Sintered neodymium-iron-boron hydrogen decrepitation device capable of improving efficiency

A NdFeB high-efficiency technology, applied in the field of sintered NdFeB processing, can solve the problems of equipment hydrogen interruption, difficult pressure monitoring, cumbersome replacement of hydrogen cylinders, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

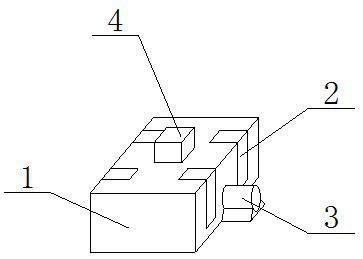

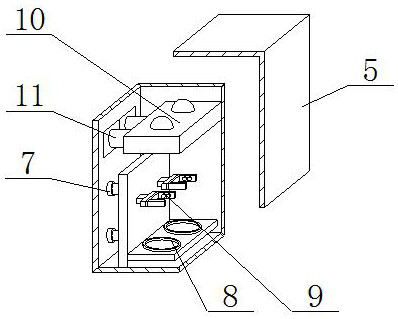

[0030] preferred, such as figure 2 As shown, the hydrogen bottle filling input device 2 includes an induction opening 5, a hydrogen bottle filling base 8, an electromagnetic controller 7, a magnetic adsorption module 9, a pressurized diversion chamber 10, and an anti-leakage protection pipeline 11. The induction opening 5 is covered with hydrogen On the top of the bottle filling input device 2, one end of the electromagnetic controller 7 is fixedly connected to the outer wall of the hydrogen bottle filling base 8, and one end of the magnetic adsorption module 9 is fixedly installed on the inner wall of the hydrogen bottle filling base 8. The top of 10 is fixedly installed inside the hydrogen bottle filling input device 2, the pressurized diversion chamber 10 is located above the hydrogen cylinder filling base 8, and one end of the anti-leakage protection pipeline 11 is fixedly connected inside the pressurized diversion chamber 10.

[0031]In this embodiment, after the hydroge...

Embodiment 2

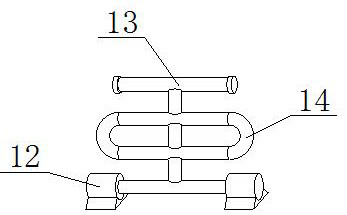

[0033] Such as image 3 As shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: heat exchange equipment 3 comprises heat production unit 12, heat molecule transfer conduit 13 and heat return pipe 14, and the two ends of heat molecule transfer conduit 13 are all fixed Connected to the inside of the heat production unit 12 , both ends of the heat return pipe 14 are fixedly connected to the inside of the heat molecule transfer conduit 13 .

[0034] Specifically, both the heat molecule transfer conduit 13 and the heat return pipe 14 are fixedly installed inside the heat exchange area 27 , and one end of the polymer extraction pipe 21 is fixedly connected inside the vacuum extraction pipe 26 .

[0035] The above-mentioned embodiments provide that by using the characteristic that the movement speed of high-temperature molecules is faster than that of low-temperature molecules, the heat production unit 12 generates heat and heats the interio...

Embodiment 3

[0037] Such as Figure 4 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the bottom of the NdFeB-hydrogen crushing processing chamber 1 is fixedly installed with a crystal storage cavity 20 and a material processing chamber 16, A broken crystal grinder 18 is fixedly installed on the top of the crystal storage cavity 20, and the bottom of the broken crystal grinder 18 is electrically connected to the inside of the energy supply layer 19. The broken crystal grinder 18 is located at the bottom of the material processing chamber 16, and the material processing chamber 16 and the junction of the broken crystal grinder 18 are movably equipped with an induction valve 17.

[0038] Specifically, a hydrogen propeller 15 is fixedly installed at the junction of the hydrogen bottle filling input device 2 and the NdFeB hydrogen crushing treatment chamber 1, and the bottom of the hydrogen propeller 15 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com