Energy-saving optimal control and fault online monitoring system and method for steam source of steam soot blower

A monitoring system and soot blower technology, which are applied in combustion methods, energy industry, indirect carbon dioxide emission reduction, etc., can solve problems such as waste of steam energy and difficulty in finding internal valve leakage through routine maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation examples of the present invention are provided below to deepen the understanding of this patent. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

[0018] The present invention will be further described in conjunction with the accompanying drawings.

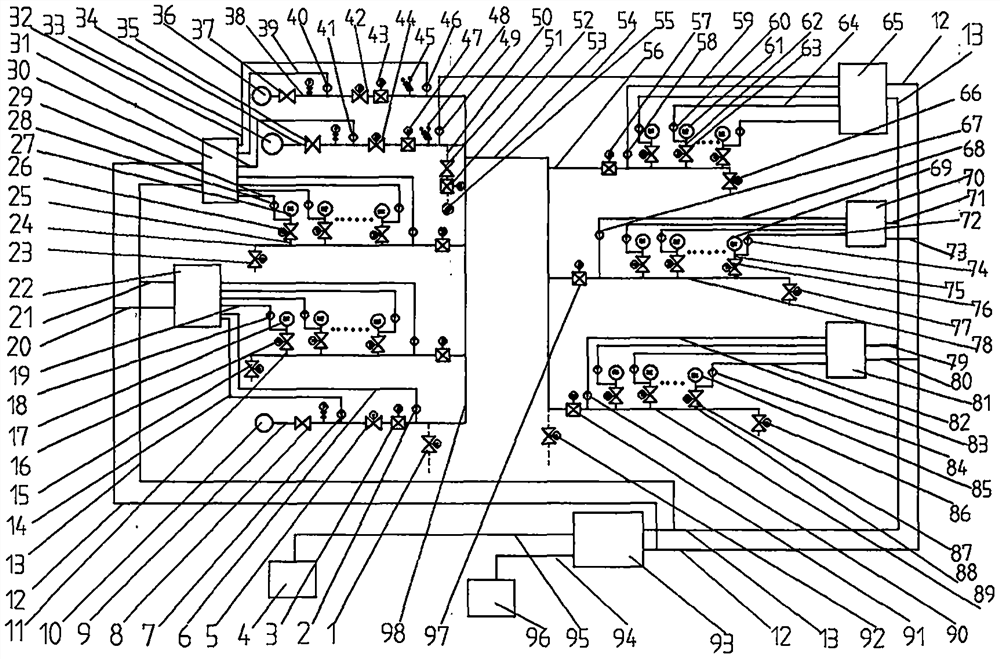

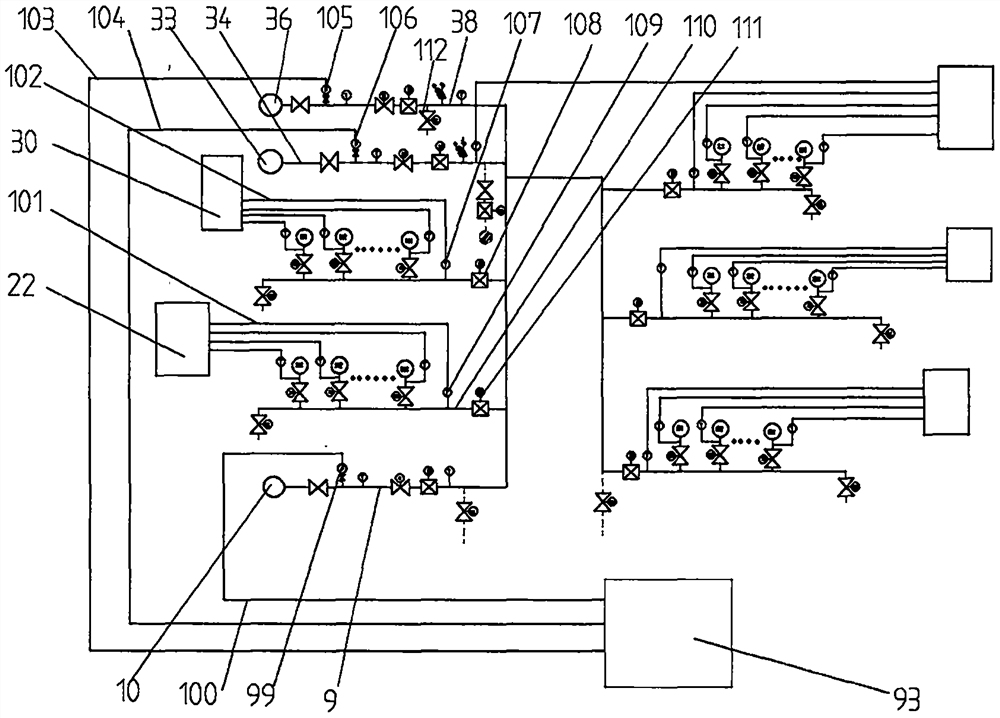

[0019] Steam soot blower steam source energy saving optimization control and fault online monitoring system and method, including the original soot blowing steam source piping system, auxiliary steam soot blowing steam source piping system, soot blower piping system, soot blowing steam main pipe 98 And branch 53, DCS system 93, characterized in that a new soot blowing steam source interface 33 has been established, a new soot blowing steam source pipeline system has been established, a steam temperature monitoring system and a steam source pressure monitoring system have been built, and a DCS end blowing system has been es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com