Continuous mud pressure monitoring communication device for ocean engineering platform

A technology of mud pressure and marine engineering, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the problems of not timely adjusting the pressure of large and small mud, easy to break through pipelines, etc., to achieve convenience Control, reduce cumbersomeness, and increase the effect of export discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

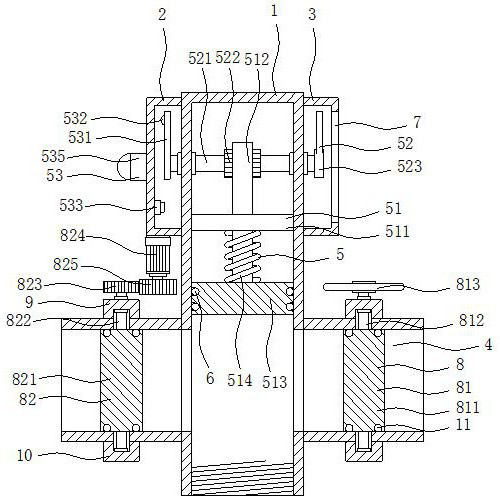

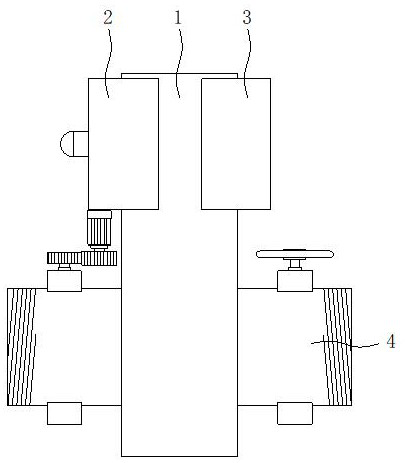

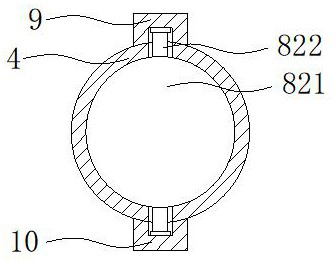

[0032] see Figure 1-6 , the present invention provides a technical solution: a continuous mud pressure monitoring communication device for offshore engineering platforms, including a hollow cylinder 1, a detection and alarm mechanism 5 and an adjustment mechanism 8, and a first protective shell 2 is fixedly installed on one side of the hollow cylinder 1 , the other side of the hollow cylinder 1 is fixedly installed with a second protective shell 3, both sides of the hollow cylinder 1 are fixedly installed with two sets of mud discharge cylinders 4, both sides of the hollow cylinder 1 are provided with water outlets, and the two sets of water outlets They are respectively located on one side of the two groups of mud discharge cylinders 4. The detection and alarm mechanism 5 includes a transmission assembly 51, a pressure value assembly 52 and an alarm assembly 53. The transmission assembly 51 is located inside the hollow cylinder 1, and the pressure value assembly 52 is located...

Embodiment 2

[0035] see Figure 1-6 On the basis of Embodiment 1, the transmission assembly 51 includes a fixed plate 511, a movable rod 512, a piston 513 and a spring 514, the outer wall of the fixed plate 511 is fixedly installed on the inner wall of the hollow cylinder 1, and the outer wall of the movable rod 512 is slidably installed on the fixed On the plate 511, the top of the piston 513 is fixedly installed on the bottom of the movable rod 512, the spring 514 is sleeved on the outer wall of the movable rod 512, the top of the spring 514 is fixedly installed on the bottom of the fixed plate 511, and the bottom of the spring 514 is connected to the piston 513. The top of the piston 513 is fixedly installed, and the outer wall of the piston 513 is provided with a first sealing groove, and the first sealing ring 6 is fixedly installed in the first sealing groove, and the outer walls of the first sealing ring 6 and the piston 513 are in contact with the inner wall of the hollow cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com