Water seal device for straw combustion and gasification furnace

A technology for a water sealing device and a gasifier, which is used in the manufacture of combustible gas, chemical industry, climate sustainability, etc., can solve problems such as external leakage, and achieve the purpose of avoiding gas leakage, preventing gas leakage, and ensuring sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

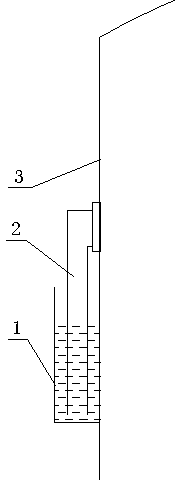

[0014] like figure 1 As shown, this embodiment provides a water sealing device for a straw burning gasifier, including a sealing water channel 1 and six connecting pipes 2, one end of the connecting pipe 2 is connected to the gasifier 3, and the The other end of the connecting pipe 2 is set at the bottom of the sealed water channel 1, and the sealed water channel 1 is set on the side furnace wall of the gasification furnace 3. The sealed water channel 1 is an annular sealed water channel 1, and the sealed water channel 1 surrounds The side fireplace wall of the gasification furnace 3 is provided, and the joint between the connecting pipe 2 and the gasification furnace 3 is coated with glass glue.

[0015] This embodiment is a water sealing device for a straw burning gasification furnace. Since one end of the connecting pipe 2 is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com