Patents

Literature

33results about How to "Reduce squib" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressor overload protection control method and device as well as fixed-frequency air conditioner

ActiveCN105180362AReduce the possibility of pipe bursts in the systemSolve the squib problemSpace heating and ventilation safety systemsLighting and heating apparatusFixed frequencyEngineering

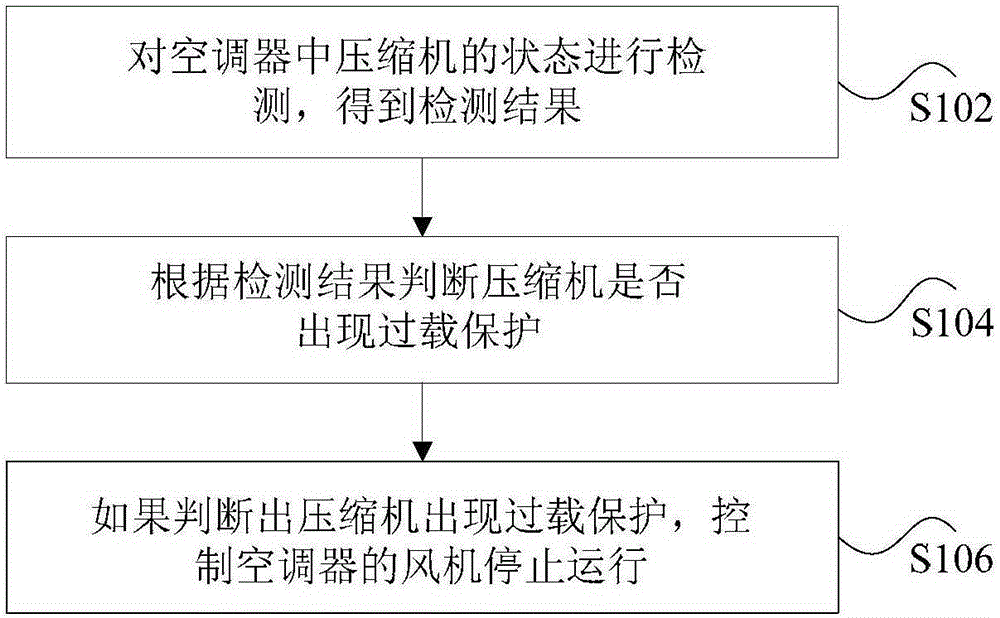

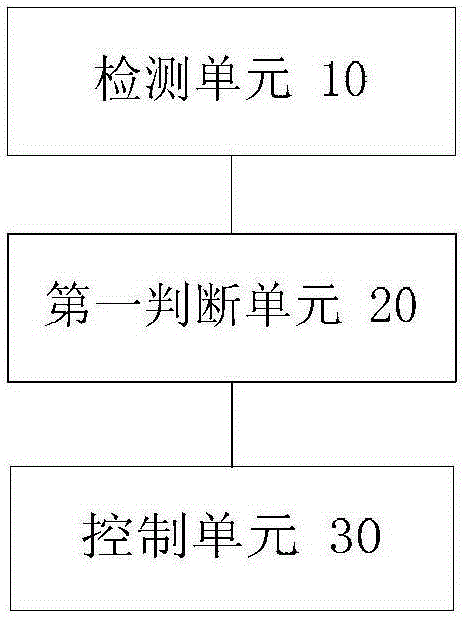

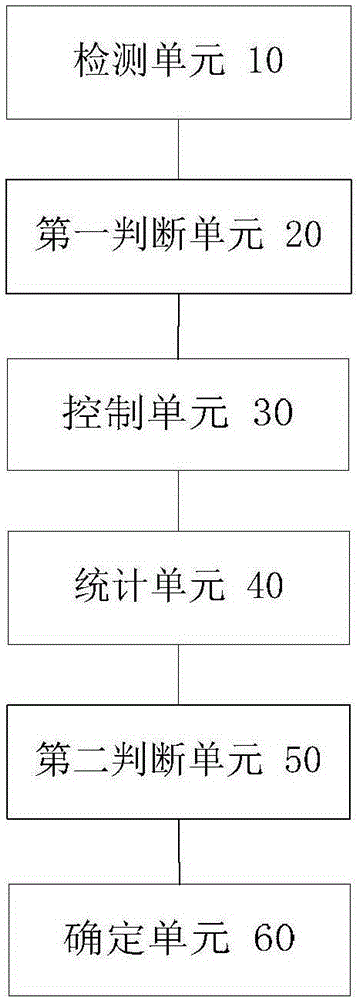

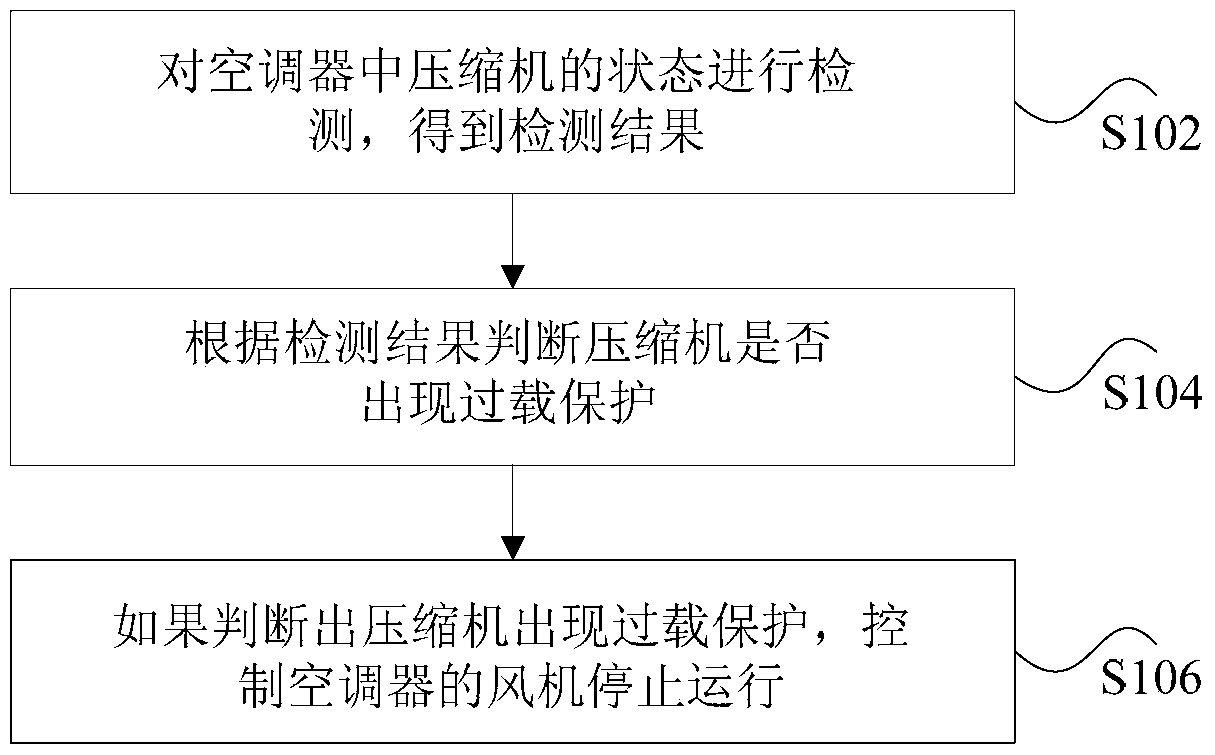

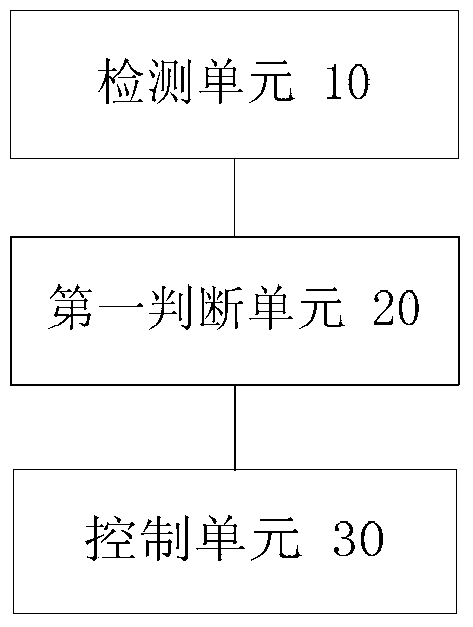

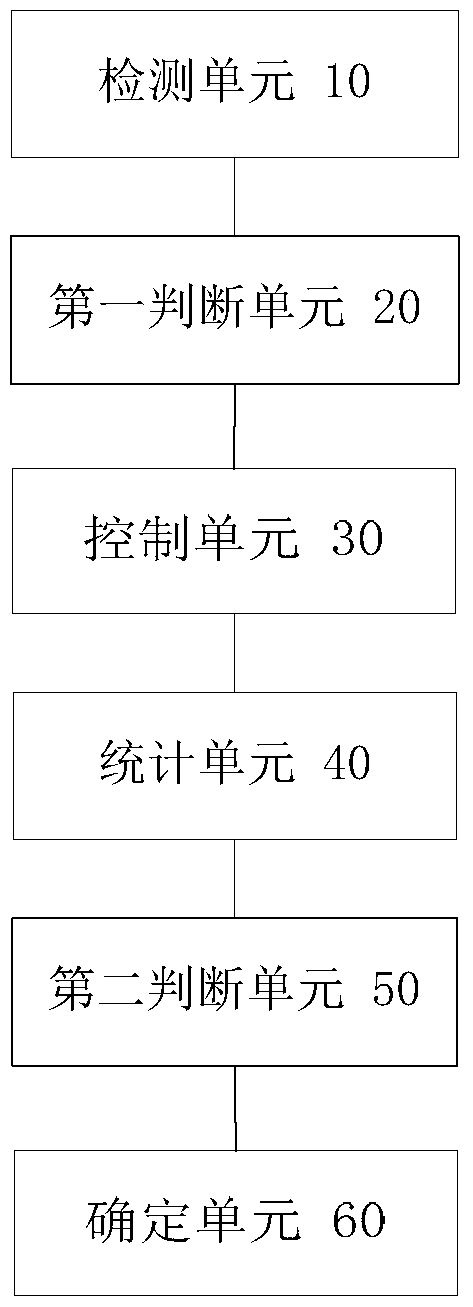

The invention discloses a compressor overload protection control method and device as well as a fixed-frequency air conditioner. The compressor overload protection control method comprises the following steps: detecting the state of a compressor in the air conditioner to obtain a detection result; judging whether the compressor has overload protection according to the detection result; if yes, controlling the draught fan of the air conditioner to stop operation. Through the compressor overload protection control method and device, the possibility that a system pipeline explodes easily caused by the situation that the compressor has overload protection is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

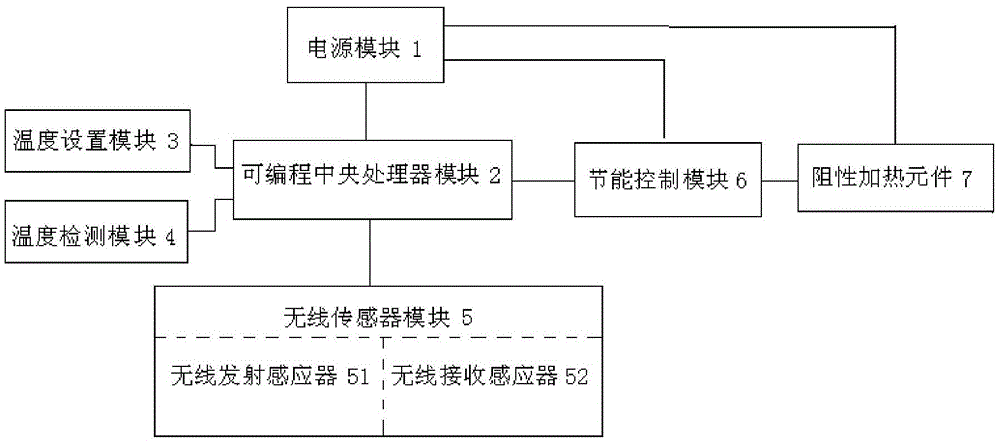

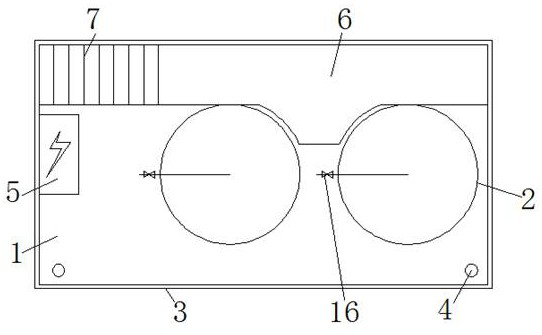

Energy-saving wireless intelligent controlled temperature control system and resistance heating element

ActiveCN103941770AImprove real-time performanceImprove thermal conductivityTemperatue controlHeating element shapesLine sensorWireless

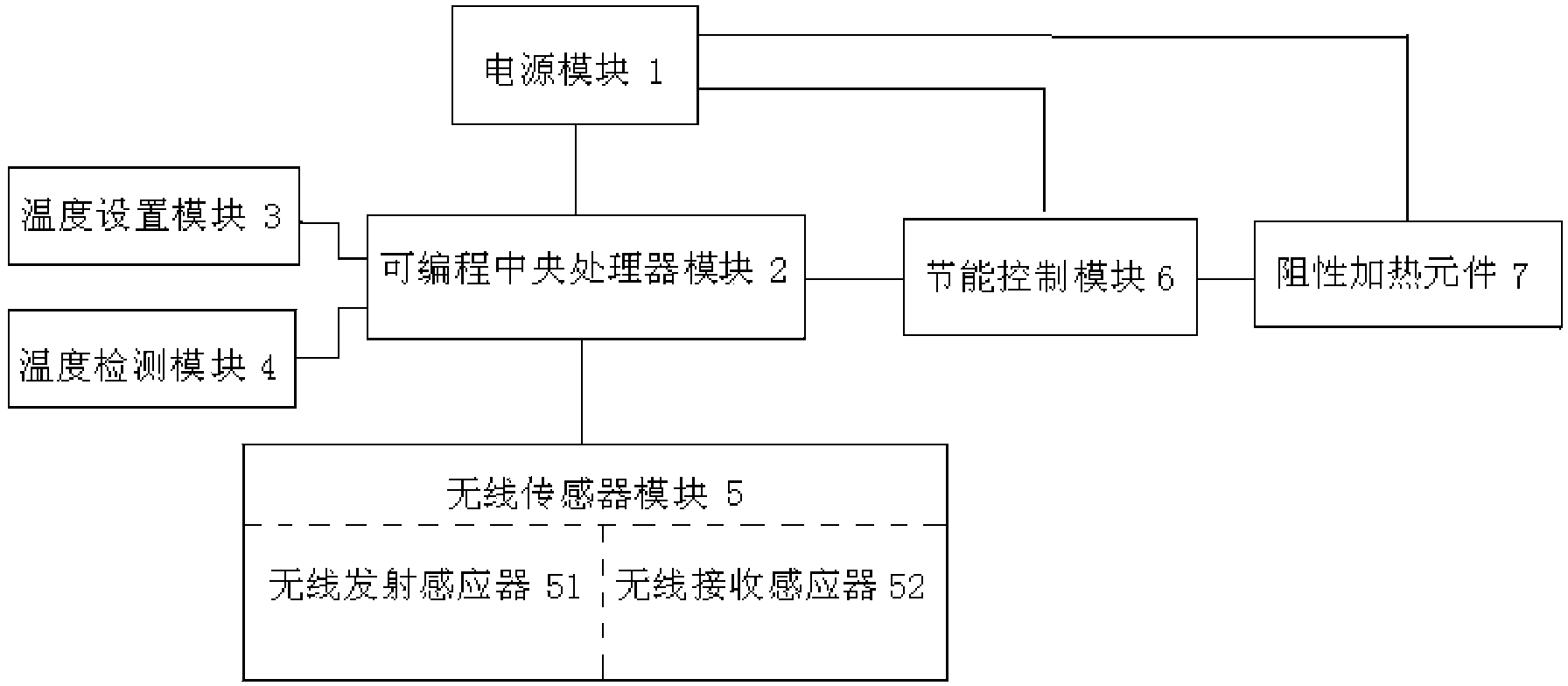

The invention discloses an energy-saving wireless intelligent controlled temperature control system and a resistance heating element. The temperature control system comprises a power supply module (1), a programmable central processor module (2), a temperature setting module (3), a temperature detecting module (4), a wireless sensor module (5), an energy-saving control module (6) and the resistance heating element (7); the central processor module (2) serves as the control core of the temperature control system, the other modules surround the temperature control system to transmit information and / or receive instructions, and real-time temperature adjustment and heating of the resistance heating element (7) can be achieved. In the energy-saving control, a silicon controllable frequency conversion control circuit or an energy-saving wireless sensor power supply is adopted to control the heating element. A wireless sensor is adopted in the aspect of temperature monitoring. A novel insulating structure is adopted for the resistance heating element. By means of the energy-saving wireless intelligent controlled temperature control system and the resistance heating element, the functions of detection, intelligent control and saving energy are achieved, and energy consumption is reduced. The temperature control system and the resistance heating element are suitable for electric water heaters and other environments for heating liquid, and are extremely high in safety.

Owner:北京暖立得热力设备有限公司

Method for protecting surface of water cooling wall tube of boiler

The invention discloses a method for protecting the surface of a water cooling wall tube of a boiler. The method includes the process steps of shot peening treatment and supersonic arc spraying, and specifically includes the following steps that a, surface pretreatment is conducted, specifically, sundries on the surface of the water cooling wall tube are cleared; b, shot peening is conducted, specifically, the surface of the water cooling wall tube are subjected to ultrasonic shot peening treatment by projectiles ejected by an ultrasonic shot-blasting machine; c, spraying is conducted, specifically, after shot peening, supersonic arc spraying equipment is used for spraying an HDS-88A coating on the water cooling wall tube after shot peening treatment, and the thickness of the coating is 0.6-0.8 mm; and d, hole sealing is conducted, specifically, the HDS-88A coating is subjected to hole sealing through a hole sealing agent. According to the method for protecting the surface of the watercooling wall tube of the boiler, the technologies of ultrasonic shot peening and supersonic spraying are combined, properties such as wear resistance, fatigue fracture resistance and corrosion resistance of the water cooling wall tube are effectively improved, and the service life of the water cooling wall tube is prolonged.

Owner:上海蜂云航空科技有限公司

Water heating device, control method thereof and water dispenser

The invention discloses a water heating device, a control method thereof and a water dispenser. The water heating device comprises a water tank, a pre-heater, a heater, a water pump, a control valve, a temperature sensor and a controller, wherein the pre-heater is communicated with the water tank, the heater is provided with an inlet and an outlet, the inlet of the heater is communicated with the pre-heater, the water pump is connected between the water tank and the inlet of the heater, the control valve is connected between the water tank and the inlet of the heater, the temperature sensor is arranged on the heater, and the controller is connected with the temperature sensor and the water pump, and controls rotating speed of the water pump according to a water temperature detecting value of the temperature sensor. According to the water heating device of the embodiment, the output water temperature can be adjusted in a stepless mode, and the water heating device has the advantages of being large in hot water output amount, high in heating efficiency, small in generated steam amount, long in service life, safe, reliable and the like.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

Method for keeping constant pressure water supply for urban water supply pipe network

InactiveCN108316408ARealize constant pressure water supplyRealize long-distance transmissionService pipe systemsWater mainsUrban water supplyEngineering

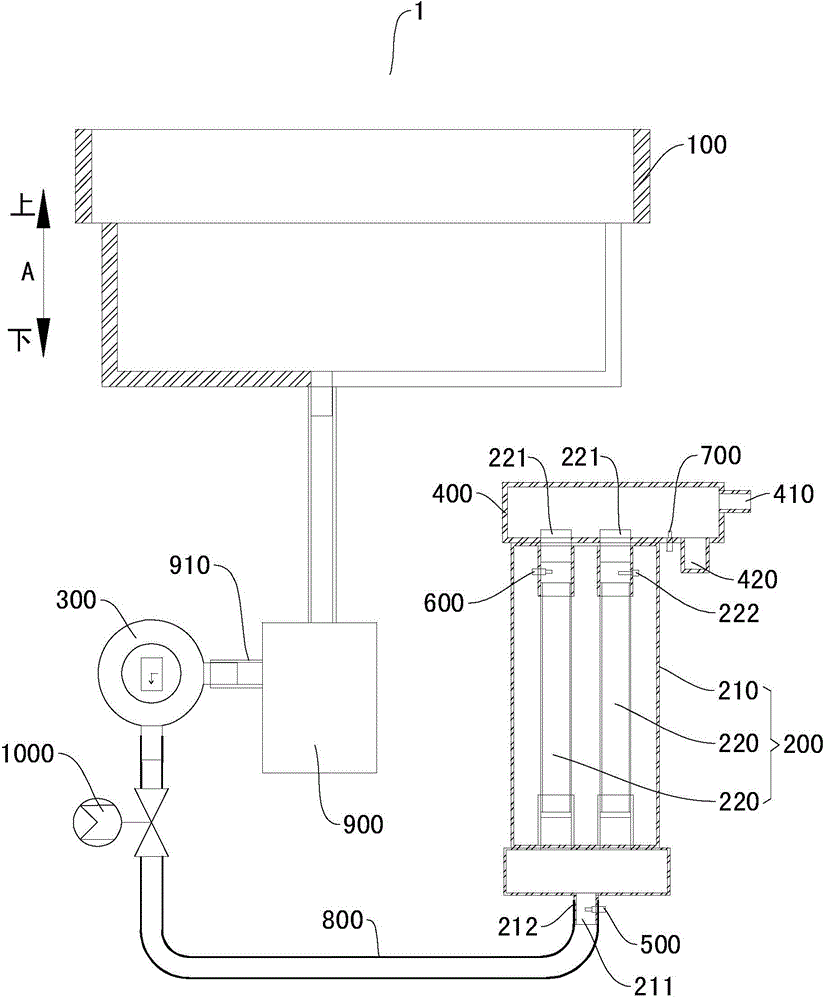

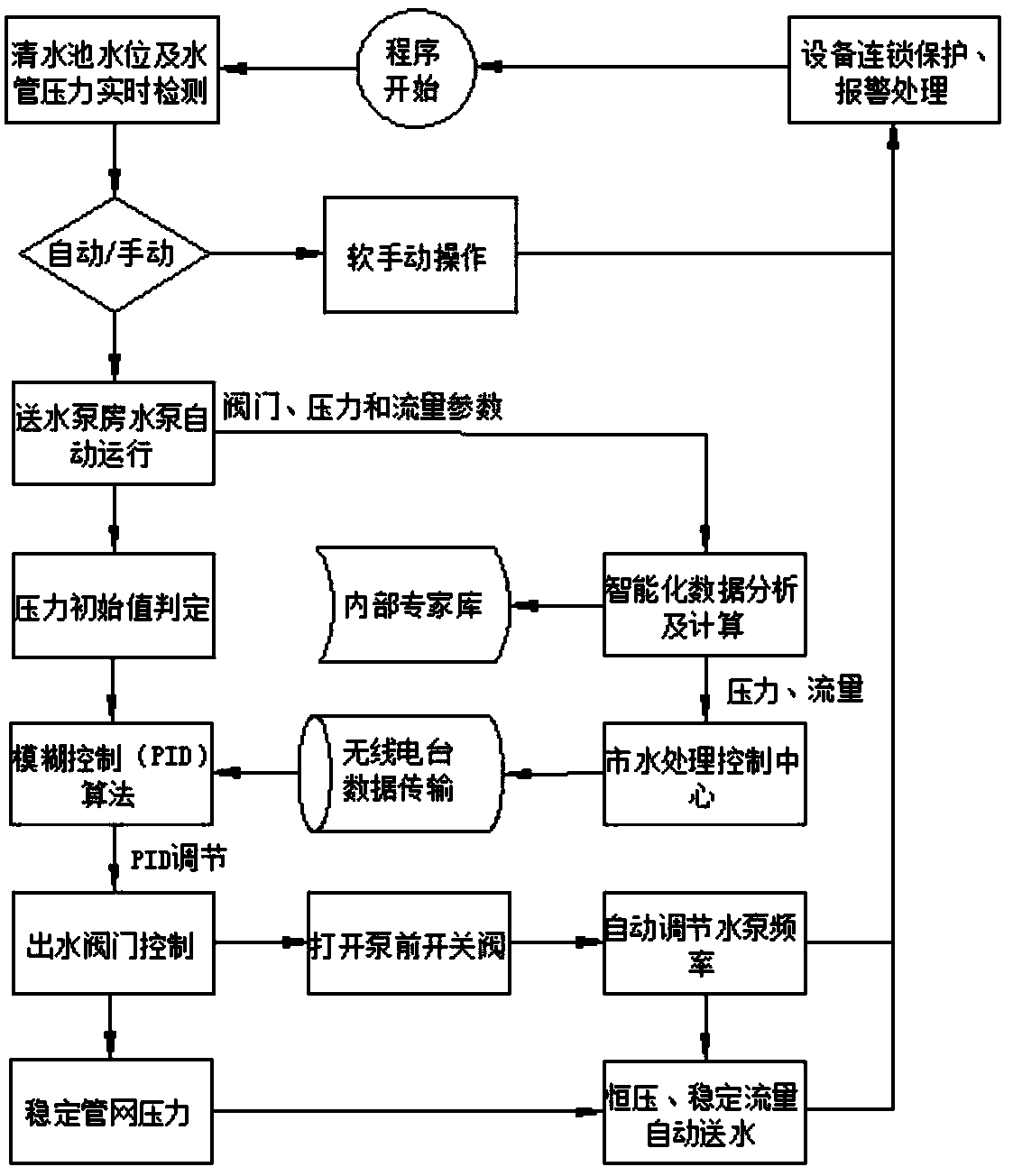

The invention discloses a method for keeping constant pressure water supply for an urban water supply pipe network. A digital radio is utilized to achieve long-distance data transmission and adopts aDSP technology for self-adaptive balance, a main digital ratio is arranged in a water system control center in the city, main digital ratios are arranged in all subordinate water plants respectively to be used for mutually transmitting data and are mainly in charge of uploading pressure and flow of a main pipe network and water plant data, a pressure transmitter and an electromagnetic flowmeter acquiring device are added on an inlet and an outlet of the pipe network respectively, a signal is wirelessly transmitted, data is transmitted to a water pump house monitoring center through a DSP, datacommunication is conducted with a PLC system of a water delivering pump house of a large earth surface water plant, a water delivering pump is interlocked with pipe network pressure data, and a waterdelivering frequency converter achieves PID control. To solve the problems of water pressure fluctuation among urban tap water pipe networks and long-distance communication, the novel control methodis provided, pressure is automatically kept balanced, and stable water supply is guaranteed.

Owner:河北天俱时自动化科技有限公司

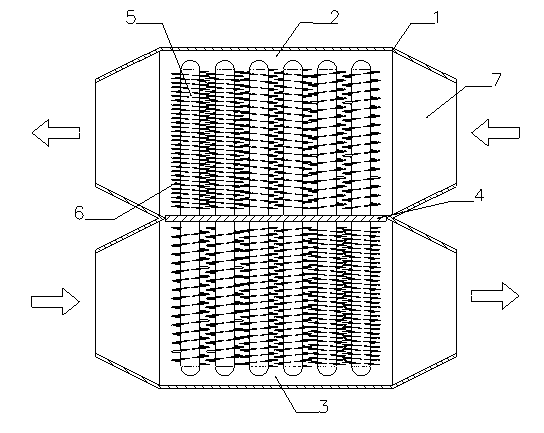

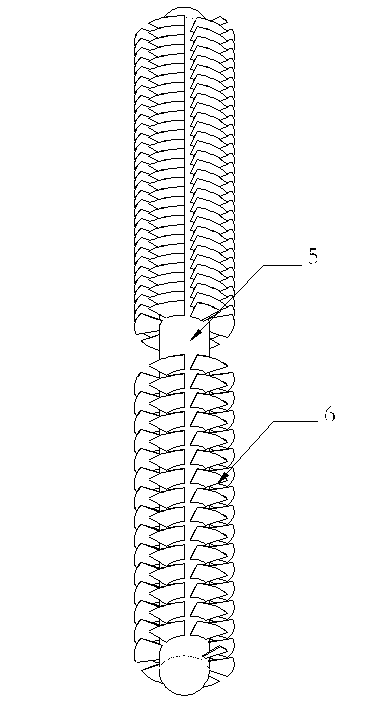

Heat pipe air pre-heater capable of preventing dew point corrosion

InactiveCN103234374AReduce corrosionReduce the problem of high temperature pipe burstCorrosion preventionIndirect heat exchangersAir preheaterEngineering

The invention discloses a heat pipe air pre-heater capable of preventing dew point corrosion. The heat pipe air pre-heater comprises a box body, wherein a partition board dividing an inner cavity of the box body into a cold flow cavity and a hot flow cavity is arranged in the box body, and the cold flow cavity and the hot flow cavity are vertically arranged and are not connected with each other. Heat pipes are inserted onto the partition board in penetrating mode, the upper sections of the heat pipes are located in the cold flow cavity, and the lower sections of the heat pipes are located in the hot flow cavity. Spiral fins are connected onto the outer surfaces of all the heat pipes, the total area of the fins on the upper sections of the front two rows of heat pipes located close to an output port at the right end of the hot flow cavity is smaller than that of the fins on the lower sections of the front two rows of heat pipes, the total area of the fins on the upper sections of the last two rows of heat pipes located close to an input port at the left end of the hot flow cavity is larger than that of the fins on the lower sections of the last two rows of heat pipes, and the total areas of the fins on the upper sections and the lower sections of the other heat pipes are identical. The heat pipe air pre-heater can effectively reduce dew point corrosion and high-temperature pipe explosion, is provided with a heat exchange device with high heat exchange efficiency and a self ash removal function, and has the advantages of being efficient, safe and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Special rubber roll material for pipeline thermal preserving heat insulating sound-proof and its production tech.

InactiveCN1861672AReduce bonding processReduce trafficThermal insulationPipe protection by thermal insulationElastomerPetroleum

This invention relates to a specialty elastomer web used for pipe warming, thermal insulating and noise insulating. It contains odor-free specialty elastomer, tackifying resin, white, light calcium carbonate, pottery clay, carbon black, age resister. The method includes (1) compound, (2) initial refine, (3)warm, (4)calender and compound, (5)press under low temperature,(6) appearance and dimension detect, (7)collect and coil. It can be used for enveloping and wrapping pipe in industry and civilian architectural, and petroleum or natural gas pipe, to prevent water freezing and pipe cracking under 0 deg.C, special -20deg.C or below. It can reduce noise to 10dB or below.

Owner:何霖

Method for eliminating W and U type pipeline air jam

ActiveCN104501650AEliminate air lockChemical cleaning goes wellFlush cleaningElimination methodProduct gas

The invention discloses a method for eliminating W and U type pipeline air jam. The method comprises the steps that 1, the two ends of a system inlet and outlet pipe connected with a W and U type pipeline are connected with temporary pipelines respectively, and the two ends of the W and U type pipeline are isolated and sealed through temporary valves; 2, an air exhaust hole and an air inflation hole are formed in the temporary pipelines at the two ends of the isolation sealing segment of the W and U type pipeline, and are connected with a vacuum pump and an inflation source respectively; 3, the vacuum pump is adopted to carry out vacuumizing on the isolation sealing segment of the W and U type pipeline, air exhausting is continuously kept, soluble gas X is inflated, repeated operation is carried out, and the air source is closed until the interior of the isolation sealing segment of the W and U type pipeline is completely replaced by the inflated soluble gas X; and 4, the temporary valve at one end of the W and U type pipeline is opened, aqueous solutions slowly enter the pipeline, the inflated soluble gas can be completely dissolved in the solutions, and no new gas is generated. The problem that the air jam is generated in the earlier stage that the W and U type pipeline is chemically cleaned is solved, and the guarantee is provided for smooth operation of subsequent chemical cleaning, the cleaning effect and normal starting and running of a power station.

Owner:XIAN THERMAL POWER RES INST CO LTD

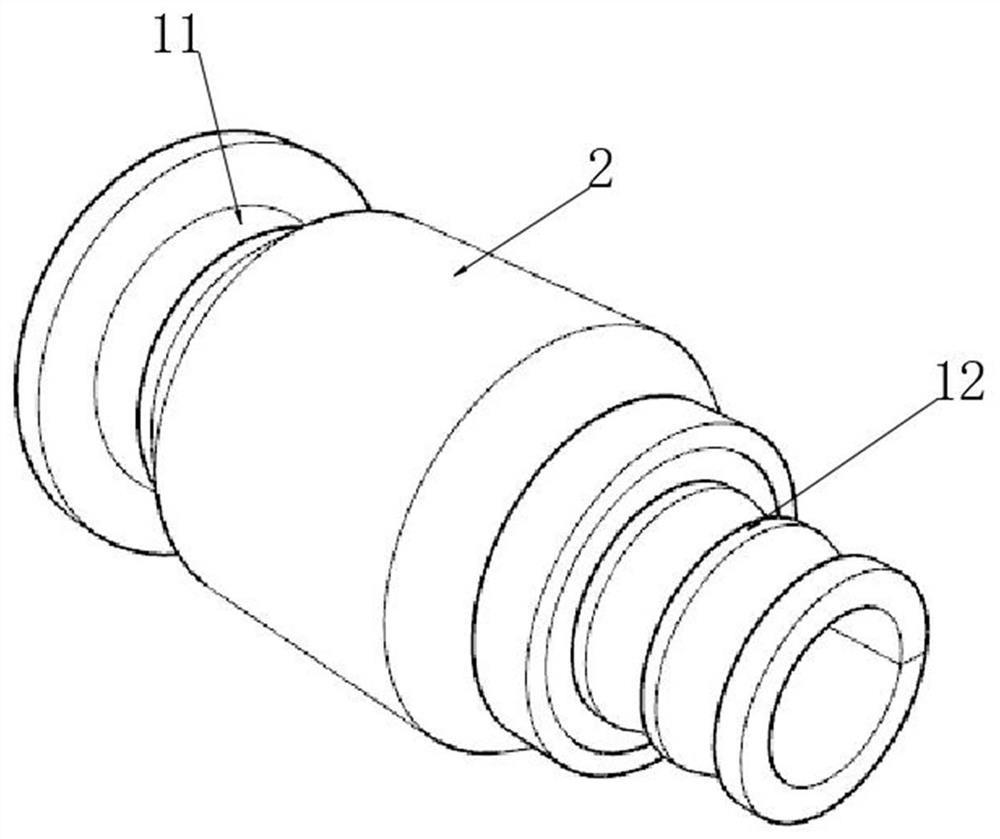

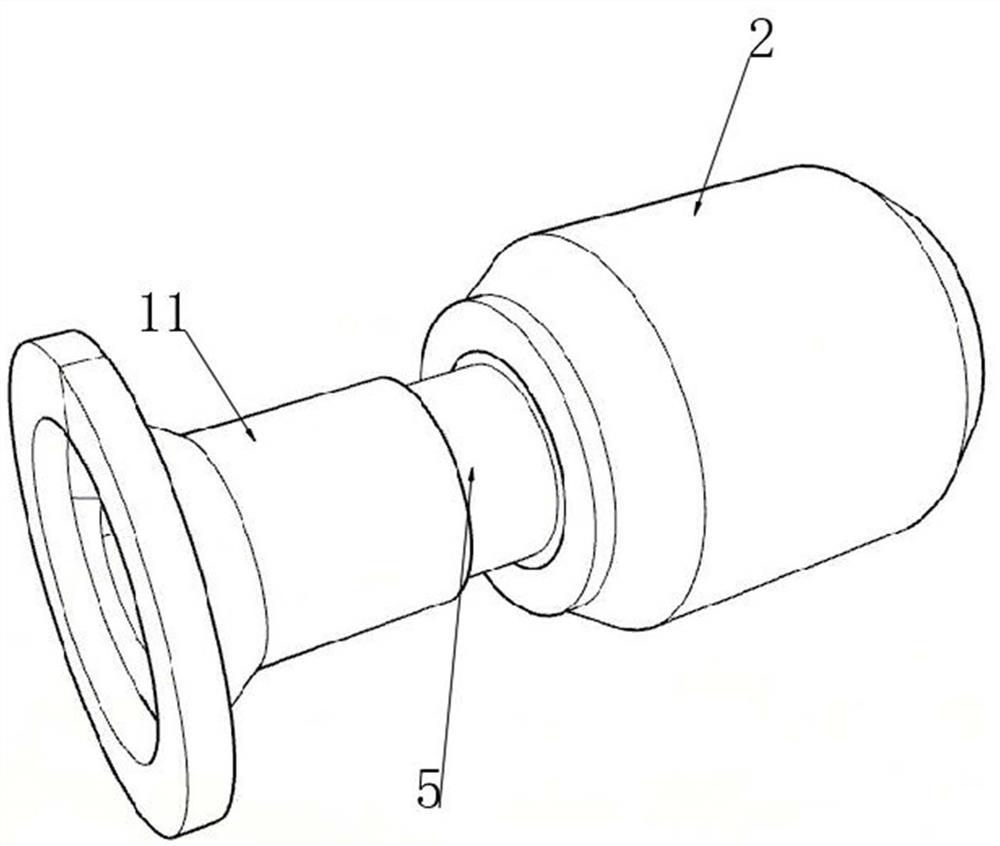

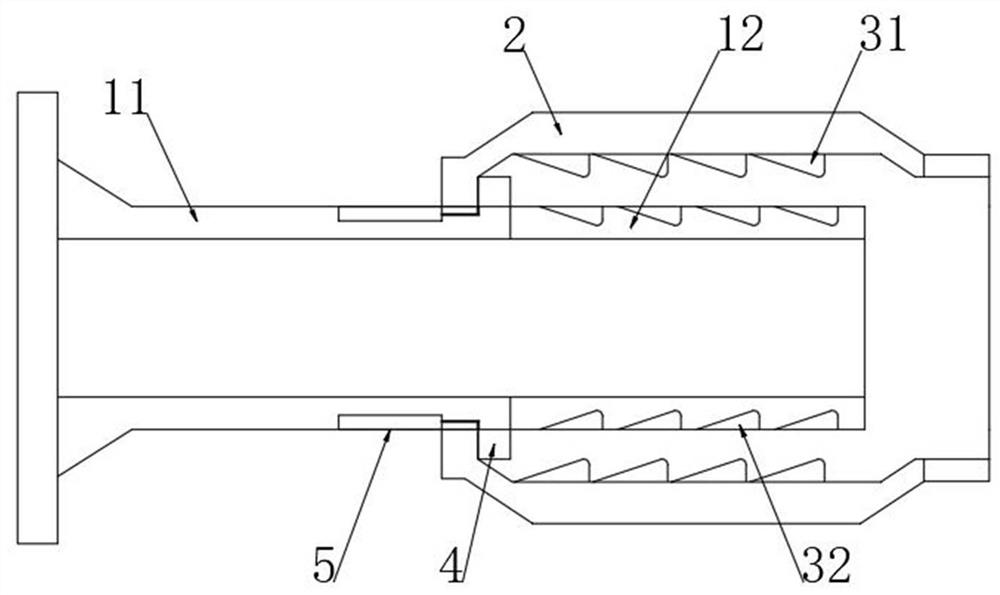

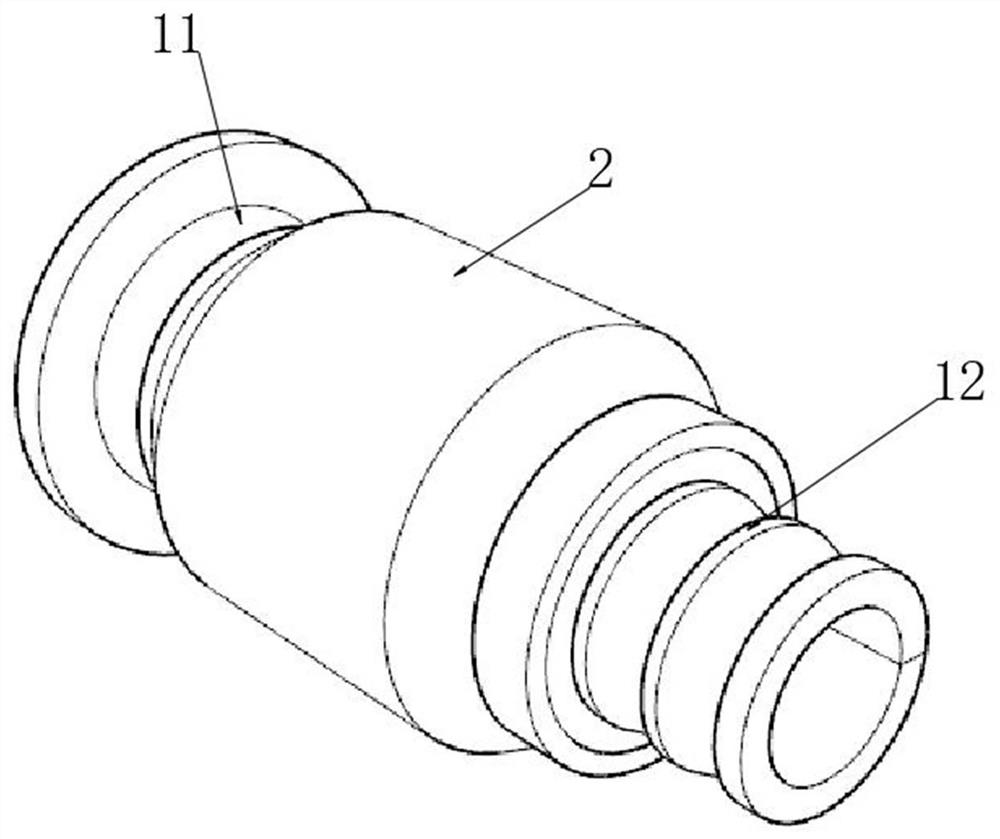

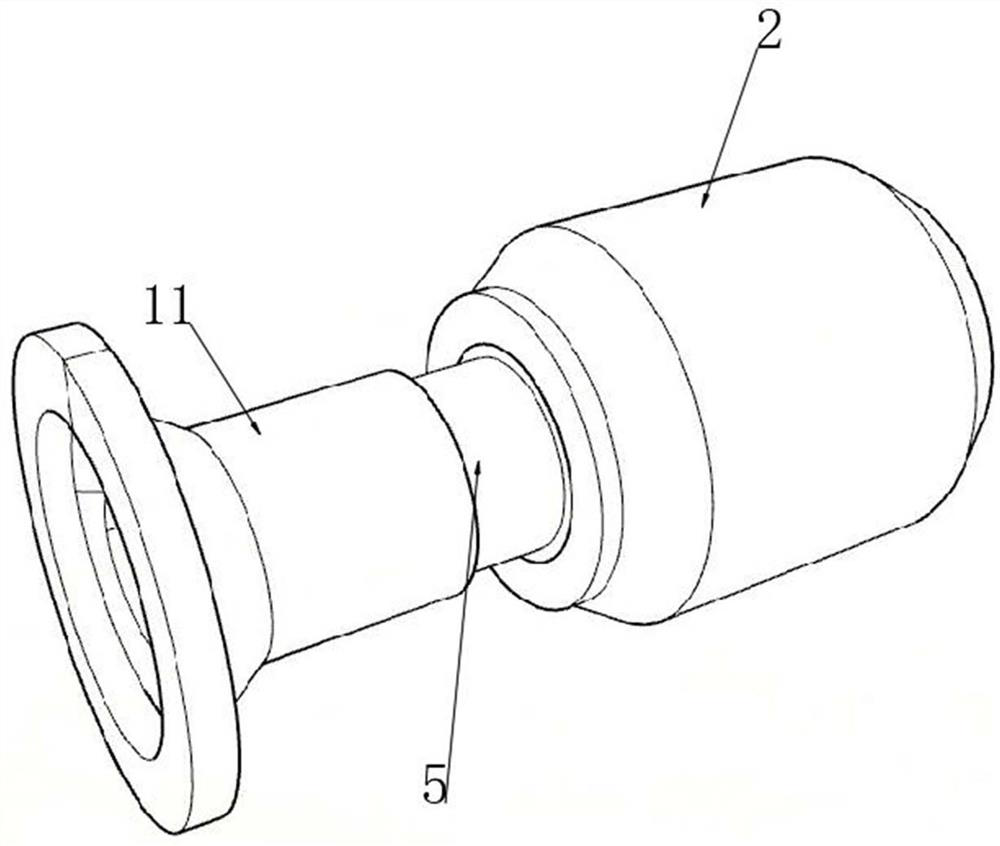

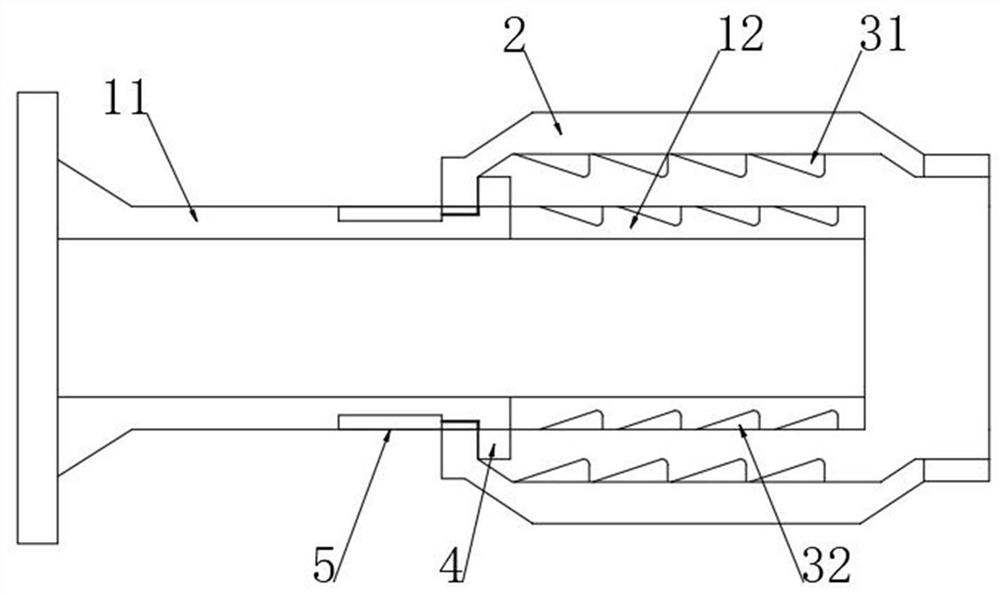

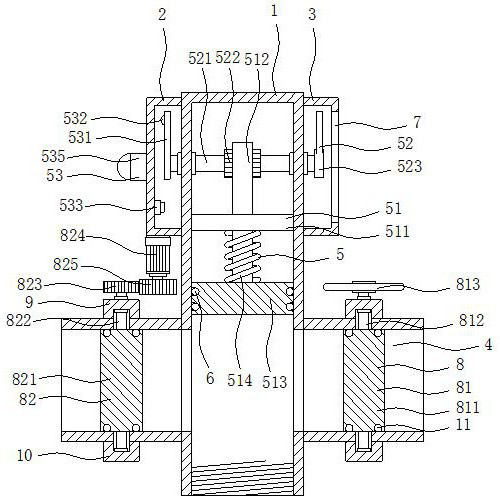

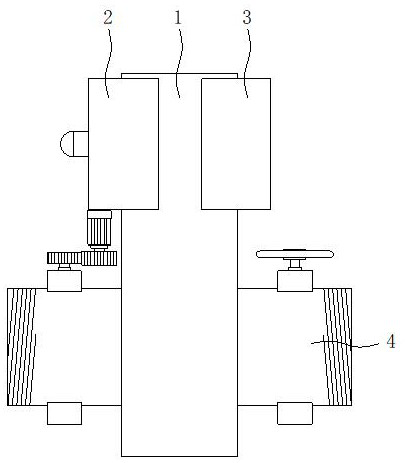

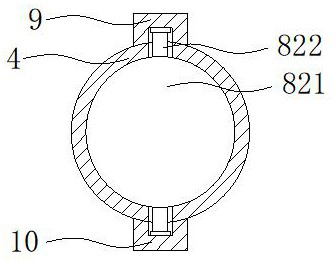

Hydraulic high-stability rubber hose connector

ActiveCN113503411AAvoid loose situationsReduce squibEngine sealsPipe couplingsClassical mechanicsHydraulic pressure

The invention discloses a hydraulic type high-stability rubber pipe joint, and belongs to the field of pipe joints. According to the hydraulic type high-stability rubber pipe joint, through the arrangement of a hydraulic variable pipe, when fluid passes through, the hydraulic variable pipe extrudes a rubber pipe and expands towards the inner wall of an outer sleeve shell under the action of fluid pressure, an outer top ring wedge extrudes the rubber pipe, at the moment, the rubber pipe is locally deformed and falls into a corresponding concave ring wedge groove, connection between a fastening rubber pipe and the connector is extruded through the pressure of the fluid, the effect that the connection stability between the fastening rubber pipe and the connector is higher along with the increase of the liquid pressure is achieved, compared with the prior art, the situation that the connector is loosened due to liquid impact force is effectively avoided, in addition when the rubber pipe and the connector are accidentally loosened, the sealing performance is weakened, part of the fluid permeates into an early warning ring groove along a liquid guide layer, the color of a developing point is changed, therefore early warning is conducted on workers, and the occurrence rate of the pipe explosion phenomenon is reduced through timely maintenance.

Owner:南通美莱达科技有限公司

Emulsified oil for mining hydraulic support

ActiveCN103937592ANo pollution in the processReduce sluggishnessLubricant compositionGlycol synthesisPetroleum oil

The invention provides an emulsified oil for a mining hydraulic support. The emulsified oil is composed of the following substances in percentage by weight: 15.0%-20.0% of mineral base oil, 8.0%-10.0% of boric acid, 10.0%-12.0% of triethanolamine, 10.0%-11.0% of petroleum sodium sulfonate, 0.5%-0.8% of benzotriazole, 20.5%-22.5% of ethylene glycol, 13.5%-15.5% of urea, 6.0%-8.0% of EDTA (Ethylene Diamine Tetraacetic Acid)-tetra sodium, 1.0%-1.5% of sodium hydroxide and the balance of water. The emulsified oil has excellent freeze-thaw property, wear resistance, extreme pressure resistance, and rust and corrosion resistance, and thus is capable of satisfying the use of the hydraulic support under the conditions of an underground severe environment.

Owner:特浦朗克材料科技(营口)股份有限公司

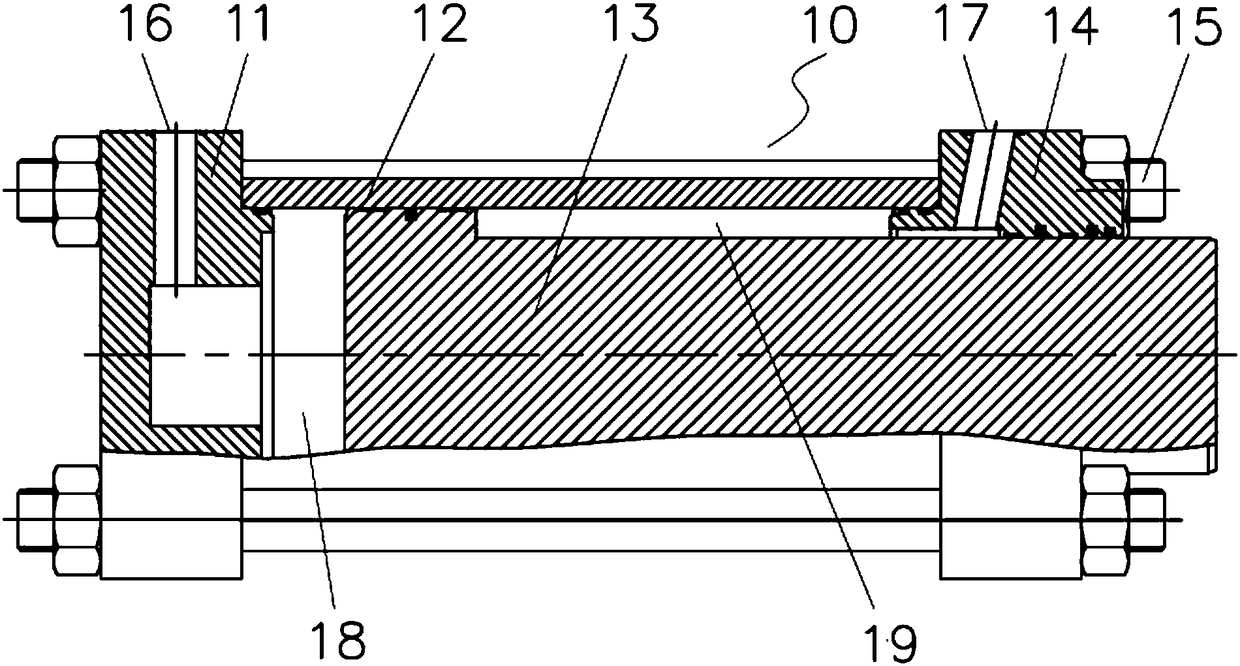

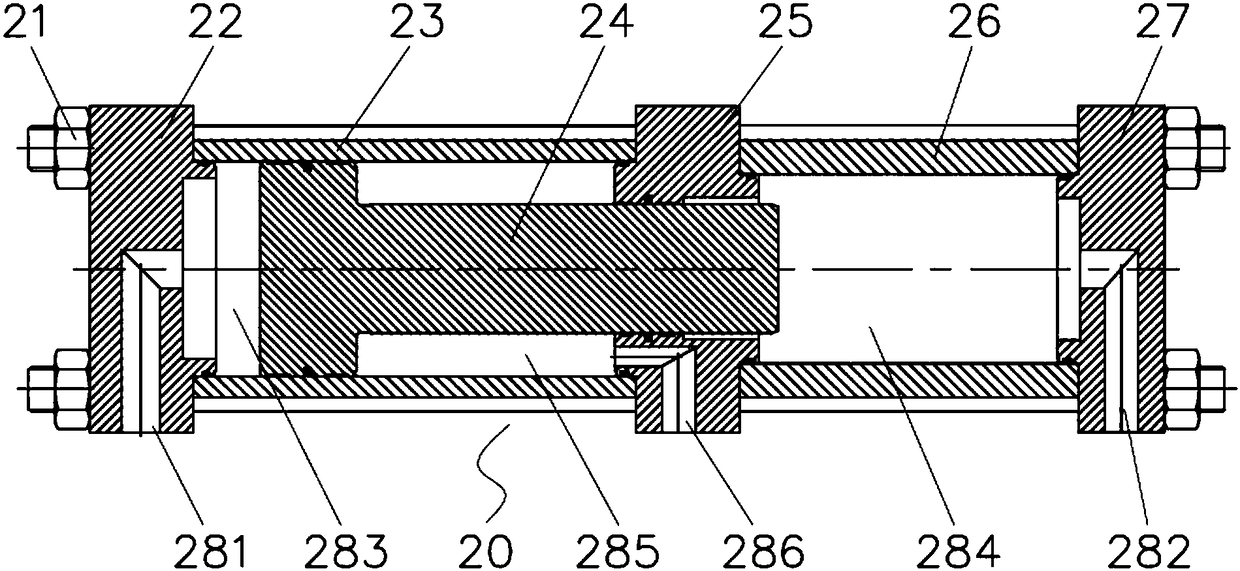

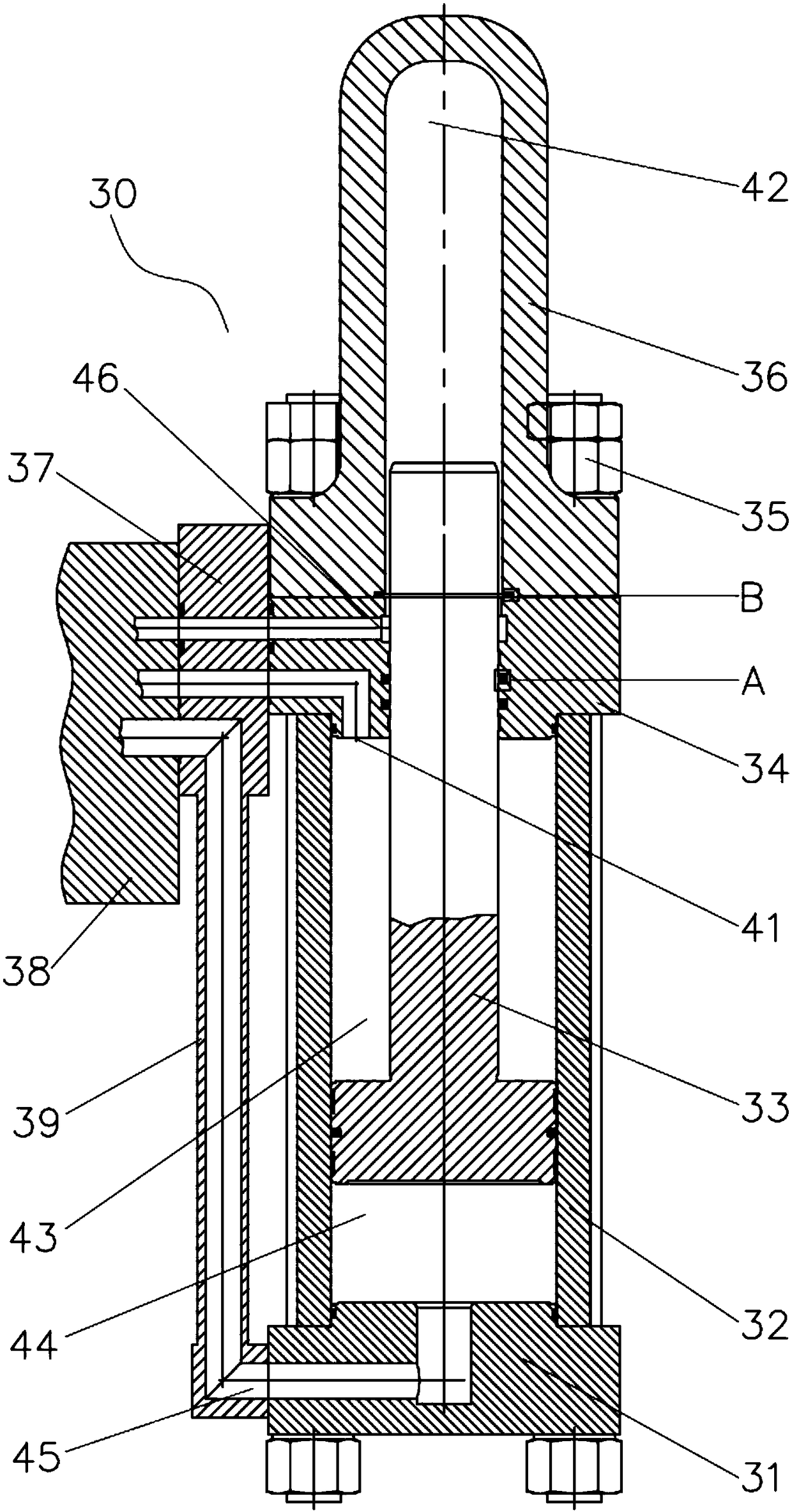

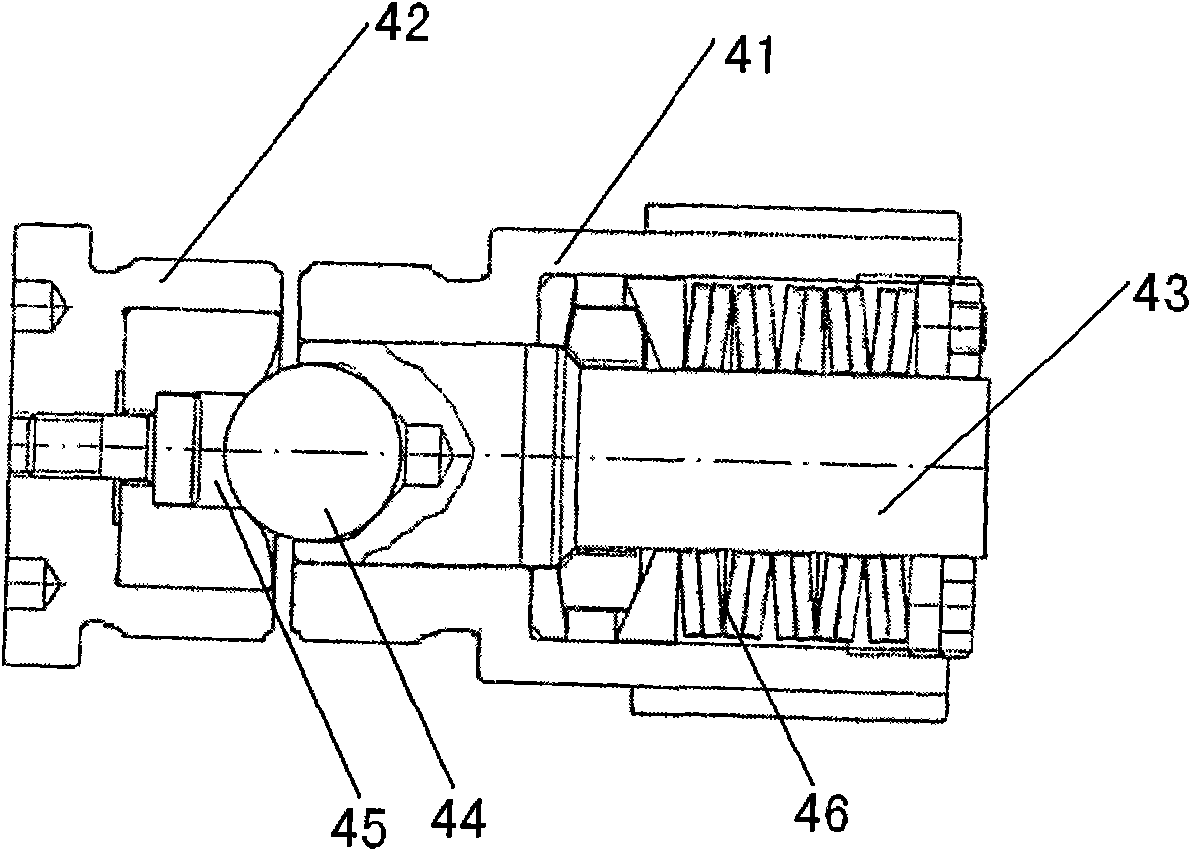

Ultrahigh pressure supercharger

InactiveCN108730242ASimple structural designSimple structureFluid-pressure convertersFluid-pressure actuatorsPulp and paper industryPiston rod

The invention relates to an ultrahigh pressure supercharger which comprises a low-pressure flange, a low-pressure cylinder barrel, a piston, a middle flange, an ultrahigh pressure cylinder barrel, a transitional plate, an oil way board and a connecting tube. The low-pressure flange is arranged at the bottom of the low pressure cylinder barrel, and the two ends of the middle flange are closely connected with the low-pressure cylinder barrel and the ultrahigh pressure cylinder barrel. The piston comprises a head part and a piston rod connected with the head part, the head part is closely attached to the inner wall of the low-pressure cylinder barrel, and the piston rod penetrates through the middle flange and extends into the ultrahigh pressure cylinder barrel. The oil way board and the transitional plate are sequentially mounted on the side portion of the middle flange through bolts. The ultrahigh pressure supercharger is reasonable in structural design and capable of sealing the pressure from 0 MPa to 80 MPa, guarantees the reliability of sealing, reduces external pipelines, lowers oil leakage potential hazards, and meanwhile increases the attractiveness.

Owner:KEDA INDUSTRIAL GROUP CO LTD

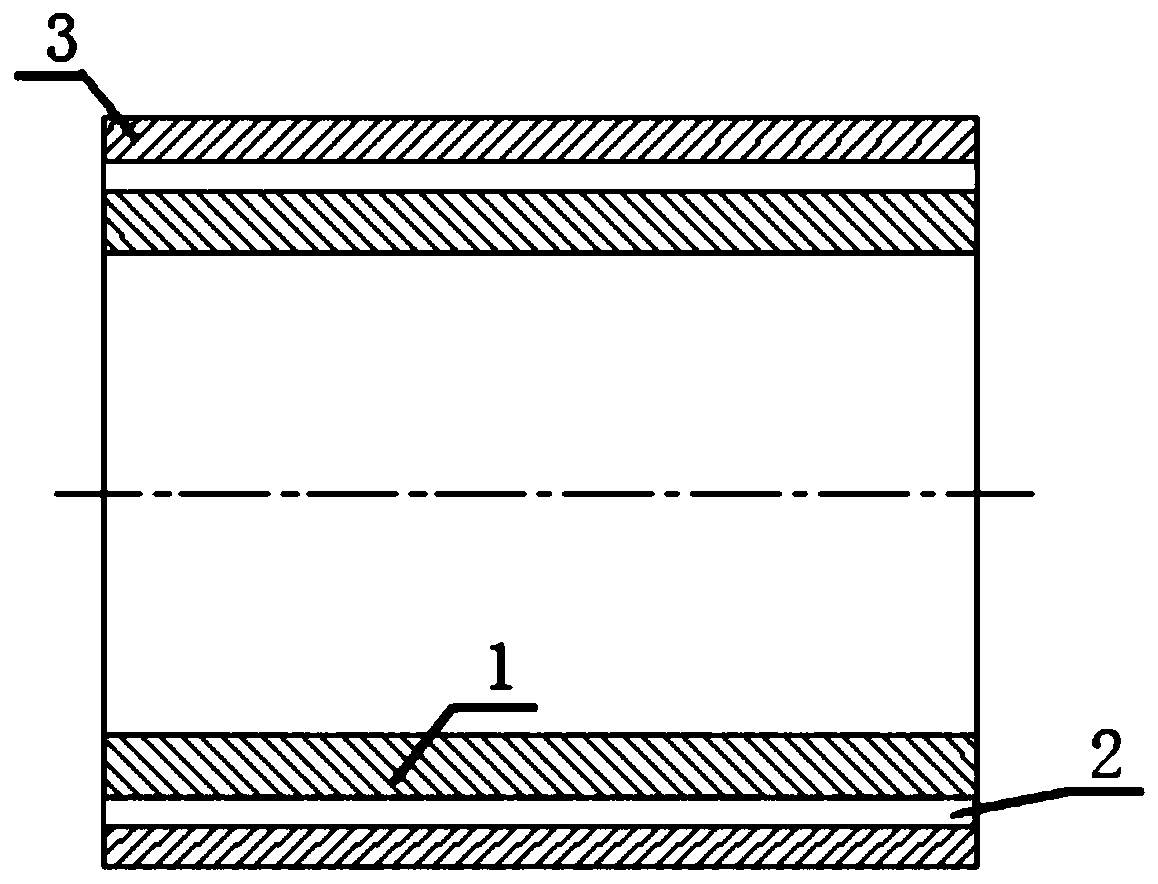

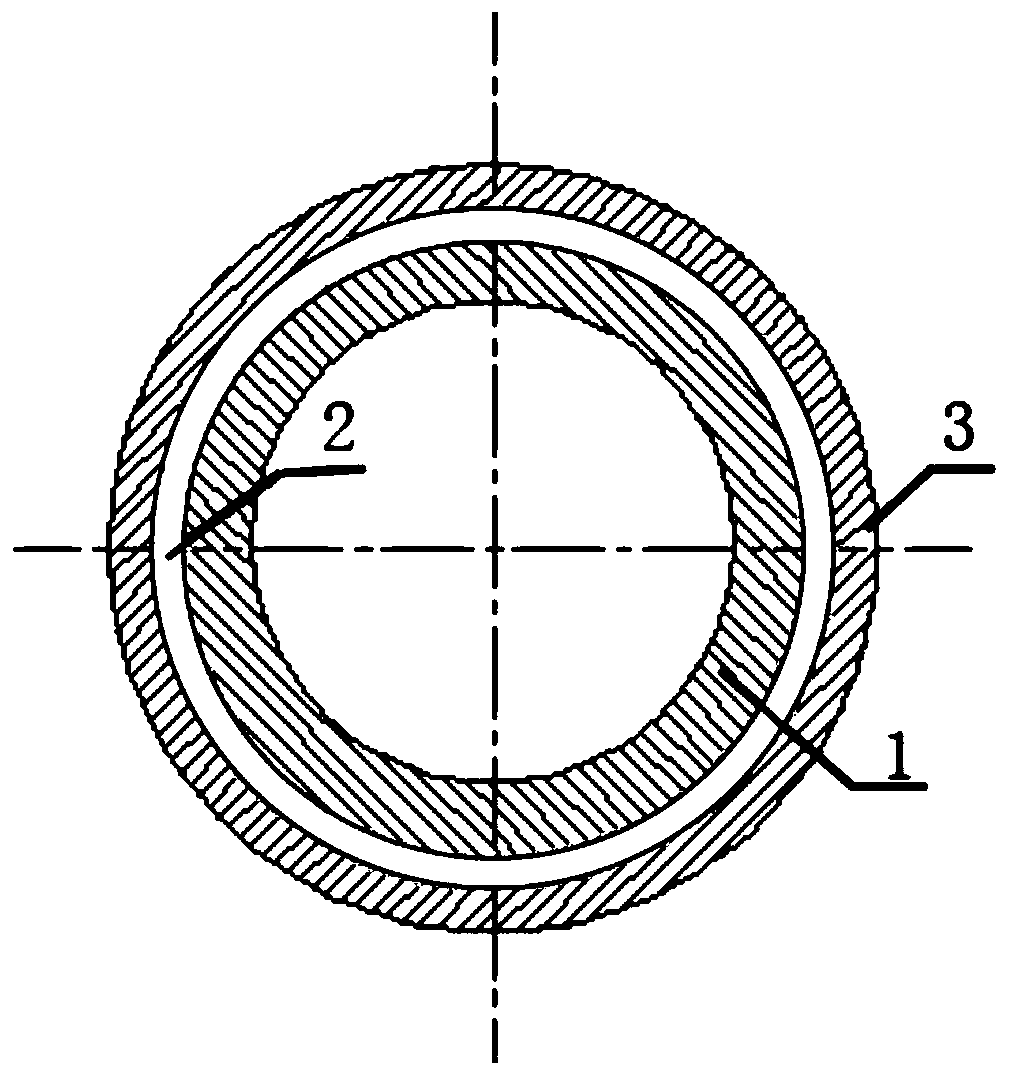

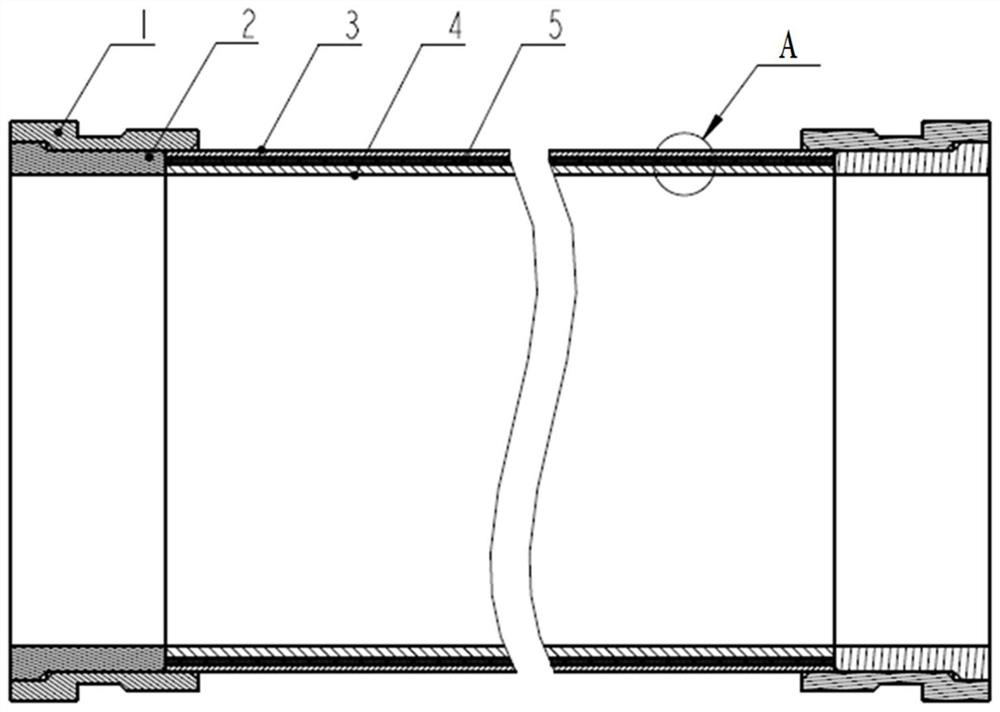

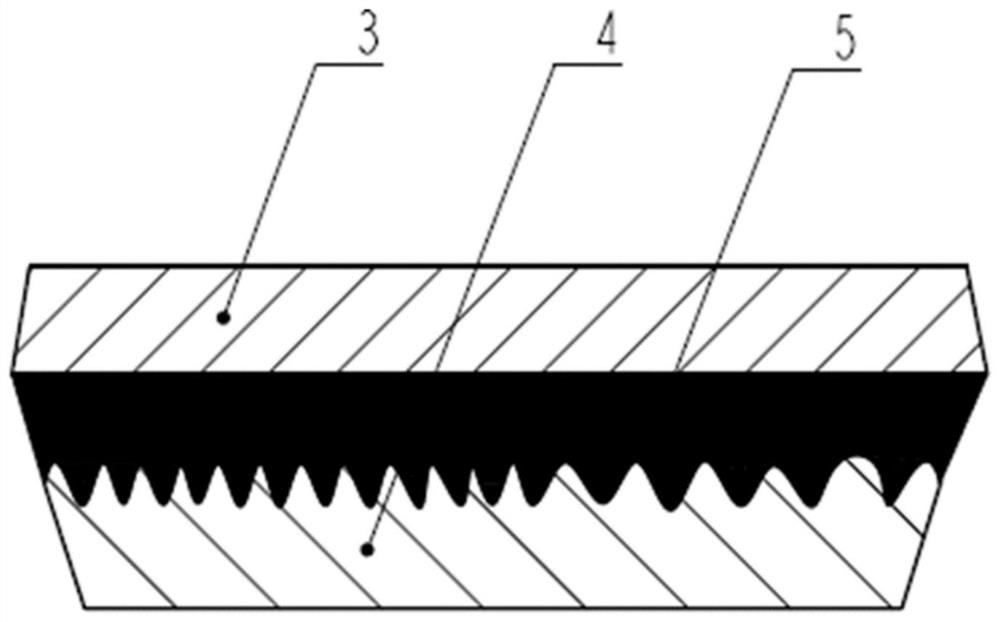

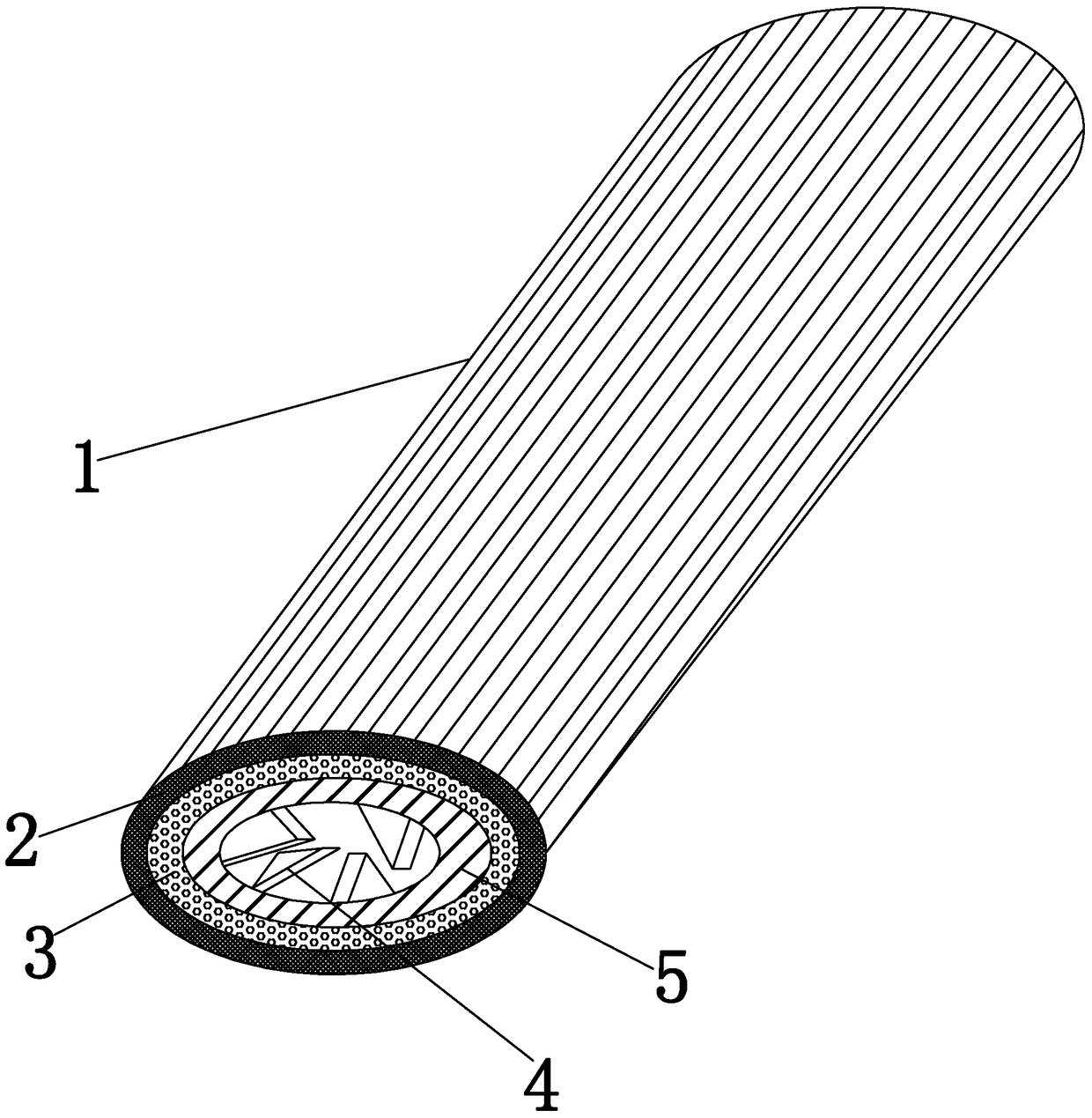

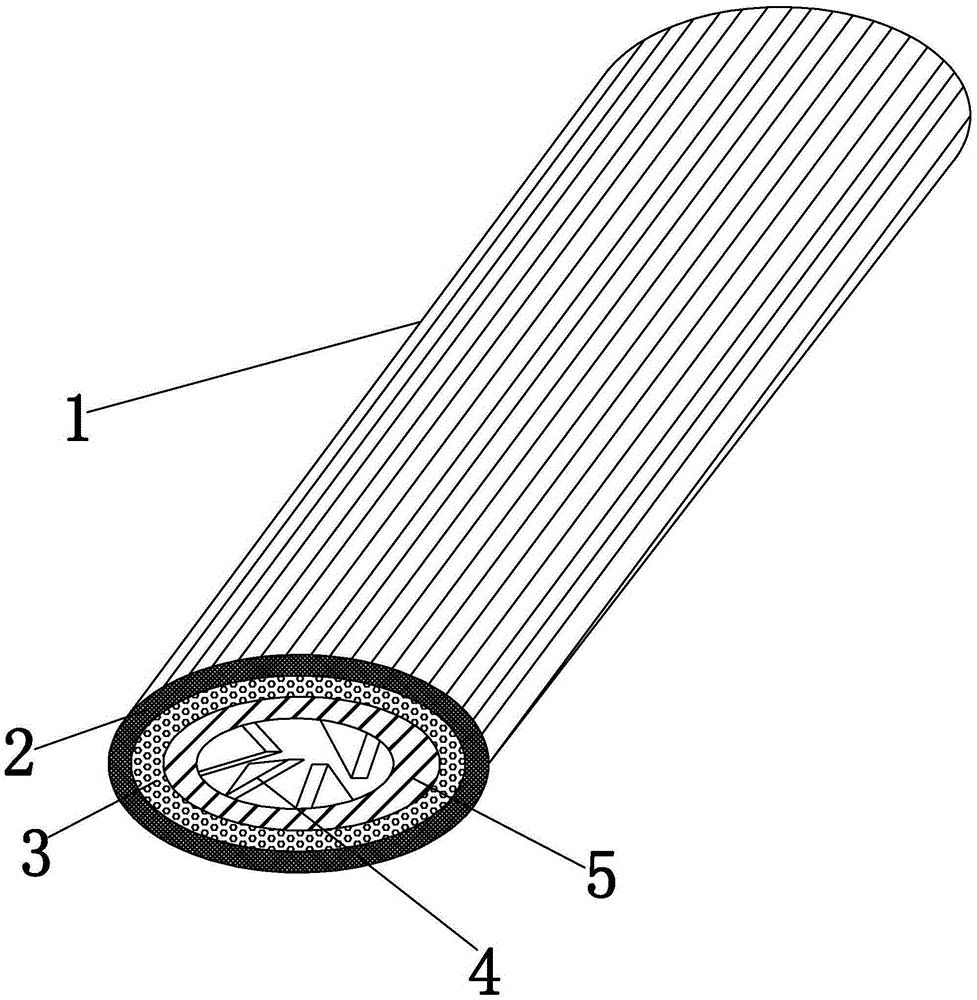

Double-metal composite tube with rubber interface structure and manufacturing method thereof

InactiveCN110450428AHigh bonding strengthReduce lining instabilityTubular articlesBonding strengthMaterials science

The invention discloses a double-metal composite tube with a rubber interface structure. The double-metal composite tube comprises a base tube, a rubber layer and an inner liner tube which are tightlycombined from outside to inside in sequence. The invention further discloses a manufacturing method of the double-metal composite tube with the rubber interface structure. According to the double-metal composite tube, the problem that the bonding strength of a base tube and a lining tube is low in the prior art is solved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

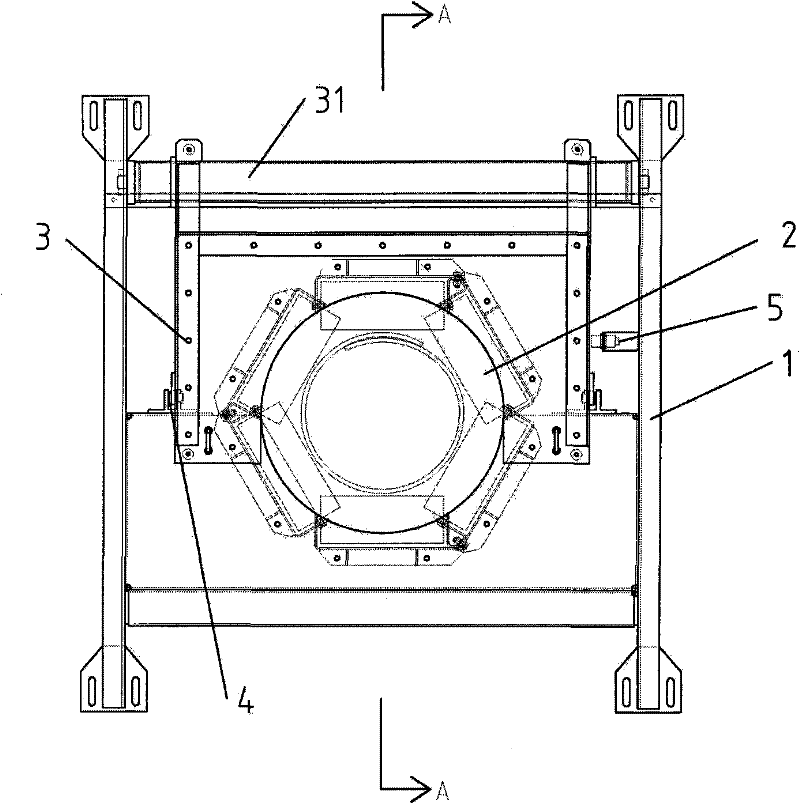

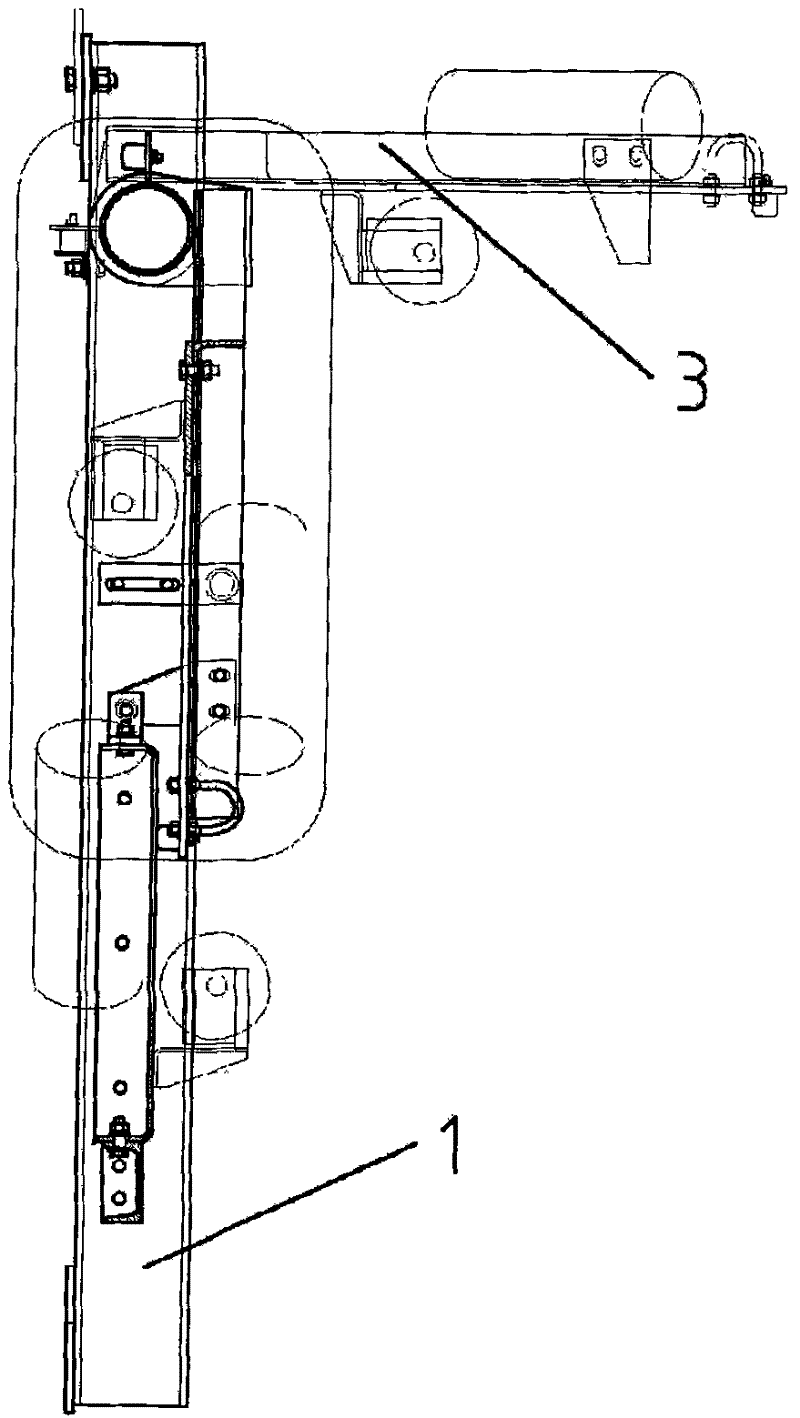

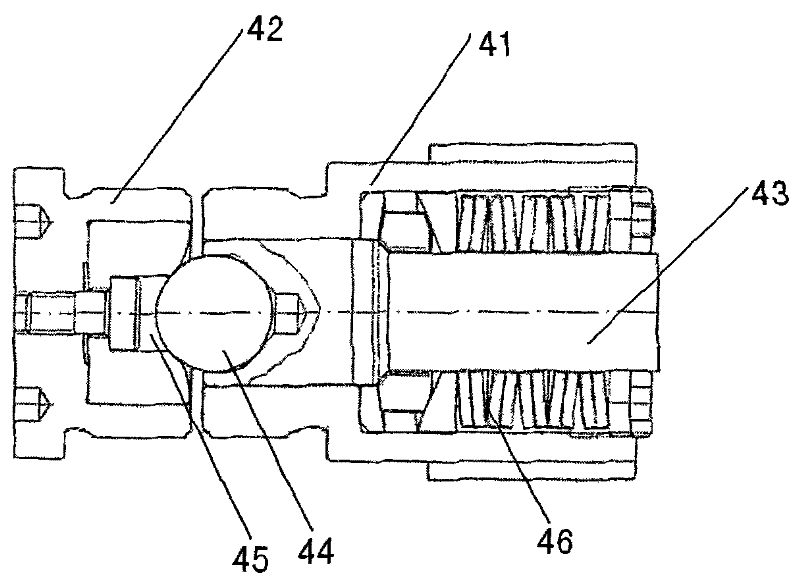

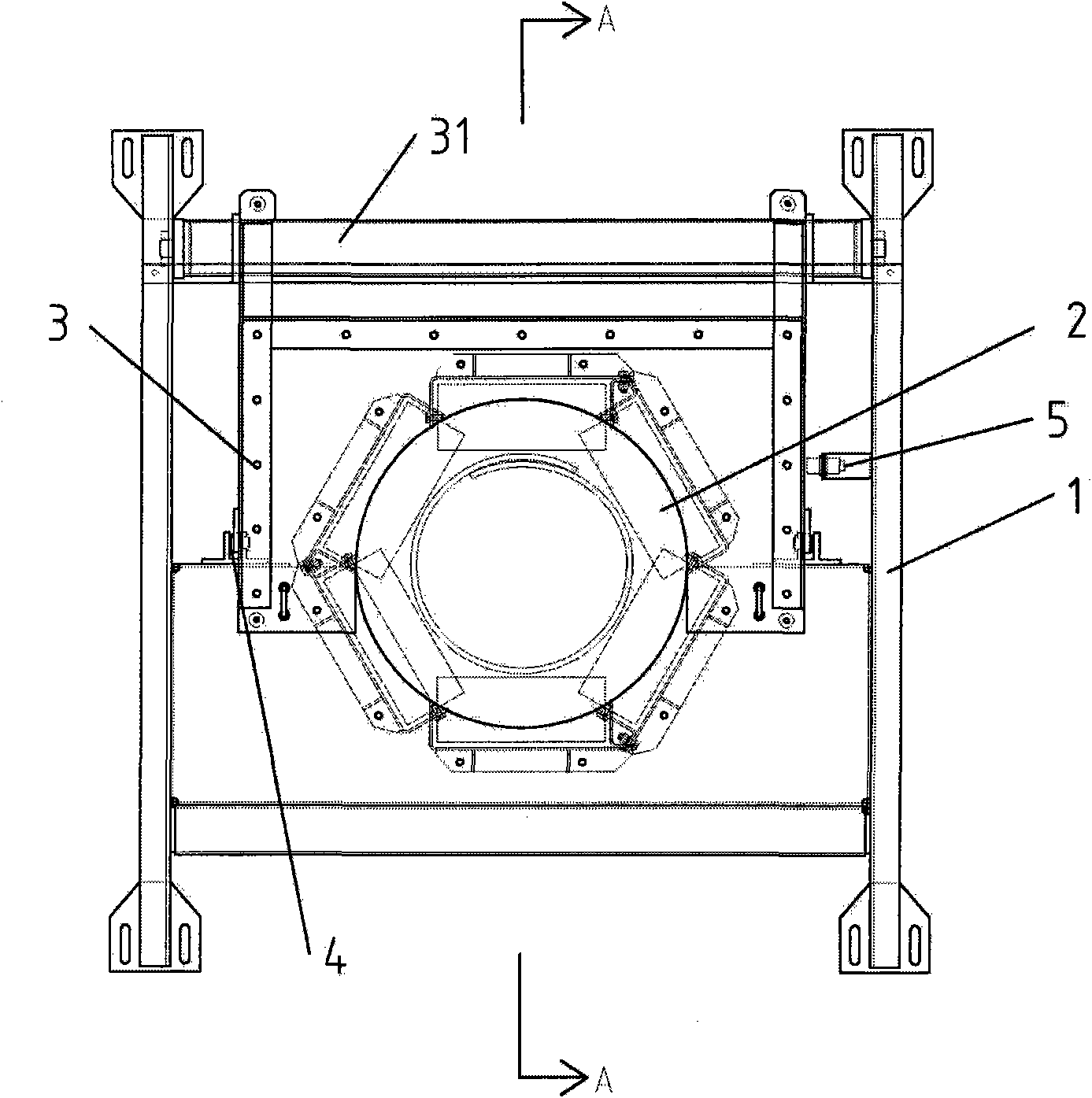

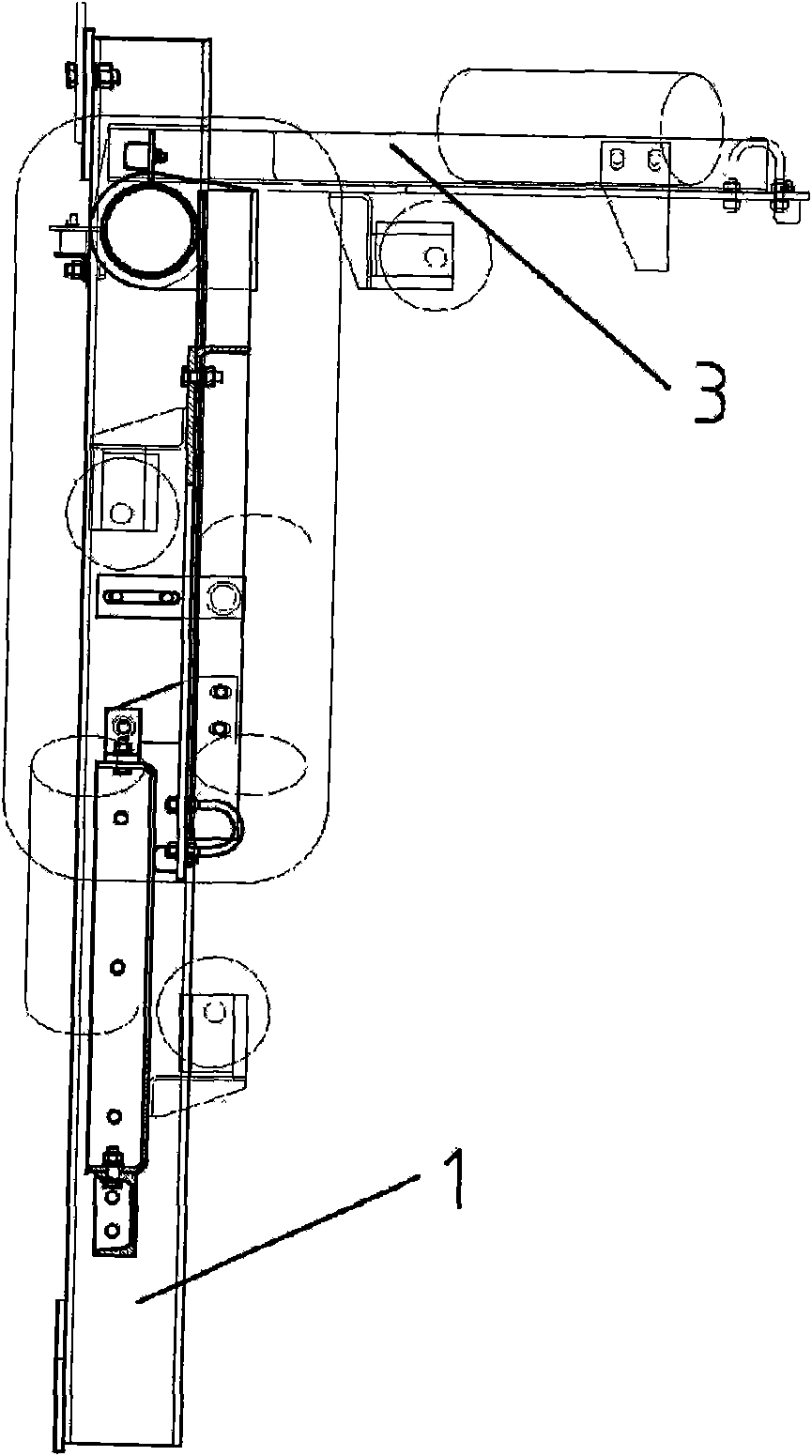

Safety baffle mechanism for tubular type belt conveyer

ActiveCN101659348BSimple structureEnsure safetyConveyorsControl devices for conveyorsEngineeringBelt conveyor

The invention relates to a safety baffle mechanism for a tubular type belt conveyer, which comprises a supporting roller rack used for supporting the tubular type conveyer belt, the supporting roller rack is provided with six supporting rollers for supporting the tubular type conveyer belt, the six supporting rollers forms a circle in the cross section direction of the tubular type conveyer belt,the three supporting rollers on the bottom edge are arranged on the supporting roller rack, the three supporting rollers on the upper edge are arranged on a baffle rack, the baffle rack is hinged on the supporting roller frame in an opening-closing mode, and two lateral sides of the baffle rack are connected with the supporting roller frame by a torsion limiter. The safety baffle mechanism has the advantages of simple structure and agile response action, and can effectively ensure the safety of the conveyer belt of the tubular type belt conveyer and reduce the possibility of tube explosion.

Owner:SHANGHAI KEDA HEAVY IND GROUP

Safety baffle mechanism for tubular type belt conveyer

ActiveCN101659348ASimple structureEnsure safetyConveyorsControl devices for conveyorsEngineeringBelt conveyor

The invention relates to a safety baffle mechanism for a tubular type belt conveyer, which comprises a supporting roller rack used for supporting the tubular type conveyer belt, the supporting rollerrack is provided with six supporting rollers for supporting the tubular type conveyer belt, the six supporting rollers forms a circle in the cross section direction of the tubular type conveyer belt,the three supporting rollers on the bottom edge are arranged on the supporting roller rack, the three supporting rollers on the upper edge are arranged on a baffle rack, the baffle rack is hinged on the supporting roller frame in an opening-closing mode, and two lateral sides of the baffle rack are connected with the supporting roller frame by a torsion limiter. The safety baffle mechanism has theadvantages of simple structure and agile response action, and can effectively ensure the safety of the conveyer belt of the tubular type belt conveyer and reduce the possibility of tube explosion.

Owner:SHANGHAI KEDA HEAVY IND GROUP

A kind of emulsified oil for mine hydraulic support

ActiveCN103937592BNo pollution in the processReduce sluggishnessLubricant compositionGlycol synthesisPetroleum oil

The invention provides an emulsified oil for mine hydraulic support, which is composed of the following substances according to the mass percentage: 15.0%-20.0% of mineral base oil, 8.0%-10.0% of boric acid, 10.0%-12.0% of triethanolamine, and 10.0% of sodium petroleum sulfonate %~11.0%, benzotriazole 0.5%~0.8%, ethylene glycol 20.5%~22.5%, urea 13.5%~15.5%, EDTA-tetrasodium 6.0%~8.0%, sodium hydroxide 1.0%~1.5% , The balance is water. The emulsified oil has good freeze-thaw properties, anti-wear, anti-extreme pressure, anti-rust and anti-corrosion properties, and can meet the conditions of the hydraulic support in the harsh environment of the underground.

Owner:特浦朗克材料科技(营口)股份有限公司

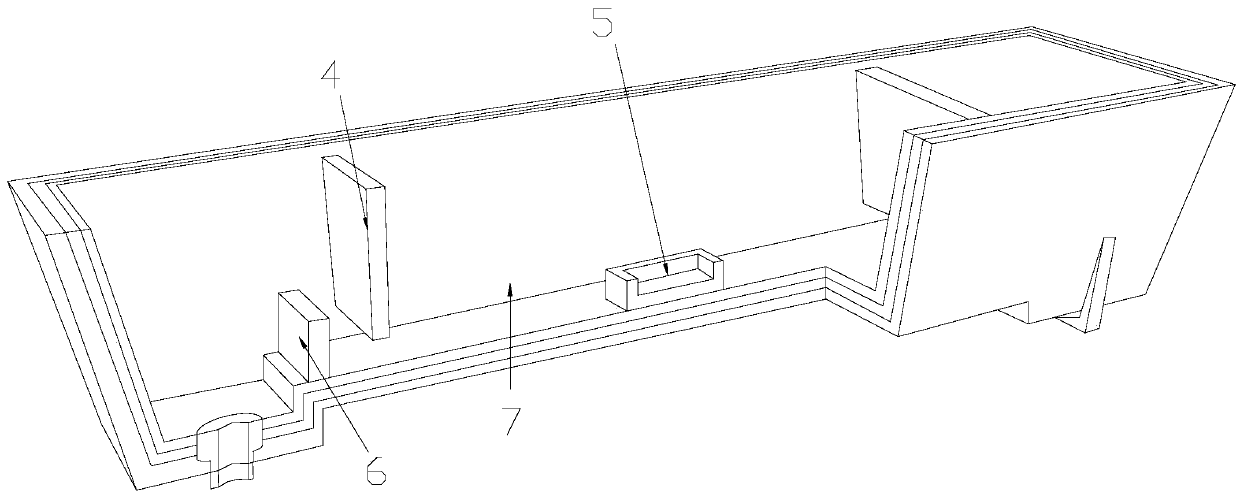

Slag-release anti-explosion tube mold for dry-type material tundish working lining of reserved weir plate groove

The invention provides a slag-release anti-explosion tube mold for dry-type material tundish working lining of a reserved weir plate groove. The slag-release anti-explosion tube mould structurally comprises a long nozzle, a mold dry type material heat insulation lining, a weir plate reserved mounting groove plate, a slag stopping wall, an impact pad, a working layer, a slag stopping dam, and a shunting and slag release device, wherein the long nozzle is fixedly connected to the bottom end of the left side of the mold dry type material heat insulation lining in an electric welding mode, and theweir plate reserved mounting groove plate is fixedly arranged on the back part of the mold dry type material heat insulation lining. If a part of ports are blocked by slag in the conveying process ofmelting liquid in a tundish die, the external working personnel can be reminded through the bright color of the melting liquid, the direct proportion value of the unfolding amplitude can be adjustedaccording to the size of the pressure value, and then the internal pressure value can be visually judged, so that an shunting interface is pressed and dredged through a single-pressure double-tractionmechanism, the slag on a pressure release mechanism can be offset to an inner material pressing plate for temporary storage, the ports can return to a smooth state, and the occurrence of the tube explosion is reduced.

Owner:庄小梅

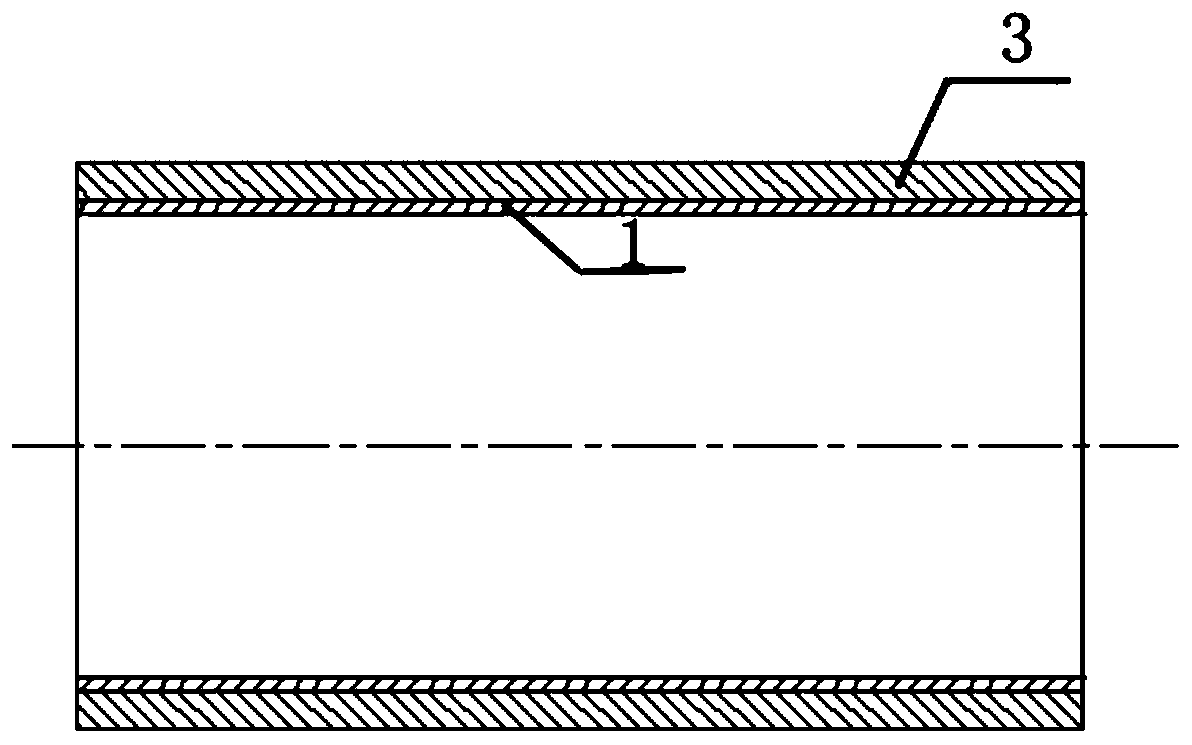

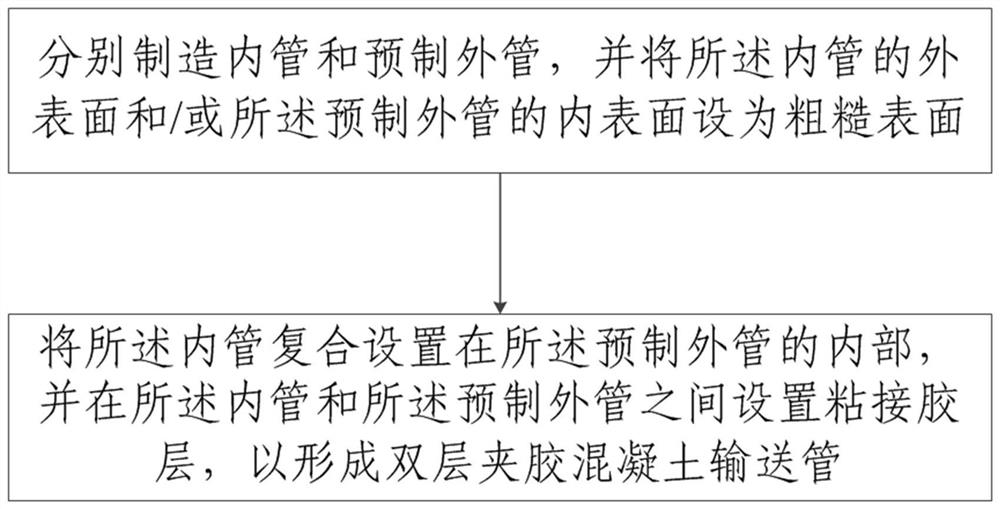

Concrete conveying pipe manufacturing method, concrete conveying pipe and pumping equipment

PendingCN114087429AAvoid block droppingReduce squibMaterial gluingRigid pipesRough surfaceEngineering

The invention provides a concrete conveying pipe manufacturing method, a concrete conveying pipe and pumping equipment. The concrete conveying pipe manufacturing method comprises the steps that an inner pipe and a prefabricated outer pipe are manufactured respectively, and the outer surface of the inner pipe and / or the inner surface of the prefabricated outer pipe are / is set to be rough surfaces; and the inner pipe is arranged in the prefabricated outer pipe in a composite mode, and a bonding glue layer is arranged between the inner pipe and the prefabricated outer pipe, so that the double-layer laminated concrete conveying pipe is formed. According to the concrete conveying pipe manufacturing method, the concrete conveying pipe and the pumping equipment, the bonding glue layer is arranged between the inner pipe and the outer pipe, and the rough surface is arranged to be connected with the bonding glue layer, so that firm compounding of the inner pipe and the outer pipe can be achieved, the phenomenon of chipping of the inner pipe can be avoided, the phenomena of pipe explosion and pipe blocking of the conveying pipe are reduced, the overall pressure bearing capacity of the conveying pipe is improved, and the cracking risk of the inner pipe is greatly reduced; and the conveying pipe is simple in structure, simple and convenient in production process, easy to implement, low in cost and suitable for mass production.

Owner:SANY AUTOMOBILE MFG CO LTD

Compressor overload protection control method and device, and fixed-frequency air conditioner

ActiveCN105180362BSolve the squib problemReduce squibPump controlPositive-displacement liquid enginesConstant frequencyOverload control

The invention discloses a compressor overload protection control method and device as well as a fixed-frequency air conditioner. The compressor overload protection control method comprises the following steps: detecting the state of a compressor in the air conditioner to obtain a detection result; judging whether the compressor has overload protection according to the detection result; if yes, controlling the draught fan of the air conditioner to stop operation. Through the compressor overload protection control method and device, the possibility that a system pipeline explodes easily caused by the situation that the compressor has overload protection is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

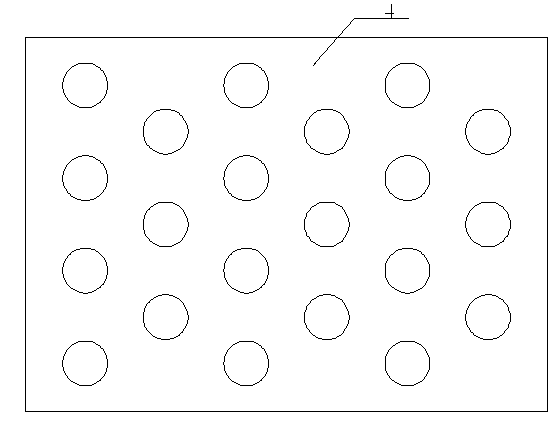

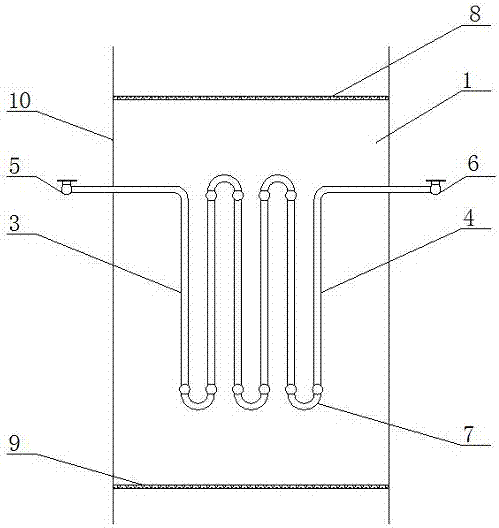

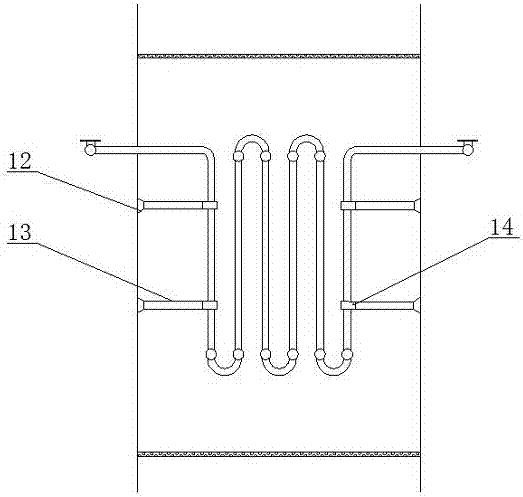

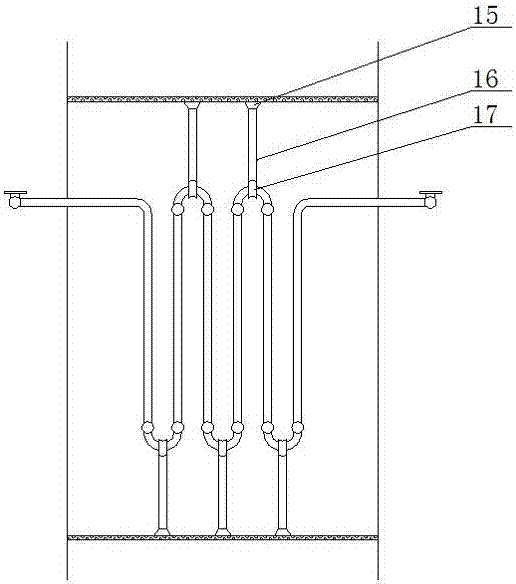

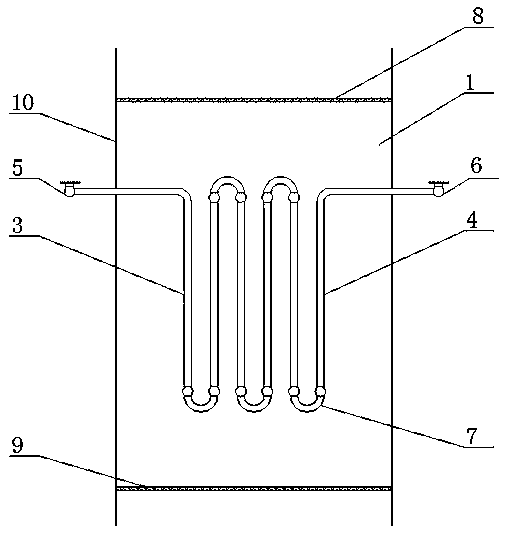

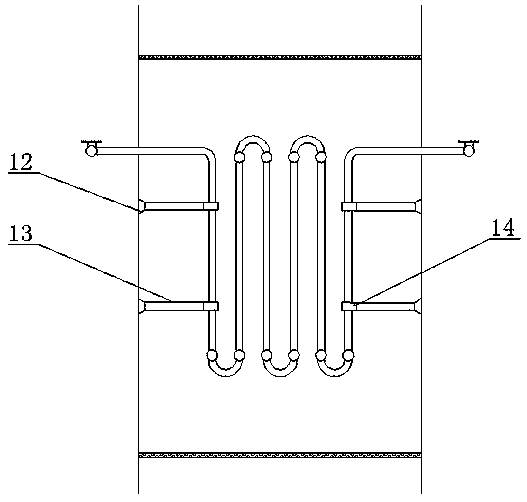

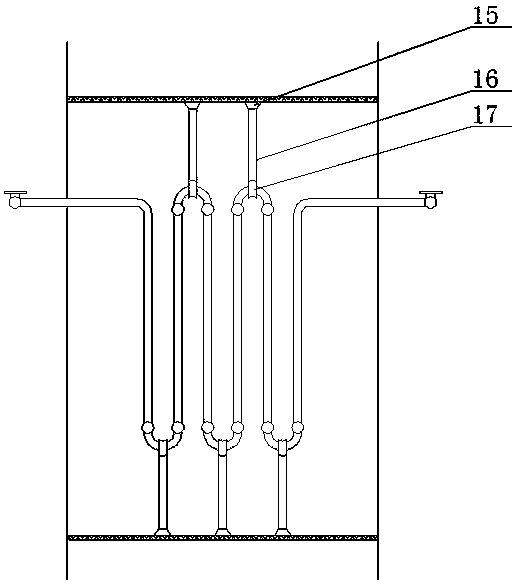

Superheater for industrial incineration boiler

ActiveCN107255283AReduce squibExtended operating cycleSteam superheatersIncinerator apparatusEngineeringSuperheater

The invention discloses a superheater for an industrial incineration boiler. The superheater comprises a plurality of heat exchanging pipes arranged in a boiler chamber, the heat exchanging pipes comprise the first heat exchanging pipes and the second heat exchanging pipes, the heat exchanging pipes are all vertically arranged in the boiler chamber, and the distances between every two heat exchanging pipes are equal; the boiler chamber further comprises inlet headers, outlet headers and U-shaped superheater tubes internally, the inlet headers are used for connecting the first heat exchanging pipes and the U-shaped superheater tubes, and the outlet headers are used for connecting the second heat exchanging pipes and the U-shaped superheater tubes; and the boiler chamber further comprises a first metal filtering plate and a second metal filtering plate, the first metal filtering plate and the second metal filtering plate are arranged horizontally, the two ends of the first metal filtering plate and the second metal filtering plate are connected with the wall of the boiler, the first metal filtering plate is located above the heat exchanging pipes, and the second metal filtering plate is located below the heat exchanging pipes.

Owner:烟台国新环保科技有限公司

An energy-saving wireless intelligent control temperature control system and resistive heating element

ActiveCN103941770BImprove real-time performanceImprove thermal conductivityTemperatue controlHeating element shapesLine sensorEngineering

The invention discloses an energy-saving wireless intelligent controlled temperature control system and a resistance heating element. The temperature control system comprises a power supply module (1), a programmable central processor module (2), a temperature setting module (3), a temperature detecting module (4), a wireless sensor module (5), an energy-saving control module (6) and the resistance heating element (7); the central processor module (2) serves as the control core of the temperature control system, the other modules surround the temperature control system to transmit information and / or receive instructions, and real-time temperature adjustment and heating of the resistance heating element (7) can be achieved. In the energy-saving control, a silicon controllable frequency conversion control circuit or an energy-saving wireless sensor power supply is adopted to control the heating element. A wireless sensor is adopted in the aspect of temperature monitoring. A novel insulating structure is adopted for the resistance heating element. By means of the energy-saving wireless intelligent controlled temperature control system and the resistance heating element, the functions of detection, intelligent control and saving energy are achieved, and energy consumption is reduced. The temperature control system and the resistance heating element are suitable for electric water heaters and other environments for heating liquid, and are extremely high in safety.

Owner:北京暖立得热力设备有限公司

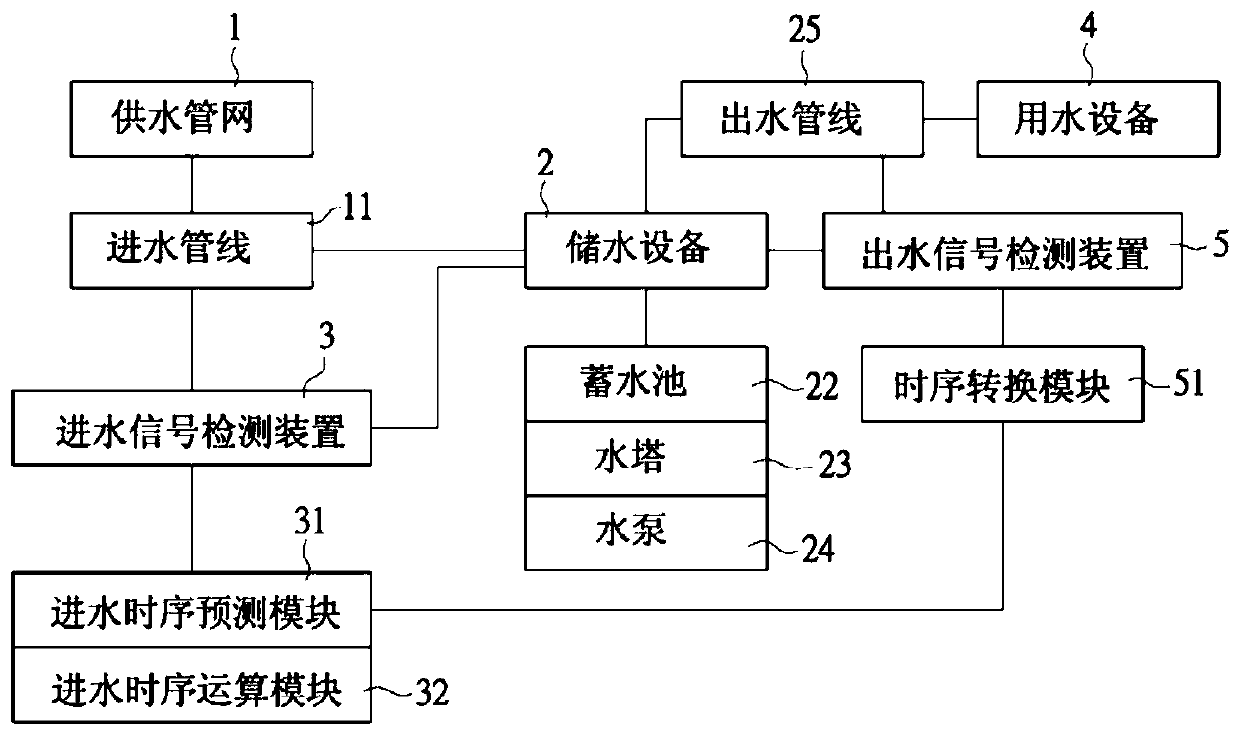

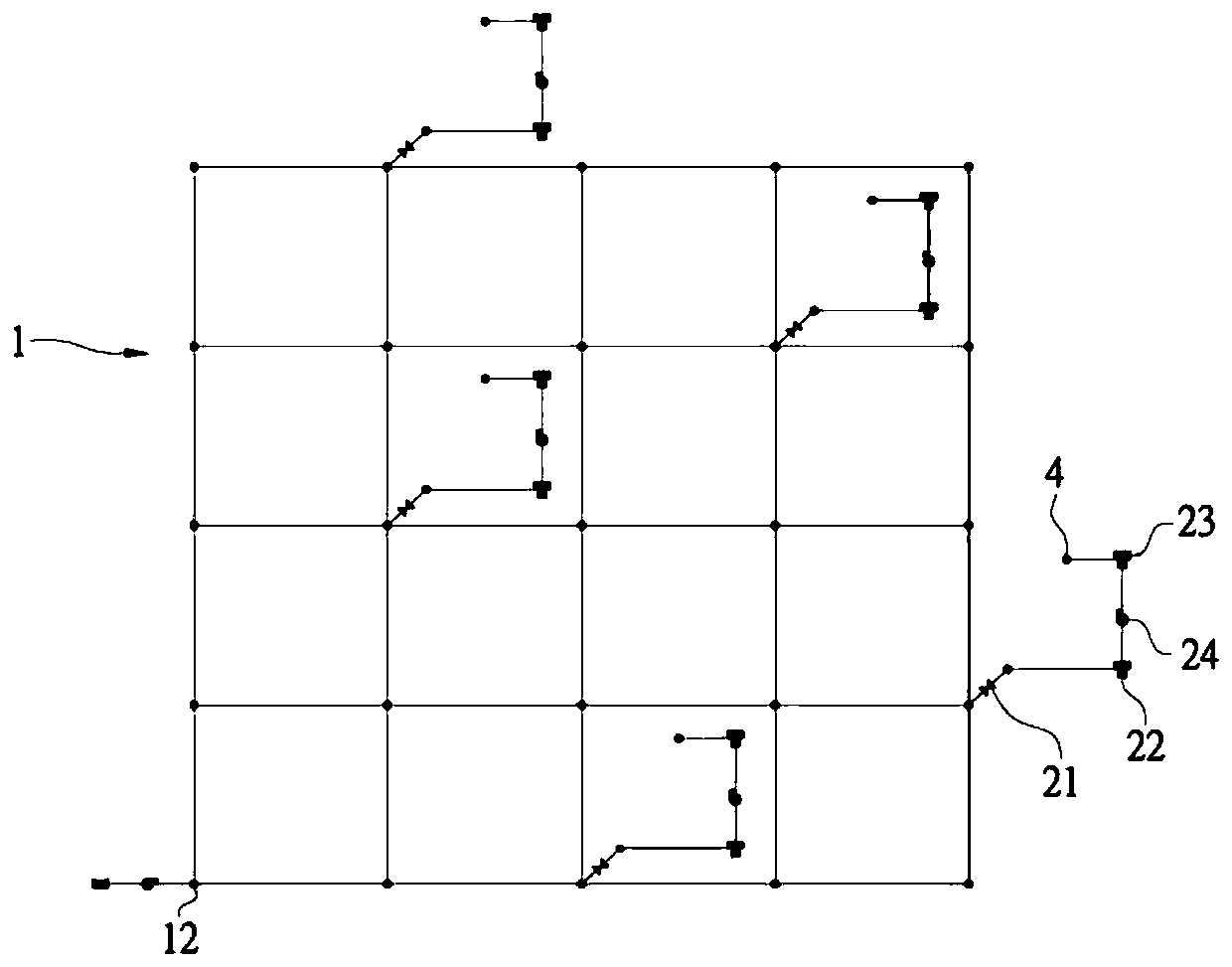

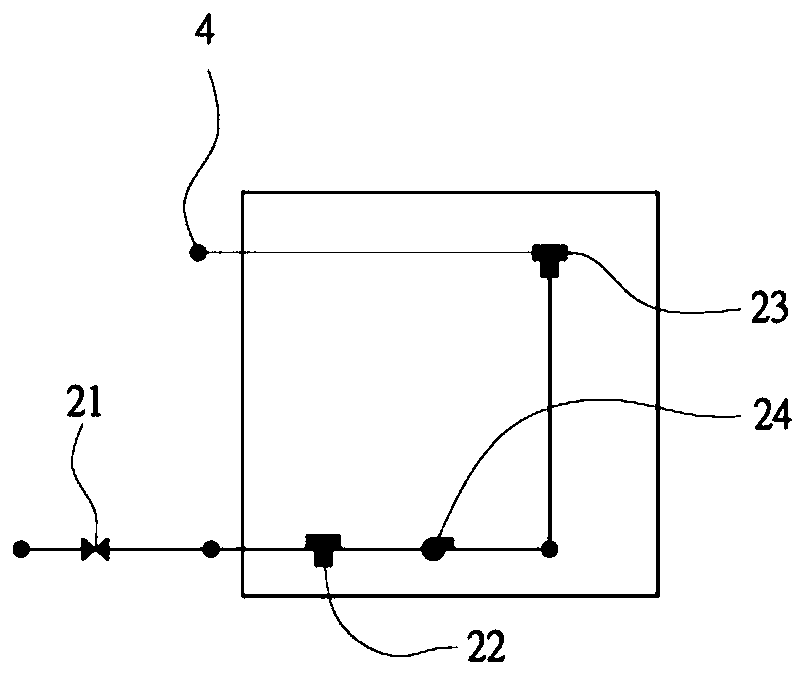

Optimal Dispatch System of Water Supply Network

ActiveCN109403425BRelieve pressureReduce the probability of water leakageService pipe systemsWater mainsWater storageStream flow

The invention relates to an optimization dispatching system for the water supply network. The optimization dispatching system includes the water supply network having at least one water inlet pipeline, and multiple water storage devices connected with the water supply network through the at least one water inlet pipeline, wherein the water inlet pipeline or the multiple water storage devices is equipped with a water inlet signal detection device, the water inlet signal detection device is connected with a water inlet timing sequence prediction module and a water inlet timing sequence operationmodule, the water inlet timing sequence prediction information is established by the water inlet timing sequence prediction module according to the received water inlet timing sequence information, the water inlet timing sequence of the water inlet pipeline is re-planned by the water inlet timing sequence operation module, so the flow and pressure fluctuation of the water supply network within the water supply period are made to be lower than those before planning of the water inlet timing sequence operation module. The system is advantaged in that the pressure and the flow of the water supply network after planning are made to be slow and stable, abrupt change of the pressure of the pipeline is reduced, and the water leakage rate and pipe explosion of the pipeline are effectively reduced.

Owner:SMARTER WATER CO LTD

A Method for Eliminating Air Locks in W-Shape and U-Shape Pipelines

ActiveCN104501650BEliminate air lockChemical cleaning goes wellFlush cleaningPipeline.airPower station

Owner:XIAN THERMAL POWER RES INST CO LTD

A hydraulic type high stability rubber hose joint

ActiveCN113503411BAvoid loose situationsReduce squibEngine sealsPipe couplingsEngineeringStructural engineering

The invention discloses a hydraulic type high-stability rubber hose joint, which belongs to the field of pipe joints. A hydraulic type high-stability rubber hose joint, through the setting of a hydraulic variable tube, when the fluid passes through, the pressure variable tube squeezes under the action of the fluid pressure Press the rubber hose and expand toward the inner wall of the outer casing, so that the outer top ring wedge squeezes the rubber hose. At this time, the rubber hose is partially deformed and then falls into the corresponding indented ring wedge groove, so that the rubber hose and the joint can be squeezed and fastened by the pressure of the fluid itself. The connection between the two achieves the effect of higher connection stability as the liquid pressure increases. Compared with the existing technology, it effectively avoids the joint loosening caused by the impact of the liquid. In addition, when the rubber hose After accidental loosening with this joint, the sealing becomes weak, and part of the fluid seeps into the early warning ring groove along the liquid guide layer, causing the color point to change color, so as to give early warning to the staff, and reduce the incidence of pipe burst through timely maintenance .

Owner:南通美莱达科技有限公司

A high-efficiency and long-life solar heat collector tube

InactiveCN105387639BIncrease heat absorptionLess heat releaseSolar heating energyAbsorbing elementsStress relievingEngineering

The invention discloses a high-efficiency and long-life solar heat collecting tube, which comprises a heat collecting tube body, a one-way infrared heat conducting layer is arranged inside the heat collecting tube body, a first inner tube is arranged inside the one-way infrared heat conducting layer, and the first inner tube is arranged inside the one-way infrared heat conducting layer. The inside of an inner tube is filled with a hard coating, the inside of the first inner tube is provided with a second inner tube, and the inside of the second inner tube is filled with a metal layer. The high-efficiency and long-life solar heat collector tube, by setting a one-way infrared heat conduction layer, can increase the heat absorption of the heat collector tube while reducing the heat release of the heat collector tube. By setting a hard coating and a metal layer, it can eliminate stress and increase toughness. Burst phenomenon at high and low temperature.

Owner:HAINING CHAODA SOLAR COLLECTOR TUBES

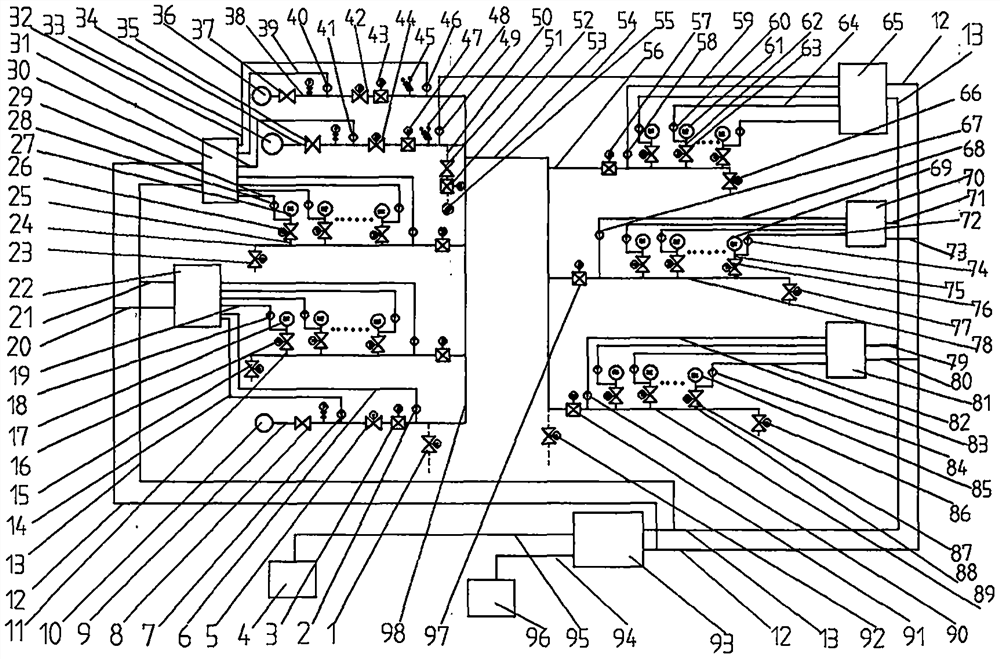

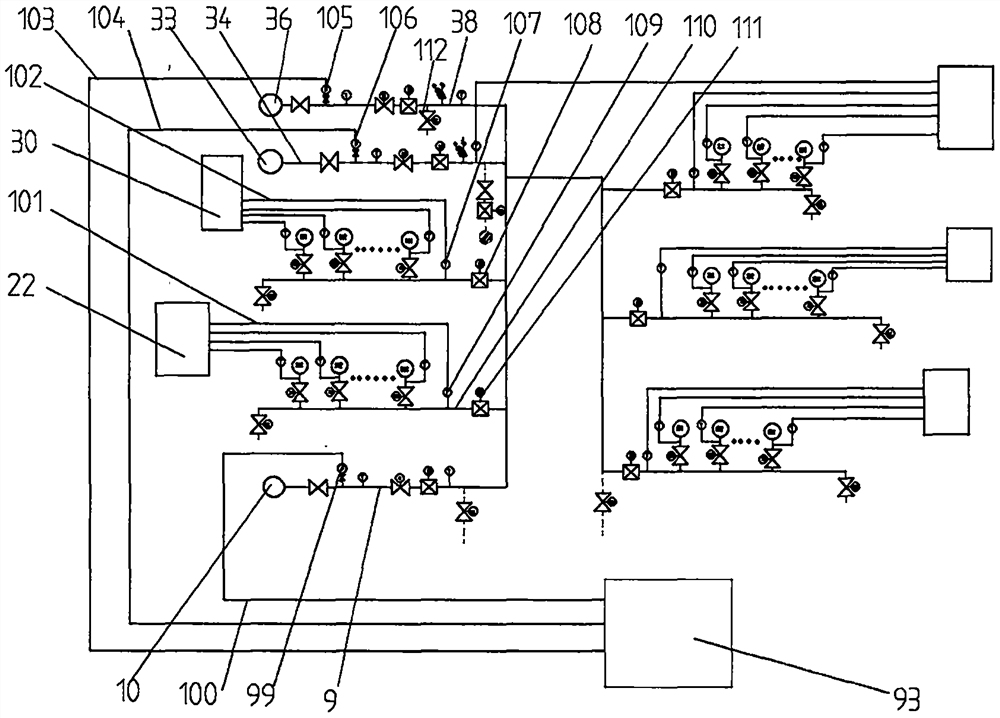

Energy-saving optimal control and fault online monitoring system and method for steam source of steam soot blower

ActiveCN112815346AAvoid damageImprove operating economyEnergy industrySolid removalThermodynamicsData acquisition

An energy-saving optimal control and fault online monitoring method for a steam source of a steam soot blower comprises an original soot blowing steam source pipeline system, an auxiliary soot blowing steam source pipeline system, a soot blower pipeline system, a soot blowing steam main pipe, a soot blowing steam branch pipe and a DCS (Distributed Control System), and is characterized in that a new soot blowing steam source interface is established, a new soot blowing steam source pipeline system is established, a steam temperature monitoring system and a steam source pressure monitoring system are established, a DCS end soot blowing steam source pipeline system energy-saving optimization model is established, a server end data acquisition and analysis processing platform, a soot blower fault criterion model, a steam temperature monitoring model and a steam source pressure monitoring model are established, and a client display platform and a display page are established.

Owner:SHANDONG SHANGAO POWER TECH CO LTD

A superheating device for industrial incineration boilers

ActiveCN107255283BReduce squibExtended operating cycleSteam superheatersIncinerator apparatusSuperheaterEngineering

The invention discloses a superheater for an industrial incineration boiler. The superheater comprises a plurality of heat exchanging pipes arranged in a boiler chamber, the heat exchanging pipes comprise the first heat exchanging pipes and the second heat exchanging pipes, the heat exchanging pipes are all vertically arranged in the boiler chamber, and the distances between every two heat exchanging pipes are equal; the boiler chamber further comprises inlet headers, outlet headers and U-shaped superheater tubes internally, the inlet headers are used for connecting the first heat exchanging pipes and the U-shaped superheater tubes, and the outlet headers are used for connecting the second heat exchanging pipes and the U-shaped superheater tubes; and the boiler chamber further comprises a first metal filtering plate and a second metal filtering plate, the first metal filtering plate and the second metal filtering plate are arranged horizontally, the two ends of the first metal filtering plate and the second metal filtering plate are connected with the wall of the boiler, the first metal filtering plate is located above the heat exchanging pipes, and the second metal filtering plate is located below the heat exchanging pipes.

Owner:烟台国新环保科技有限公司

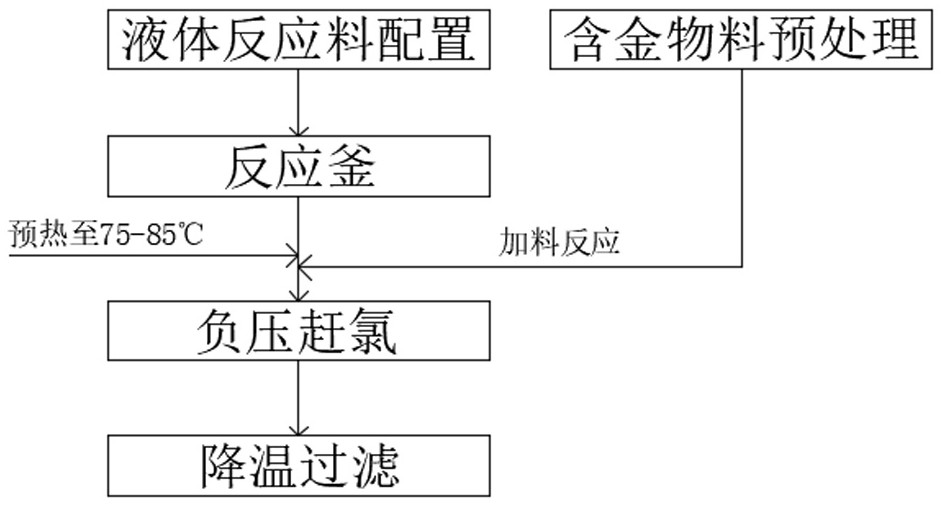

A negative pressure chlorination gold separation process

Owner:厦门海峡黄金珠宝产业园有限公司

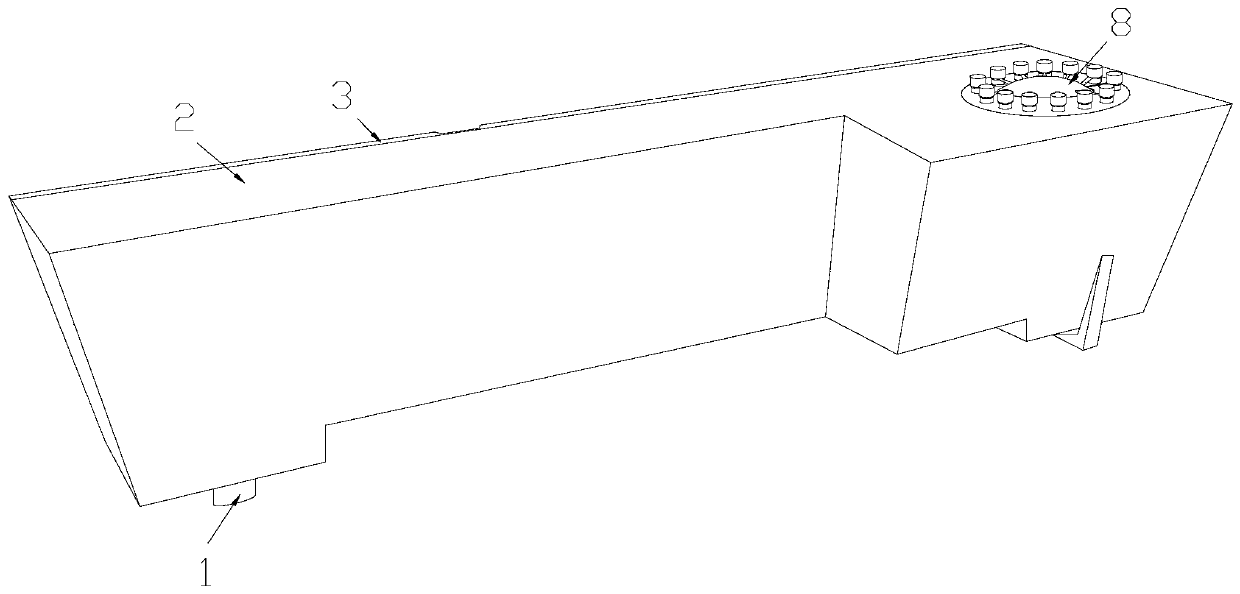

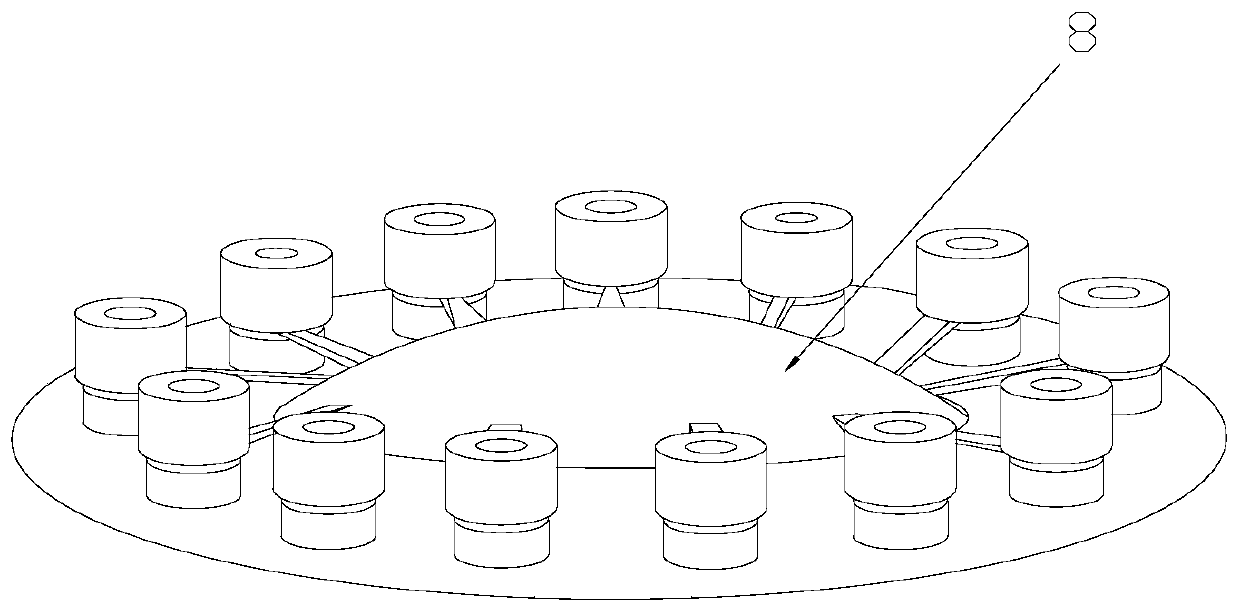

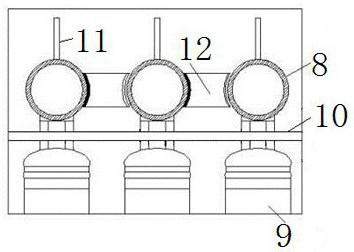

Improved multi-tube filter

PendingCN114100241AExtended service lifeAvoid bending deformationStationary filtering element filtersEngineeringMechanical engineering

The invention relates to an improved multi-tube filter which comprises a base, a plurality of filter cylinders are arranged on the base, water baffles are arranged on the periphery of the upper portion of the base, a plurality of liquid collecting tubes and a plurality of filter elements in threaded connection with the liquid collecting tubes are arranged in the filter cylinders, and clamping structures are arranged at the threaded connection positions of the filter elements and the liquid collecting tubes. Vertical supporting plates are arranged on the upper portions of the liquid collecting pipes, transverse partition blocks are arranged between the adjacent liquid collecting pipes, and a filter valve is arranged at an inlet of the filter cylinder. It can be guaranteed that the screwed filter element is not prone to falling off, the liquid collecting pipe is not prone to bending deformation, the connecting portion of the liquid collecting pipe and the wall of the filter cylinder is not prone to damage, impurities in fluid can be filtered out, the impurities are prevented from being attached to the interior of the valve body, and the phenomenon of pipe explosion caused by pressure increase is avoided.

Owner:WUXI XINGSHENG ENVIRONMENTAL PROTECTION EQUIPCO

Continuous mud pressure monitoring communication device for ocean engineering platform

InactiveCN113653115APressure controlIncrease the outlet displacementMechanical machines/dredgersEngineeringSlurry pipeline

The invention discloses a continuous mud pressure monitoring communication device for an ocean engineering platform, and relates to the technical field of ocean engineering. The continuous mud pressure monitoring communication device for the ocean engineering platform comprises a hollow cylinder, a detection alarm mechanism and an adjusting mechanism. One side of the hollow cylinder is fixedly provided with a first protective shell, the other side of the hollow cylinder is fixedly provided with a second protective shell, and the two sides of the hollow cylinder are each fixedly provided with two sets of mud discharging cylinders. Through threads in the hollow cylinder, the hollow cylinder can be installed at an outlet of a slurry pipeline in a threaded mode, so that the interior of the hollow cylinder is communicated with the interior of the slurry pipeline, the pressure intensity in the hollow cylinder is the same as that in the slurry pipeline, then through cooperative use of a fixing plate, a movable rod, a piston, a spring, a rotating shaft, a transmission gear and a pressure pointer, the pressure intensity in the slurry pipeline can be detected, and the detected pressure intensity value can be displayed through the scales on a glass sheet, so that a worker can conveniently and reasonably regulate and control the pressure intensity in the slurry pipeline.

Owner:重庆鑫杰力科技有限公司

Efficient long-service-life solar heat collection tube

InactiveCN105387639AIncrease heat absorptionLess heat releaseSolar heat devicesSolar thermal energy generationStress relievingEngineering

The invention discloses an efficient long-service-life solar heat collection tube. The solar heat collection tube comprises a heat collection tube body, and a one-way infrared heat conduction layer is arranged inside the heat collection tube body; a first inner tube is arranged inside the one-way infrared heat conduction layer, and filled with a hard coating; and a second inner tube is arranged inside the first inner tube, and the second inner tube is filled with a metal layer. According to the efficient long-service-life solar heat collection tube, as the one-way infrared heat conduction layer is arranged, the heat releasing of the heat collection tube can be reduced while the heat absorption of the heat collection tube is increased; and as the hard coating and the metal layer are arranged, the stress can be removed, the toughness can be increased, and the tube blasting phenomenon at the low temperature and the high temperature can be reduced.

Owner:HAINING CHAODA SOLAR COLLECTOR TUBES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com