Pressure-limiting overflow device for hydraulic axial plunger pump

An axial piston pump and overflow device technology, applied in pump control, pump testing, liquid variable capacity machinery, etc., can solve the problems of no pressure monitoring and increase the difficulty of processing mainstream pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

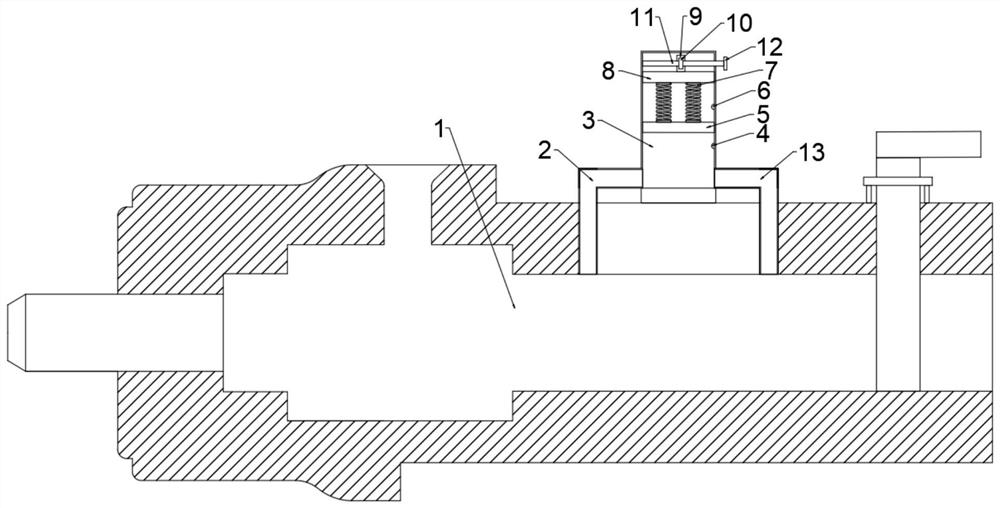

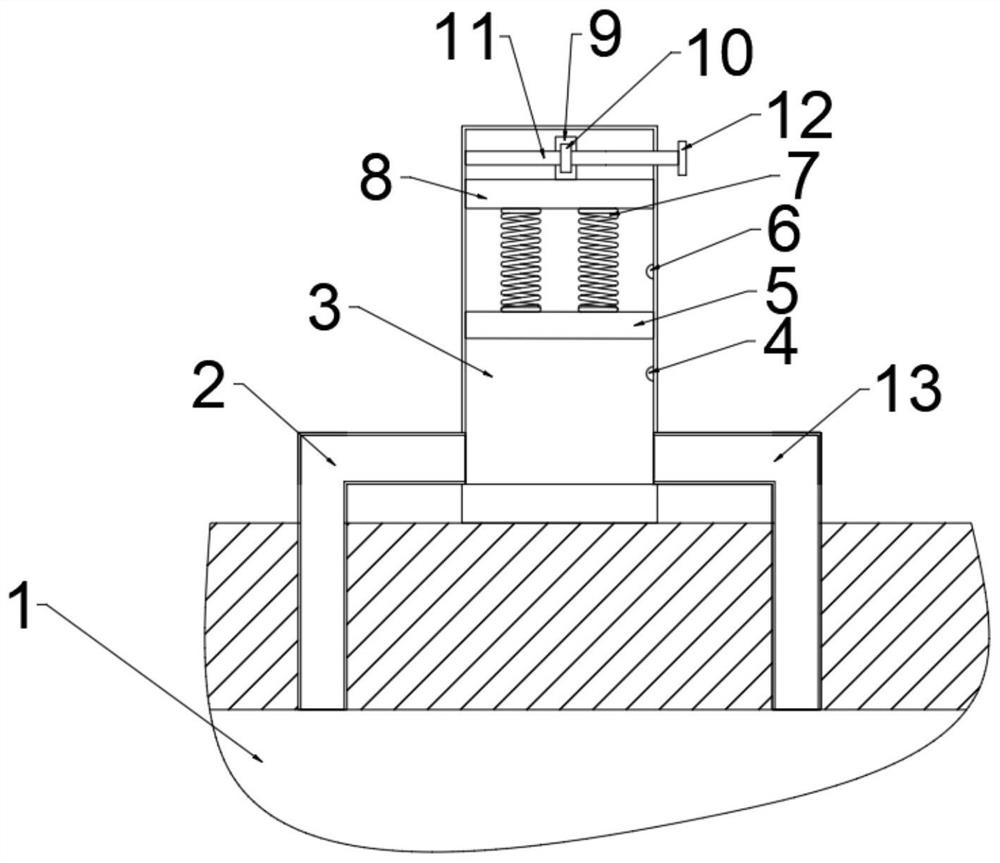

[0031] refer to Figure 1 ~ Figure 2 , a pressure limiting overflow device for a hydraulic axial piston pump, comprising a flow pipe 1, the side of the flow pipe 1 is bolted to an inflow pipe 2 and the end of the inflow pipe 2 away from the flow pipe 1 is bolted to a pressure measuring pipe 3 , the inside of the pressure measuring tube 3 is provided with a pressure measuring mechanism, the pressure measuring mechanism includes a lower sensor 4, a sliding plate 5, an upper sensor 6, a first spring 7 and a sealing adjustment plate 8, and the inside of the pressure measuring tube 3 is slidably connected with a sliding plate 5 and the side of the sliding plate 5 far away from the inflow pipe 2 is bolted with several first springs 7, and the end of the first spring 7 far away from the sliding plate 5 is bolted with a sealing adjustment plate that is sealed and slidably connected with the inner shell wall of the pressure measuring tube 3 8. An adjustment mechanism for adjusting the ...

Embodiment 2

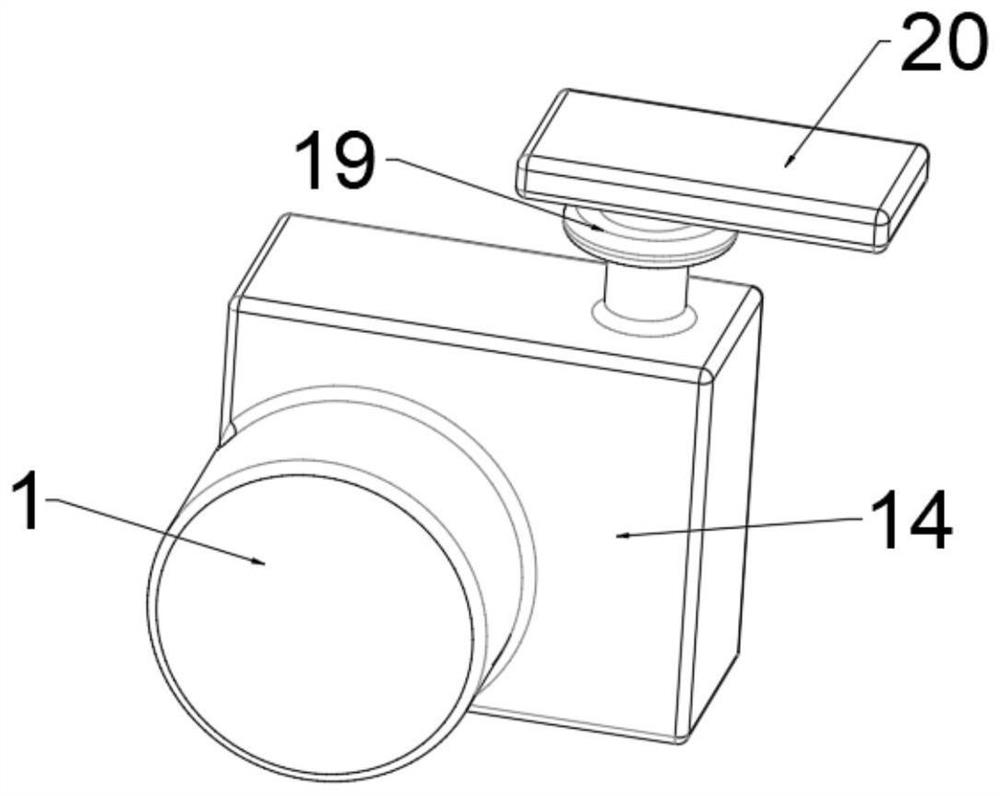

[0038] refer to Figure 5 , a pressure limiting overflow device for a hydraulic axial piston pump. Compared with Embodiment 1, the limiting mechanism of this embodiment includes a fixed block 18, a limiting plate 22 and a second spring 23, and the inside of the limiting box 14 A fixed block 18 is connected with a bolt near the position of the driving gear 17, and a plurality of limiting plates 22 abutting against the driving gear 17 are rotatably connected on the fixed block 18, and a second spring is arranged between the limiting plate 22 and the fixing block 18. 23. The limit plate 22 is provided with an electromagnetic mechanism on the side close to the fixed block 18. When the device is running, the limit plate 22 is used to limit the position of the driving gear 17, so as to avoid the blocking plate driving the connecting shaft 15 under the action of pressure. Rotate, and after adjustment, can avoid blocking plate to produce sliding, increase the applicability of device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com