Automatic deviation rectifying system and tire applying same

An automatic deviation correction and tire technology, which is applied in tire measurement, vehicle parts, tire parts and other directions, can solve the problems of inaccurate measurement of deviation correction data and insufficient deviation correction, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

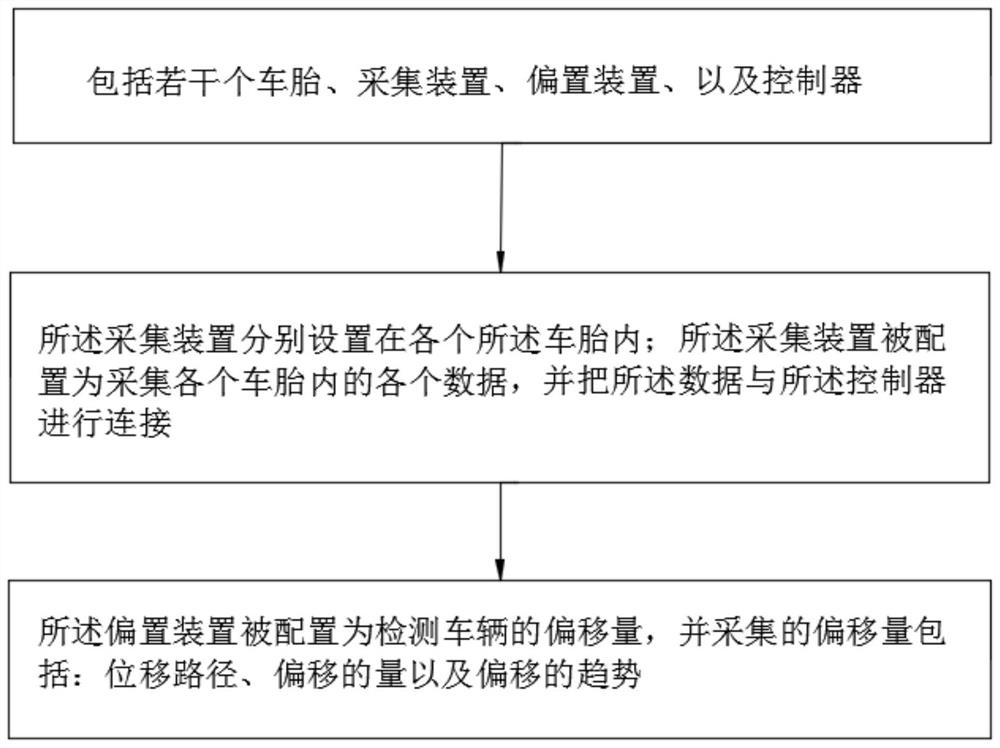

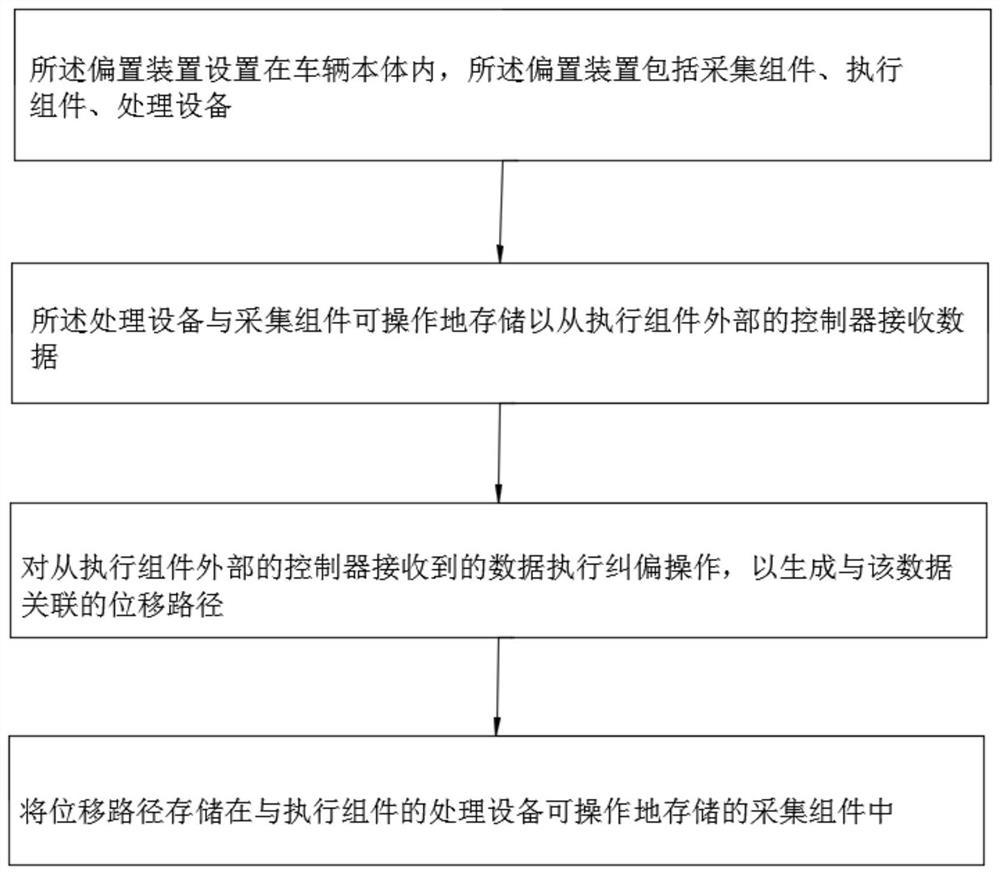

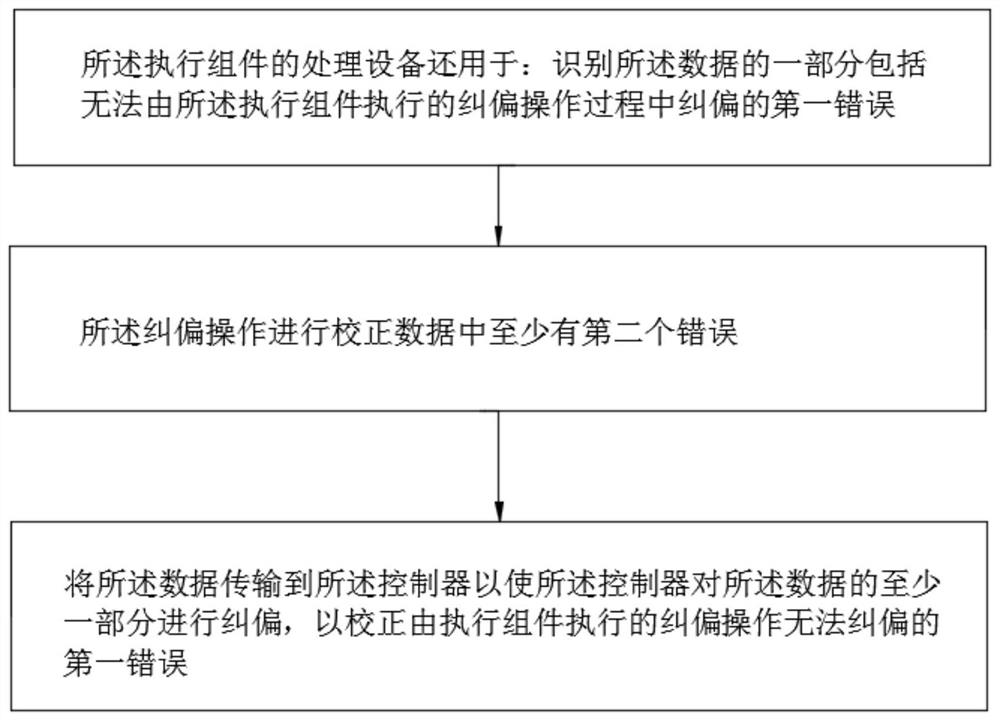

[0038] Embodiment 1: An automatic deviation correction system and a tire using the same, including several tires, a collection device, a biasing device, and a controller, the collection devices are respectively arranged in each of the tires; the collection device is configured In order to collect various data in each tire and connect the data with the controller; the biasing device is configured to detect the offset of the vehicle, and the collected offset includes: displacement path, offset The amount and the tendency of the offset; the set device and the bias device are respectively in control connection with the controller. The biasing device is provided in the vehicle body, and the biasing device includes an acquisition assembly, an execution assembly, and a processing device, the processing device and the acquisition assembly being operatively stored to receive data from a controller external to the execution assembly; The data received by the controller external to the e...

Embodiment 2

[0039]Embodiment 2: This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improvement on the basis thereof. Specifically, this embodiment provides an automatic deviation correction system and a tire using the same. , including several tires, a collection device, a biasing device, and a controller, the collection devices are respectively arranged in each of the tires; the collection device is configured to collect various data in each tire, and put the The data is connected with the controller; the biasing device is configured to detect the offset of the vehicle, and the collected offset includes: the displacement path, the amount of the offset and the trend of the offset; the set device, The biasing devices are respectively in control connection with the controller. Specifically, in this embodiment, a wheel 1 is also provided, and the collecting device is arranged on the wheel 1 . The collection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com