Indirect printing press with movable inserted roller assembly and roller assembly thereof

A kind of printing machine, indirect technology, applied in the direction of printing machine, rotary printing machine, printing, etc., can solve the problems of high pressure, excessive compensation, deflection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

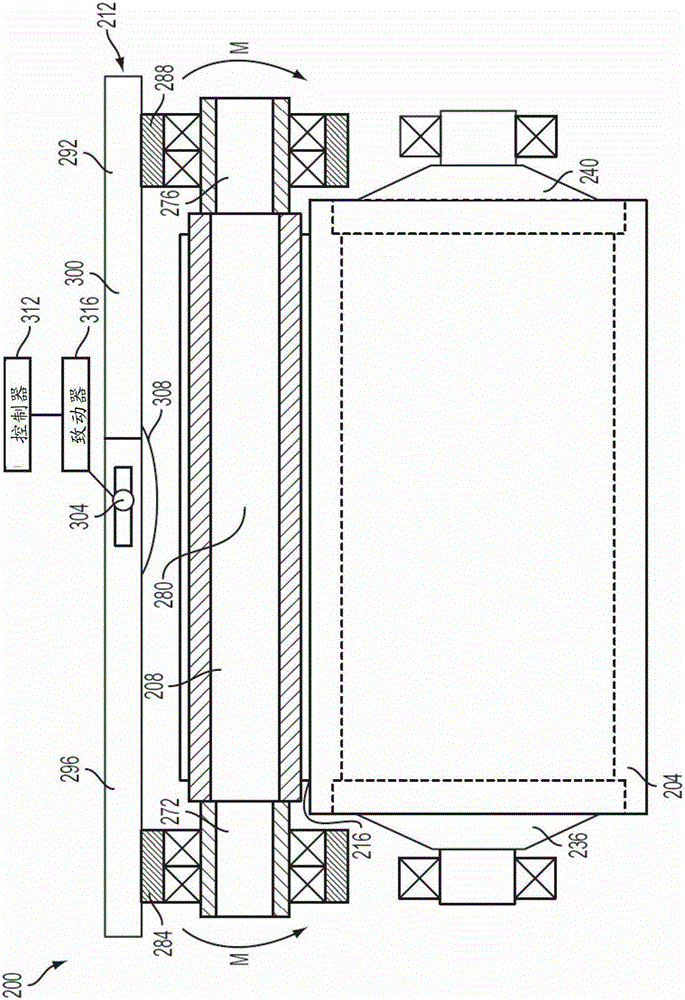

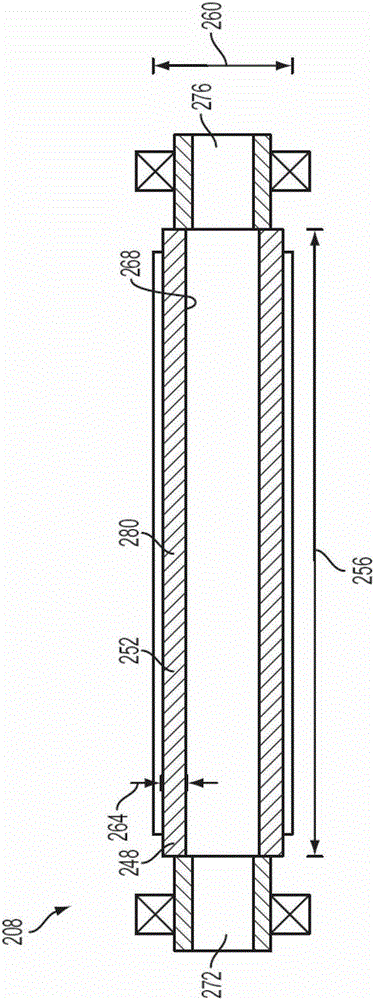

[0023] figure 1The illustrated image transfer system 200 includes an image receiving member 204 , a transfix roller 208 , and a support assembly 212 that accommodates deflection at the center of the transfix roller 208 and pressure variations along a nip 216 . The transfix roller 208 is configured to move into and out of engagement with the image receiving member 204 in a known manner. The transfix roller 208 is configured to apply pressure to the image receiving member 204 and form a nip 216 to transfer an ink image from the image receiving member 204 to the media passing through the nip 216 . The support assembly 212 is configured to apply different amounts of pressure to the central region and the end portions of the transfix roller 208 . The pressure applied by support assembly 212 to transfix roller 208 at nip 216 is transmitted through transfix roller 208 to image receiving member 204 .

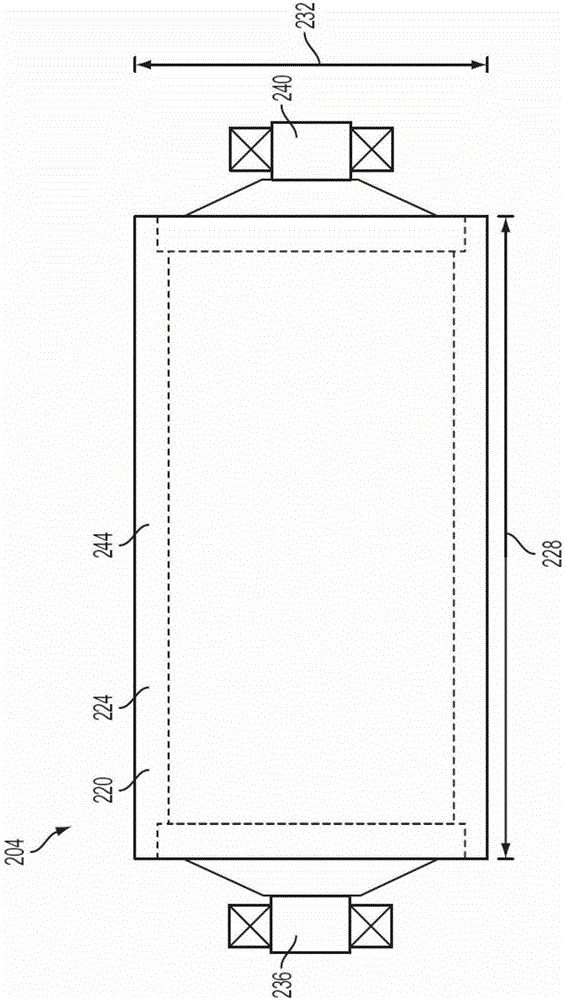

[0024] figure 2 Detailed features of the image receiving member 204 are depict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com