Experimental device and method for simulating in-situ fluidized mining of deep metal ore

An experimental device, metal mine technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of single monitoring parameters, defects in experimental devices and methods, and few experimental devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

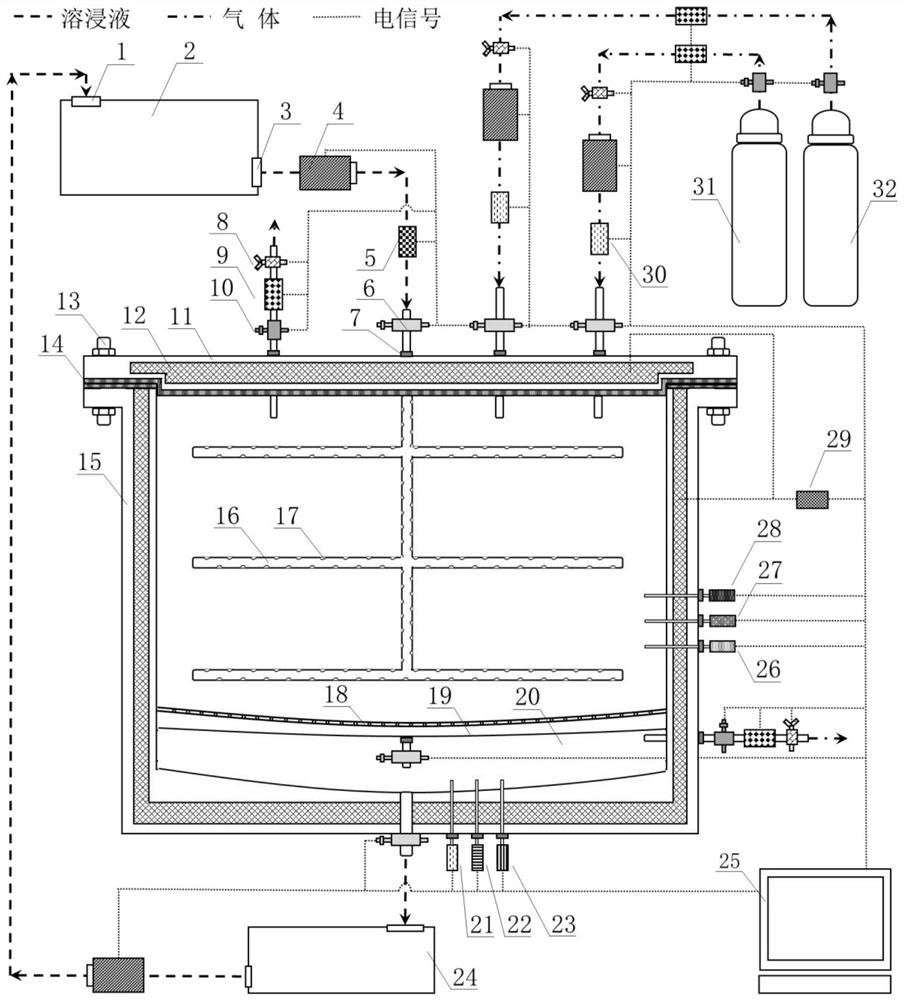

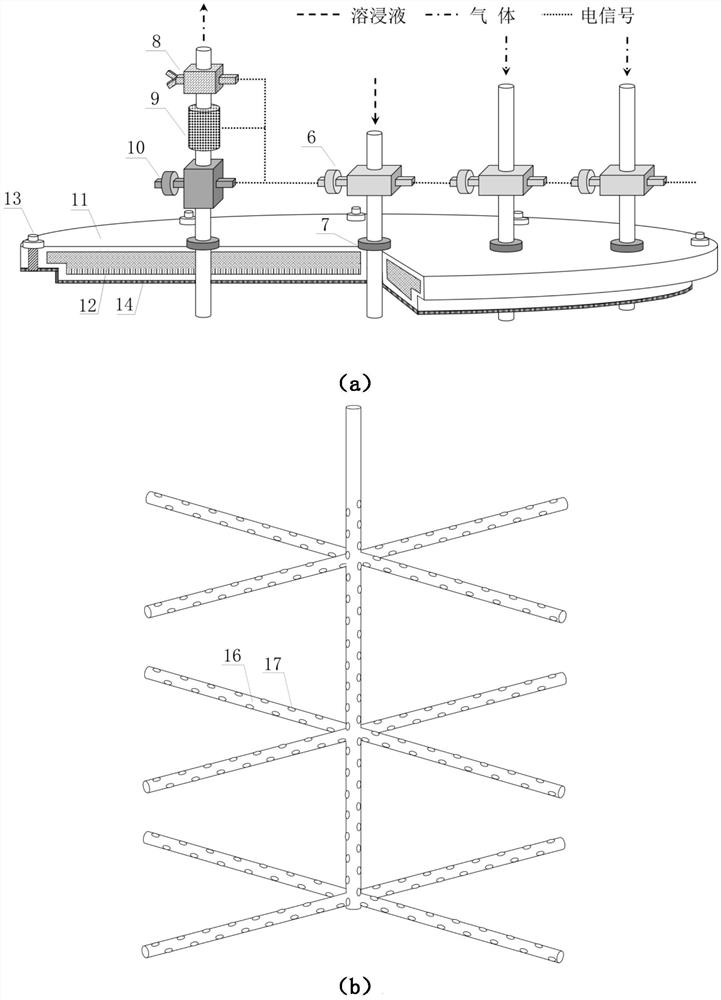

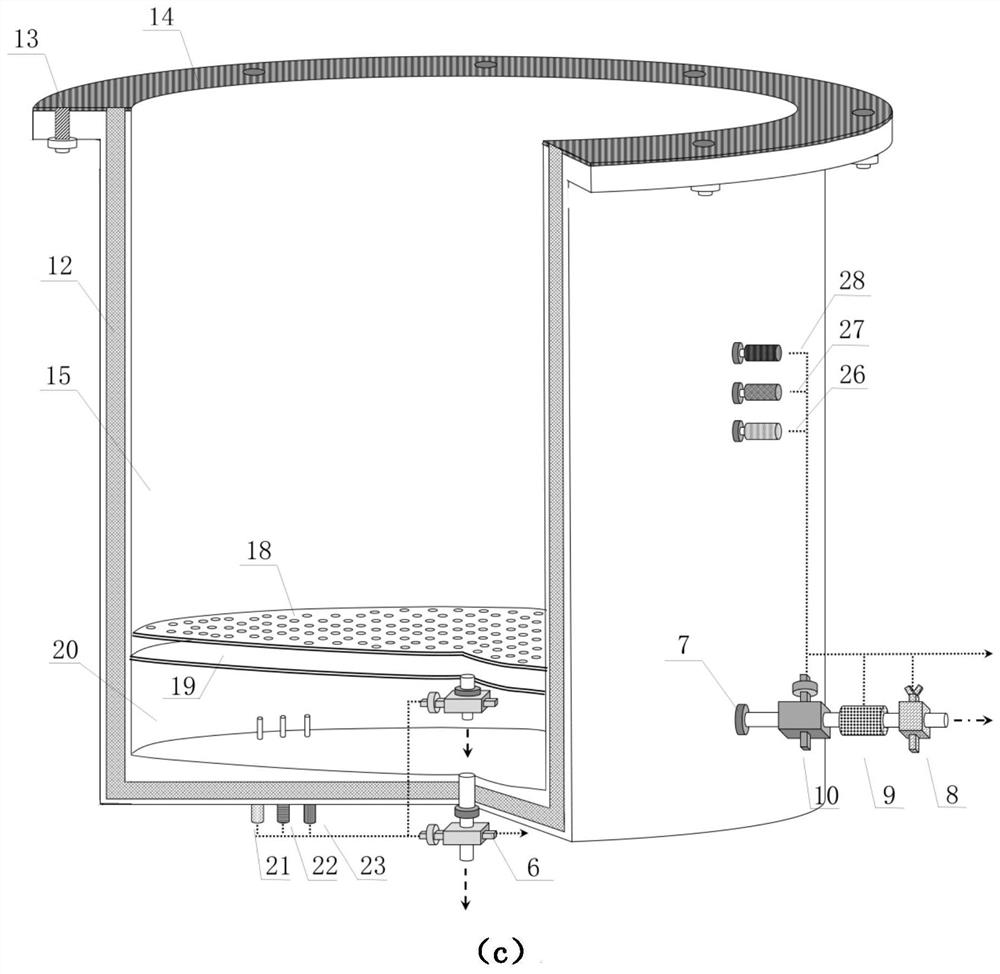

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0029] The invention provides an experimental device and method for simulating in-situ fluidized mining of deep metal mines.

[0030] Such as figure 1As shown, the device includes a solution spray circulation system, an ore leaching reaction system, a temperature control system, an air pressure control system and a data integration control system, wherein the solution spray circulation system includes a return liquid port 1, a liquid storage tank 2, a liquid outlet Port 3, pumping motor 4, liquid flow meter 5, liquid injection pipeline 16, liquid injection hole 17 and liquid collection tank 24, ore leaching reaction system includes reaction tank top cover 11, fixing bolts 13, sealing gasket 14, reaction tank Body 15, porous partition 18, sink surface 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com