control system, wherein the containing box is used for containing the test fluid; the test tank is provided with an oil delivery pipe fixing component; the pipeline system is used for communicating the containing box with the oil delivery pipe and comprises a flow pipe and a high-pressure pump, wherein the flow pipe is communicated with the containing box and the oil delivery pipe, and the high-pressure pump is connected with the flow pipe and provides hydraulic energy; the central control system is connected with the high-pressure pump and controls to start or close the high-pressure pump; and the central control system also comprises a pressure test component recording the oil pipe bursting pressure. The oil pipe is mounted in the test tank through the oil delivery pipe fixing component, the flow pipe of the pipeline system is communicated with the oil pipe and the containing box, and the high-pressure pump provides hydraulic energy to the test fluid so that the test fluid rushes into the oil pipe to simulate the oil pressure borne by the oil pipe during work; and the pressure test component is used for recording the hydraulic pressure borne by the oil pipe.

Owner:王永旺

Method of replacing an underground pipe section

An improved method for replacing existing underground sewer pipe is accomplished without excavation, pipe bursting, or pipe reaming. First, vertical sight holes are drilled into the ground and through the existing pipe. Slurry material from the vertical hole drilling fills the old pipe. Then, a pilot hole is drilled in a first direction through the old pipe. Then, a reaming tool is pulled in the opposite direction so as to enlarge the pilot hole and grind out the old pipe, while simultaneously pulling the new pipe into position behind the reaming tool. The broken old pipe and slurry are vacuumed out of the vertical relief holes.

Owner:DIMITROFF TED R

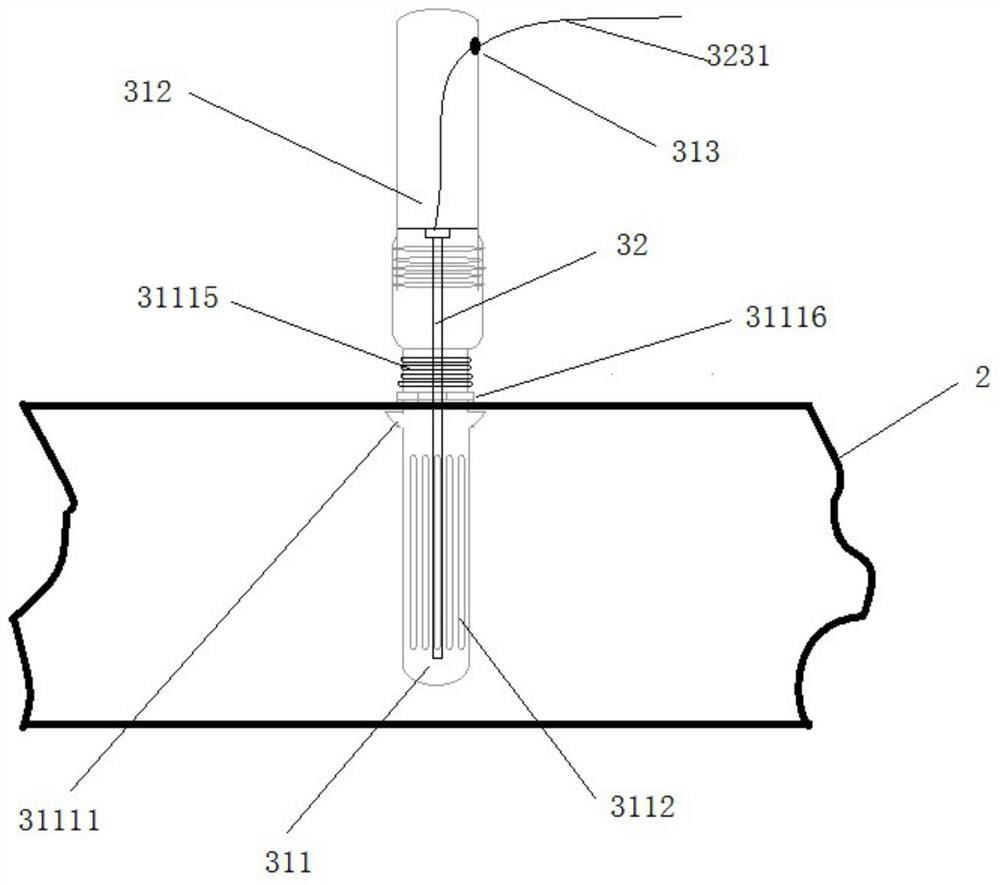

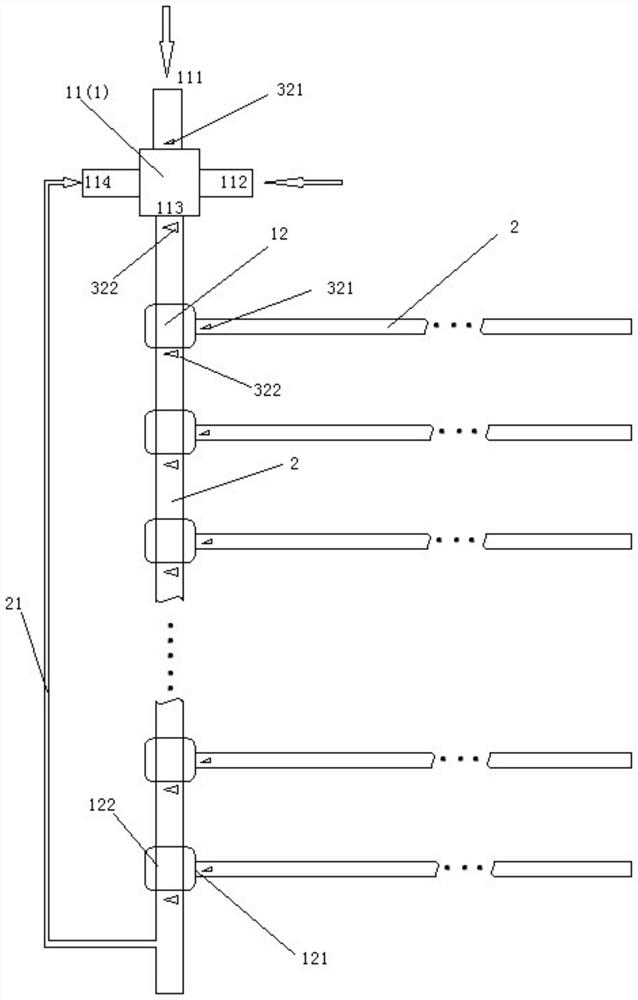

Pipe condition control intelligent irrigation valve, irrigation system and irrigation method

ActiveCN111742680ARealize management feedback controlEasy to set upLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserPipe burstingAgricultural engineering

The invention discloses a pipe condition control intelligent irrigation valve, an irrigation system and an irrigation method. After an electric valve opening degree control device receives in-pipe fluid information transmitted by a pipe condition detection sensor, a valve element of an electric valve is driven to rotate to the proper valve opening degree according to preset fluid information, thewater amount, pressure and flow speed in a water hose are accurately controlled, accurate water and fertilizer irrigation is achieved, the problems of pipe disengaging or pipe bursting, the water hammer phenomenon, water and fertilizer waste, water and fertilizer pipe wall corrosion and the like caused by pressure differences can be avoided, a block chain agricultural management system can be conveniently built, and intelligent agricultural management on the national scale becomes possible. A sensing element of the pipe condition detection sensor stretches into the water hose through a probe protection structure. The structure is simple and reliable, installation is convenient, on the basis of effectively obtaining the in-pipe fluid information, the sensing element is protected against impact damage, the detection cost of the intelligent irrigation system is greatly reduced, and large-area application and popularization are convenient.

Owner:TAIZHOU JUNGANG COPPER CO LTD

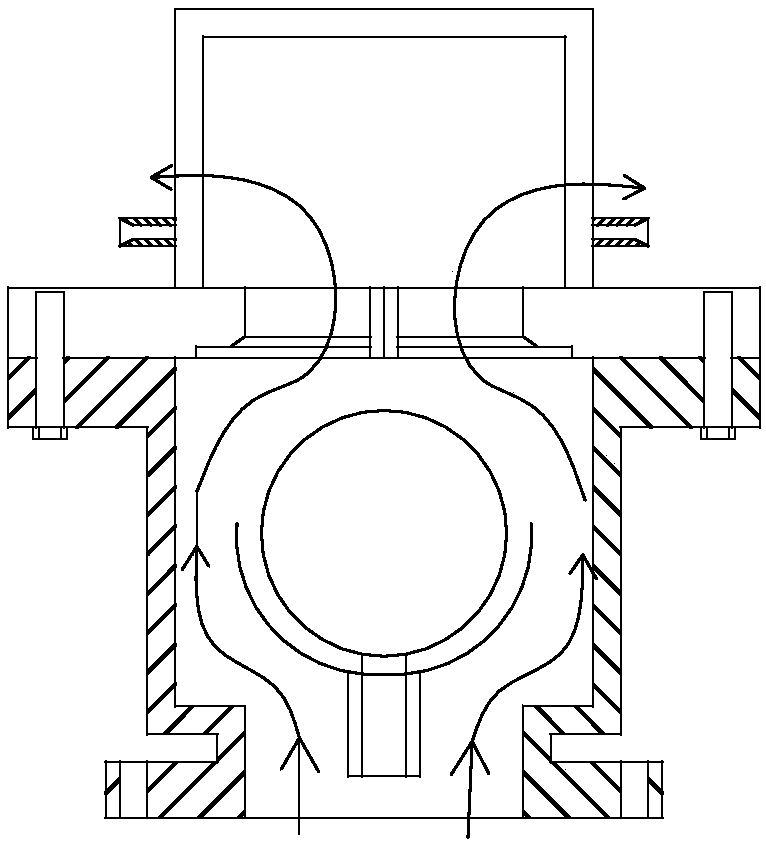

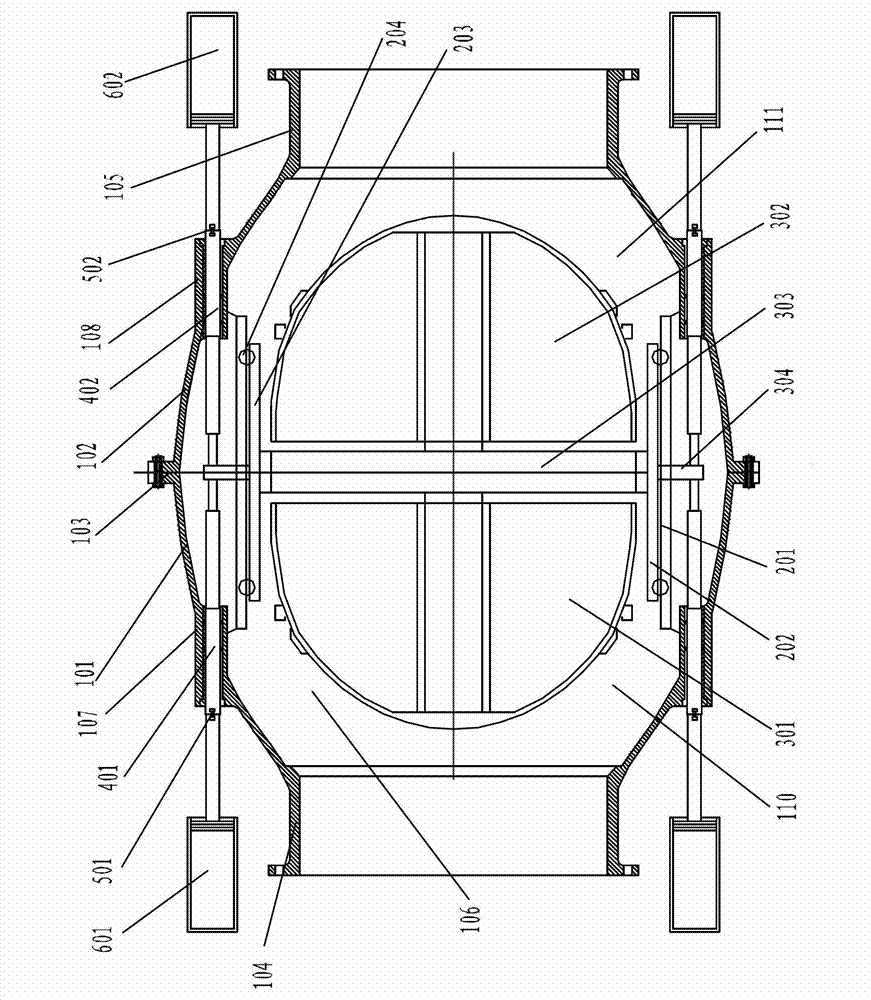

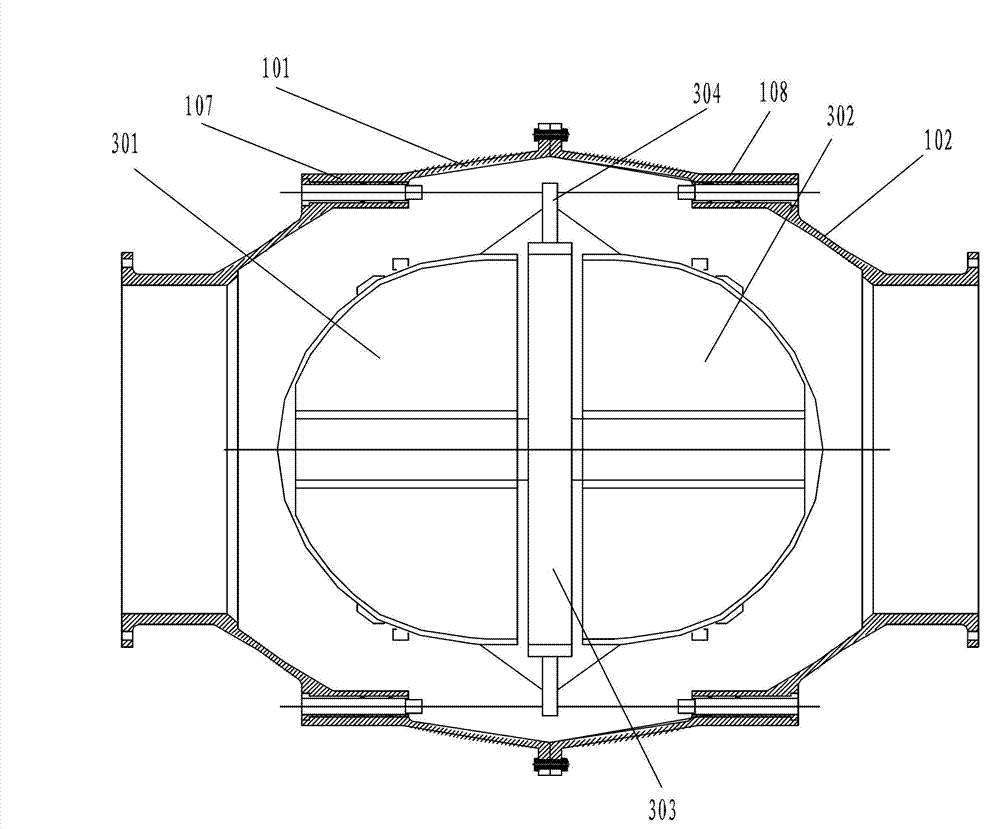

Pipe bursting and flow limiting valve

ActiveCN103032615ALess leakage flowImplementation creates problemsEqualizing valvesSafety valvesPipe burstingEngineering

The invention discloses a pipe bursting and flow limiting valve. The pipe bursting and flow limiting valve comprises a valve body, a flow guide body, a flow limiting body, supporting and moving structures, a sliding block, a sliding rod, a damping device and a tension trigger structure, wherein two ends of the valve body are provided with medium circulating pipes, the flow guide body, the flow limiting body, the supporting and moving structures, the sliding block and the sliding rod are arranged in the valve body, the flow guide body is arranged in a cavity formed by a valve body shell along a medium flowing direction, the flow limiting body and the flow guide body are oppositely arranged, a flow limiting passage is formed between a flow limiting surface of the flow limiting body and the inner wall of the valve body shell, the flow guide body and the flow limiting body are supported between the supporting and moving structures, the sliding block is connected with the flow guide body and the flow limiting body, the sliding rod is connected with the sliding block, the damping device which is used for moving the sliding block is connected with one end of the sliding rod, the tension trigger structure is connected with the other end of the sliding rod, and the damping device and the tension trigger structure are arranged outside the valve body. The pipe bursting and flow limiting valve disclosed by the invention is reasonable and simple in structural arrangement, flexible in motion and is particularly suitable for pipe bursting and flow limiting of a large-scale water pipeline in a no-power area.

Owner:WUHAN DAYU VALVE

Treatment method for pipeline plugging of power station boiler

The invention discloses a treatment method for boiler pipe blockage in a power station, which specifically includes: step a) taking a steel wire rope and a net bag, and flexibly connecting the steel wire rope and the net bag; Insert the hand hole into the header, and then use compressed air to blow it to the other end of the hand hole. The operator grabs the plastic bag and the fiber rope from the hand hole, and then slowly drags the fiber rope to drive the steel wire rope through the inside of the header. Reach the hand hole; step c) control the net bag to catch the foreign matter; step d) drag the wire rope at one end to take out the foreign matter wrapped in the net bag from the hand hole at one end. Compared with the prior art, the present invention has the following advantages and beneficial effects: through the low-cost, simple-step, and easy-to-operate treatment method for power plant boiler pipe blockage provided by the present invention, it avoids dirt or slag cleaning, or large-scale Pipeline blockage caused by metal wastes will prevent pipe explosion accidents, which improves work efficiency and service life.

Owner:XIANGTAN HONGYUAN ELECTRONICS SCI & TECH CO LTD

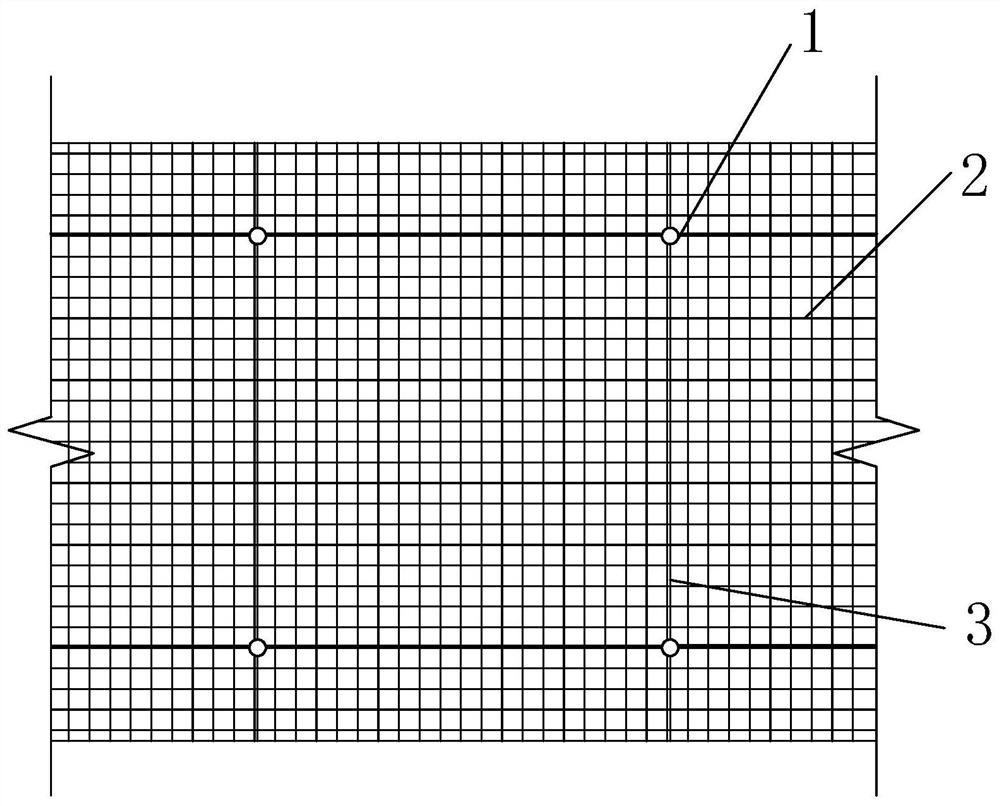

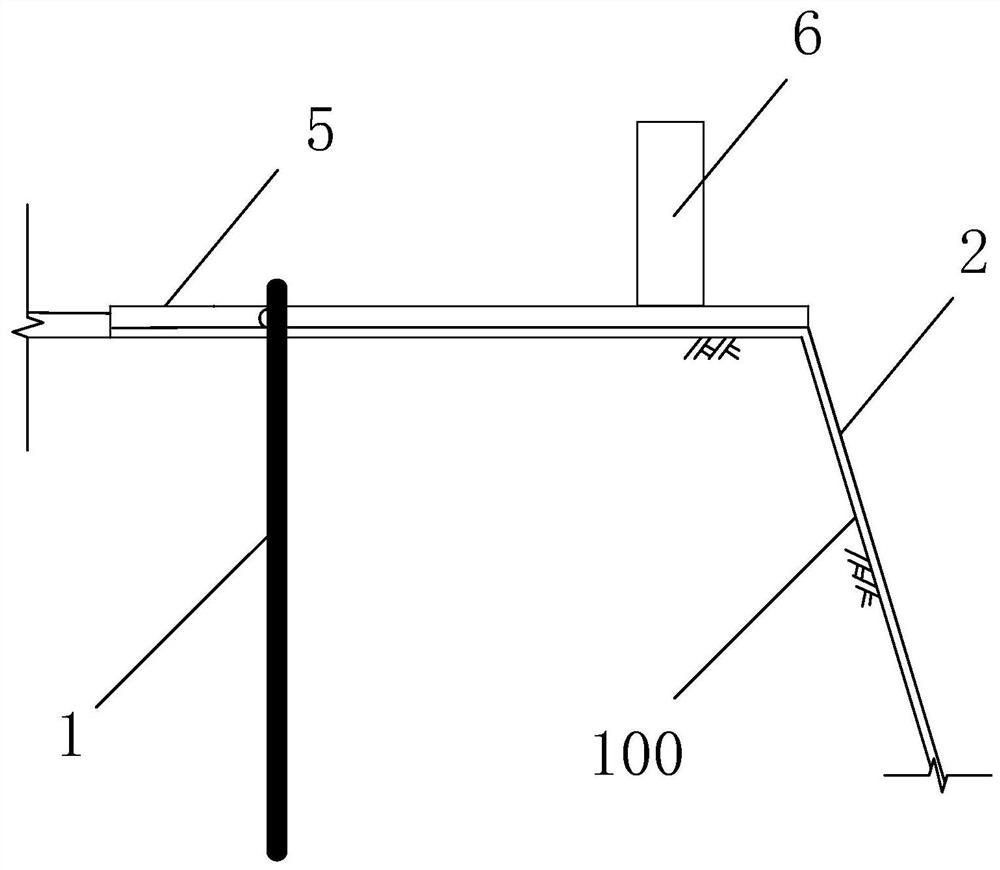

Green fabricated slope supporting structure and construction method thereof

PendingCN111779006AReduce the risk of pipe burstsNo pollution in the processExcavationsBulkheads/pilesShotcreteSoil nailing

The invention belongs to the technical field of building deep foundation pit slope protection, and discloses a green fabricated slope supporting structure and a construction method thereof. The supporting structure comprises a plurality of soil nails, a green fabricated surface layer and connecting parts, wherein the soil nails are arranged on a slope at intervals, one ends of the soil nails are fixed into a soil body of the slope, and the other ends of the soil nails protrude from the surface of the soil body; the green fabricated surface layer is laid on the slope surface, the ends of the soil nails protrude from the surface of the green fabricated surface layer, and the green fabricated surface layer is separately provided with flanges at the top and toe of the slope; and two ends of the connecting parts are separately connected to every two adjacent soil nails to form horizontal connection and vertical connection. According to the green fabricated slope supporting structure and theconstruction method thereof, steel bar meshes are not required to be weaved, and concrete spraying is not required, so that the risk of concrete delivery pipe bursting is reduced; no air pollution problems exist, and the construction period is shortened; and the soil can be directly inserted on the supporting structure, the green fabricated surface layer can be laid on the supporting structure, the preparation work is less, the construction is convenient and quick, and the cost is low.

Owner:中国建筑土木建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com