Patents

Literature

116results about How to "Prevent sideways" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

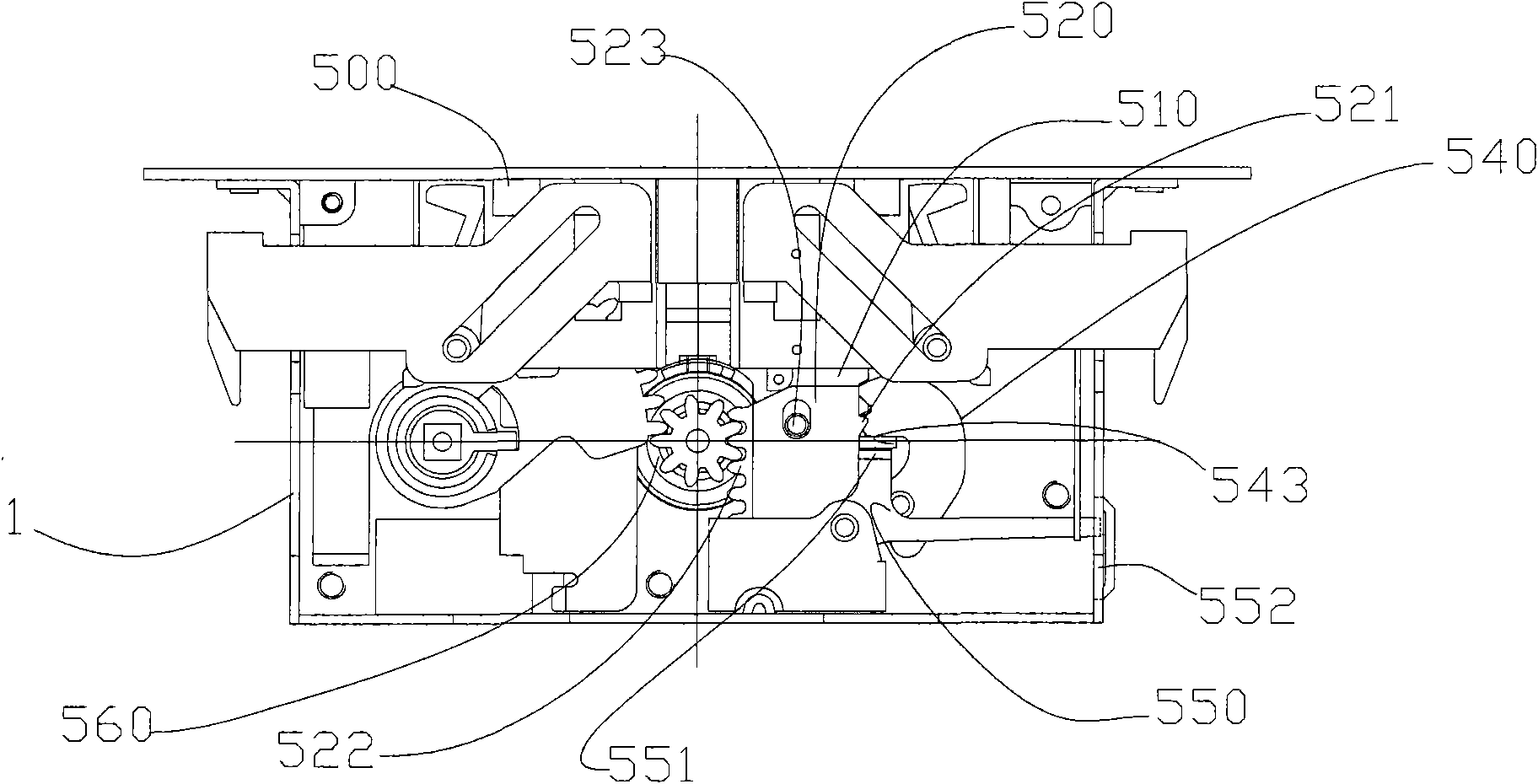

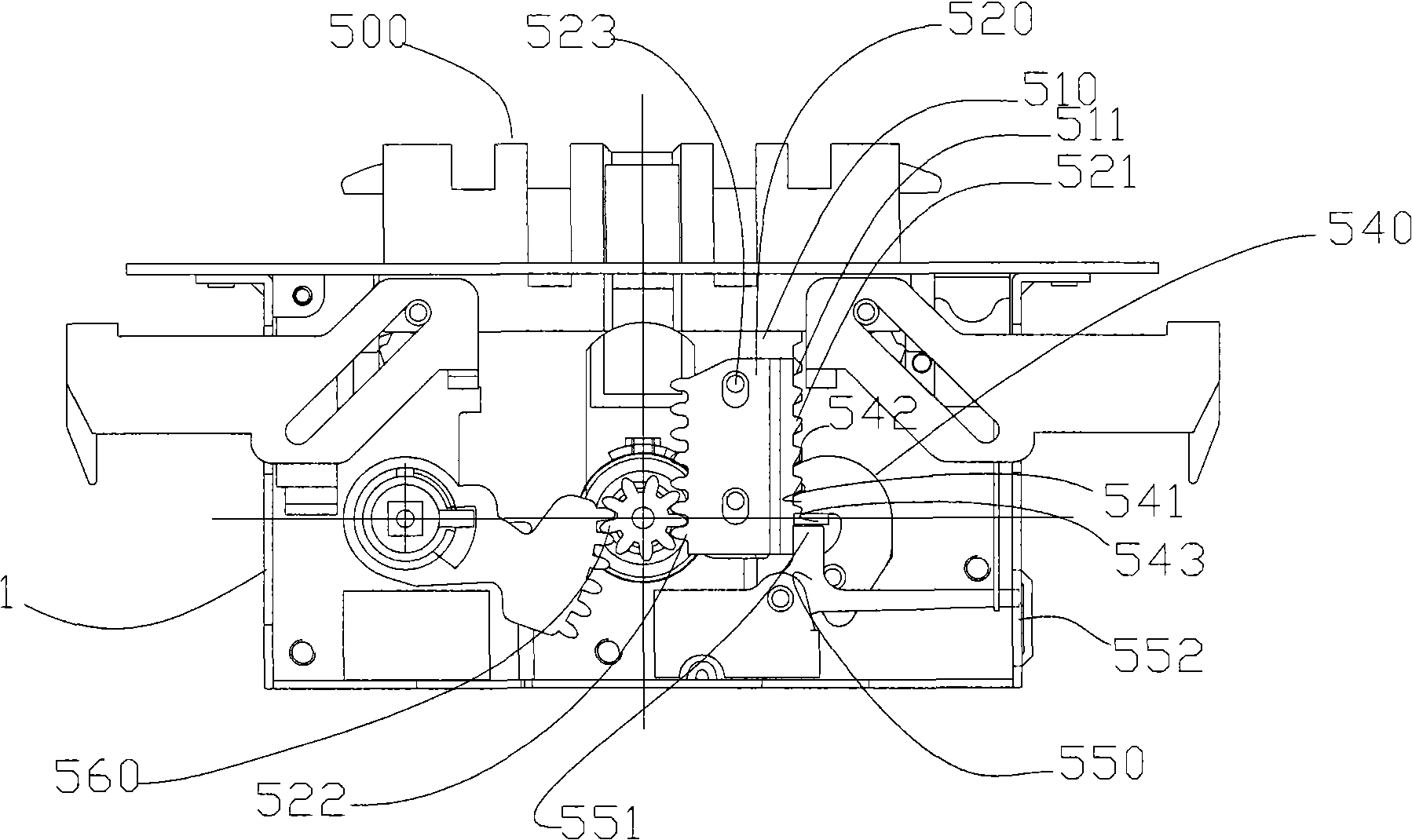

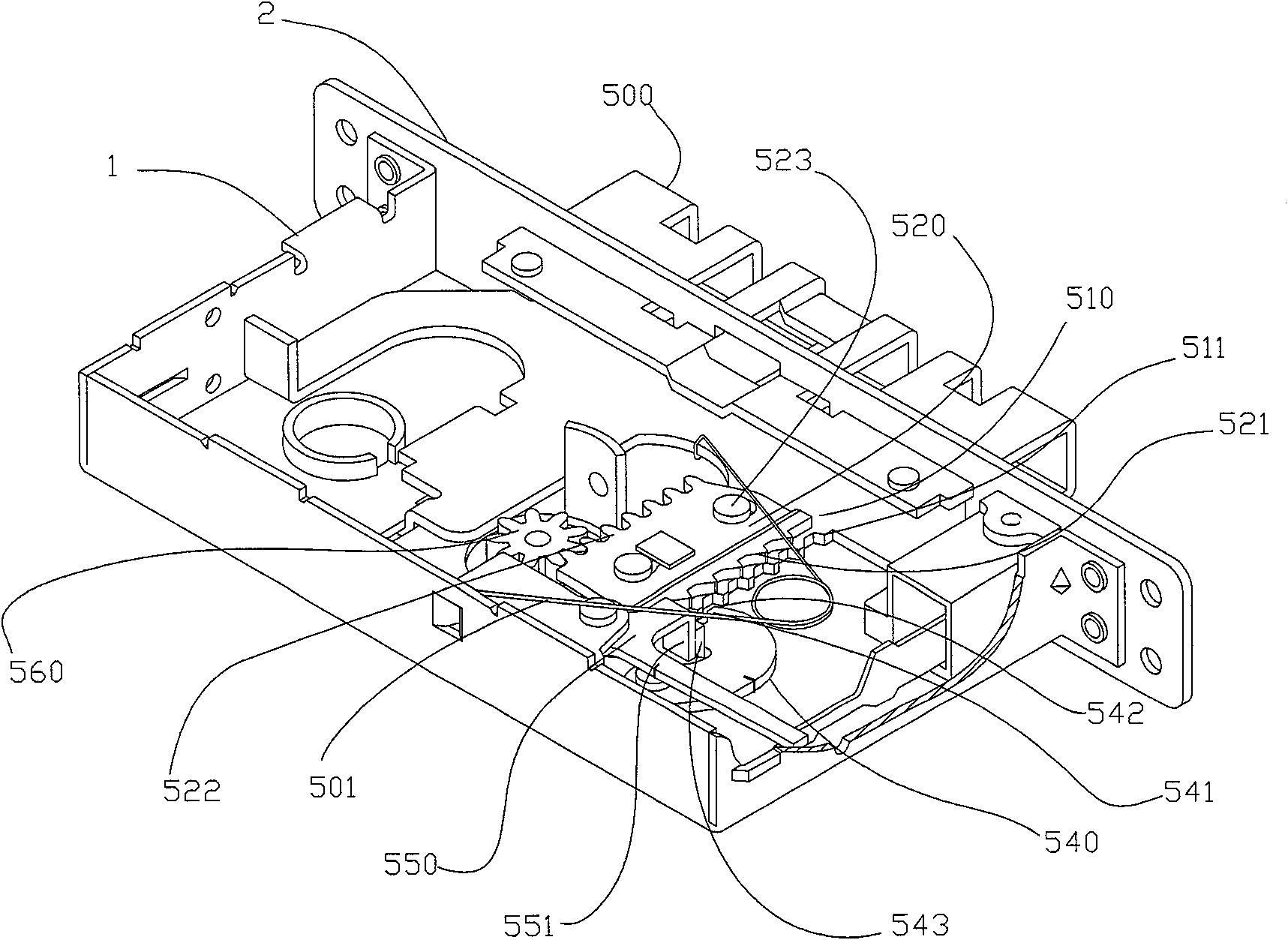

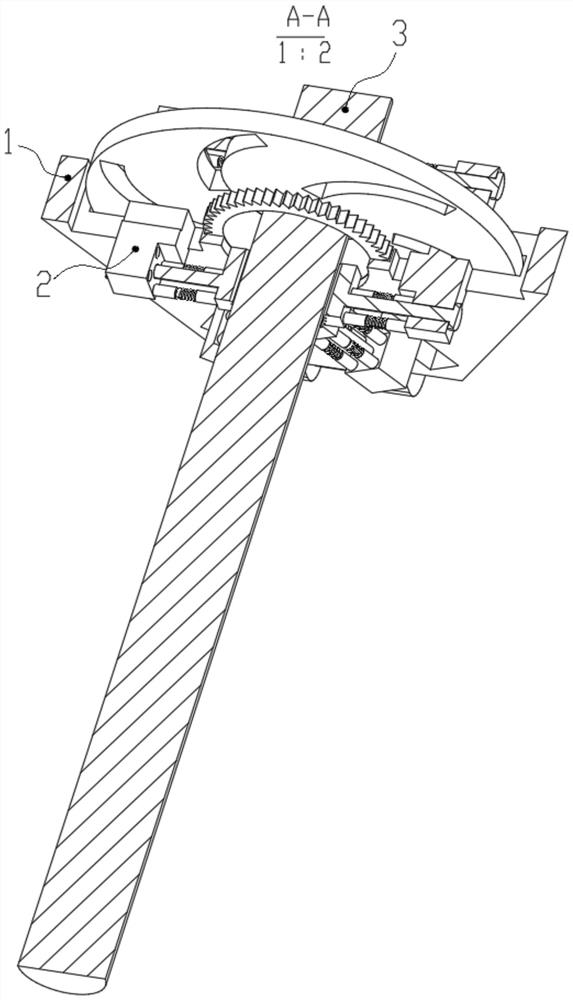

An automatic door lock

ActiveCN101566026ASimple structureCompact structureBuilding locksHandle fastenersLocking mechanismEngineering

The invention provides an automatic door lock, comprising a lock shell having a dead bolt hole molded with dead lock hole; a lock assembly installed on the lock shell panel and the lock shell bottom panel corresponding to a molded lock installation hole; a bolt mechanism installed in the lock shell capable of moving along the direction perpendicular to the lock shell panel; a locking control mechanism for controlling the bolt in the bolt mechanism extruding from and retracting into the panel; and a bolt locking mechanism matched with the door handle operating mechanism. The automatic door lock implements engagement and disengagement of the stop member with a fixed stripe and a movable stripe by coupling of the fixed and the movable stripe, the stop member is capable of engaging with the fixed and the movable stripe at different positions, incomplete unlocking operation due to extrusion of a bolt partially retracted into the shell is prevented.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

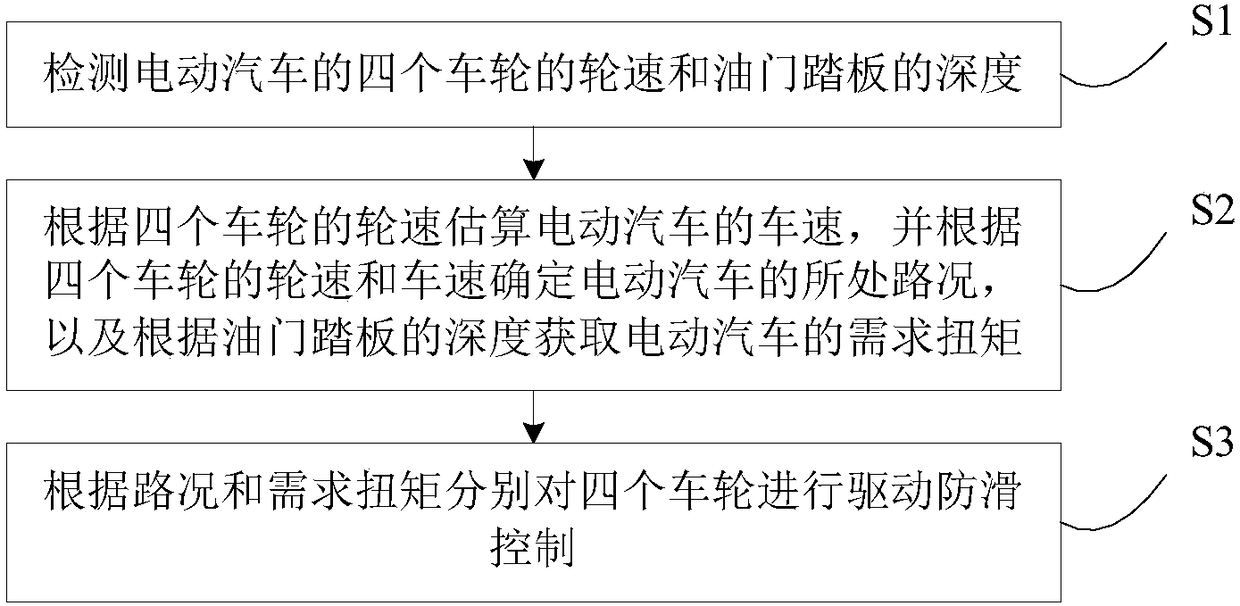

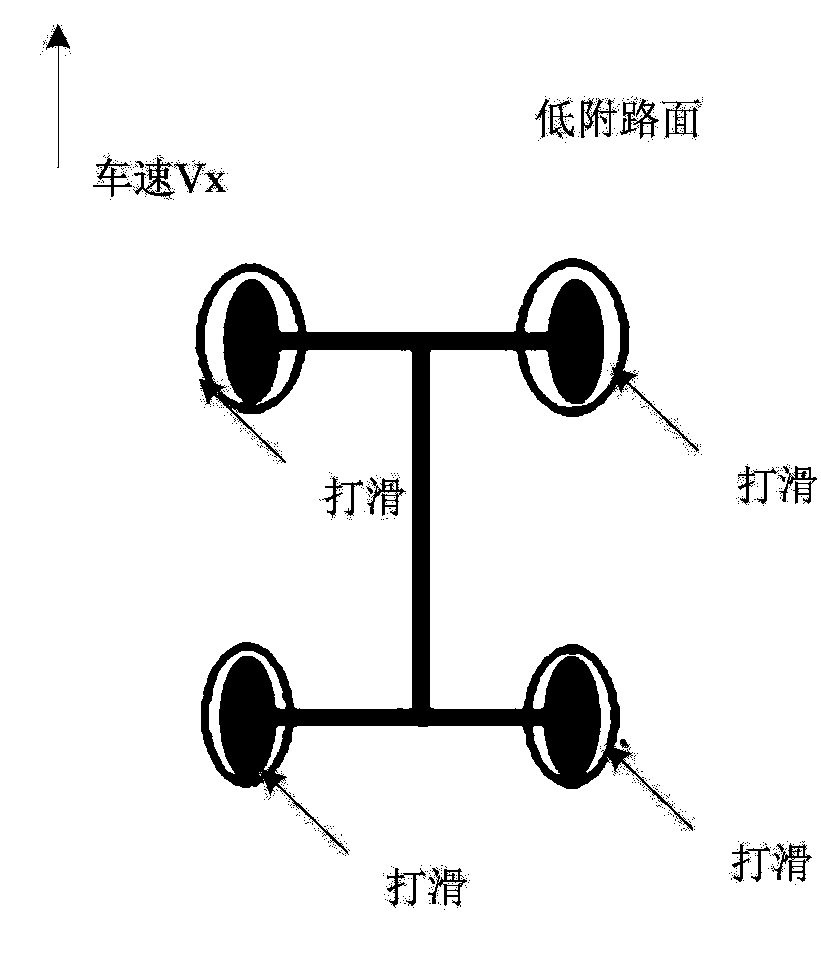

Driving anti-slip control method and device of four-drive electric vehicle

ActiveCN108248455AImprove escape performancePrevent sidewaysSpeed controllerElectric devicesRoad surfaceElectric vehicle

The invention discloses a driving anti-slip control method and device of a four-drive electric vehicle. The control method comprises the following steps of detecting wheel speeds of four vehicle wheels of the electric vehicle and the depth of an accelerator pedal; according to the vehicle speeds of the vehicle wheels, estimating the vehicle speed of the electric vehicle, determining the road conditions of the electric vehicle according to the wheel speeds of the vehicle wheels and the vehicle speed, and obtaining demand torque of the electric vehicle according to the depth of the accelerator pedal, wherein the road conditions comprise the low tire-road friction starting pavement, the joint pavement and the bisection pavement; conducting driving anti-slip control on the vehicle wheels respectively according to the road conditions and the demand torque. By means of the driving anti-slip control method, it can be guaranteed that after the electric vehicle enables the anti-slip function, the rear vehicle wheels do not turn very fast, the electric vehicle does not skew, the yaw velocity is within a certain range, ground adhesive force can be utilized to the greatest extent, and the capability for the electric vehicle to get rid of the trouble is improved.

Owner:BYD CO LTD

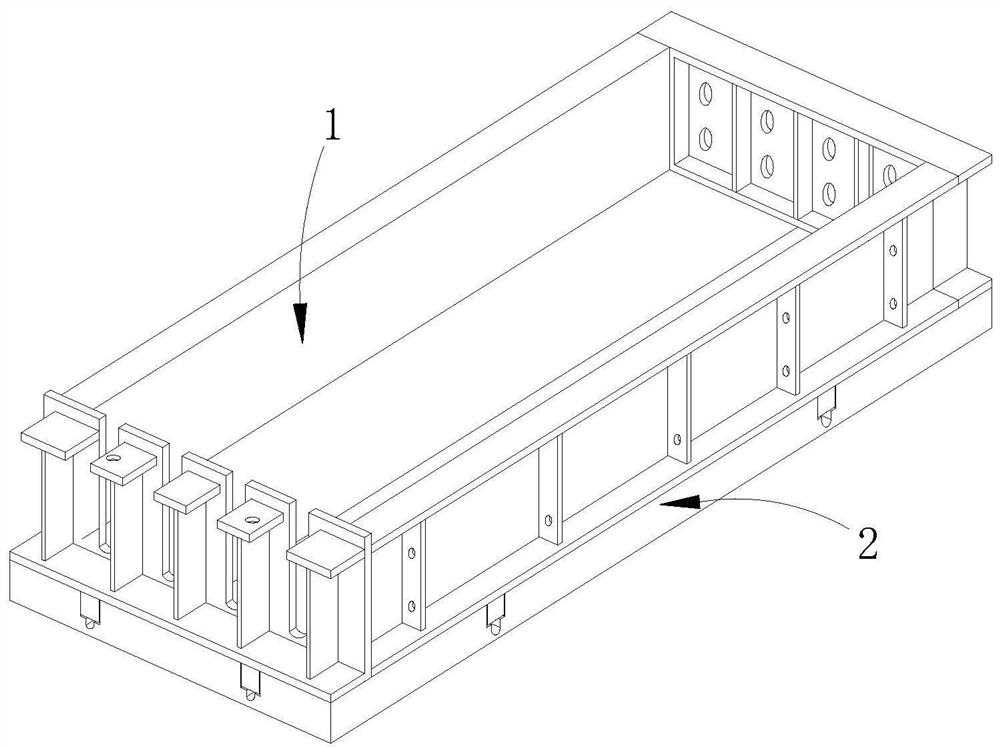

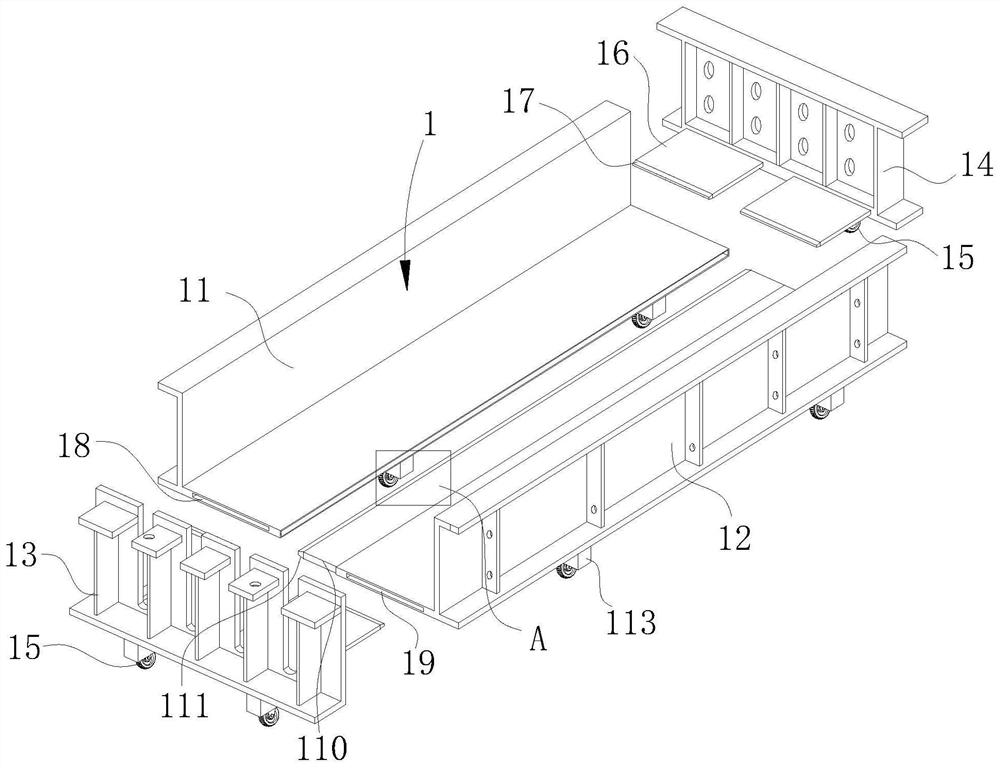

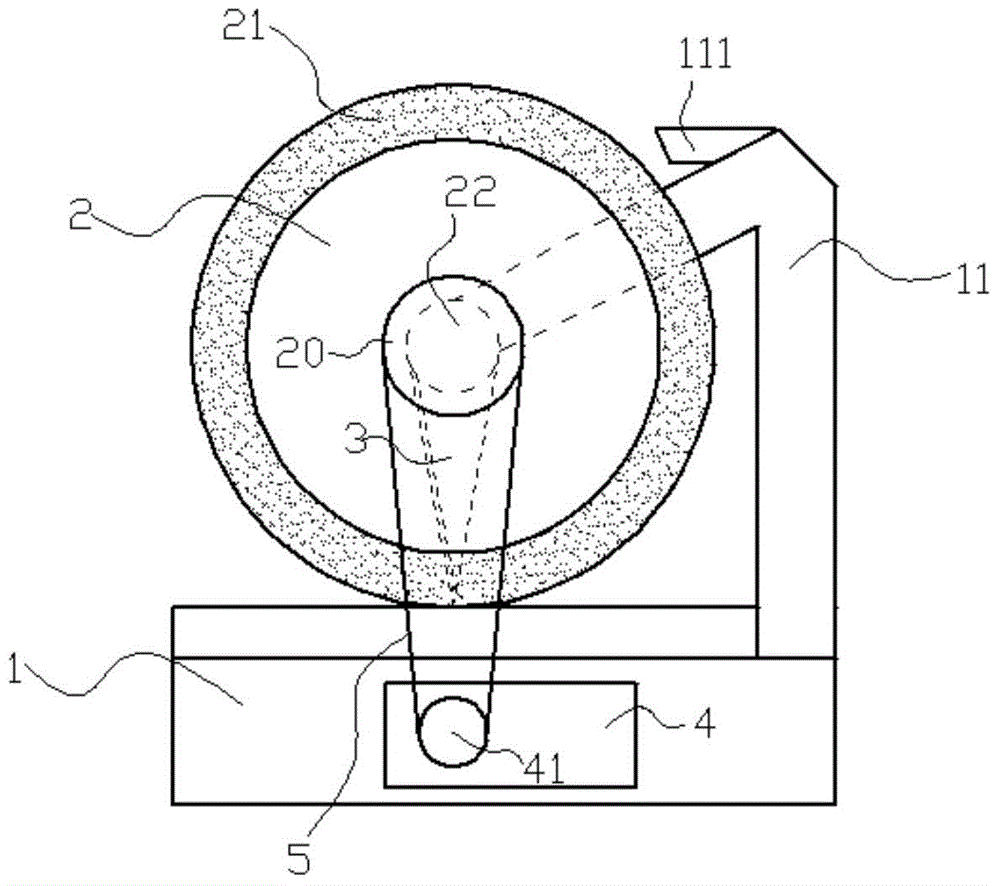

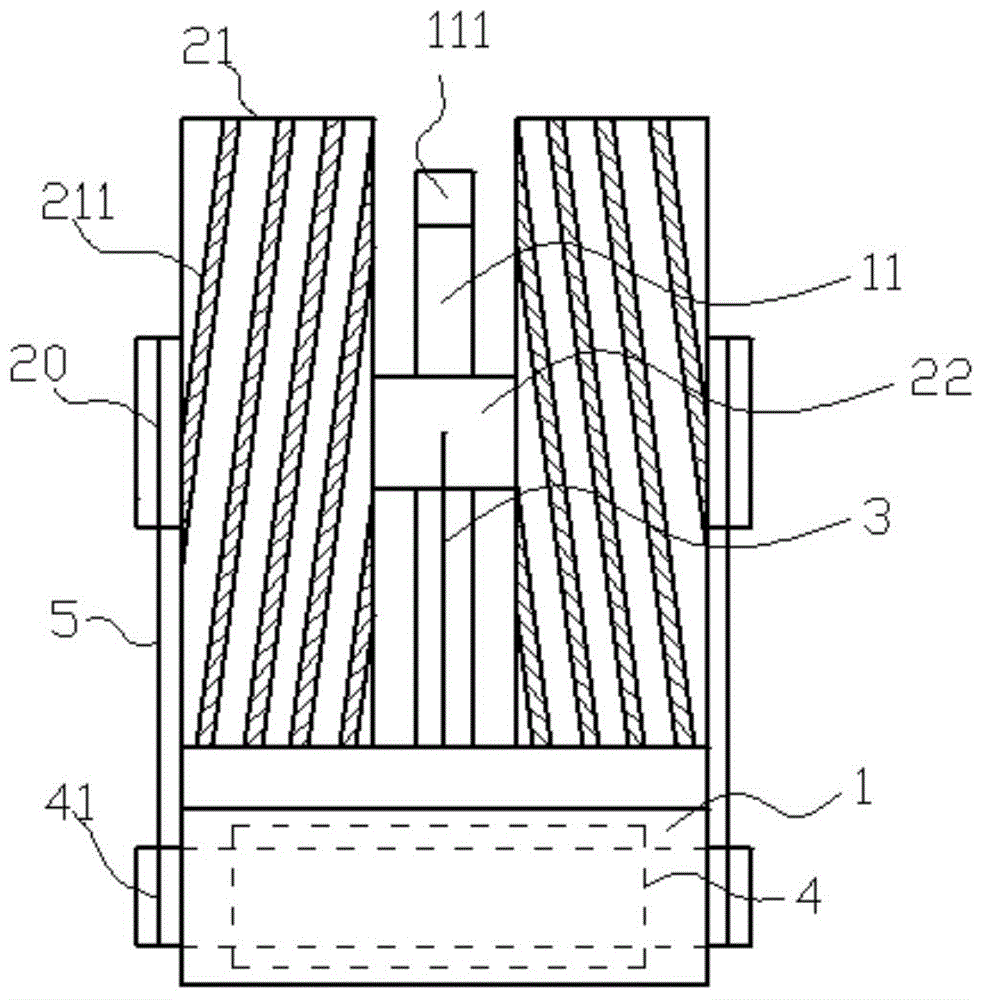

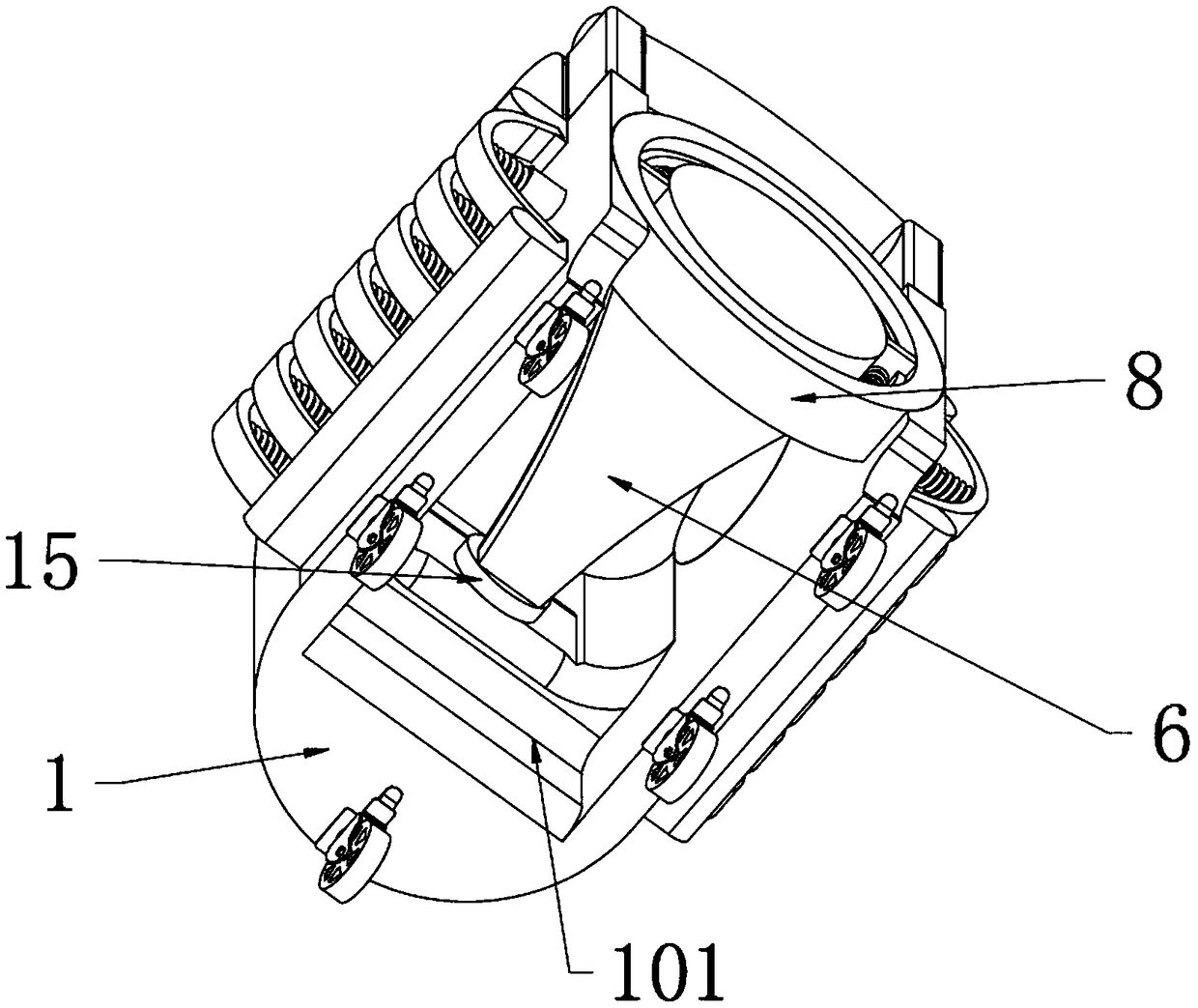

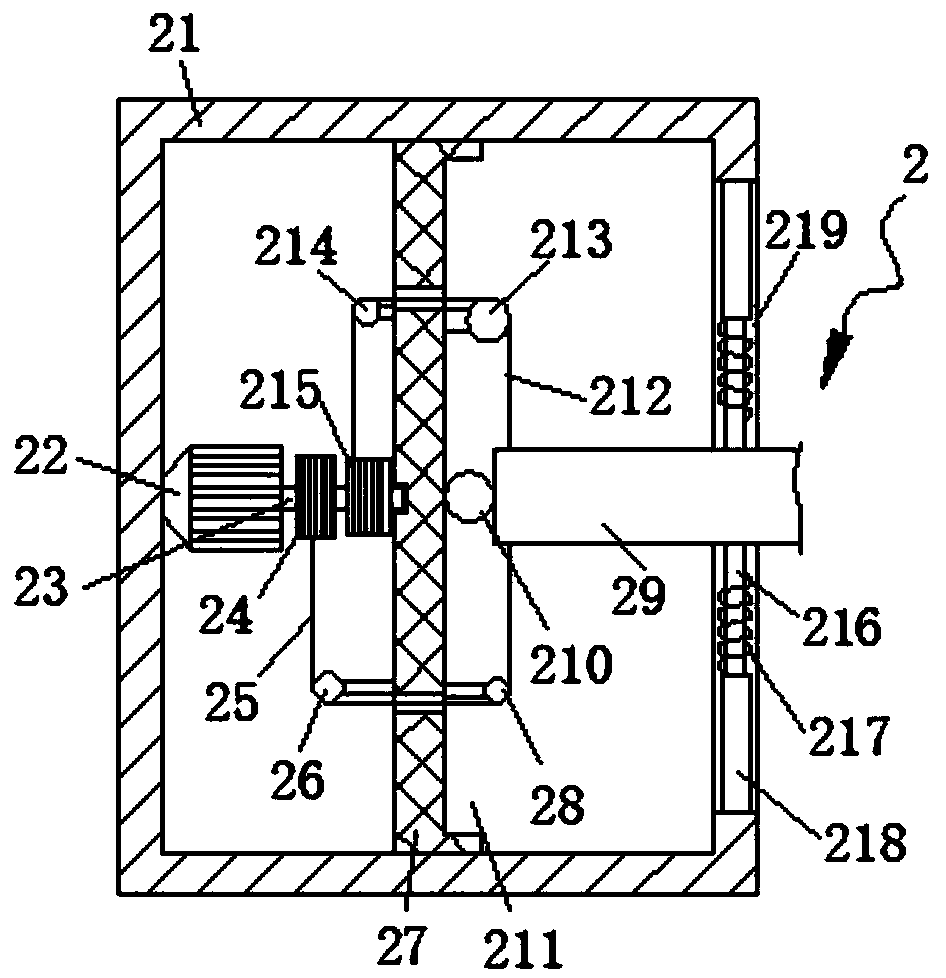

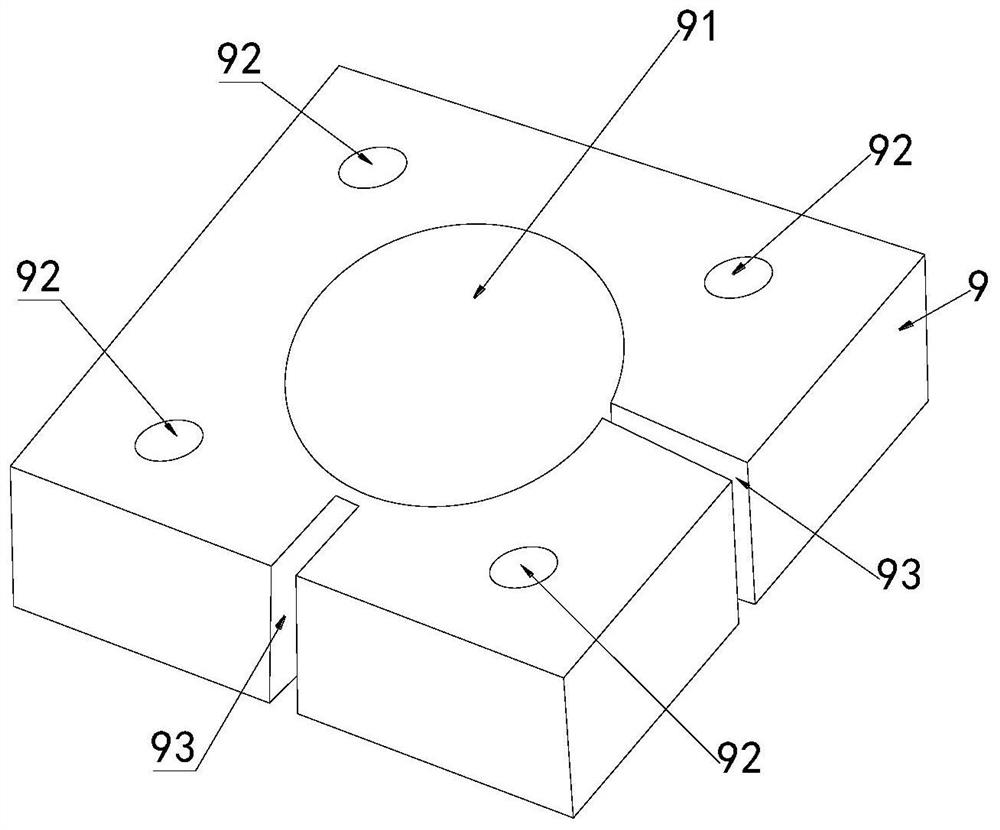

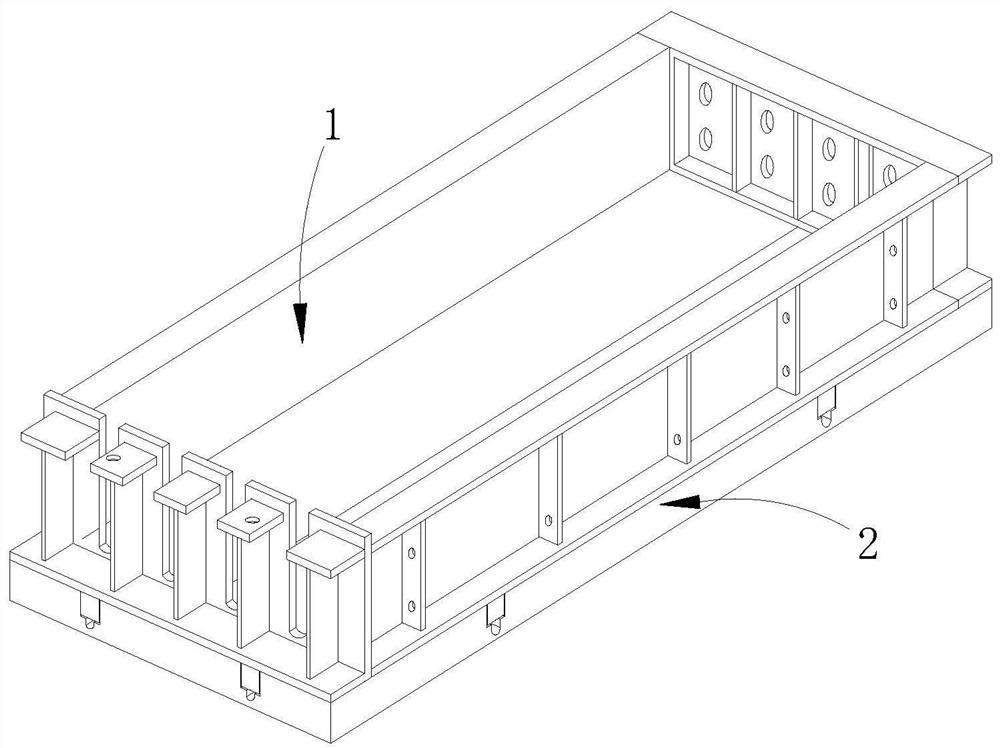

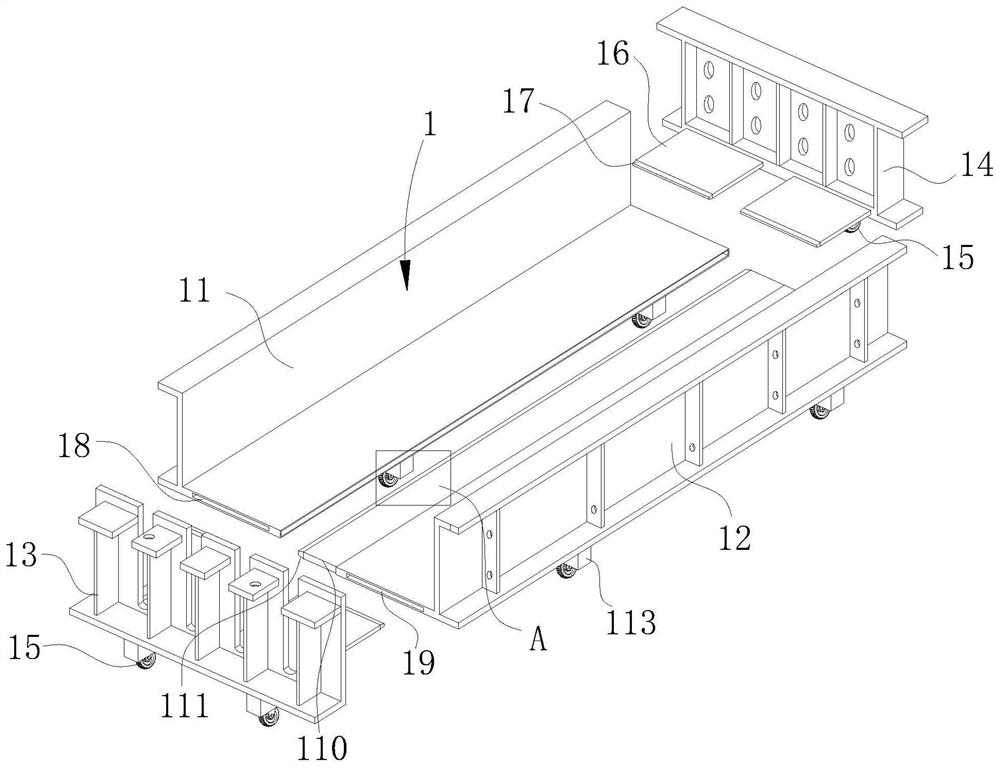

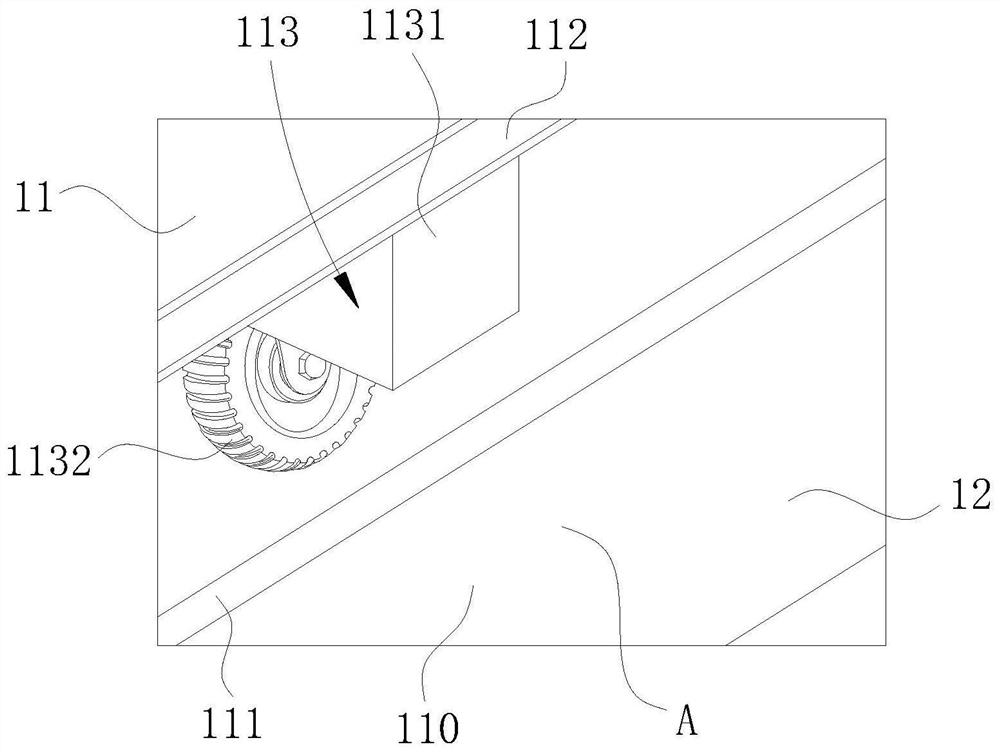

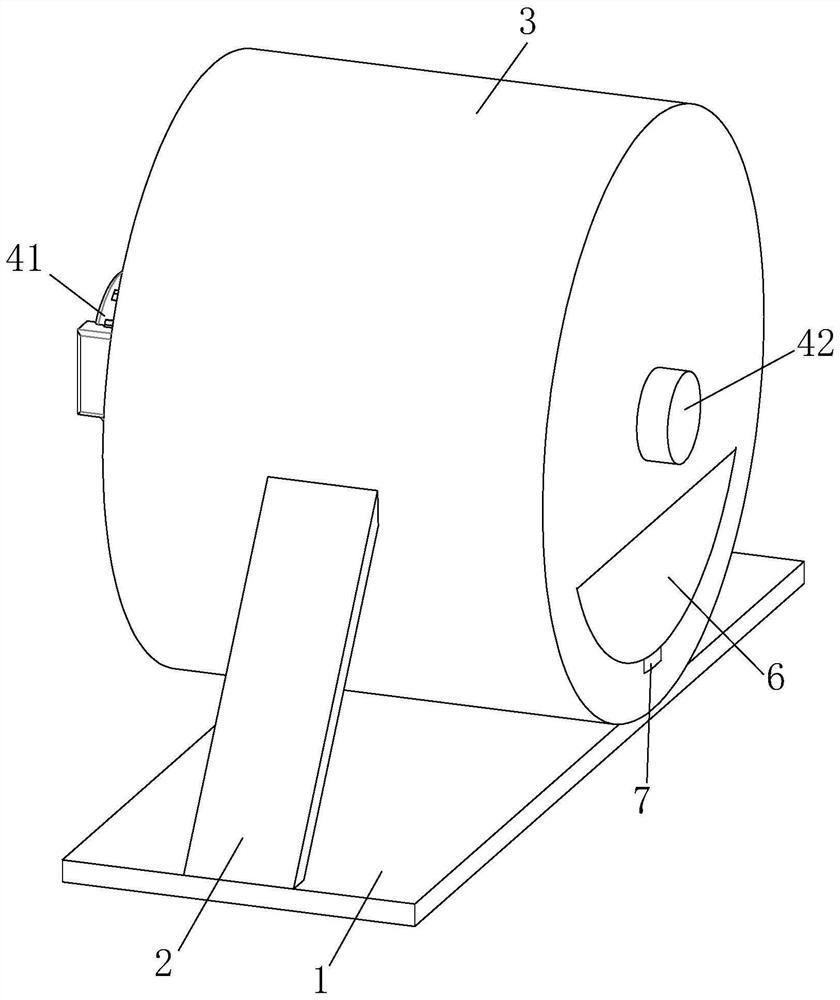

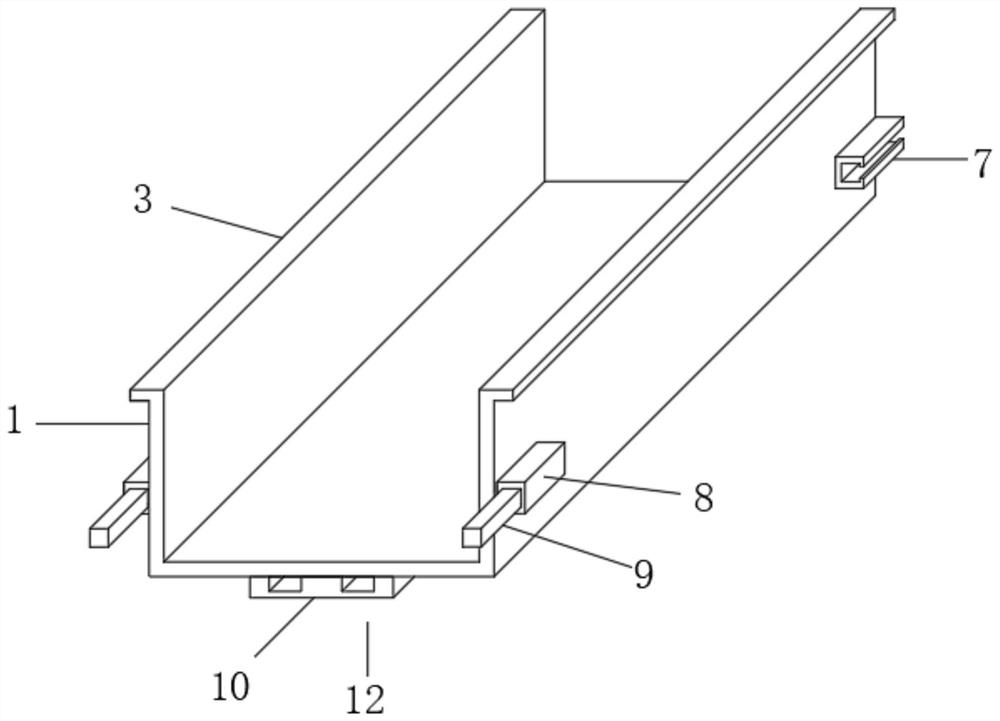

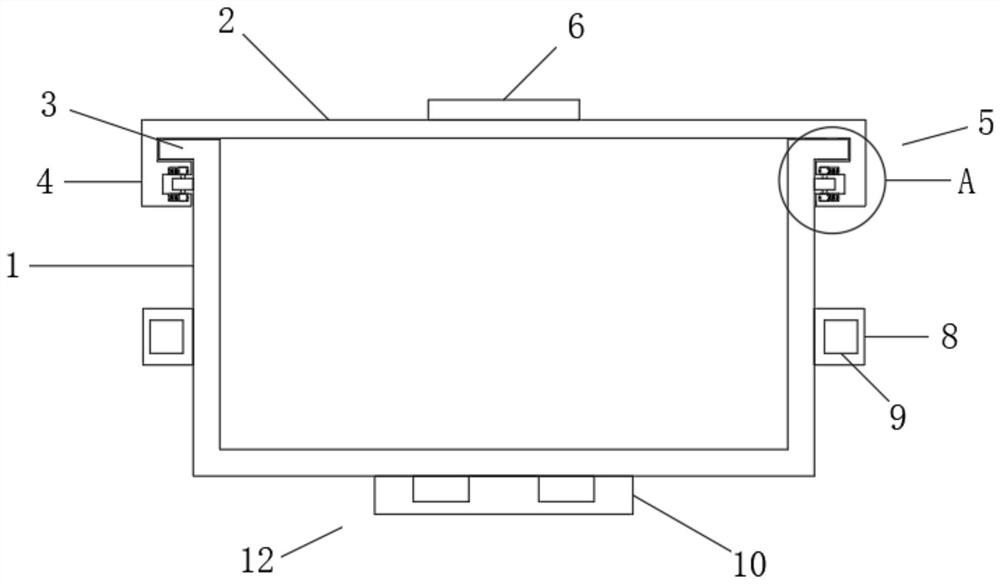

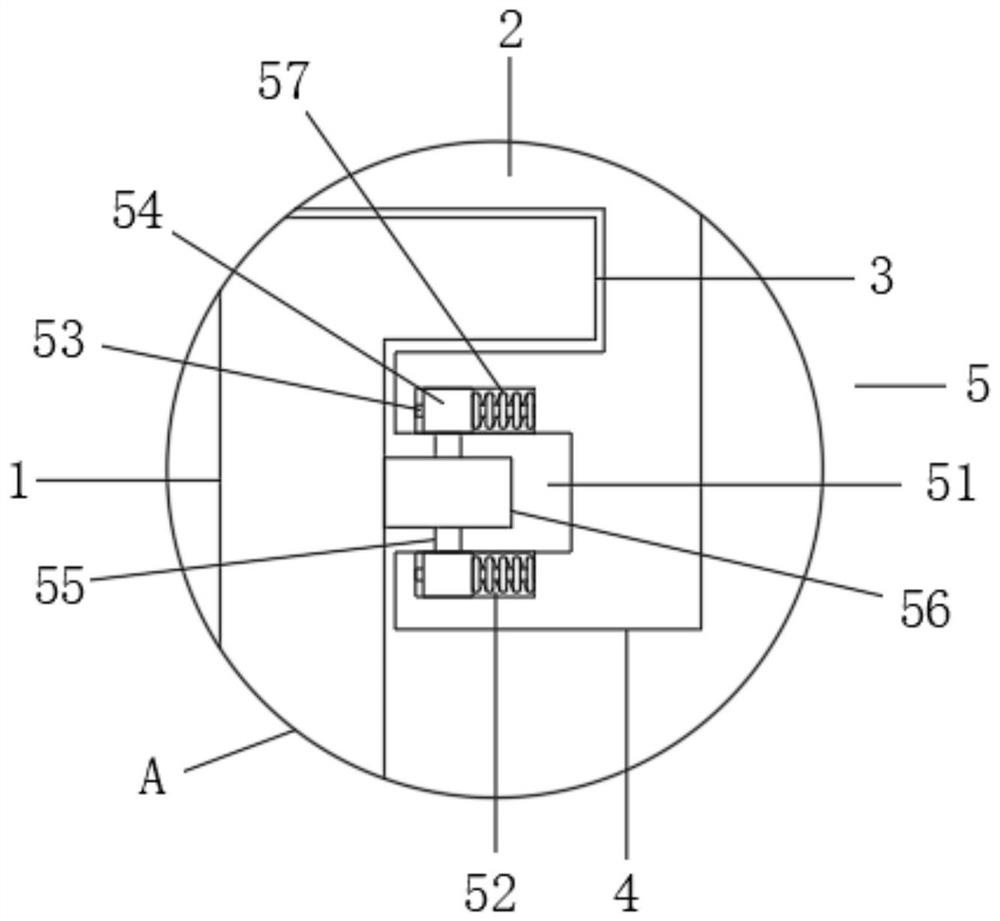

Assembly type precast concrete member die

ActiveCN111605050AEasy to assemble and disassembleAvoid damageMouldsMould fastening meansPrecast concreteArchitectural engineering

The invention relates to an assembly type precast concrete member die. The assembly type precast concrete member die comprises a die mechanism and a bearing mechanism. According to the assembly type precast concrete member die, the die adopts an assembly structure, so that when a prefabricated member is molded and demoulded, the effect of rapidly disassembling and assembling the prefabricated member is achieved through a die split mechanism; meanwhile, in the disassembly and assembly process, the prefabricated member is not required to be carried and overturned, so that the prefabricated member is prevented from being damaged; and specifically, the die is composed of a first master die, a second master die, a first slave die and a second slave die, during form removal, firstly the first slave die and the second slave die are disassembled and assembled, and then one of the first master die or the second master die is removed, so that the demoulding of the prefabricated member is realized.

Owner:界首市宝业瑞祥建筑工业化有限公司

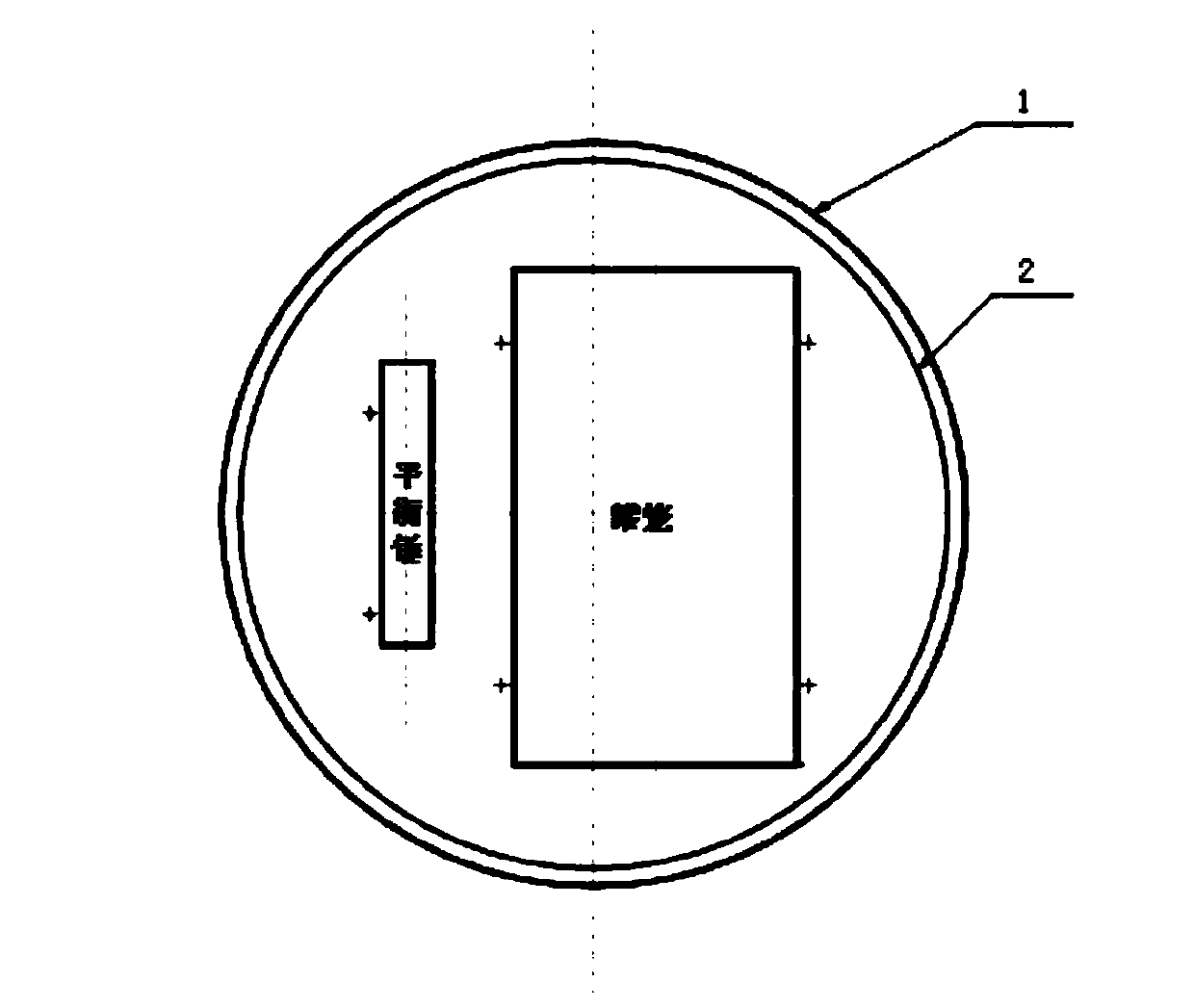

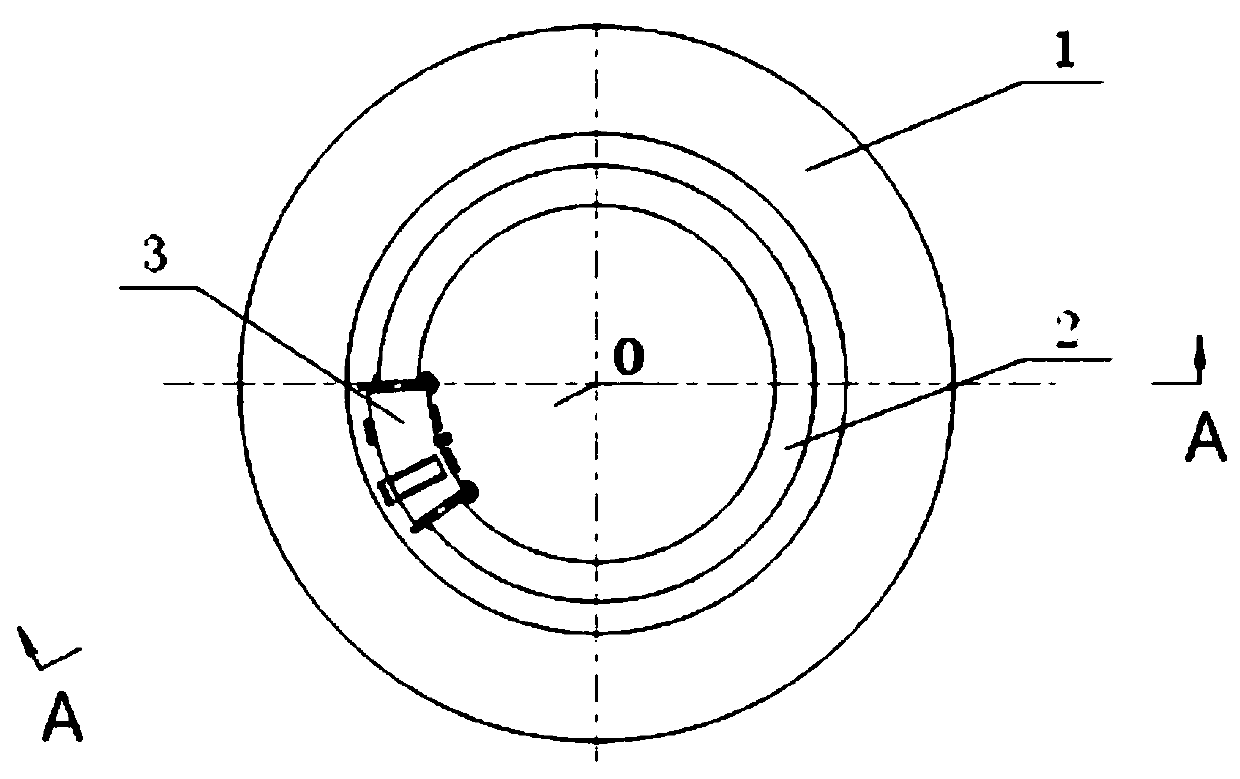

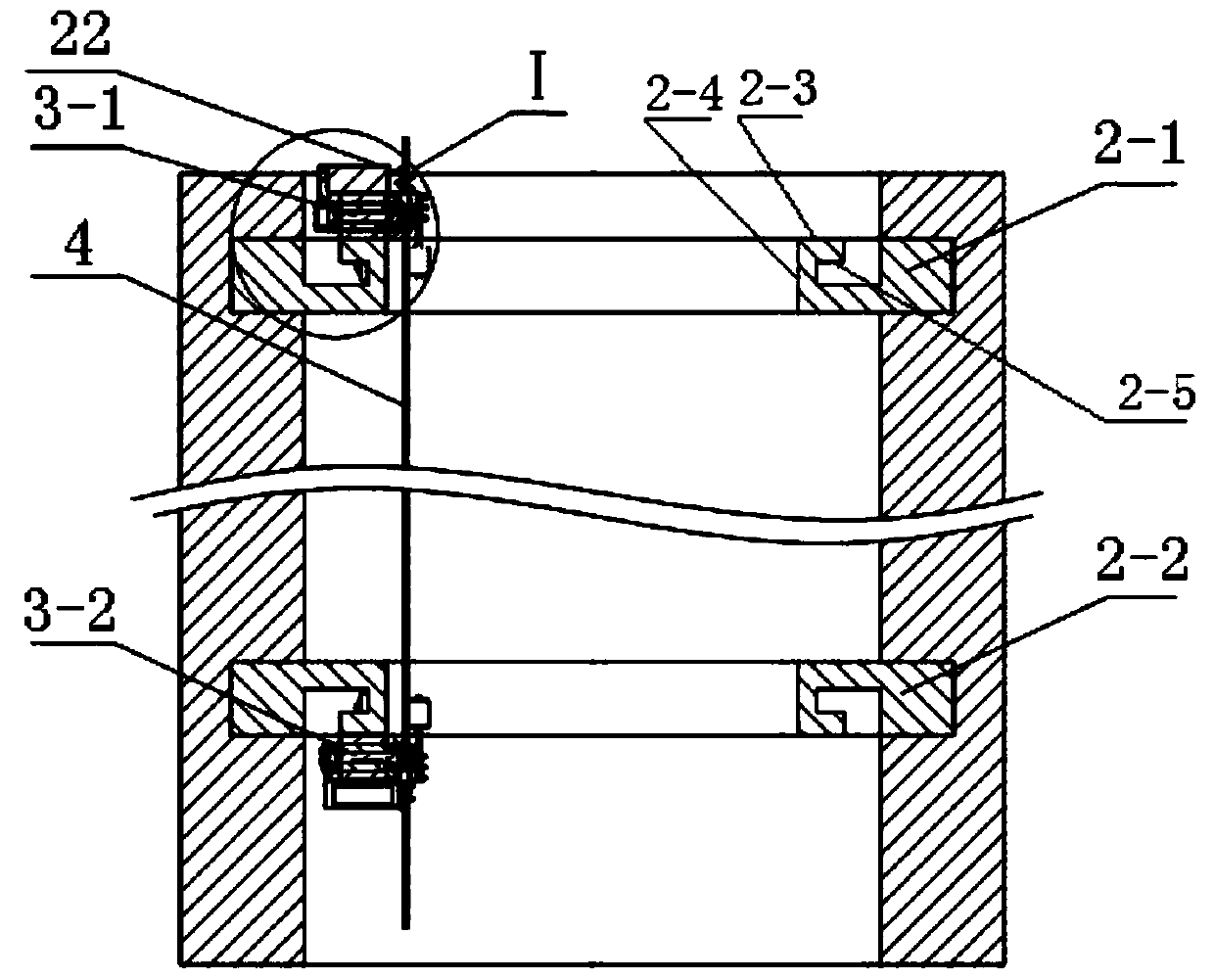

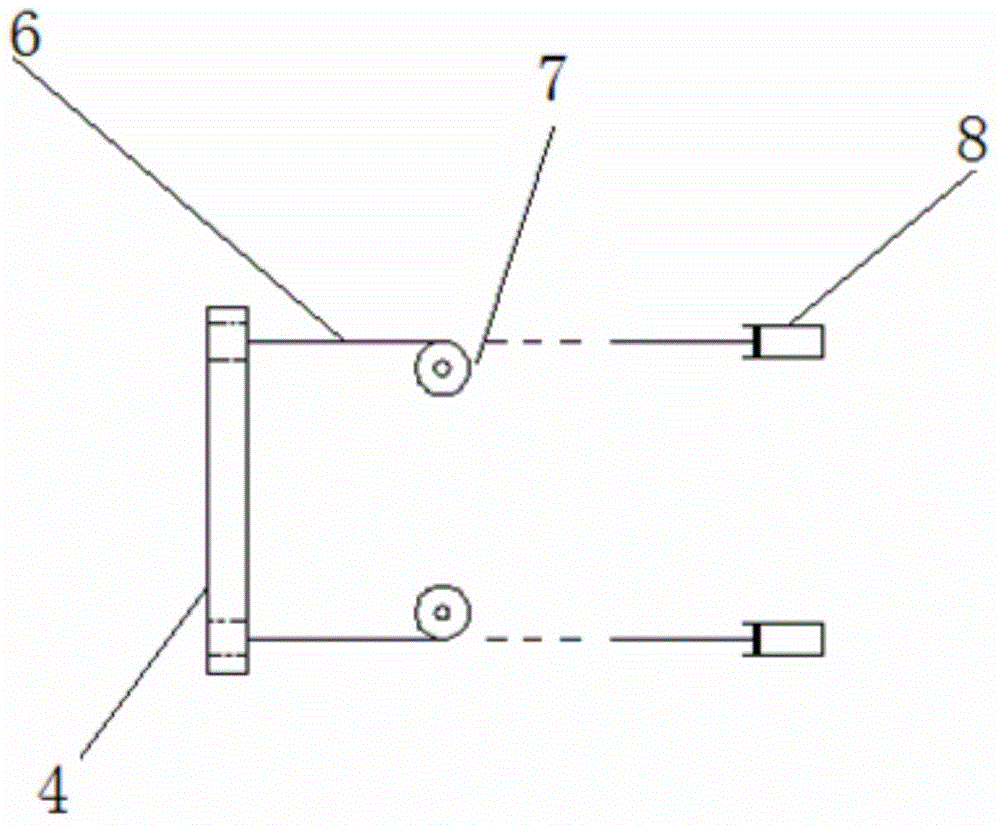

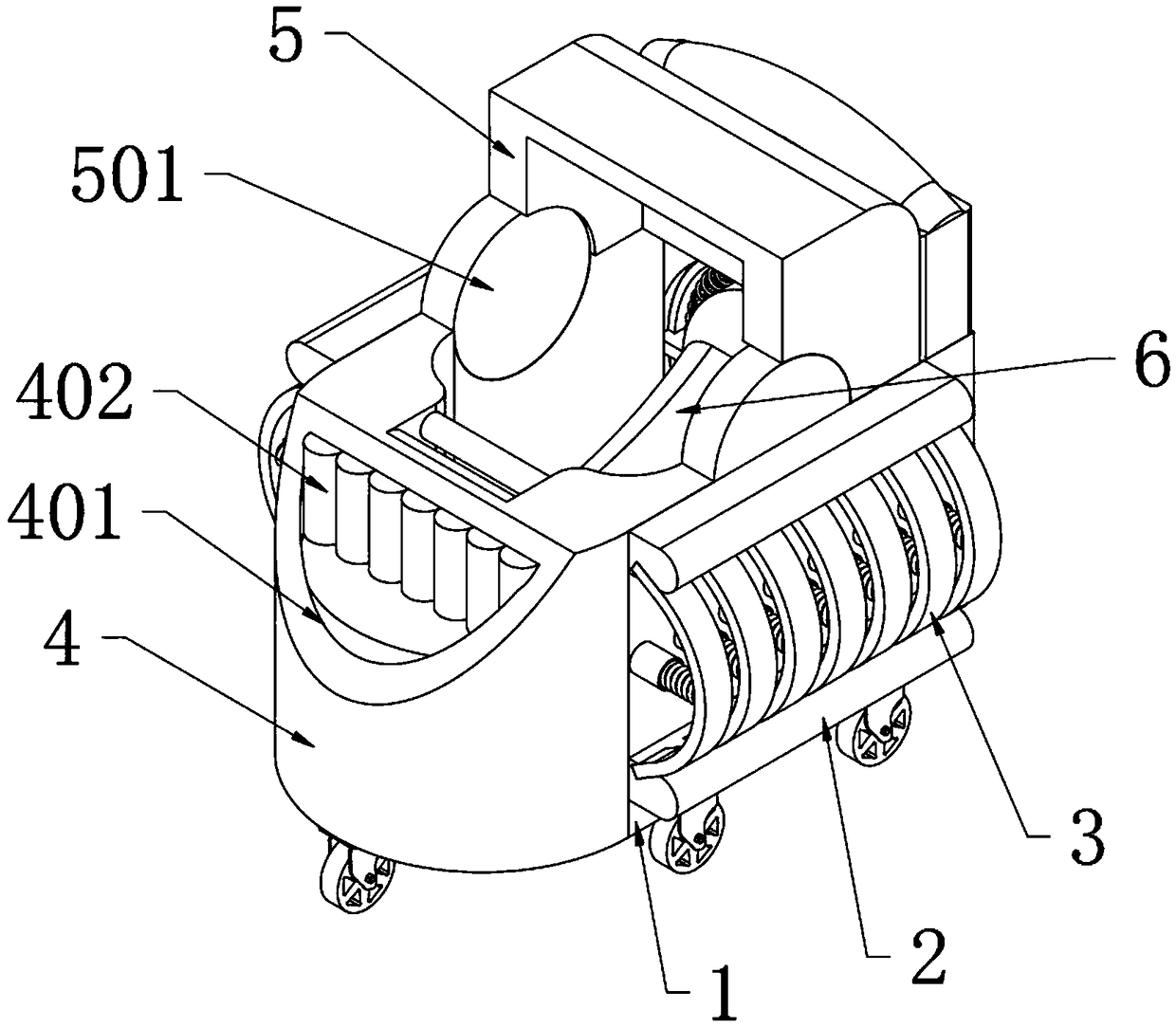

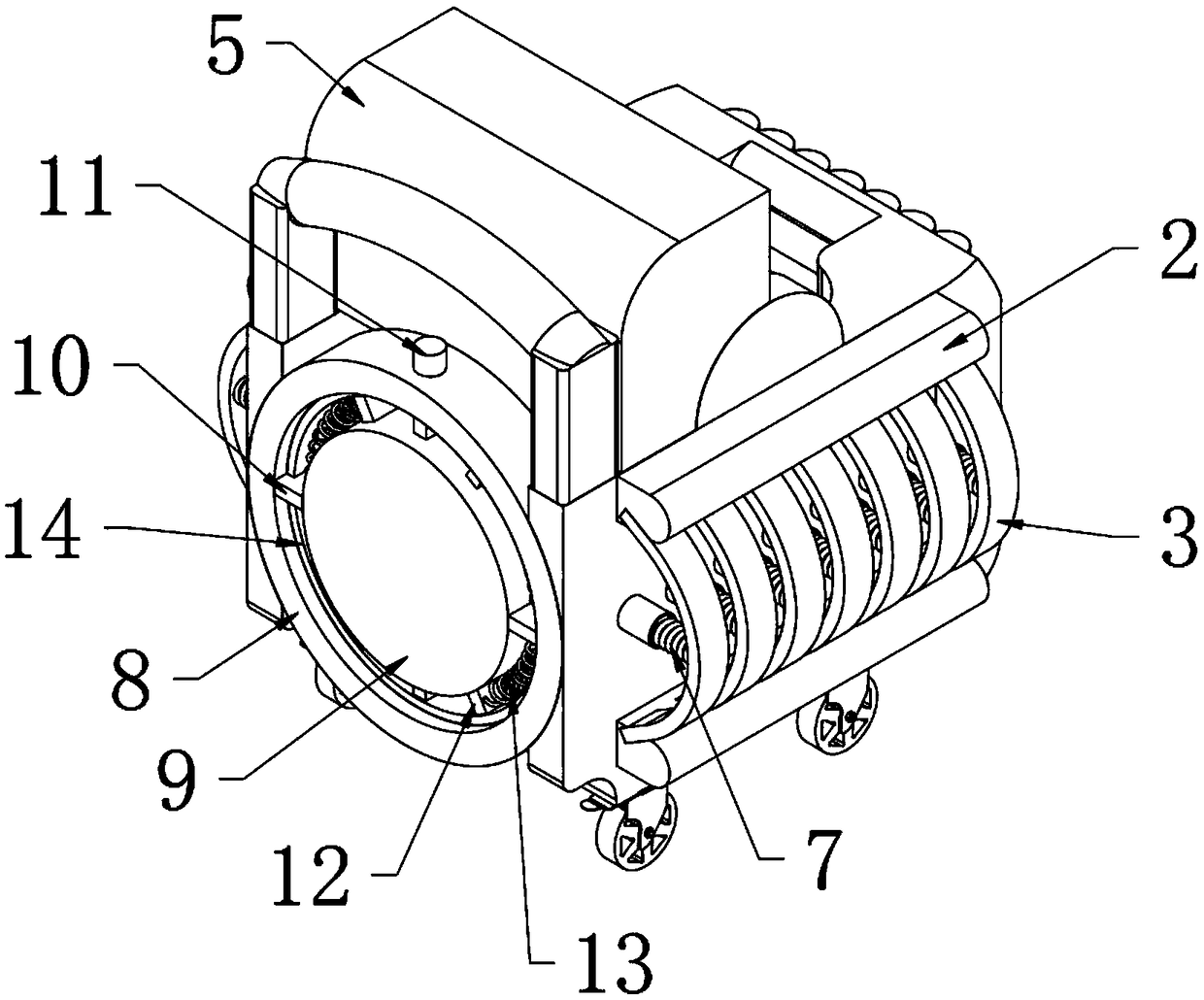

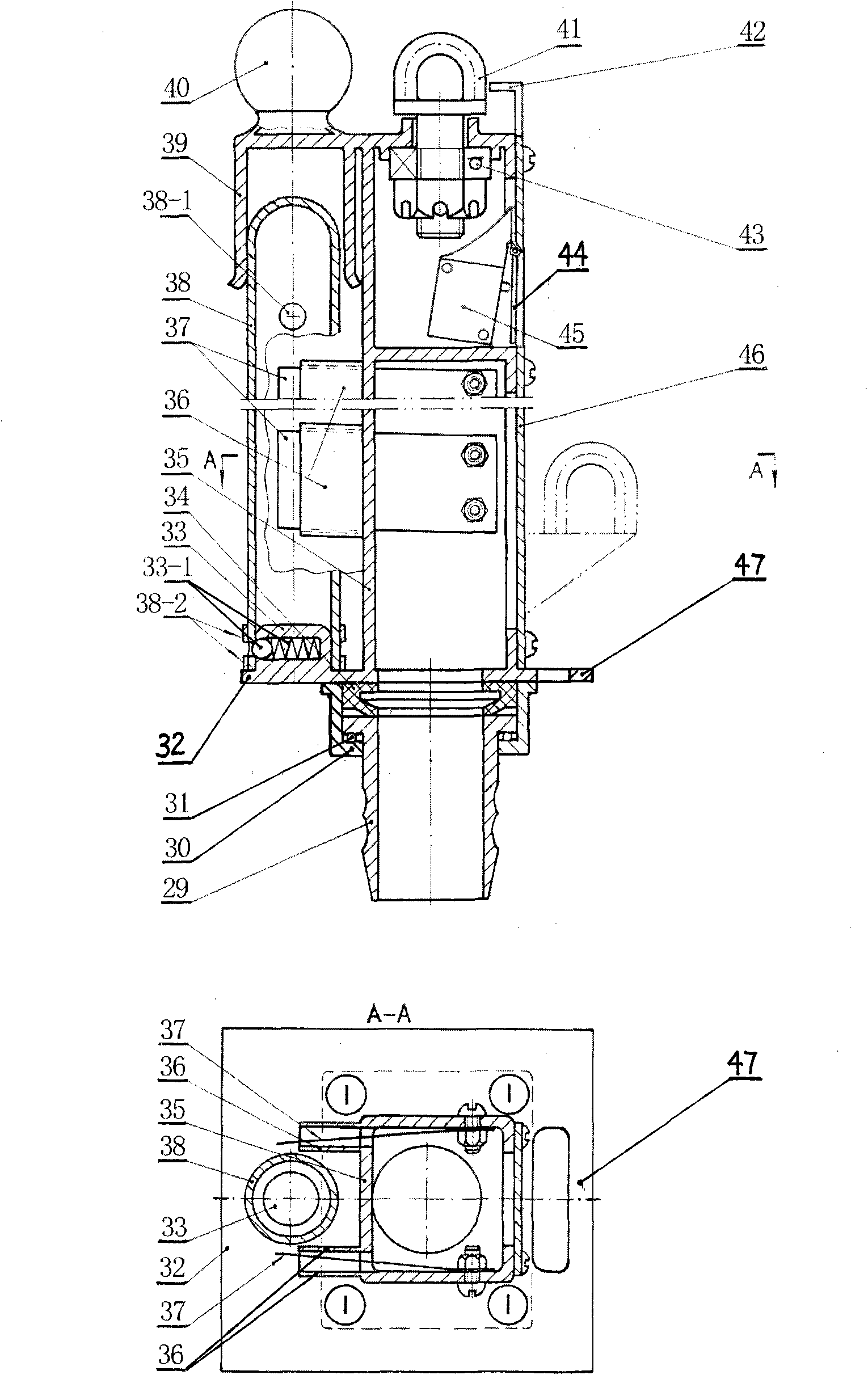

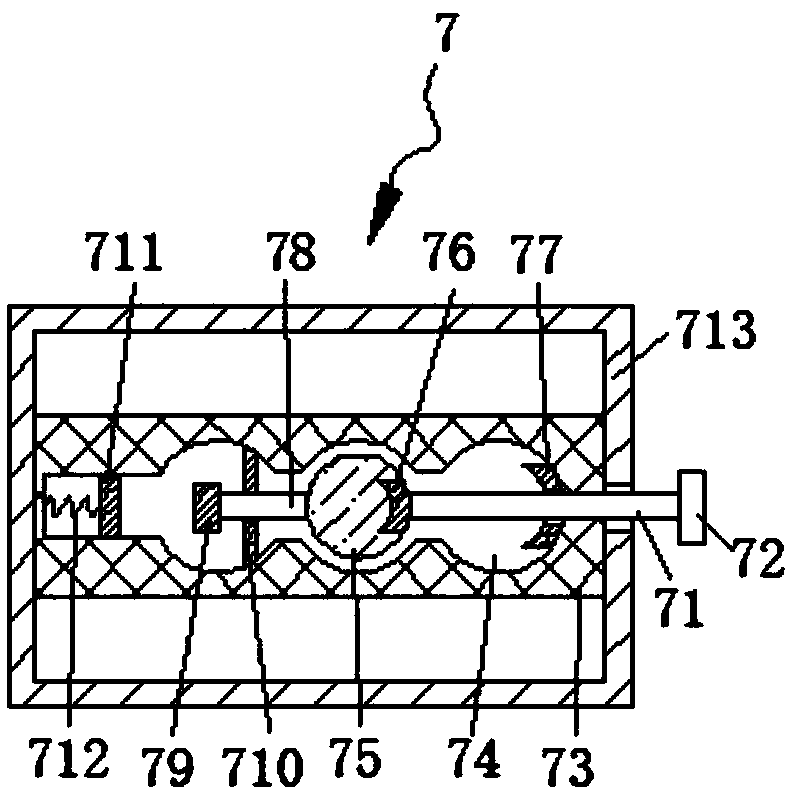

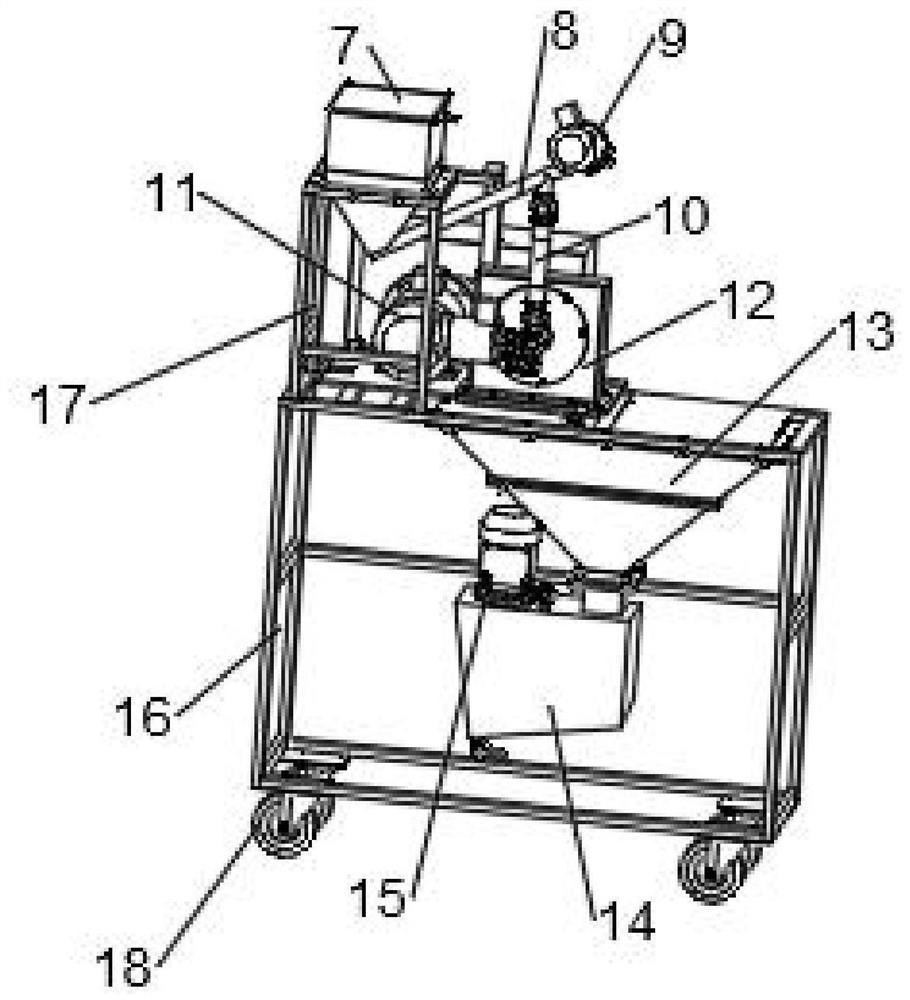

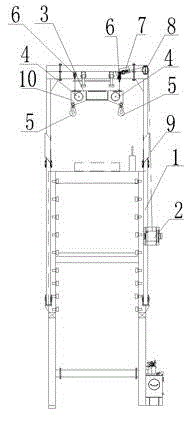

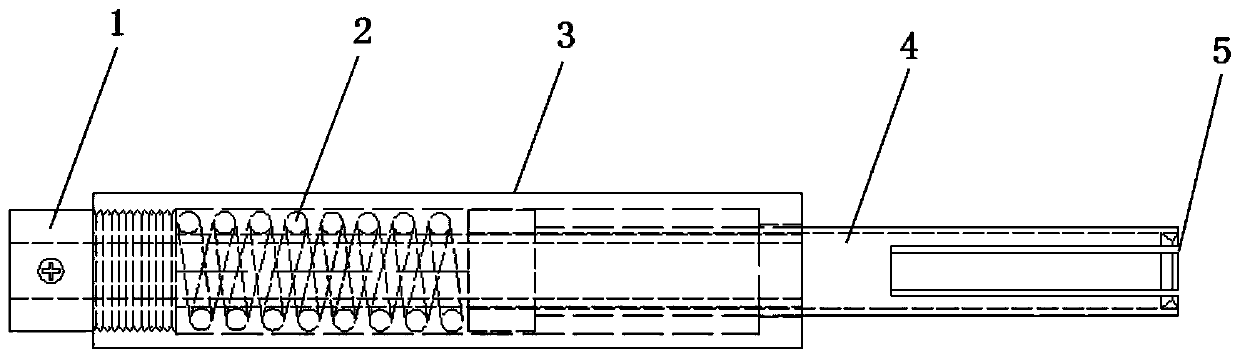

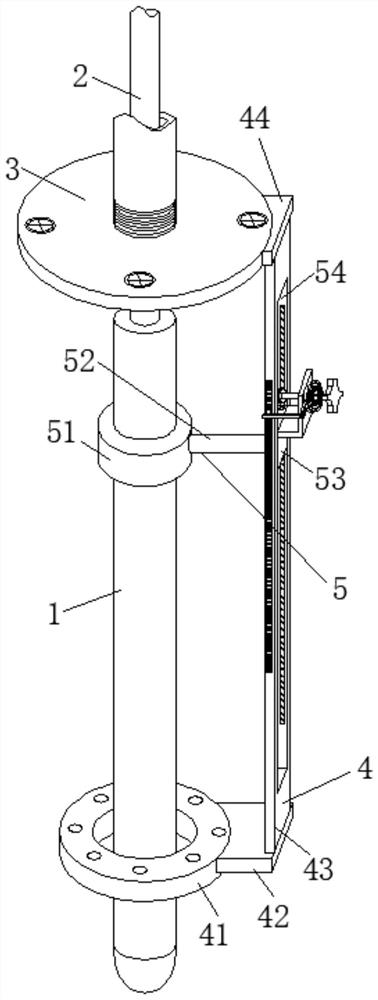

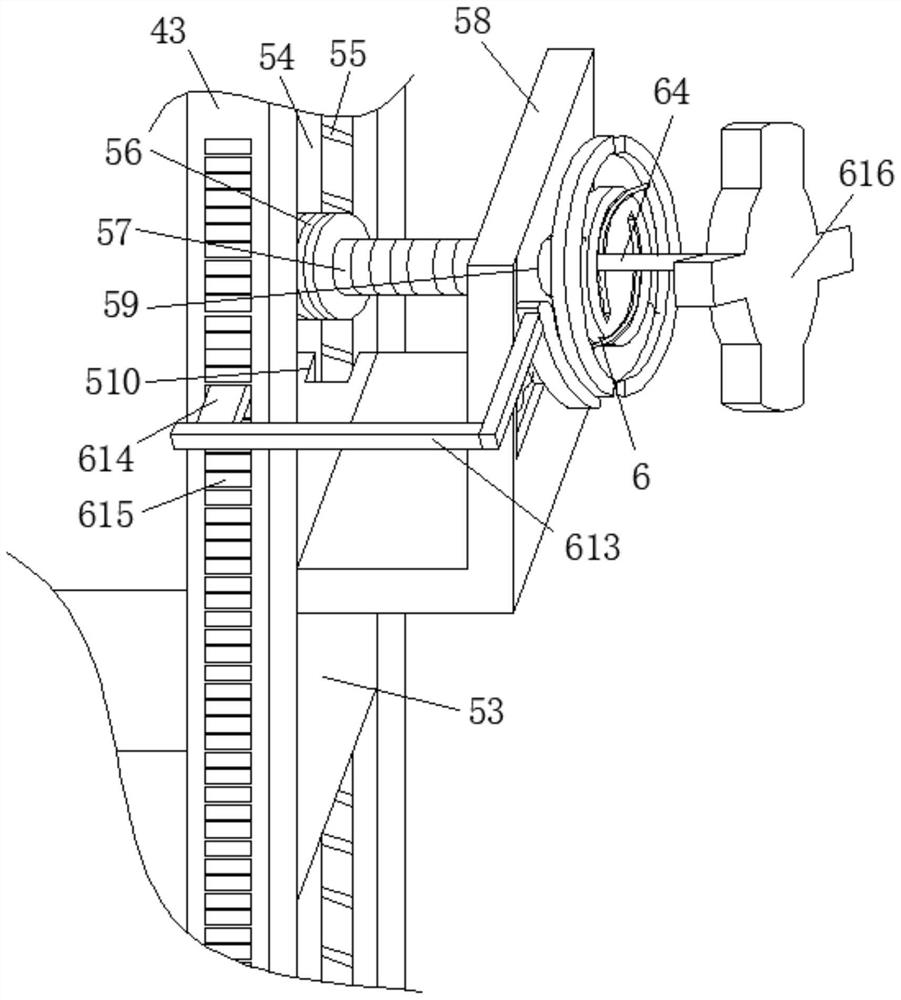

Shaft inspection system and steel wire rope movement device thereof

The invention discloses a shaft inspection system and a steel wire rope movement device thereof. The steel wire rope movement device comprises steel wire rope movement tracks and a movement mechanism;the movement mechanism comprises a shell, a driving motor and several movement idler wheels; the shell is provided with a steel wire rope locking mechanism; the movement idler wheels comprise a driving idler wheel and driven idler wheels; each movement idler wheel is positioned and supported through one idler wheel shaft; a motor base of the driving motor is fixedly installed on the shell, and the power output end of the driving motor is connected with the idler wheel shaft for supporting the driving idler wheel through a speed reducer; the driving idler wheel can drive all the driven idler wheels to move along the steel wire rope movement tracks under power drive of the driving motor. It can be seen that by means of the shaft inspection system, while a shaft inspection robot conducts inspection on the longitudinal direction of a shaft along a steel wire rope, the steel wire rope can move in the circumferential direction of the shaft wall, and thus the problem that a mine monitoring network constituted by the inspection robot cannot cover the interior of the shaft is solved.

Owner:CHINA UNIV OF MINING & TECH

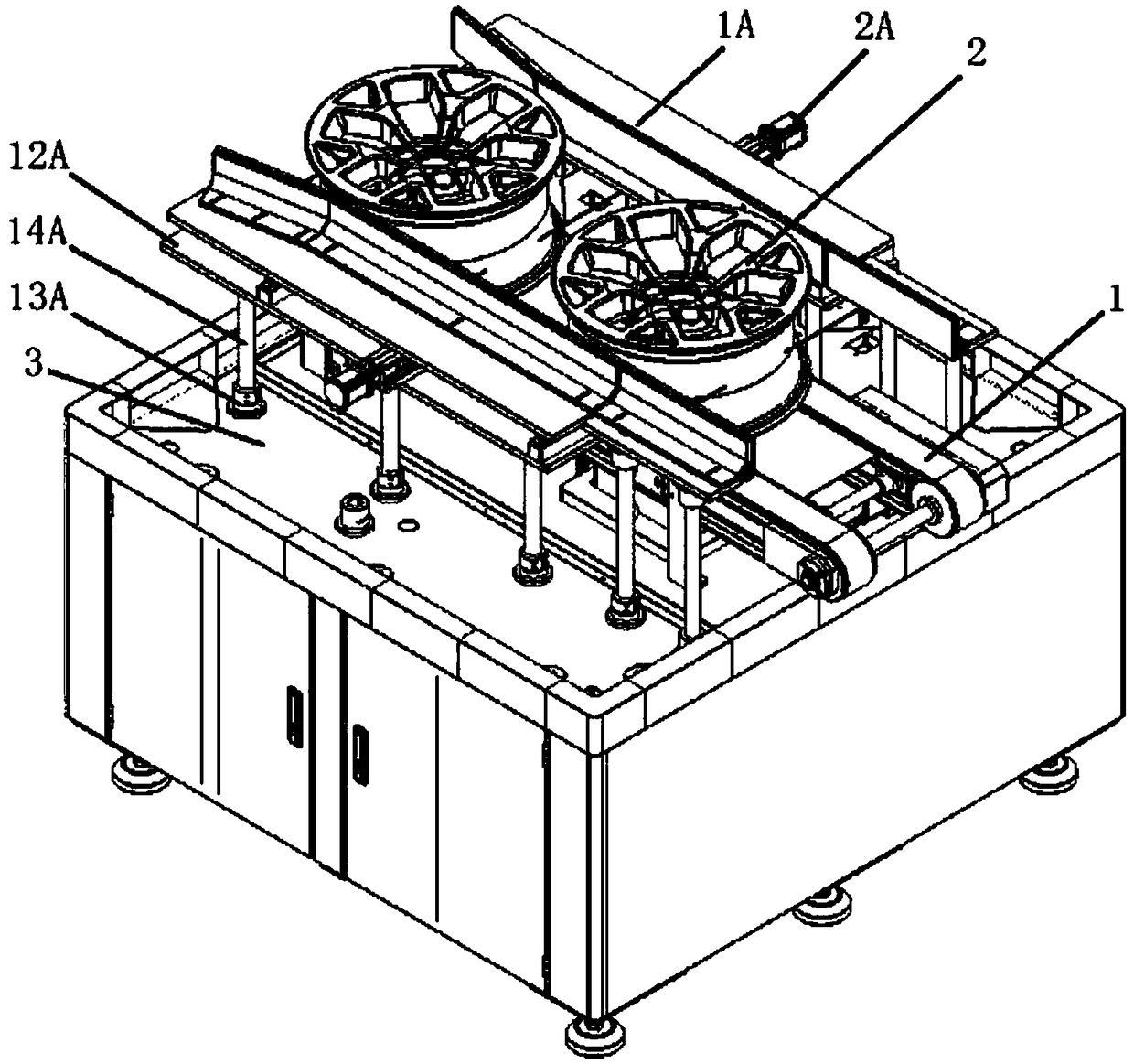

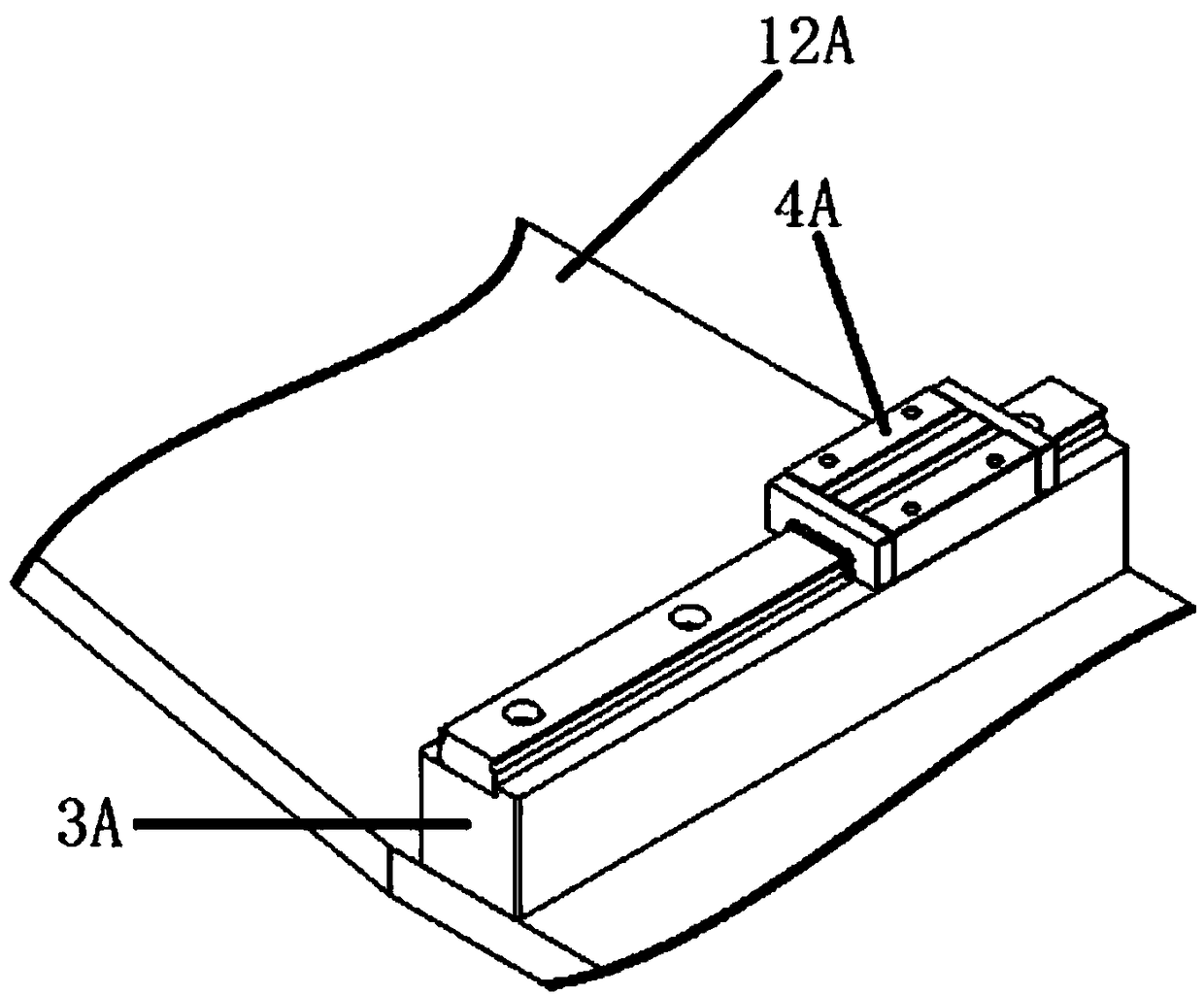

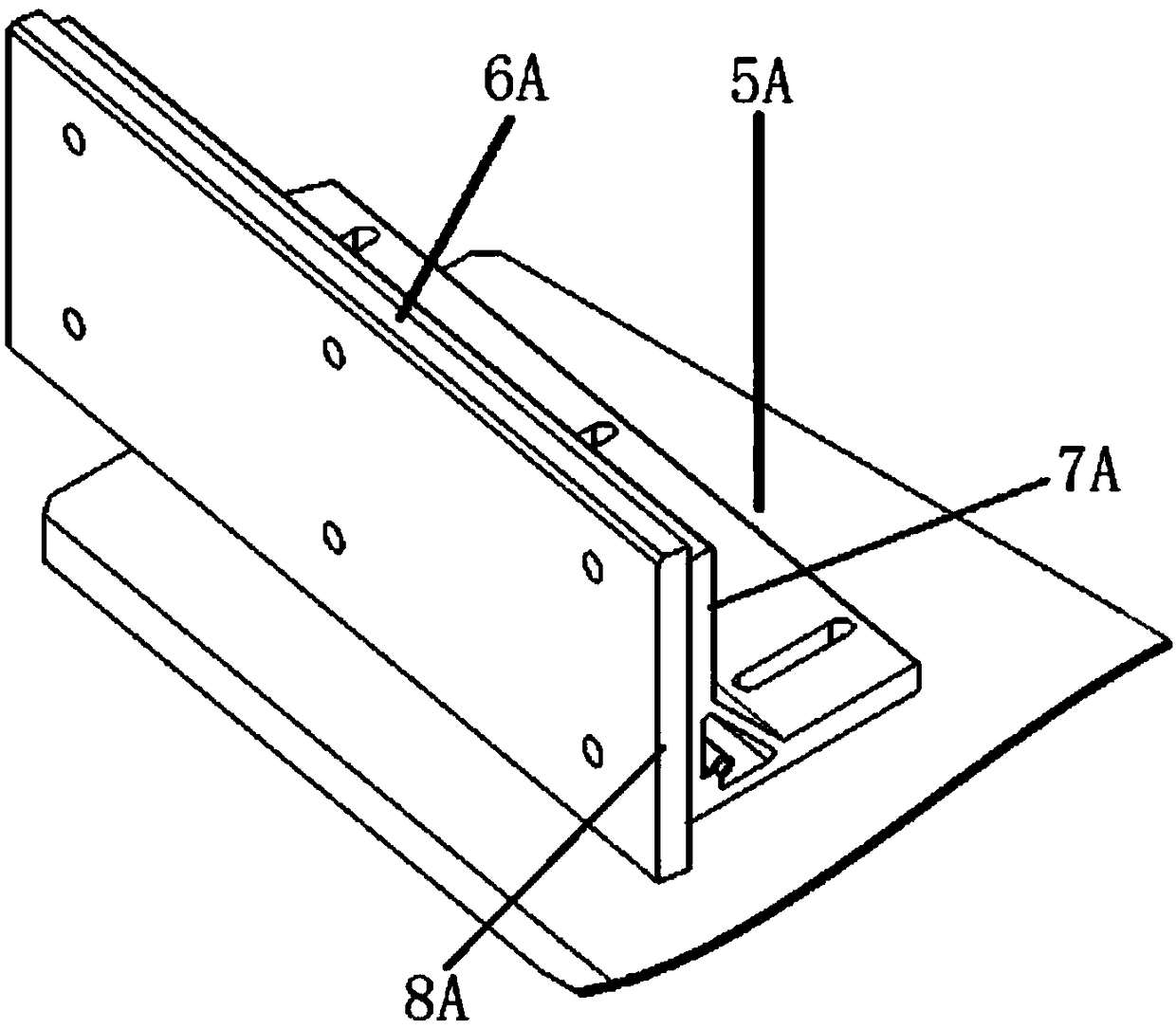

Conveying device

PendingCN108529150AEasy to adjustReduce error rateConveyor partsMechanical conveyorsEngineeringMechanical engineering

Owner:苏州优纳科技有限公司 +2

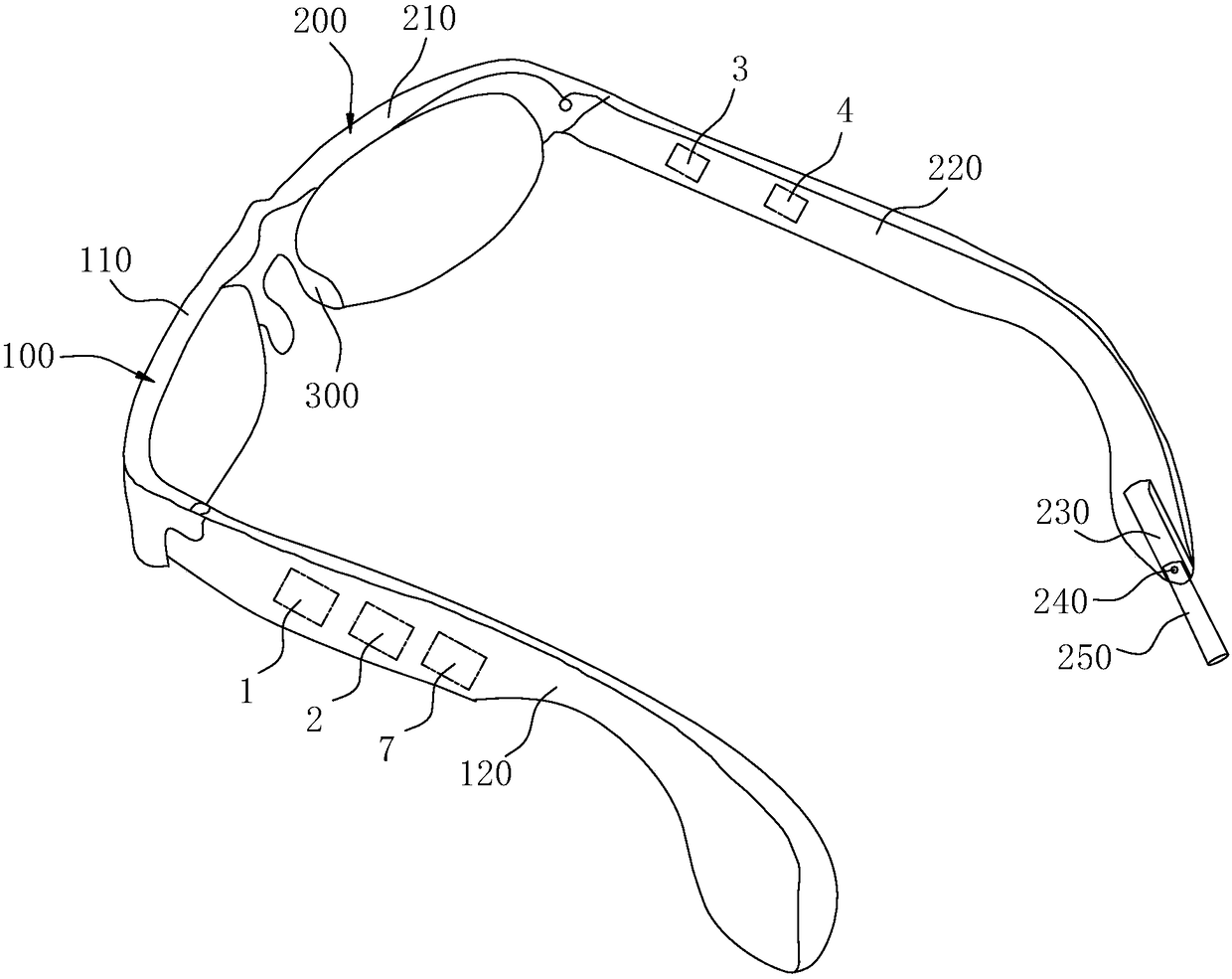

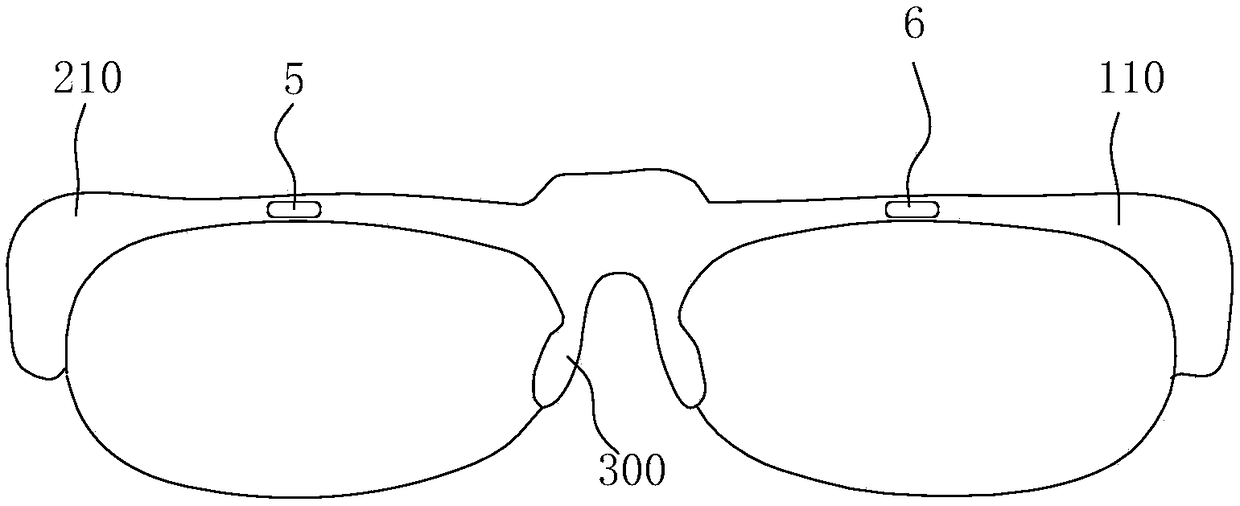

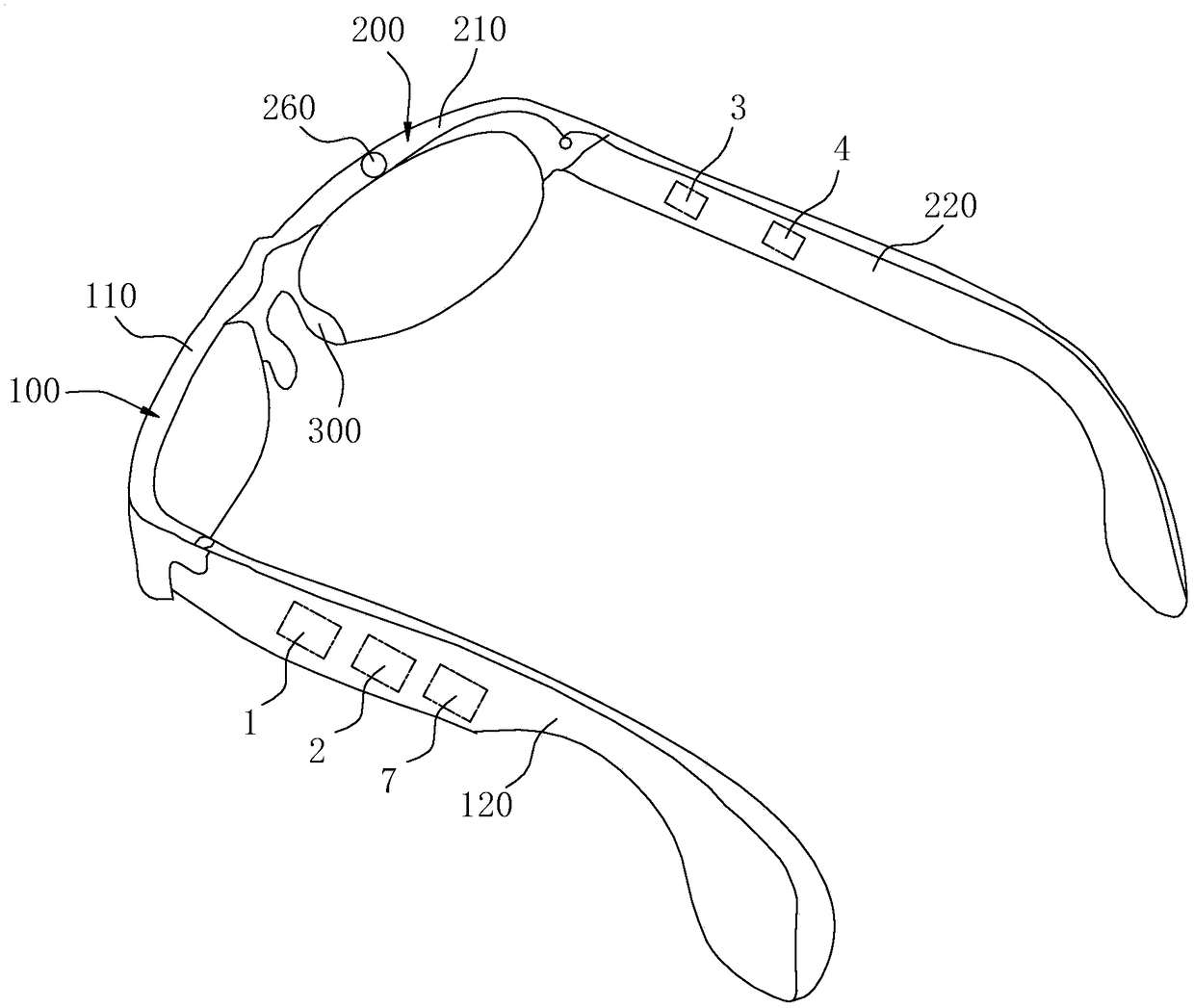

Intelligent glasses frame, glasses and method for controlling intelligent glasses frame

ActiveCN108490644AImprove balanceImprove comfortMeasurement devicesNon-optical adjunctsComputer science

The invention discloses an intelligent glasses frame. The intelligent glasses frame comprises a lens frame body and processing components arranged on the lens frame body for correcting bad habits of using eyes; the lens frame body comprises a left frame and a right frame which are symmetrically arranged; the left frame are connected with the right frame; the processing components comprise a firstset of processing components and a second set of processing components of equal weight; and the first set of processing components are mounted on the left frame and the second set of processing components are mounted on the right frame to balance the left side and right side of the lens frame body. The invention also provides glasses. The glasses comprise a frame of the glasses and lenses arrangedon the frame of the glasses; the frame of the glasses adopts the intelligent glasses frame, is high in wearing comfort, and can correct a user's bad habits of using eyes. The invention further provides a method for controlling the intelligent glasses frame. The method can correct the user's bad habits of using eyes.

Owner:深圳市天之链科技有限公司

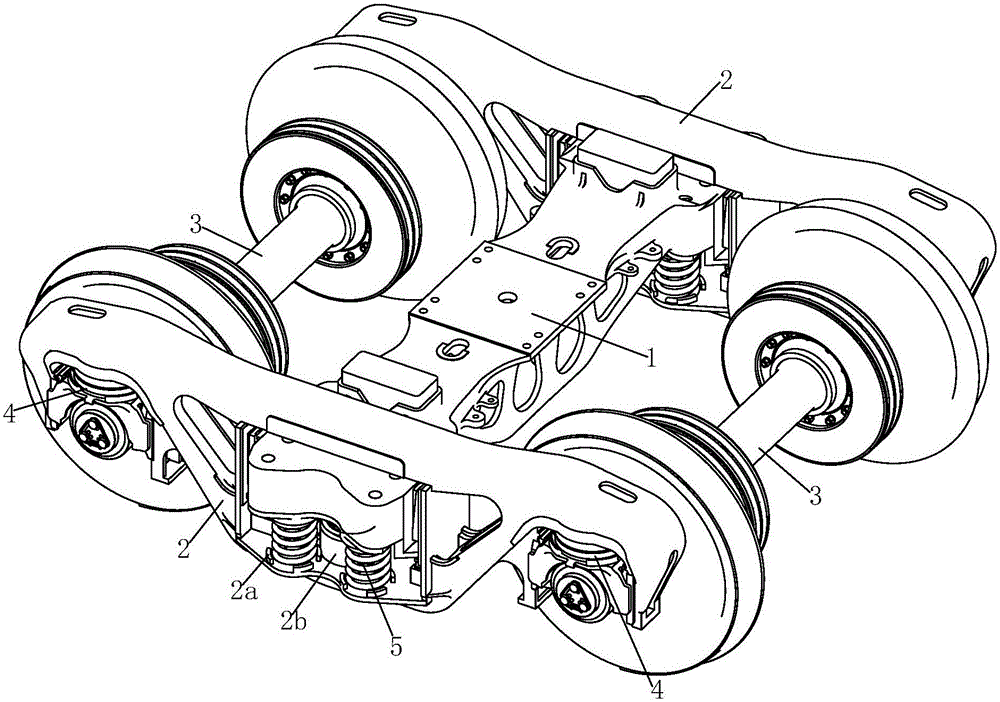

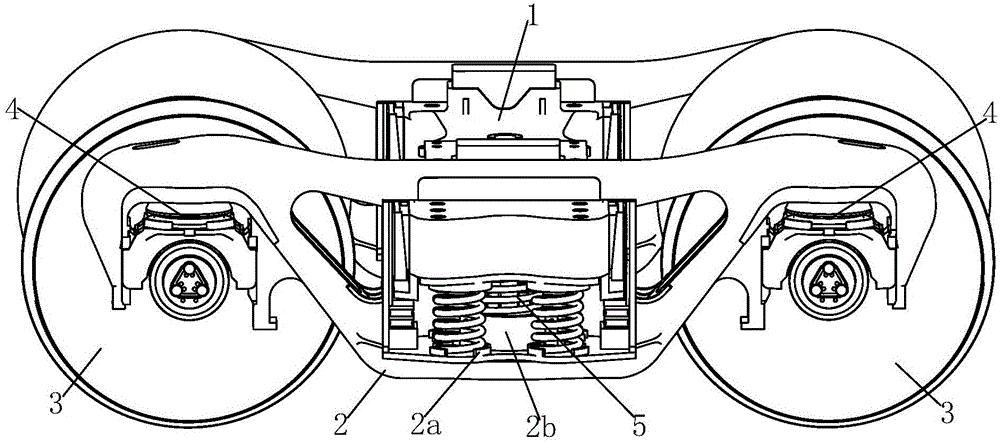

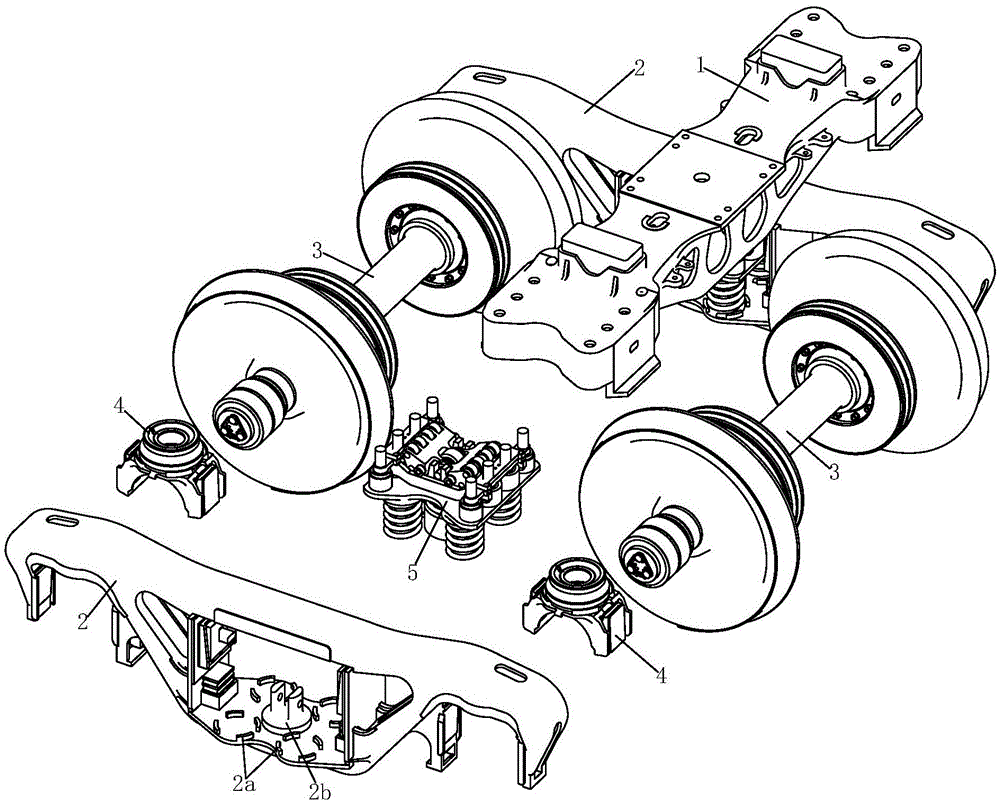

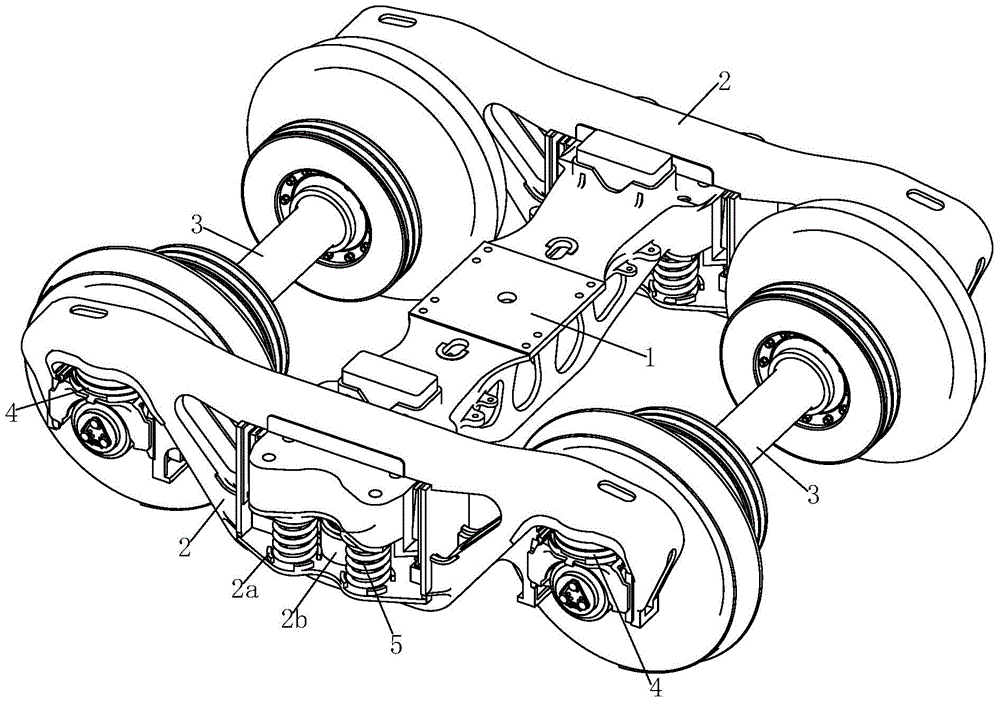

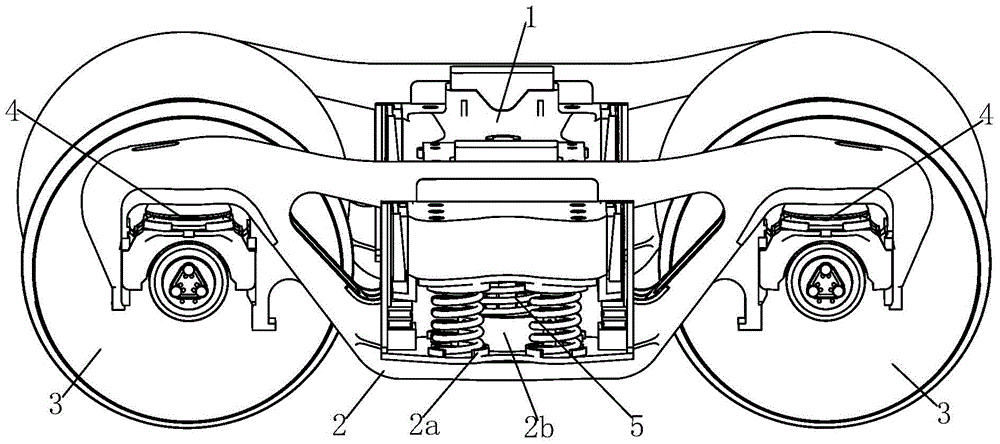

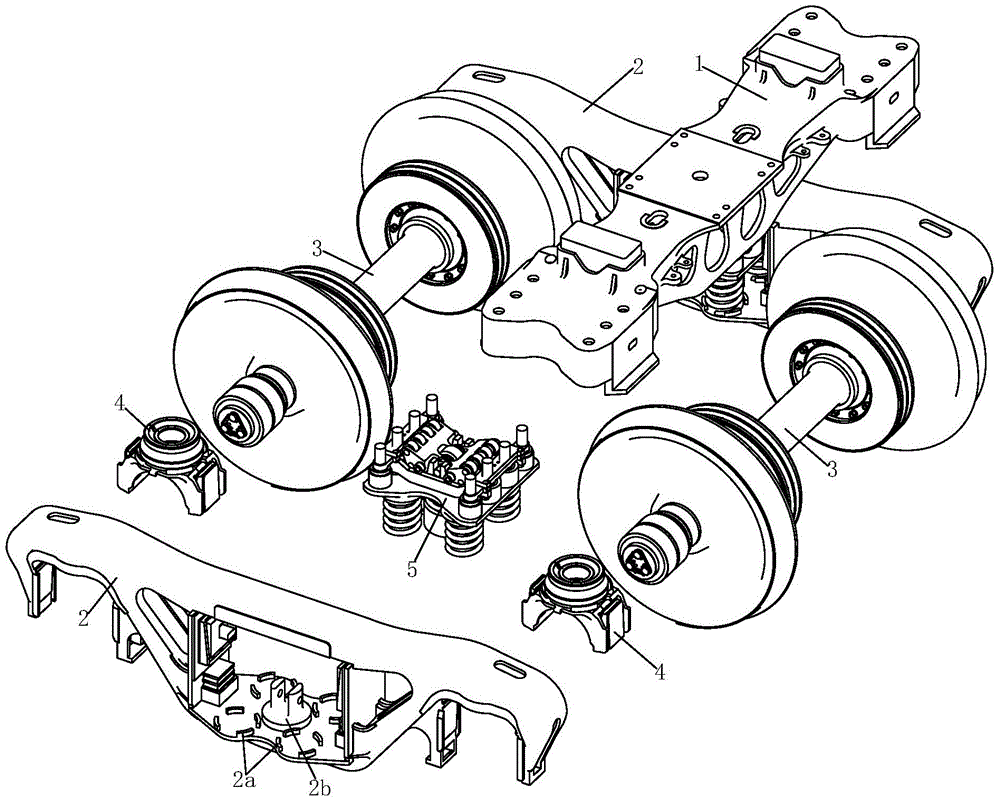

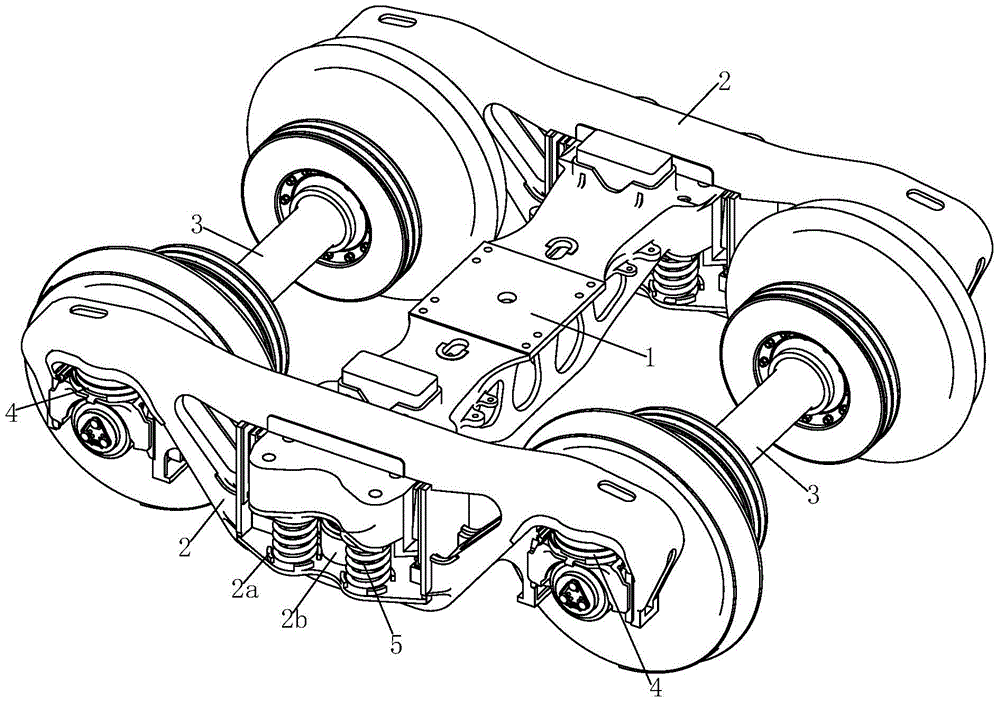

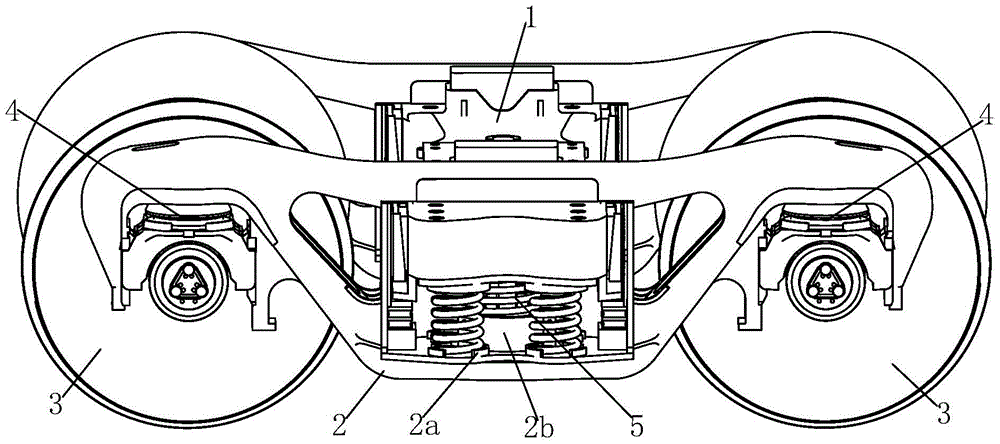

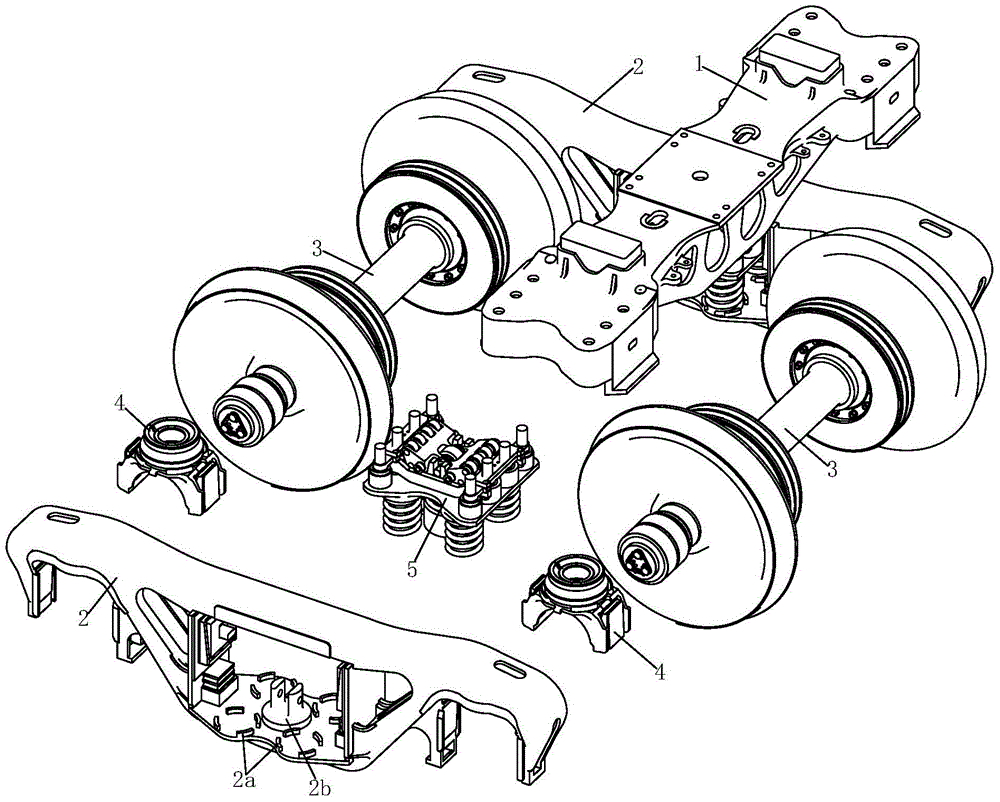

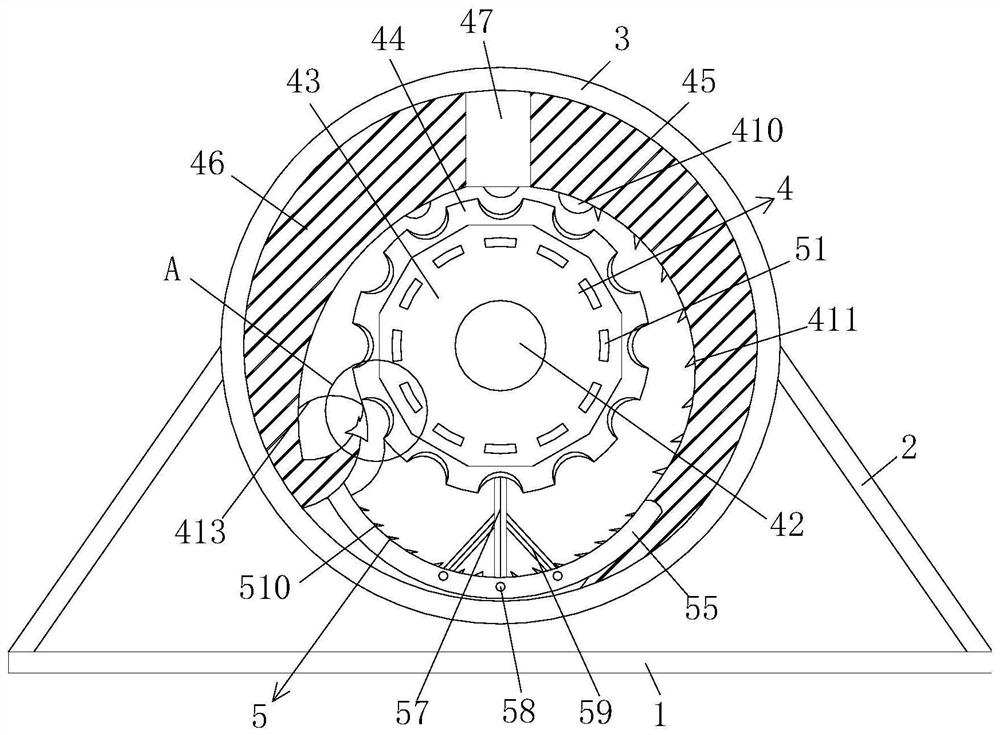

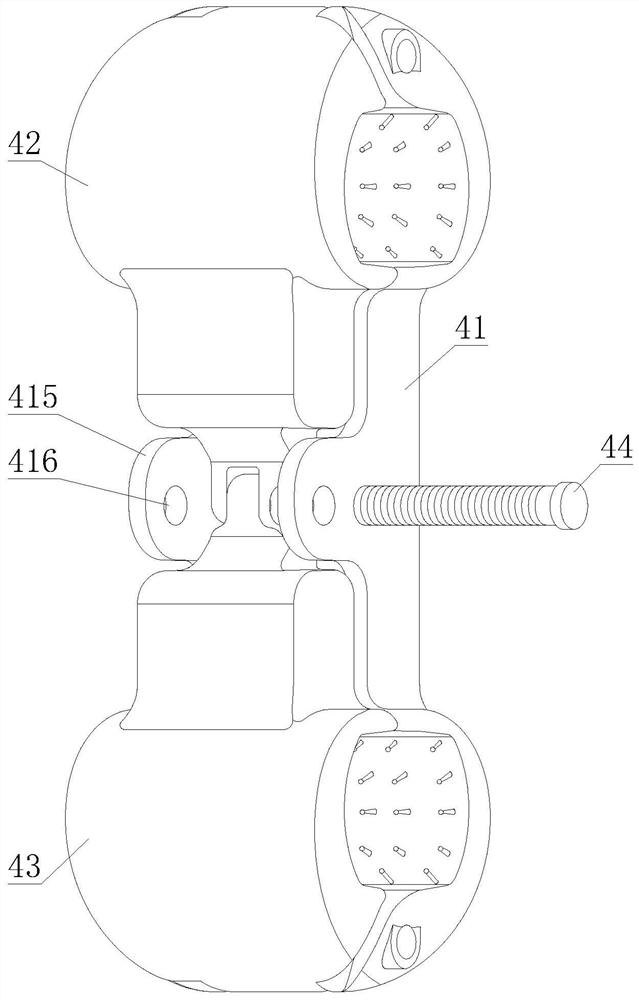

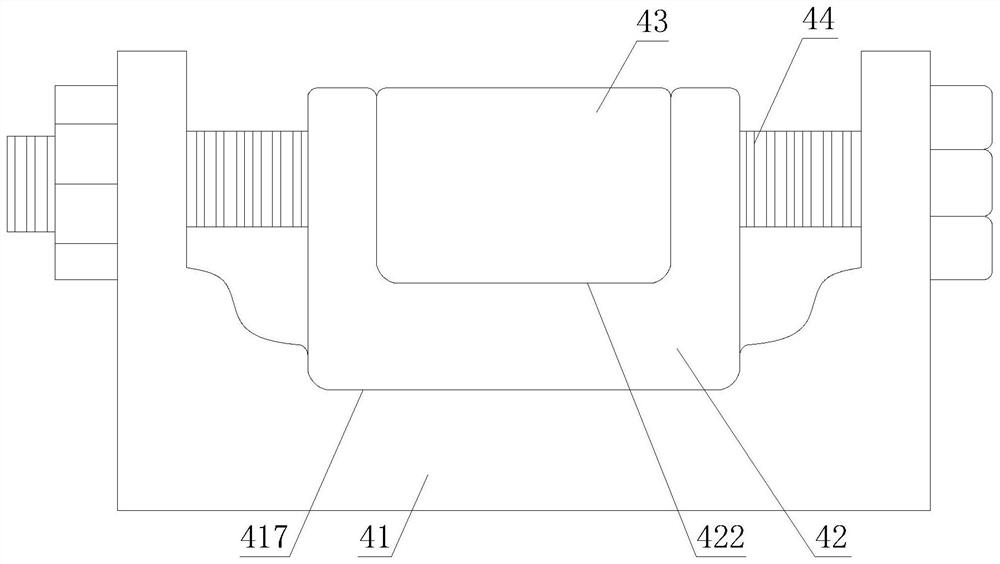

Height self-adjusting bogie of railway wagon

ActiveCN105059306ARealize automatic height adjustmentAchieve automatic reductionBogie-underframe connectionsBogieEngineering

Provided is a height self-adjusting bogie of a railway wagon. The two ends of side frame components of the bogie are arranged on wheel axle components in a bearing mode, height self-adjusting devices are arranged between a swing bolster and the side frame components, each height self-adjusting device comprises a bearing support plate installed on a central square frame through bearing springs, struts are arranged on the two sides of each bearing support plate, each strut is sleeved with a tapper sleeve assembly, a middle support plate is stacked on each bearing support plate, the two sides of the middle support plate are arranged on outer taper sleeves of the tapper sleeve assembly in a sleeved mode respectively, a limiting frame is arranged on the upper portion of the middle support plate, the two sides of the limiting frame are arranged on the struts in a sleeved mode respectively, convex rings are arranged on the bottom face of the limiting frame, through holes are formed in the center of the middle support plate and the center of the bearing support plate respectively, a pull rod is installed in the through holes, the upper end of the pull rod is hinged to the hinge end of a left crank throw and the hinge end of a right crank throw, the free ends of the left crank throw and the free ends of the right crank throw are each provided with upper rolling wheels and lower rolling wheels, limiting rolling shafts are arranged in the middle of the left crank throw and the middle of the right crank throw, a return spring is arranged below the middle support plate, the upper surface of the middle support plate abuts against the lower rolling wheels, the upper rolling wheels abut against the inner surface of the swing bolster, and the swing bolster is arranged on the struts in a sleeving mode. The height self-adjusting bogie of the railway wagon is suitable for railway wagons.

Owner:CRRC YANGTZE CO LTD

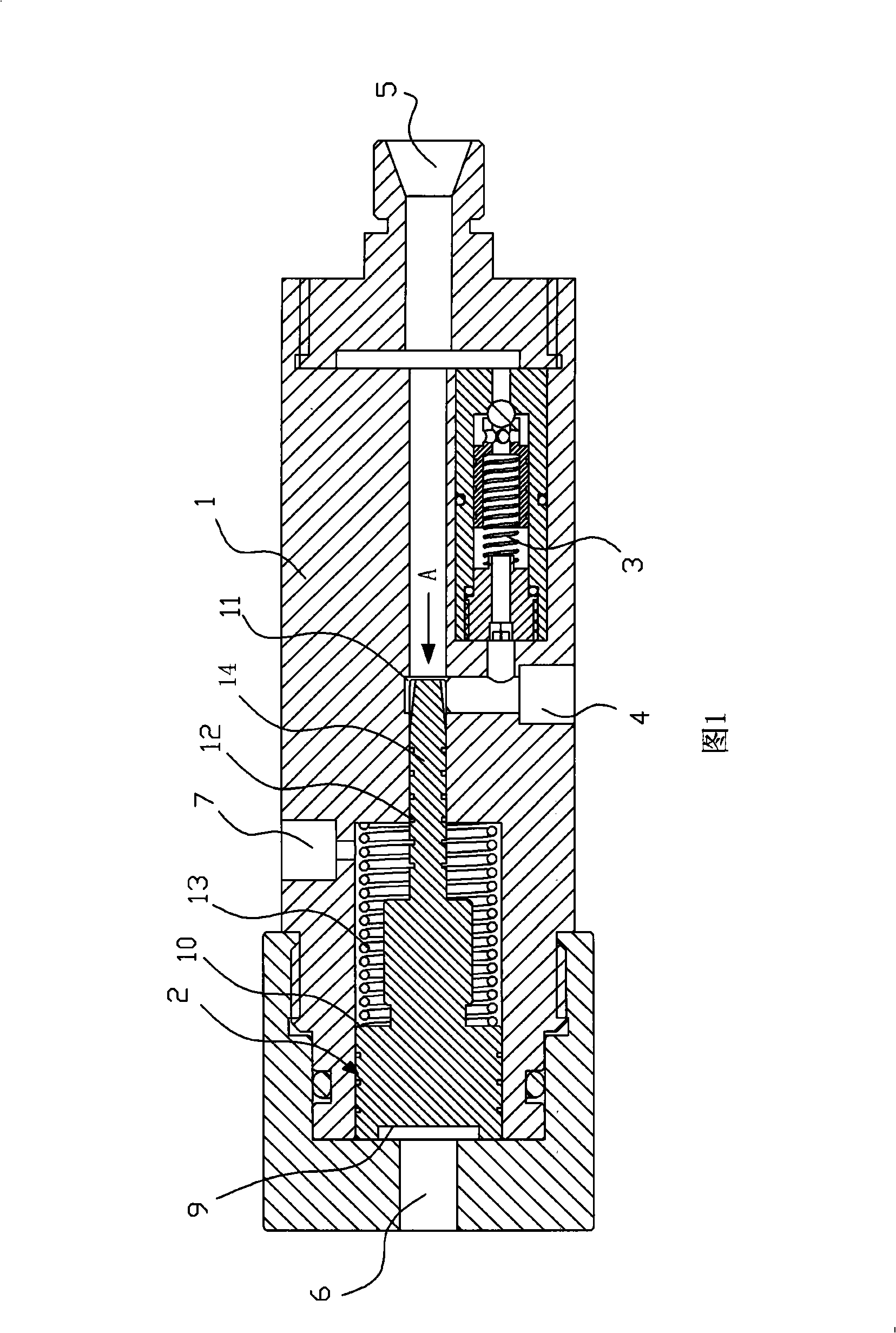

Double-feedback fluid-control one-way throttle velocity modulation composite valve

ActiveCN101349148ADrill back quicklyPrevent sidewaysWell/borehole valve arrangementsSealing/packingFluid controlEngineering

The invention discloses a double feedback hydraulic control one-way throttle governing combination valve which comprises a valve body. A first oil channel and a second oil channel for passing high-pressure oil are connected in series on the valve body. The valve body is also provided with a throttle valve for switching on or off the first oil channel and the second oil channel, a one-way valve is arranged in parallel between the first oil channel and the second oil channel, and the valve body is also provided with two feedback oil ports for controlling the opening status of the throttle valve. The combination valve adopts two hydraulic pressure signals to control the size of a throttle orifice; the one-way valve and the throttle valve are integrated into a whole; the throttle valve works while doing the forward movement, and the one-way valve works while doing the backward movement; and the two pressure signals have no impact on the one-way valve. Thus, the throttle orifice works and the drilling rate is slower when a core is drilled during the coring process; and the one-valve works to realize rapid drilling and retreating when the rapid drilling and retreating is required.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Height self-adjusting device of railway wagon

ActiveCN105059307ARealize automatic height adjustmentAchieve automatic reductionBogie-underframe connectionsAgricultural engineeringEngineering

The invention discloses a height self-adjusting device of a railway wagon. The height self-adjusting device of the railway wagon comprises a bearing support plate installed on a central square frame through bearing springs, struts are arranged on the two sides of the bearing support plate, each strut is sleeved with a tapper sleeve assembly, a middle support plate is installed on the bearing support plate in a stacking mode, the two sides of the middle support plate are installed on outer taper sleeves of the tapper sleeve assembly in a sleeved mode, a limiting frame is arranged on the upper portion of the middle support plate, the two sides of the limiting frame are arranged on the struts in a sleeved mode respectively, convex rings are arranged on the bottom face of the limiting frame, through holes are formed in the center of the middle support plate and the center of the bearing support plate respectively, a pull rod is installed in the through holes, the upper end of the pull rod is hinged to the hinge end of a left crank throw and the hinge end of a right crank throw, the free ends of the left crank throw and the free ends of the right crank throw are each provided with upper rolling wheels and lower rolling wheels, limiting rolling shafts which can form limiting with the limiting frame are arranged in the middle of the left crank throw and the middle of the right crank throw, the left crank throw and the right crank throw are located on the upper portion of the middle support plate, a return spring is arranged below the middle support plate, and the upper surface of the middle support plate abuts against the lower rolling wheels. The height self-adjusting device of the railway wagon is suitable for railway wagons.

Owner:CRRC YANGTZE CO LTD

Collision energy absorption device of emergency lane

InactiveCN104863074APrevent sidewaysSafe parkingRoadway safety arrangementsEnergy absorptionAbsorbed energy

The invention discloses a collision energy absorption device of an emergency lane. The collision energy absorption device mainly comprises a fastened barrier, constraint enclosing walls and an energy absorption baffle, wherein the energy absorption baffle has the function of absorbing energy, the constraint enclosing walls can prevent vehicles from tilting, and the fastened barrier can stop vehicles out of control, so that the vehicles cannot continue to go forward . A set of collision energy absorption device is mounted at the tail end of the emergency lane, when a vehicle runs down a long slope, the brake of the vehicle is invalid, and the vehicle is forced to run into the emergency lane, so that vehicles running at different speeds can be guaranteed to be braked by a braking bed of the emergency lane in a limited distance at first, and then are forced to pass through the collision energy absorption device mounted at the tail end of the emergency lane, and finally, the vehicles stop safely and reliably.

Owner:GUANGXI UNIV

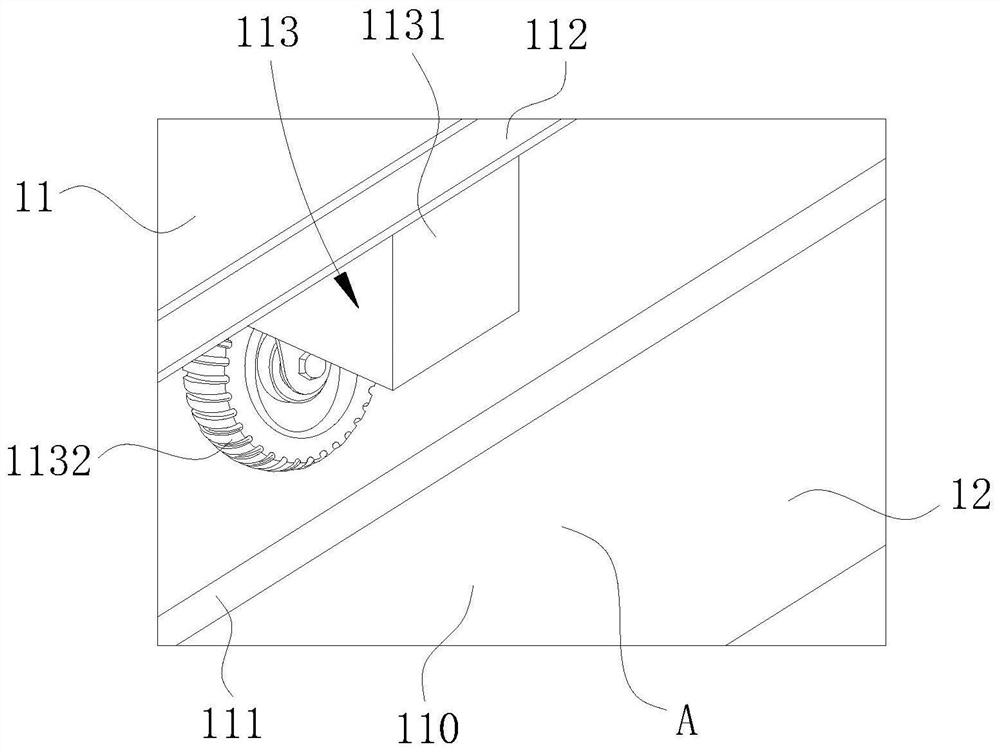

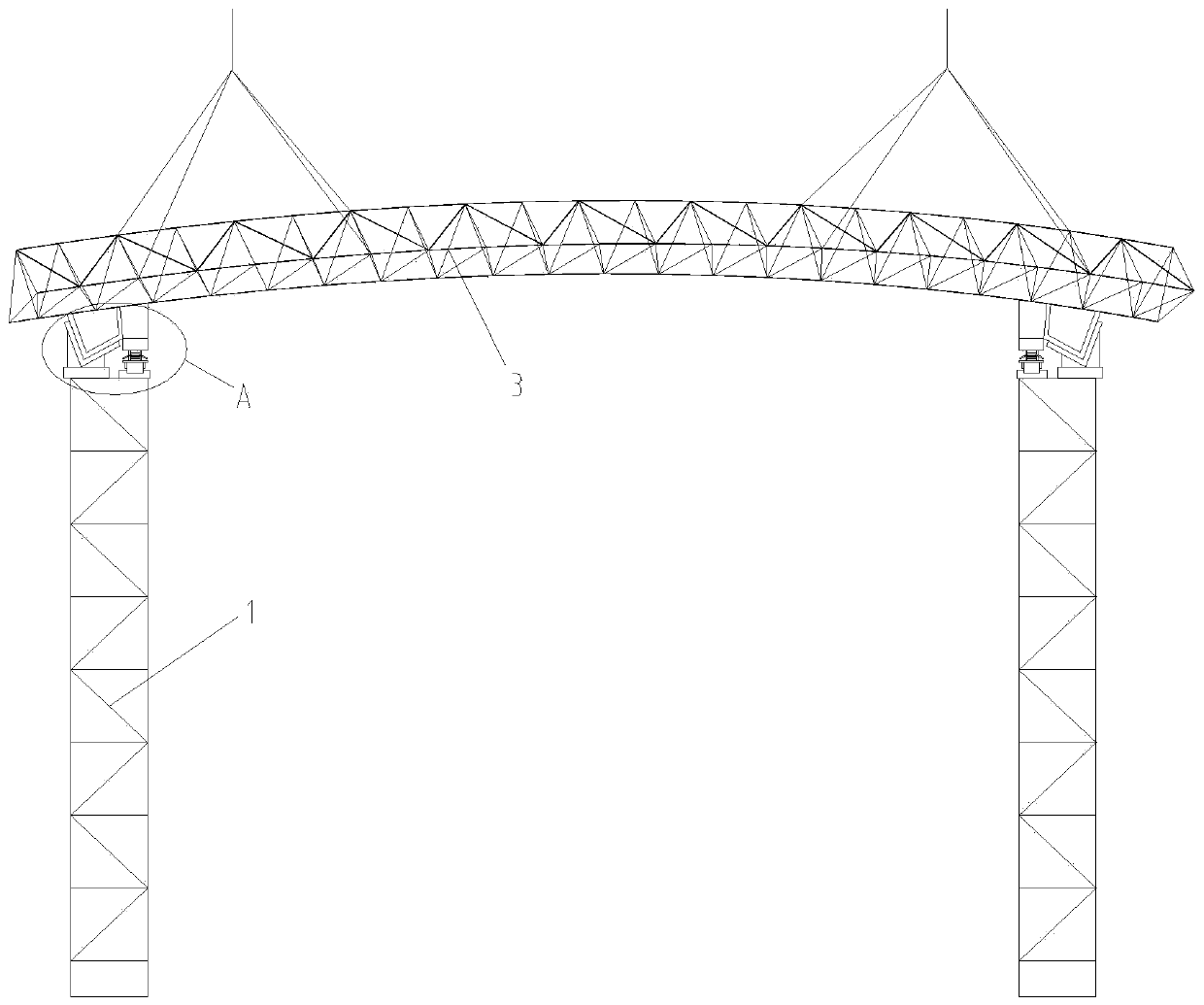

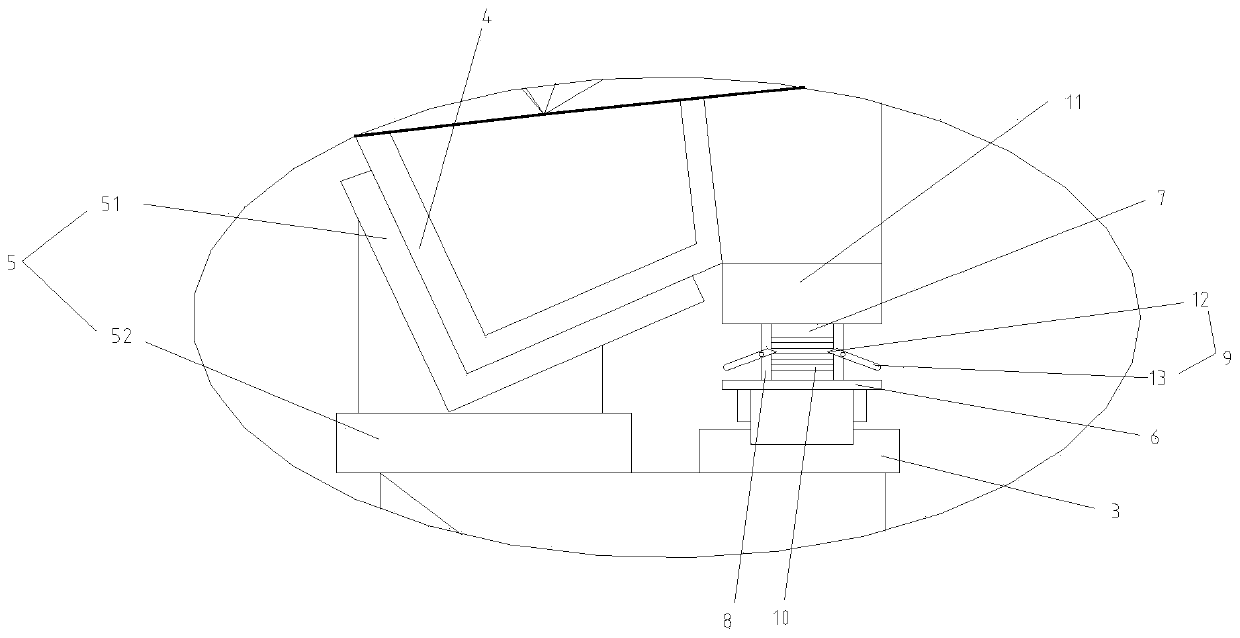

Large-span steel structure roof hoisting construction method in complex environment

ActiveCN110863568AReduce collisionEnsure structural stabilityBuilding roofsArchitectural engineeringLong span

The invention discloses a large-span steel structure roof hoisting construction method in a complex environment, and belongs to the field of large roof hoisting engineering. According to the method, asegmented steel truss roof is hoisted at three equal division points through two crawler cranes, meanwhile, the structure stability is ensured through the 30-60-degree included angle between a chainand the steel truss roof, collision between the structures can be reduced through a road wheel assembly and a walking track, in addition, the construction cost can be reduced, the construction steps are simplified, and the operation safety is improved. The segmented steel truss roof is stably moved to the tops of required vertical supporting columns, supporting seats and fixing pieces are connected into a whole, then, positioning grooves are separated by adjusting locking units, and accordingly, the road wheel assembly is integrally dismantled. Side slip in the construction process is avoided,accordingly, the safety is improved, meanwhile, the installation accuracy of the steel truss roof is ensured, operation steps are decreased, and the construction cost is reduced.

Owner:CHINA MCC17 GRP

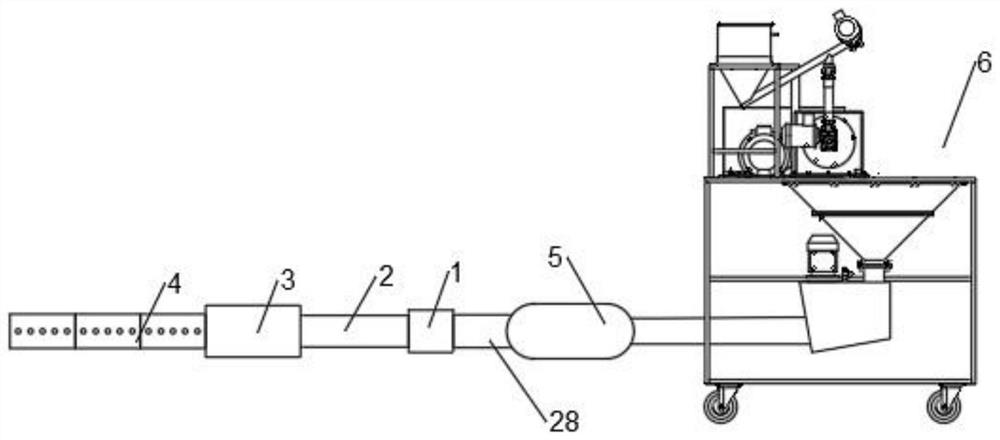

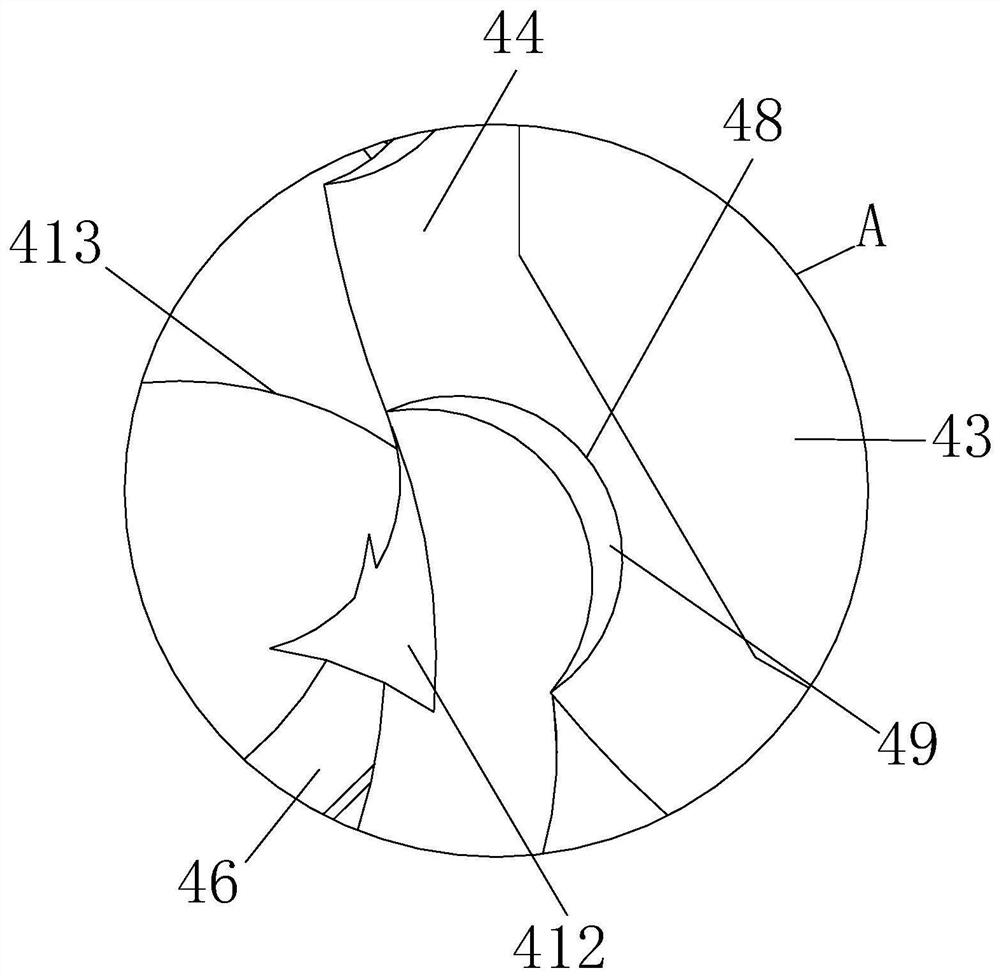

Silk cutter

ActiveCN104358099ANeat cutPrevent slidingSevering textilesMetal working apparatusMechanical engineeringEngineering

The invention relates to a silk cutter, which comprises a base, a pair of press wheels and a cutter, wherein the press wheels respectively comprise two rotary shafts, two rubber tires and a common center shaft, the two rubber tires are fixedly arranged at the exteriors of the rotary shafts, each center shaft is arranged just above the base through an L-shaped elastic bracket which is fixedly arranged on the base, the two press wheels are symmetrically arranged at the two sides of the L-shaped elastic bracket, the cutter is fixedly arranged at the center of each center shaft, a driving mechanism is arranged in the base, a driving rod of the driving mechanism extends out of the two side walls of the base, and the two ends of the driving rod are respectively connected with the rotary shafts of the press wheels through a conveying belt. The silk cutter has the advantages that a regular silk can be easily cut, and the skewing is effectively prevented.

Owner:刘骏

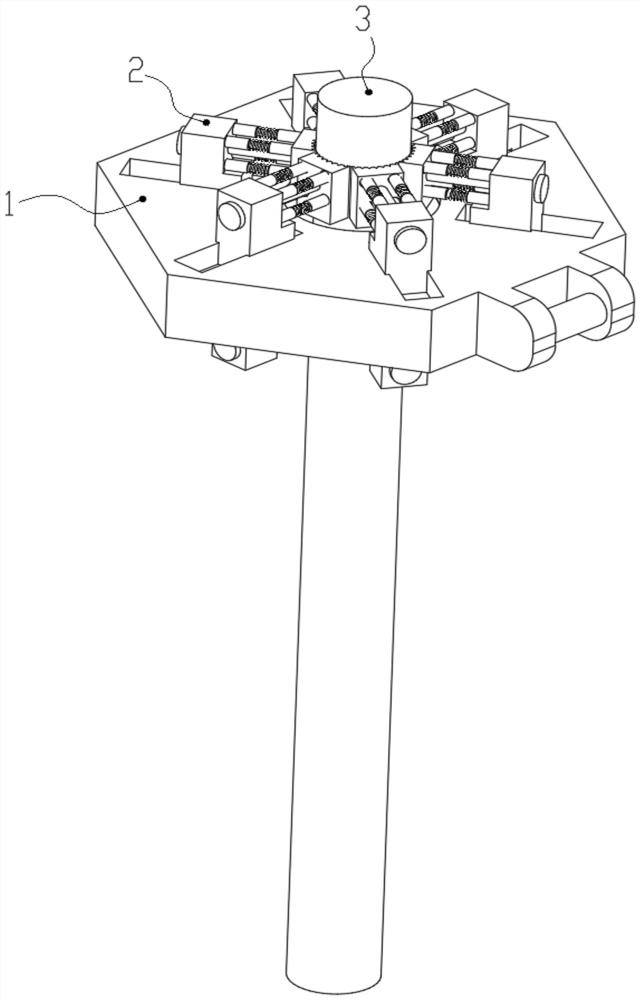

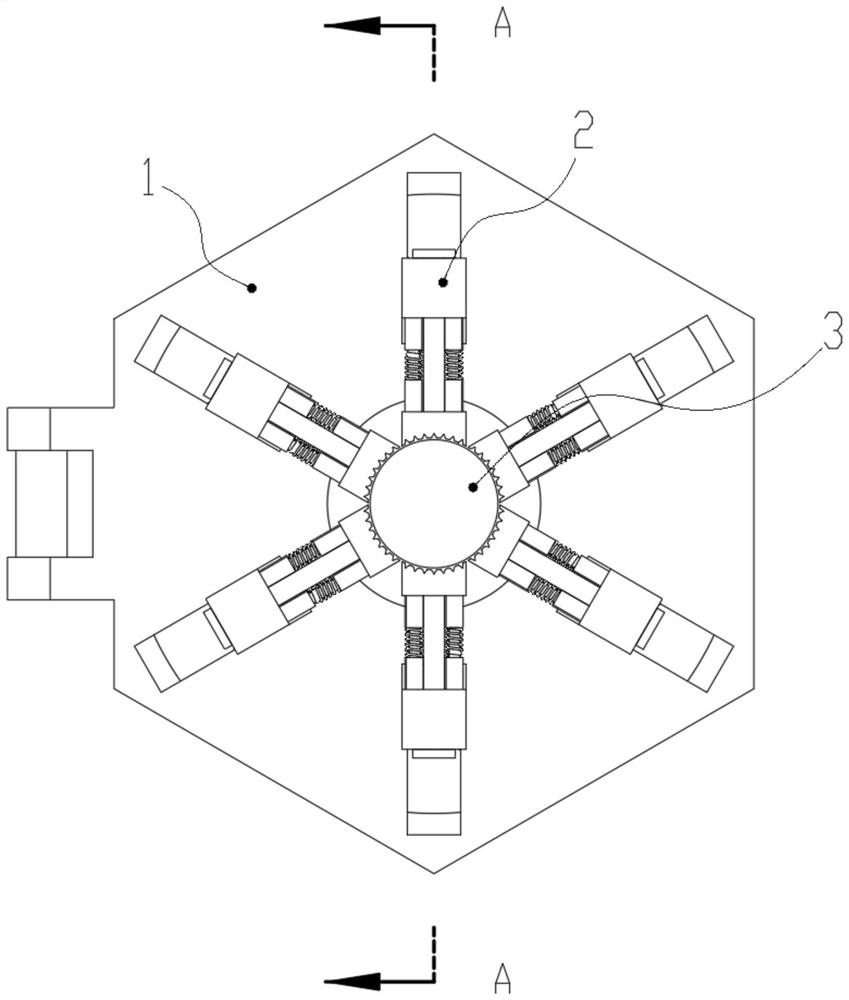

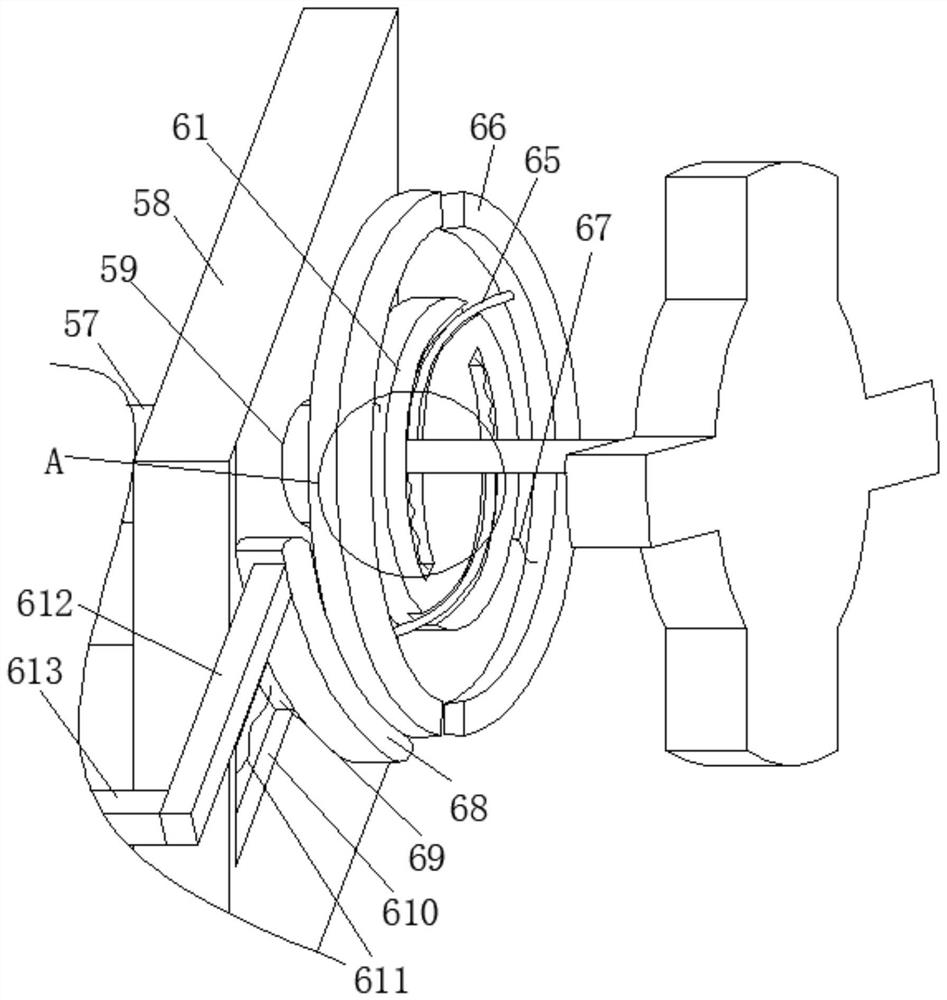

Electric pole correction device for electric power engineering

The invention discloses an electric pole correcting device for electric power engineering. The device comprises an adjusting mechanism, limiting mechanisms and an electric pole; the inner end face of the adjusting mechanism is evenly, equidistantly and slidably connected with the six sets of limiting mechanisms for positioning in a clamped mode; and the electric pole is movably connected with the inner end faces of the limiting mechanisms in a clamped mode. According to the electric pole correcting device for electric power engineering, by arranging the adjusting mechanism, during correction, a fixed motor can provide enough power for rotation of a guide disc through a connecting gear, and meanwhile, when the guide disc rotates, limiting displacement can be conducted on the limiting mechanisms through six sets of guide grooves at the same time, so that the six sets of limiting mechanisms can conduct centrifugal or centripetal displacement at the same time. Therefore, the follow-up adjusting mechanism can conveniently control the limiting mechanisms to stably limit the electric poles with different radiuses, the adaptability of the device is improved, and meanwhile the stability of limiting the electric poles is also improved.

Owner:沈婷园

Mating safety device of baby care walker

The invention provides a mating safety device of a baby care walker. The mating safety device comprises a baby carriage body, an inner sliding body and a bearing; the front end of the baby carriage body is fixedly provided with a front blocking body; the left side wall and right side wall of the baby carriage body are fixedly provided with two mutually parallel side guard bodies, and the side guard bodies are located at the upper end and lower end of the baby carriage body respectively; the rear end of the top plane of the baby carriage body is fixedly provided with a ceiling, and the left andright ends of the ceiling are inlaid in the left side wall and right side wall of the baby carriage body respectively. The mating safety device of a baby care walker has the advantages that through the arrangement of buffer plates and damping springs, the seven convex arc-shaped buffer plates are fixedly inlaid between the side guard bodies to achieve the protection of a baby in the walker, the cambered included angle is formed on the joint between the side guard bodies and the buffer plates, when the walker slants, the included angle formed on the joint between the side guard bodies and thebuffer plates can be exactly hung on an external protrusion to avoid whole lateral falling of the walker.

Owner:王少明

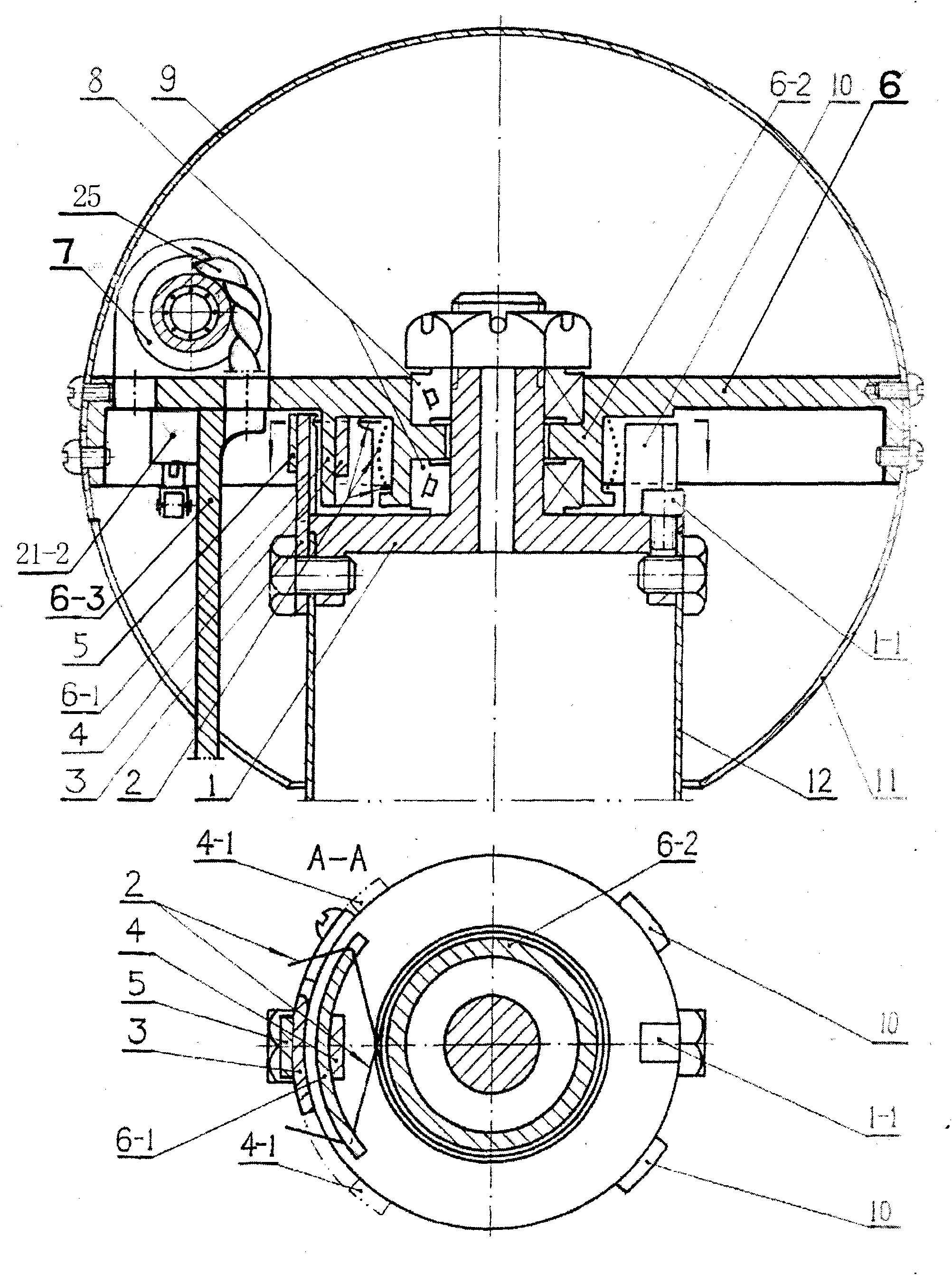

Flag flying rotary type hanging device and air-supply flying device

InactiveCN101625818APrevent sidewaysGood implementation conditionsTowersFlags/bannersEngineeringTorsion spring

The invention provides a flag flying rotary type hanging device and an air-supply flying device, relating to a flag pole which is used for supply wind to keep a flag flying when wind does not blow; wherein a lifting pulley rotates around the top end of the flag pole. In the flag flying rotary type hanging device, a shaft seat (1) is fixedly arranged on a top end plane of the flag pole (12), and arotating disk (6) is rotatably arranged on the shaft seat (1) by a bearing (8); because the lifting pulley (7) is arranged on the rotating disk (6), a flying flag can pull the rotating disk (6) to deflect correspondingly along with different wind directions; under the effect of torsion force of a torsion spring (2) which is hooked between a torsion spring rotation hanging plate (6-1) and a main-direction hanging plate (3) and is arranged on a bearing torsion spring seat pole (6-2), the deflected rotating disk (6) rotates to a rotating direction selected by the lifting pulley (7) when natural wind is reduced to stop. A flag can fly in different wind directions and supplies a condition for wind supplying and the flying of the flag by.

Owner:高旭奕

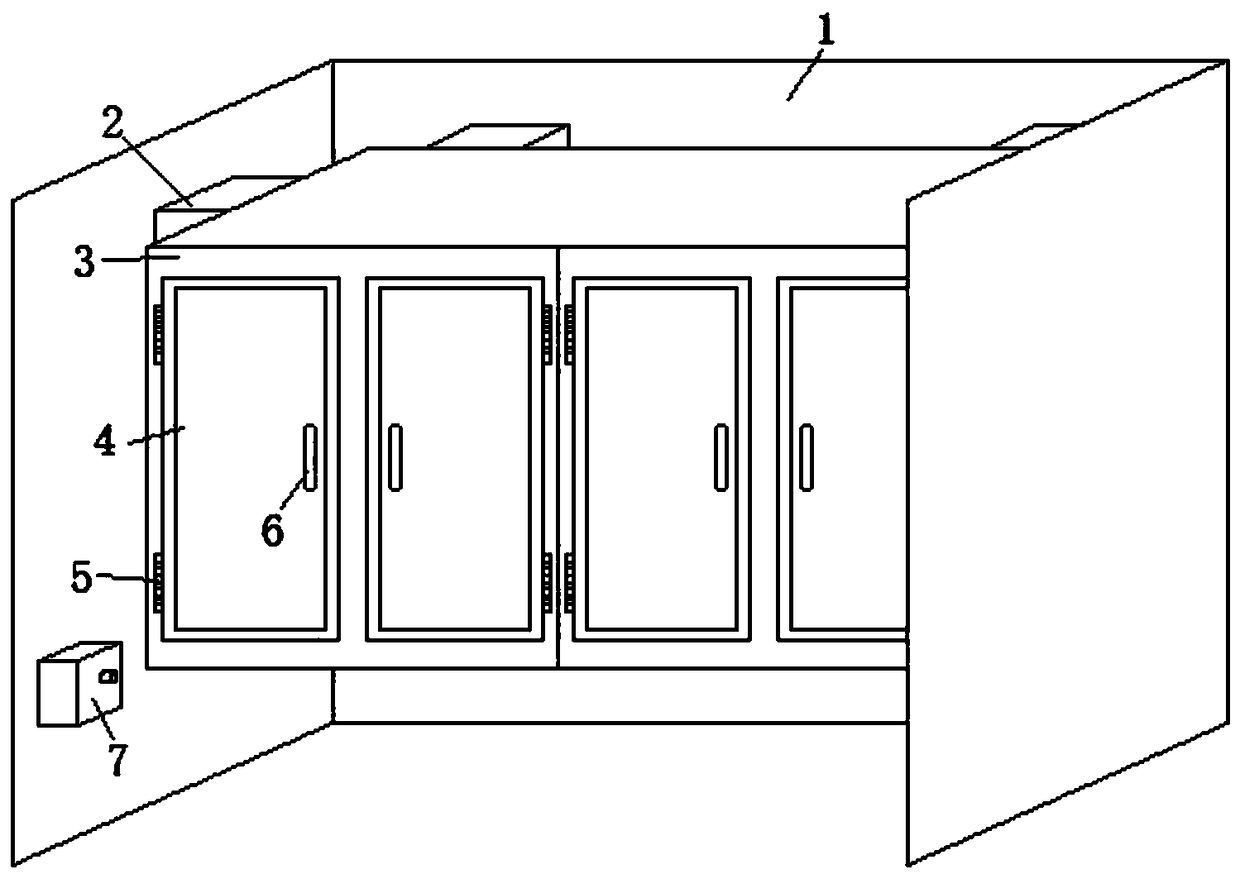

Height adjustable device for cabinet

InactiveCN108937221ALift controlAchieve liftingKitchen cabinetsMovable shelf cabinetPush and pullCoupling

The invention discloses a height adjustable device for a cabinet. A lifting device comprises a lifting frame, the inner side wall of the lifting frame is fixedly connected with a motor, the motor is fixedly connected with a connecting rod through a coupling, the other end of the connecting rod is rotatably connected to the side wall of a fixing plate, and the fixing plate is fixedly connected tothe inner side wall of the lifting frame. The device is provided with the lifting device and a control device, the lifting and lowering of the cabinet can be achieved by the cooperation of the liftingdevice and the control device, in the lifting device, the motor is a positive and negative rotation motor, the positive and negative rotation of the motor is achieved by the control device, thereby achieving the effect of lifting and lowering the cabinet, in the control device, the contact of a first contact piece, a second contact piece, a third contact piece and a fourth contact piece can be achieved by pushing and pulling a pressing plate, and the positive and negative rotation of the motor is achieved by controlling the switching on and off of two series connection circuits, thereby controlling the lifting and lowering of the cabinet.

Owner:合肥久新不锈钢厨具有限公司

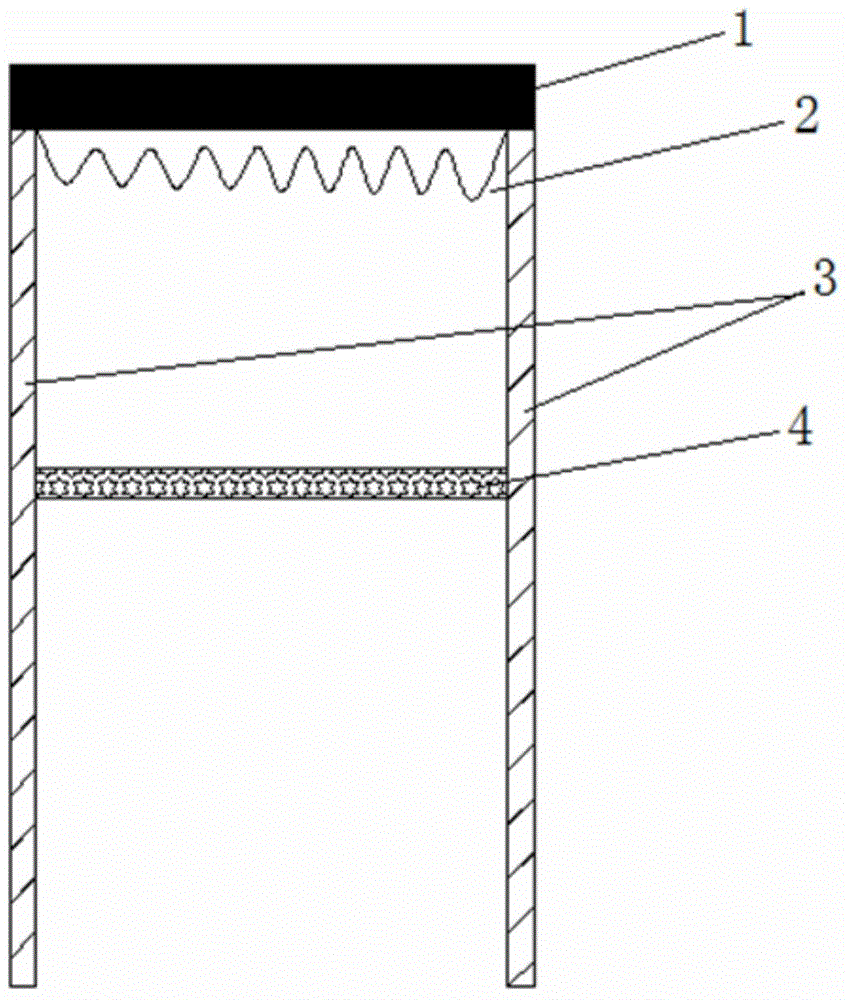

Inorganic material for reinforcement

The inorganic material is prepared from, by weight, 30-90 parts of specially-made cement, 0.1-20 parts of an accelerator, 6-35 parts of stone powder, 0.4-26 part of bentonite, 0.2-10 parts of sulfate,0.1-15 parts of a water reducing agent, 0.1-18 parts of silicon-calcium powder, 0.1-17 parts of an early strength agent, 0-10 parts of fine powder, 0-5 parts of iron powder, 0.2-20 parts of fly ash and 0.3-11 parts of gypsum. A vertical anchor rod hole is drilled in a coal-rock mass by using an anchor rod drilling machine, an anchor rod is inserted into the anchor rod hole, inorganic materials are mixed according to a water-cement ratio of (0.28-0.4): 1, and grouting is performed by using the anchor rod to reinforce the coal-rock mass. The inorganic material has the effects of preventing fireand ensuring safe production of a coal mine and roadway utilization; repeated roadway repair is completely eradicated, slope deviation and roof fall are prevented, operation is easy, and safety and reliability are achieved; and the inorganic material is economical and applicable.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

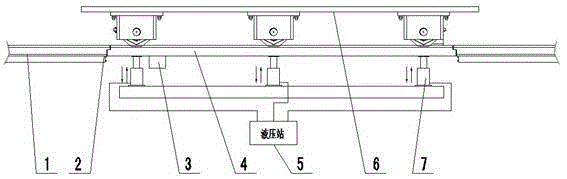

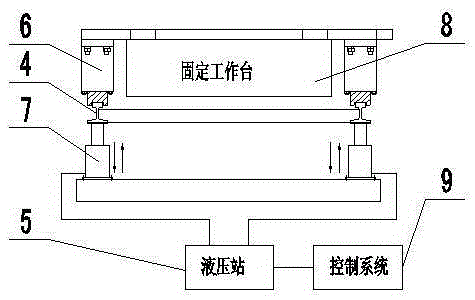

Lifting device for building material press rails

InactiveCN105235266AMeet continuous production process requirementsIncrease productivityPressesHydraulic cylinderButt joint

The invention relates to a device of a sheet pile conveying system of a building material press, in particular to a lifting device for building material press rails. The lifting device comprises the rails. The rails comprise the fixed rails and the lifting rail, the lifting rail is located below a fixed work table on the lower part of the press and is in butt joint with the fixed rails at the two ends. A hydraulic cylinder is arranged on the bottom of the lifting rail. According to the invention, a pass-type trolley can convey sheet piles for an upper pressurization type press, the requirement of the continuous production process can be met, the production efficiency can be improved, the structure is simple, maintenance is convenient and the service life is long.

Owner:TANGSHAN SINOMA HEAVY MASCH CO LTD

Automatic deviation rectifying system and tire applying same

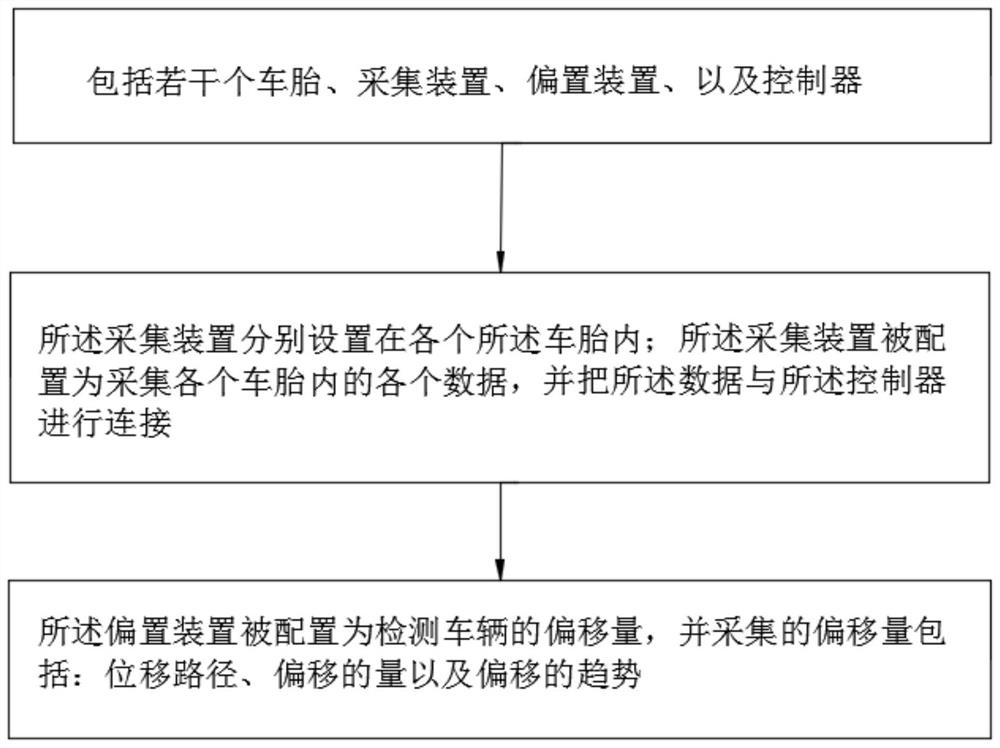

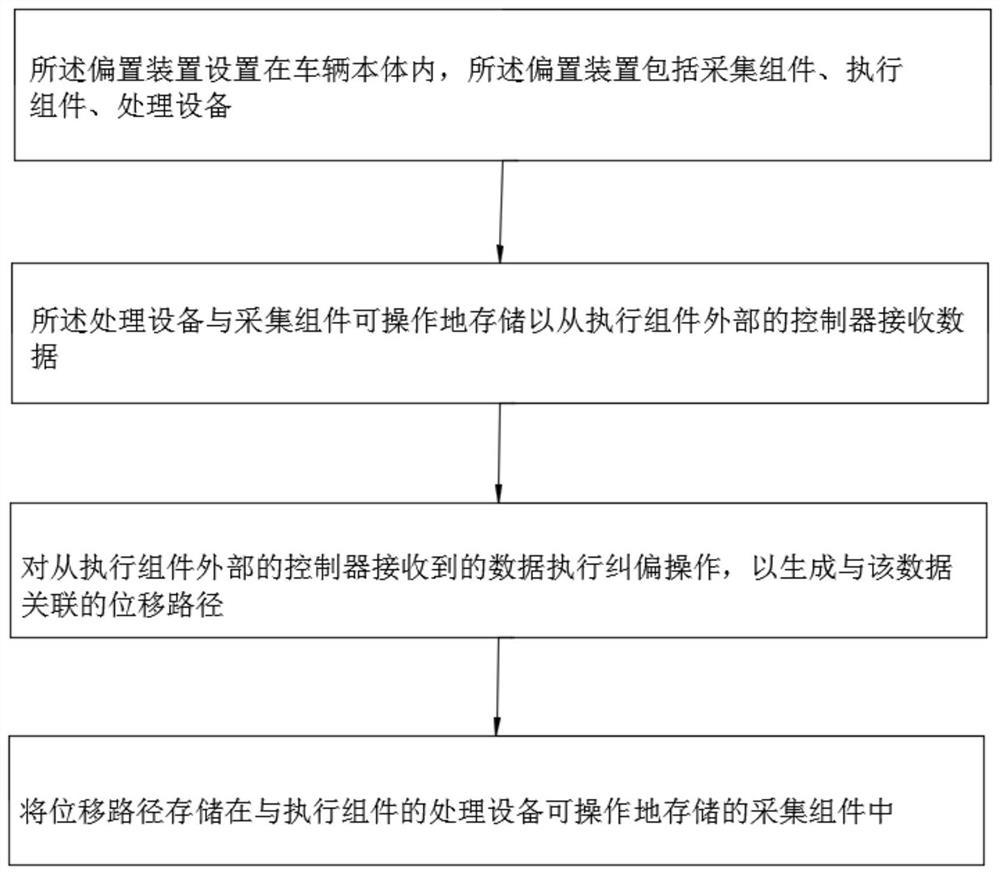

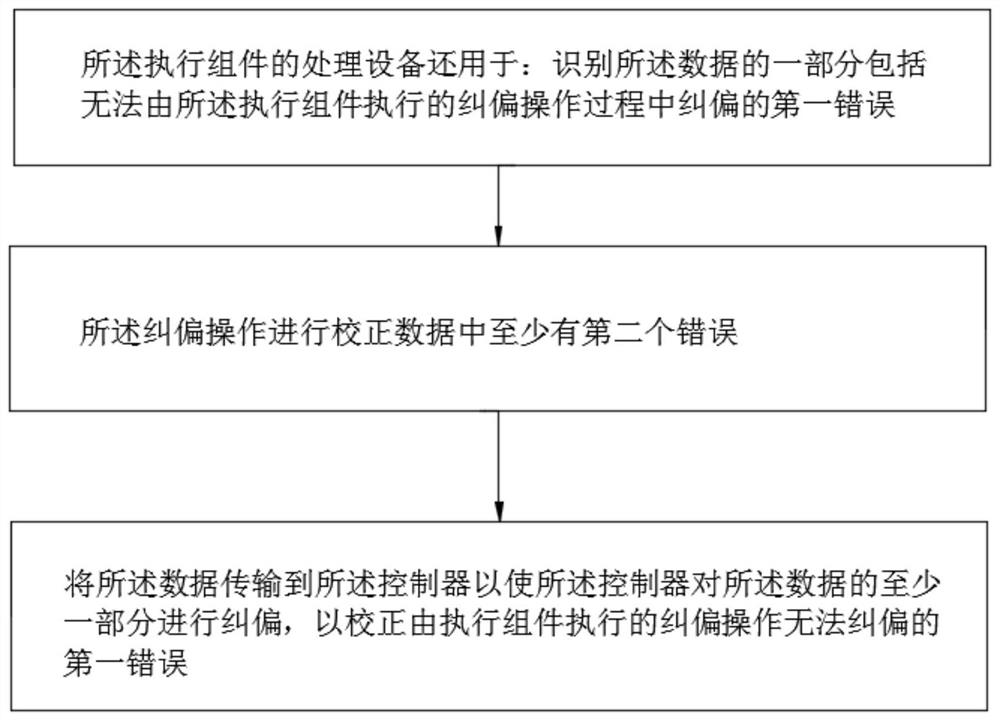

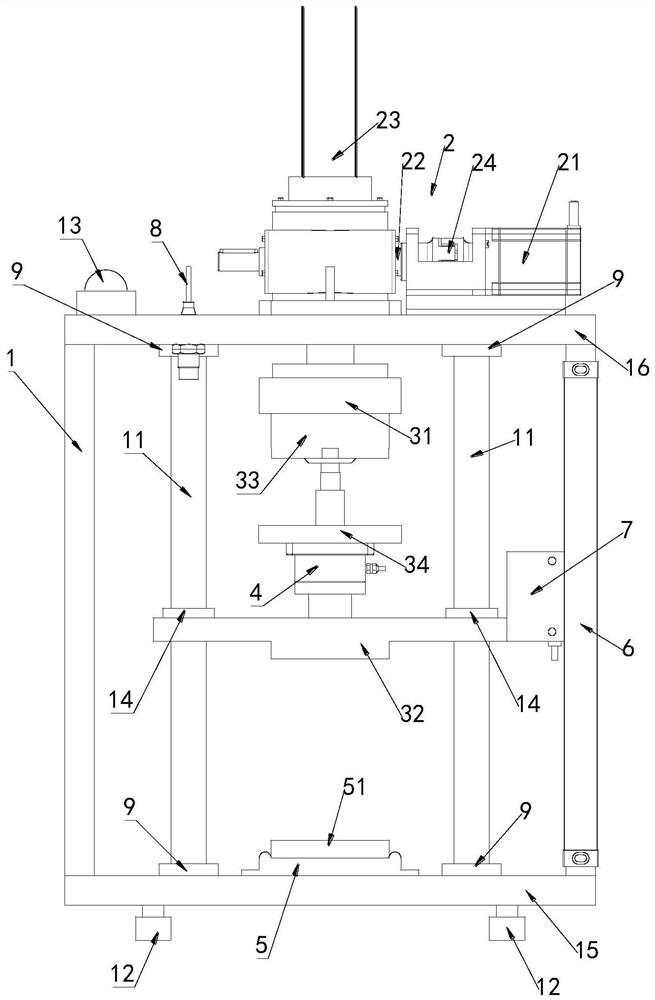

InactiveCN111907515AEfficient collection effectPrevent sidewaysTyre measurementsElectric/fluid circuitControl engineeringControl cell

The invention provides an automatic deviation rectifying system and tires applying the same. The automatic deviation rectifying system comprises a plurality of tires, collecting devices, an offset device and a controller, and the collecting devices are arranged in the tires respectively; the acquisition device is configured to acquire data in each tire and connect the data with the controller; wherein the offset device is configured to detect the offset of the vehicle, and the acquired offset comprises a displacement path, an offset amount and an offset trend; and the acquisition device and the bias device are respectively in control connection with the controller. By adopting the tire pressure detection mechanism and the detection table, the change of the table pressure can be detected, afault signal is sent to the controller or the control unit, and the controller or the control unit processes the existing fault, so that the fault of lateral deviation or turnover of a vehicle is prevented.

Owner:佛山市龙生光启科技有限公司

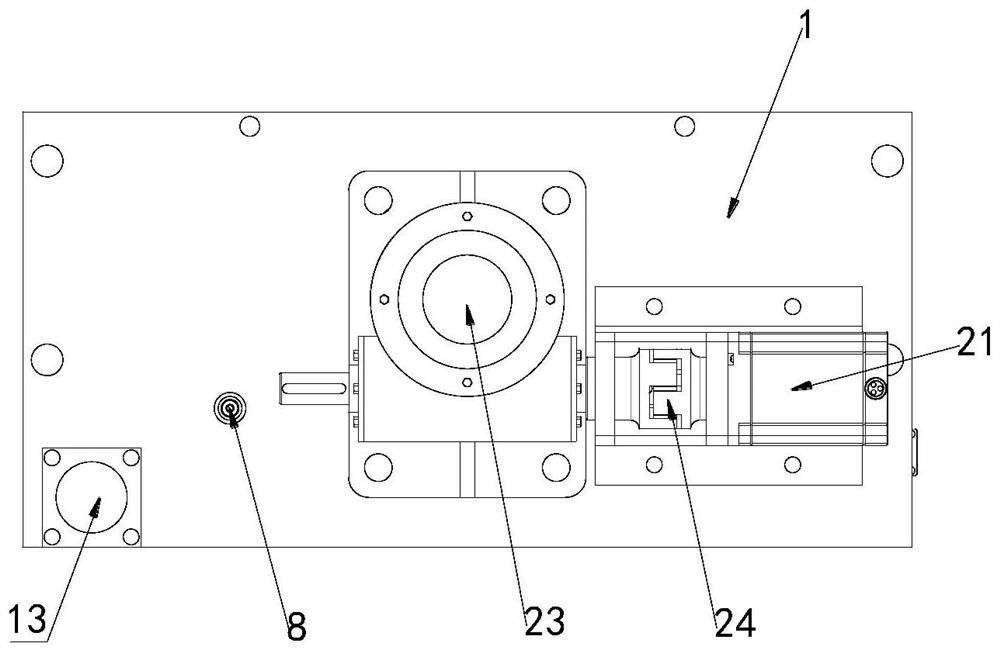

Soft material fluidity detection device

ActiveCN112485157AThe principle is feasibleThe comparison result is accurateFlow propertiesPhysicsEngineering

The invention relates to a soft material fluidity detection device. The detection device comprises a support, a driving device, an upper pressing mechanism, a pressure detection device, a lower supporting part and a displacement detection device, the driving device is installed on the support, and the driving device is connected with the upper pressing mechanism and drives the upper pressing mechanism to move downwards; and the lower supporting part is located in the support and located below the upper pressing mechanism, the pressure detection device is installed on the upper pressing mechanism, and the displacement detection device is installed on the support and detects displacement of the upper pressing mechanism. The driving device is used for driving the upper pressing mechanism to move downwards, the upper pressing mechanism is used for extruding materials on the lower supporting part, the displacement detection device on the support and the pressure detection device on the upper pressing mechanism are used for obtaining a displacement measurement value and a force measurement value in the pressure implementation process at the same time, the flow characteristics of the material are obtained by measuring the relationship between the pressure and the displacement when the material is forced to move, the principle feasibility is high, and the result can be accurately compared.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

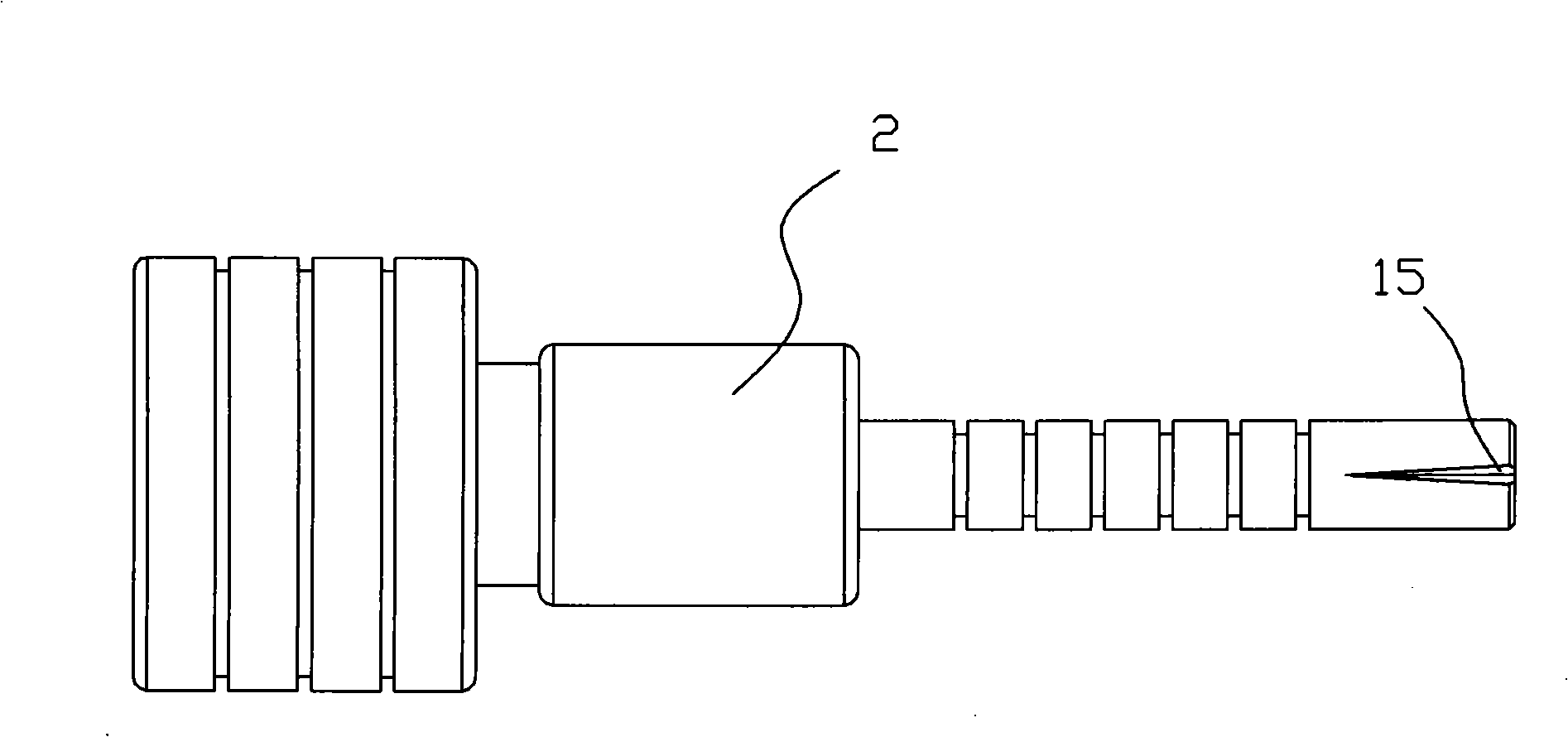

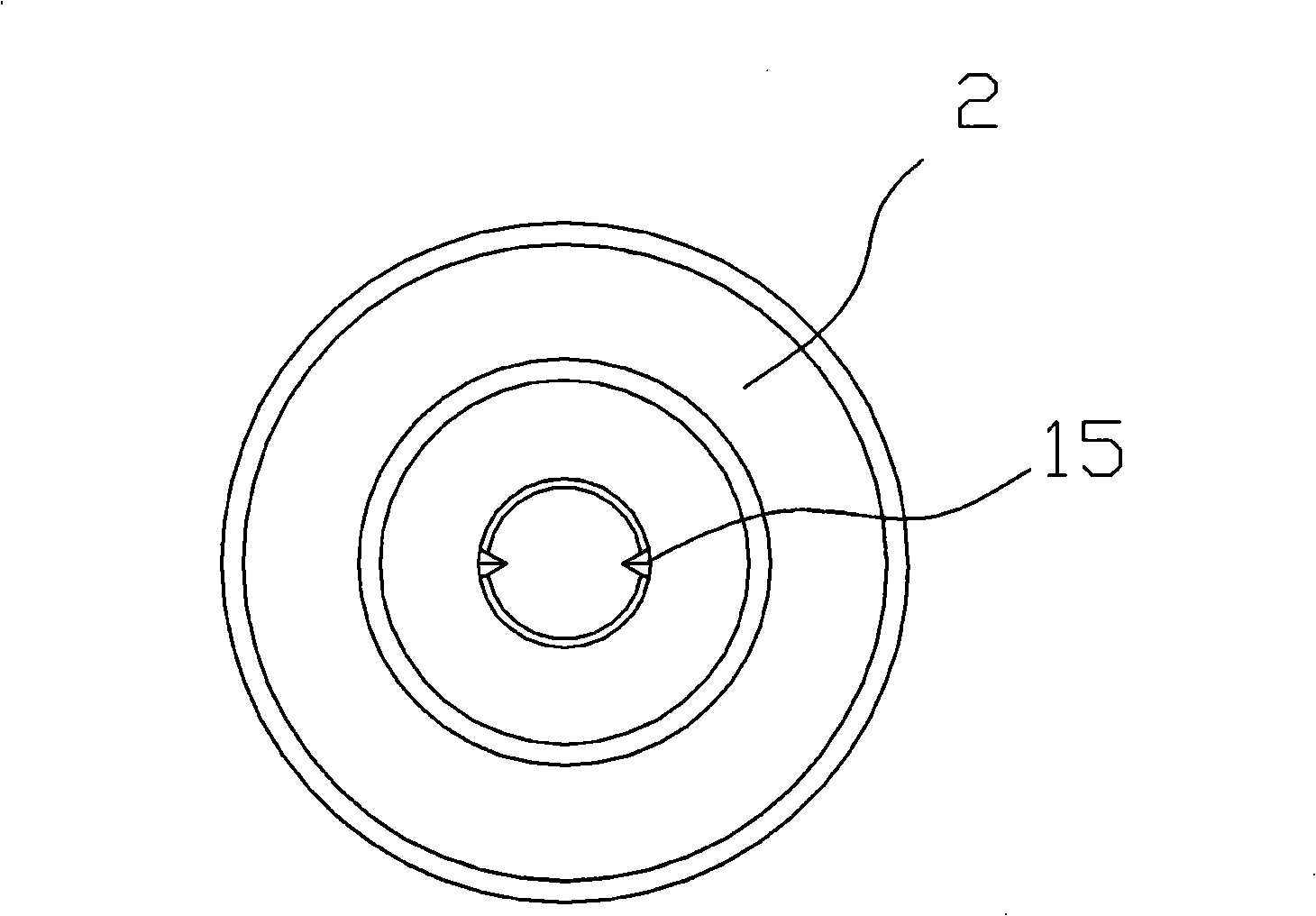

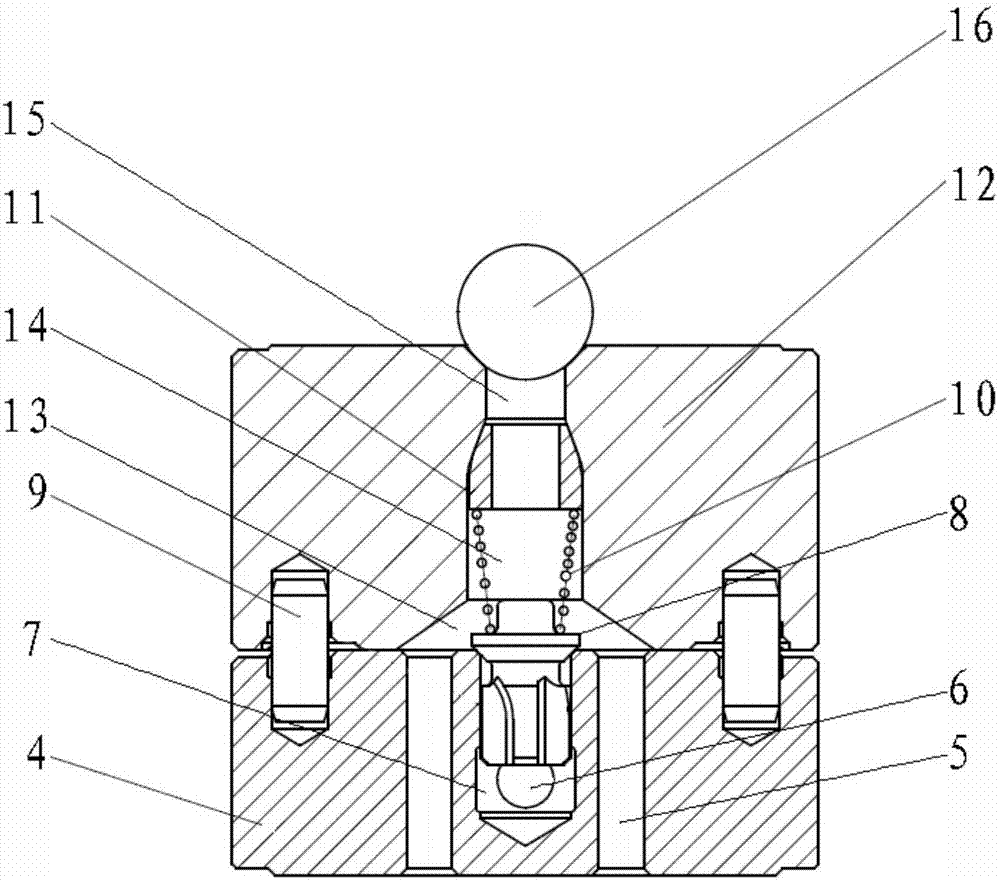

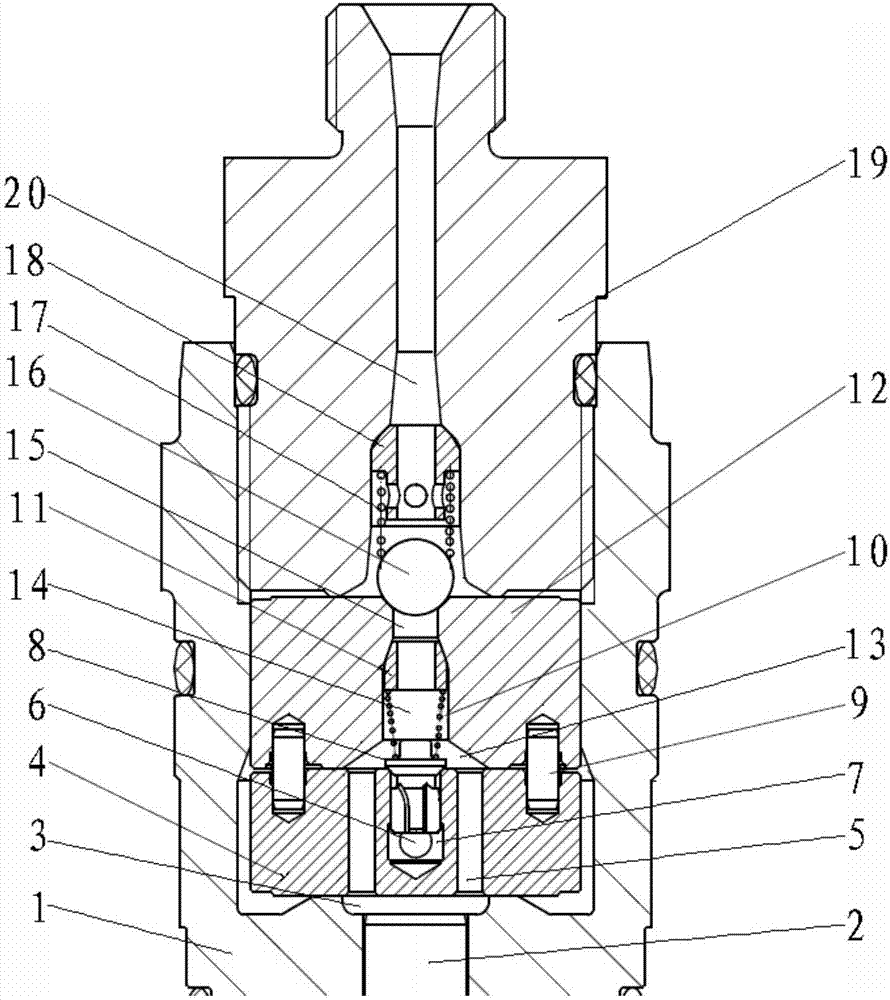

High-pressure common rail pump and oil inlet and outlet valve module for same

PendingCN107989730ANot easy to wearTightly sealedMachines/enginesFuel injecting pumpsEngineeringInlet valve

The invention provides an oil inlet and outlet valve module. The oil inlet and outlet valve module comprises an oil inlet mechanism and an oil outlet mechanism; the oil inlet mechanism comprises an oil inlet valve base, an oil inlet valve element, and an oil inlet valve elastic part; an inner guide hole communicating with the oil inlet hole is formed in the top end of the oil inlet valve base; theoil inlet valve element comprises a reversely conical sealing part; under the effect of the oil inlet valve elastic part, the reversely conical sealing part realizes sealing fit with an opening end of the inner guide hole; the oil outlet mechanism comprises an oil outlet valve base, an oil outlet valve element and an oil outlet valve elastic part; an oil outlet through hole, communicating with the opening end of the inner guide hole of the oil inlet mechanism, is formed in the oil outlet valve base; the oil outlet valve element is a spherical valve; and under the effect of the oil outlet valve elastic part, the spherical valve realizes sealing fit with an oil outlet end of the oil outlet through hole. The invention further provides a high-pressure common rail pump and the oil inlet and outlet valve module for the high-pressure common rail pump. The oil inlet and outlet valve module is simple in machining, not easy to wear and tight in sealing; and the high-pressure common rail pump istight in sealing and stable in pressure.

Owner:北油电控燃油喷射系统(天津)有限公司

An assembled concrete prefabricated component mold

ActiveCN111605050BAchieve demouldingEasy to assemble and disassembleMouldsMould fastening meansStructural engineeringMechanical engineering

The invention relates to an assembled concrete prefabricated component mold, including a mold mechanism and a supporting mechanism; in the invention, the mold adopts an assembled structure, so that when the prefabricated component is molded and demolded, the mold mechanism can be disassembled to achieve convenient disassembly and assembly of the prefabricated At the same time, during the disassembly process, there is no need to carry and flip the prefabricated components, so as to prevent the damage of the prefabricated components. Specifically, the mold consists of No. 1 master mold, No. 2 master mold, No. 1 slave mold and No. 2 Assembling the slave molds, when removing the molds, first disassemble the No. 1 slave mold and the No. 2 slave mold, and then remove one of the No. 1 master mold or No. 2 master mold, so that the demoulding of the prefabricated component can be realized.

Owner:界首市宝业瑞祥建筑工业化有限公司

Railway wagon self-adjusting device

ActiveCN105059307BRealize automatic height adjustmentAchieve automatic reductionBogie-underframe connectionsAgricultural engineeringTruck

The invention discloses a height self-adjusting device of a railway wagon. The height self-adjusting device of the railway wagon comprises a bearing support plate installed on a central square frame through bearing springs, struts are arranged on the two sides of the bearing support plate, each strut is sleeved with a tapper sleeve assembly, a middle support plate is installed on the bearing support plate in a stacking mode, the two sides of the middle support plate are installed on outer taper sleeves of the tapper sleeve assembly in a sleeved mode, a limiting frame is arranged on the upper portion of the middle support plate, the two sides of the limiting frame are arranged on the struts in a sleeved mode respectively, convex rings are arranged on the bottom face of the limiting frame, through holes are formed in the center of the middle support plate and the center of the bearing support plate respectively, a pull rod is installed in the through holes, the upper end of the pull rod is hinged to the hinge end of a left crank throw and the hinge end of a right crank throw, the free ends of the left crank throw and the free ends of the right crank throw are each provided with upper rolling wheels and lower rolling wheels, limiting rolling shafts which can form limiting with the limiting frame are arranged in the middle of the left crank throw and the middle of the right crank throw, the left crank throw and the right crank throw are located on the upper portion of the middle support plate, a return spring is arranged below the middle support plate, and the upper surface of the middle support plate abuts against the lower rolling wheels. The height self-adjusting device of the railway wagon is suitable for railway wagons.

Owner:CRRC YANGTZE CO LTD

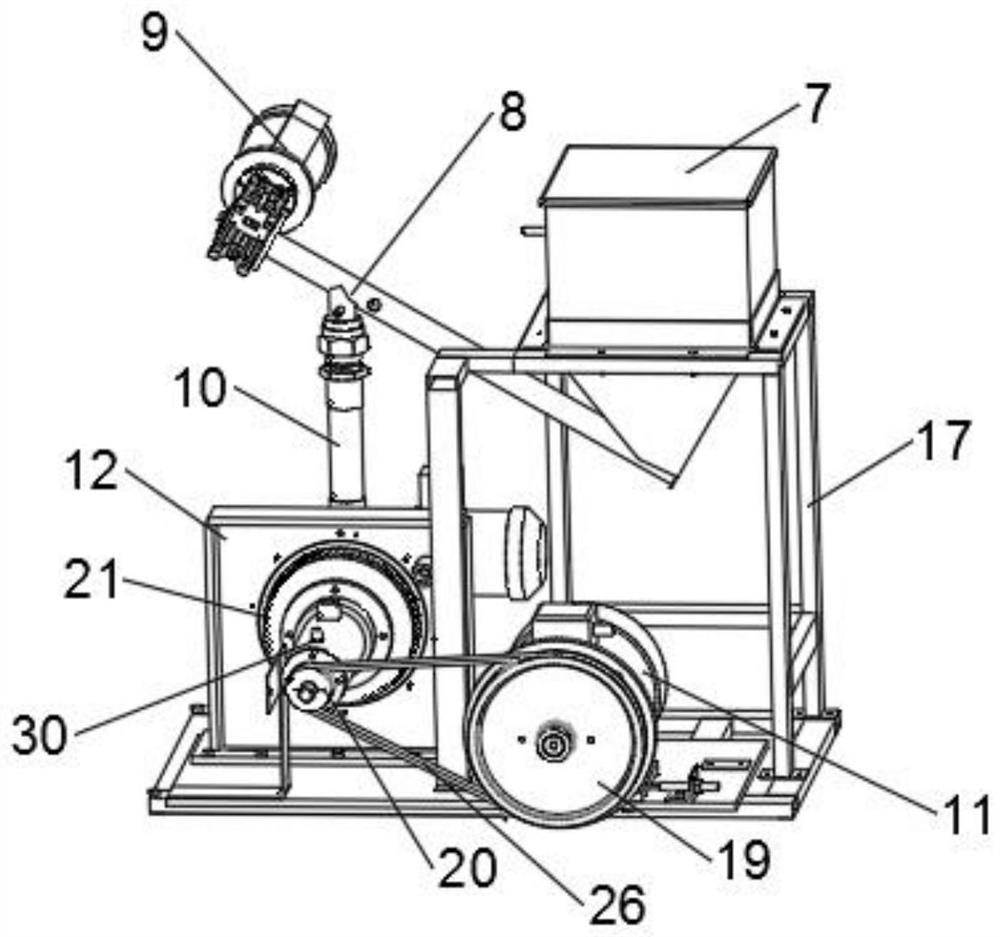

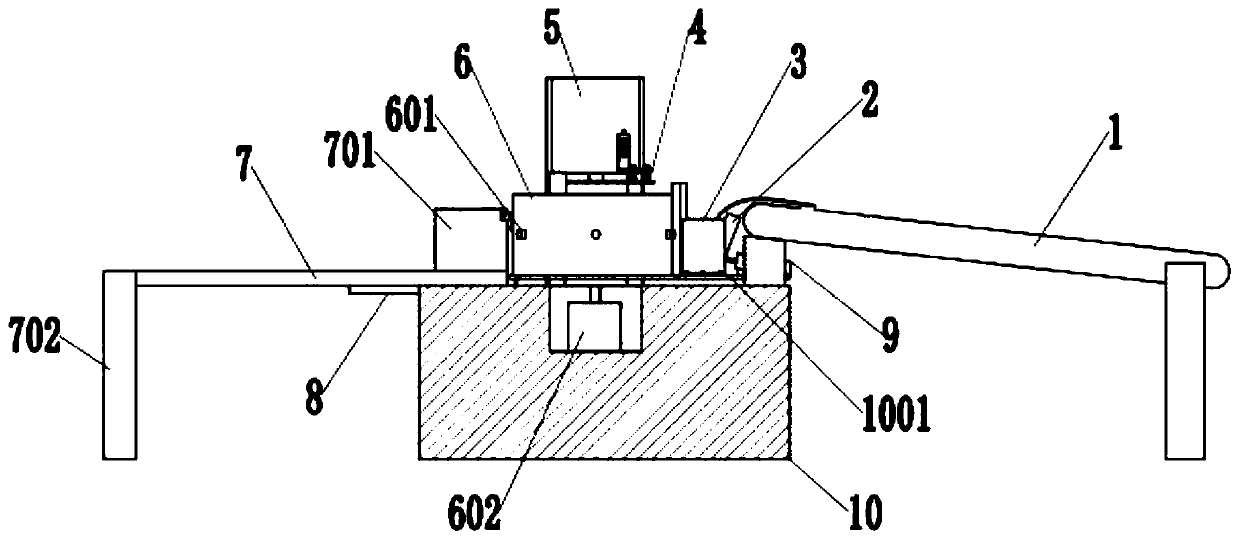

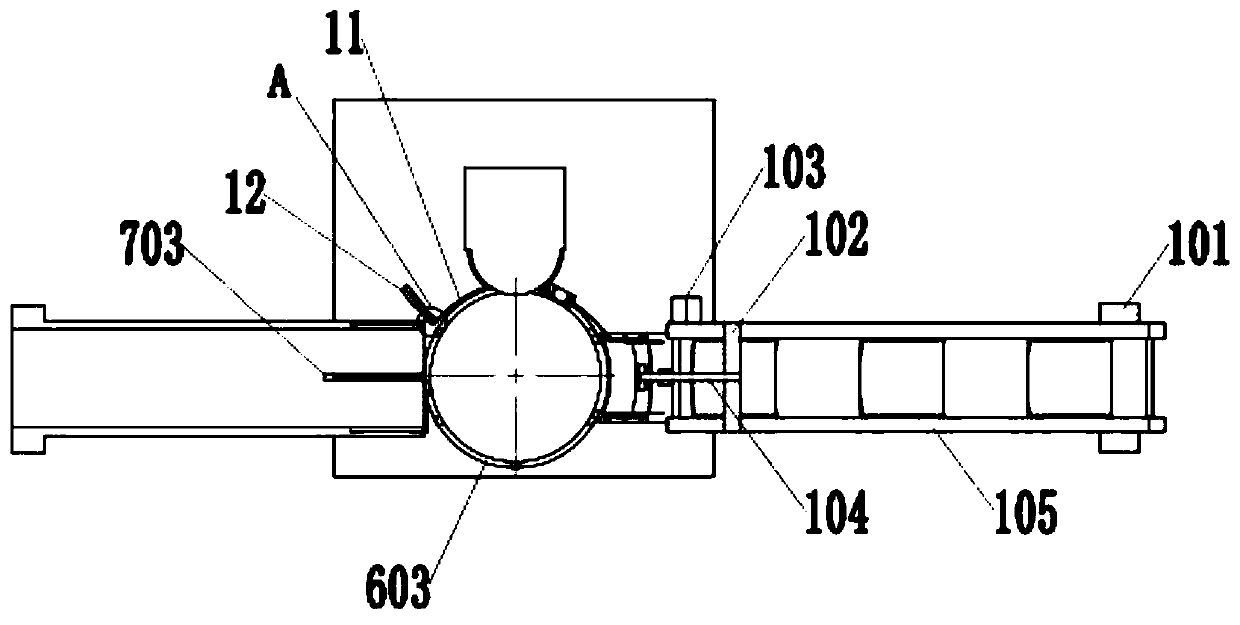

Drum brake pad abrasion line processing equipment

PendingCN110293472ALabor savingFast processingGrinding machinesGrinding feedersSlide plateEngineering

The invention discloses drum brake pad abrasion line processing equipment which comprises a feeding conveyor belt, a tableting device, a grinding machine, a rotating table, a discharging sliding plateand a workbench, wherein the grinding machine and the rotating table are arranged on the workbench; the rotating table is arranged close to the grinding machine; dialing bulges are uniformly arrangedon the side wall of the rotating table; a rotating motor connected with the rotating table is arranged in the workbench; the feeding conveyor belt and the discharging sliding plate are correspondingly arranged on two sides of the rotating table; a bracket is arranged between the feeding conveyor belt and the rotating table; first baffle plates are arranged on two sides of the bracket; a second air cylinder used for pushing brake pads is arranged below the feeding conveyor belt; second baffle plates are arranged on two sides of the end, close to the rotating table, of the discharging sliding plate; pulling pieces are arranged between the first baffle plates and the second baffle plates, and positioned between the rotating table and the grinding machine; a dialing hole is formed in the discharging sliding plate; a first air cylinder is arranged below the discharging sliding plate; and a pulling block is arranged at the end part of the first air cylinder and matched with the dialing hole.

Owner:山东梁山耐驰汽车零部件有限公司

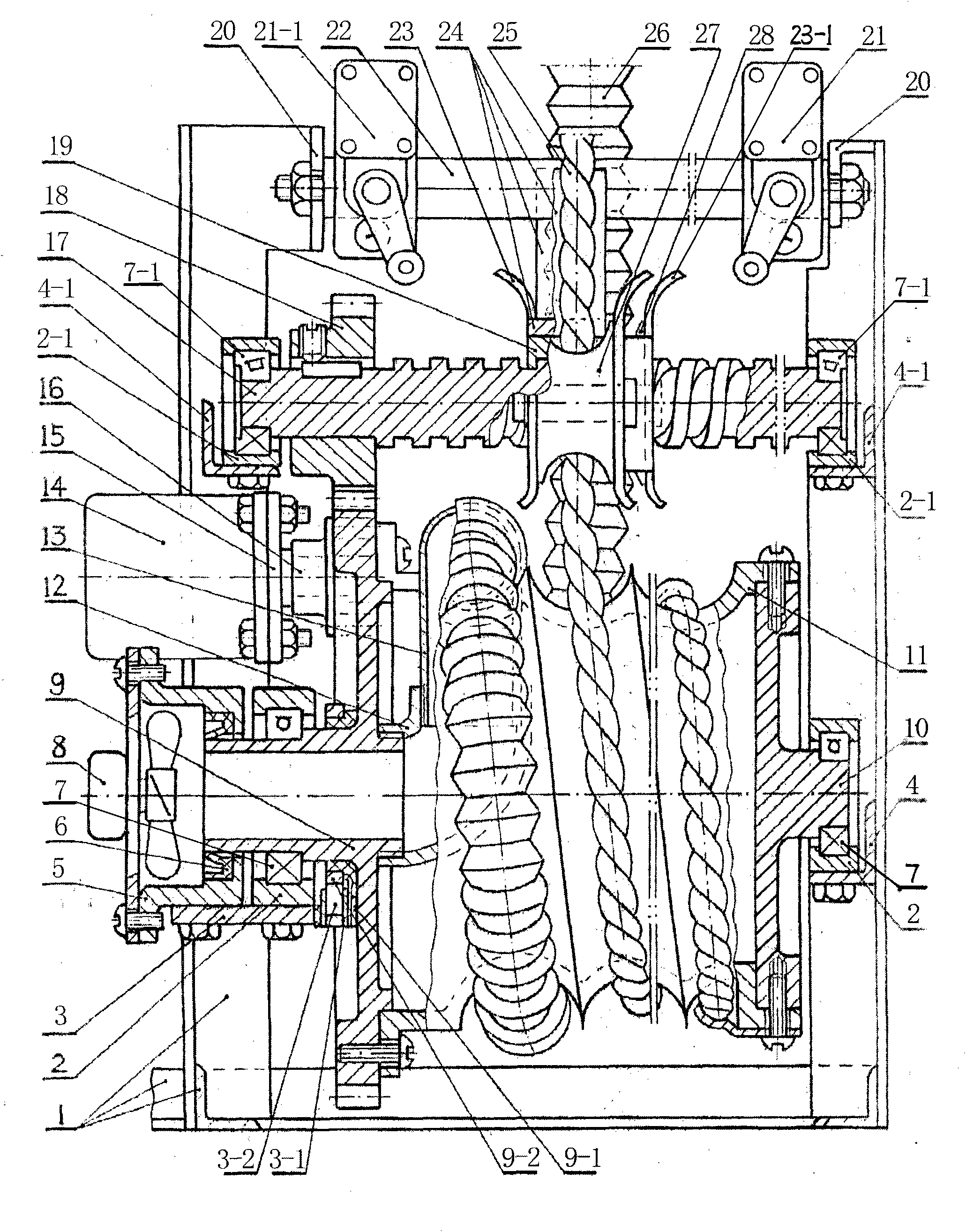

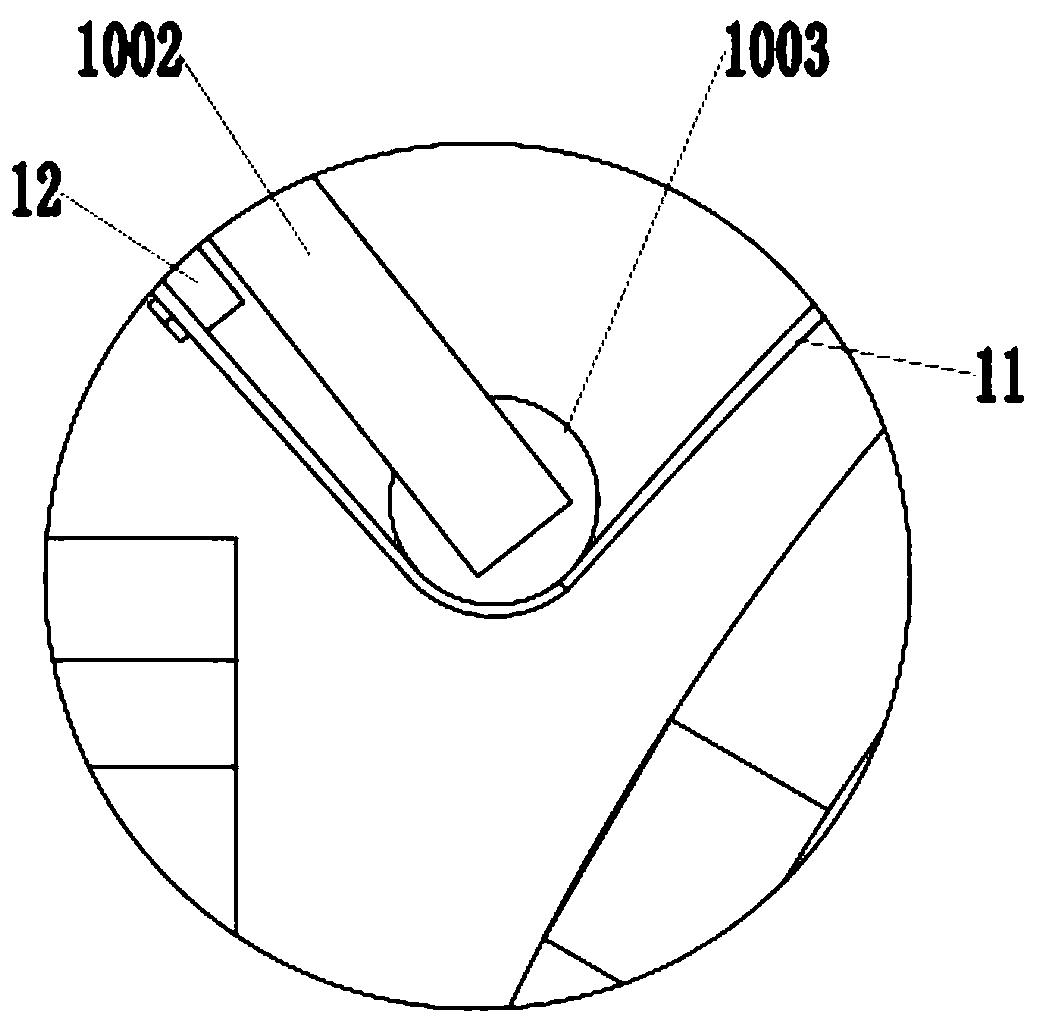

Lifeboat hoisting structure

The invention provides a lifeboat hoisting structure. By means of the lifeboat hoisting structure, the situation that when a lifeboat is hoisted and placed, the lifeboat shakes large, and side deflection of the lifeboat is caused is effectively prevented, and safety of staff in the lifeboat can be guaranteed. The lifeboat hoisting structure is characterized in that the lifeboat hoisting structure comprises a door frame type hoisting arm, and a winch is arranged on the hoisting arm; a suspension type cross beam is arranged at the upper end of the hoisting arm, and each of the two ends of the cross beam is provided with a movable roller and a hoisting hook; fixed rollers are arranged in the positions, corresponding to the two ends of the cross beam, of the hoisting arm; one end of the hoisting arm is provided with a middle roller corresponding to the fixed roller at the end; a supporting roller corresponding to the middle roller is arranged on the hoisting arm; the central axis of the fixed rollers longitudinally intersects with the central axis of the middle roller; the central axis of the fixed rollers horizontally intersects with the central axis of the supporting roller; a hoisting rope is sequentially wound across the winch, the supporting roller, the middle roller, the fixed roller at one end and the movable rollers and is finally fixed to the fixed roller at the other end.

Owner:WUXI SHENGOU MARINE EQUIP

Pipe squeezing device for waste recycling

The invention provides a pipe squeezing device for waste recycling. The pipe squeezing device comprises a bottom supporting plate used for supporting the bottom of the device, two side plates, a squeezing cylinder used for squeezing a pipe, an adaptive squeezing mechanism used for squeezing a steel pipe and an arrangement feeding mechanism used for feeding. The two side plates are fixedly connected to the surface of the bottom supporting plate; the squeezing cylinder is fixedly connected between the two side plates; and the adaptive squeezing mechanism is arranged on the squeezing cylinder. The invention relates to the field of pipe squeezing. According to the pipe squeezing device for waste recycling, the specific structure capable of continuously squeezing and cutting the pipes is designed to solve the problems that it is inconvenient to intensively squeeze the pipes and the squeezing difficulty is high during existing pipe squeezing work. Therefore, the problems are solved that a general squeezing machine cannot intensively squeeze the waste pipes, the pipes are embedded into metal wastes in the iron squeezing process of an iron squeezing machine, a lot of space is occupied, and the waste metal packaging effect is affected to a certain extent.

Owner:国网新疆电力有限公司博尔塔拉供电公司

Furnace program control upstairs cable bridge convenient to splice, and use method thereof

The invention discloses a furnace program control upstairs cable bridge convenient to splice, and a using method thereof. The furnace program control upstairs cable bridge convenient to splice comprises cable bridge main bodies and a cable bridge cover plate, flanges are arranged at the tops of the two sides of the cable bridge main bodies, and edge legs are arranged at the two ends of the bottom of the cable bridge cover plate. The cable bridge has the beneficial effects that the two cable bridge main bodies are subjected to primary auxiliary connection through matched insertion of the U-shaped channel steel and the steel bars, lateral deviation of the two cable bridge main bodies during splicing is prevented, and friction between the cable bridge cover plate and the cable bridge main bodies is reduced through the rolling assemblies, and the cable bridge cover plate can completely cover the cable bridge main bodies better; and the auxiliary connection between the two cable bridge main bodies can be further facilitated through the auxiliary connection assembly, the two cable bridge main bodies are prevented from being directly separated during splicing or dismounting, and the safety of a worker during mounting is improved.

Owner:成渝钒钛科技有限公司

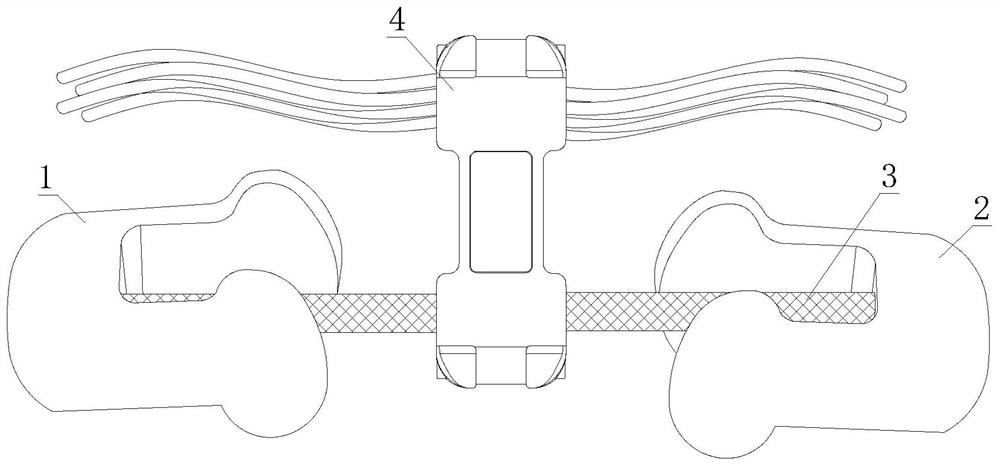

Anti-vibration hammer with convenient replacement structure and machining process of anti-vibration hammer

InactiveCN111682487APrevent slidingFirmly connectedDevices for damping mechanical oscillationsDamperMachining process

The invention discloses an anti-vibration hammer with a structure convenient to replace and a machining process of the anti-vibration hammer, and belongs to the technical field of damper. The hammer comprises a left hammer head, a right hammer head, a supporting rod and a wire clamp, wherein a left hammer head is welded to the left end of the supporting rod, and a right hammer head is welded to the right end of the supporting rod; a wire clamp is installed in the middle of the supporting rod; the wire clamp comprises a main clamp body, an upper clamp body, a lower clamp body and a locking bolt, wherein the edge of the middle of the main clamp body protrudes outwards to form a side lug, a screw hole is formed in the side lug, and a guide groove is formed in the inner wall of the middle of the main clamp body. The wire clamp part which is liable to be damaged is replaced independently, so the cost is saved; the pin can be directly inserted into the stranded wire in an opening and closingaccess mode, so the connection between the wire clamp and the stranded wire is increased; the upper clamp body is positioned through the guide groove, and the lower clamp body is positioned through the limiting groove, so the screw hole and the pin hole are rapidly in a coaxial state, lateral deviation is avoided, and a foundation is provided for rapid screwing-in of the locking bolt.

Owner:安徽省含山县兴建铸造厂

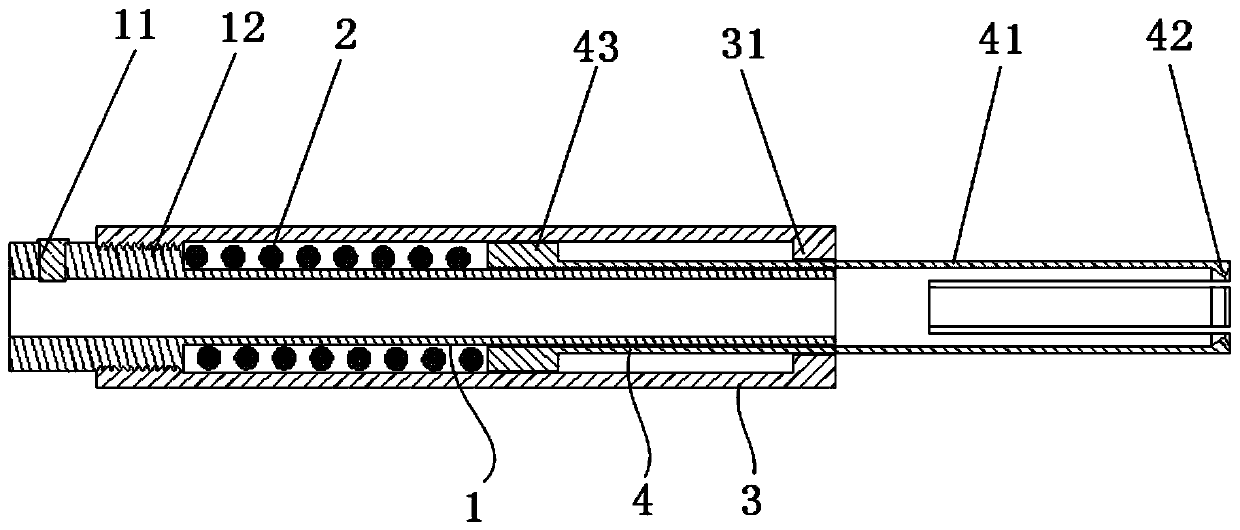

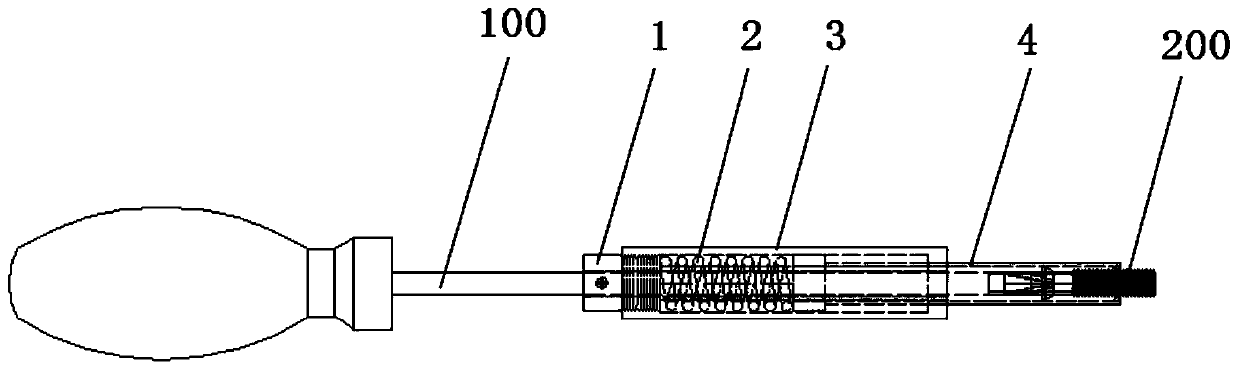

Screw clamping device mounted on screwdriver

The invention provides a screw clamping device mounted on a screwdriver. According to the adopted scheme, the screw clamping device comprises an outer sleeve, an inner sleeve, a clamping assembly andan elastic compression part; a fastener mounting hole is formed in the upper part of the inner sleeve, and the inner sleeve and the outer sleeve are detachably connected together; the upper part of the clamping assembly is mounted on the lower part of the outer sleeve in an embedded mode and the clamping assembly can slide in the longitudinal direction of the outer sleeve. An opening used for allowing screws to be loaded in is formed in the lower part of the clamping assembly, and the clamping assembly can expand outwards at the opening of the clamping assembly and clamp the screws; and the elastic compression part is mounted in the outer sleeve and located between the inner sleeve and the clamping assembly According to the screw clamping device, the screws can be prevented from falling and laterally deviating due to the lack of magnetic attraction of a screwdriver head, and thus the locking attachment efficiency of the screws and the operability of quick locking adsorption of the screws in a narrow and long space are improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Medical instrument for nephrology department

InactiveCN113069620AEasy to adjustPromote absorptionCannulasEnemata/irrigatorsEngineeringRenal function

The invention relates to a medical instrument for nephrology department. The medical instrument comprises a tube body, a guide supporting rod and a supporting frame tube, wherein the guide supporting rod is fixedly arranged at an upper end of the tube body, the guide supporting rod is movably arranged in the supporting frame tube, a limiting assembly is arranged outside the tube body, and the limiting assembly is used for limiting and guiding the tube body. By improving existing equipment for treating chronic renal insufficiency, the improved equipment for treating chronic renal insufficiency can realize an adjustable performance of a heating contact, so that in an actual use process, the adjustable performance of the heating contact can be realized, medicaments can be added to different parts of the intestinal tract, and a traditional Chinese medicine decoction at different parts can be heated through the medical instrument, so that the traditional Chinese medicine decoction can be better absorbed.

Owner:刘包生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com