Circulating feeding roller of pressing machine and adjusting method of circulating feeding roller

A technology of feeding rollers and presses, which is applied in the direction of roller tables, conveyors, conveyor objects, etc., can solve the problems of unstable feeding of rollers, uniform pressure of rollers, and easy crushing of steel plates, so as to improve operating efficiency and avoid steel plates Deflection, the effect of reducing contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

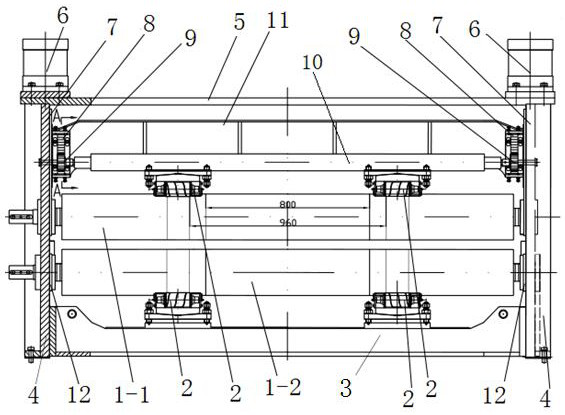

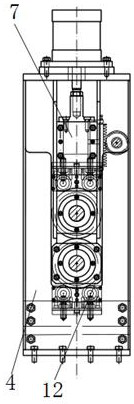

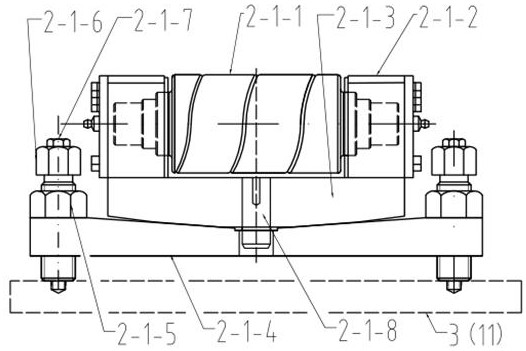

[0025] A circulating feeding roller of a press is installed on a frame assembled from a base 3, two side plates 4 and a top plate 5. The circulating feeding roller includes a lower roller 1-2 with a fixed height and a height-adjustable The upper roller 1-1, the position of the lower roller 1-2 is at the bottom, and its two ends are respectively installed on the roller seats 12 of the side plates 4 at both ends of the frame through bearings, the position of the upper roller 1-1 is at the top, and its The two ends are respectively installed on the sliders 7 of the side plates 4 at both ends of the frame through bearings. The roller base 12 is fixed on the side plate 4, so the height position of the lower roller 1-2 is fixed, and the slide block 7 is slidingly fitted on the side plate 4, so the lifting action of the slide block 7 on the side plate 4 It can simultaneously drive the upper roller 1-1 to adjust the height. The slider 7 is connected and controlled by the cylinders 6 ...

Embodiment 2

[0032] This embodiment discloses a method for adjusting the circulating feeding roller of a press, which is used to adjust the circulating feeding roller of a press described in Embodiment 1, including the following steps:

[0033] S1. Loosen the lock nut and lock bolt of the support roller assembly, and adjust the gap between the support roller and the circulating feeding roller by screwing the length of the adjustment bolt. Measure the deformation of the circulating feeding roller until the error of the data on both sides does not exceed the predetermined value. After meeting the requirements, tighten the lock nut and lock bolt.

[0034] S2. After the adjustment, put a certain width of carbon paper between the upper and lower rollers, roll it through the lower and upper rollers for one rotation, take out the carbon paper to check the indentation, if the indentation in the middle part is lighter, repeat the above steps, and feed to the circulation Adjust the protruding direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com