Die pouring system of die casting parts

A technology for parts and molds, applied in the field of mold gating system for die-casting parts, can solve the problems of mold complexity and increase in manufacturing cost, and achieve the effects of low production cost, reduced impact, and reduced gas involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

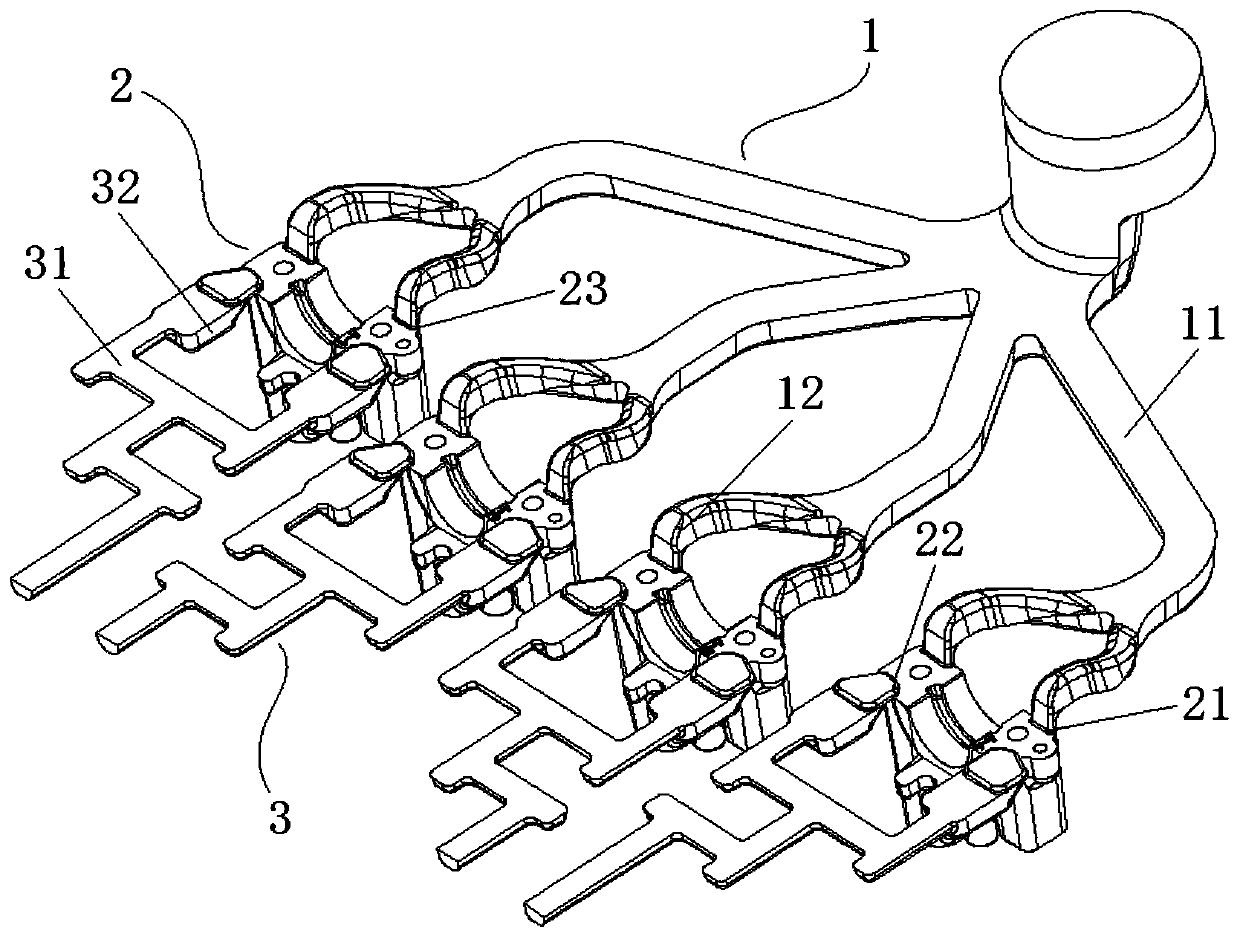

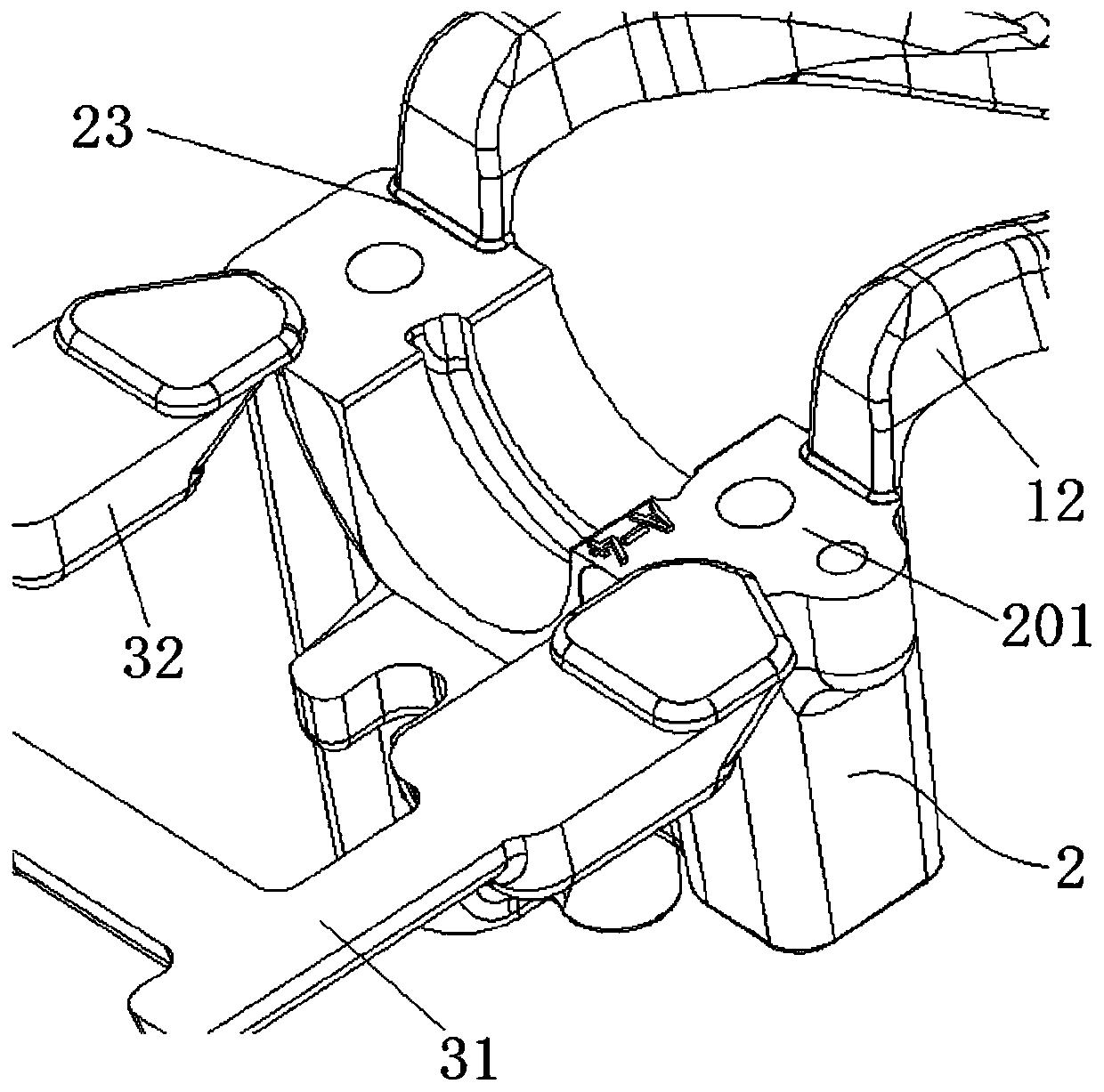

[0033] Such as Figure 1-2 As shown, this embodiment provides a mold pouring and draining system for die-casting parts, which is mainly used in pouring of auto parts;

[0034] The runner system 1 includes several horizontally arranged main runners 11, one end of the main runner 11 is the input end of the molten metal, and the output end of the main runner 11 is provided with several branch runners 12; Wherein, along the conveying direction of the branch runners 12 , the cross-sectional areas of several branch runners 12 gradually become smaller.

[0035] As a preferred solution, when the main runner 11 and the branch runner 12 need to be bent and set, the bends on the main runner 11 and the branch runner 12 are all set with a smooth transition, without Sudden contraction or expansion to avoid pressure loss caused by the collision of molten metal with the side wall of the pipe.

[0036] A number of gates 21 are provided on the parting surface 201 of the molding cavity 2 . In ...

Embodiment 2

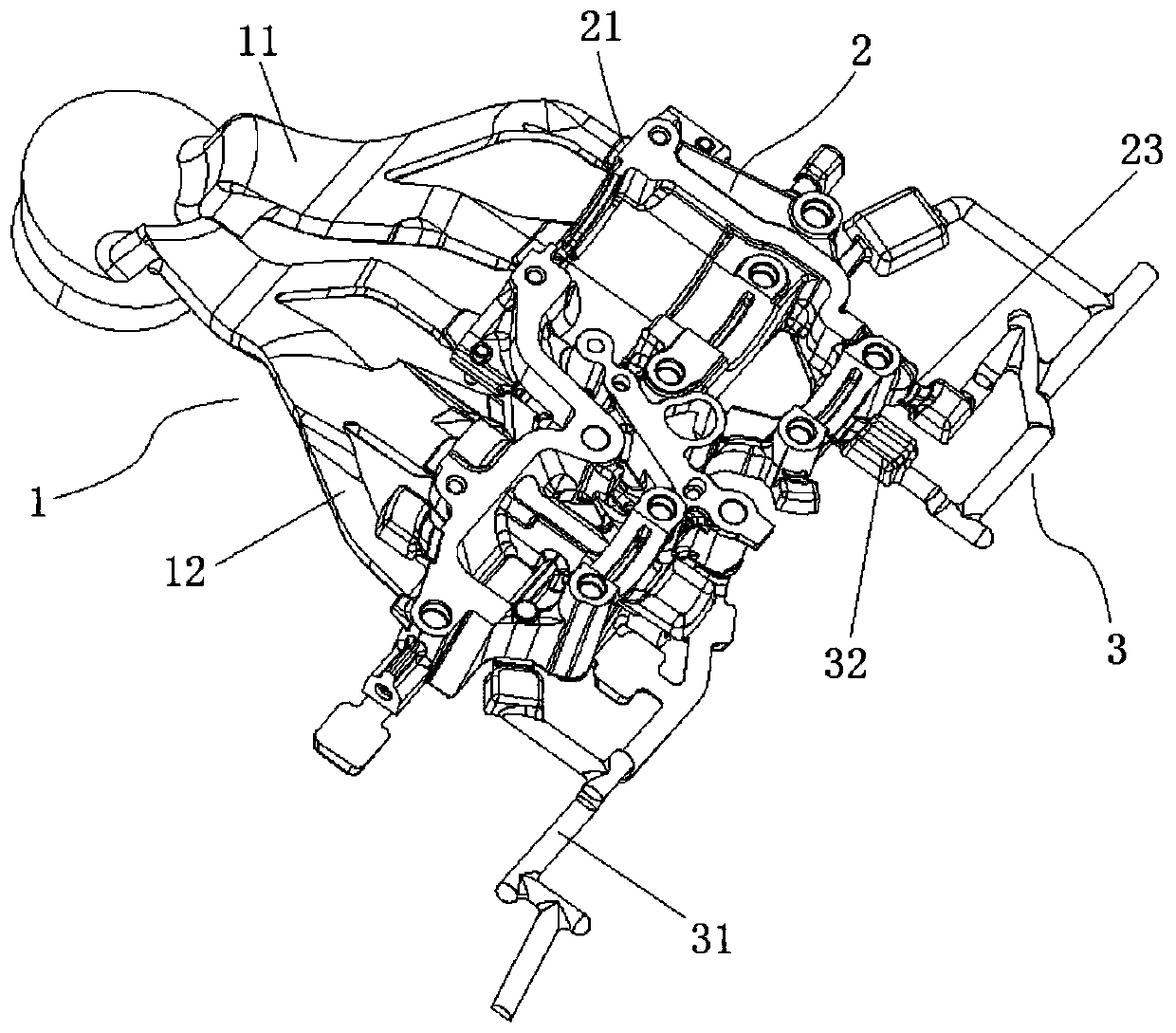

[0045] Such as image 3As shown, a mold pouring system for die-casting parts is provided in this embodiment. The main difference from Embodiment 1 is that this embodiment is mainly applied to the pouring operation of the engine bracket; it includes a runner system 1, a molding cavity 2 and the overflow system 3; during casting, the molten metal is input to the runner system 1, and transported to the molding cavity 2 through the runner system 1 to carry out the casting of the engine bracket, part of the molten metal and the casting process The gas generated in the process is output through the overflow system 3 .

[0046] The runner system 1 includes several main runners 11 and several branch runners 12, the output ends of the main runners 11 and the input ends of the branch runners 12 are connected at an angle, as a preferred solution The angle formed at the connection between the main runner 11 and the branch runner 12 is an obtuse angle; and the connection between the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com