Patents

Literature

35results about How to "Pressure regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

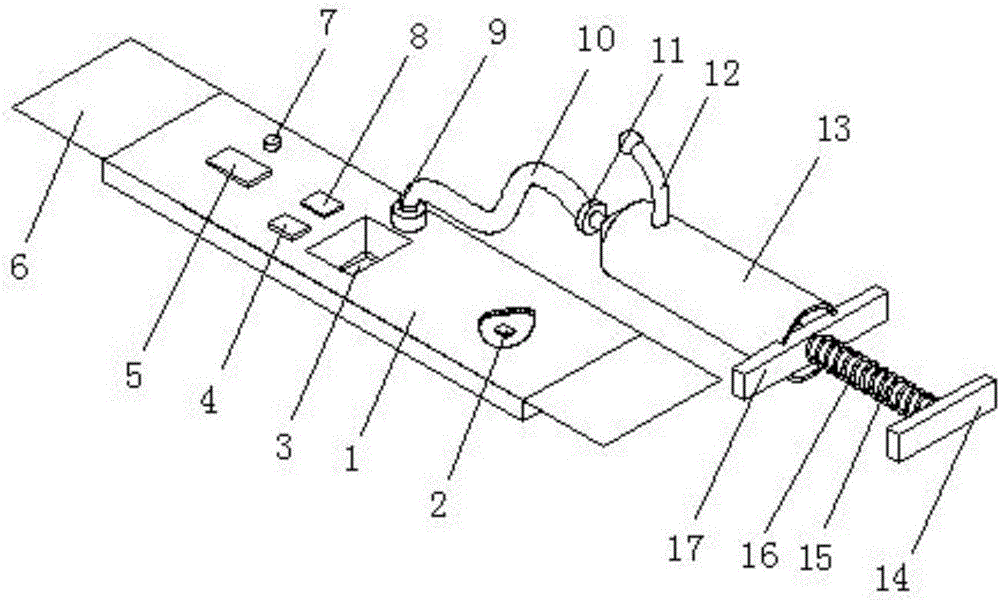

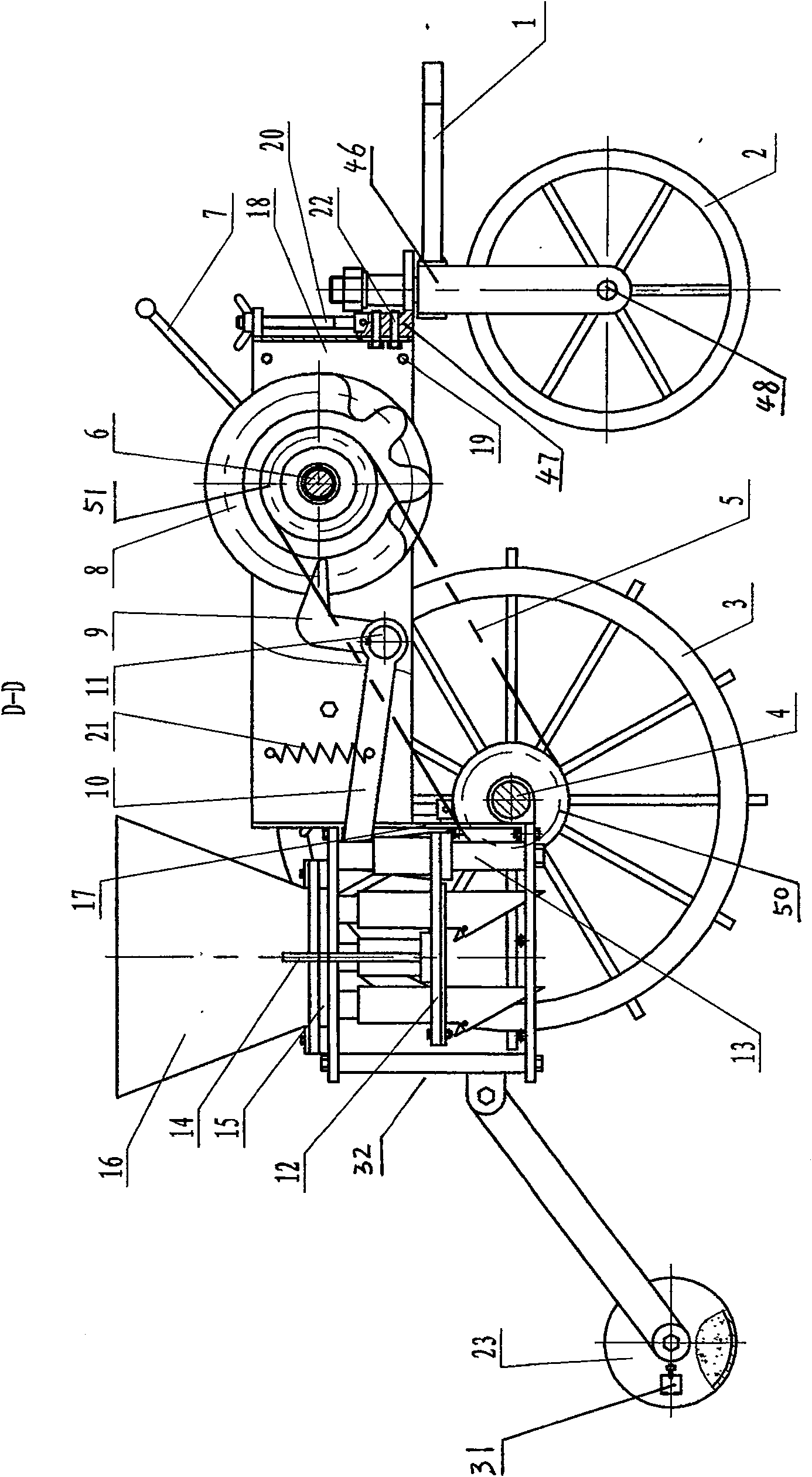

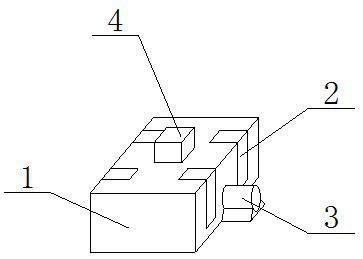

Seed sowing machine

InactiveCN101258799AFertilizer orderlyImprove working accuracySeed depositing seeder partsRegular seed deposition machinesDrive shaftAgricultural engineering

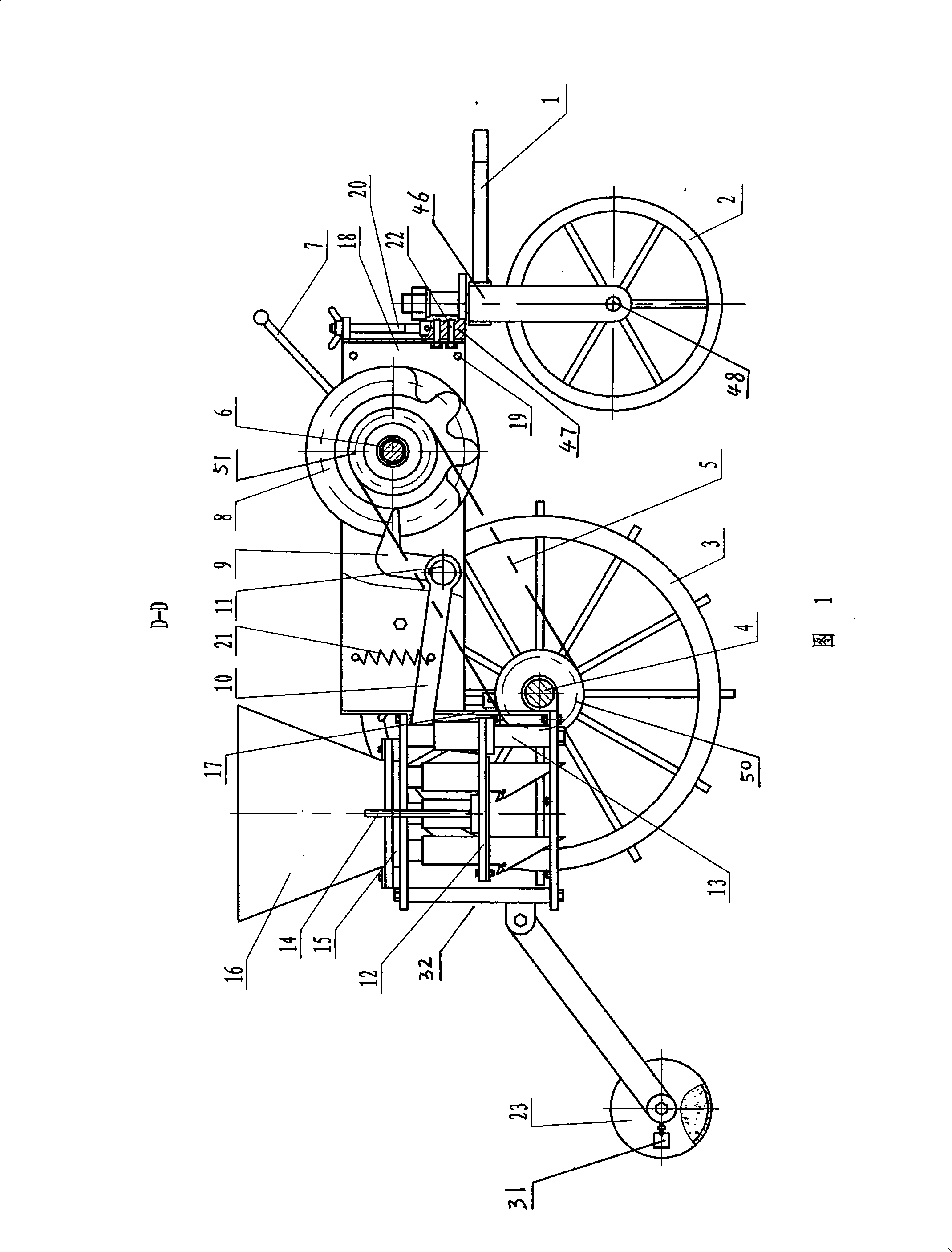

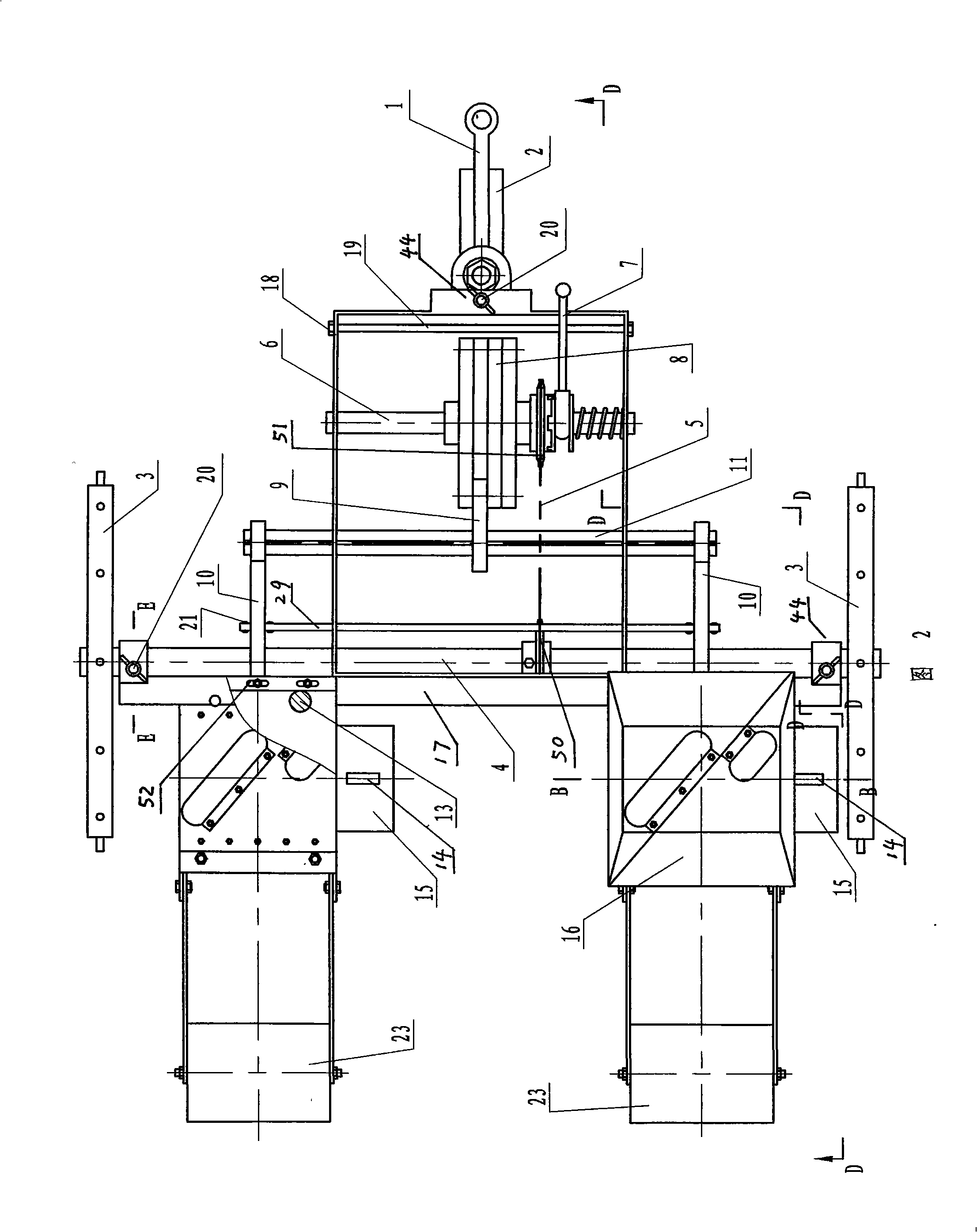

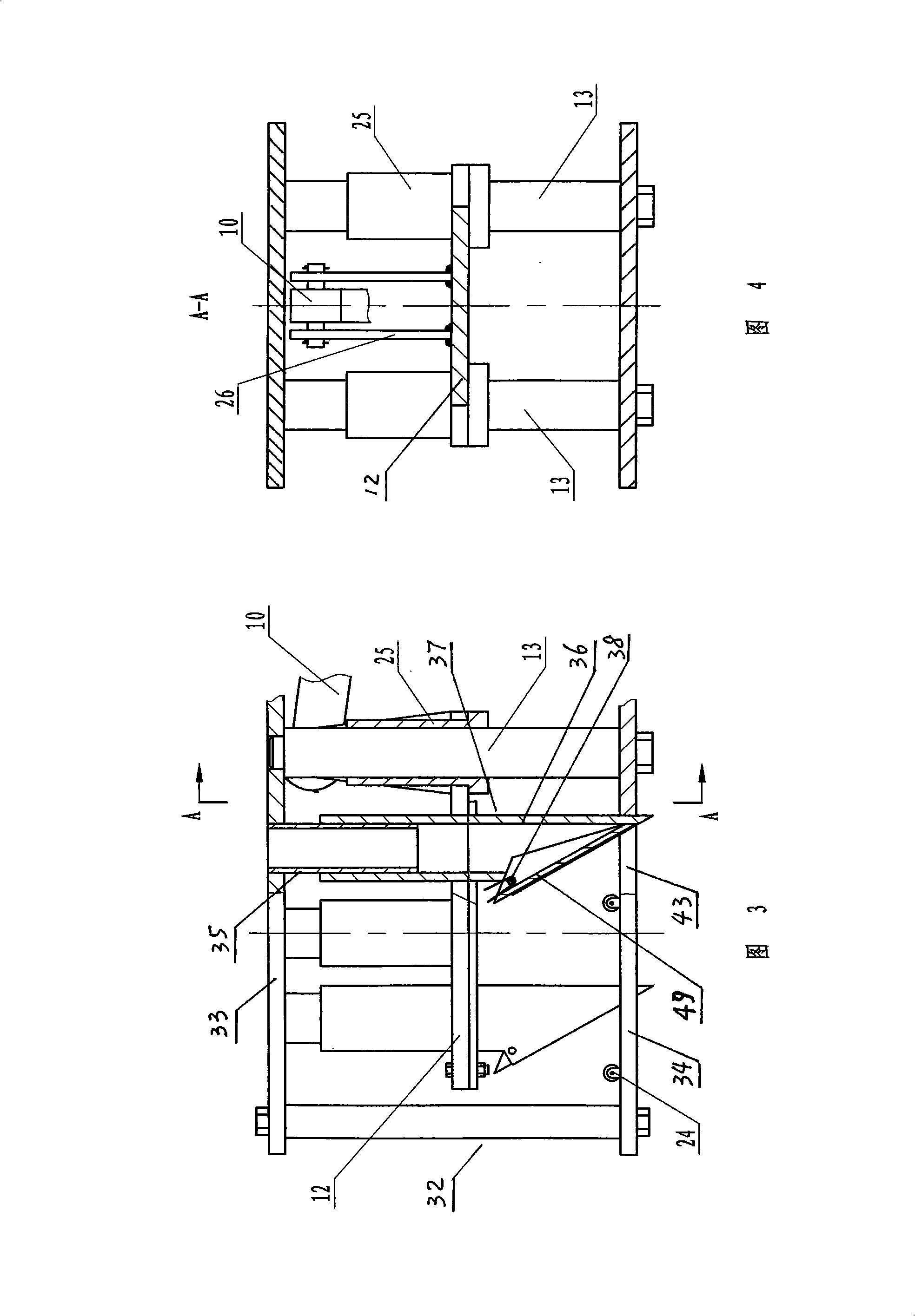

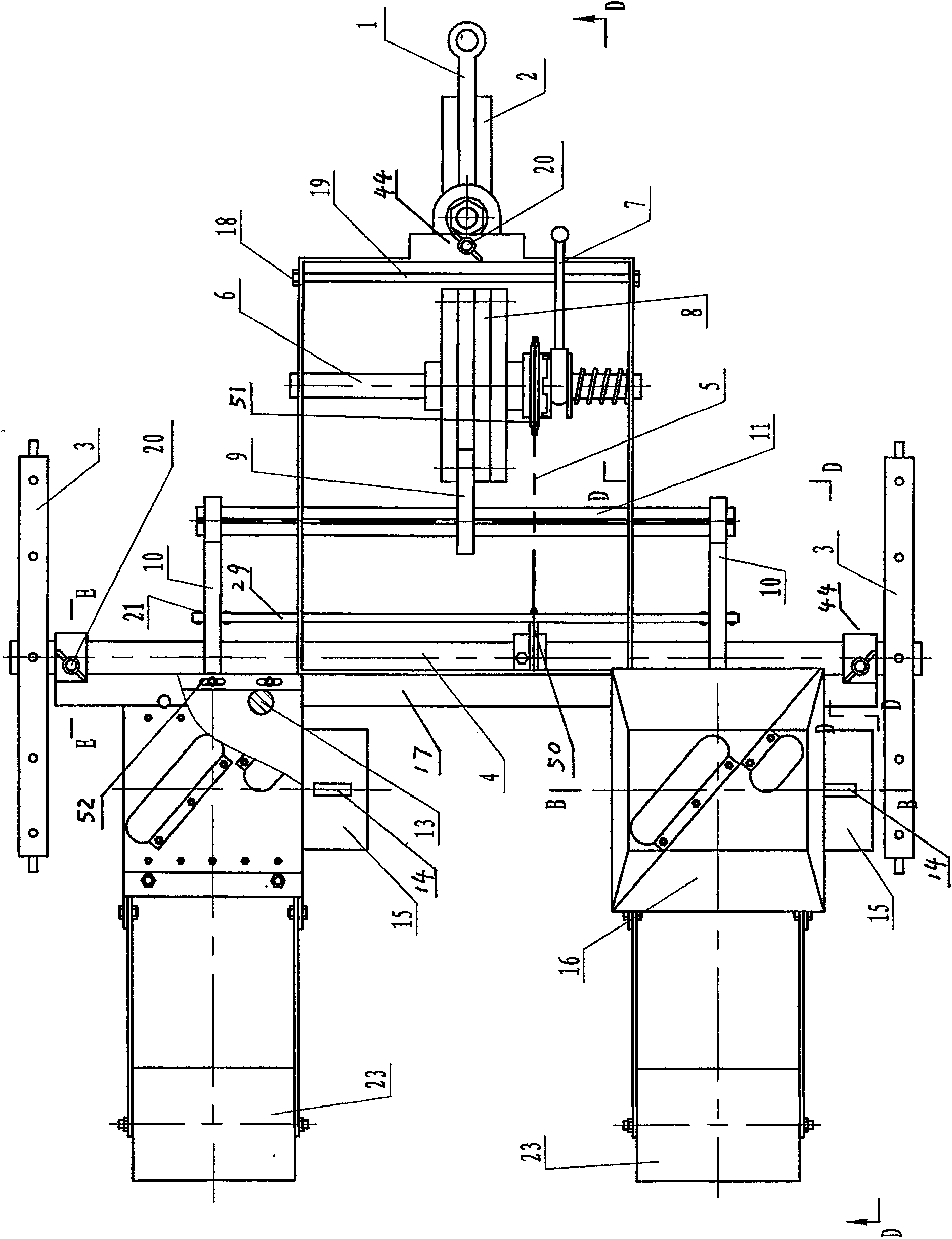

The invention provides a transplanter which is used for matching with the power machinery of a hand tractor, etc., and applicable for hole seeding of corn and soybean. The transplanter of the invention comprises a guide wheel, a pull bar, walking wheels, a seed manure box and a duck-billed transplanter. The transplanter is characterized in that: the seed manure box is fixedly connected on a seed manure bracket, a seed control plate is arranged between the bottom part of the seed manure box and the upper plate of the seed manure bracket, the seed mating limited port of the seed control plate is matched with a seed mating cam which is fixedly connected on a seeding displacement rack, the fixed mouth of the duck-billed transplanter is fixedly connected on the seeding displacement rack, the duck-billed transplanter is matched with the seeding limited port of the lower plate of the seed manure bracket, the driving chain wheel on a driving shaft is connected with the driven chain wheel of a driven shaft, a cam group which is fixedly connected with the driven shaft is contacted with a bending arm which is fixedly connected on a joint shaft, the bending arm is coaxially and fixedly connected with a swing arm which is articulated on the seeding displacement rack. The transplanter of the invention has the advantages of reasonable structure, adjustable seeding depth, plant spacing and spacing between ridges, reliable action, long service life, high working efficiency, good seeding quality, etc.

Owner:刘国成

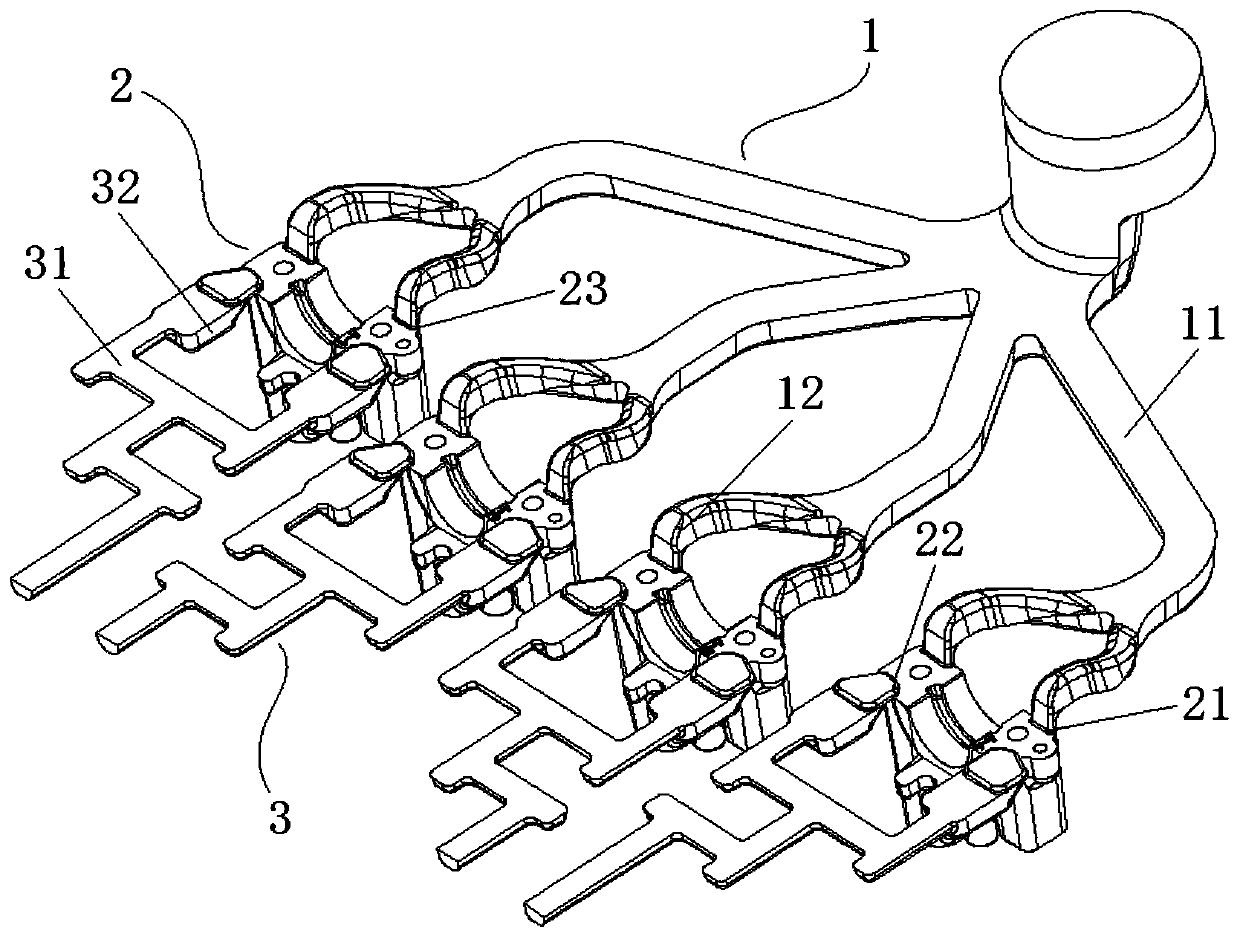

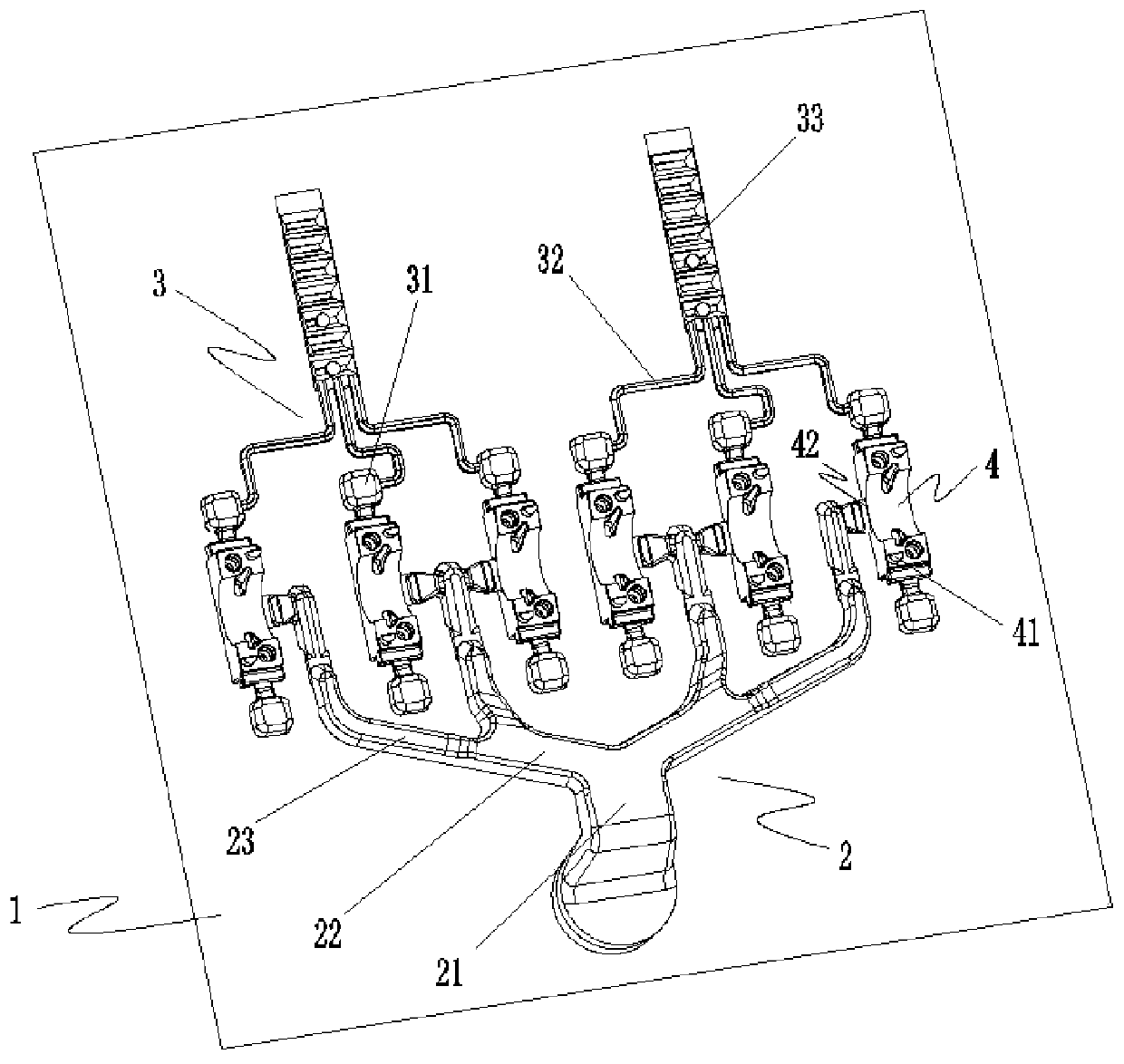

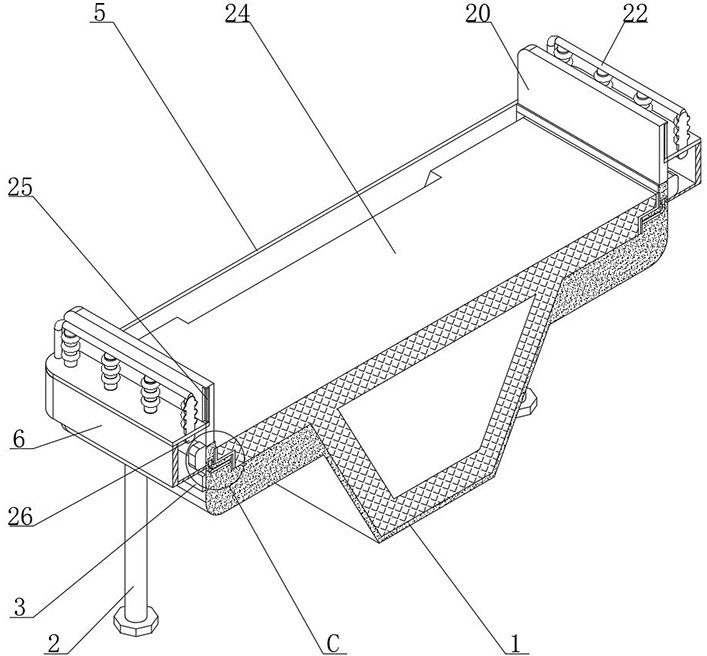

Die pouring system of die casting parts

The invention provides a die pouring system of die-casting parts. The die pouring system comprises a pouring gate system and a forming cavity, the pouring gate system comprises a plurality of main pouring gates, a plurality of branch pouring gates are arranged at the output ends of the main pouring gates, the cross sectional areas of the main pouring gates and / or the branch pouring gates are gradually reduced along the conveying direction of molten metal; a plurality of pouring inlets are formed in the forming cavity, the pouring inlets communicate with the output ends of the branch pouring gates in a one-to-one correspondence mode; along the conveying direction of the molten metal, a plane where the pouring inlets are located serves as the top face of the forming cavity, the molten metaldirectly falls on the bottom face of the forming cavity after entering the forming cavity from the pouring inlets; and the distance value between the setting position of the pouring inlets and the bottom face of the forming cavity comprises the maximum height value of a casting to be formed in the forming cavity. According to the die pouring system of the die-casting parts, the generation of air holes and shrinkage cavities in the inner part of the casting can be reduced, the product quality can be improved, and the production cost can be reduced under the conventional die-casting condition.

Owner:ZHANJIANG DENI VEHICLE PARTS

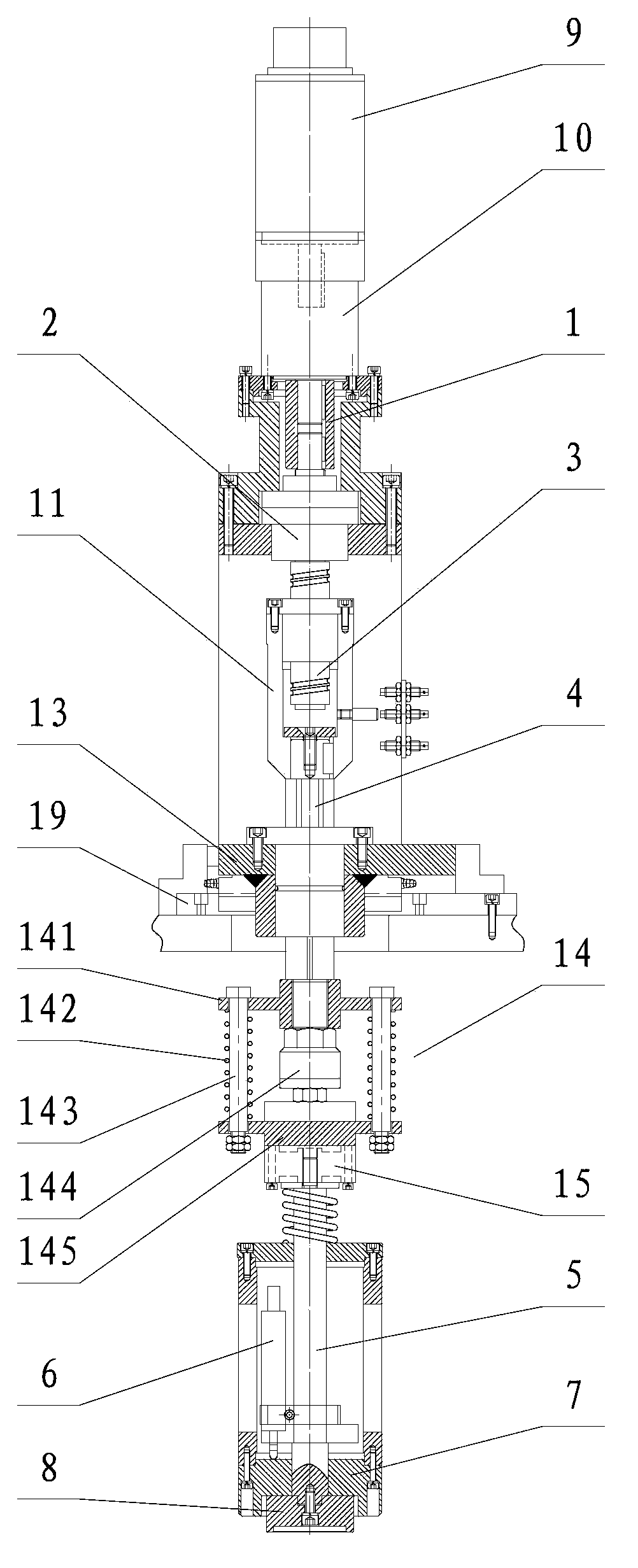

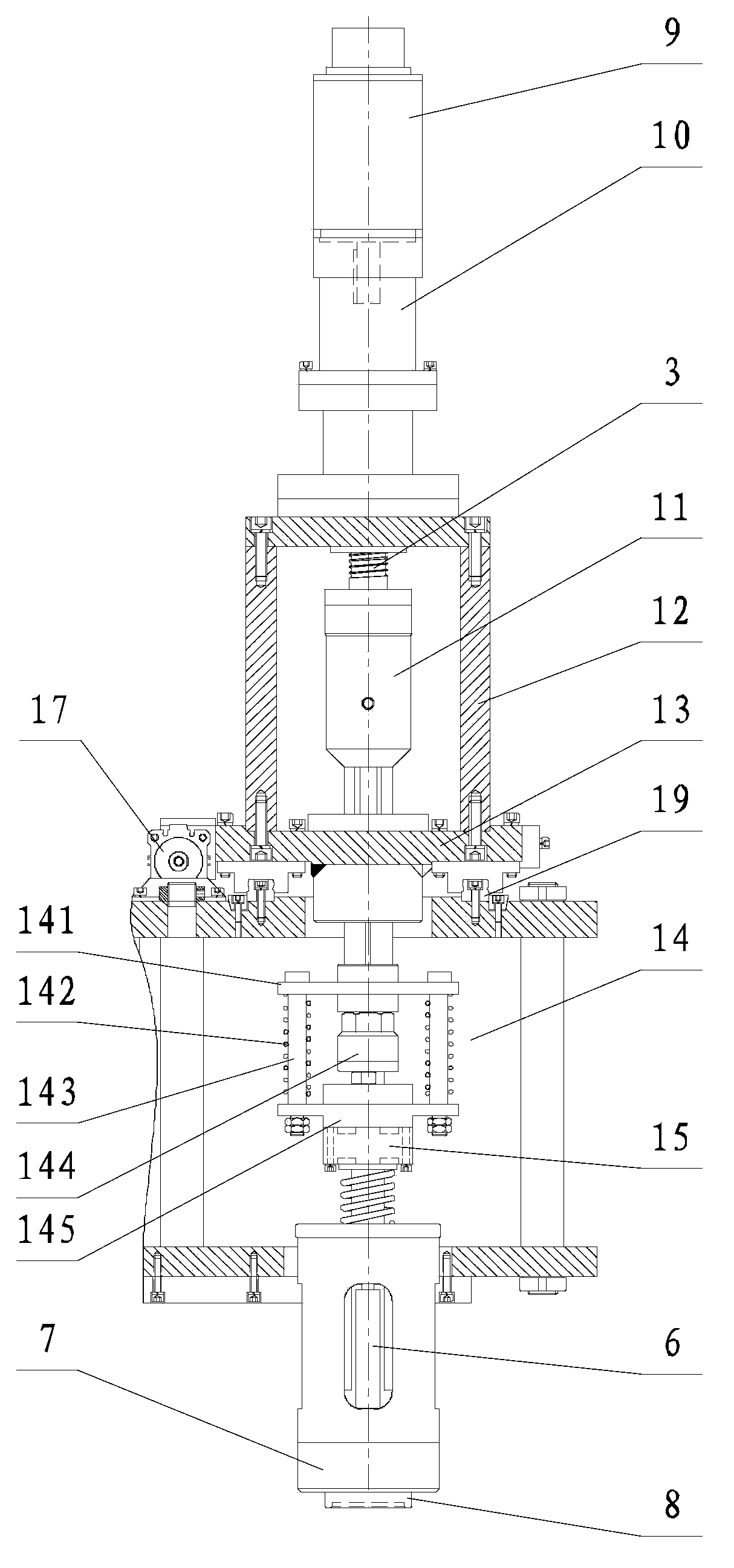

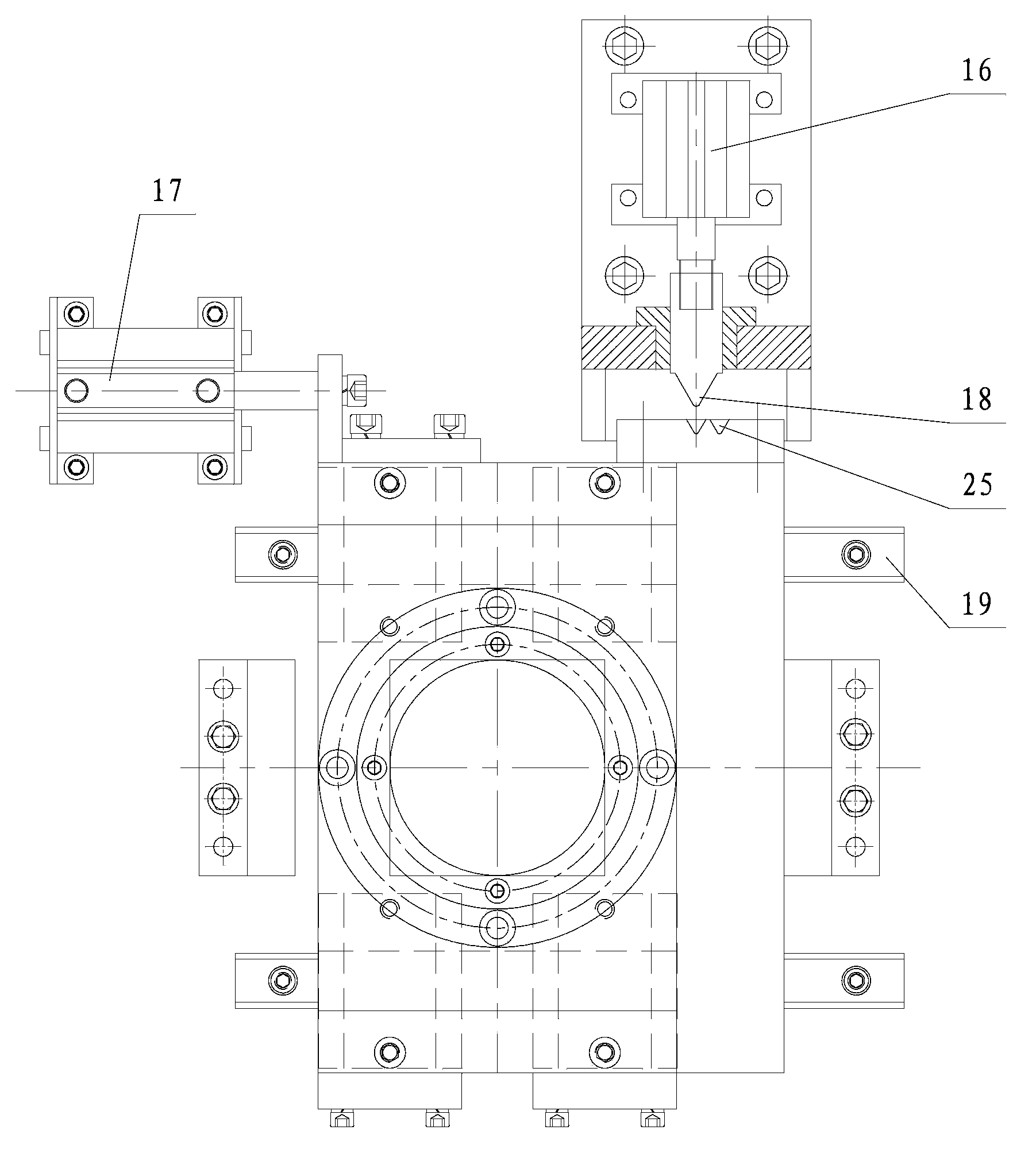

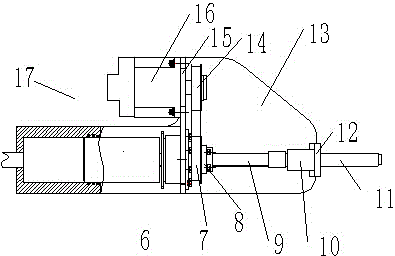

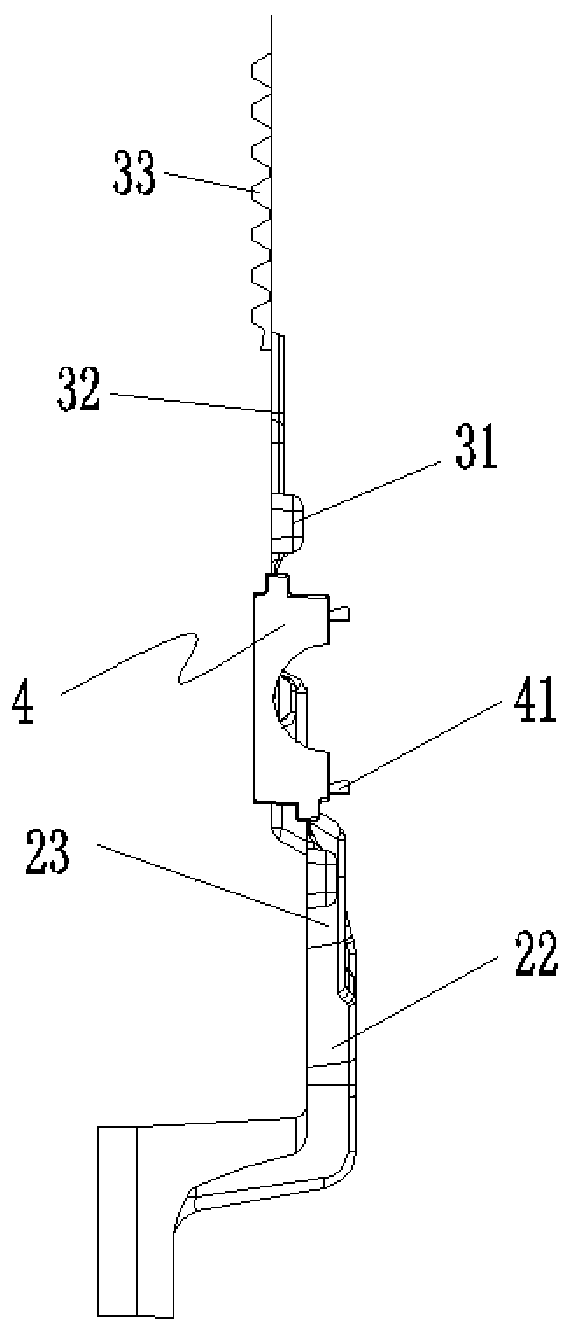

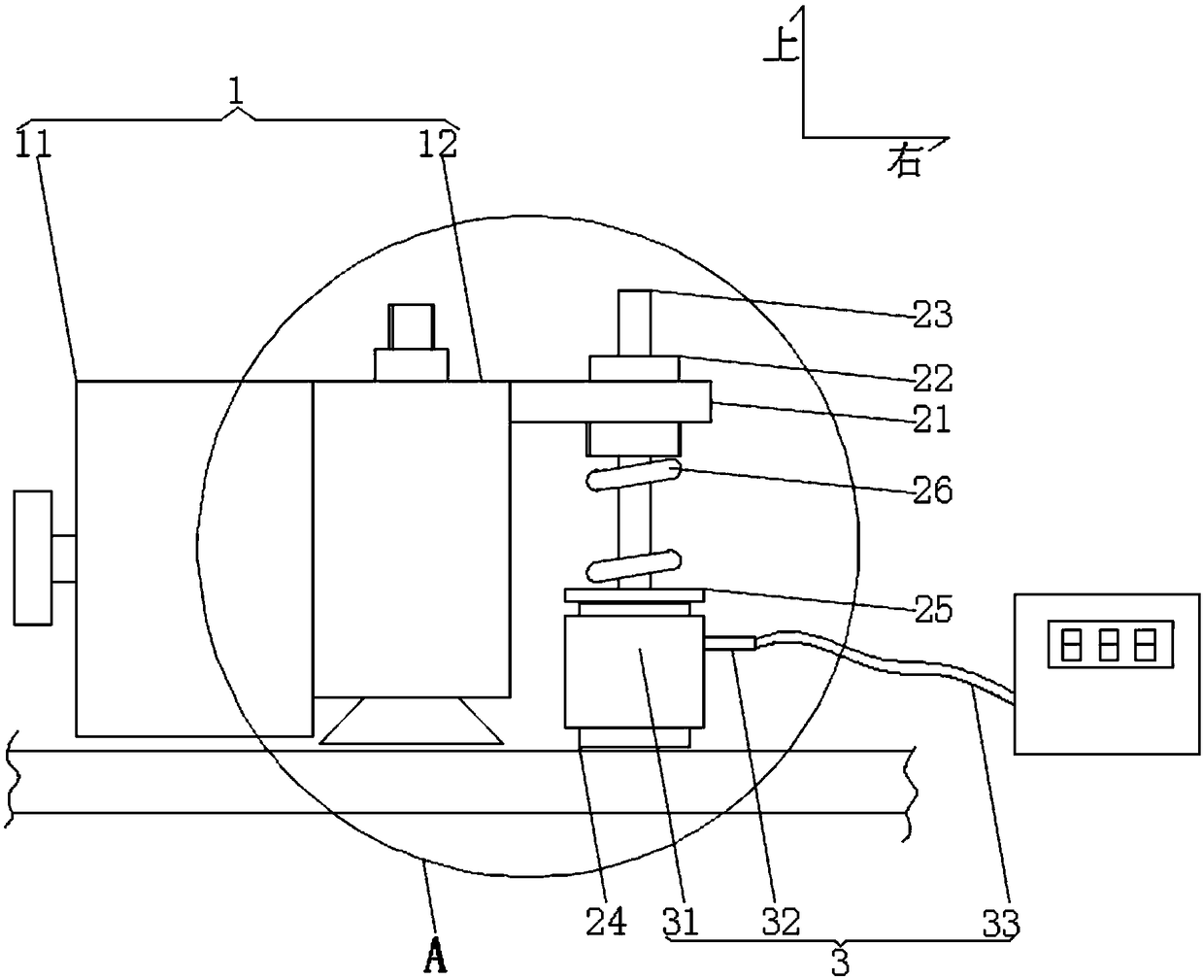

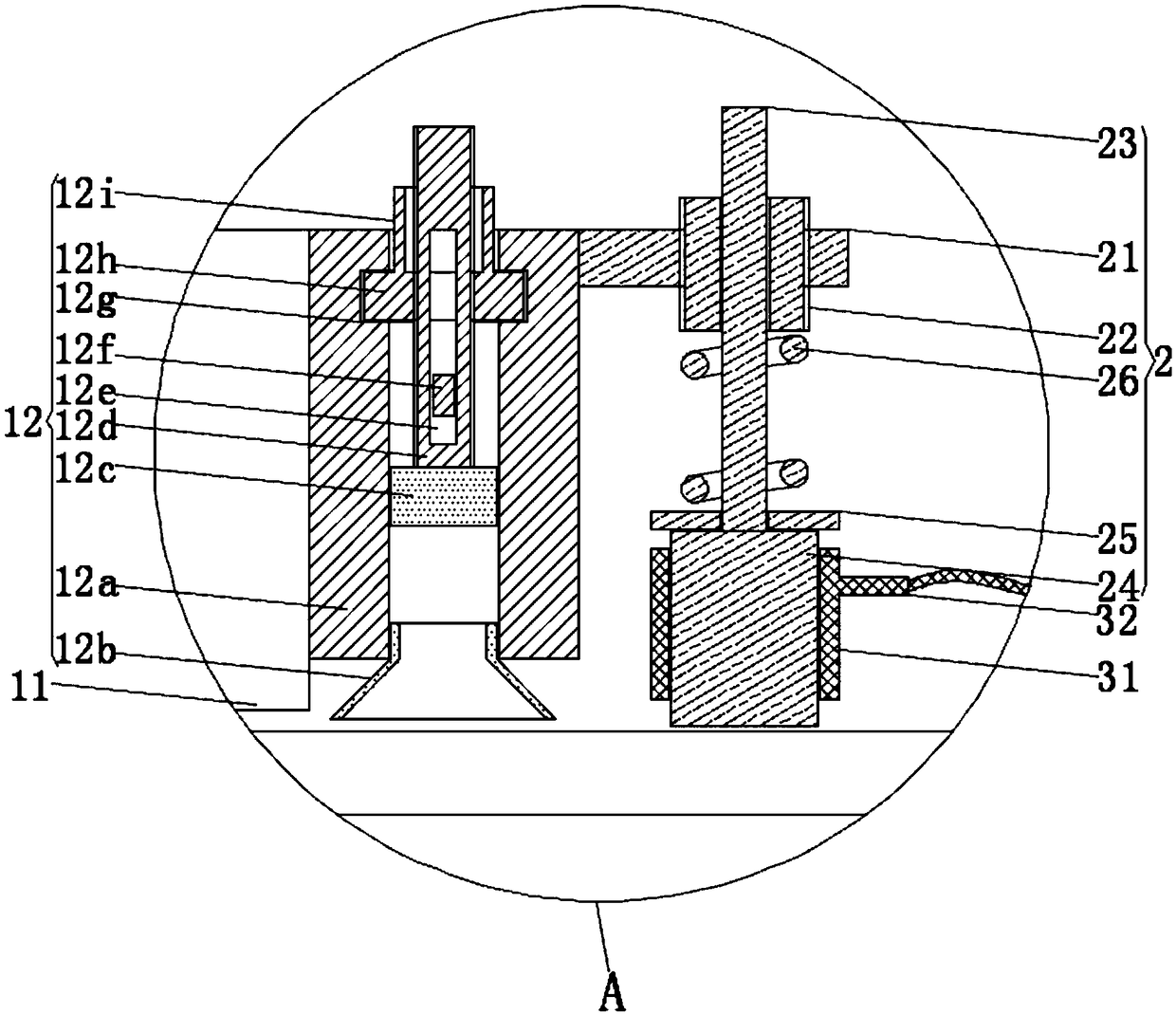

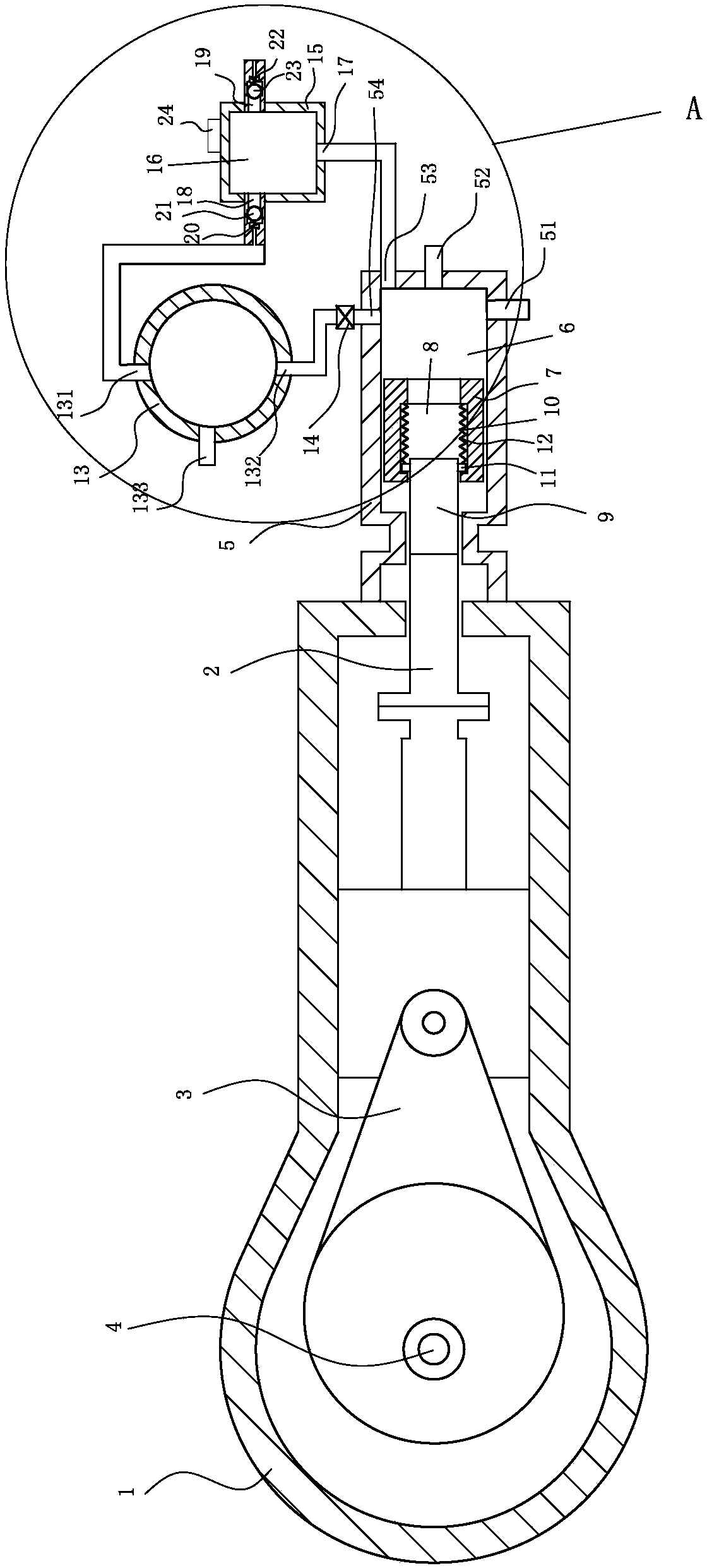

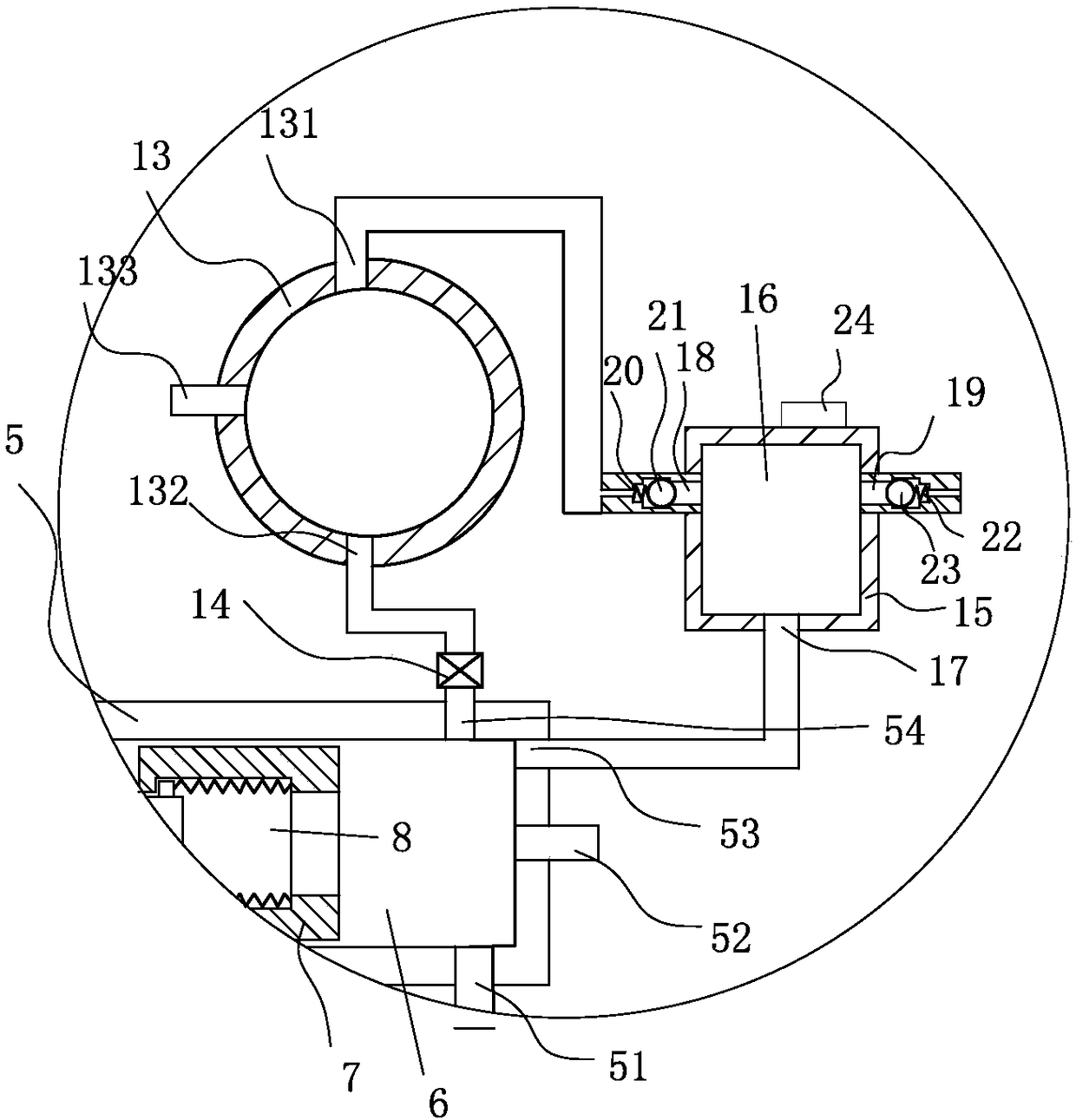

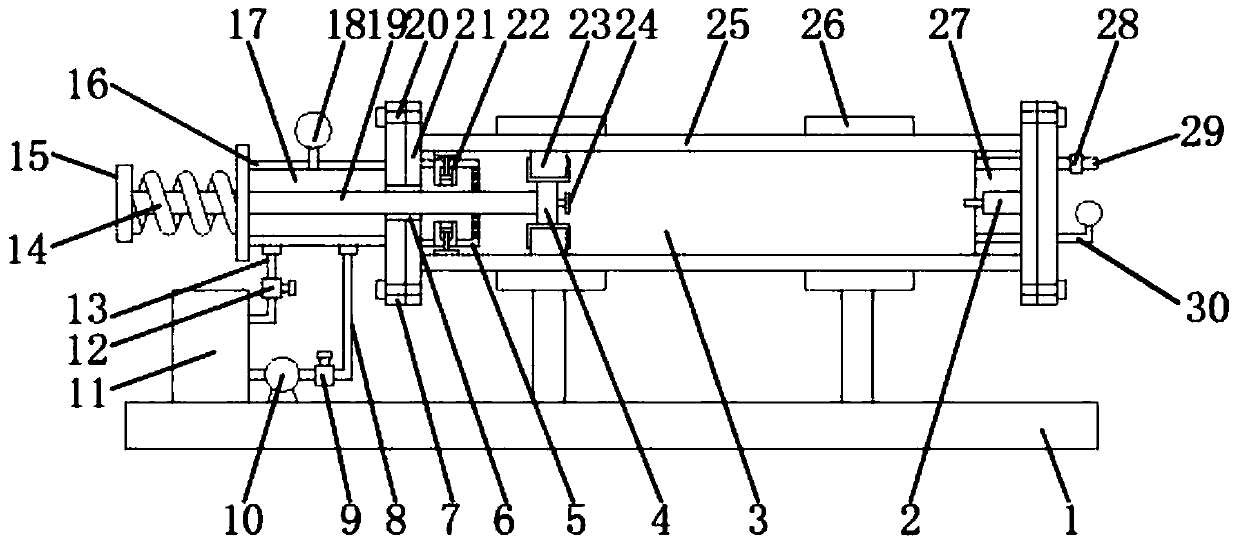

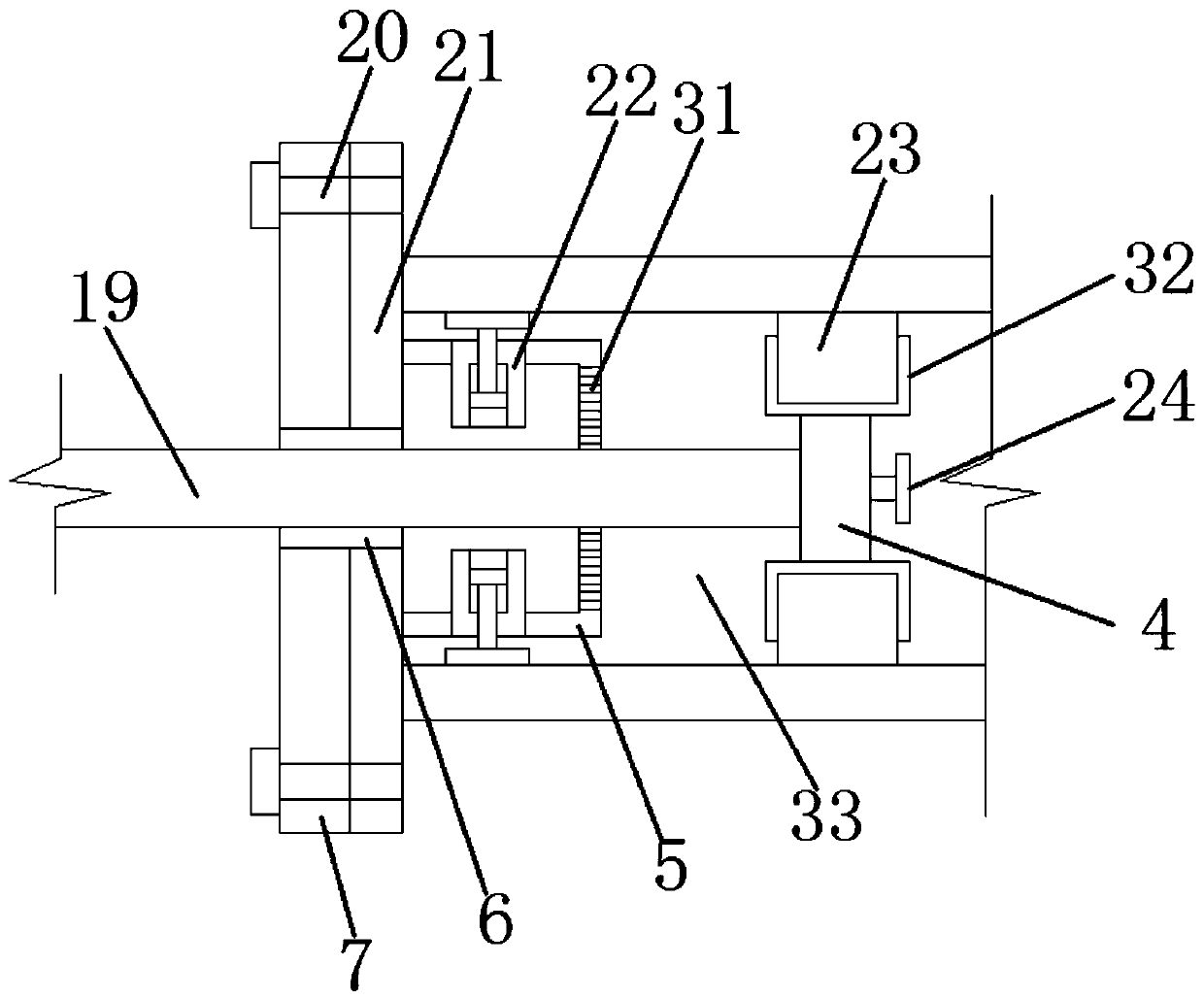

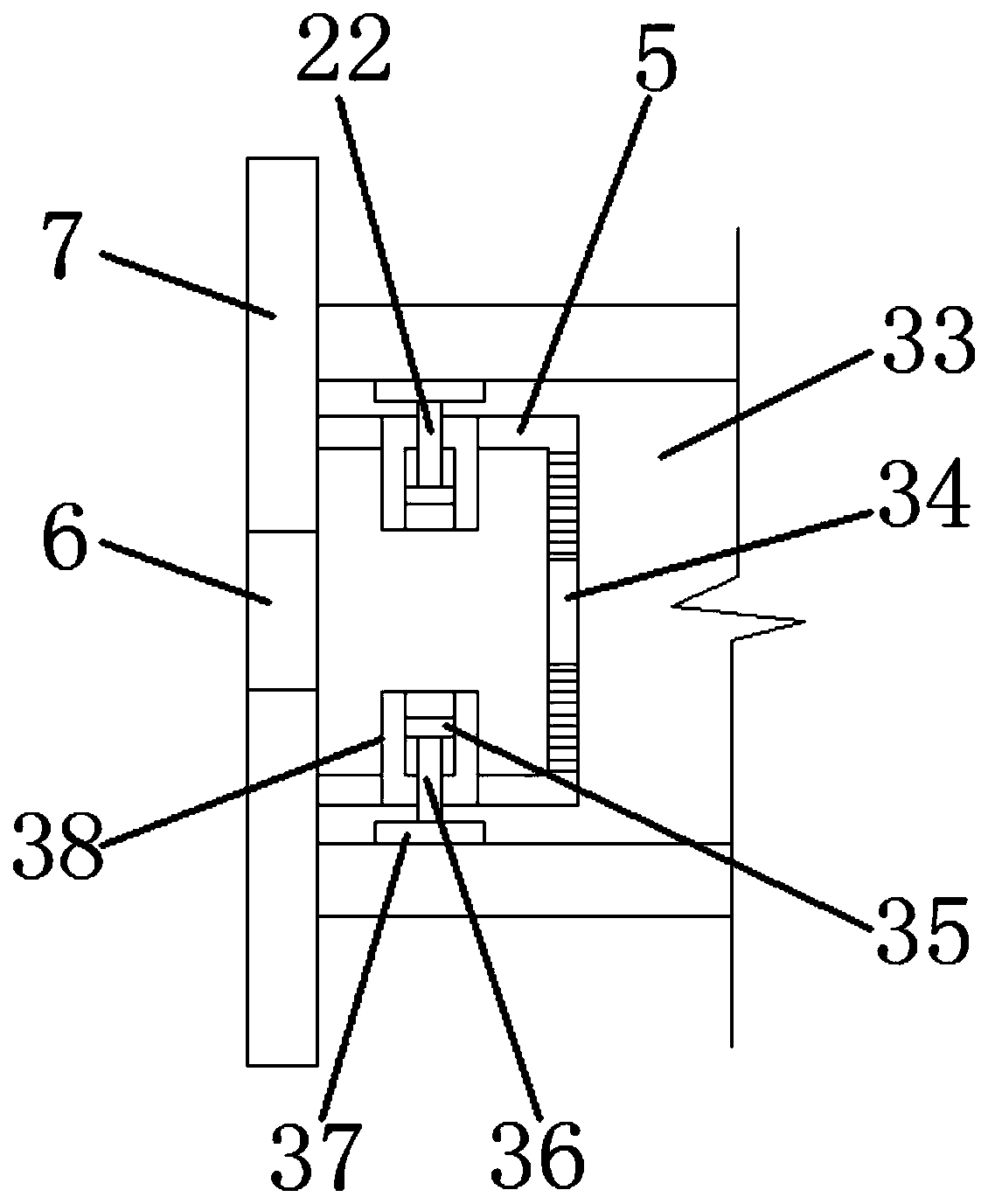

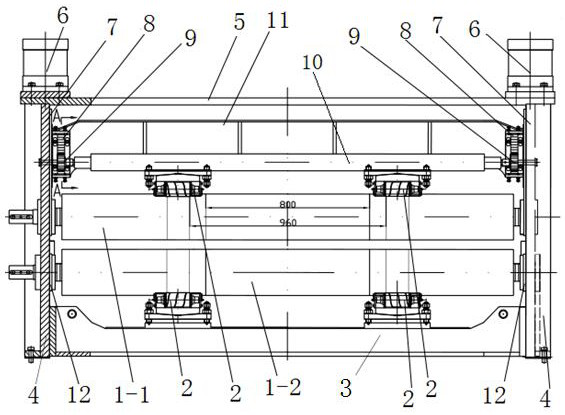

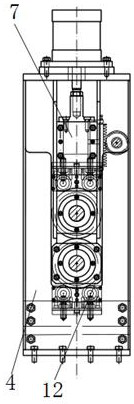

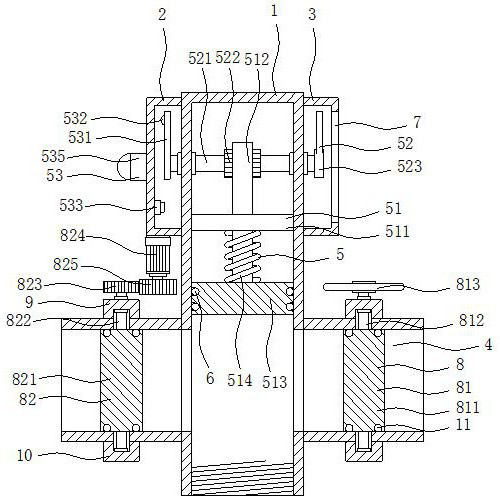

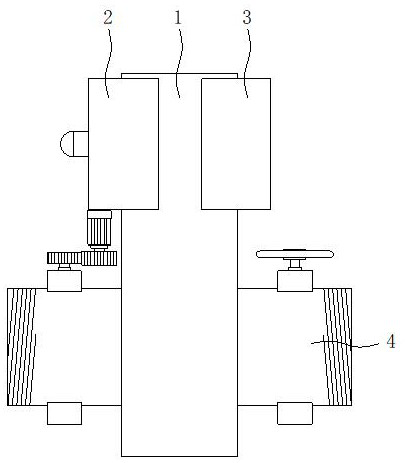

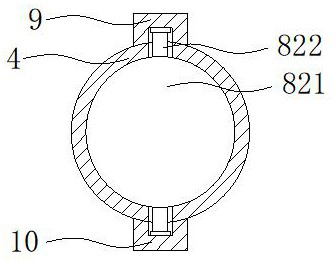

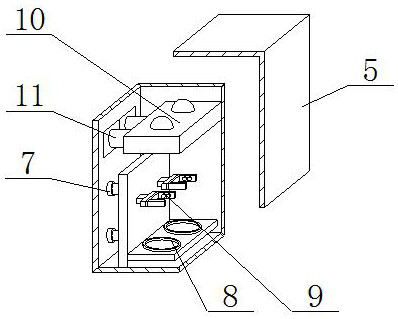

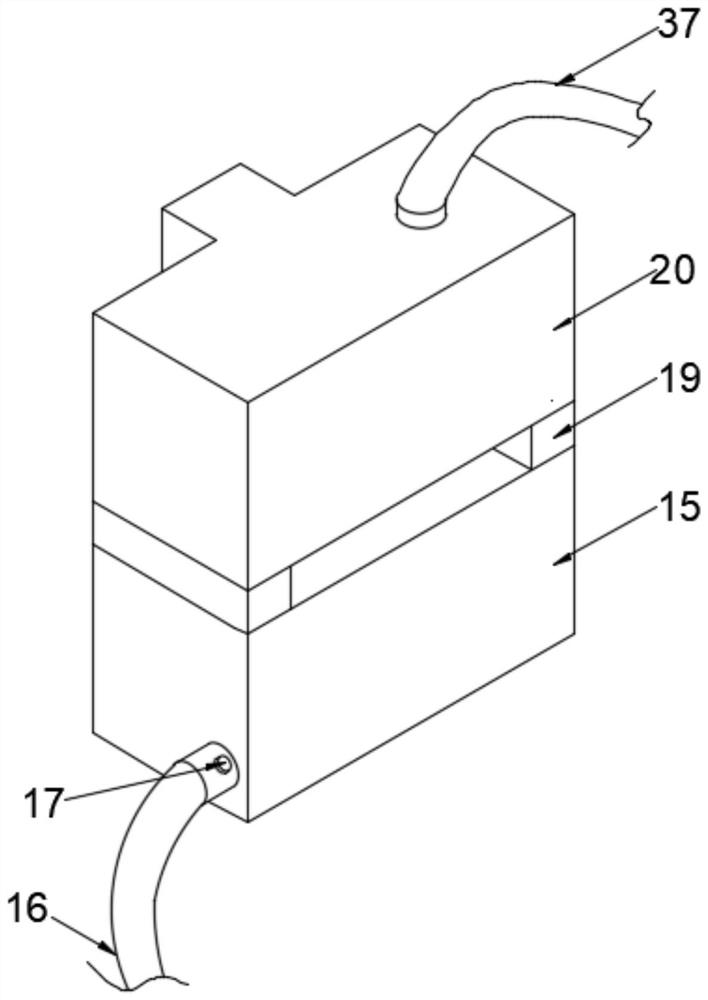

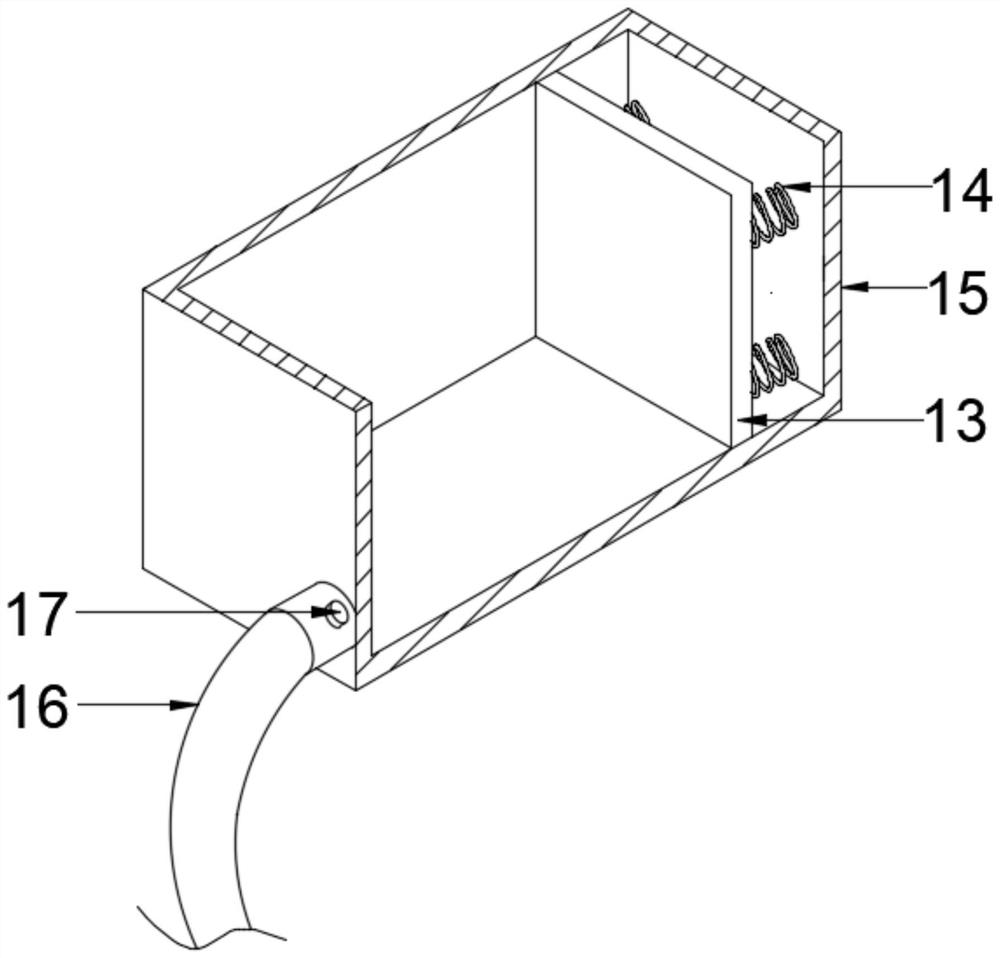

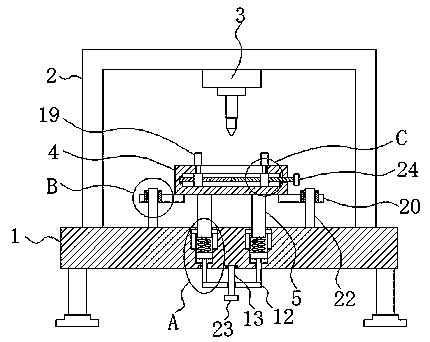

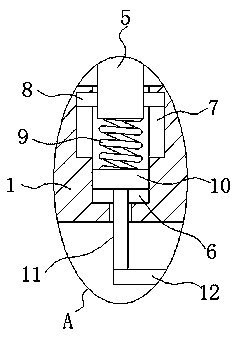

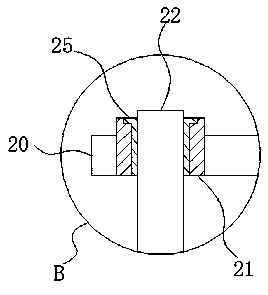

Servo pressurizing based depth measuring mechanism capable of variable pitch adjustment

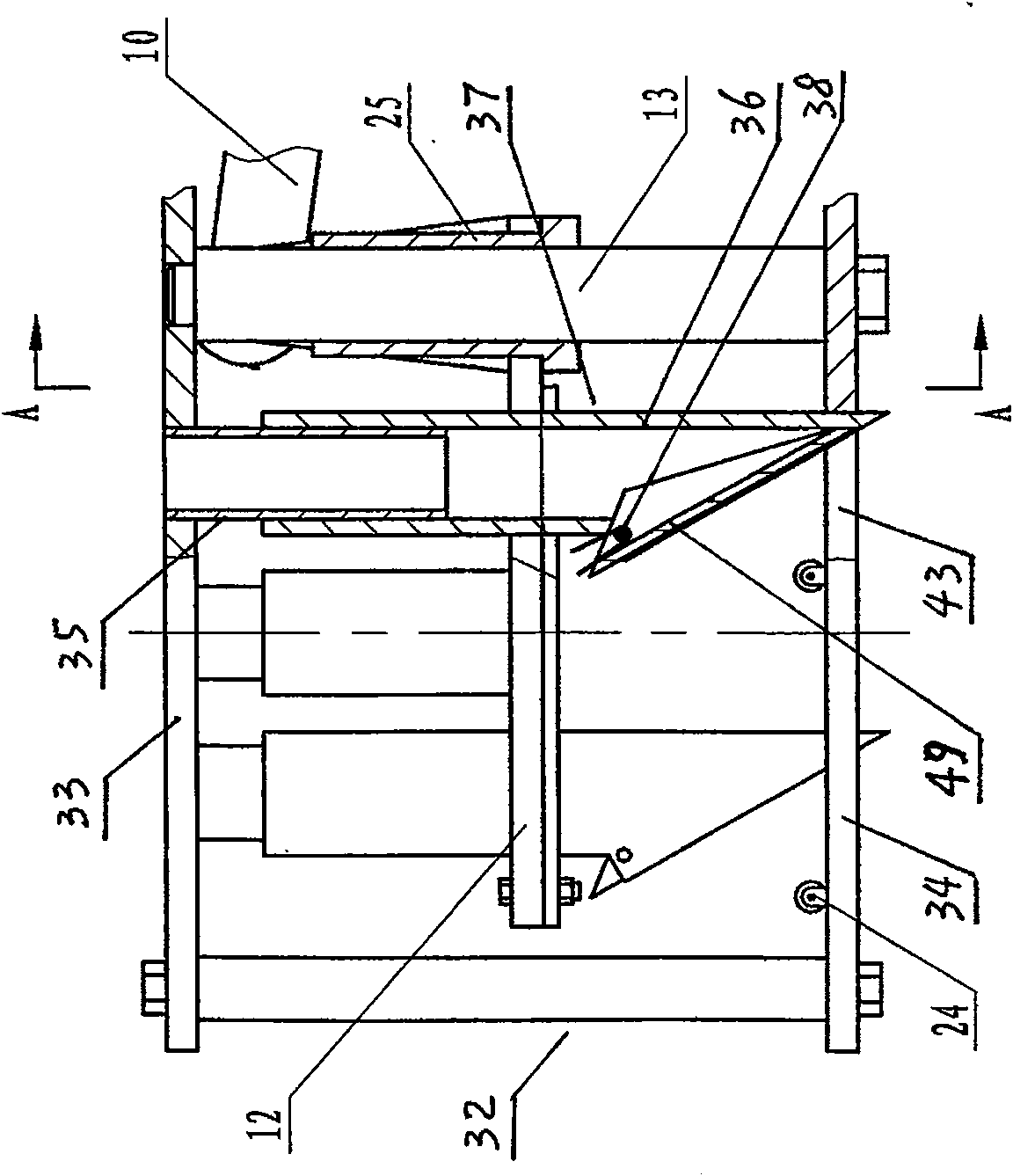

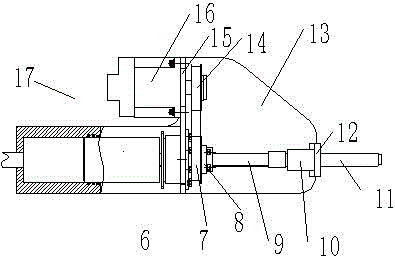

The invention relates to a device for measuring the depth between a differential bearing in an automobile gearbox and the contact surface of a gearbox housing and a dust-proof cover, and specifically relates to a servo pressurizing based depth measuring mechanism capable of variable pitch adjustment. The mechanism comprises a servo pressure measurement portion and a variable pitch adjustment portion. The variable pitch adjustment portion comprises a displacement cylinder, a linear guide rail and a displacement connection board. The servo pressure measurement portion is installed on the displacement connection board and is driven to perform reciprocating motion on the linear guide rail through the displacement cylinder. The servo pressure measurement portion comprises a servo motor, a decelerator, a ball screw, a connection frame, a floating adjustment portion, a pressure sensor, a connection shaft, a displacement sensor, a pressure head and a measurement pressure head. The servo motor is connected with the ball screw through the decelerator. One end of the connection frame is in threaded connection with the ball screw. The other end of the connection frame is successively connected with the floating adjustment portion, the pressure sensor, the connection shaft, the pressure head and the measurement pressure head. The mechanism provided by the invention has the advantages of adjustable measuring pressure, diversified suitable models, reliable work and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

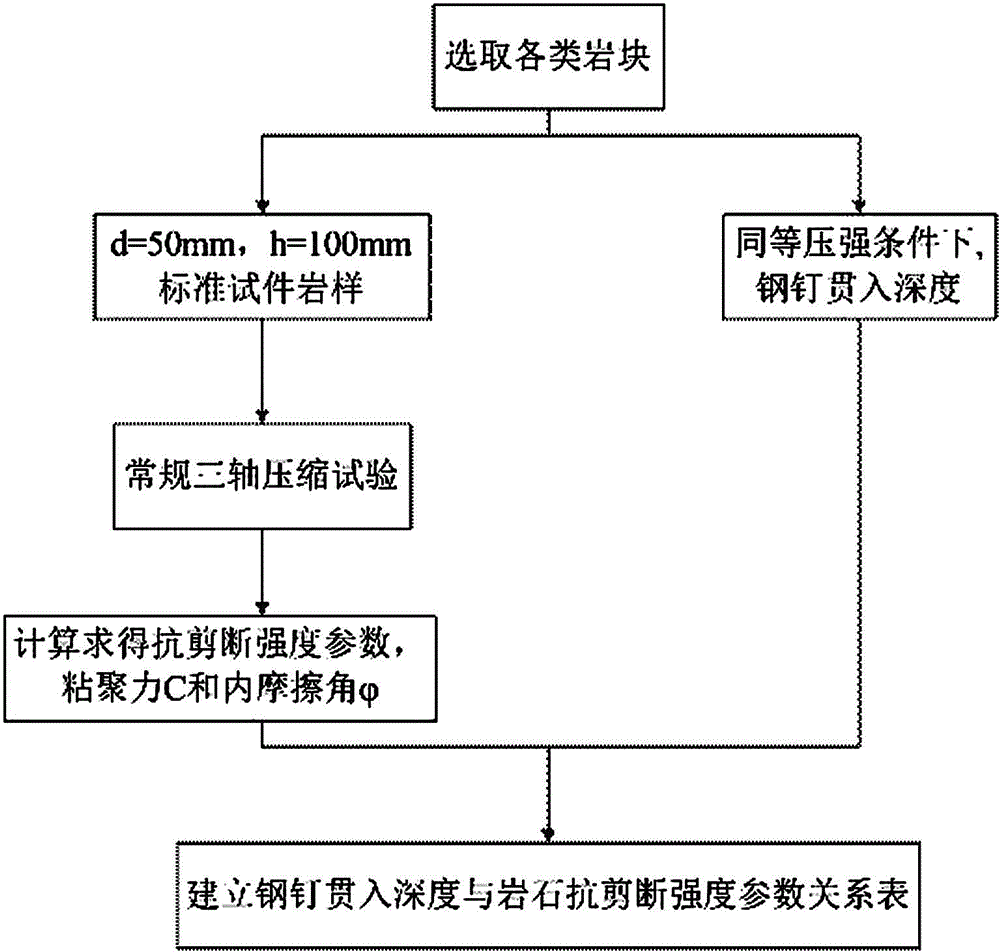

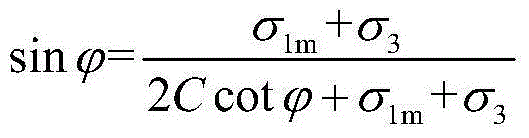

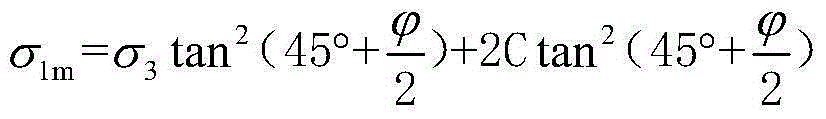

Method utilizing nail shooting to measure rock cohesion C and internal friction angle (Phi)

InactiveCN104990866AImprove assay reliabilityPressure regulationUsing mechanical meansMaterial analysisEngineeringHigh pressure

The invention discloses a method utilizing nail shooting to measure the rock cohesion C and internal friction angle (Phi). The method comprises the following steps: (1) generating high pressure gas by an air compressor, introducing the high pressure gas into a nail shooting gun through an exhaust pipe, and shooting steel arranging nails into a rock under the pressure of the high pressure gas; (2) measuring the length of steel arranging nails in the rock by a steel ruler; (3) according to the linear molar strength envelope line, calculating the rock cohesion C and internal friction angle (Phi). In the provided method, a nail shooting gun shoots steel arranging nails into a rock, then the length of the steel arranging nails in the rock is measured, and finally relationship among the length, the rock cohesion C and internal friction angle (Phi) is established. The method has the advantages of reliability, simple structure, and convenient operation.

Owner:CHINA THREE GORGES UNIV

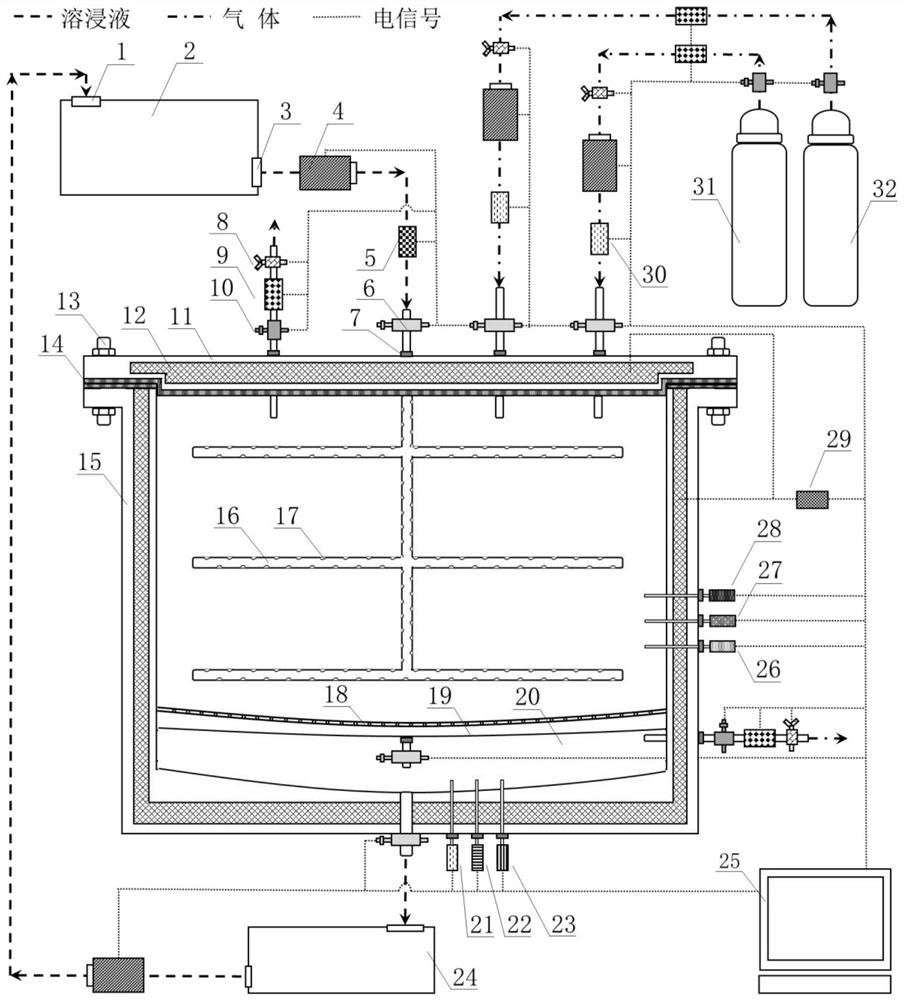

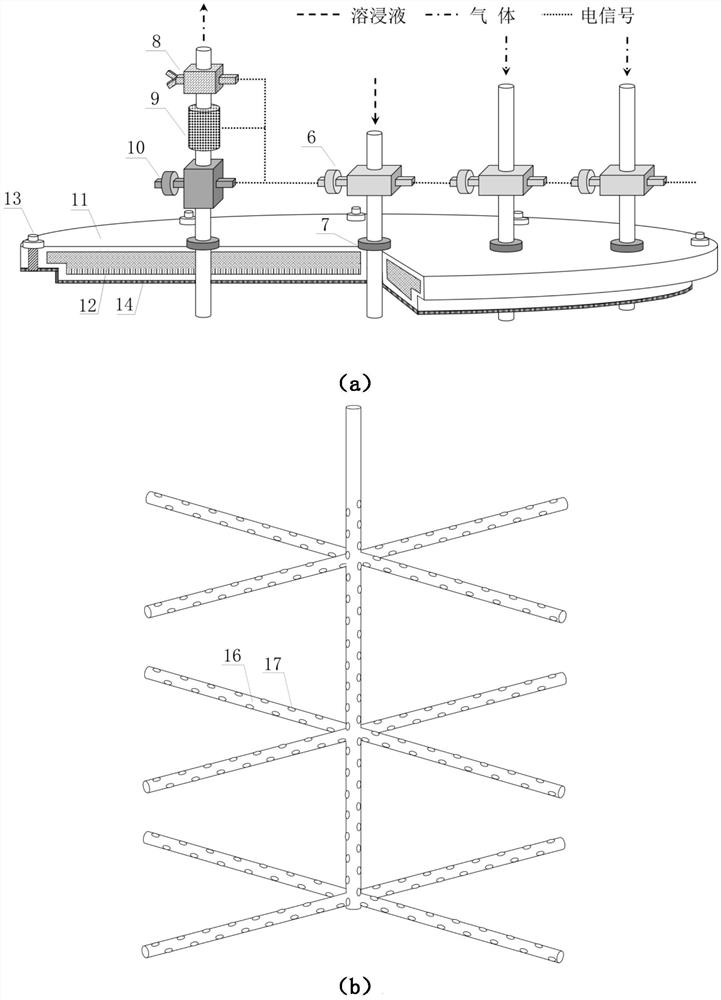

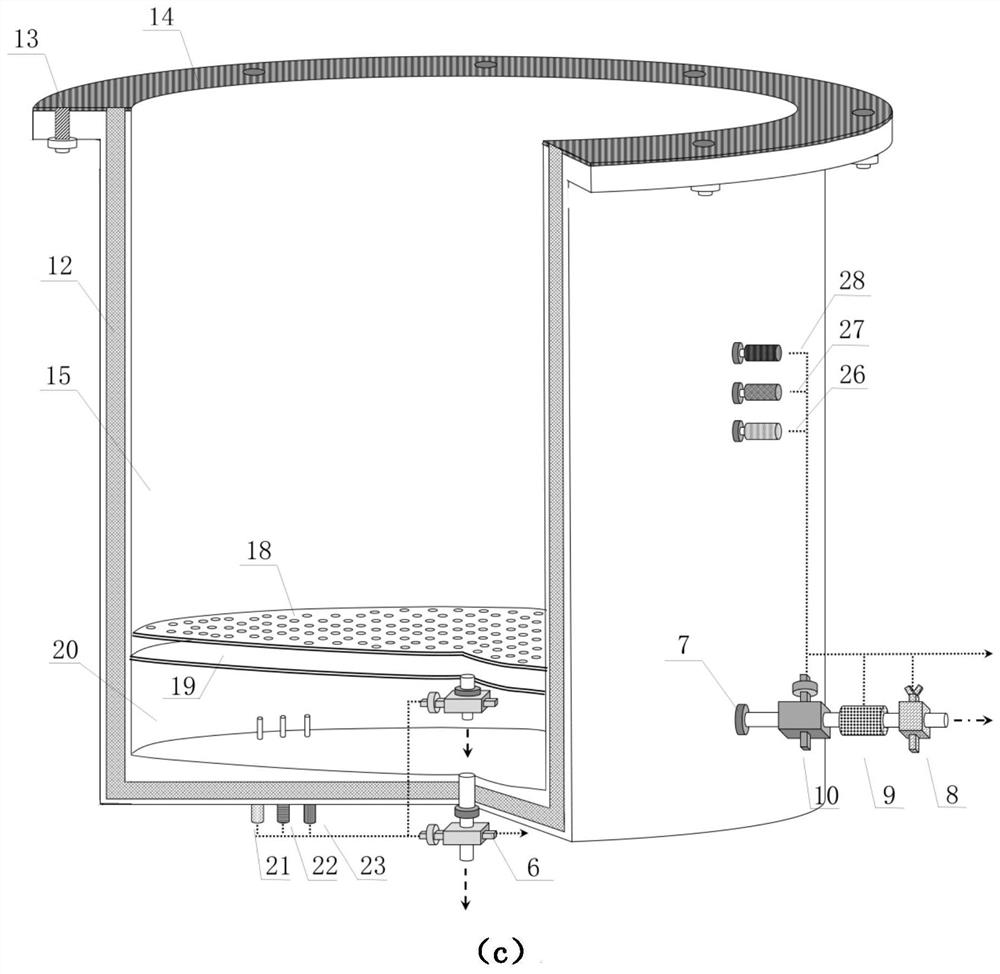

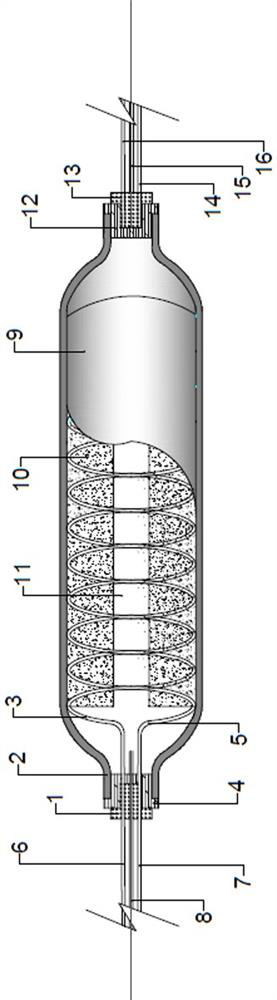

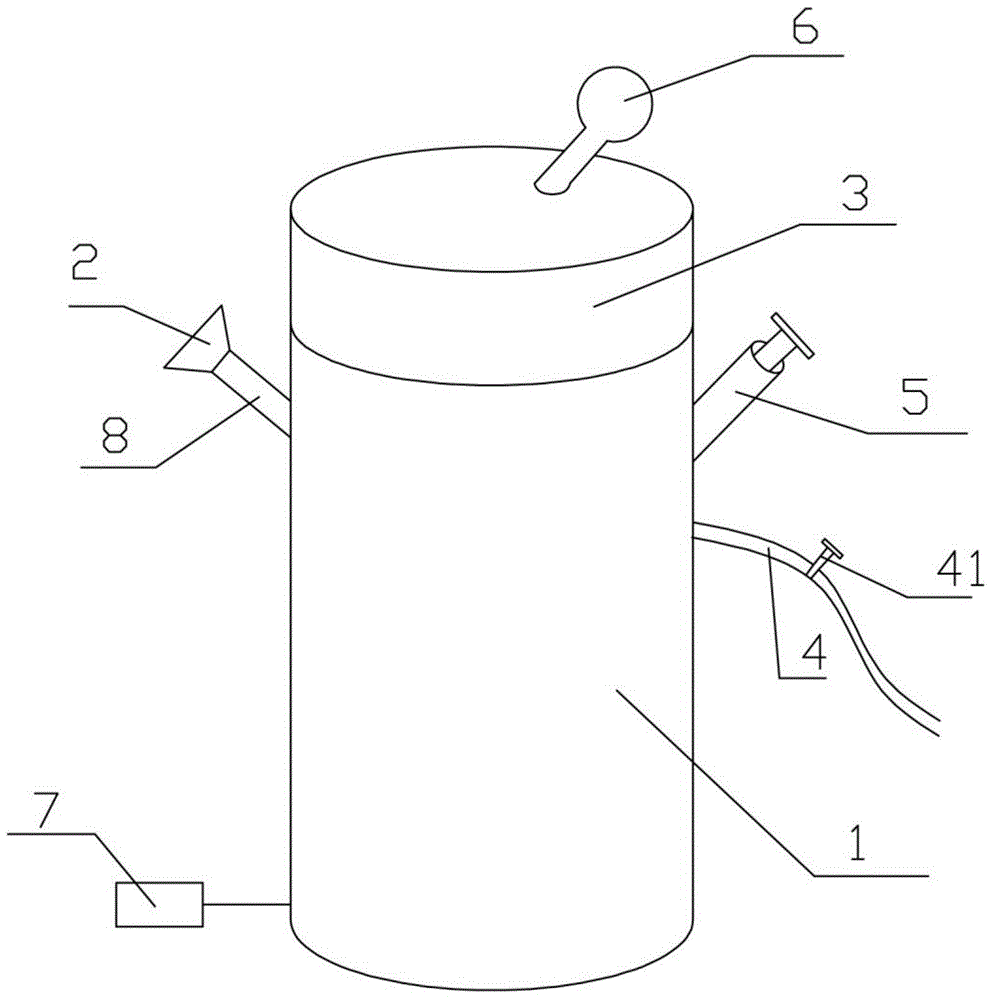

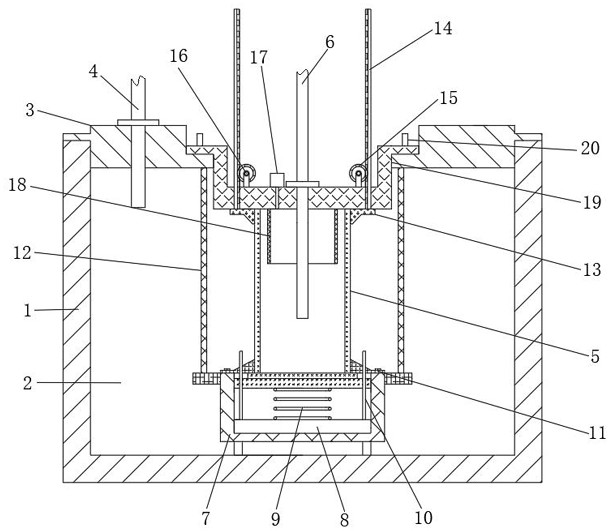

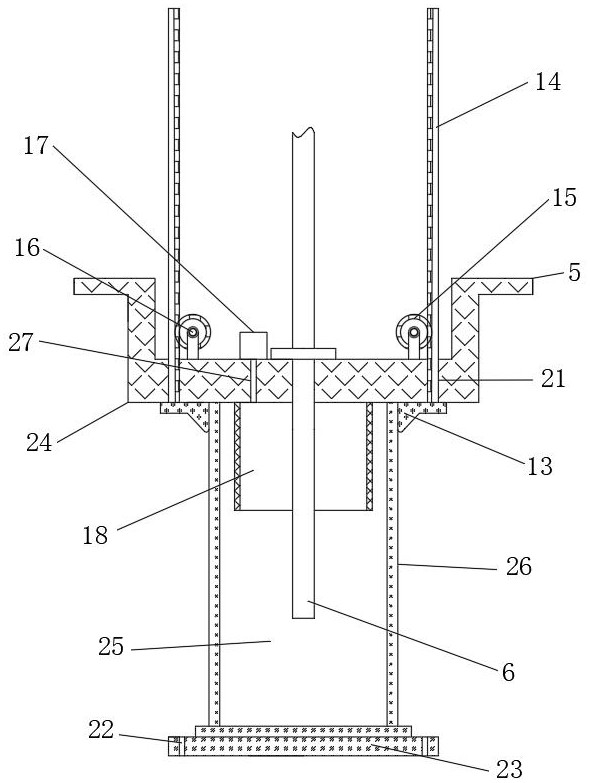

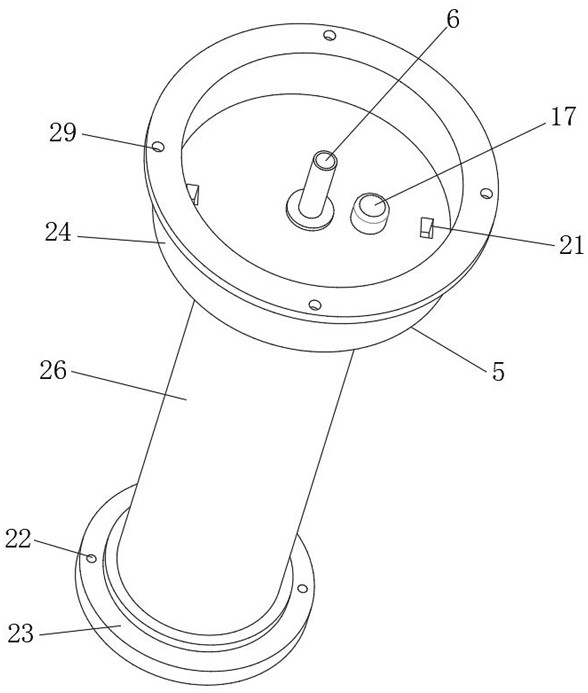

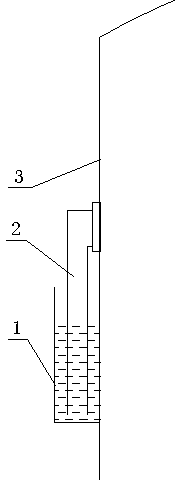

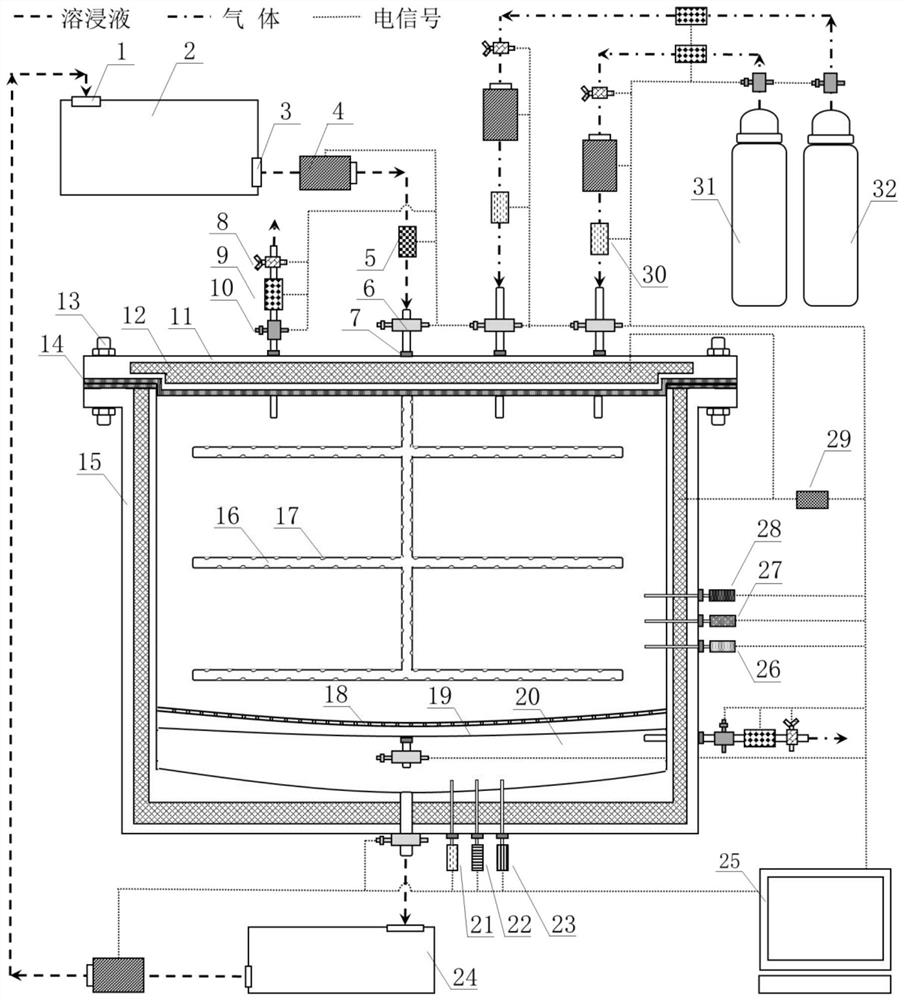

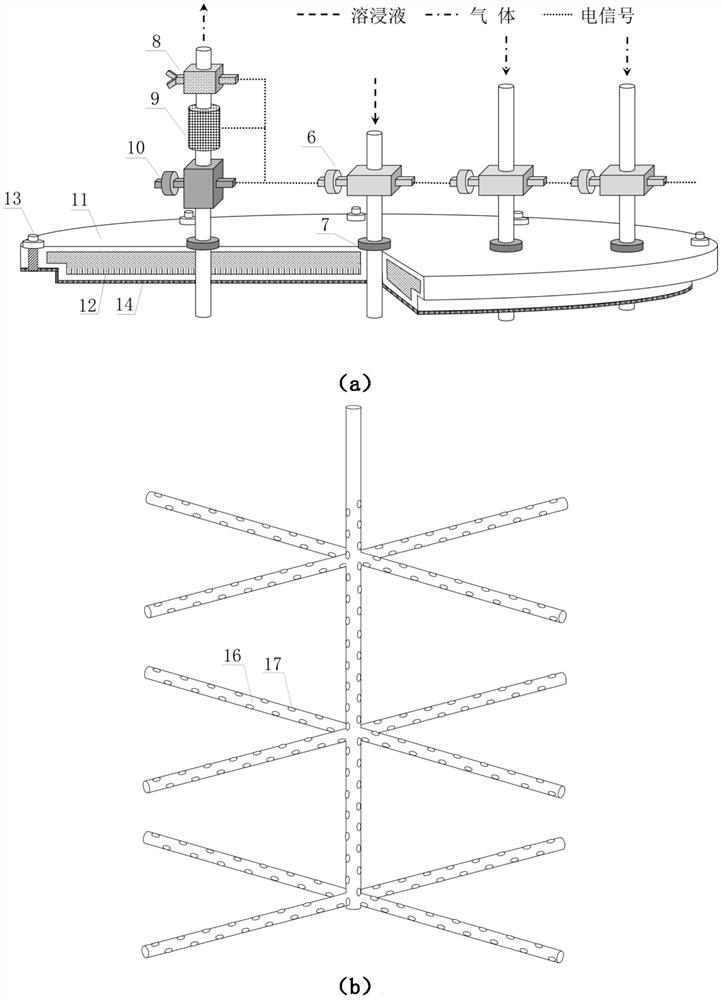

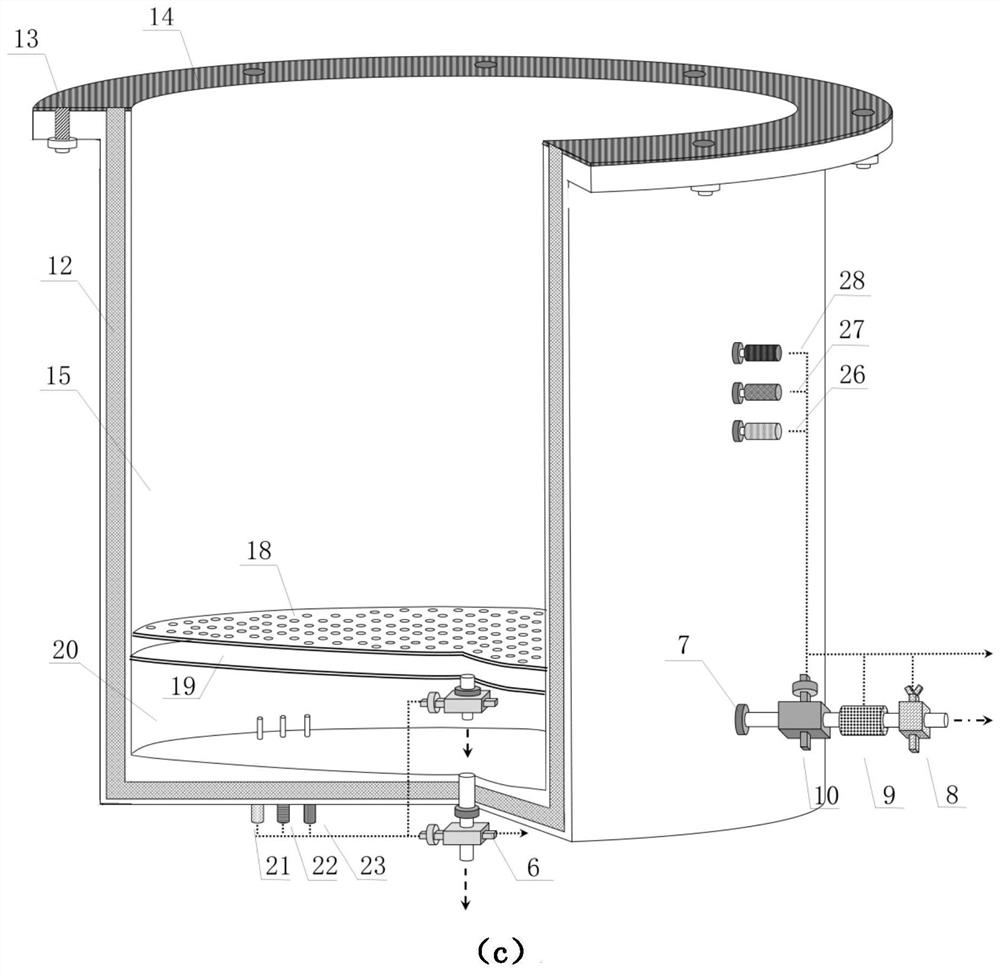

Experimental device and method for simulating in-situ fluidized mining of deep metal ore

ActiveCN111855902APressure regulationTemperature environment controlMaterial analysisCo2 storageLiquid storage tank

The invention provides an experimental device and method for simulating in-situ fluidized mining of deep-ground metal ore, and belongs to the technical field of deep-ground resource fluidized mining.The device comprises a reflux opening, a liquid storage tank, a liquid outlet, a pumping motor, a fluid flow meter, an electric control airtight valve, a sealing ring, a safety valve, a pressure gauge, a pressure release valve, a reaction tank top cover, an electric heating temperature control layer, a fixing bolt, a sealing washer, a reaction tank body, a liquid injection pipeline, a liquid injection hole, a porous partition plate, a liquid collection curved surface, a liquid collection bin, a pH sensor, a redox potential sensor, an ion concentration sensor, a liquid collection tank, a data centralized control visualization terminal, a temperature sensor, an oxygen concentration sensor, an air pressure sensor, an electric control temperature changer, a gas flowmeter, an O2 storage tank and a CO2 storage tank. According to the device and method of the invention, the temperature and the air pressure of the experimental device are visible and adjustable; and the pH value, the oxidation-reduction potential, the ion concentration and other parameters are measurable and controllable; and a research device and a method reference are provided for in-situ fluidized mining of the deep metalore.

Owner:UNIV OF SCI & TECH BEIJING +1

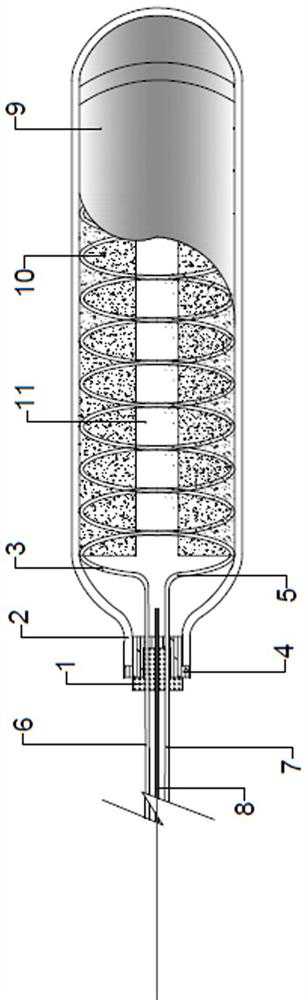

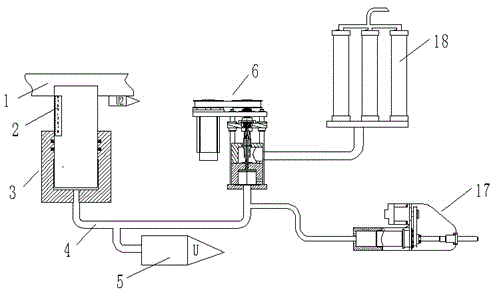

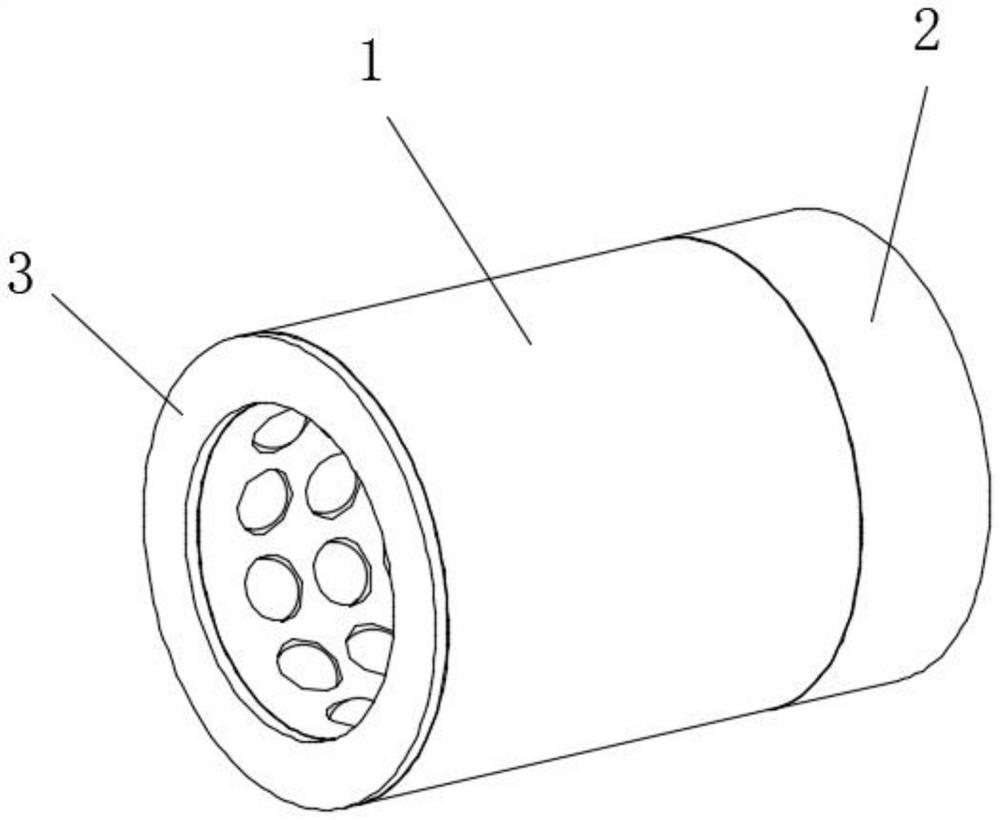

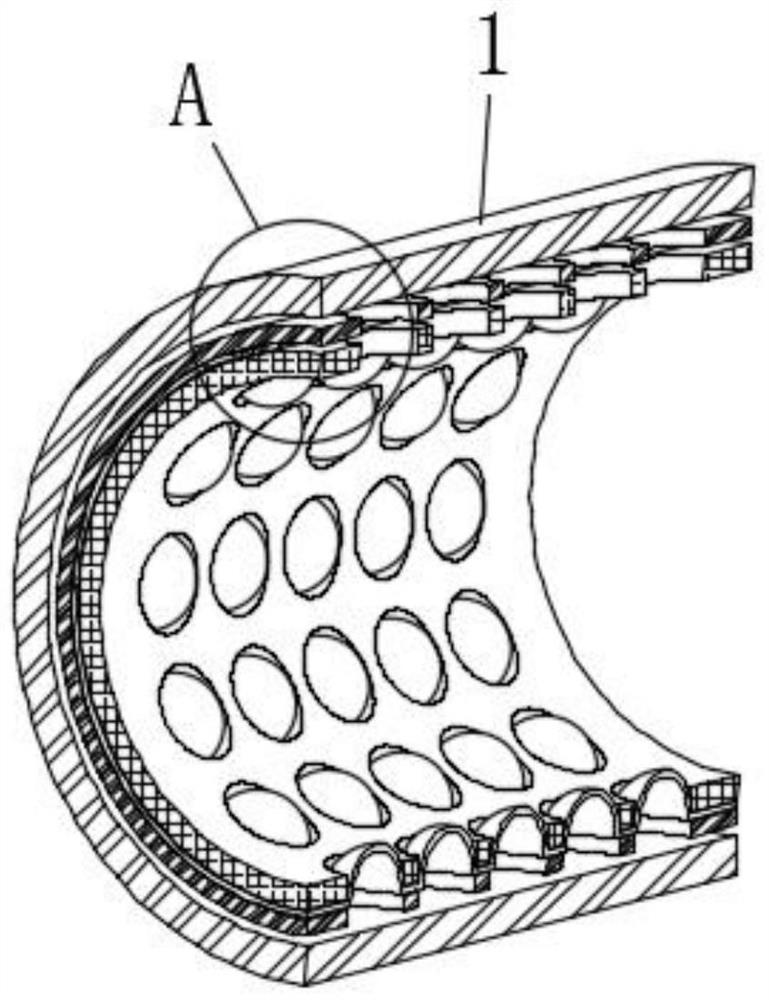

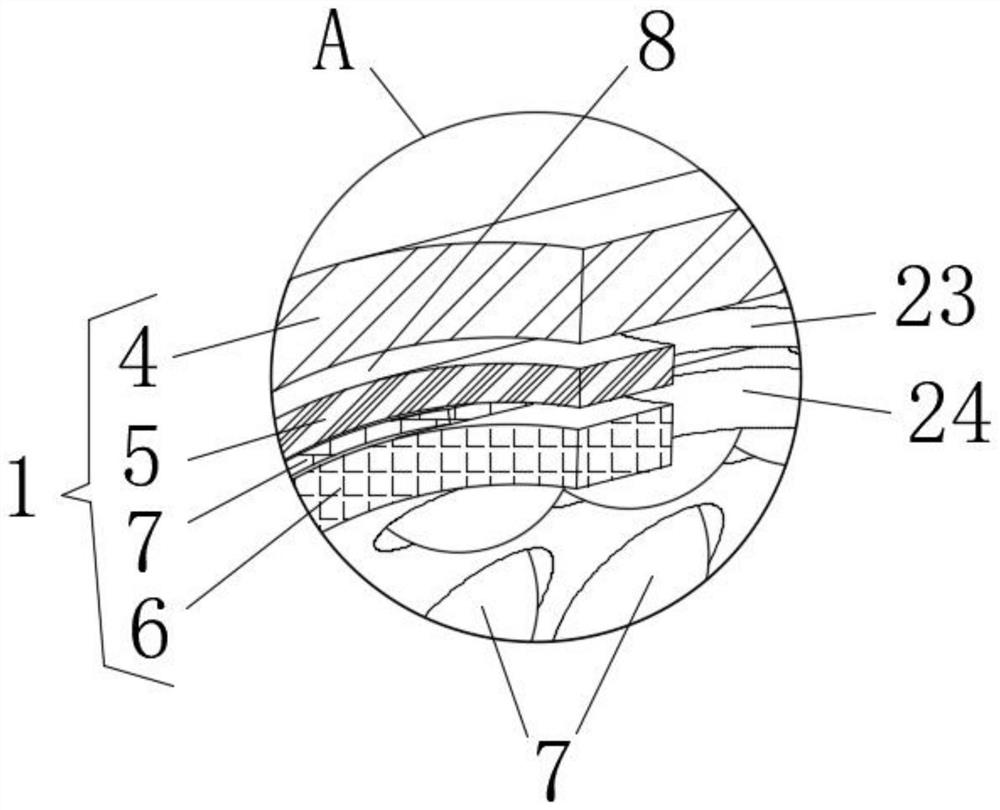

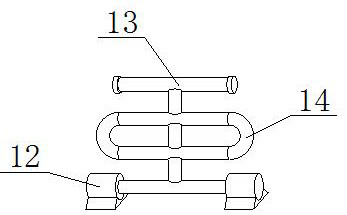

Solid hydrogen source device for hydrogen fuel

ActiveCN112066242ASimple structureEasy to processVessel mounting detailsReactant parameters controlHeat mass transferEngineering

The invention relates to a solid hydrogen source device for hydrogen fuel, and belongs to the technical field of hydrogen storage devices. Safety, portability and environmental adaptability of a solidhydrogen source to hydrogen utilization are achieved. According to the solution, a tank opening is formed in a hydrogen storage tank, a valve is mounted at the tank opening, a sealing ring is mountedbetween the valve and the tank opening, a heat exchange pipeline is of a double-spiral structure and is fixedly arranged on the inner wall of the hydrogen storage tank in a coiling manner, and a heatmass transfer inlet and a heat mass transfer outlet of the heat exchange pipeline respectively penetrate through the valve and extend to the outside of the hydrogen storage tank; a cavity is formed in the axis position in a tank body of the hydrogen storage tank, a hydrogen charging / discharging pipeline penetrates through the valve and communicates with the cavity, a plurality of material bins are arranged on the periphery of the cavity, the size of each material bin is not smaller than 4 / 5 of that of an inner cavity of the tank body of the hydrogen storage tank, a diaphragm is arranged on aside wall of each material bin, and the material bins are filled with solid hydrogen storage alloy powder. The device is simple in structure, safe, efficient, portable and suitable for various environments and has good reproducibility and stability.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Device for preventing scar hyperplasia of operation suture wound

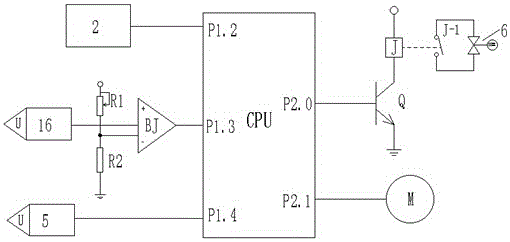

InactiveCN106236347AAvoid scaringEasy refillPneumatic massageNon-surgical orthopedic devicesExhaust valveInjury mouth

The invention discloses a device for preventing scar hyperplasia of an operation suture wound. The device comprises an airbag, an air pressure sensor is arranged in the airbag, medical tapes are arranged at the two ends of the airbag, a power source, a display screen and a controller are arranged on the upper surface of the airbag, and the power source, the display screen and the controller are in hot sealing with the airbag. A vent valve is mounted on the upper surface of the airbag, and a first connector is arranged on one side of the middle of the upper surface of the airbag. According to the device for preventing scar hyperplasia of the operation suture wound, the airbag is inflated through a handheld inflation device, inflation is convenient and can be operated with one hand, air pressure in the airbag is detected through the air pressure sensor, the inflation device and the vent valve are arranged, therefore, the pressure of a pressurizing device is regulated and controlled, the pressure of the pressurizing device can be adjusted conveniently, the pressure can be adjusted according to the wound healing condition, scar hyperplasia is avoided, and the treatment effect is good. The device can be reused simply by replacing the medical tapes after being used once, and the treatment cost is reduced.

Owner:杜萍

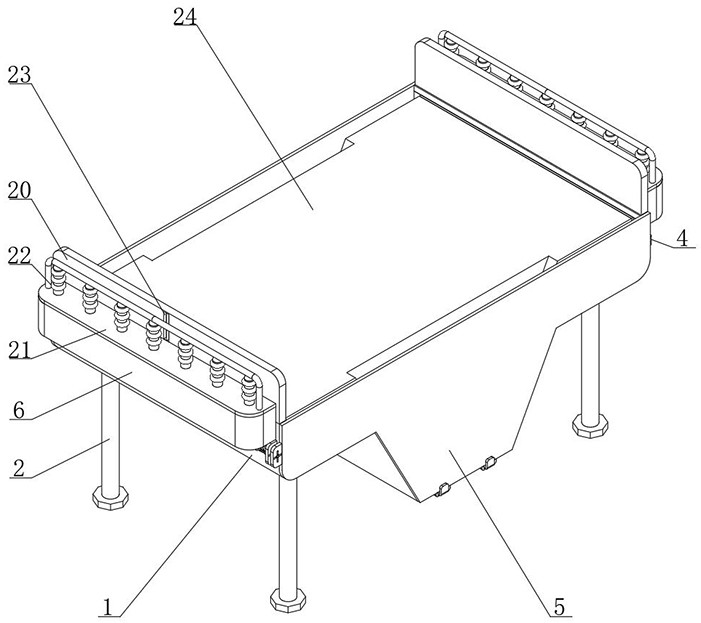

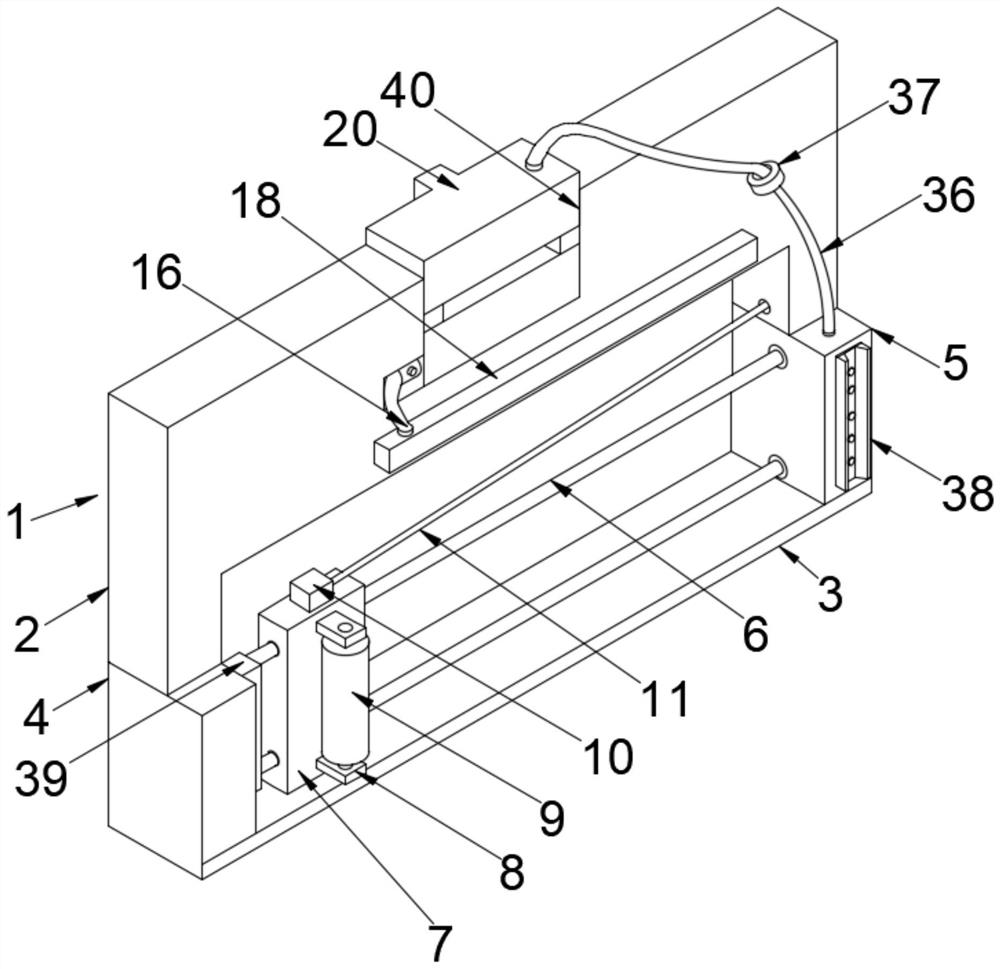

Level flattening printing table adjusting and controlling device

ActiveCN104691102AAdjust the pressureSimple structurePrinting press partsHydraulic cylinderEngineering

A level flattening printing table adjusting and controlling device comprises an execution hydraulic cylinder, a pressurizing hydraulic cylinder, an electric control valve, a gas-liquid converter and a drive portion. The execution hydraulic cylinder, the pressurizing hydraulic cylinder and the electric control valve are in communication through hydraulic pipes. The pressurizing hydraulic cylinder is connected with the drive portion. The electric control valve is communicated with the gas-liquid converter. The level flattening printing table adjusting and controlling device is simple in structure and easy to operate. Compared with an existing level flattening table controlling device, the level flattening printing table adjusting and controlling device saves the operation time, improves the work efficiency and has a function of adjusting the extent of the pressure on the table position.

Owner:YUTIAN BOYU PRINTING MACHINERY CO LTD

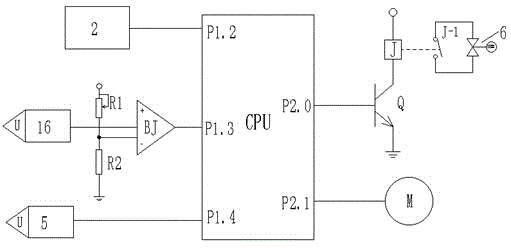

A medicine atomization inhaler

InactiveCN105233376APressure regulationEffective temperature controlMedical devicesMedical atomisersBooster pumpElectric heating

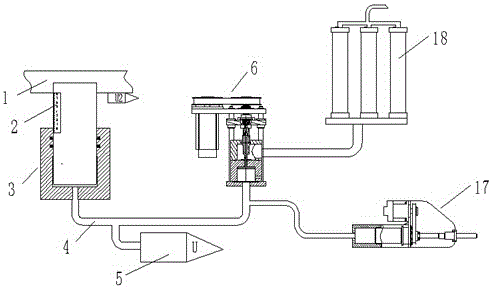

The invention relates to a medicine atomization inhaler comprising an atomization tank which is in the shape of a round barrel and is provided with an opening in the upper end, a mask communicated with the atomization tank through a pipe body, a cover covering the opening and being screwed to the inner wall at the opening of the atomization tank through threads and provided with a medicine adding opening, a pressure-stabilizing pipe communicated with the outer side wall of the atomization tank, a booster pump fixedly arranged on the outer wall of the upper portion of the atomization tank, a medicine adding part communicated with the inside of the atomization tank through the medicine adding opening, a temperature sensor arranged on the inner wall of the pipe body and connected with an electric heating device, and the electric heating device capable of regulating the temperature in the atomization tank according to the temperature signals detected by the temperature sensor. With the temperature sensor and the electric heating device, the temperature of gas in the atomization tank can be effectively regulated and the temperature of gas can be prevented from being too high or too low; the booster pump can regulate the pressure intensity in the atomization tank.

Owner:李道恒

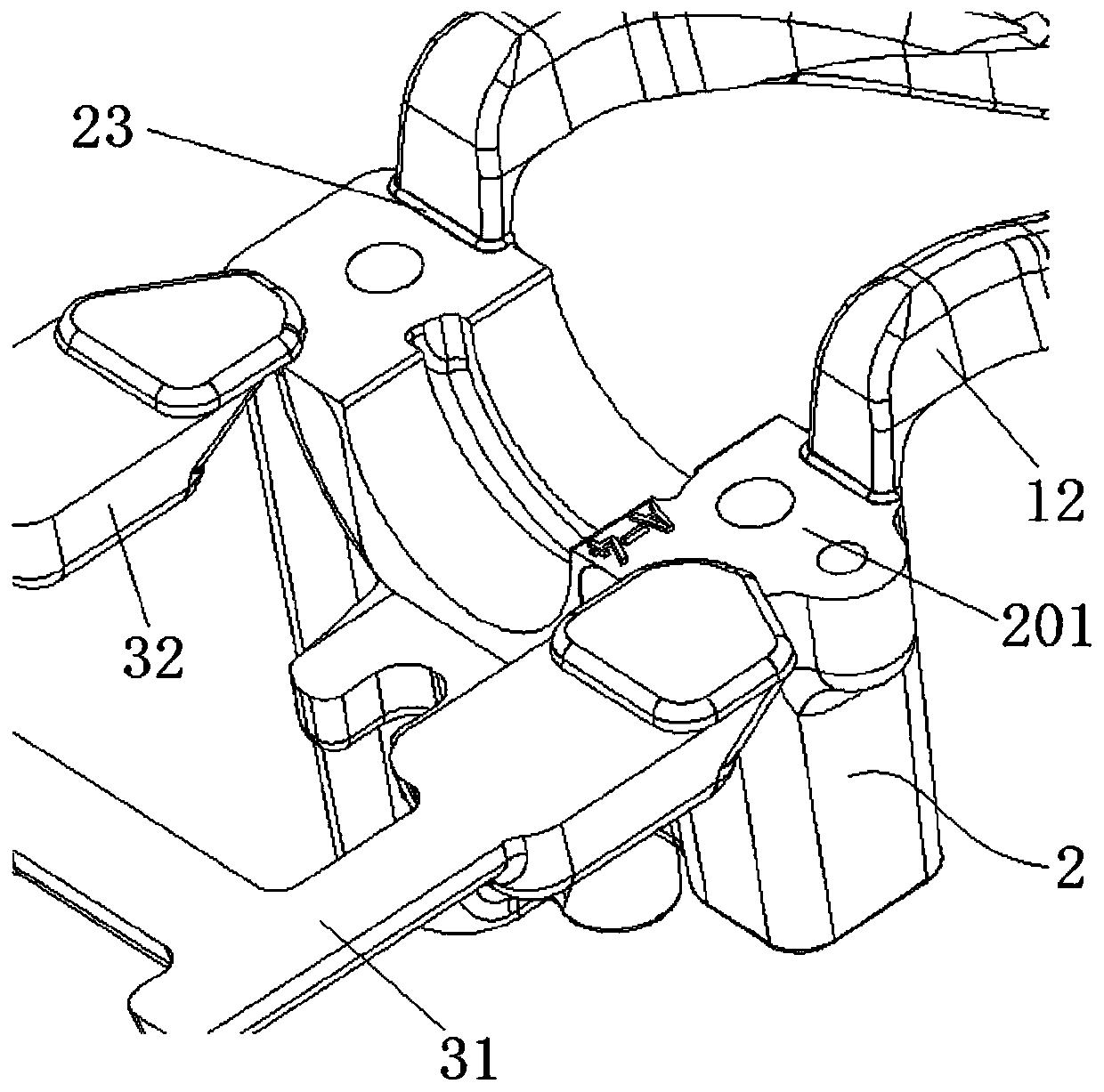

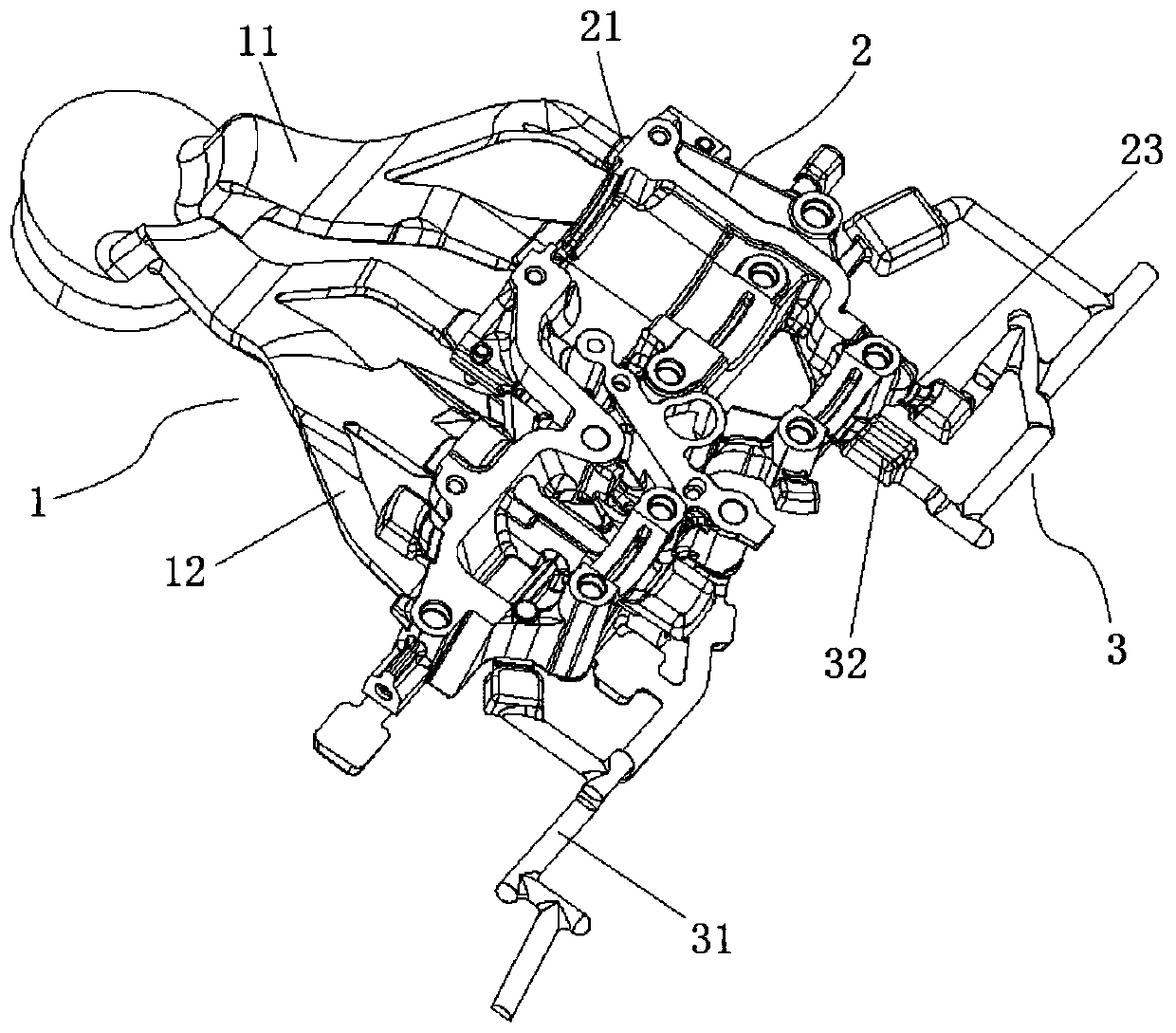

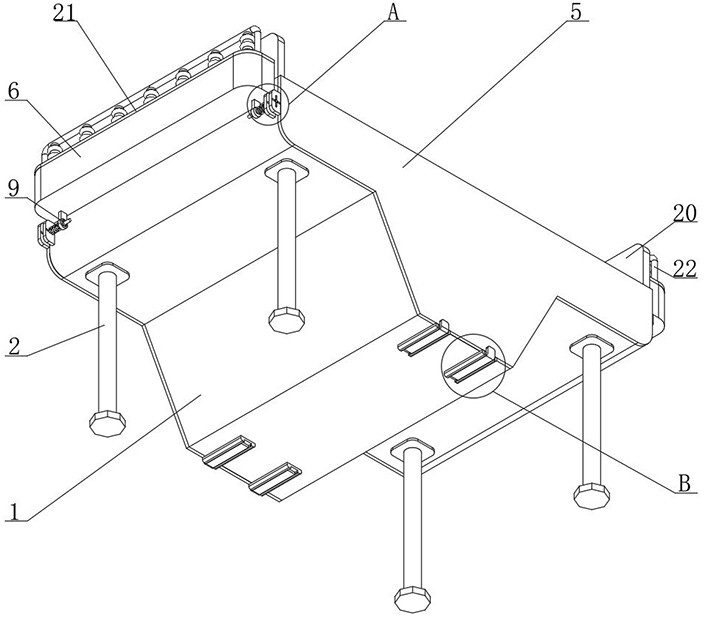

Die pouring system for U-shaped automobile parts

InactiveCN111438332AAvoid energy lossReduce wearFoundry mouldsFoundry coresEngineeringStructural engineering

The invention provides a die pouring system for U-shaped automobile parts. The die pouring system for the U-shaped automobile parts mainly comprises a runner system and a demoulding mechanism; the runner system comprises a main runner, a plurality of secondary runners and branch runners; in the conveying direction of pouring liquid, the cross sectional areas of the secondary runners and the branchrunners are gradually reduced; the output ends of the branch runners communicate with an inner pouring gate of a U-shaped forming cavity, and the inner pouring gate is not overlapped with the side wall of the U-shaped forming cavity in the input direction of the inner pouring gate; and the demoulding mechanism comprises a thimble accommodating hole and a thimble, the thimble accommodating hole communicates with the U-shaped forming cavity, a barb part is arranged at one end, close to the U-shaped forming cavity, of the thimble, and the barb part is connected with a casting which is poured into the U-shaped forming cavity in a hooking manner. According to the die pouring system, the casting quality can be effectively improved, the problem of insufficient movable die side tightening force caused by the structure of the product can be avoided, and normal production activities can be ensured.

Owner:ZHANJIANG DENI VEHICLE PARTS

Intelligent sewage MBR integrated treatment equipment

The invention relates to the technical field of sewage treatment, in particular to intelligent sewage MBR integrated treatment equipment which comprises a sewage treatment tank, an inner cavity of the sewage treatment tank is set as a treatment inner cavity, a cross beam is arranged at the upper end of the treatment inner cavity, and an MBR separation pipe mounted on the cross beam is vertically arranged in the middle of the treatment inner cavity; the MBR separation pipe comprises a top plate mounted on the cross beam, a chassis slidably mounted in the base at the lower end of the treatment inner cavity, and a filter membrane connected with the chassis and the top plate, and has the beneficial effects that the gear is arranged to drive the rack to lift up and down, so that the scraping ring is driven to clean the outer wall of the filter membrane, and the base is matched to drive the filter membrane to be straightened; the pressure in the filtering inner cavity is adjusted through the cooperation of the lining pipe and the pressure adjusting air pump, the air pressure of the cavity at the upper end of the lining pipe is increased through the pressure adjusting air pump, reverse water outlet is formed, particles in the micropores are discharged reversely, and the filtering membrane is thoroughly cleaned.

Owner:李国安

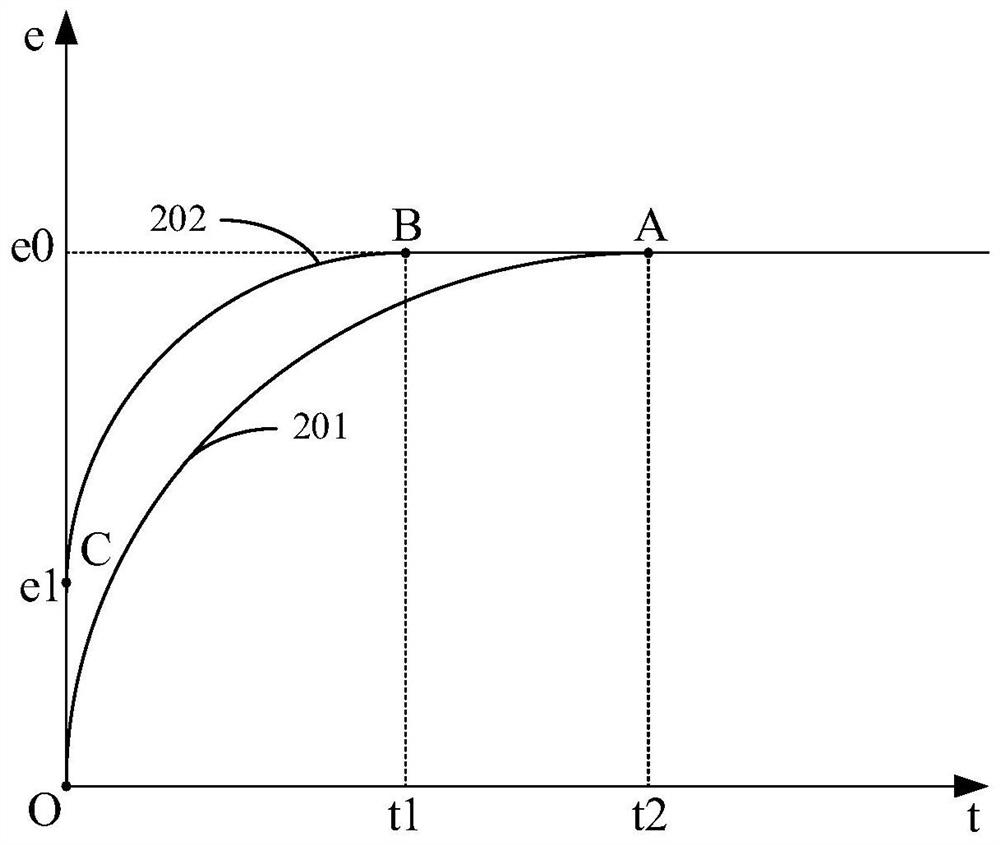

Optimization control method for differential pressure and flow at tail end of main pipe network

PendingCN114508702APressure regulationGuaranteed uptimeFluid pressure measurementPipeline systemsDifferential pressureEngineering

The invention relates to the related technical field of building construction, in particular to an optimal control method for the tail end pressure difference and flow of a main pipe network, and the optimal control method for the tail end pressure difference and flow of the main pipe network comprises the steps that the tail end pressure difference of the main pipe network is measured through a detection assembly, and the detection assembly comprises a detection assembly body, a rear connecting seat and a front connecting seat; the front connecting base is an annular plate, and the inner side face of the front connecting base is fixedly connected with the front side ends of the outer pipe wall, the middle pipe wall and the inner pipe wall. The detection assembly composed of the detection assembly body, the rear connecting seat and the front connecting seat is arranged, and the detection assembly body is composed of the outer pipe wall, the middle pipe wall, the inner pipe wall and the elastic layer, so that the elastic layer is pressed by the pressure in the inner pipe wall, and the change of the air pressure in the air cavity is caused; therefore, the pressure of the tail end of the main pipe network is detected, the overall pipe pressure of the main pipe network is better regulated and controlled, and stable operation of the main pipe network is effectively guaranteed.

Owner:青岛西海岸市政新能源热力有限公司

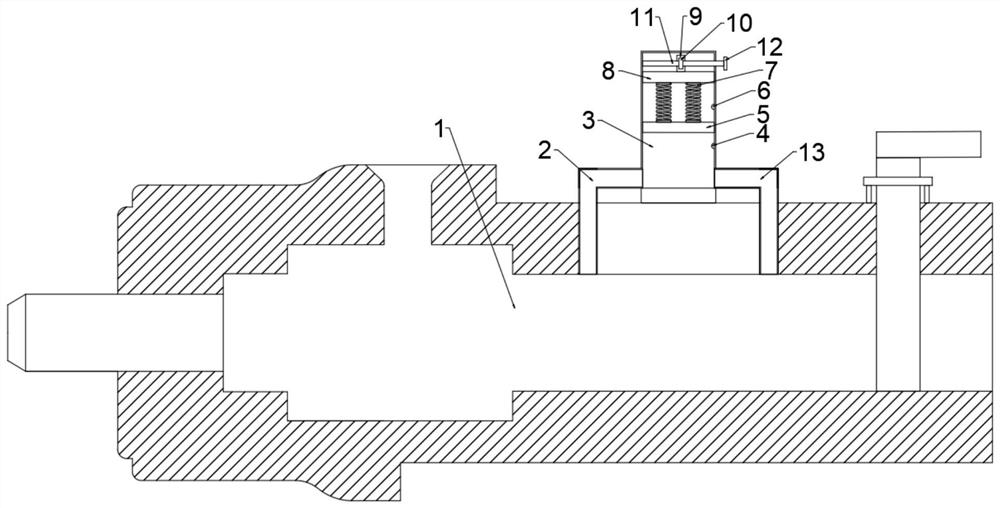

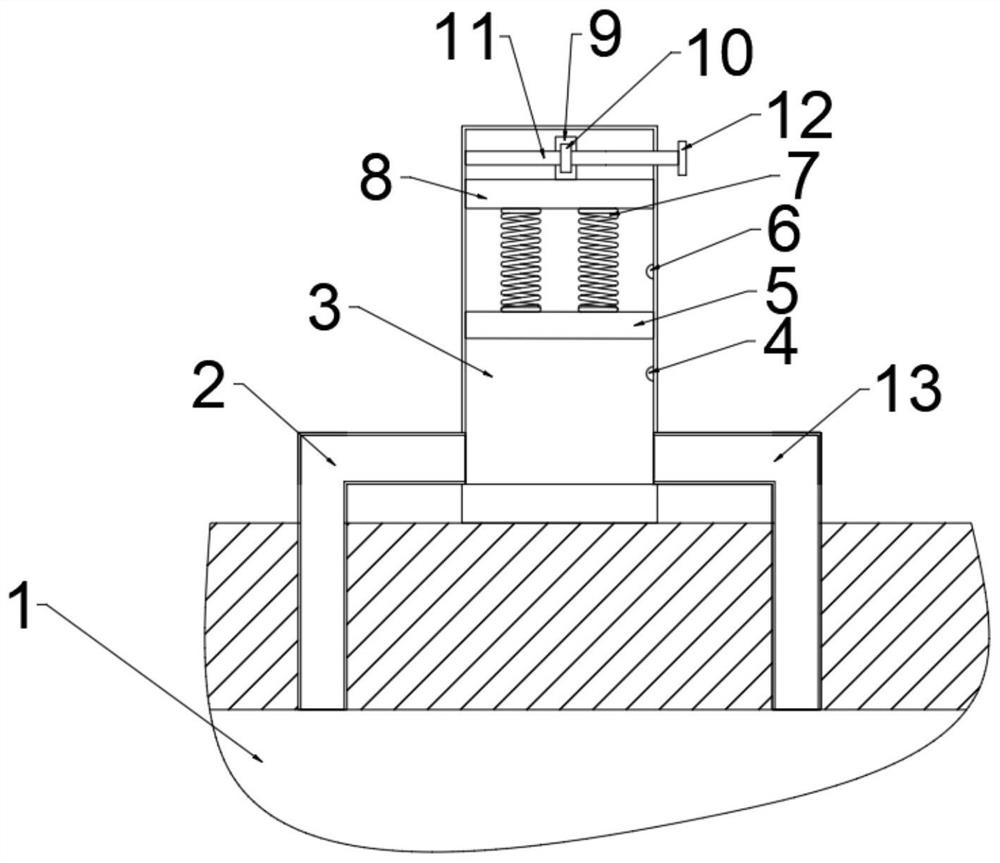

Epoxy resin heating and pressurizing device

PendingCN108822749AGood adhesionReduce air pressureAdhesive processes with adhesive heatingTemperature controlEpoxy

The invention relates to an epoxy resin heating and pressurizing device, which comprises a fixing device, a pressurizing device and a heating device. The fixing device comprises a magnetic base and anegative pressure adsorption device; the pressurizing device comprises a side-placing upper plate, an external thread cylinder, a sliding inserted link, a crimping lower head, a heat-insulating lantern ring and a compression spring; the heating device includes a temperature sensor, a temperature control device and a power source. The epoxy resin heating and pressurizing device can be fixed by magnetic force or adsorption; the epoxy resin can be pre-coated on the lower end surface of the crimping lower end, and the compression spring drives the heat-insulating lantern ring and the crimping lower head downwards to generate pressure on the epoxy resin; the external thread cylinder rotates to adjust the compression degree and elastic force of the compression spring, and then the pressure on the epoxy resin is adjusted; and the epoxy resin can be heated through the heating device; the temperature sensor detects temperature of a heating tape and transmits the temperature to the temperature control device; and the temperature control device controls the temperature.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

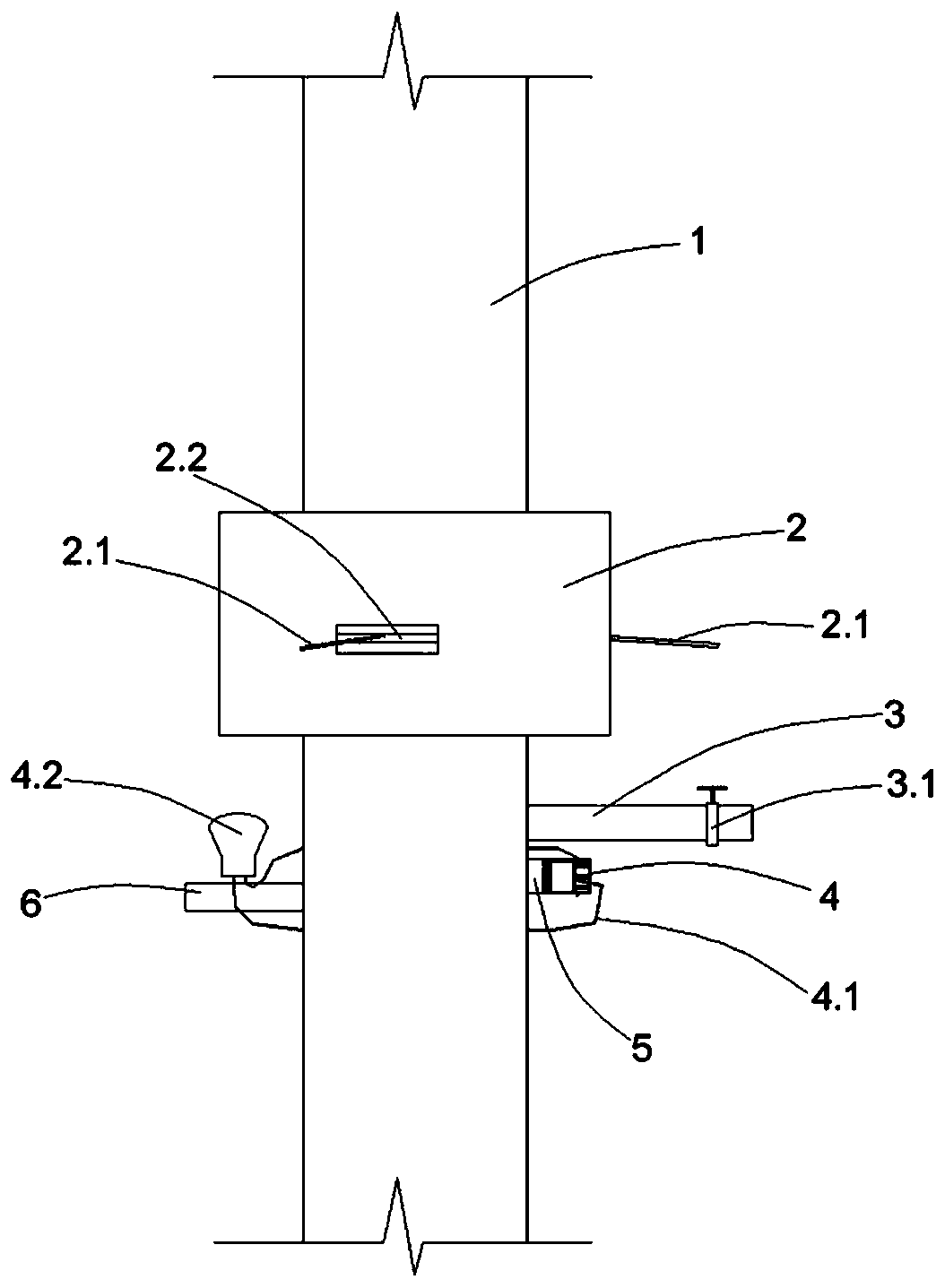

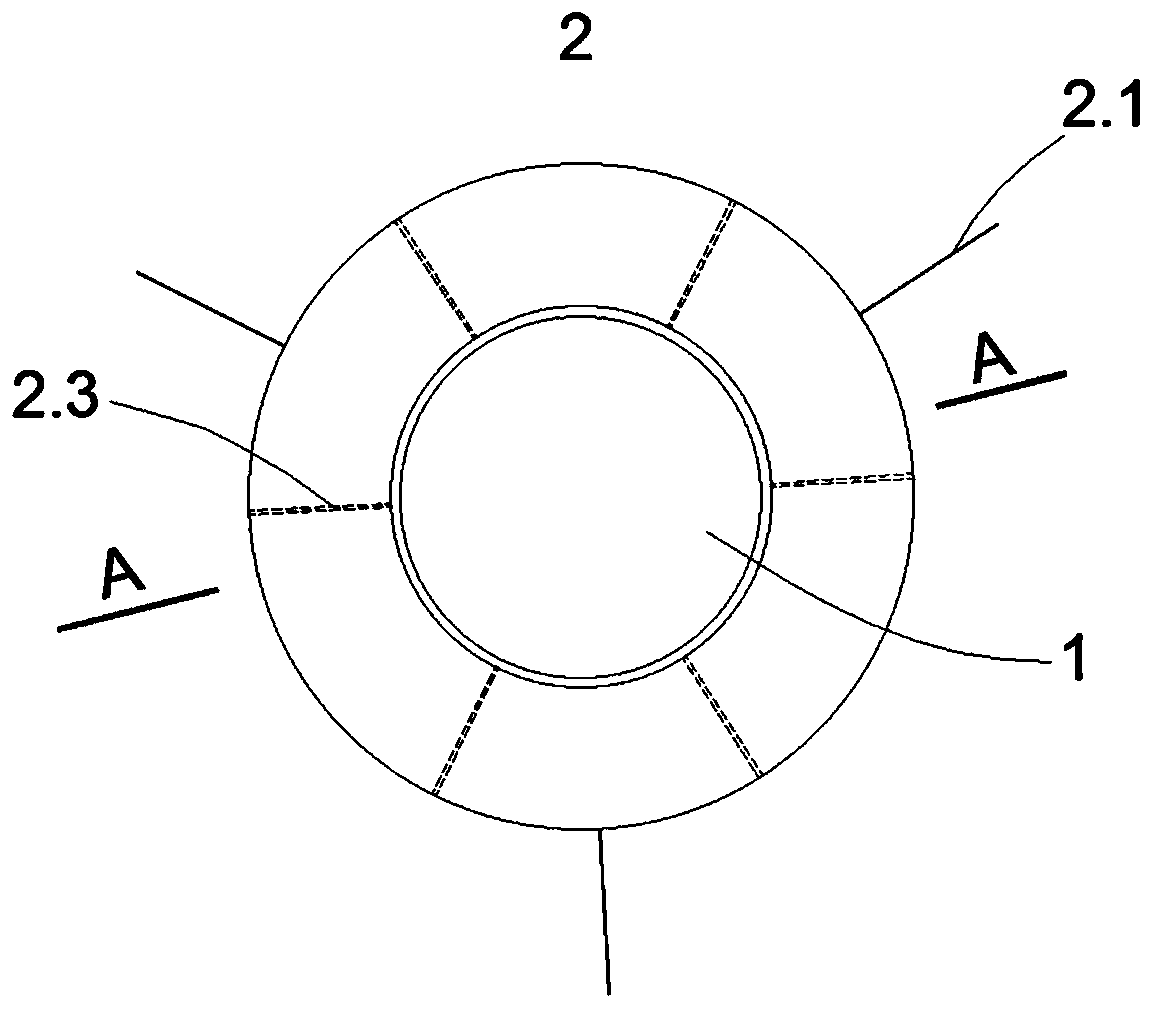

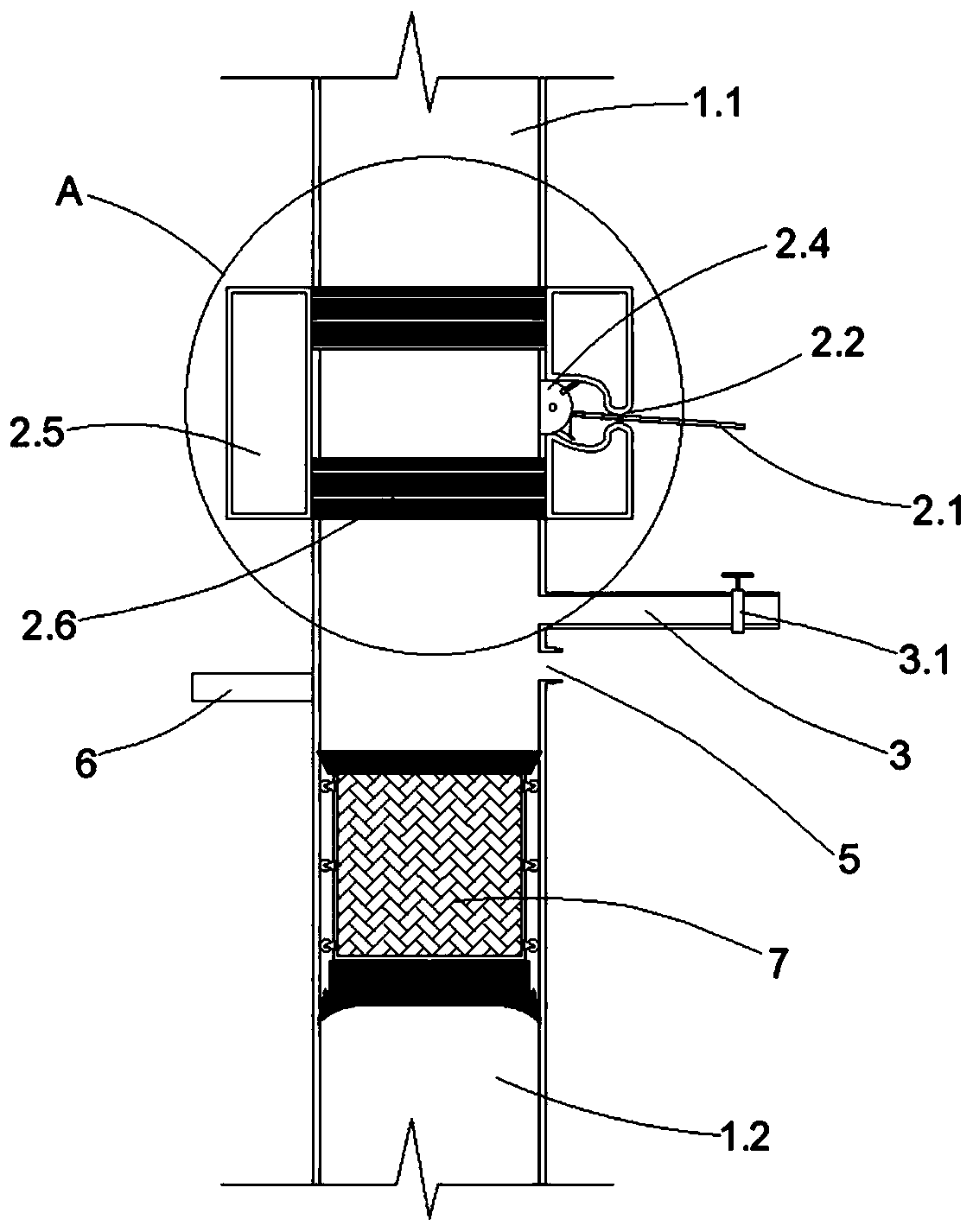

Water seal device for straw combustion and gasification furnace

InactiveCN103820164AAvoid damageAffect the service lifeChemical industryCombustible gas productionCombustionWater channel

The invention provides a water seal device for a straw combustion and gasification furnace. The water seal device comprises a sealed water channel and more than one communication pipe, wherein a pipe orifice of one end of the communication pipe is communicated with the gasification furnace, a pipe orifice of the other end of the communication pipe is arranged at the bottom of the sealed water channel, and the sealed water channel is arranged on a side furnace wall of the gasification furnace, is an annular sealed water channel and is arranged around the side furnace wall of the gasification furnace. Through the adoption of the water seal device for the straw combustion and gasification furnace, the straw combustion and gasification furnace can be effectively sealed to avoid gas leakage and guarantee successful gas collection; at the same time, when the intensity of pressure in the gasification furnace increases or decreases, the intensity of pressure in the gasification furnace can be appropriately adjusted, thereby guaranteeing that the intensity of pressure in the gasification furnace is in a reasonable range, and avoiding the influence on the service life of the gasification furnace due to the fact that the gasification furnace is damaged because the change of the intensity of pressure in the gasification furnace is too large.

Owner:XINGHUA SANNONG PLANT ASH

Pressure-limiting overflow device for hydraulic axial plunger pump

InactiveCN113074104AChange pressure rangeImprove applicabilityPump testingPump controlSlide plateMechanics

The invention discloses a pressure-limiting overflow device for a hydraulic axial plunger pump, and relates to the field of hydraulic transmission. The pressure-limiting overflow device comprises a runner pipe, an inflow pipe is arranged on the side of the runner pipe, a pressure measuring pipe is arranged at one end, away from the runner pipe, of the inflow pipe, a pressure measuring mechanism is arranged in the pressure measuring pipe, a flow limiting box is arranged in the conveying direction of the runner pipe, and a flow limiting mechanism is arranged in the flow limiting box. When the device runs, hydraulic oil in a circulation pipe enters the pressure measuring pipe through an inflow pipe, the elastic force of a first spring is not enough to enable a sealing adjusting plate to relatively slide, when the pressure in the runner pipe is changed, a sliding plate slides in the pressure measuring pipe, when the sliding plate touches a lower sensor or an upper sensor, an alarm is given out, consequently, operator is reminded of regulation and control, if the detected pressure range needs to be adjusted, the vertical position of the sealing adjusting plate can be adjusted by using an adjusting mechanism, so that the monitored pressure range can be changed, and the device is suitable for large-scale popularization.

Owner:XIAN AERONAUTICAL UNIV

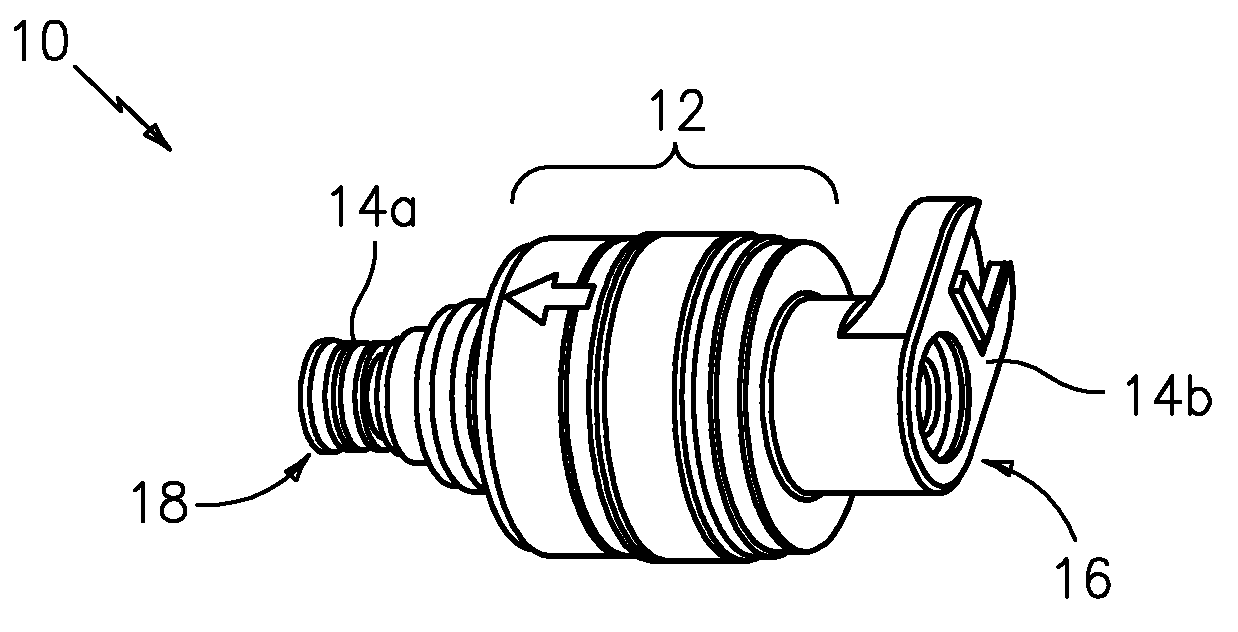

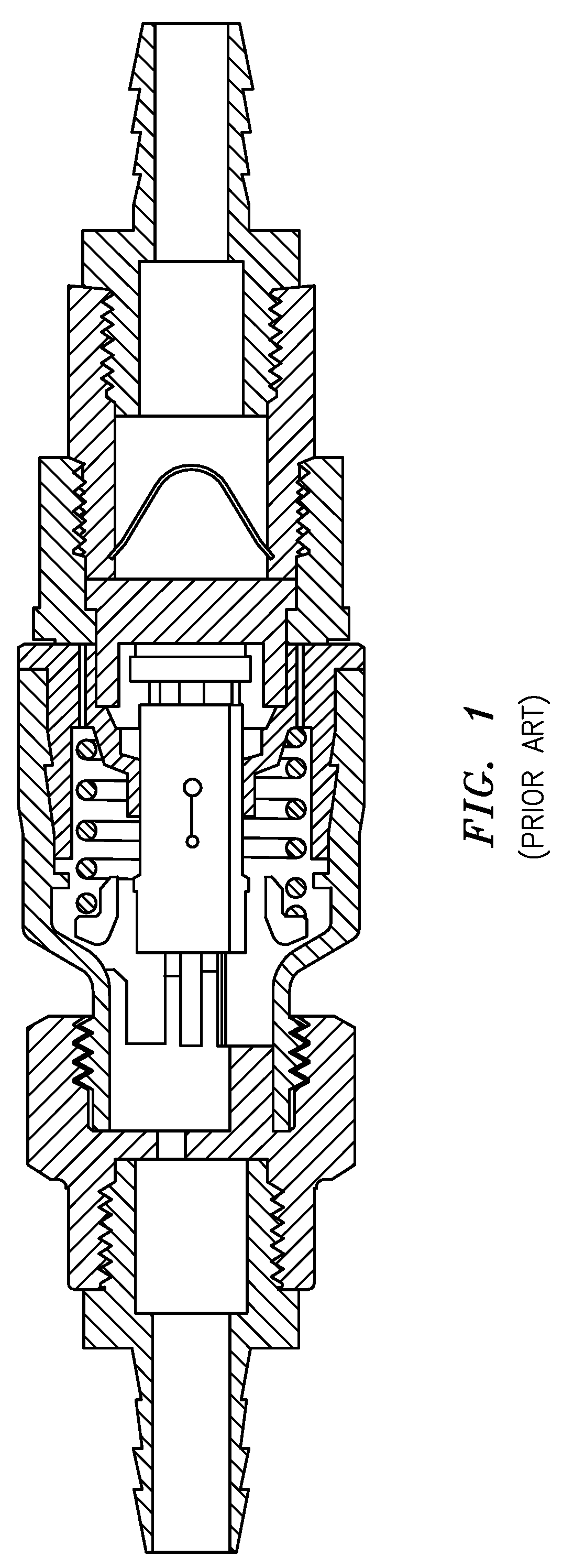

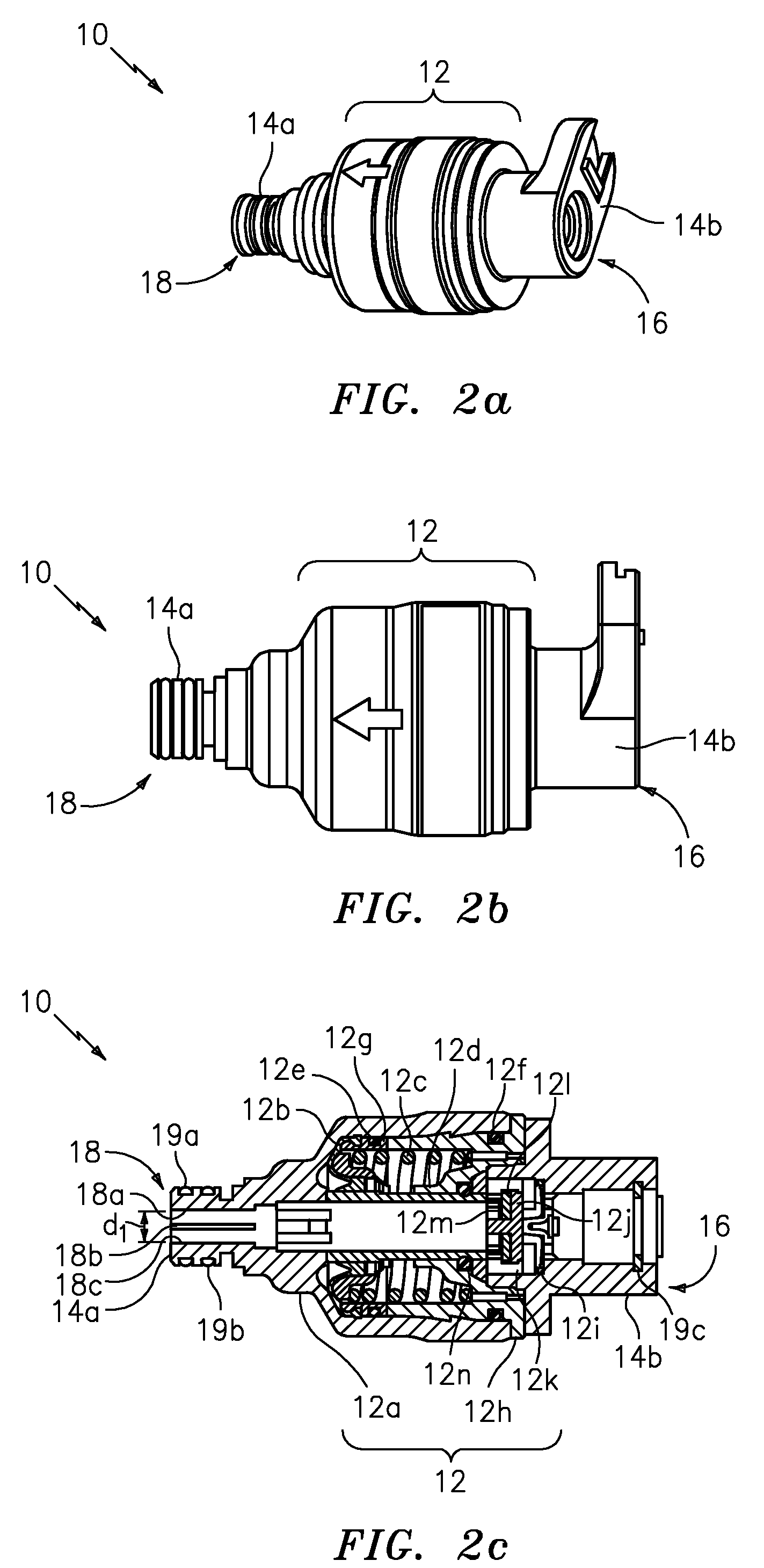

Compact beverage pressure regulator

ActiveUS20090126799A1Eliminate the problemPressure regulationCheck valvesEqualizing valvesEngineeringBiomedical engineering

The present invention provides a new and unique pressure regulator featuring a body member for regulating the pressure of a fluid flowing therein, the body member having two ends, one end for receiving the fluid and another end for providing pressure regulated fluid; and a quick-disconnect device arranged on at least one end for coupling the body member to a corresponding quick-disconnect device that forms part of a device that either provides the fluid or receives the pressure regulated fluid. The pressure regulator may have two quick-disconnect devices, each quick-disconnect device being arranged on a respective end of the body member. The quick-disconnect device may include a male quick-disconnect device for coupling to a corresponding female quick-disconnect device that forms part of either a hose or a dispenser for providing the fluid or a pump for receiving the pressure regulated fluid; or a female quick-disconnect device for coupling to a corresponding male quick-disconnect device that forms part of either a hose or a dispenser for providing the fluid or a pump for receiving the pressure regulated fluid. The present invention may also include a method for coupling such a quick-disconnect device of such a pressure regulator to such a corresponding quick-disconnect device of a pump for providing fluid flow, as well as a combination of such a pressure regulator and such a pump for providing fluid flow.

Owner:XYLEM IP HLDG

Plunger pump for pumping ultralow-temperature liquid nitrogen

PendingCN108150376AFracturing work is stableGood for observing pressurePump testingPump installationsEngineeringLiquid nitrogen

The invention relates to the field of plunger pumps, in particular to a plunger pump for pumping ultralow-temperature liquid nitrogen, and mainly solves the problem of influence on the fracturing operation by reduction of pressure after emission of liquid nitrogen due to emission of the liquid nitrogen by an overflow port after gasification through heat absorption. The plunger pump comprises a box; a plunger is slidingly arranged on the box, and one end penetrates out of the box; the box is provided with a pumping device at the outer end of a plunger; the pumping device comprises a shell fixedly arranged on the box; a cavity is formed in the shell; a push rod is slidingly arranged in the cavity; a through hole is formed in the axis of the push rod; a connecting rod is inserted in the through hole, and can slide relative to the push rod; a groove is formed in the inner surface of the push rod; the push rod is provided with a convex block in the groove; a spring is arranged in the groove; one end of the connecting rod penetrates out of the shell, and is connected with an outer end of the plunger; and a feeding device is arranged between a pressure measuring port and a feeding port atthe external of the shell.

Owner:福建双环能源科技股份有限公司

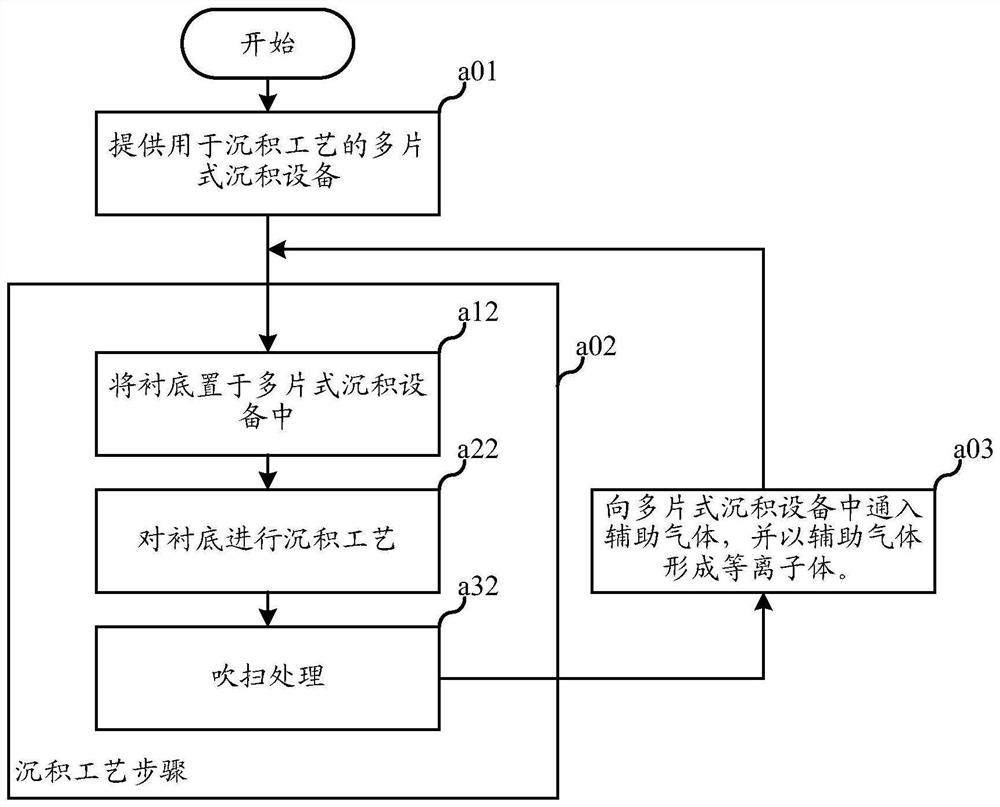

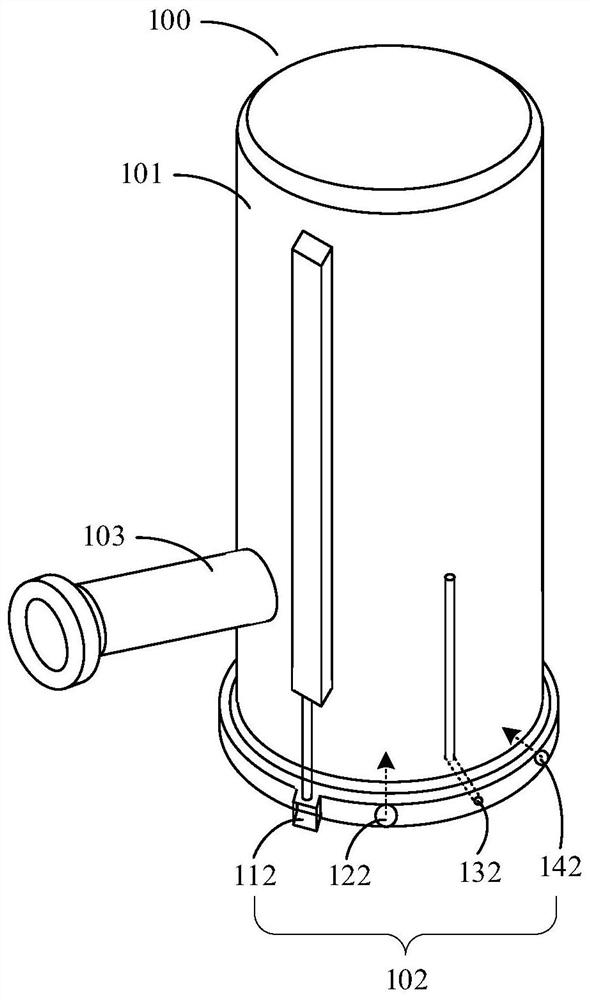

Semiconductor manufacturing method and multi-piece deposition equipment

ActiveCN113529057AIncrease the amount of residual chargeIncrease productivityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDeposition process

The embodiment of the invention provides a semiconductor manufacturing method and multi-piece type deposition equipment. The semiconductor manufacturing method comprises the following steps of performing a first round of deposition process on a substrate in the multi-piece type deposition equipment; taking out the substrate after the first round of deposition process is completed; introducing auxiliary gas into the multi-piece type deposition equipment, and forming plasma by the auxiliary gas; placing a substrate to be deposited into the multi-piece type deposition equipment; and performing a second round of deposition process on the substrate in the multi-piece type deposition equipment. According to the method, in a time interval of the waiting time of the first round of deposition process and the second round of deposition process, the auxiliary gas is introduced to be converted into the plasma, so that the quantity of residual charges in the multi-piece type deposition equipment is increased; and when the second round of deposition process starts, the quantity of the residual charges in the multi-piece type deposition equipment is relatively large, the radio frequency required by the deposition process can be quickly generated, and the generation time of the radio frequency is greatly shortened, so that the production efficiency of the substrate is improved.

Owner:CHANGXIN MEMORY TECH INC

Mortar pumping system and pumping pipeline

PendingCN109707620AReduce impactAvoid rigid contactPositive displacement pump componentsPump controlMortarEngineering

The invention relates to a mortar pumping system and pumping pipeline with controllable mortar pumping height. The pumping pipeline comprises a conveying main pipe and a conveying branch pipe arrangedon the conveying main pipe, a valve is arranged on the conveying branch pipe, and a monitoring unit, a sliding unit arranged in the conveying main pipe and an intercepting unit arranged on the conveying main pipe are further included; the sliding unit is used for blocking the gushing end of mortar; the intercepting unit is used for blocking the sliding unit pushed against the mortar at a corresponding position of the conveying main pipe; and the monitoring unit is used for monitoring the pressure of the mortar, so that an operator adjusts the motor pressure. The pumping pipeline realizes thelimitation of the height of the mortar rising height through the cooperation of the sliding unit and the intercepting unit, the monitoring unit is arranged, so that the operator can accurately and timely adjust the mortar pressure, finally, the discharge pressure of the mortar is moderate, and the problem of serious leakage of the mortar caused by the large pressure is solved.

Owner:GUANGZHOU FOURTH CONSTR

Experimental device and method for simulating in-situ fluidized mining of deep metal mines

ActiveCN111855902BPressure regulationTemperature environment controlMaterial analysisLiquid storage tankEngineering

The invention provides an experimental device and method for simulating in-situ fluidized mining of deep-earth metal mines, belonging to the technical field of deep-earth resource fluidized mining. The device includes a liquid return port, a liquid storage tank, a liquid outlet, a pumping motor, a liquid flow meter, an electronically controlled airtight valve, a sealing ring, a safety valve, a pressure gauge, a pressure relief valve, a reaction tank top cover, an electric heating control Temperature layer, fixing bolts, sealing gaskets, reaction tank, liquid injection pipeline, liquid injection hole, porous partition, liquid sink surface, liquid sink, pH sensor, redox potential sensor, ion concentration sensor, liquid collection tank, Visual terminal for data collection control, temperature sensor, oxygen concentration sensor, air pressure sensor, electronically controlled temperature changer, gas flow meter, O 2 Storage tank, CO 2 tank. The invention realizes visually adjustable temperature and air pressure of the experimental device, and measurable and controllable parameters such as pH value, oxidation-reduction potential, ion concentration, etc., and provides research device and method reference for in-situ fluidized mining of deep metal mines.

Owner:UNIV OF SCI & TECH BEIJING +1

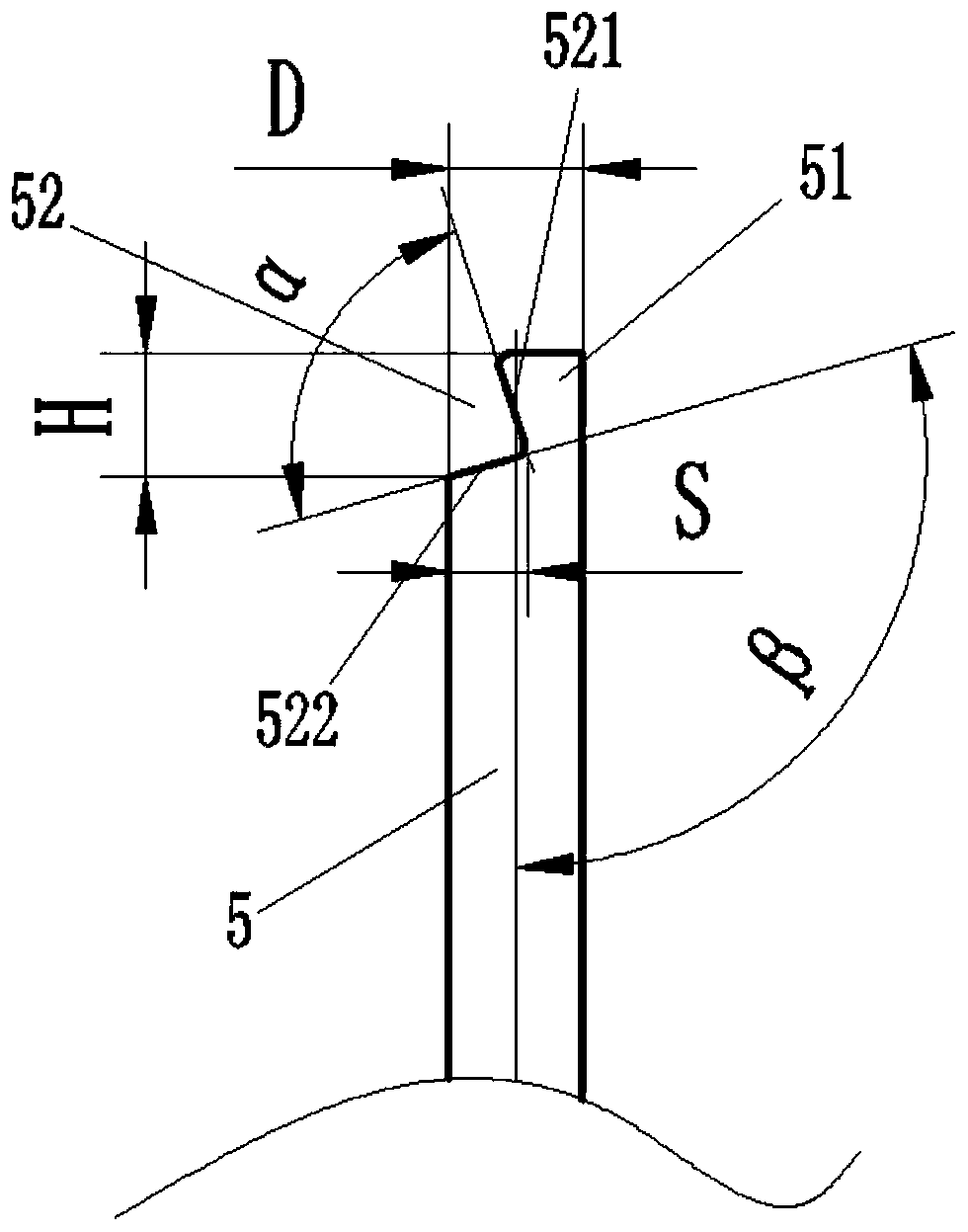

Seed sowing machine

InactiveCN100584186CReduce resistancePlanting ridge distance adjustmentSeed depositing seeder partsRegular seed deposition machinesDrive shaftAgricultural engineering

The invention provides a transplanter which is used for matching with the power machinery of a hand tractor, etc., and applicable for hole seeding of corn and soybean. The transplanter of the invention comprises a guide wheel, a pull bar, walking wheels, a seed manure box and a duck-billed transplanter. The transplanter is characterized in that: the seed manure box is fixedly connected on a seed manure bracket, a seed control plate is arranged between the bottom part of the seed manure box and the upper plate of the seed manure bracket, the seed mating limited port of the seed control plate is matched with a seed mating cam which is fixedly connected on a seeding displacement rack, the fixed mouth of the duck-billed transplanter is fixedly connected on the seeding displacement rack, the duck-billed transplanter is matched with the seeding limited port of the lower plate of the seed manure bracket, the driving chain wheel on a driving shaft is connected with the driven chain wheel of a driven shaft, a cam group which is fixedly connected with the driven shaft is contacted with a bending arm which is fixedly connected on a joint shaft, the bending arm is coaxially and fixedly connected with a swing arm which is articulated on the seeding displacement rack. The transplanter of the invention has the advantages of reasonable structure, adjustable seeding depth, plant spacing and spacing between ridges, reliable action, long service life, high working efficiency, good seeding quality, etc.

Owner:刘国成

A control device for flat platen printing platform

ActiveCN104691102BPressure regulationControl stop motionPrinting press partsHydraulic cylinderEngineering

Owner:YUTIAN BOYU PRINTING MACHINERY CO LTD

A water pressure test device for high pressure oil and gas pipelines

ActiveCN107860661BPrevent slippageNot easy to slip offMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses a water pressure testing device for a high-pressure-resisting oil-gas pipeline. The device comprises a testing base, a piston plate, a water storing tank, a water pressure testing barrel, a piston rod, a slipping-preventing propping device and a high-pressure-resistant oil-gas pipeline, wherein a pipe fixing clamp is welded to the upper end of the testing base; the high-pressure-resistant oil-gas pipeline is clamped through the pipe fixing clamp; flange plates are arranged at two ends of the high-pressure-resistant oil-gas pipeline and are connected to end sealing plates through bolts; the water pressure testing barrel is welded to the outer side of the end sealing plate which is connected to one end of the high-pressure-resistant oil-gas pipeline. The device is convenient to assemble and disassemble, and high in stability; water is pumped into the water pressure testing barrel to pressurize to drive the piston plate to forwards slide so as to compress air in acompressing chamber, and thus the pressure resistance of the high-pressure-resistant oil-gas pipeline can be detected; the operation is convenient and quick; the detection and test are easy to operate; the device is applicable to the performance testing of the high-pressure-resistant oil-gas pipeline.

Owner:江苏禹衡工程质量检测有限公司

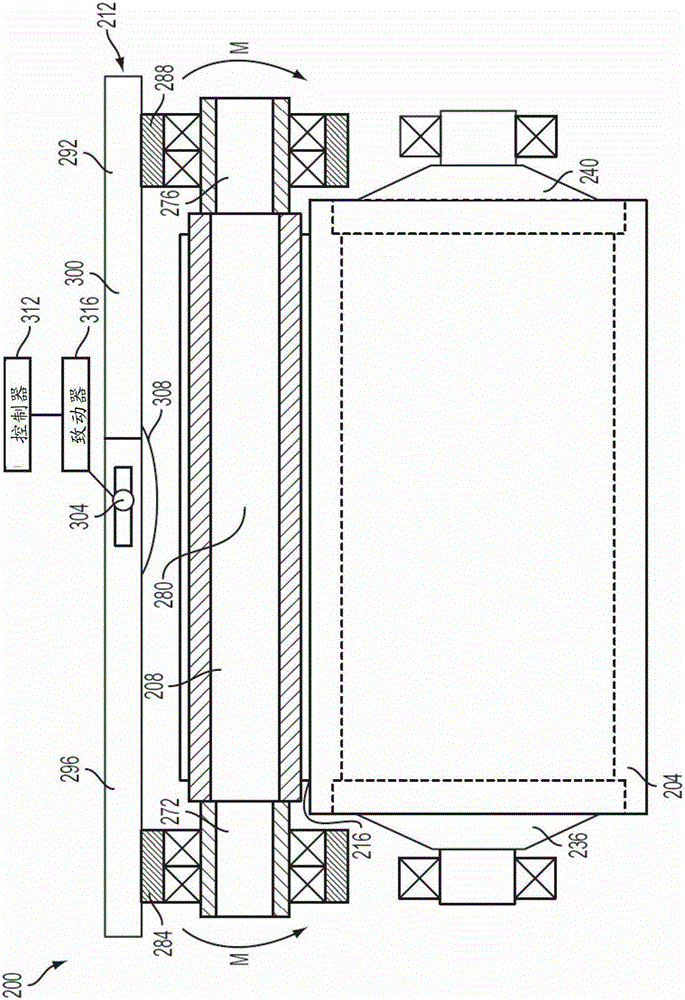

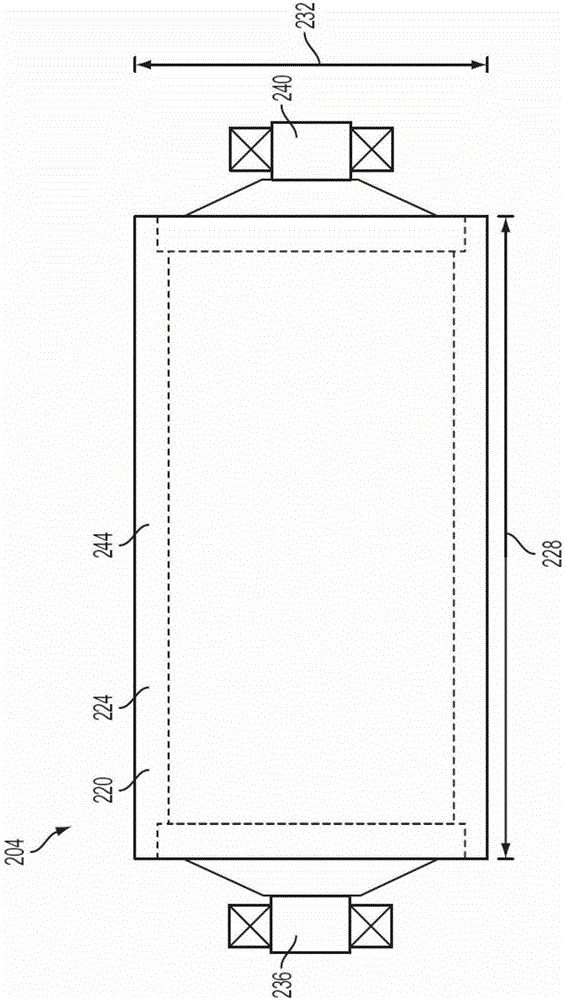

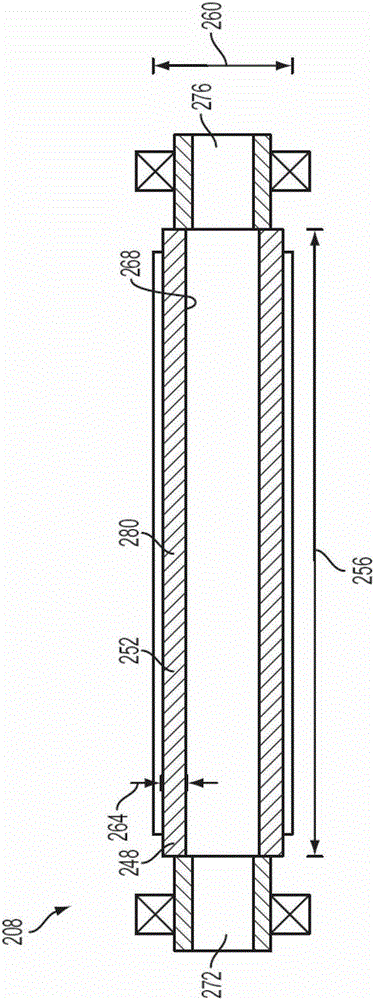

Indirect printing press with movable inserted roller assembly and roller assembly thereof

The present invention discloses an indirect printing press having a movable interposed roller assembly that enables the pressure in the transfer nip to be adjusted more precisely. The roll assembly includes: a thin-walled roll having a first end and a second end; a first pivotable collar supporting the first end of the roll and configured to apply a first moment to the roll. the first end of the roller; a second pivotable collar supporting the second end of the roller and configured to apply a second moment to the second end of the roller; and causing actuator. The actuator is operably connected to the first collar and the second collar and is configured to pivot the first collar and the second collar to apply the first moment and the second moment to the first end and the second end of the roller.

Owner:XEROX CORP

Concrete beam burr automatic generation structure and method thereof

ActiveCN113863674AEasy to separatePrevent sidewaysForms/shuttering/falseworksBridge erection/assemblyConcrete beamsAdhesive glue

The invention discloses a concrete beam burr automatic generation structure, and relates to the related technical field of concrete. The concrete beam burr automatic generation structure comprises a box beam mold and a supporting column used for supporting and positioning, wherein one side of the box beam mold is fixedly connected with a positioning plate, hinge modules are symmetrically and movably installed at the two ends of the positioning plate, and a side panel is fixedly installed at one end of each hinge module. The invention further discloses a method of the concrete beam burr automatic generation structure. The method comprises the steps of A, side face sealing; B, position fixing; C, adjusting and positioning; D, pressure increasing adjusting; E, glue adding; and F, proportional blending. According to the concrete beam burr automatic generation structure and the method thereof, a glue pumping machine and a glue conveying pipe are arranged, the volume of internal glue is detected in an induction mode, so that the glue is sprayed out through a glue spraying plate to be mixed with the concrete, a generated mixed layer is torn off after being solidified, burrs are generated on the two sides of a box beam, the flowing direction of the glue in the glue conveying pipe is adjusted through a flow divider, so that the glue uniformly flows into the mixed layer on the two sides of a box beam body, and the forming quality of the burrs is improved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

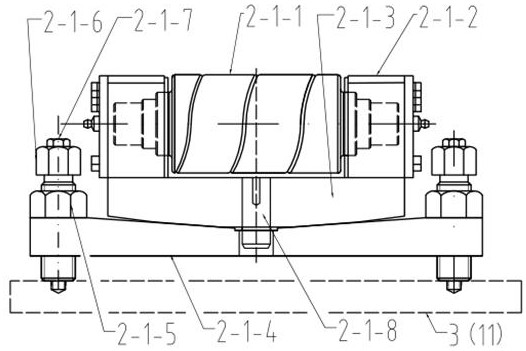

Circulating feeding roller of pressing machine and adjusting method of circulating feeding roller

PendingCN113479549AAvoid plate deflectionGuaranteed lifeConveyorsConveyor partsStructural engineeringIndustrial engineering

The invention relates to a circulating feeding roller of a pressing machine. The circulating feeding roller of the pressing machine comprises a lower roller and an upper roller which are arranged up and down and have the same structure, and is characterized in that each of the upper roller and the lower roller comprises a working section in the middle, transition conical sections extending outwards along the two sides of the working section and supporting sections extending outwards along the transition conical sections on the two sides; the upper portion of the upper roller is provided with two supporting roller assemblies, the two supporting roller assemblies are detachably installed on an upper sliding base and act on the supporting sections on the two sides of the upper roller downwards respectively, the lower portion of the lower roller is provided with the two supporting roller assemblies, and the two supporting roller assemblies are detachably installed on the base of a frame and act on the supporting sections on the two sides of the lower roller upwards respectively. The two ends of the upper sliding base are fixedly connected with the sliding blocks on side plates. According to the circulating feeding roller of the pressing machine and an adjusting method of the circulating feeding roller, pressure between circulating feeding rollers can be adjusted by additionally arranging an adjusting supporting rollers, service life is long, cost is low, and very high practicability and economic value are achieved.

Owner:烟台宝井钢材加工有限公司

Continuous mud pressure monitoring communication device for ocean engineering platform

InactiveCN113653115APressure controlIncrease the outlet displacementMechanical machines/dredgersEngineeringSlurry pipeline

The invention discloses a continuous mud pressure monitoring communication device for an ocean engineering platform, and relates to the technical field of ocean engineering. The continuous mud pressure monitoring communication device for the ocean engineering platform comprises a hollow cylinder, a detection alarm mechanism and an adjusting mechanism. One side of the hollow cylinder is fixedly provided with a first protective shell, the other side of the hollow cylinder is fixedly provided with a second protective shell, and the two sides of the hollow cylinder are each fixedly provided with two sets of mud discharging cylinders. Through threads in the hollow cylinder, the hollow cylinder can be installed at an outlet of a slurry pipeline in a threaded mode, so that the interior of the hollow cylinder is communicated with the interior of the slurry pipeline, the pressure intensity in the hollow cylinder is the same as that in the slurry pipeline, then through cooperative use of a fixing plate, a movable rod, a piston, a spring, a rotating shaft, a transmission gear and a pressure pointer, the pressure intensity in the slurry pipeline can be detected, and the detected pressure intensity value can be displayed through the scales on a glass sheet, so that a worker can conveniently and reasonably regulate and control the pressure intensity in the slurry pipeline.

Owner:重庆鑫杰力科技有限公司

Sintered neodymium-iron-boron hydrogen decrepitation device capable of improving efficiency

InactiveCN112658267AExquisite designHydrogen crushing reaction is normalMagnetic materialsMetallurgyHydrogen tank

The invention discloses a sintered neodymium-iron-boron hydrogen decrepitation device capable of improving efficiency, and relates to the technical field of sintered neodymium-iron-boron processing. The sintered neodymium-iron-boron hydrogen decrepitation device comprises a neodymium-iron-boron hydrogen decrepitation treatment chamber, hydrogen cylinder filling feeding equipment, heat exchange equipment and equipment internal vacuum treatment equipment, wherein the hydrogen cylinder filling feeding equipment is movably installed inside the neodymium-iron-boron hydrogen decrepitation treatment chamber, the heat exchange equipment is fixedly installed at the bottom of the neodymium-iron-boron hydrogen decrepitation treatment chamber, and the bottom of the equipment internal vacuum treatment equipment is fixedly installed at the top of the neodymium-iron-boron hydrogen decrepitation treatment chamber. According to the sintered neodymium-iron-boron hydrogen decrepitation device, through the principle of mutual production between current and magnetic force of an electromagnetic controller, electric power is provided for the electromagnetic controller so as to generate a magnetic field, a hydrogen tank is adsorbed to a hydrogen cylinder filling base, a magnetic force adsorption module also utilizes the characteristic that the magnetic field adsorbs a metal object, hydrogen is injected into a pressurization flow transfer bin, the hydrogen is delivered into the device through an anti-leakage protection pipeline for hydrogen decrepitation, and the hydrogen cylinder is quite convenient to replace.

Owner:GANZHOU FORTUNE ELECTRONICS

Vehicle spraying cleaning machine based on electric appliance automation

PendingCN113320501ASolve the problem of manual wipingLabor savingVehicle drying apparatusCleaning apparatus for vehicle exteriorsElectric machineryStructural engineering

The invention discloses a vehicle spraying cleaning machine based on electric appliance automation and belongs to the field of vehicle cleaning. The vehicle spraying cleaning machine comprises a device body; the device body comprises a wiping device, a spraying device and an air drying device; the wiping device comprises a left supporting box; two motors opposite in rotating direction are fixedly connected into the left supporting box; output shafts of the two motors penetrate through the left supporting box and are fixedly connected with screw rods; the left sides of the screw rods are in threaded connection with a sliding plate; the bottom of the sliding plate is slidably connected with a bottom plate; the top of the left side and the top of the right side of the bottom plate are slidably connected with a left supporting box and a right supporting box correspondingly; the ends, away from the left supporting box, of the screw rods are rotationally connected to the left side of the right supporting box; supporting plates are fixedly connected to the upper side and the lower side of the front portion of the sliding plate correspondingly; wiping rollers are connected to the inner sides of the two supporting plates through pin shafts; and a fixing block is fixedly connected with the top of the sliding plate. the labor force of workers is reduced, automatic spraying iscompletedwhile automatic wiping is performed,and a wet vehicle body can bequickly air-dried;.

Owner:吴军

Intelligent phone mainboard chip mounting device

InactiveCN110913602APressure regulationEasy to clamp and positionPrinted circuit assemblingStructural engineeringMechanical engineering

The invention relates to the technical field of chip mounting equipment, and further discloses an intelligent mobile phone mainboard chip mounting device. The device includes a chip mounting table , supporting legs are fixedly connected to four corners of the bottom of the chip mounting table; a U-shaped frame is fixedly mounted on the upper surface of the chip mounting table; an automatic chip mounter is fixedly mounted on the lower surface of the top of the U-shaped frame; a support plate is arranged below the automatic chip mounter; a clamping and positioning mechanism is mounted on the supporting plate; sliding rods are symmetrically and fixedly connected to the lower surface of the supporting plate. Annular grooves matched with the sliding rods are symmetrically formed in the upper surface of the chip mounting table. The bottom end of the sliding rod extends into the annular groove, the sliding rod is slidably connected with the annular groove, sliding grooves are symmetrically formed in the inner wall of the annular groove, sliding blocks matched with the sliding grooves are symmetrically and fixedly connected to the rod wall of the sliding rod, the sliding blocks are slidably connected with the sliding grooves, the sliding blocks abut against the side walls of the top ends of the sliding grooves, and springs are fixedly connected to the bottom end of the sliding rod. According to the intelligent mobile phone mainboard chip mounting device, the pressure borne by the mobile phone mainboard during patch can be conveniently regulated and controlled according to needs.

Owner:惠州海弘科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com