Double-metal composite tube with rubber interface structure and manufacturing method thereof

A bimetallic composite pipe and interface structure technology, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of low bonding strength of the base pipe and the lining pipe, and achieve the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

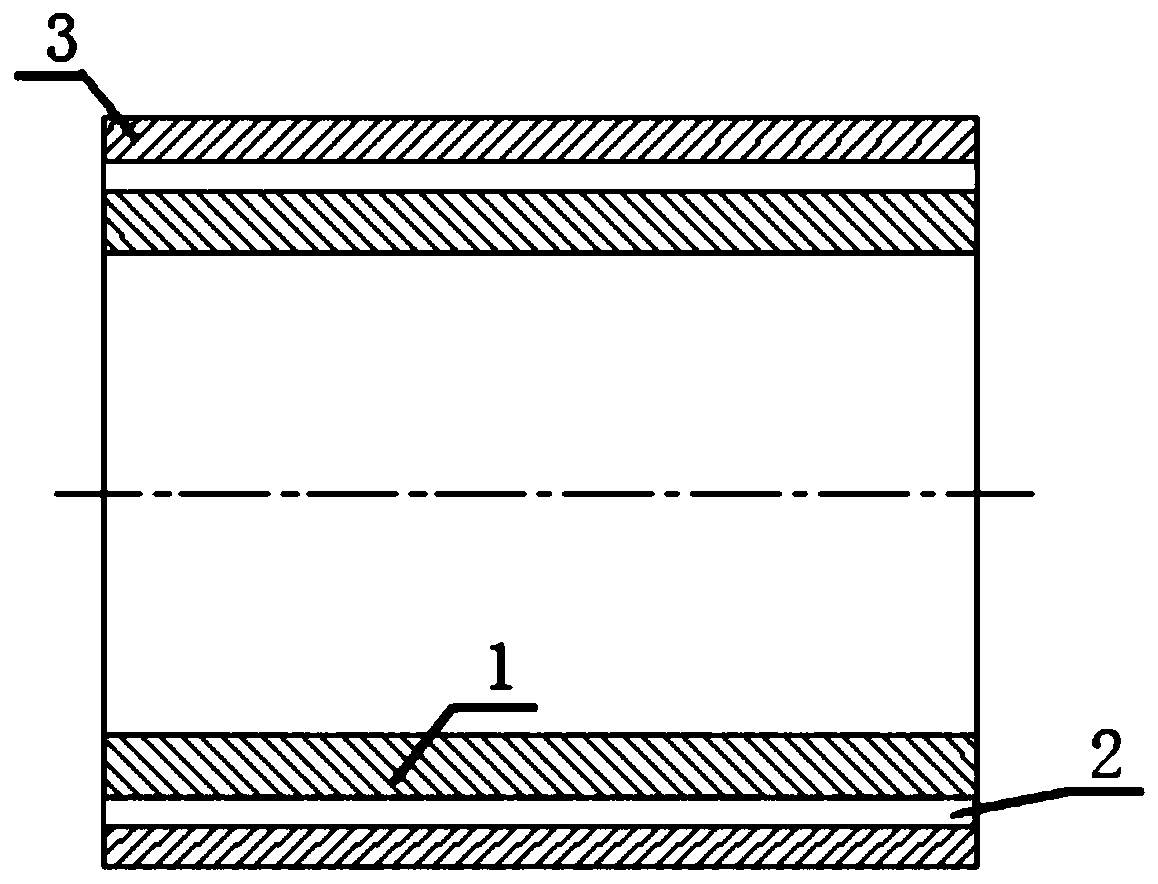

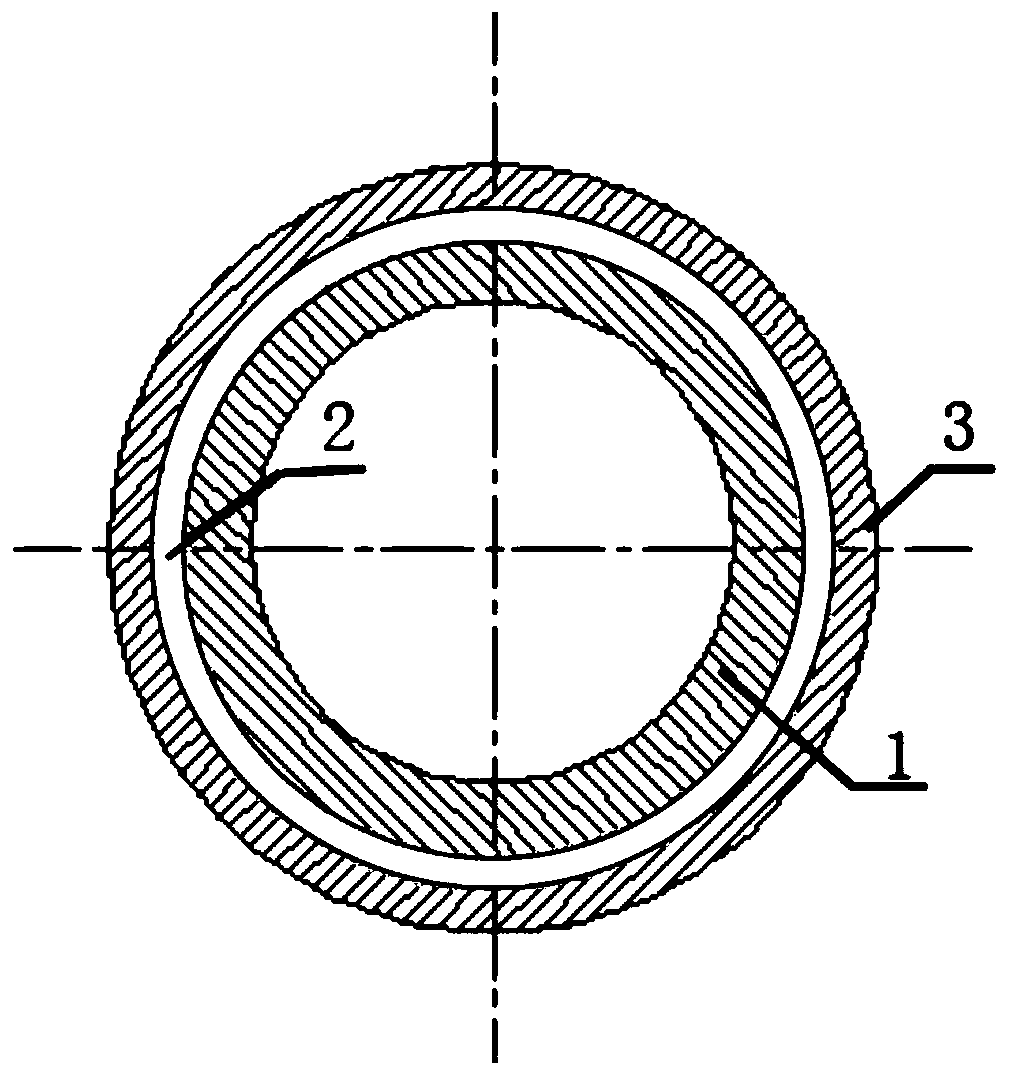

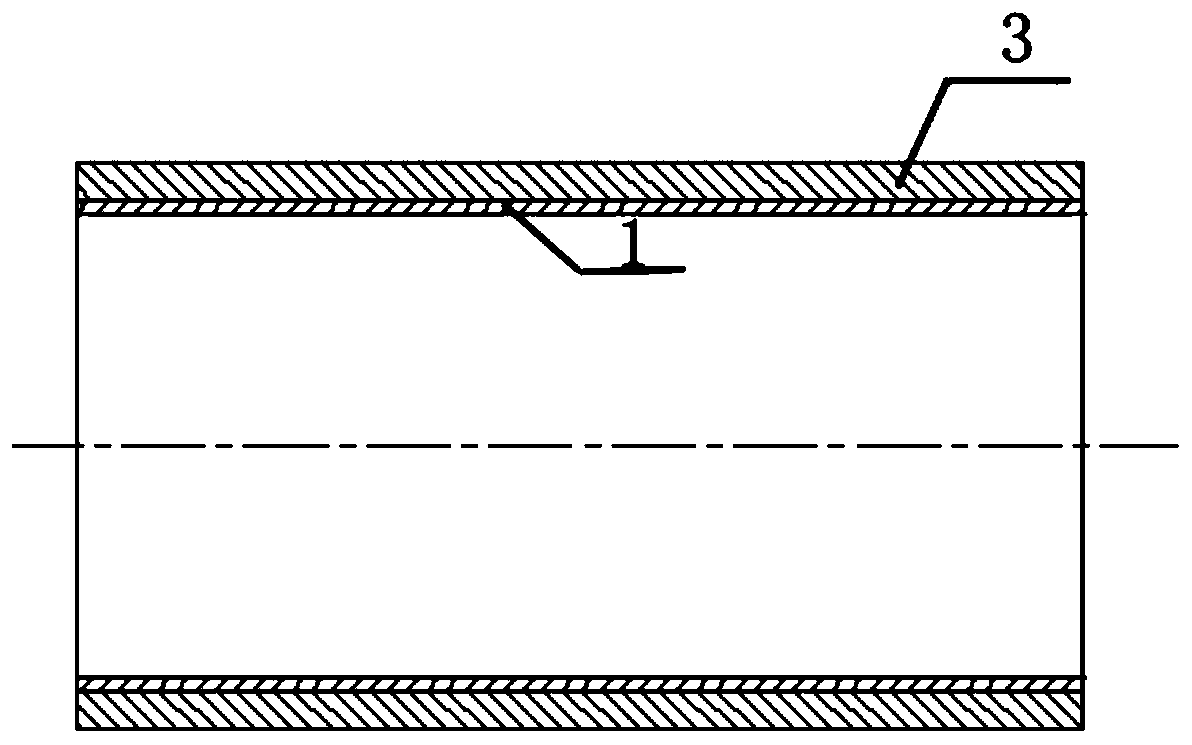

[0046] Steps 1-7 are performed, wherein the base pipe 3 is a carbon steel pipe, the rubber layer 5 is made of hydrogenated nitrile rubber, and the inner liner 4 is a stainless steel pipe.

Embodiment 2

[0048] Steps 1-7 are performed, wherein the base pipe 3 is a low-alloy steel pipe, the rubber layer 5 is made of hydrogenated nitrile rubber, and the inner liner 4 is a stainless steel pipe.

Embodiment 3

[0050] Steps 1-7 are performed, wherein the base pipe 3 is a low-alloy steel pipe, the rubber layer 5 is made of nitrile rubber, and the inner liner 4 is an iron-nickel alloy steel pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com