Pressure resistance valve for nuclear grade air passage

An air duct and pressure-resistance technology, which is applied in the direction of valve lift, valve details, valve devices, etc., can solve problems affecting normal work, valve pressure difference increase, and exceeding closing pressure, etc., to achieve flexible actions and meet the requirements of exhaust air , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

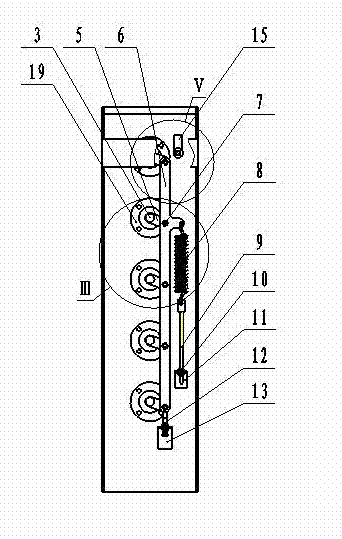

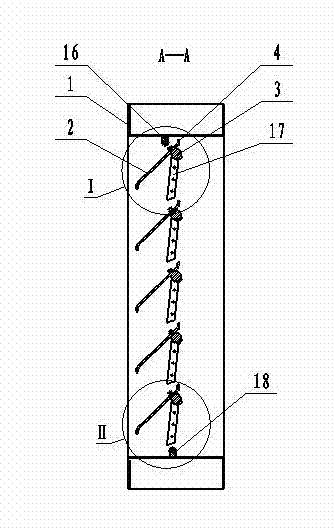

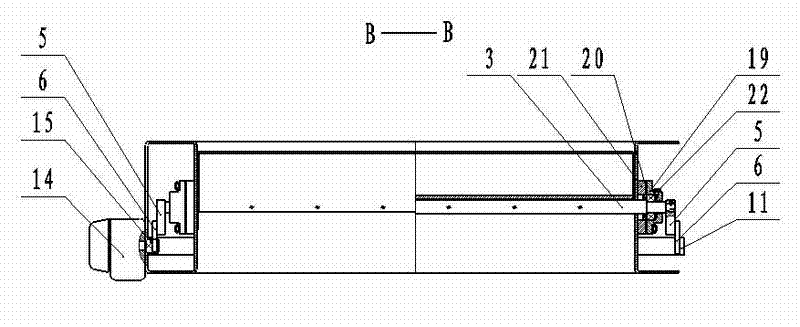

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Depend on Figure 1-9 It can be seen from the illustrated embodiment that this embodiment includes a valve body 1, a valve seat, a blade and its automatic reset mechanism and an emergency protection mechanism; In the example, the number of leaves is 5). The rotating shaft 3 corresponding to each blade, the rocker arm 5, and a pair of symmetrical left and right reset sub-mechanisms, the blade 2 is fixed on its corresponding rotating shaft 3 by bolts 4, and the two ends of the rotating shaft 3 pass through bearings 22 and the bearing cover 19 are installed on the rotating shaft support 21 fixed on the valve body 1; the two ends of the rotating shaft 3 are respectively fixedly connected with one end of the corresponding rocker arm 5 through keys; the left and right reset sub-mechanisms The structure is the same, the left reset s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com