Test method of high-temp, component creep life

A technology of creep life and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve problems such as errors, amplification, and low reliability of life evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

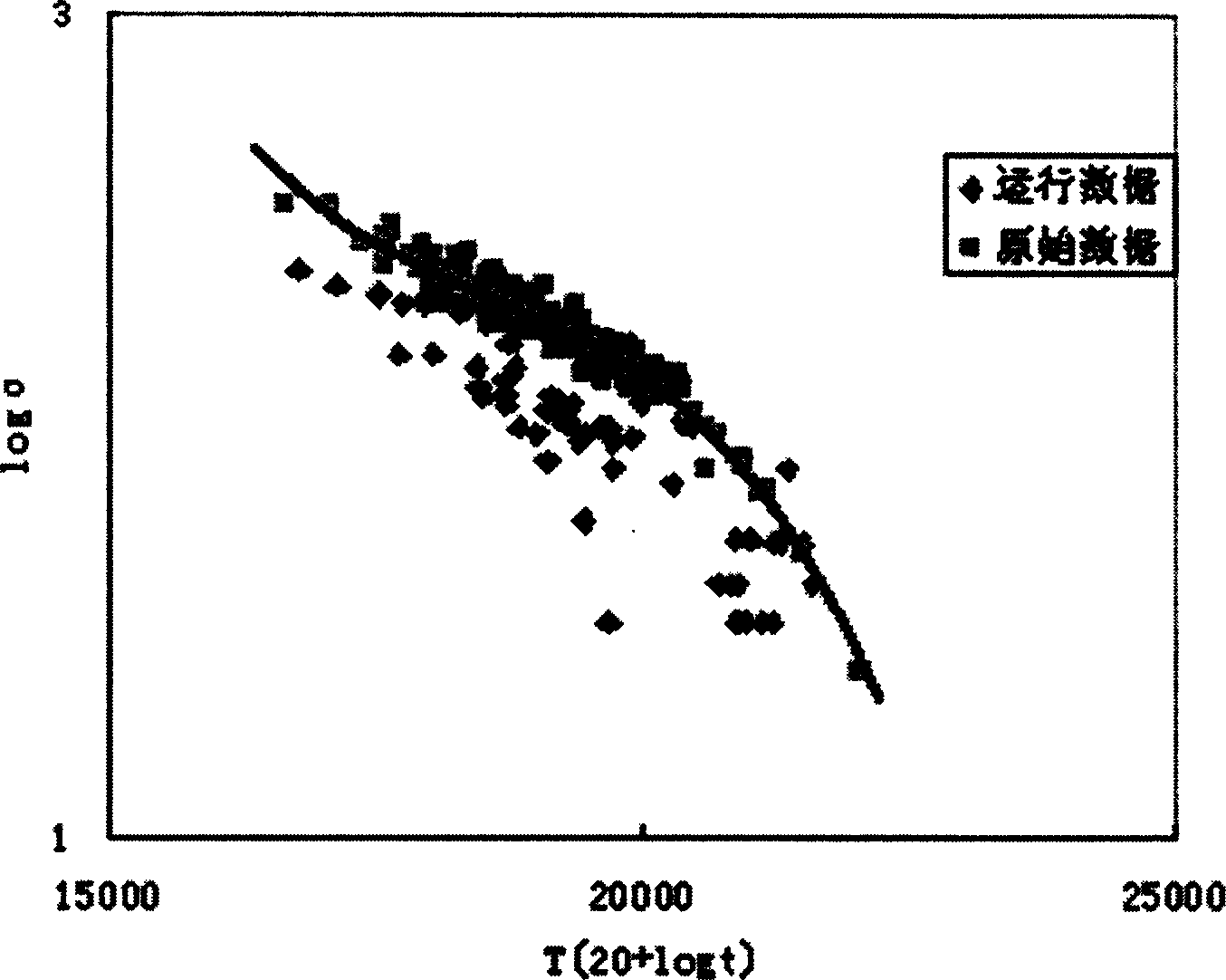

[0019] Using a unified idea and simulation method, the typical curves and relational expressions of the aging factor correction method for various boiler materials and steam turbine materials are given. figure 1 The characteristic curve of the aging factor Ca of 12Cr1MoV steel commonly used in power plant boilers gradually decreases with the change of service stress and temperature-time state is given, in which the abscissa is the LMP parameter, and the ordinate is the logarithmic stress.

[0020] Select 12Cr1MoV steel pipe samples with different aging degrees obtained after actual use, and first use the quantitative aging degree test method to evaluate the aging degree of each pipe sample. The aging degree of the unused new material is zero, and the aging degree of the creep failure pipe sample is 100%.

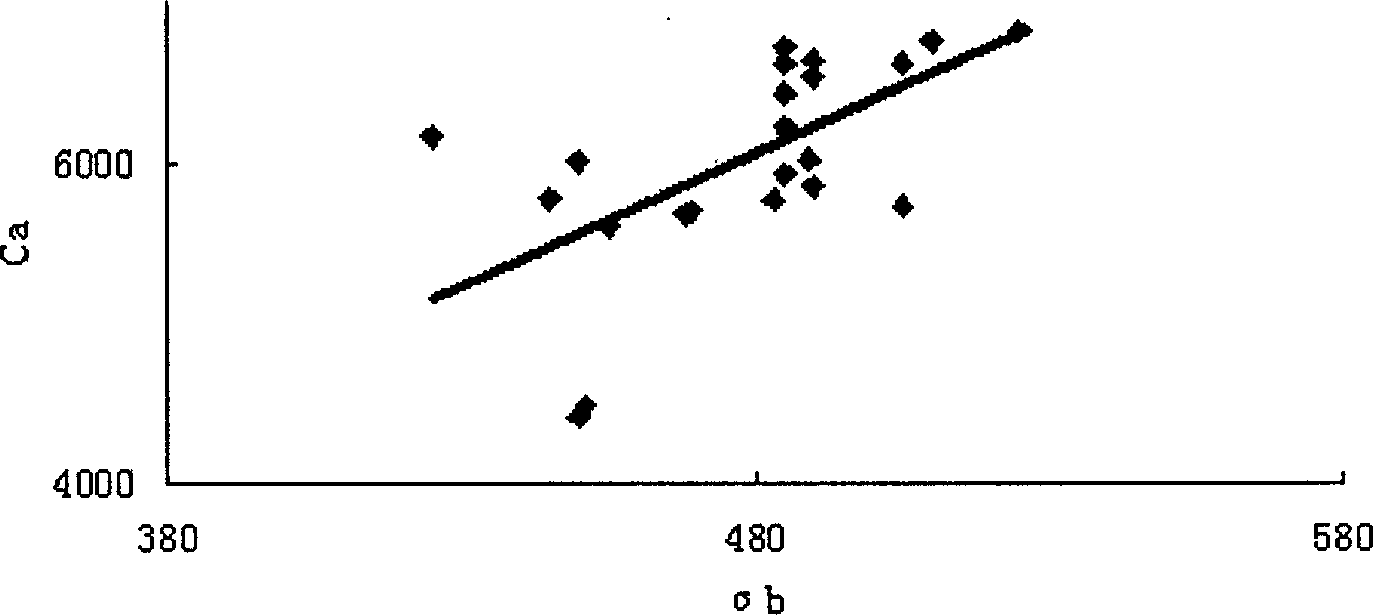

[0021] For samples of each aging degree, the variable stress simulation test is carried out at a constant temperature T and the variable temperature simulation test is carri...

Embodiment 2

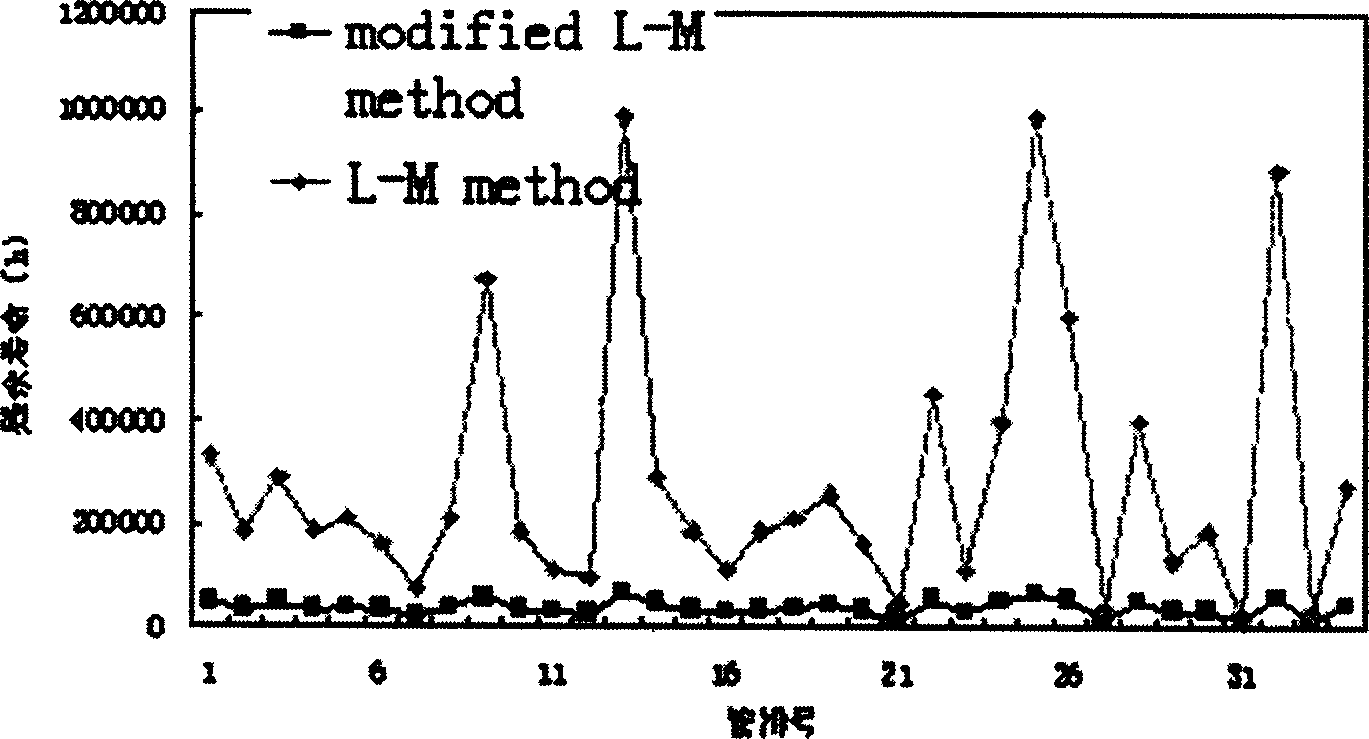

[0026] The target is a high-temperature superheater component that has been used for 80,000 hours in a power plant and has been seriously aged. Due to the difference in the use environment, the aging degree of the 34 superheater tubes in the tube row is significantly different, resulting in a significant difference in the remaining life.

[0027] The invention is used to quantitatively evaluate the aging degree of each superheater tube; the indirect evaluation method of the metal wall temperature of the boiler tube is used to quantitatively evaluate the equivalent temperature of the metal wall temperature of each superheater tube; the circumferential stress of the boiler tube is used to calculate method, quantitatively evaluate the actual circumferential stress of each superheater tube.

[0028] The residual life of the same pipe row was evaluated by two new and old methods respectively, and the results are shown in image 3 .

[0029] It can be seen from the results that, us...

Embodiment 3

[0033] In November 2002, the residual life of the convection superheater of the No. 2 boiler of Huaneng Huaiyin Power Plant was evaluated by using the aging factor correction method. The basic method is the same as above.

[0034] Among them, the life evaluation results of 84 tubes in the lower elbow part of the hot section of the superheater are as follows: Figure 4 shown. It can be seen from the results that after 60,000 hours of actual use, the residual life of some pipe sections is less than 20,000 hours, and the remaining life of individual pipes is only a few thousand hours, so they must be replaced as soon as possible. The power plant adopted this suggestion and has replaced the hot section of the superheater as a whole to ensure the reliability of equipment operation.

[0035] The abscissa in the figure is the number of 1 to 84 pipes, and the ordinate is the result of the remaining life (hours) corresponding to each pipe calculated and evaluated.

[0036] The actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com