Patents

Literature

98results about How to "Improve escape performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

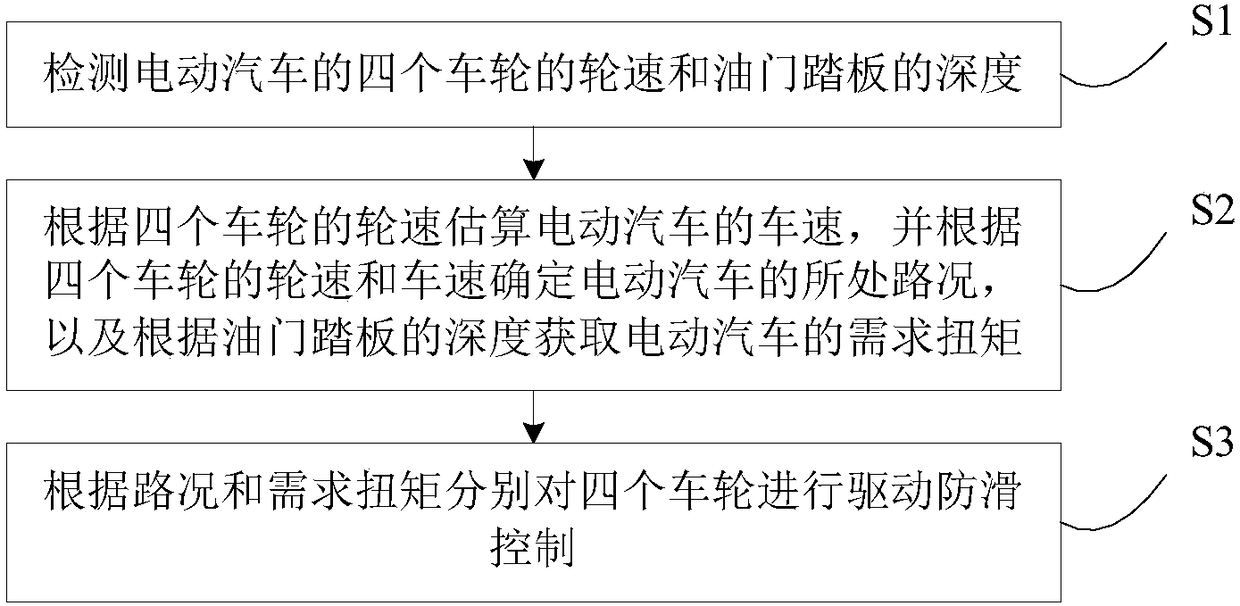

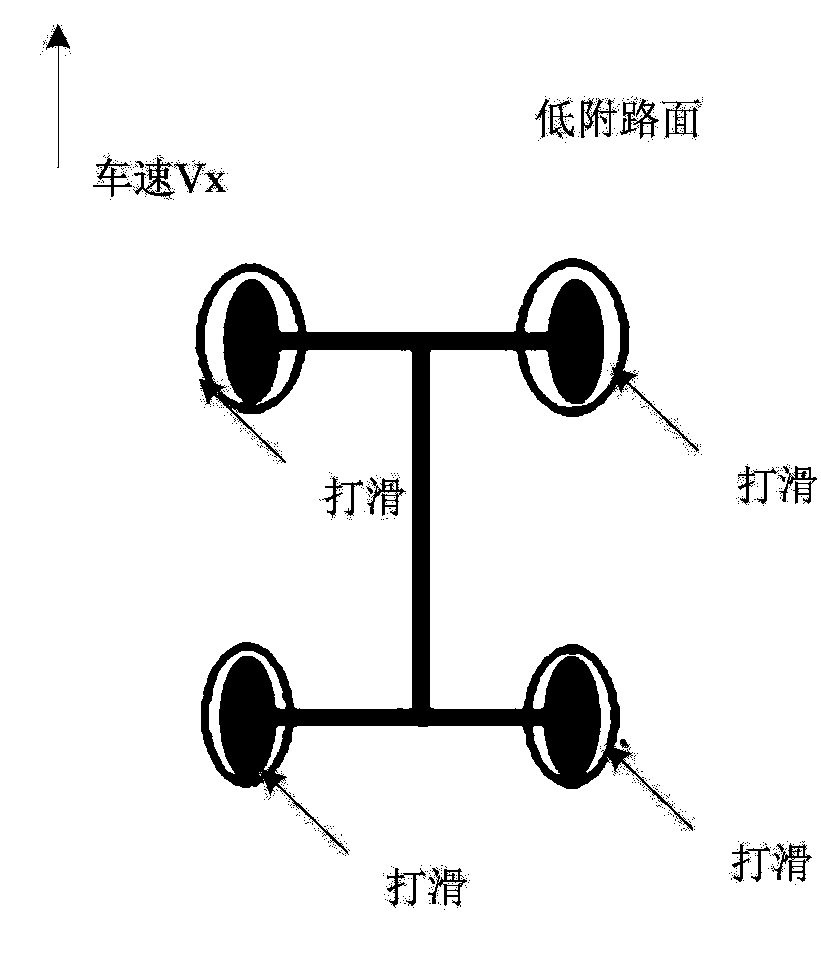

Driving anti-slip control method and device of four-drive electric vehicle

ActiveCN108248455AImprove escape performancePrevent sidewaysSpeed controllerElectric devicesRoad surfaceElectric vehicle

The invention discloses a driving anti-slip control method and device of a four-drive electric vehicle. The control method comprises the following steps of detecting wheel speeds of four vehicle wheels of the electric vehicle and the depth of an accelerator pedal; according to the vehicle speeds of the vehicle wheels, estimating the vehicle speed of the electric vehicle, determining the road conditions of the electric vehicle according to the wheel speeds of the vehicle wheels and the vehicle speed, and obtaining demand torque of the electric vehicle according to the depth of the accelerator pedal, wherein the road conditions comprise the low tire-road friction starting pavement, the joint pavement and the bisection pavement; conducting driving anti-slip control on the vehicle wheels respectively according to the road conditions and the demand torque. By means of the driving anti-slip control method, it can be guaranteed that after the electric vehicle enables the anti-slip function, the rear vehicle wheels do not turn very fast, the electric vehicle does not skew, the yaw velocity is within a certain range, ground adhesive force can be utilized to the greatest extent, and the capability for the electric vehicle to get rid of the trouble is improved.

Owner:BYD CO LTD

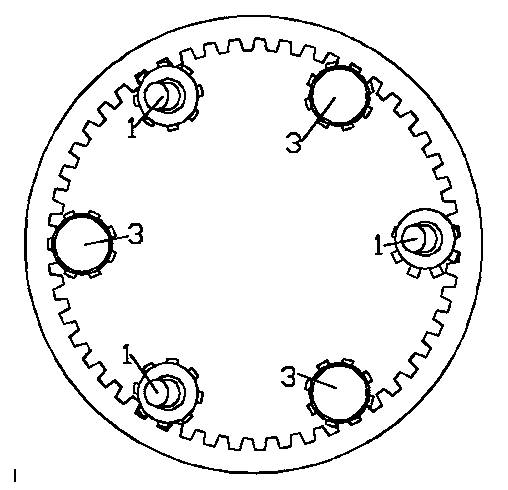

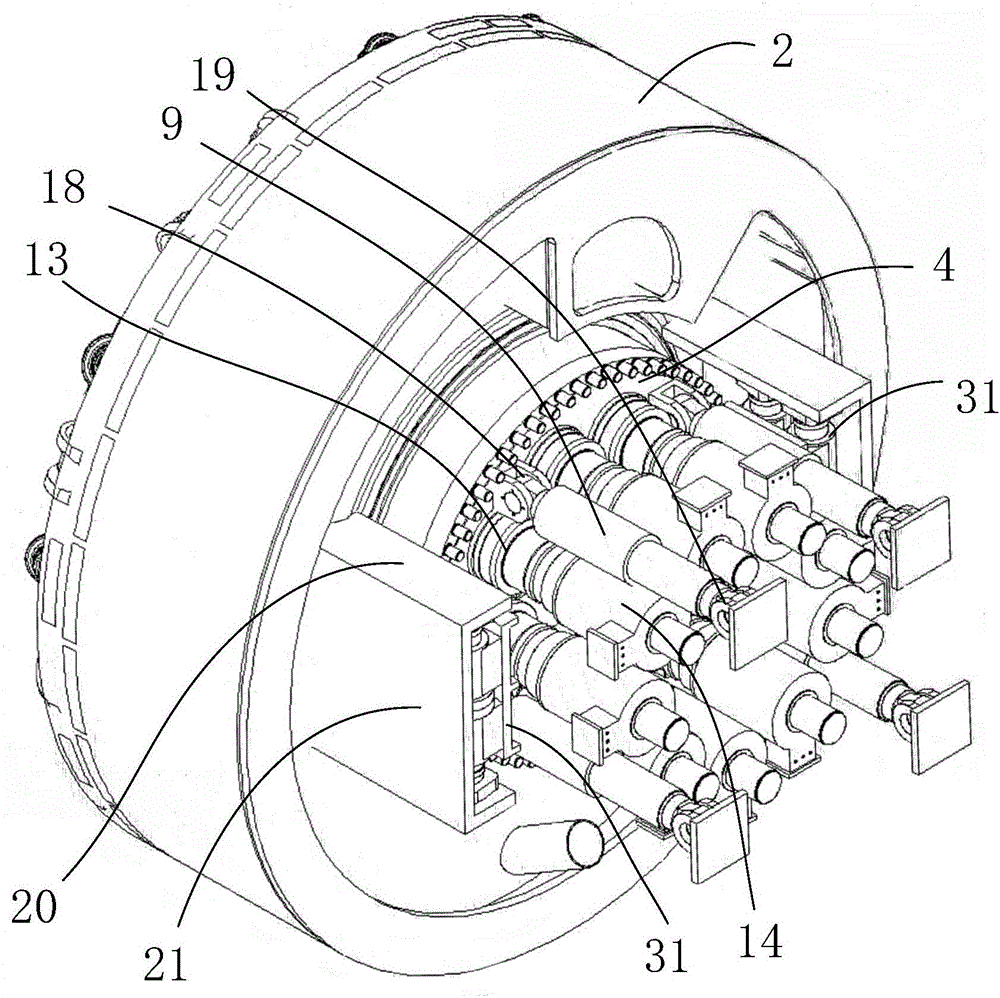

Compound driving device of TBM cutting disc motor hydraulic motor

The invention discloses a compound driving device of a hydraulic motor of a TBM (tunnel boring machine) cutting disc motor. The compound driving device comprises a big gear ring and a variable frequency motor driving mechanism, wherein the variable frequency motor driving mechanism comprises a first pinion, a first speed reducer and a variable frequency motor; the first pinion and the big gear ring are meshed; an output shaft of the first speed reducer and the first pinion are fixedly connected; an input shaft of the first speed reducer and an output shaft of the variable frequency motor are connected; in addition, the compound driving device also comprises a hydraulic motor driving mechanism, wherein the hydraulic motor driving mechanism comprises a second pinion, a second speed reducer, a viscosity clutch and a hydraulic motor; the second pinion and the big gear ring are meshed; an output shaft of the second speed reducer and the second pinion are fixedly connected; an input shaft of the second speed reducer and an output shaft of the viscosity clutch are connected; and an input shaft of the viscosity clutch and an output shaft of the hydraulic motor are connected. By utilizing the compound driving device, geological adaptability of a TBM cutting disc driving system and trouble-out ability of the TBM are obviously improved, so that driving characteristics of the cutting disc and geological characteristics of rock are matched, and the use ratio of the installed power is improved.

Owner:ZHEJIANG UNIV

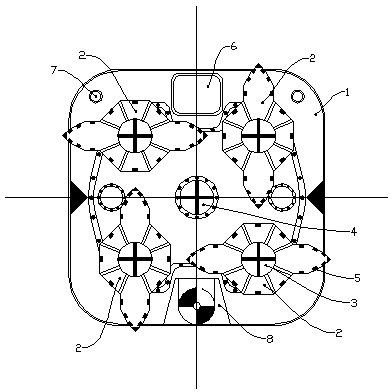

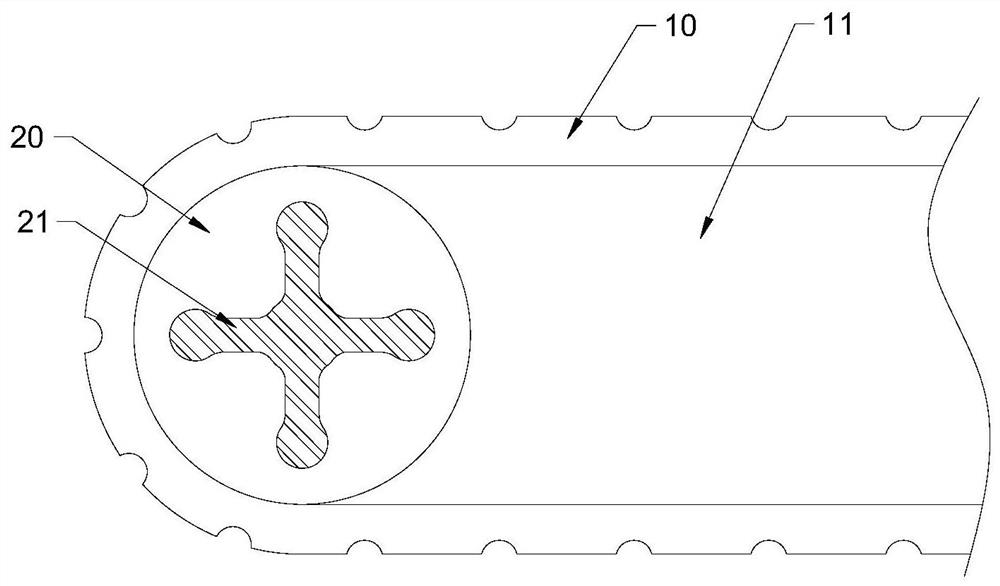

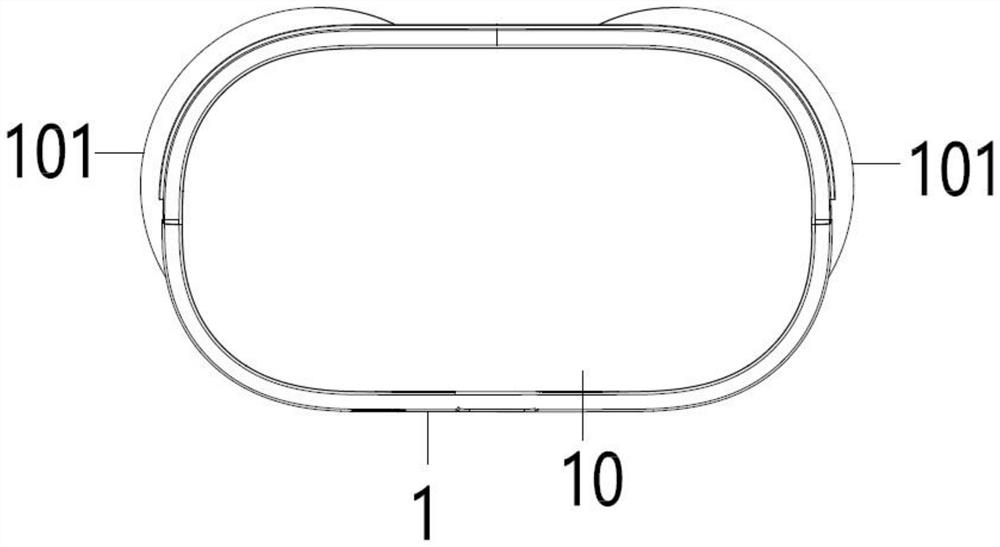

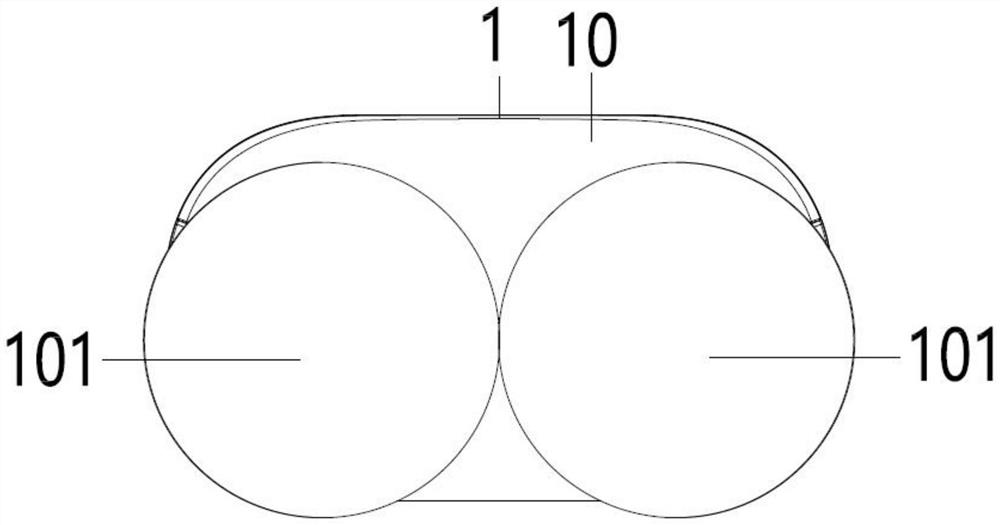

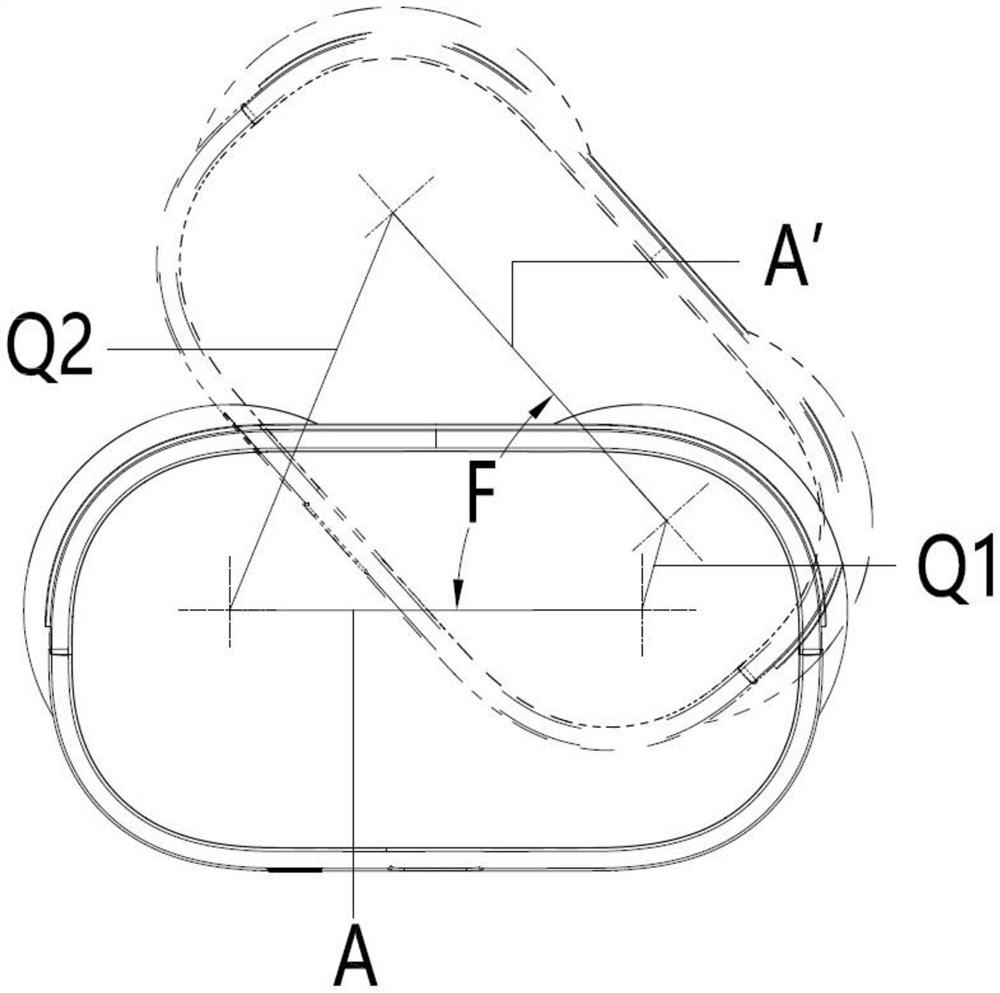

All-cross-section cutting rectangular pipe-pushing machine cutting mechanism

InactiveCN103410445AImprove the ability to get out of troubleSimple structureDrilling without earth removalFace contourEngineering

The invention relates to an all-cross-section cutting rectangular pipe-pushing machine cutting mechanism used in rectangular pipe-pushing devices used in non-excavation engineering. The mechanism comprises an installing seat, four cutterheads with cutting surfaces located on the same plane are installed on the front end face of the installing seat, centers of rotating shafts of the four cutterheads are respectively located on four vertexes of a square and are driven by an identical spindle located at the center of the installing seat to synchronously rotate at a uniform speed, the end face contour of every cutterhead is a long shape with the dimension in the length direction larger than the dimension in the width direction, cutting blades are arranged on the edge of the cutterheads, the length direction of every cutterhead is perpendicular to the length direction of the cutterheads adjacent to the cutterhead, the maximum cutting radius of every cutterhead and the maximum cutting radius of the adjacent cutterhead have an overlapped part, and the four cutterheads do not interfere with each other when rotating synchronously at the uniform speed. Rectangular all-cross-section cutting can be achieved, the all-cross-section cutting rectangular pipe-pushing machine cutting mechanism is high in difficulty overcoming capability, simple in structure and high in reliability, the technical requirements for constructors are low, and soil mass is mixed fully.

Owner:ZHENJIANG ANDA COAL MINE SPECIAL EQUIP

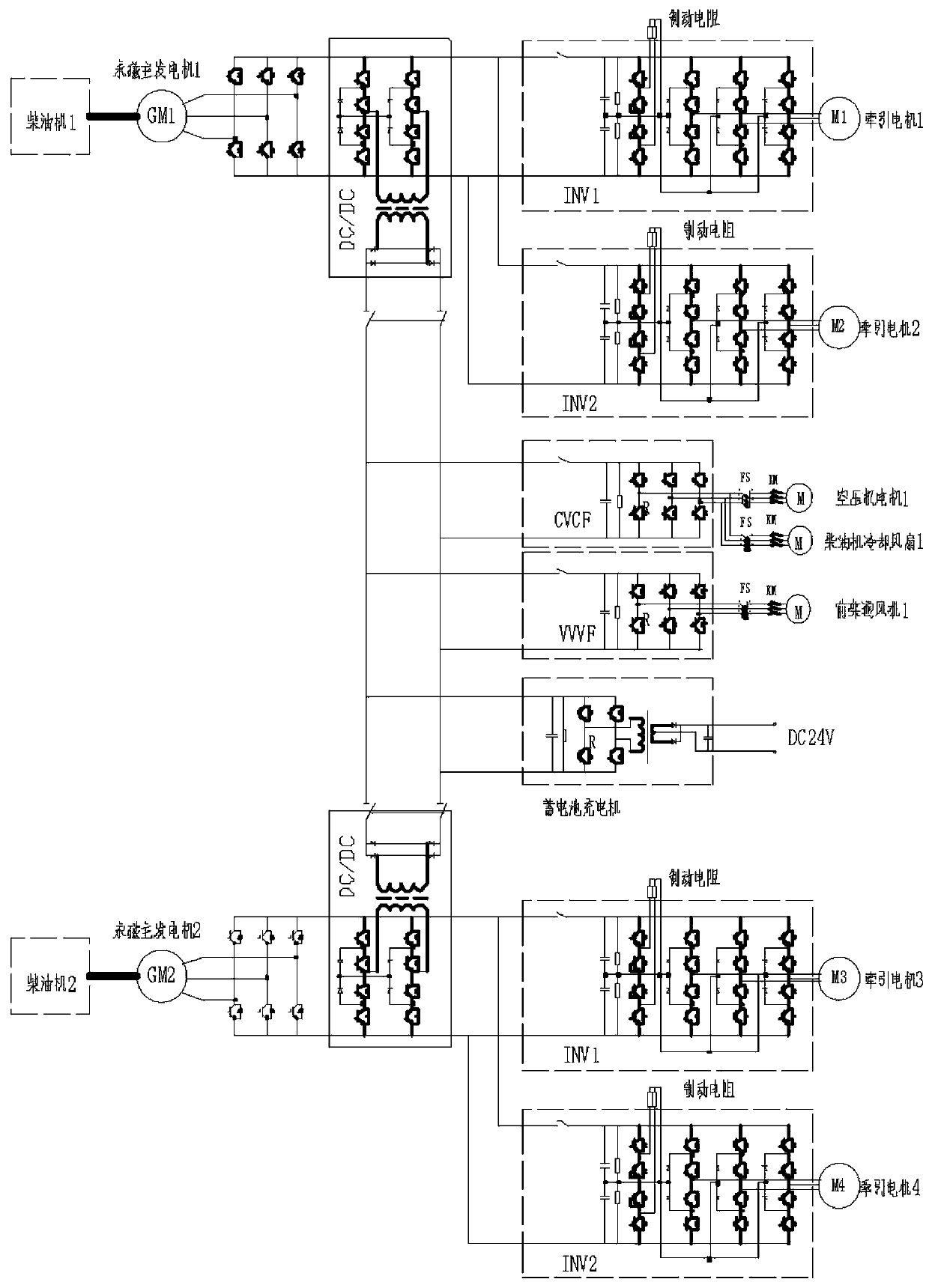

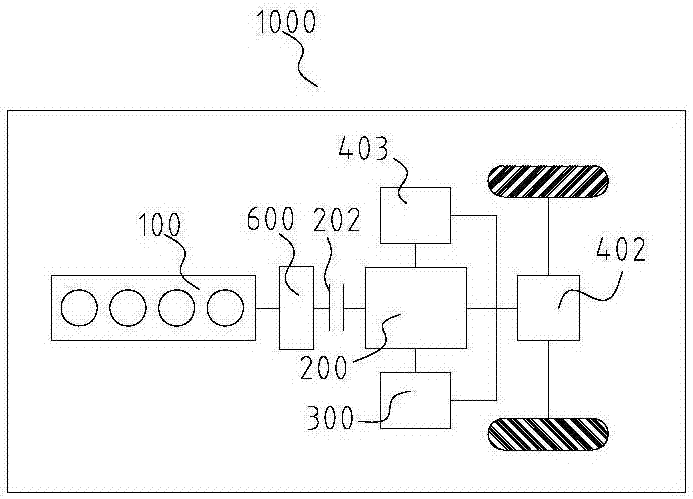

Vehicle alternating current transmission system

ActiveCN110834550AEasy to manufactureIncrease power generationRailway vehiclesPropulsion using engine-driven generatorsElectric generatorDc converter

The invention relates to an alternating current transmission system, in particular to a vehicle alternating current transmission system, and solves the defects and the problems of a transmission way of an existing heavy track car. The system comprises a traction system and an auxiliary system, wherein the traction system consists of a first traction system and a second traction system; the first traction system and the second traction system have the same structure and independently comprise a diesel engine, a permanent magnet synchronous generator, a four-quadrant traction rectifier, a traction inverter and an asynchronous traction machine; the auxiliary system comprises an auxiliary system direct current bus which is connected with an auxiliary inverter; the direct current bus of the rectifier of the first traction system is connected with the auxiliary system direct current bus through a first DC / DC converter and a first fling-cut switch; and the direct current bus of the rectifierof the second traction system is connected with the auxiliary system direct current bus through a second DC / DC converter and a second fling-cut switch. The alternating current transmission system isespecially suitable for a GCD-1000II heavy track car and is also suitable for other vehicles.

Owner:CRRC YONGJI ELECTRIC CO LTD

Self-moving device escaping method and self-moving device

ActiveCN110192814AImprove escape performanceImprove work efficiencyCarpet cleanersFloor cleanersComputer hardwareMobile device

The invention discloses a self-moving device escaping method which comprises the steps that a self-moving device is driven to move forwards; whether the self-moving device can continue moving forwardor not is determined; if the self-moving device cannot continue moving forwards, the self-moving device is controlled to perform a first escaping pre-processing operation; if the self-moving device cannot continue moving forwards after performing the first escaping pre-processing operation, the self-moving device performs a second escaping pre-processing operation; the self-moving device is drivento retreat; whether the self-moving device can successfully retreat or not is determined; if the self-moving device can successfully retreat, the self-moving device is controlled to perform a third escaping pre-processing operation; and if the self-moving device cannot successfully retreat, the self-moving device is controlled to perform a fourth escaping pre-processing operation. According to the scheme, the self-moving device is enabled to perform the escaping operation to be away from a trapped point in time when being stuck by an object or trapped during the moving process, the escaping performance of the self-moving device is increased, the efficiency of the self-moving device is improved, and the product use experience is improved.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

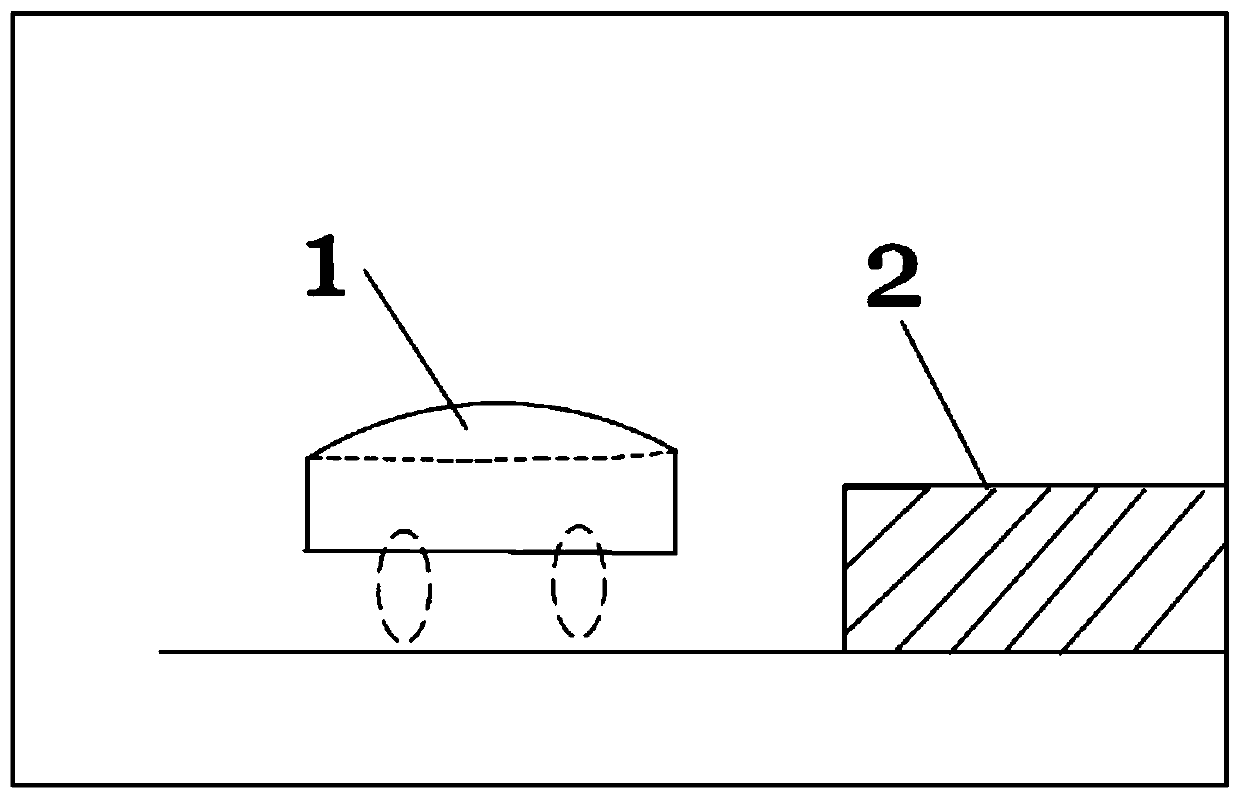

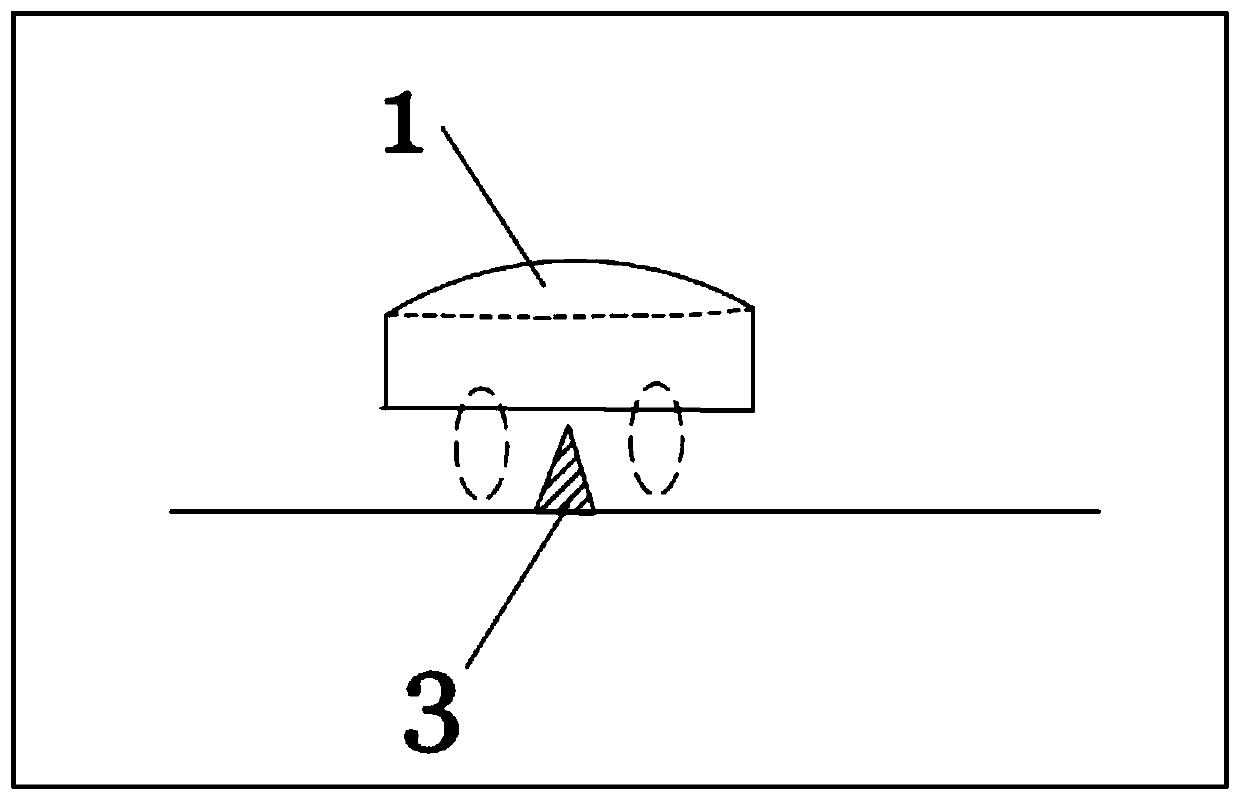

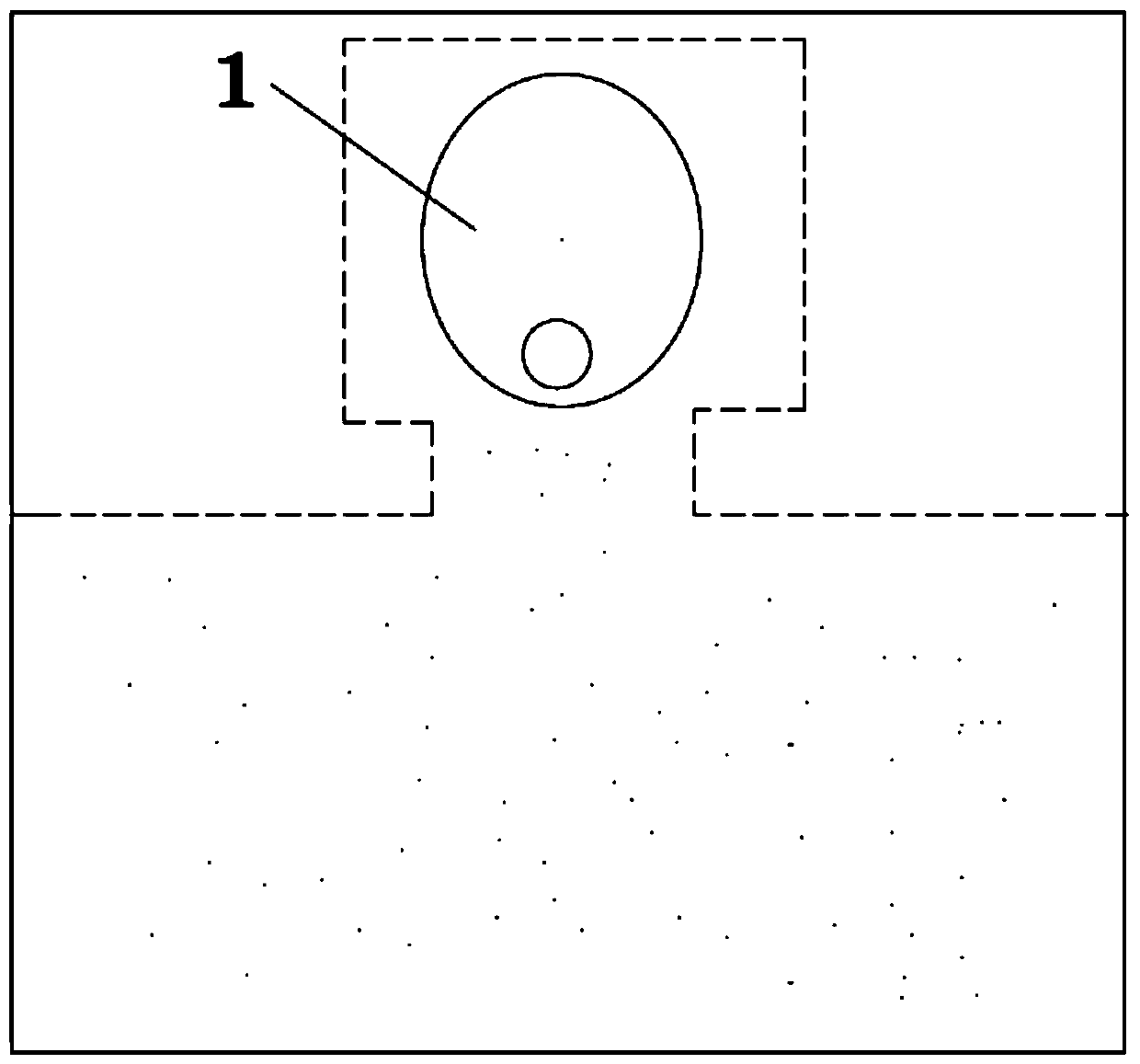

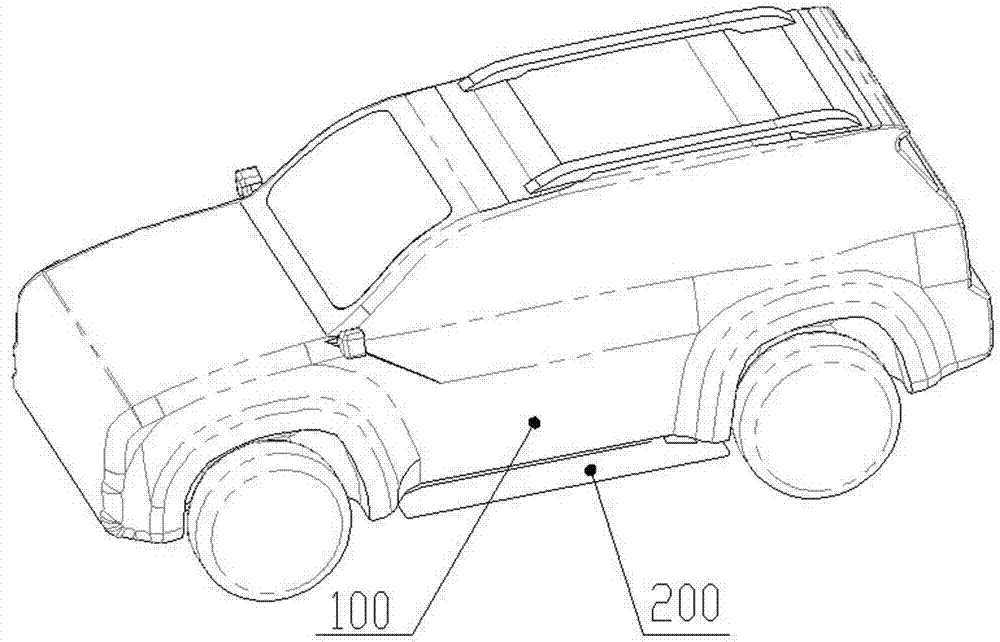

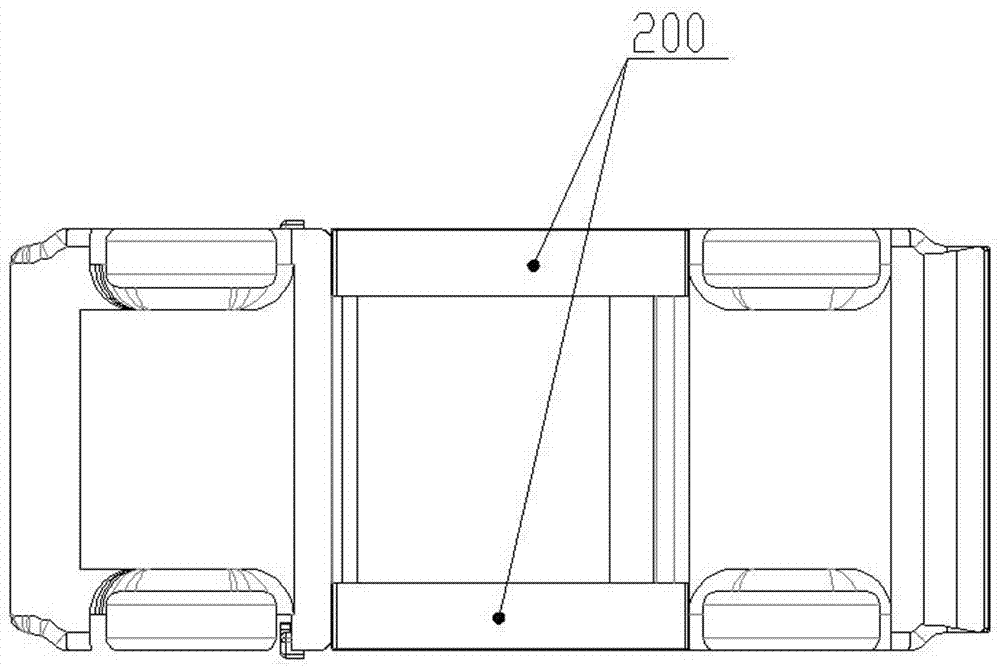

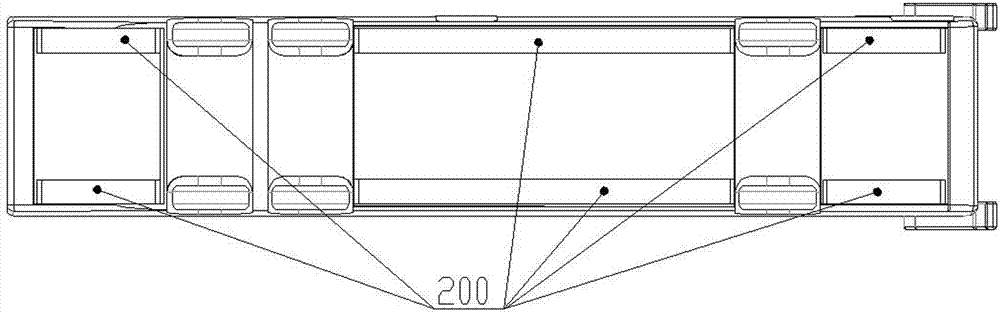

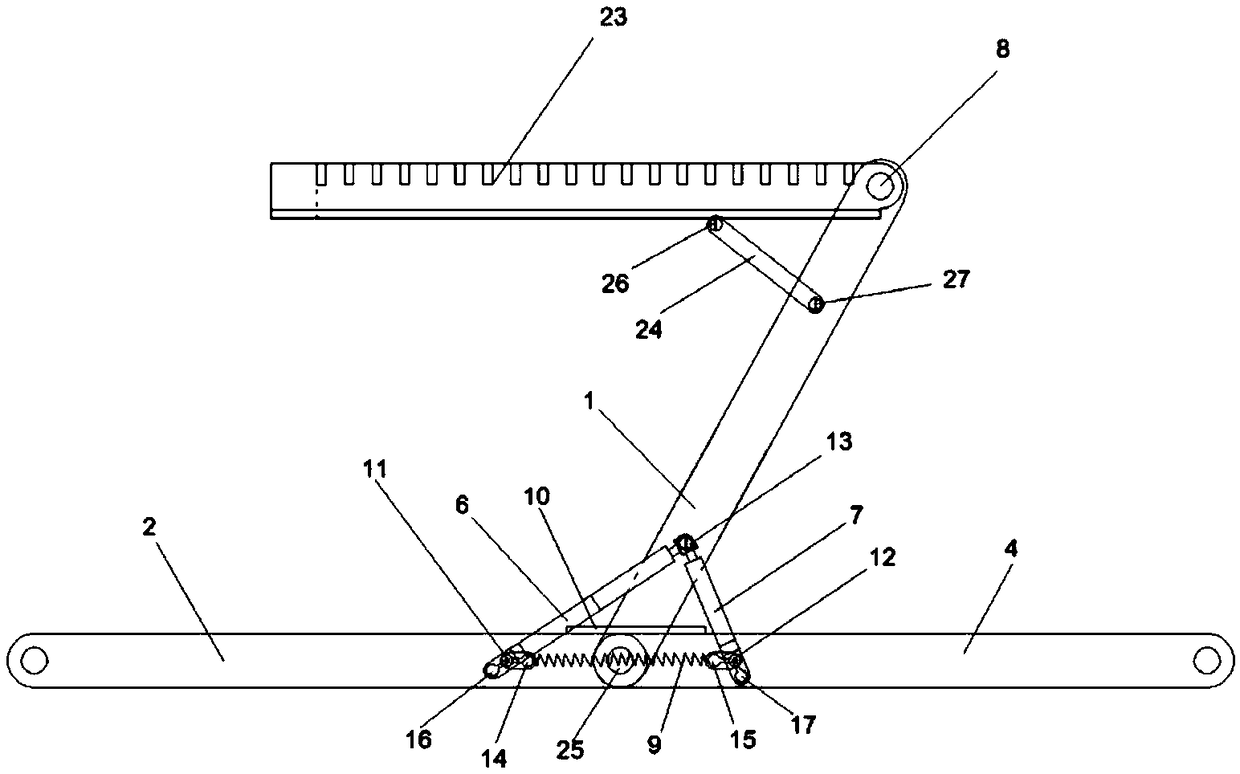

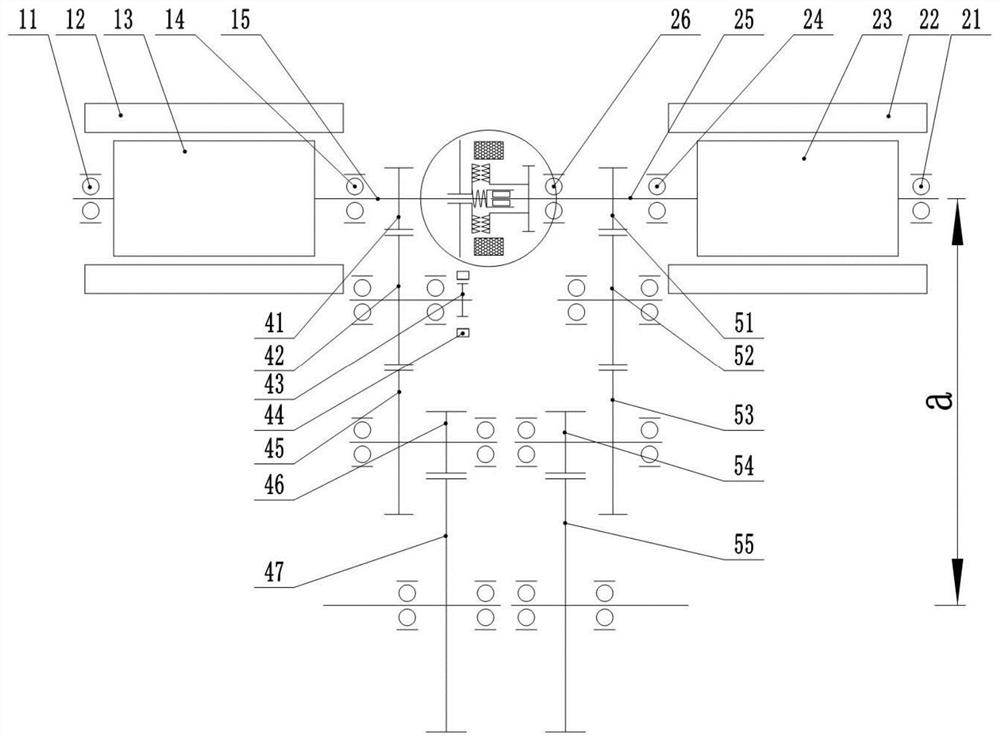

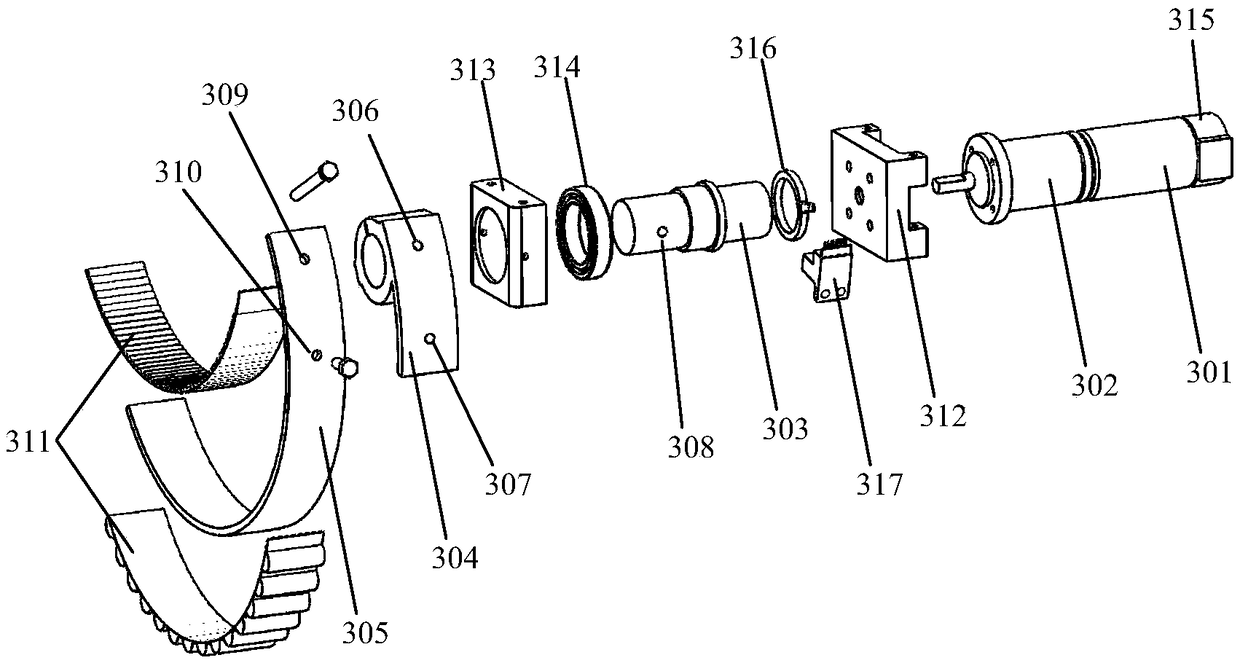

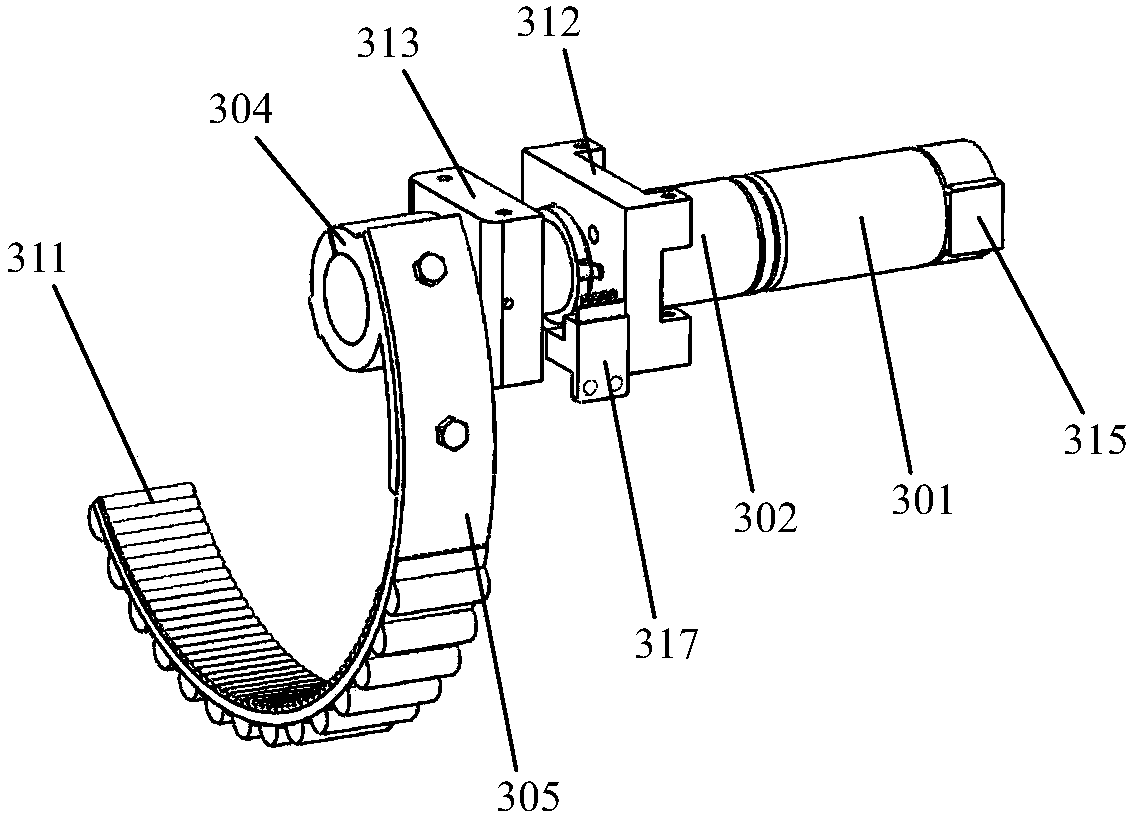

Auxiliary driving system and vehicle

ActiveCN106864430AIncrease friction area and friction capacityImprove the ability to get out of troubleVehicle modificationsEndless track vehiclesEngineeringRoad condition

The invention discloses an auxiliary driving system and a vehicle. According to the embodiment of the invention, the auxiliary driving system is constructed on the basis of a parallelogram mechanism, the rack part and a framework opposite to the rack part of the of the parallelogram mechanism can keep parallel all the time, so that bearing of a supporting framework is distributed relatively evenly in the front and back directions and not affected by opening stroke. When in the opening state, the auxiliary driving system is used for extricating of the vehicle or auxiliary driving under a certain road condition; and when in a folded state, greater influence on traversability of the vehicle is reduced, so that the auxiliary driving system can be always prepared on the vehicle, and the situation that the auxiliary driving system is mounted only when the vehicle is caught in a sandy land and the like is not needed. The auxiliary driving system can effectively increase the friction area and friction ability, so that the auxiliary driving system is used for improving the extricating ability.

Owner:JINAN JIANGFUWAN AUTOMATION TECH

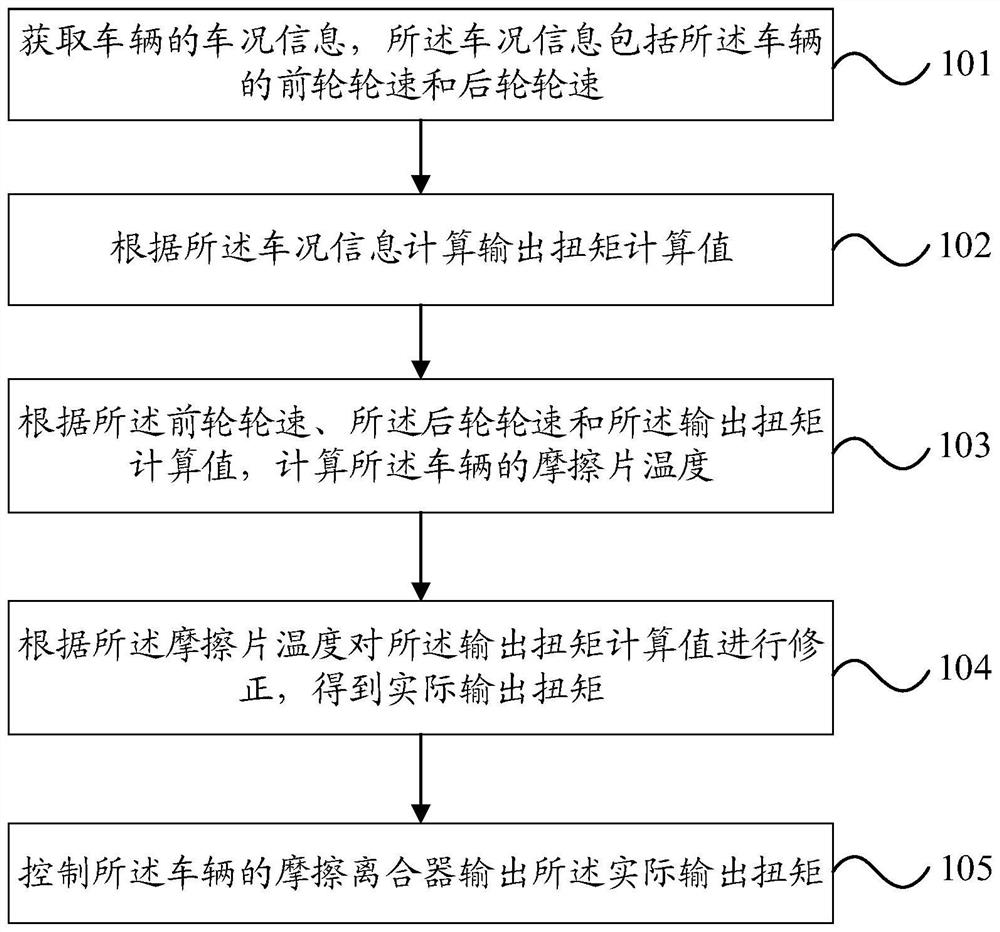

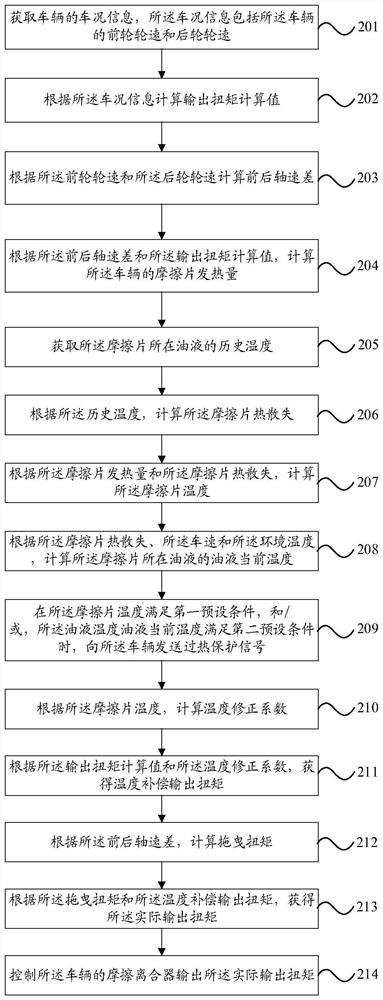

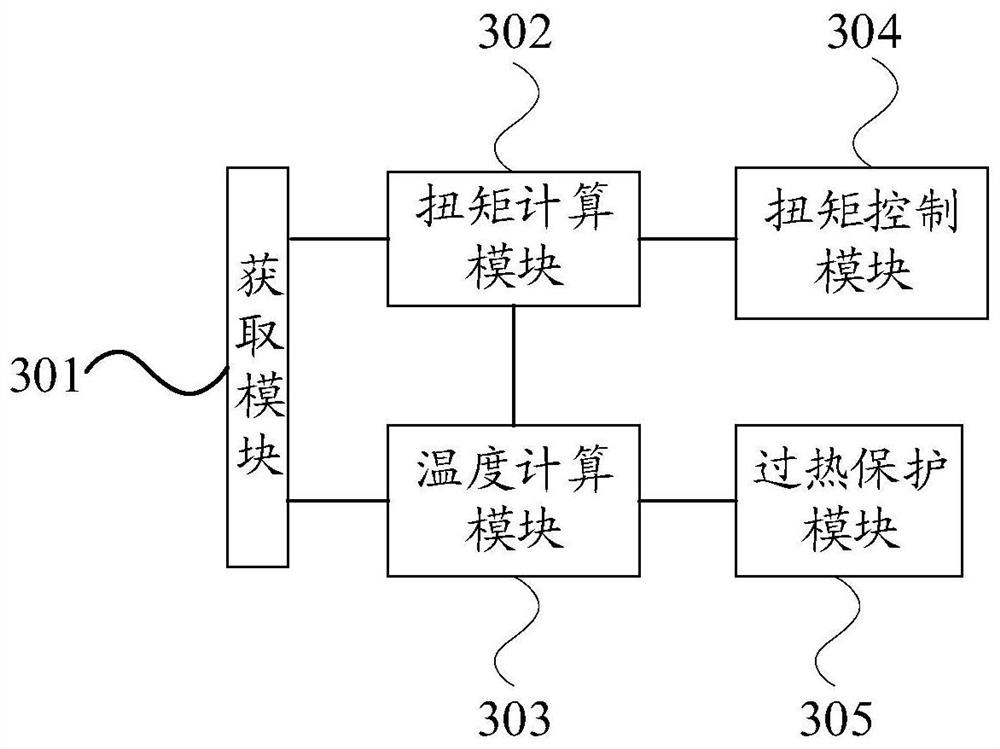

Intelligent four-wheel drive control method and system and vehicle

ActiveCN111791869AHigh control precisionReduces ablative damageBrake control systemsFriction clutchesControllabilityClutch

The invention provides an intelligent four-wheel drive control method and system and a vehicle. The intelligent four-wheel drive control method comprises the following steps: acquiring vehicle condition information of a vehicle; calculating an output torque calculation value of the vehicle; with combination of front wheel speed, rear wheel speed and output torque calculation values, calculating the temperature of the friction plate of the vehicle; and finally, correcting the output torque calculation value according to the temperature of the friction plate to obtain an actual output torque, and controlling a friction clutch of the vehicle to output the actual output torque. According to the intelligent four-wheel drive control method, the temperature of the friction plate is directly obtained according to the real-time vehicle condition information, and the accuracy is higher; meanwhile, the output torque calculation value is corrected through the temperature of the friction plate, thecontrol accuracy of the output torque is improved, then the controllability and the escape capacity of the whole vehicle are improved, and the probability that the friction plate is ablated and damaged is reduced.

Owner:GREAT WALL MOTOR CO LTD

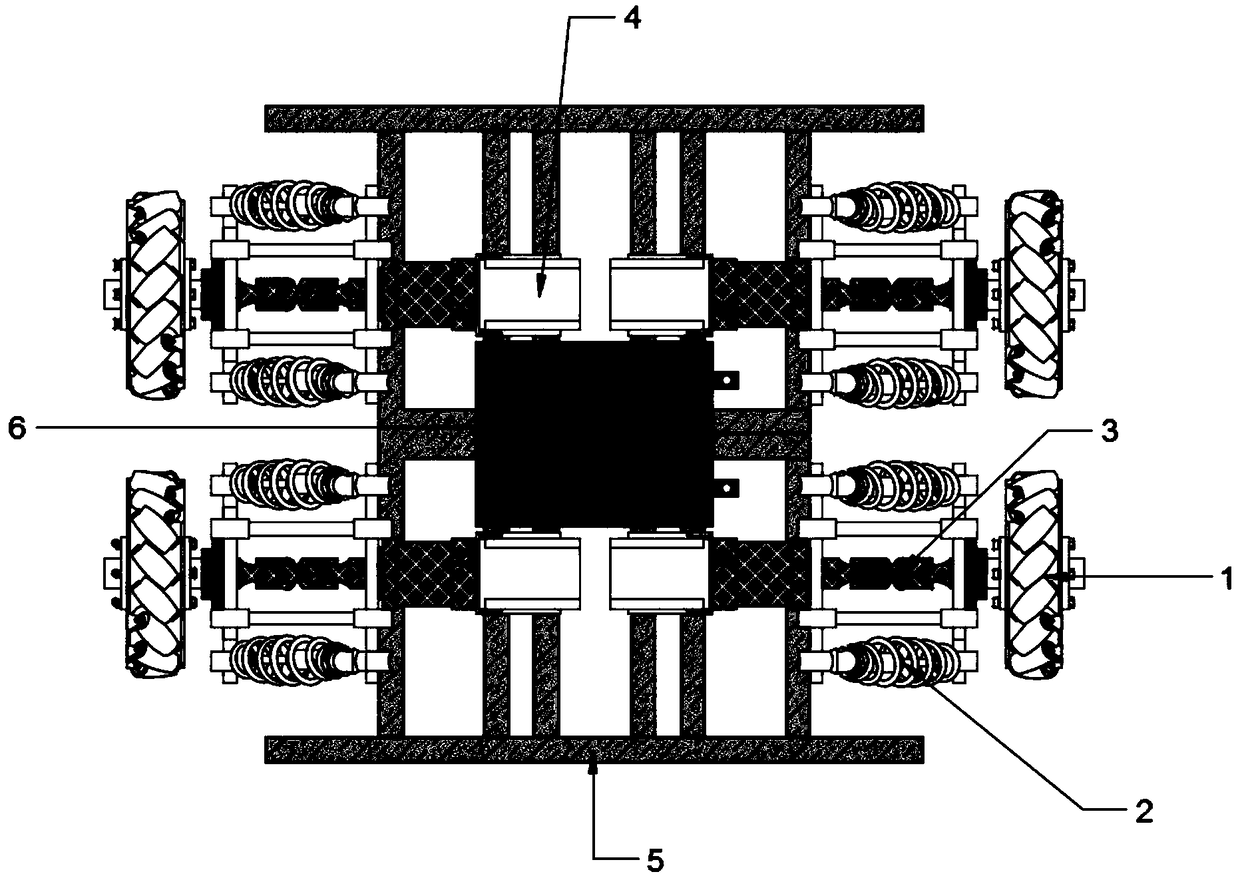

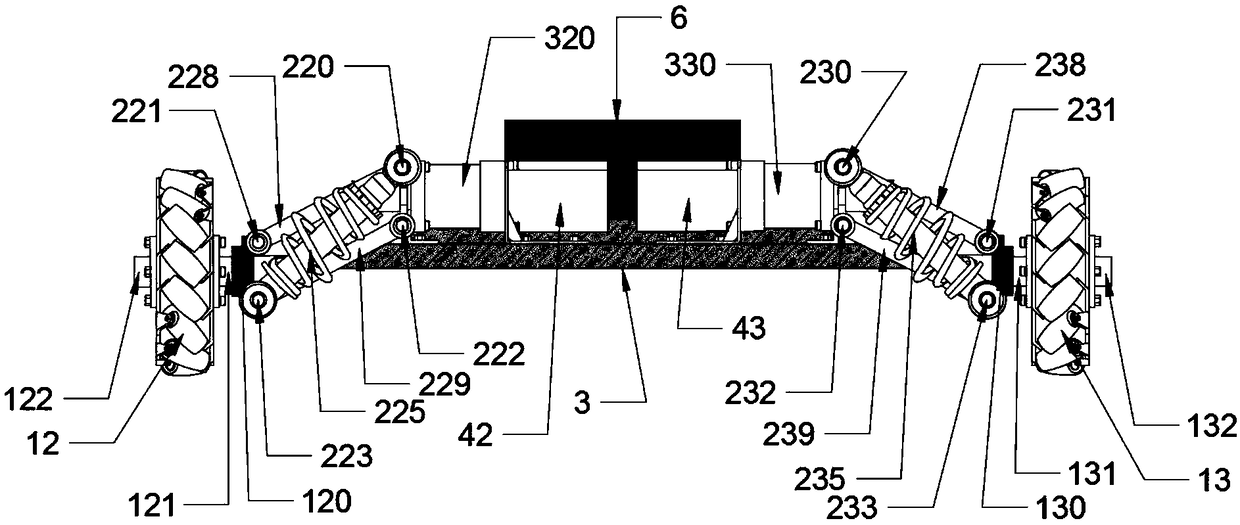

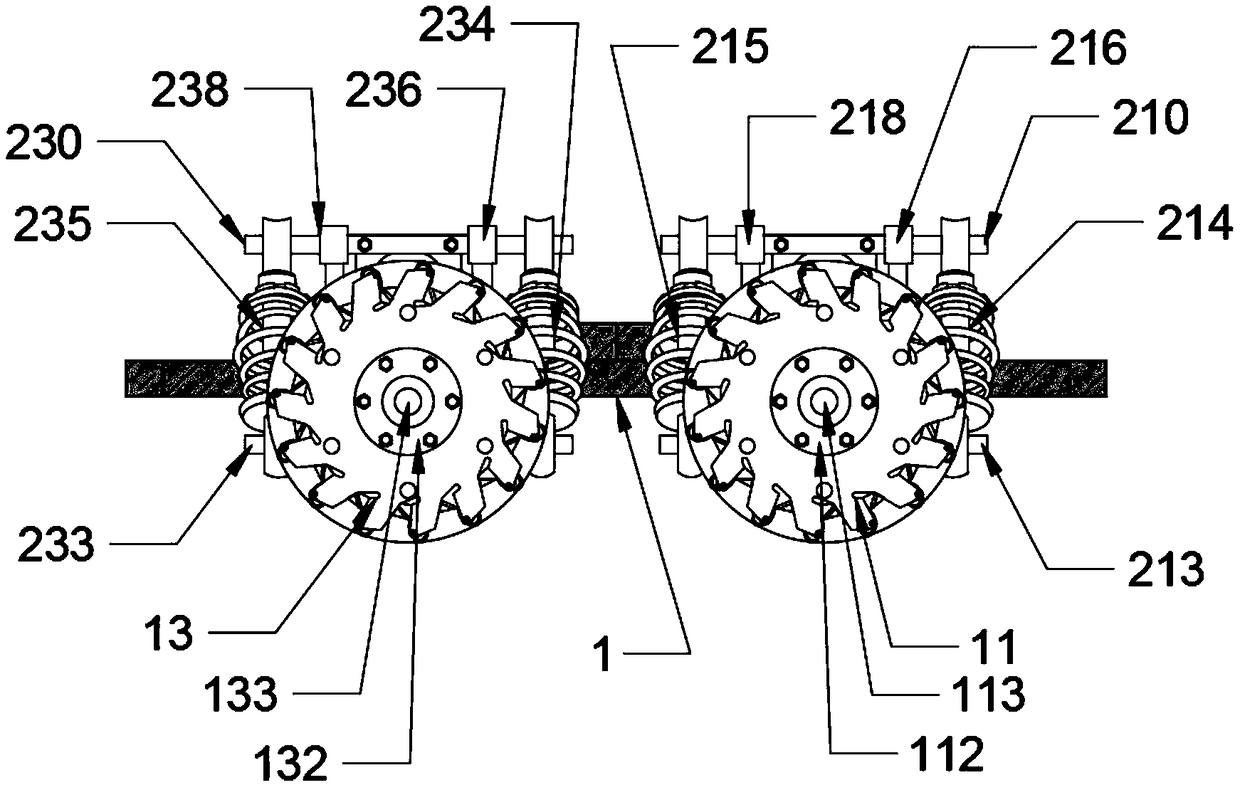

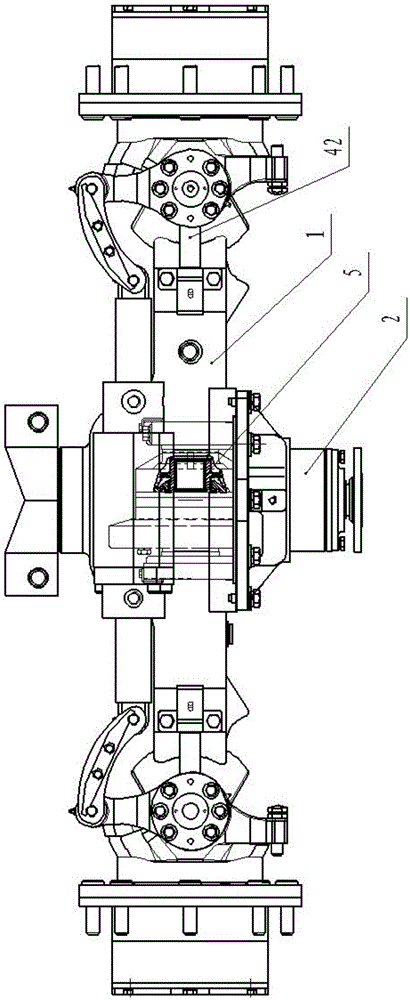

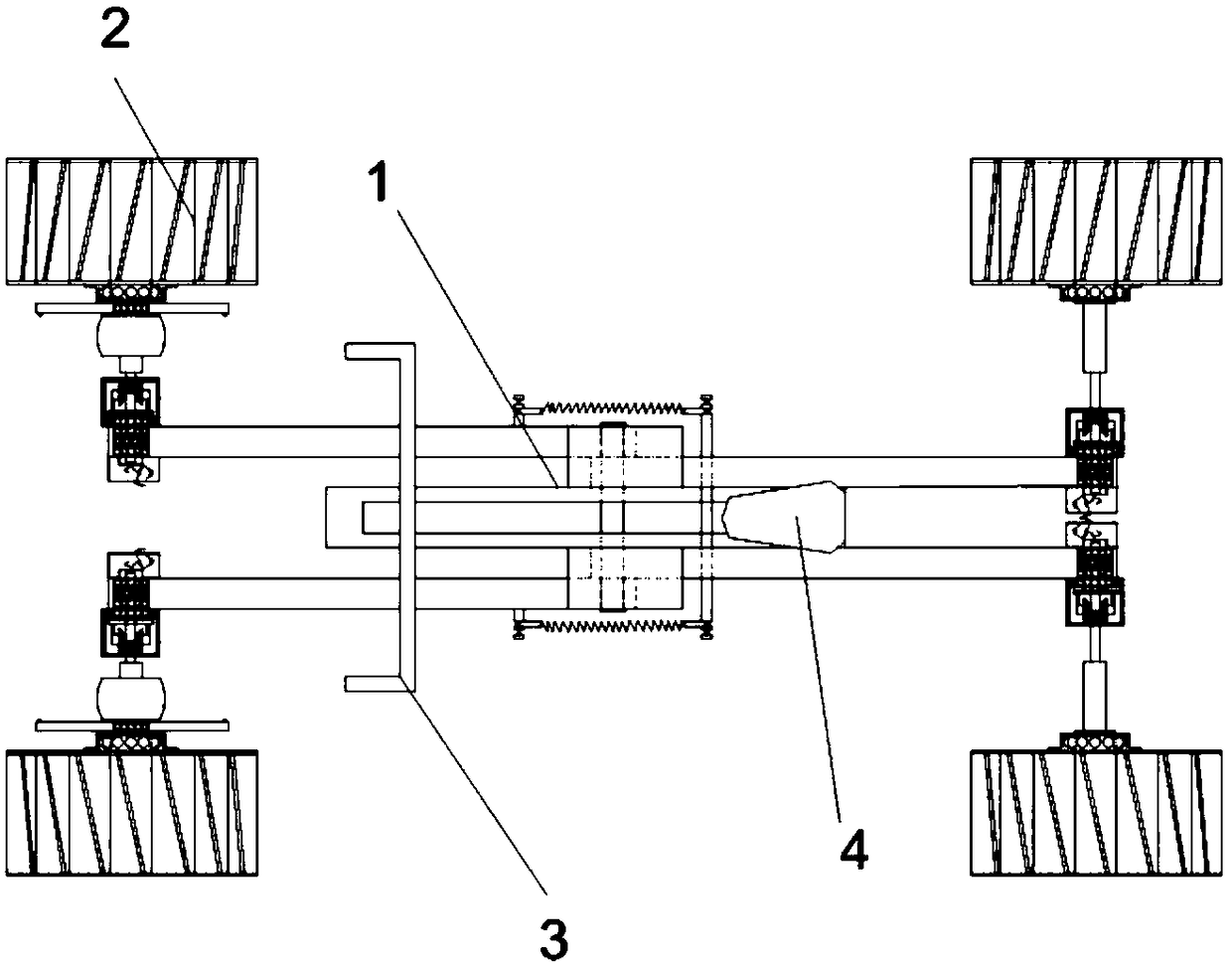

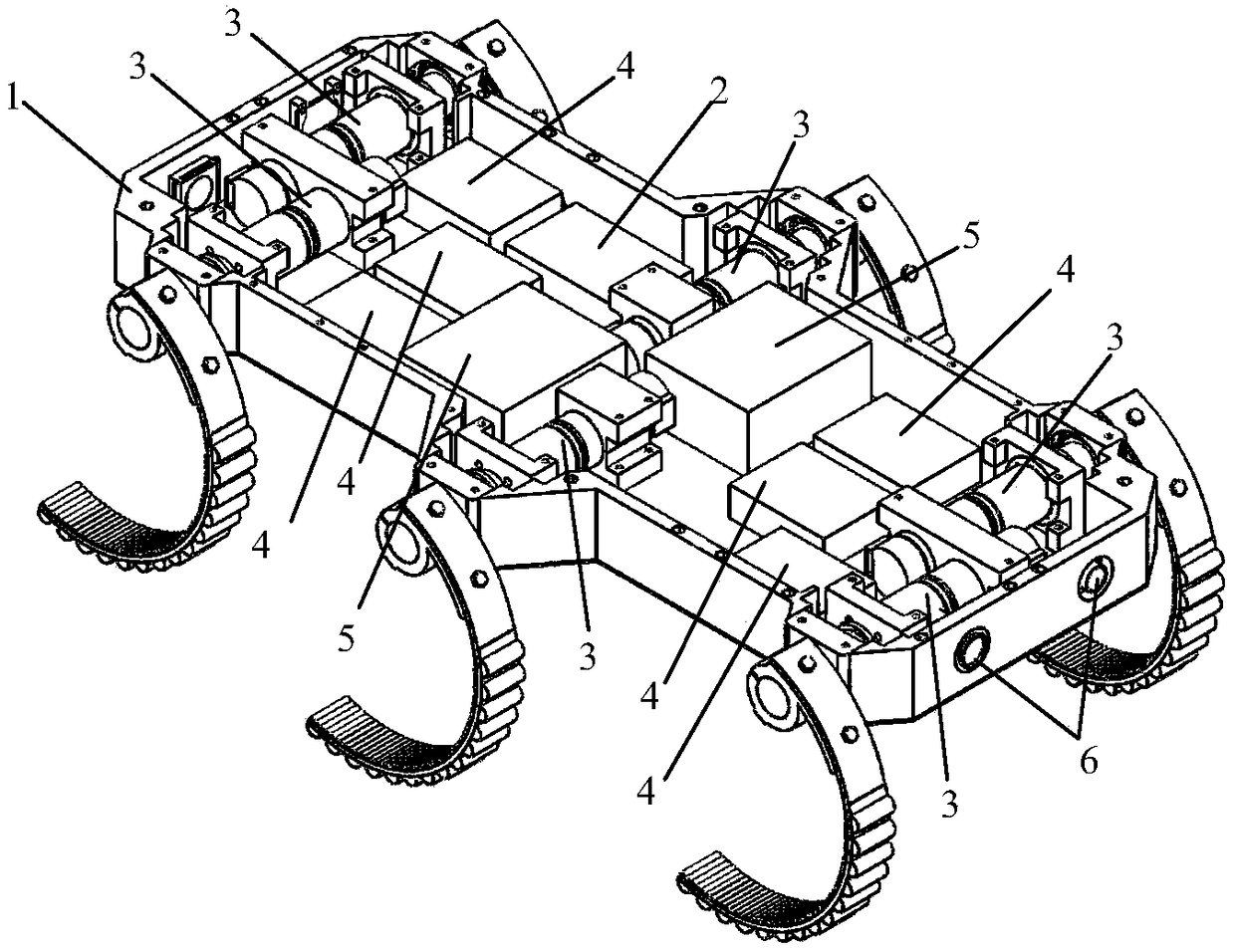

All-dimensional wheeled mobile robot chassis

PendingCN108860362ASmall turning radiusHigh displacement accuracyElectric propulsion mountingResilient suspensionsReduction driveControl theory

The invention discloses an all-dimensional wheeled mobile robot chassis. The chassis comprises wheels, a suspension unit, a transmission unit, a driving unit, a chassis frame and a power unit. Mecanumwheels are adopted as the wheels of a robot, compared with other wheels, the Mecanum wheels can achieve pivot steering, translation and pozidriv walking, and the turning radius of the robot is greatly reduced, so that the robot is more flexible and passes through the narrow and small space conveniently; each wheel is provided with an independent driving motor, and a 57 stepping motor and a speedreducer are adopted, so that the robot is high in displacement precision and has point fixing and positioning effects; the mobile robot bears a heavy load, can bear a weight of 100 kg and is high in slope climbing capacity and driving force; each wheel is provided with an independent damping unit, the wheels cannot influence one another on the uneven ground, so that the robot keeps stable, the damping effect is improved, and accordingly the capacity of getting rid of the difficulty is improved.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

Electronic differential for electric vehicle

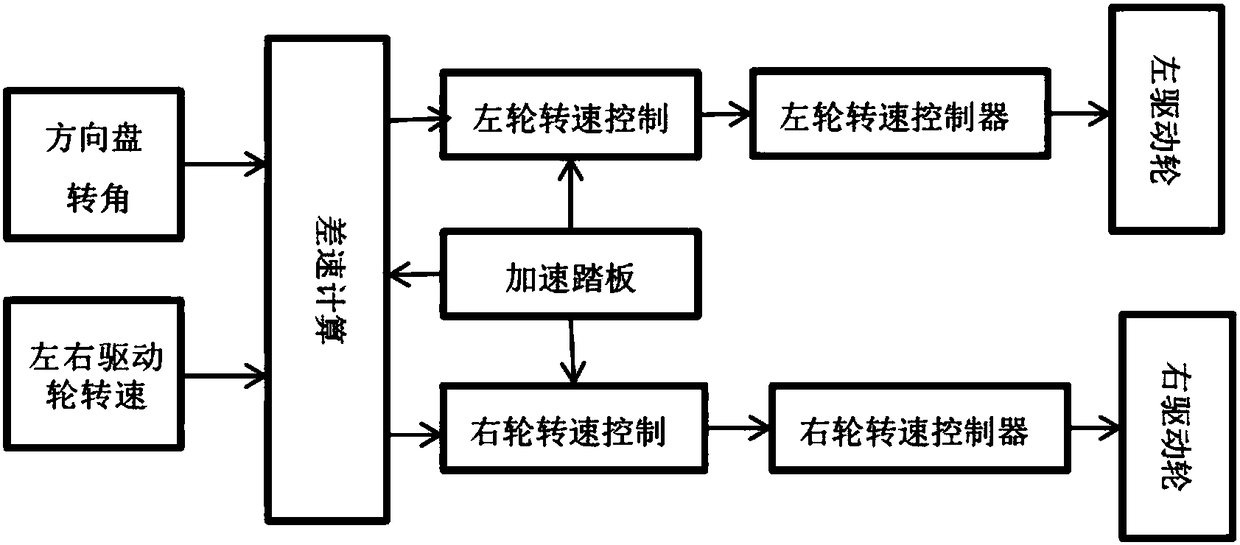

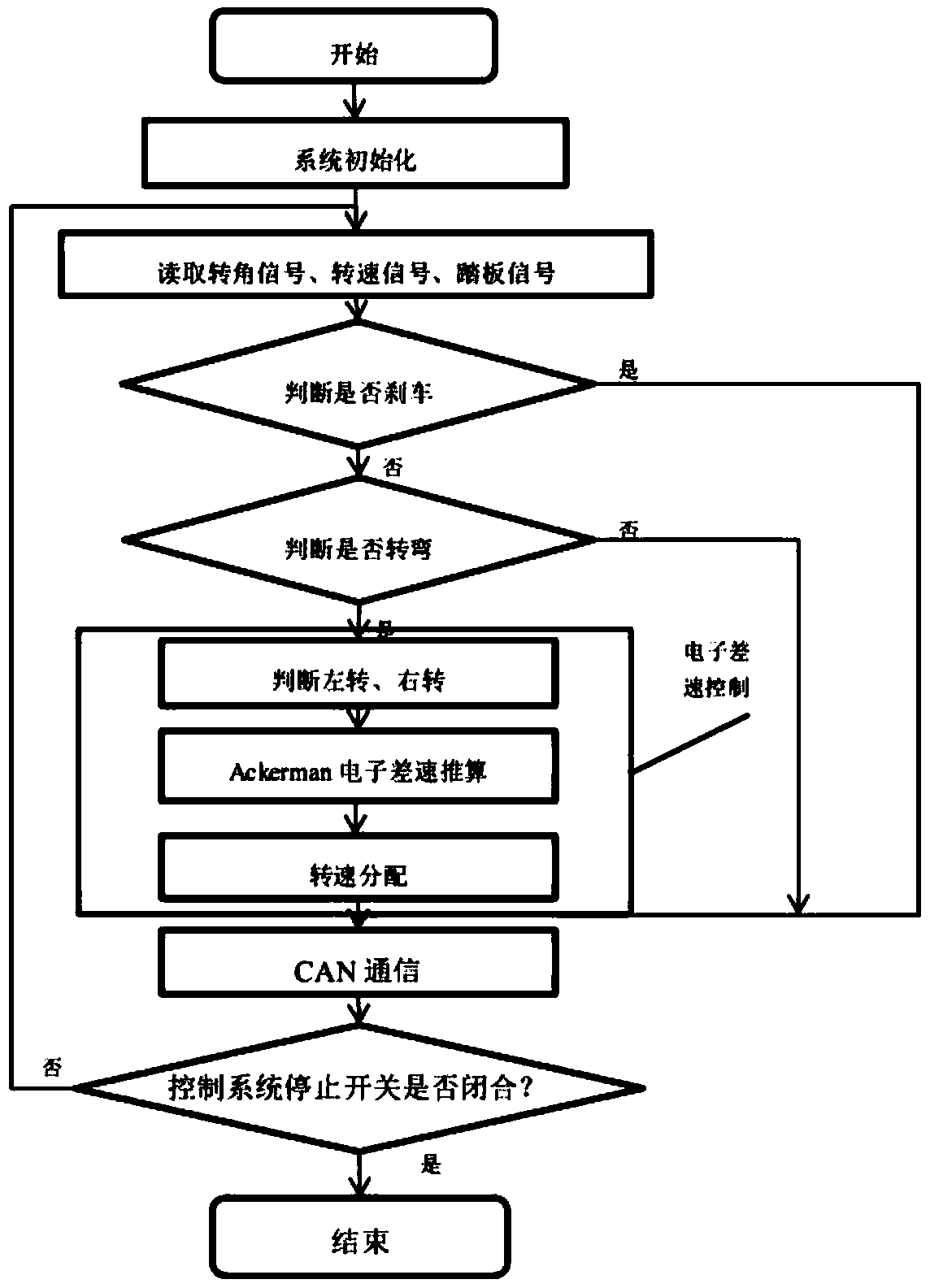

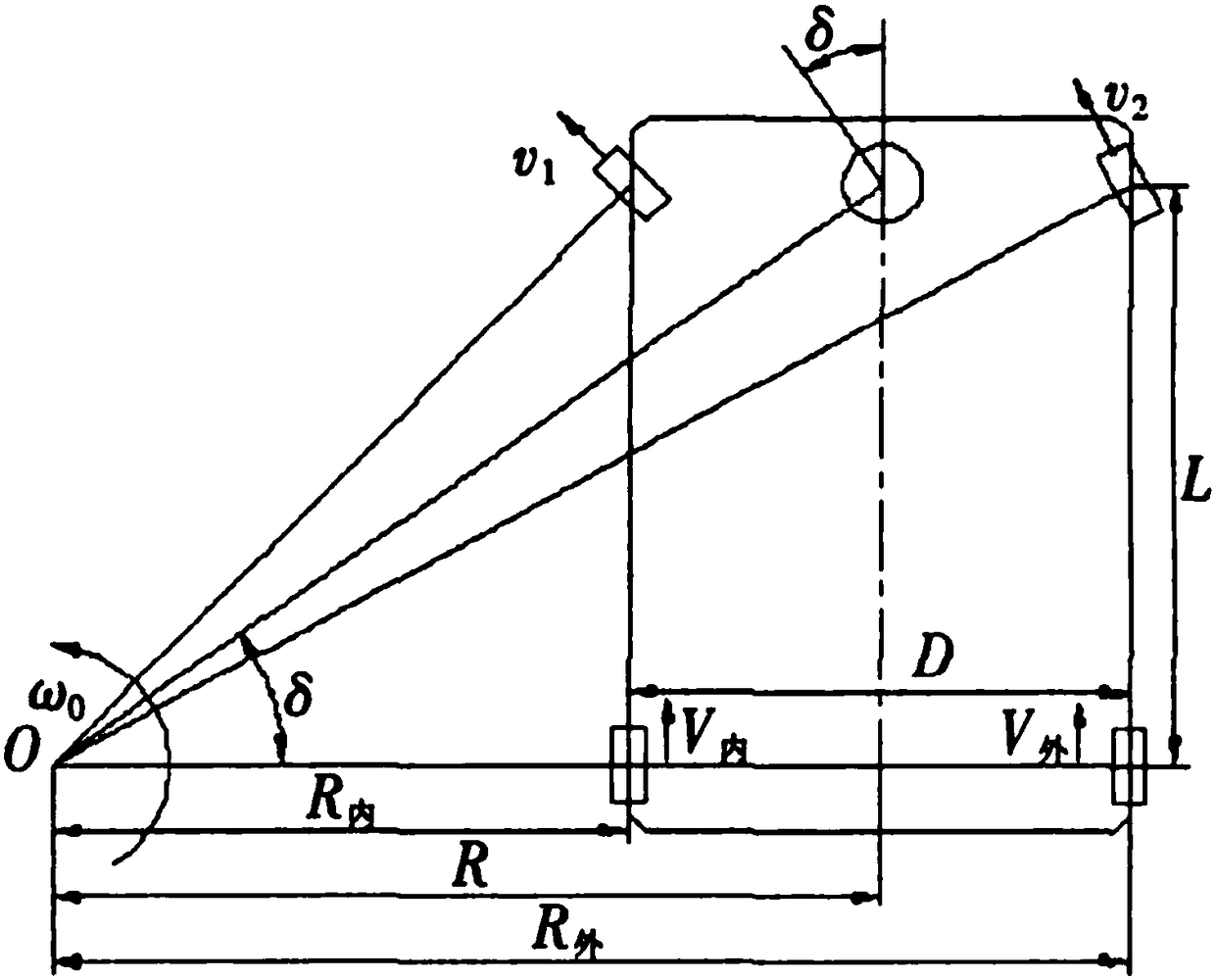

InactiveCN108466570AEasy to controlControl does not limitSpeed controllerElectric vehicle charging technologyDrive wheelElectronic differential

The invention relates to an electronic differential for an electric vehicle. The electronic differential is used for the double-motor rear drive electric vehicle and comprises a vehicle controller andfurther comprises left and right driving wheel rotating speed controllers, a steering wheel rotation angle sensor, left and right driving wheel rotating speed sensors and an accelerator pedal sensorwhich are connected with the vehicle controller. The vehicle controller comprises a braking judging module used for judging whether the electric vehicle is in a braking state or not, a turning judgingmodule used for judging whether the electric vehicle is in a turning state or not, a differential control module with a preset speed equation model, and a vehicle speed sensor breakdown judging module used for judging whether a vehicle speed sensor breaks down or not. Data collected by all the sensors are input into the vehicle controller and calculated by the speed equation model, and then the rotating speeds of a left driving wheel and a right driving wheel are distributed by the left and right driving wheel rotating speed controllers. According to the electronic differential, the capability of the vehicle for getting out of trap is promoted by a large margin, the number of parts of a transmission system is decreased, and the transmission efficiency of the vehicle is improved.

Owner:WUHAN UNIV OF TECH

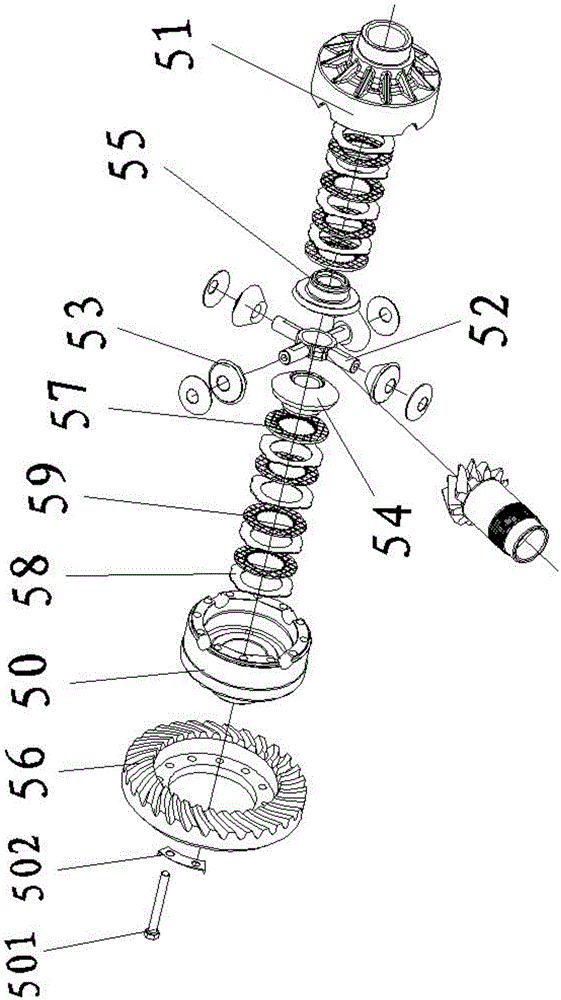

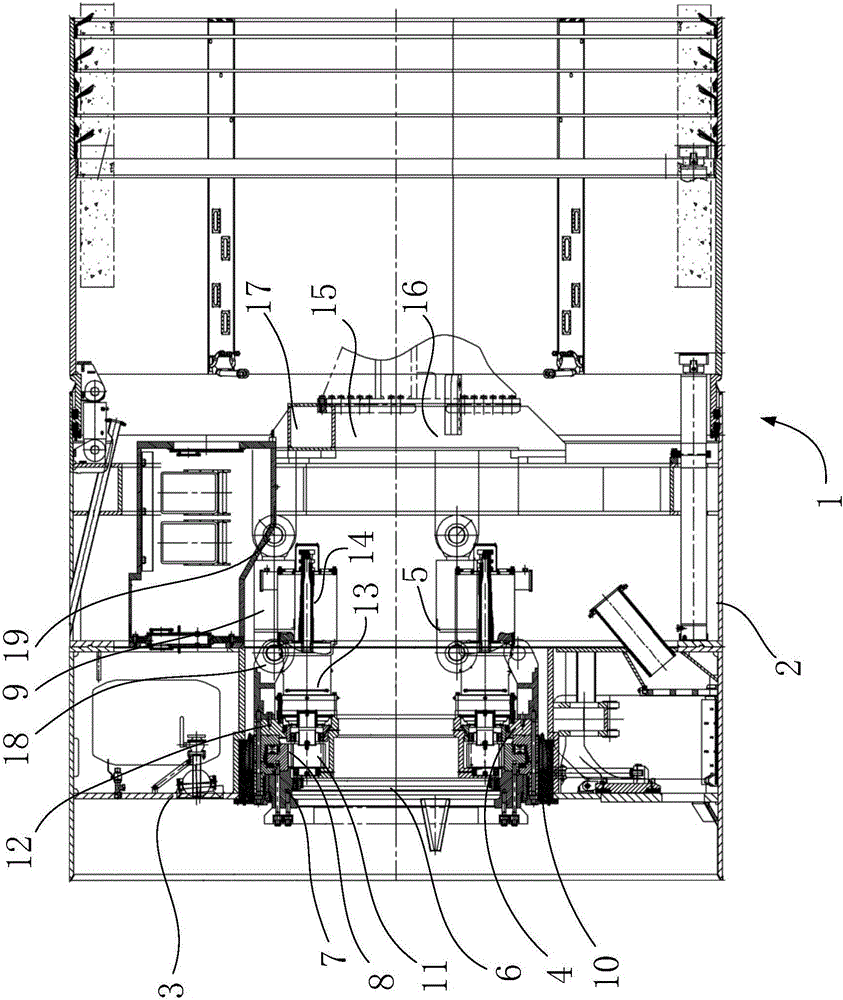

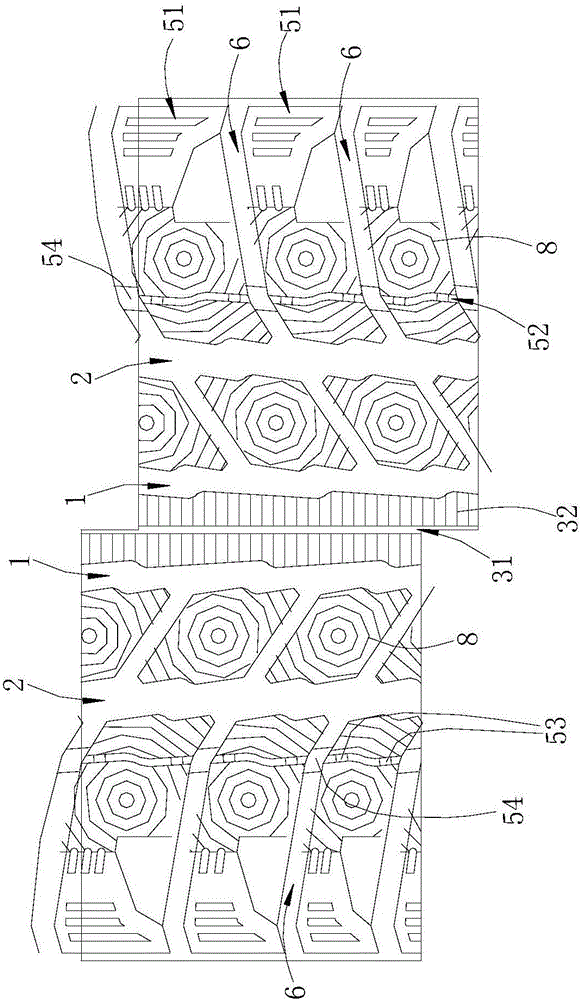

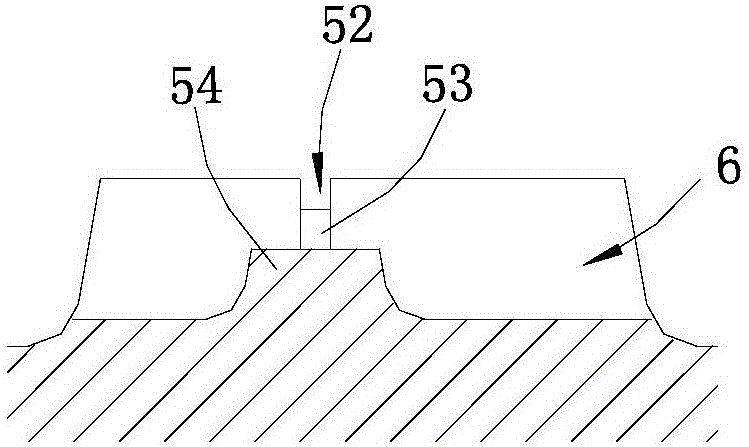

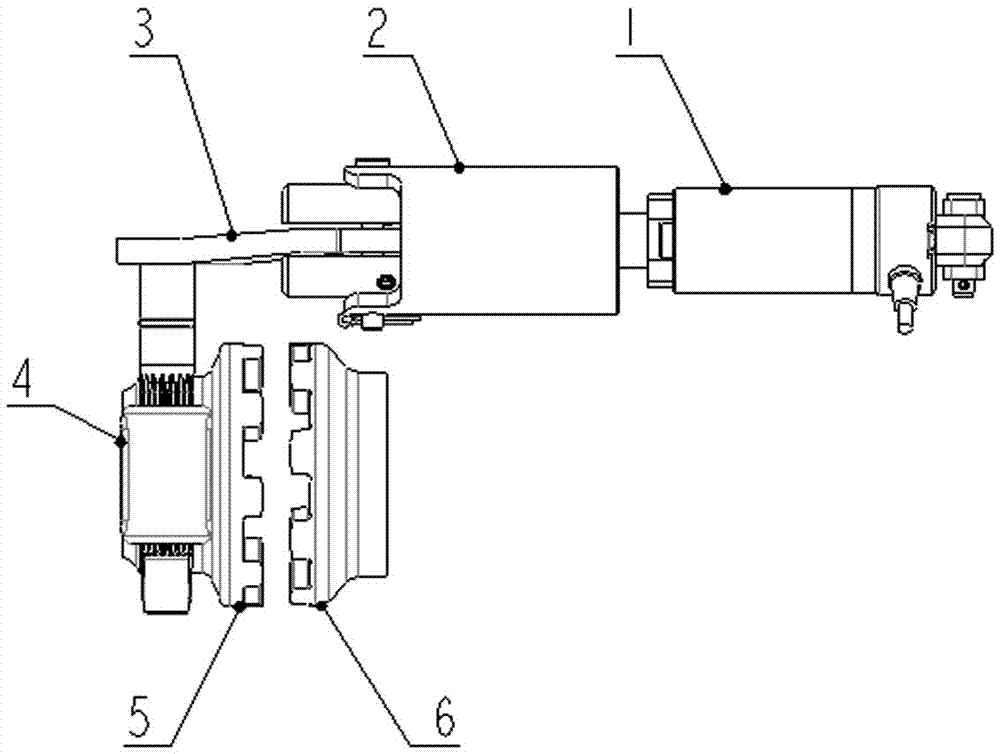

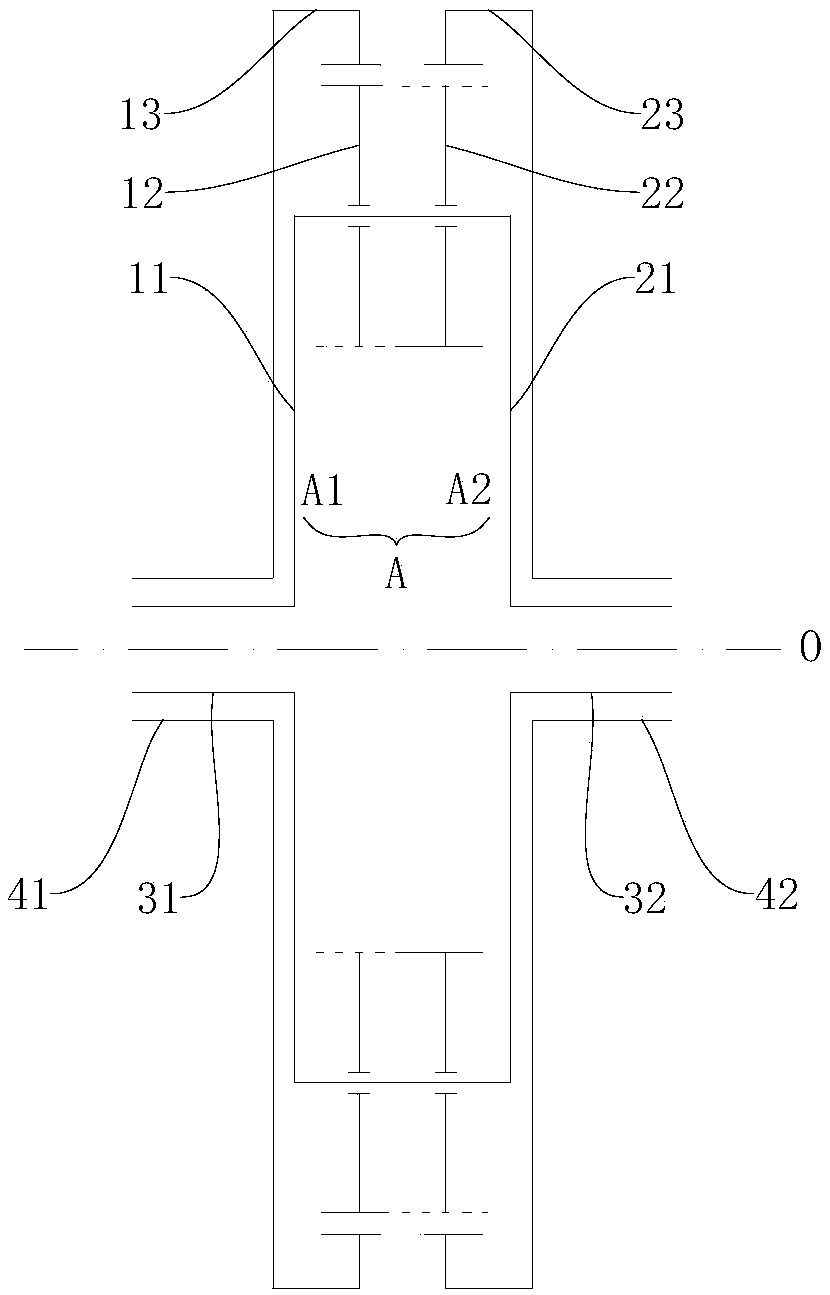

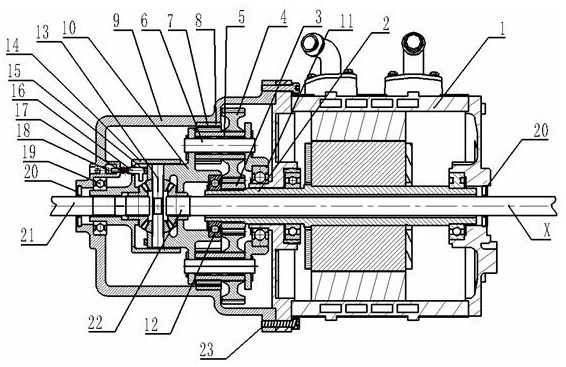

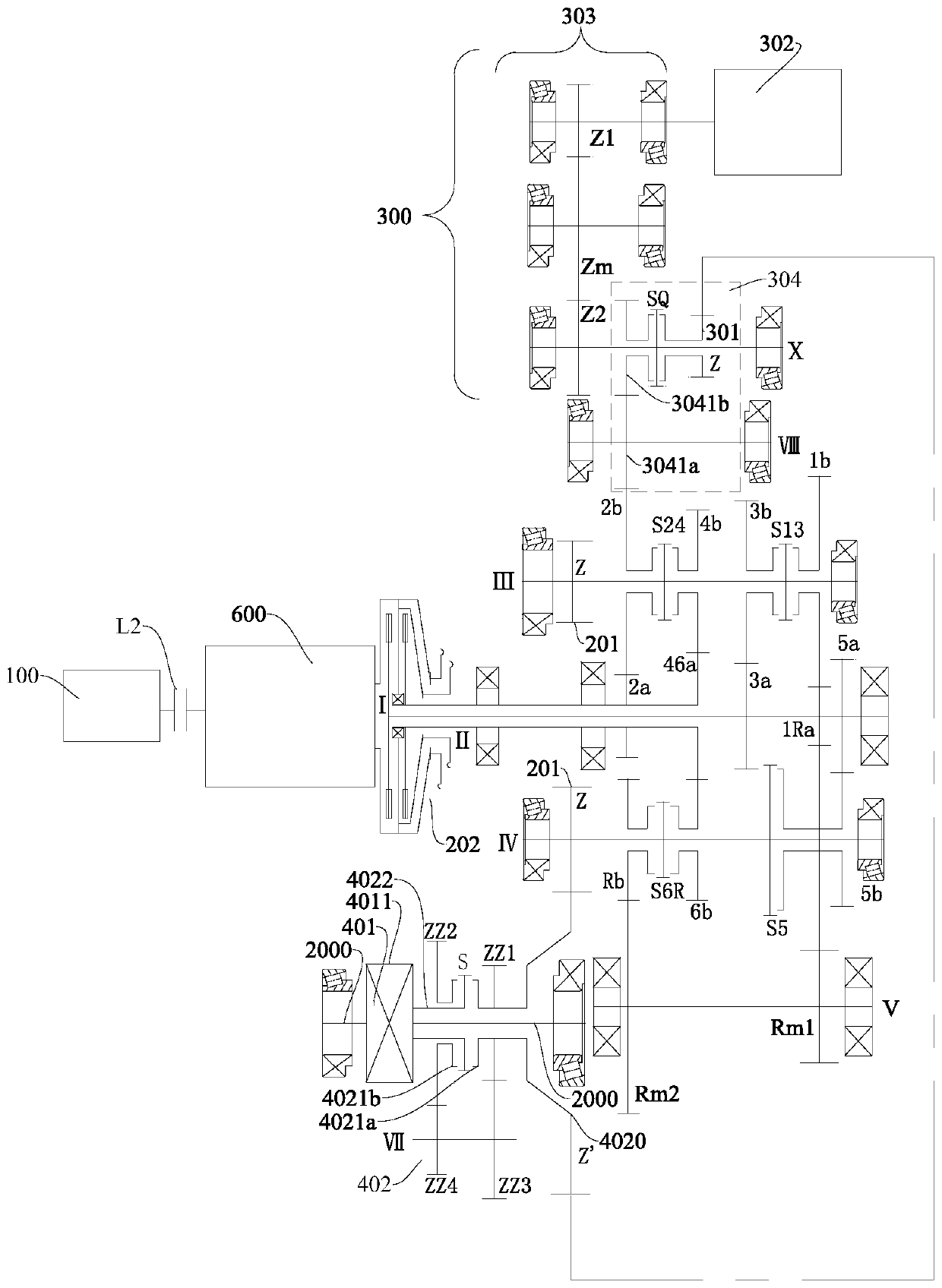

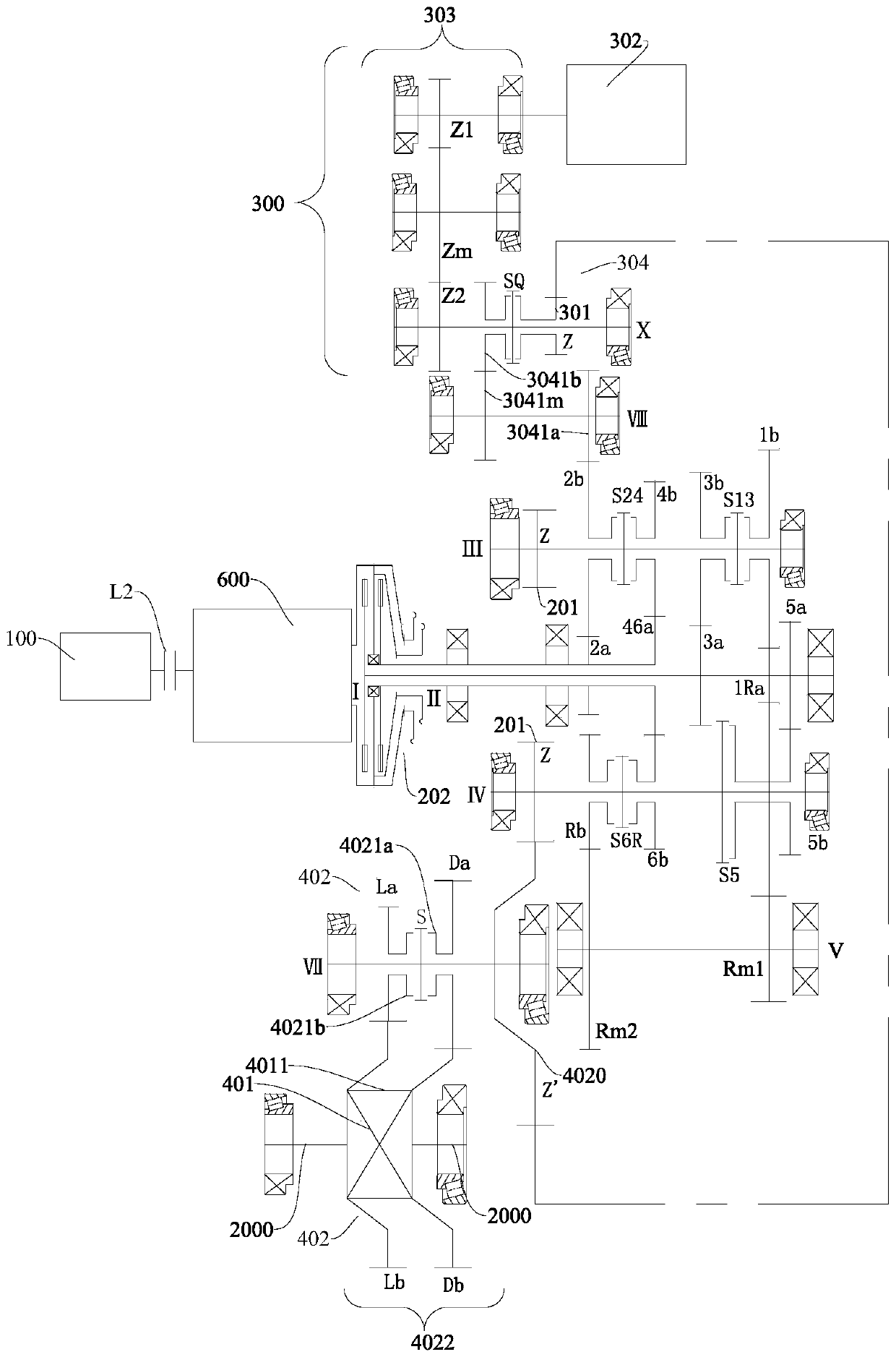

Hydraulic four-wheel-drive cross-country forklift

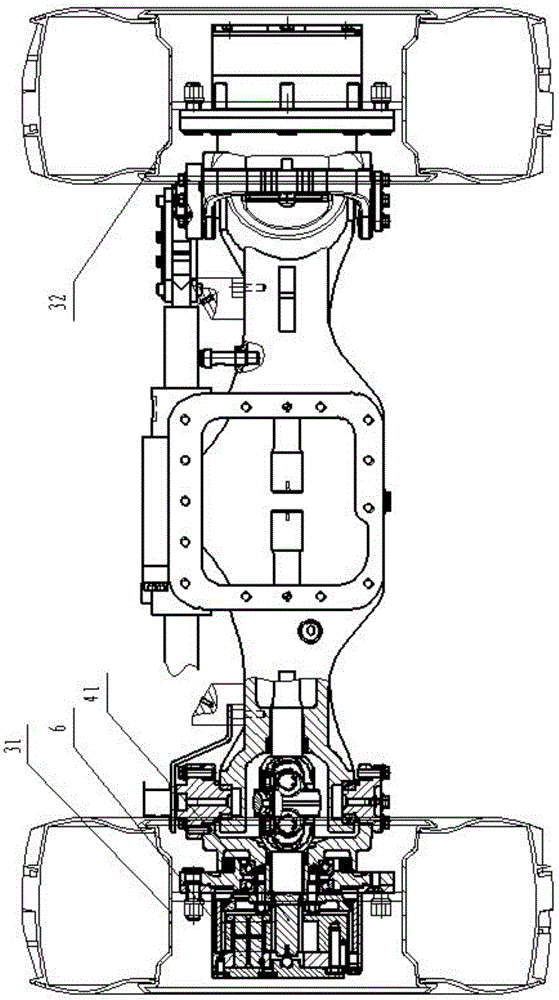

InactiveCN105584960AGood technical effectGreat tractionLifting devicesTransmission elementsLow speedReduction drive

The invention relates to a cross-country forklift and discloses a hydraulic four-wheel-drive cross-country forklift. The hydraulic four-wheel-drive cross-country forklift comprises an axle body assembly (1). The axle body assembly comprises a front axle body assembly body and a rear axle body assembly body. Both the front axle body assembly body and the rear axle body assembly body are provided with main speed reducers (2) which comprise the front main speed reducer and the rear main speed reducer. A left axle shaft assembly and a right axle shaft assembly (41 and 42) which are connected with a left wheel hub and a right wheel hub (31 and 32) correspondingly are arranged on the two sides of the axle body assembly correspondingly. The hydraulic four-wheel-drive cross-country forklift is characterized in that the forklift further comprises a power gear shifting gearbox provided with a front output shaft and a rear output shaft; the power gear shifting gearbox is connected with the front main speed reducer and the rear main speed reducer through the front output shaft and the rear output shaft correspondingly; both the front main speed reducer and the rear main speed reducer are internally provided with differential locks (5); the differential locks (5) are connected with the left axle shaft assembly and the right axle shaft assembly (41 and 42) through splines. The hydraulic four-wheel-drive cross-country forklift is large in traction at a low speed, fast in acceleration, large in transmission torque, high in difficulty-relief capacity, capable of achieving independent distribution of torque and the rotation speed at the same time, large in transmission torque and stable in locking performance.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

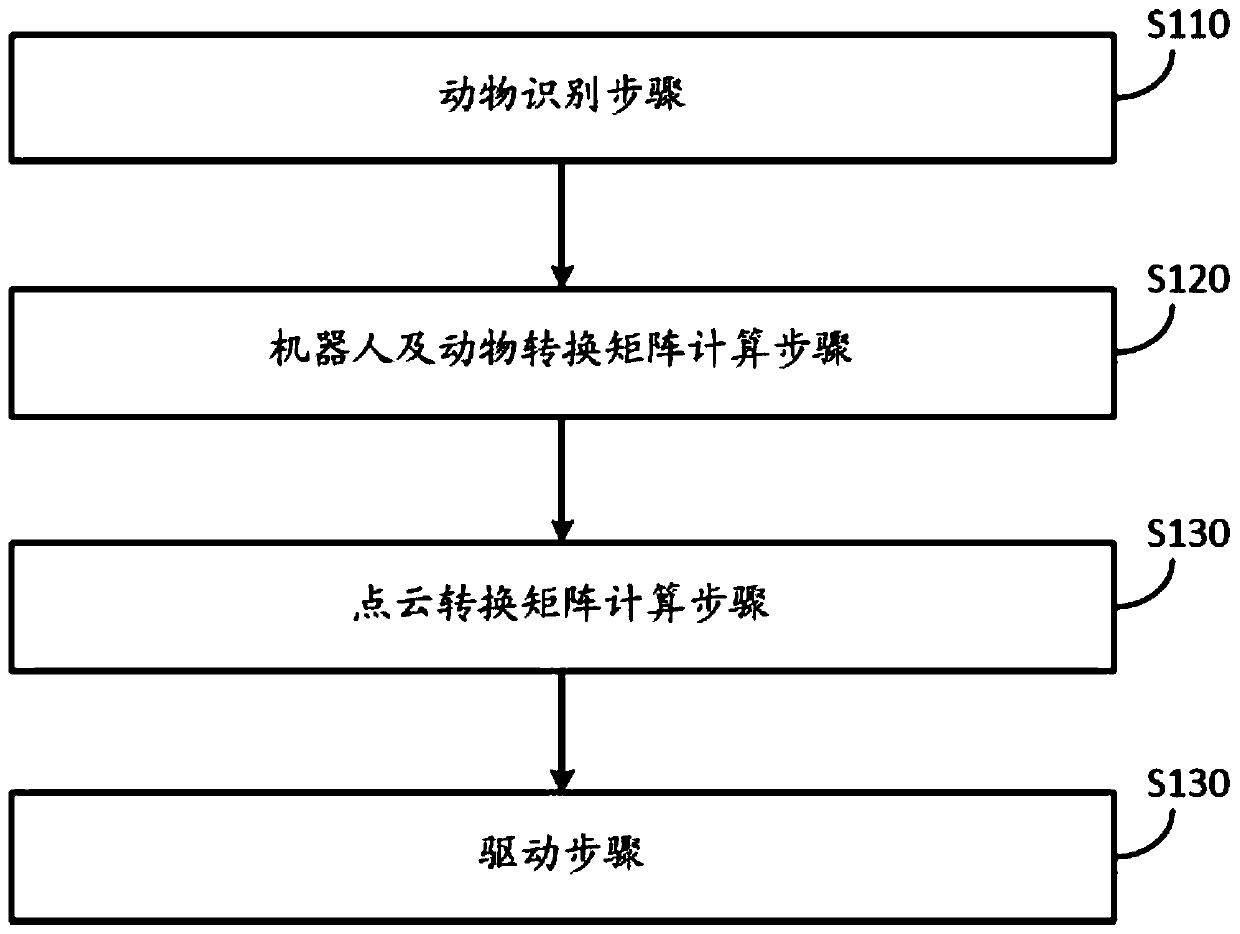

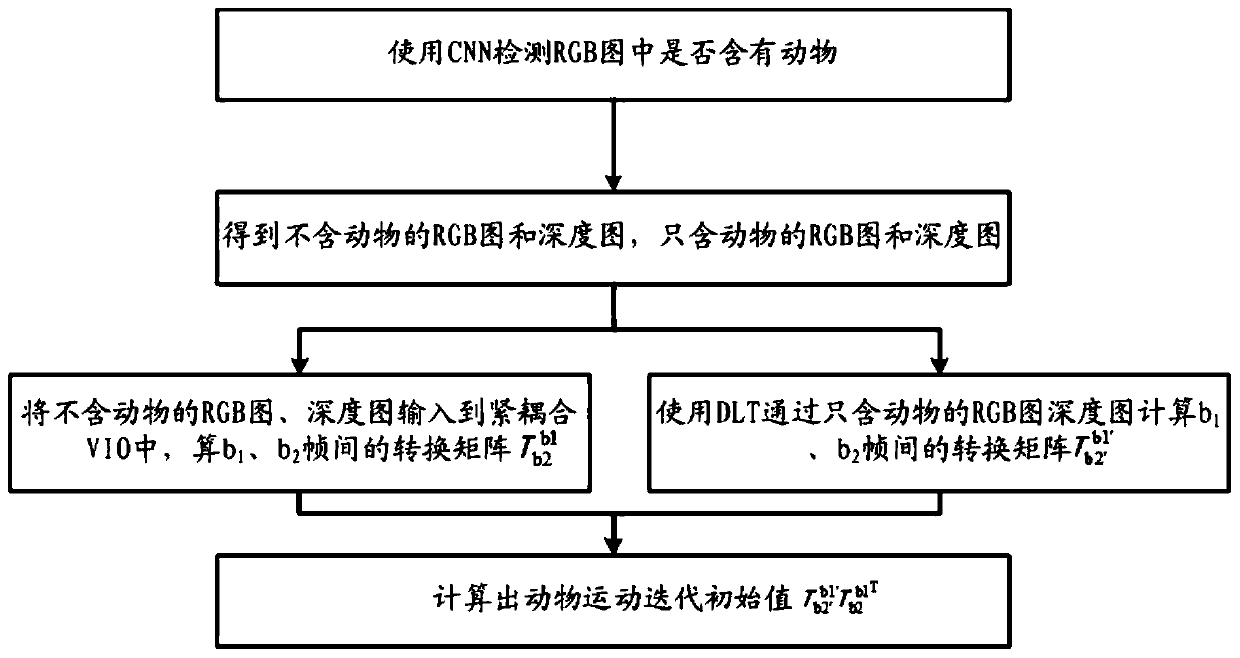

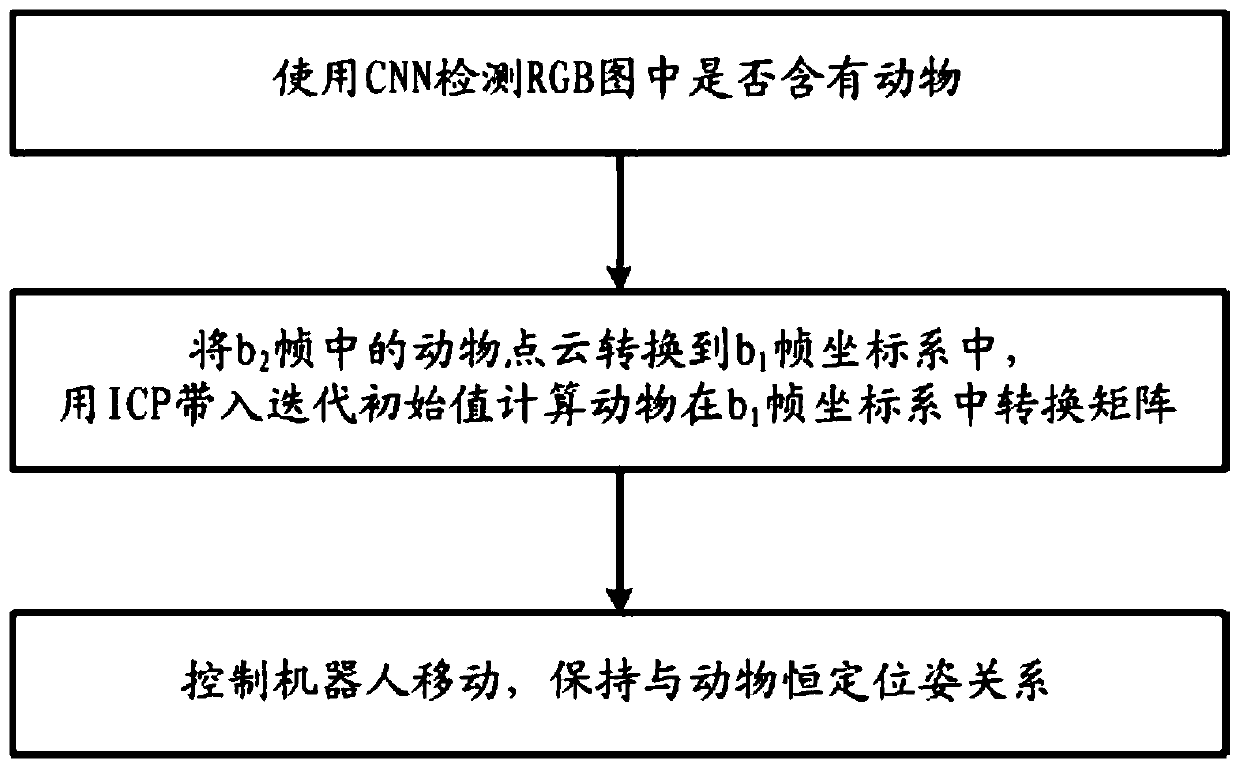

Self-moving robot animal recognition and avoidance method and storage medium thereof

ActiveCN110175523AImprove escape performanceImprove practicalityBiometric pattern recognitionPosition/course control in two dimensionsAnimal sciencePoint cloud

The invention discloses a self-moving robot animal recognition and avoidance method and a storage medium thereof, and the method comprises the steps: collecting the environmental information around aself-moving robot, obtaining an RGB image and a depth image, and carrying out the recognition of an animal through employing a CNN; removing pixels of the animal , to achieve the visual inertia speedometer calculating a conversion matrix between the b1 frame and the b2 frame of the mobile robot to extract pixels of an animal part, calculating a conversion matrix between the b1 frame and the b2 frame to convert a depth map of an animal into a point cloud map, and matching the point cloud maps between the b1 frame and the b2 frame by using ICP; and enabling the conversion matrix of the animal under the b1-frame coordinate system to drive the self-moving robot to move, so that the conversion matrix of the coordinate system after movement and the b1-frame reference system is a pose relationship which enables the self-moving robot to keep constant with the animal. According to the invention, the escape capability of the self-moving robot is improved, and the practicability, intelligence andenvironmental interactivity of the self-moving robot are also improved.

Owner:NANJING HUAJIE IMI TECH CO LTD

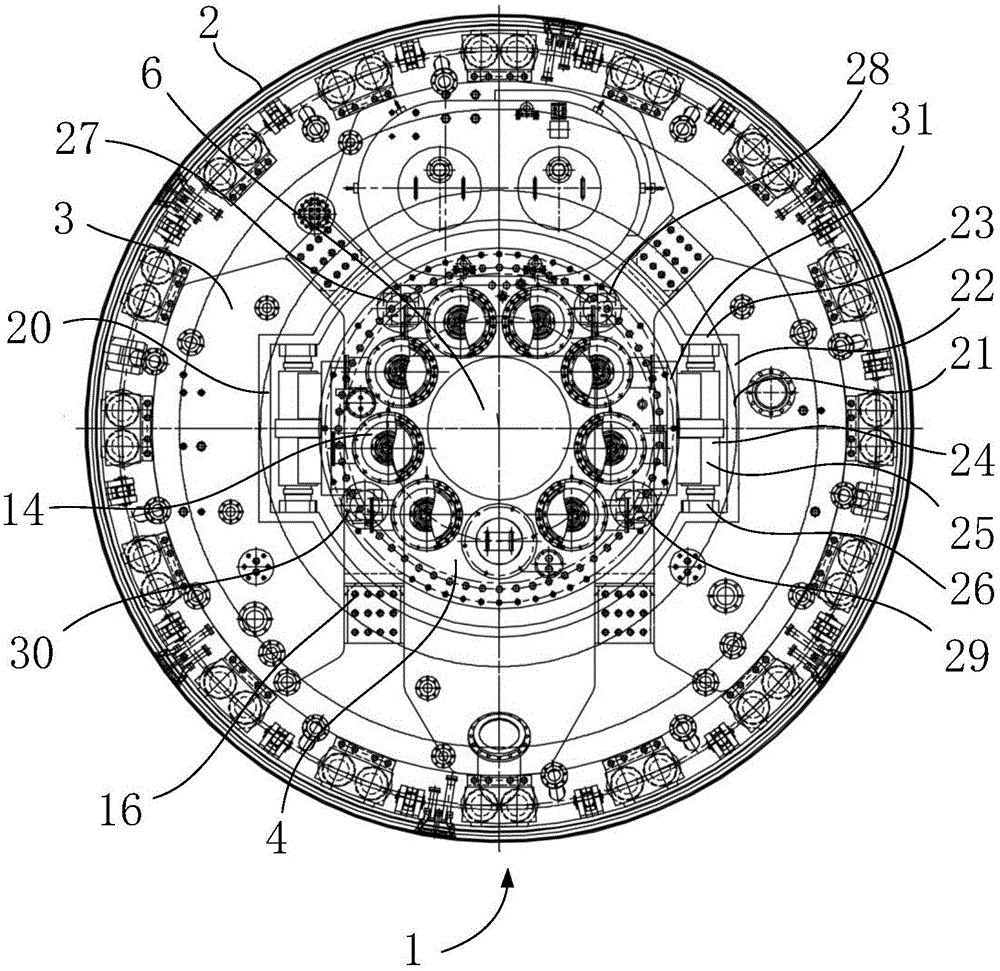

Shield tunnel heading machine

The invention provides a shield tunnel heading machine. The shield tunnel heading machine comprises a cylindrical shield shell, a cutter head, a first driving mechanism and a second driving mechanism; the cutter head is arranged at the front end of the shield shell; the first driving mechanism is rotatably connected with the shield shell; the second driving mechanism is connected with the first driving mechanism; the first driving mechanism comprises a rotating shaft; one end of the rotating shaft is connected with the cutter head; the first driving mechanism is used for driving the cutter head to rotate; and the second driving mechanism is used for driving the first driving mechanism to swing so as to drive the cutter head to swing. After the cutter head swings, pressure of space between cutters at the edge of the cutter head and a stope face of a tunnel can be relieved, a technicist changes the cutters conveniently, labor intensity is reduced, and cutter changing efficiency is improved. In addition, when the edge of the cutter head is jammed by hard substances (such as rock), the cutter head can be released from the hard substances by swinging, and releasing capability of the shield tunnel heading machine is further improved.

Owner:RAILWAY CONSTR HEAVY IND XINJIANG CO LTD +1

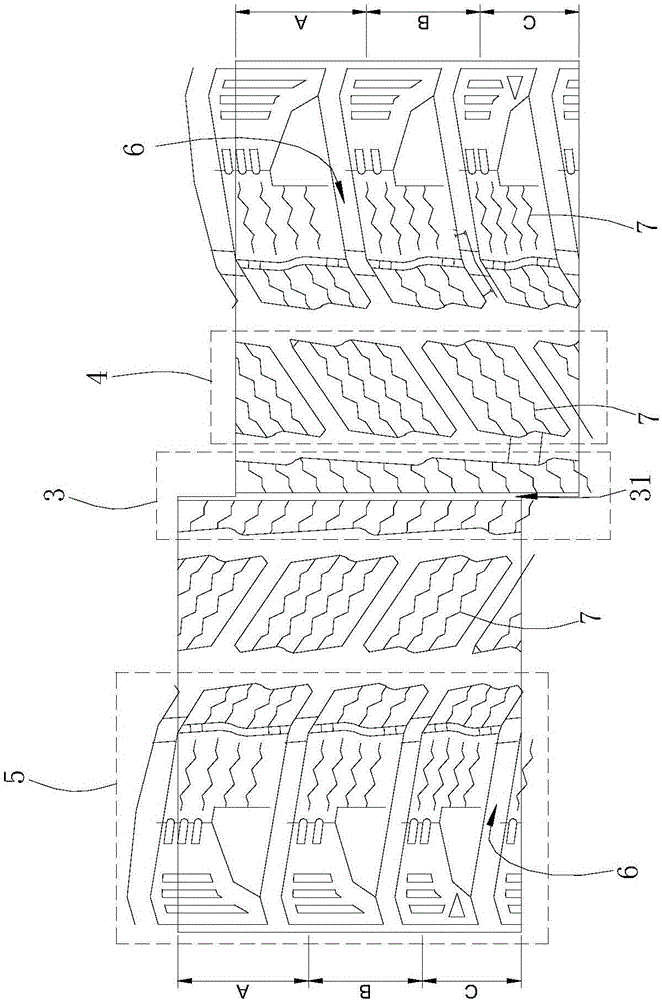

Snow tire

ActiveCN106335325AImprove drainage capacityOrientationTyre tread bands/patternsRoad surfaceEngineering

The invention provides a snow tire. A tread is divided into a center land part, two auxiliary side land parts and two side land parts through two circumferential main slots and two circumferential auxiliary slots, wherein the center land part is provided with a circumferential shallow slot; a plurality of bulges are formed at the edges of the two sides of the center land part; a plurality of cross slots are formed in the outer surface of the tire; one end of each cross slot extends to the edge of the tread, and the other end of each cross slot extends to the circumferential main slot; bulges are formed at the edges of pattern blocks of the auxiliary side land parts; bulges are arranged at the edges of pattern blocks of the side land parts; circumferential annular slots are further formed in the side land parts; the circumferential annular slots are circumferentially formed along the outer surface of the tread; the circumferential annular slots are provided with a plurality of reinforcing ribs; the two sides of each reinforcing rib respectively extend to the wall of the circumferential annular slot. The circumferential main slots and the circumferential auxiliary slots form a design of four straight grooves of patterns, which sufficiently penetrate the cross slots, so that water drainage capacity on ice snow covered pavements and slippery pavements is improved; patterns on the two sides of the tread distribute in a V-shaped way, have directivity, break the ice snow covered pavements when the tire moves, and ensure that ice and snow and cumulated water are discharged to the two sides and the rear part.

Owner:ANHUI HEDING TIRE TECH CO LTD

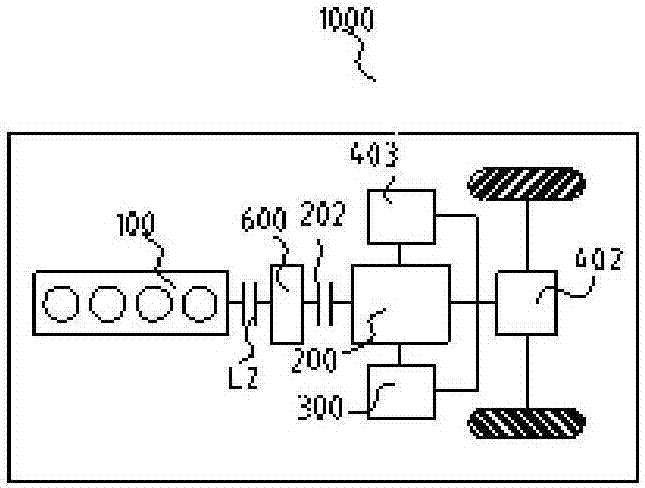

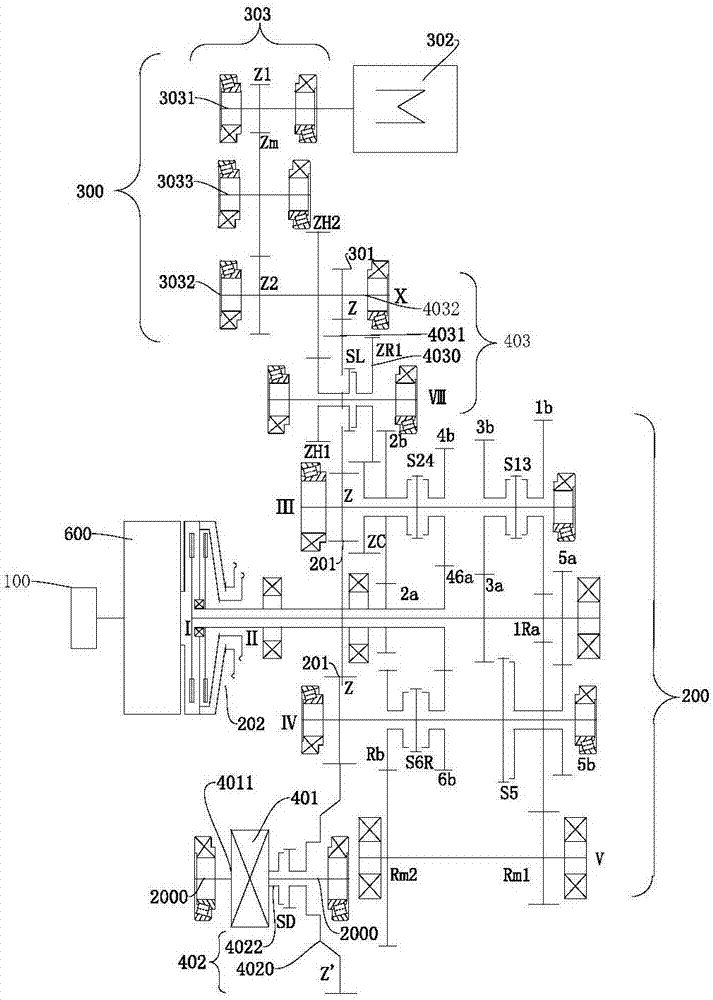

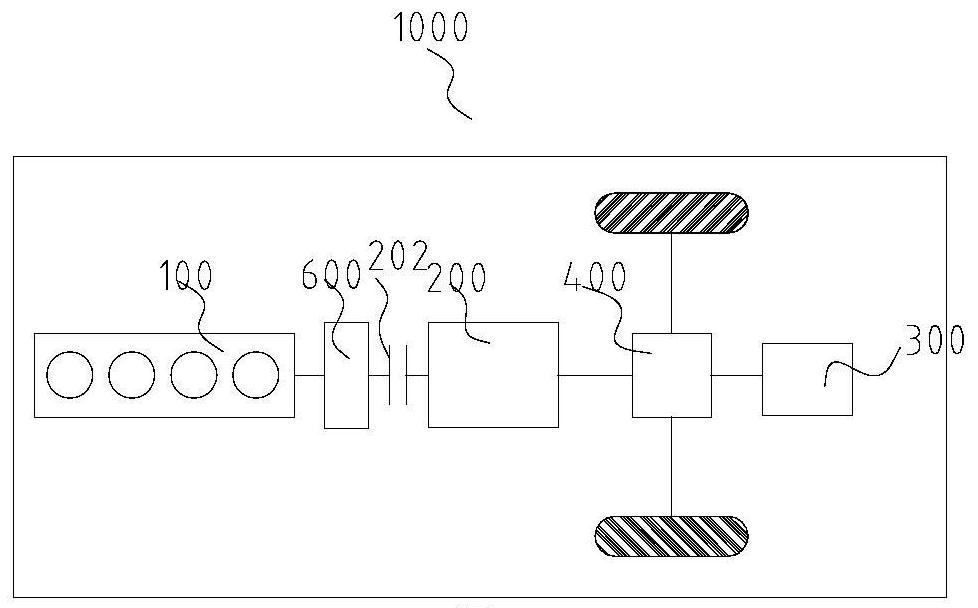

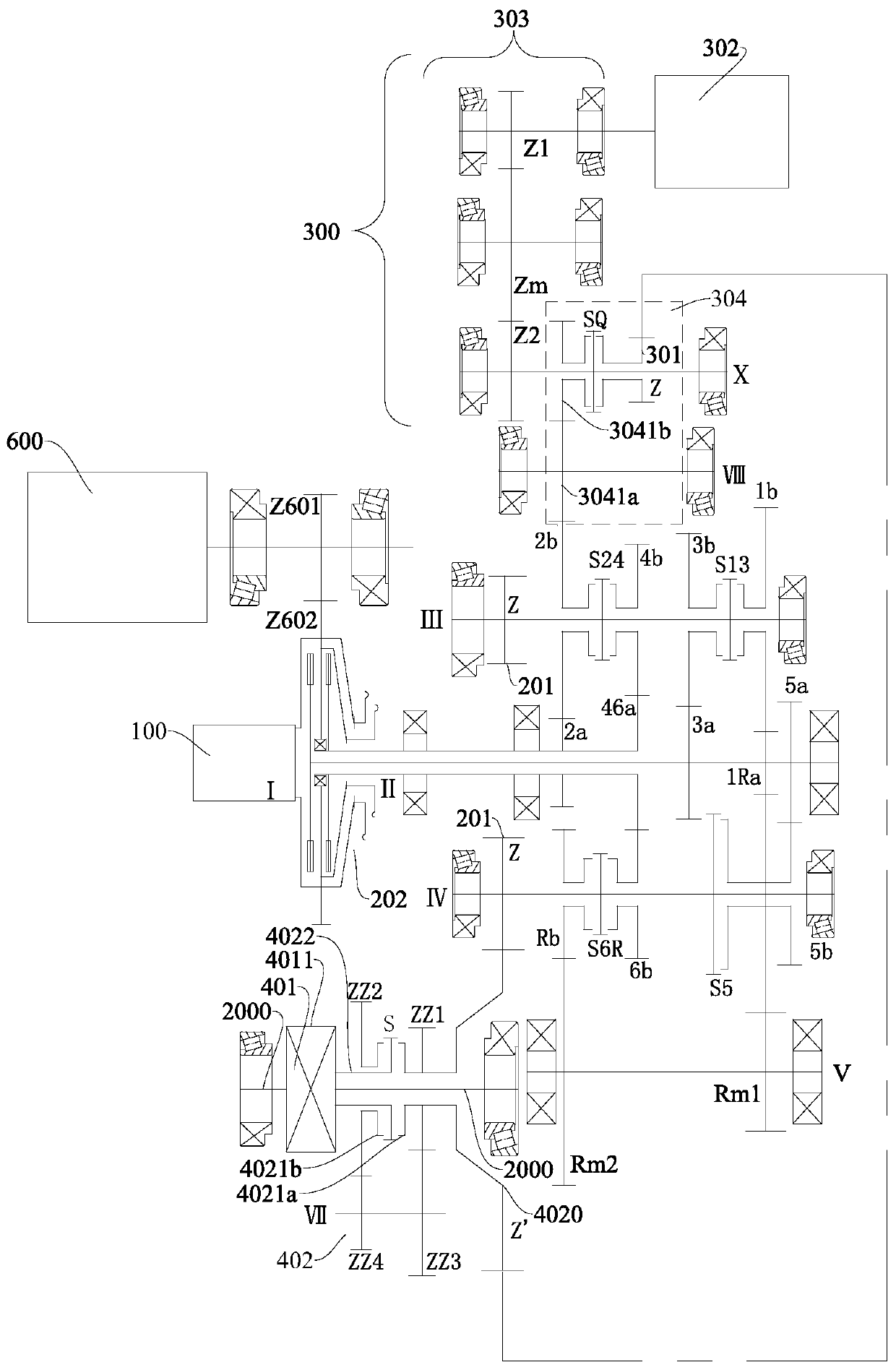

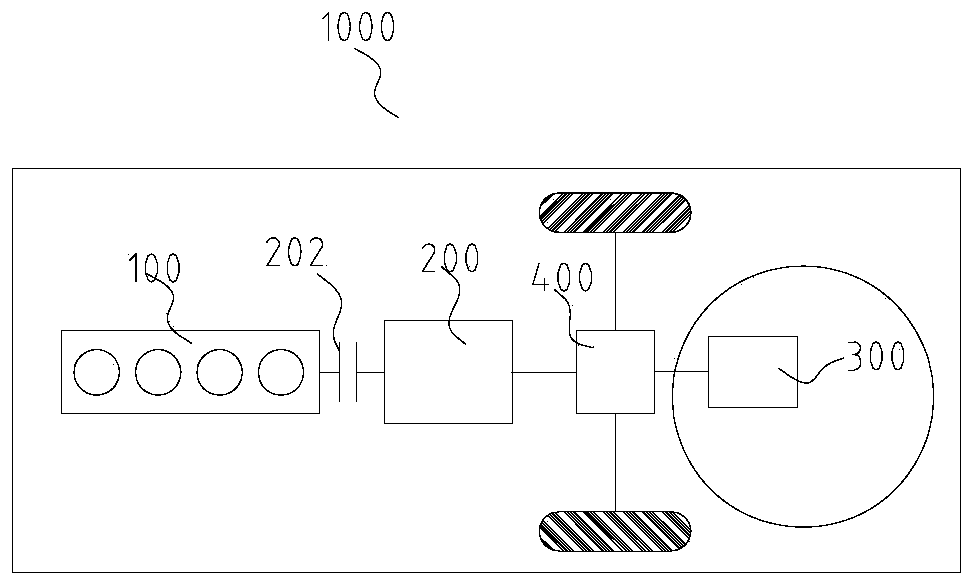

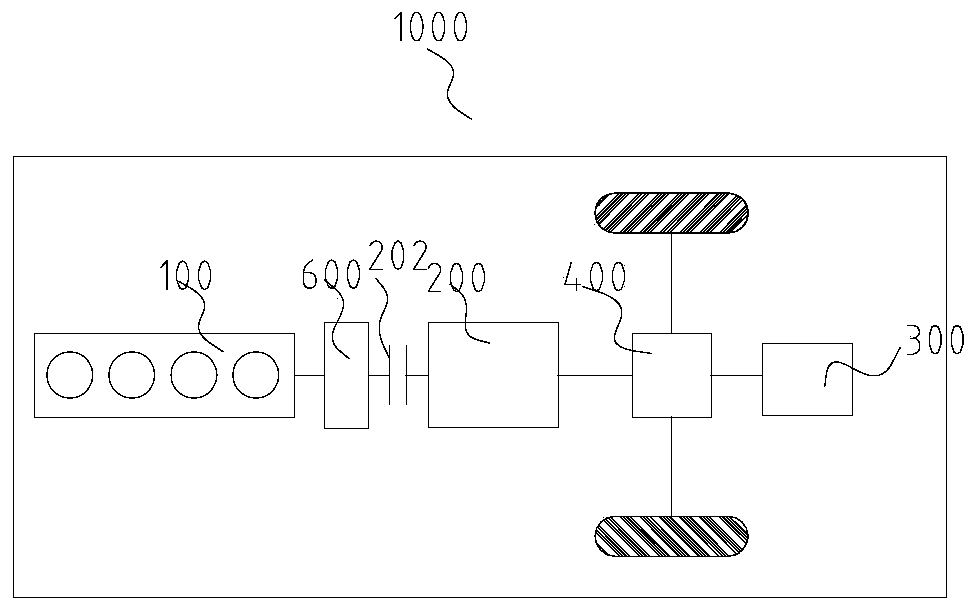

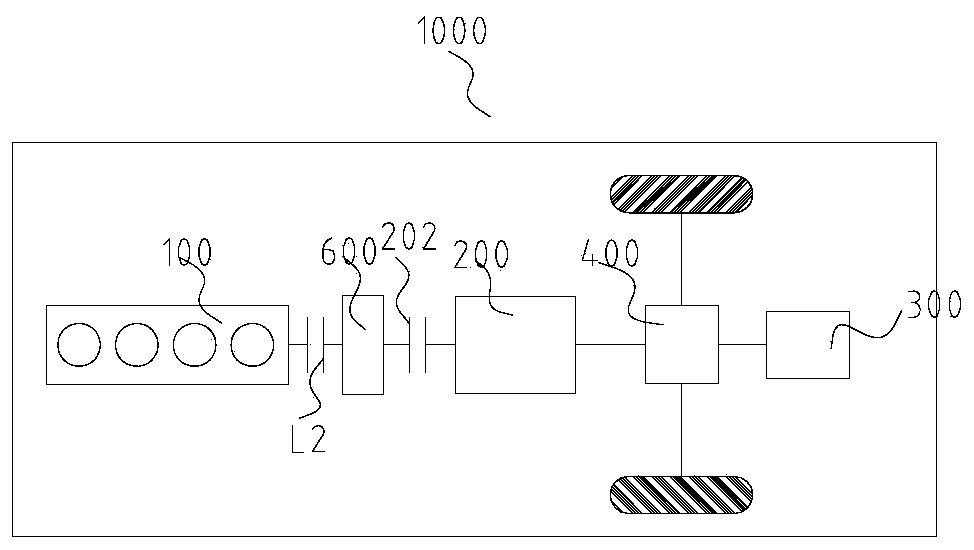

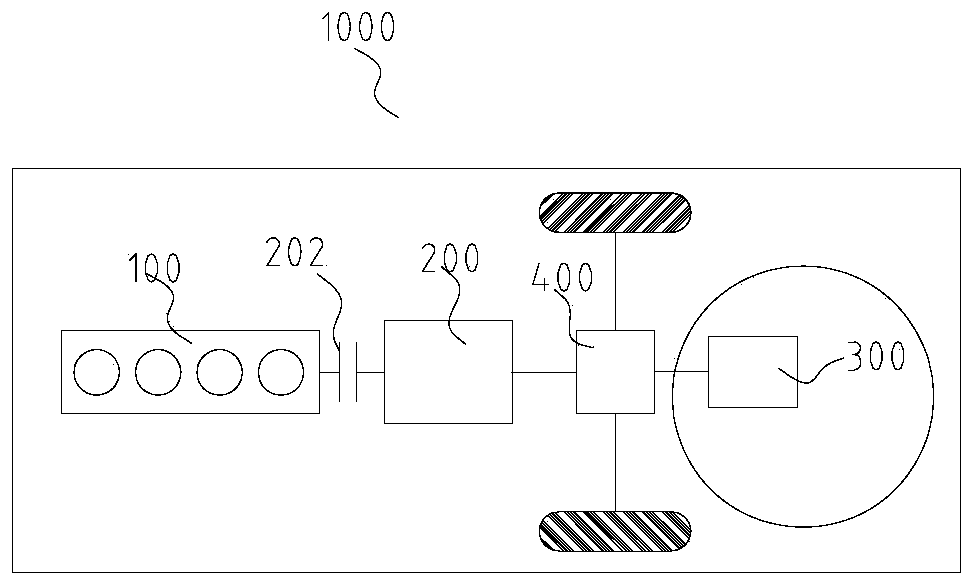

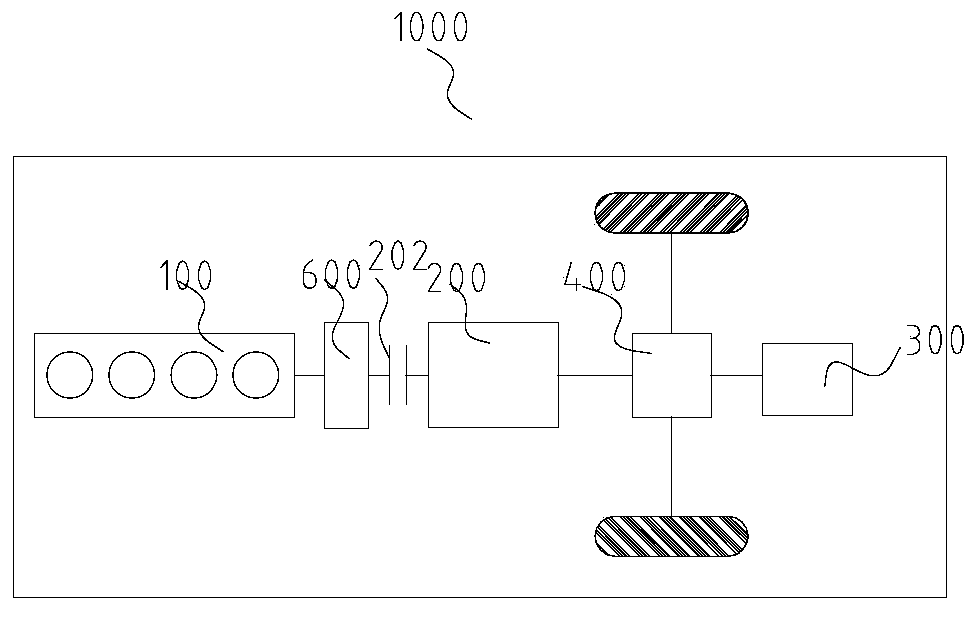

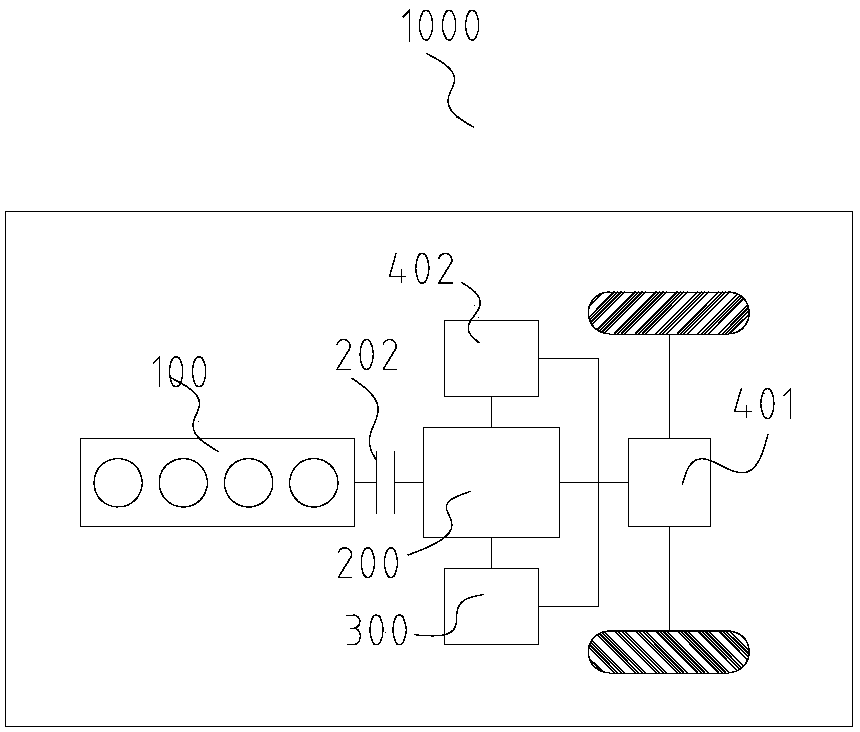

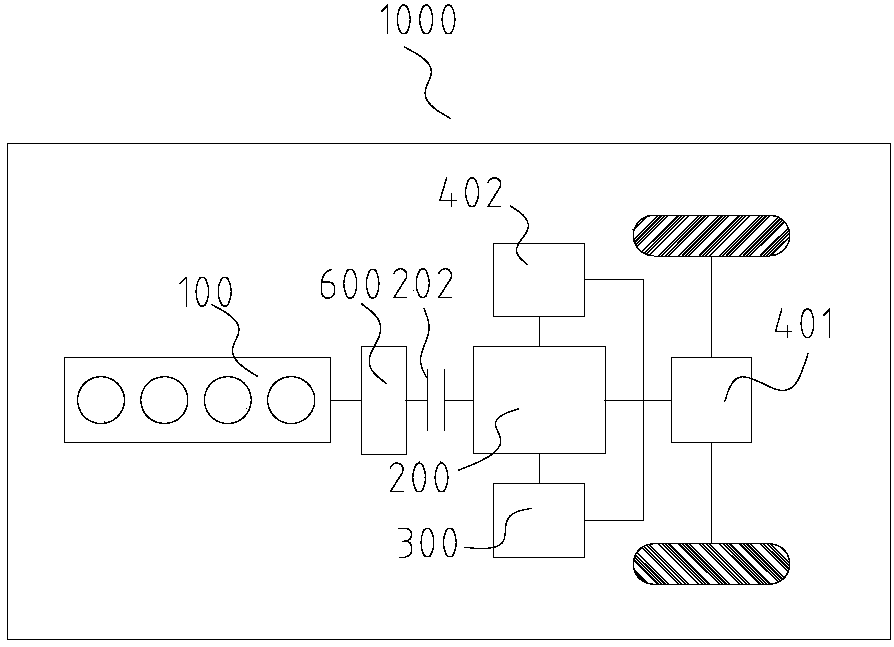

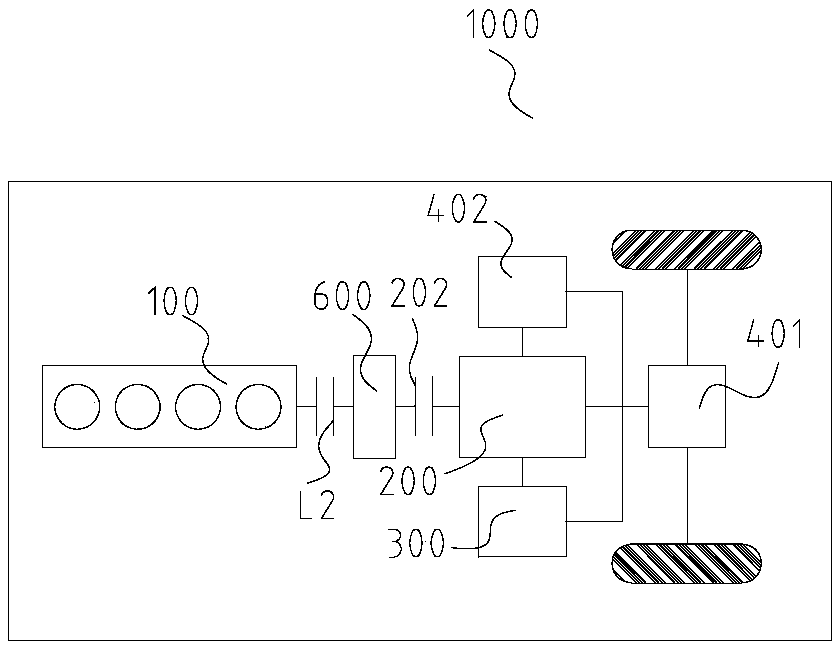

Power transmission system and vehicle with same

ActiveCN108001205AImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingPower couplingDrivetrain

The invention discloses a power transmission system and a vehicle with the same. The power transmission system includes an engine, a first motor generator unit, a second motor generator dynamically coupled directly or selectively with the engine, a system power output part, a first mode conversion device through which at least one of the engine and the first motor generator unit is coupled or disconnected with the system power output part, and a second mode conversion device through which the engine and the first mode conversion device can be dynamically coupled or disconnected, wherein the engine and the first mode conversion device are coupled by power through the second mode conversion device so that the power from the engine can be output to the first mode conversion device after speedreduction by the second mode conversion device. In this way, the driving mode of the vehicle can be enriched and the vehicle can adapt to different road conditions.

Owner:BYD CO LTD

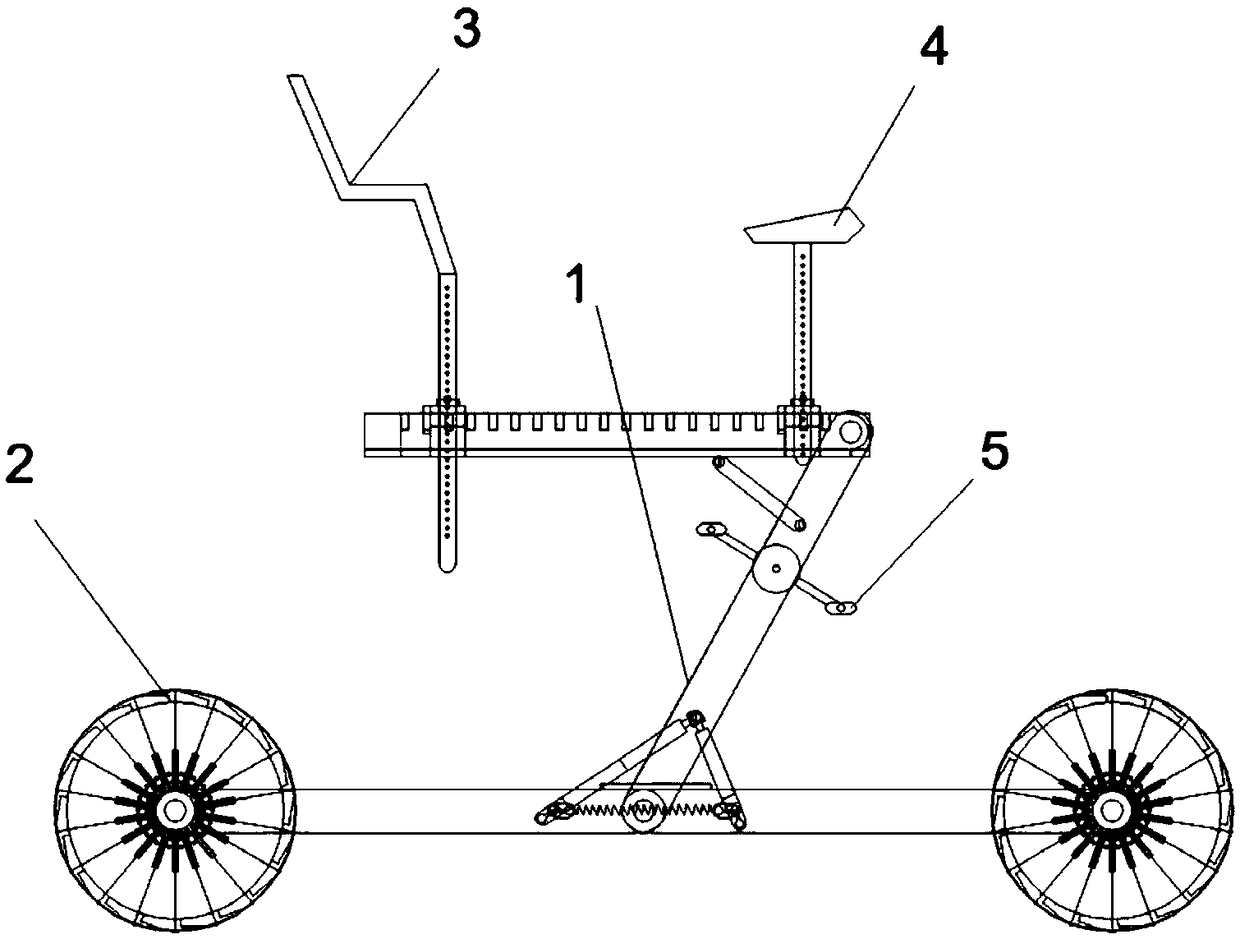

Foldable all-terrain bicycle

InactiveCN109110029AComfortable rideEasy to assemble and disassembleFoldable cyclesTerrainVehicle frame

The invention discloses a foldable all-terrain bicycle including a frame, wheels mounted on the frame, a seat, a handle, pedals, a wheel drive transmission system, and a wheel differential system, theframe includes a frame rail, a frame rail and a wheel support frame, and the frame rail, the frame rail, the frame rail and the wheel support are connected by a frame hinge. The handle and a seat aremount on that cross bar of the frame, a wheel comprises a hub, a tire plate unit and a tire drive shaft, the wheel drive transmission system comprises a center drive mechanism, a front wheel drive mechanism and a rear wheel drive mechanism, a wheel differential system comprises a differential and a differential locking mechanism, and a differential comprises a differential housing, a differentialdrive shaft, a differential drive shaft and a drive gear set. The invention is convenient to disassemble, assemble and fold, convenient to travel and carry, stable to ride, good in shock absorbing effect, capable of passing through various bad road conditions and switching between different road conditions, good in safety and reliability, and wide in application range.

Owner:杭州宝骊科技有限公司

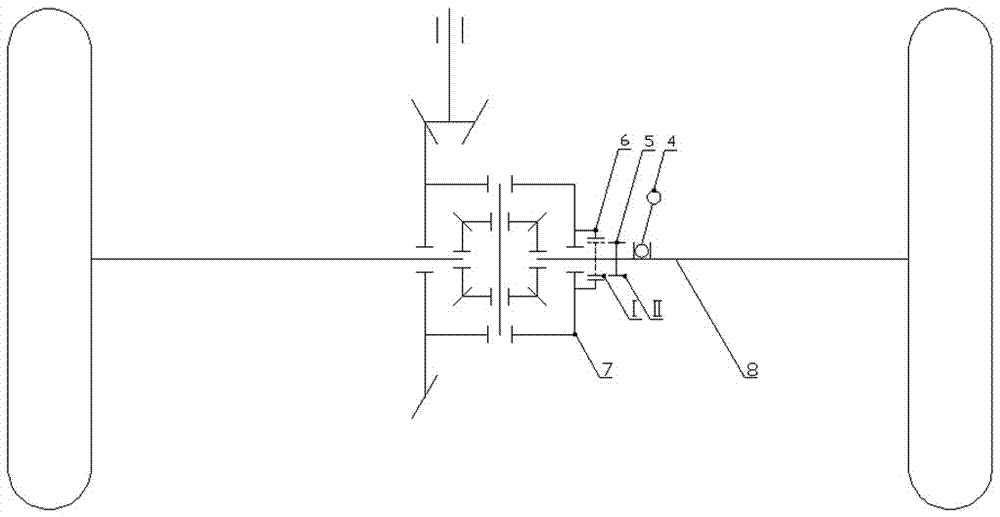

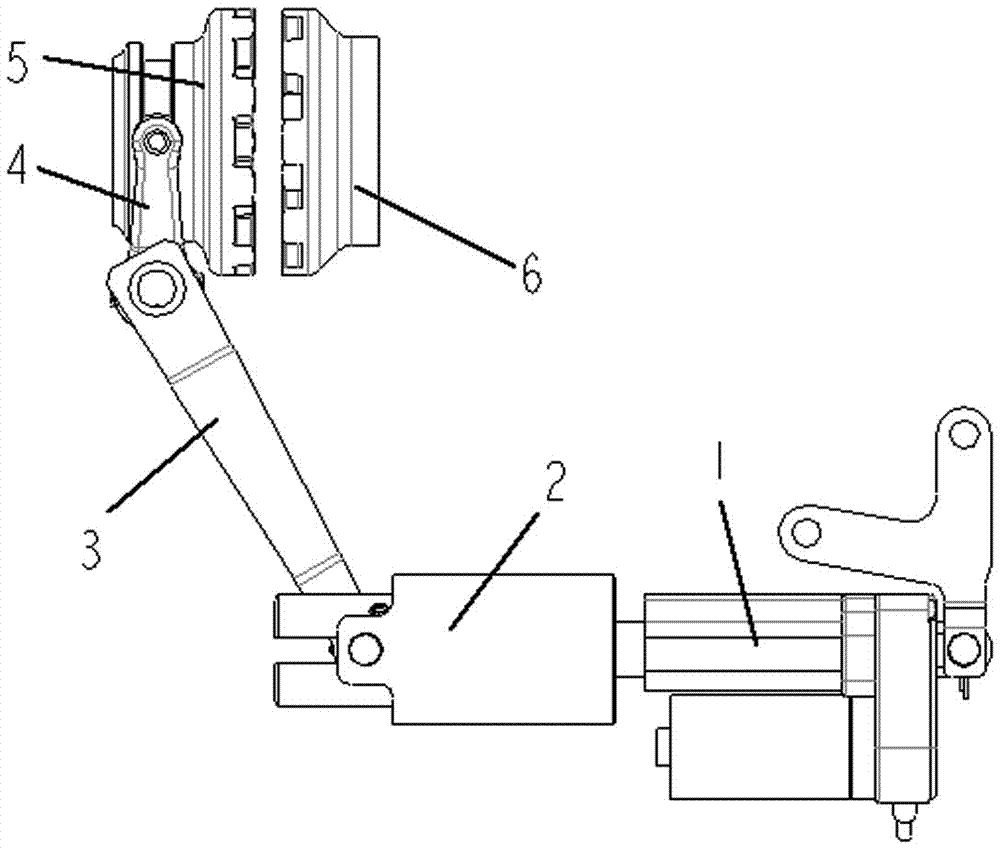

Differential lock control device and vehicle

ActiveCN107989981ATimely lockTimely and accurate lockingDifferential gearingsEmbedded systemRoad condition

The invention relates to a differential lock control device and a vehicle and aims at providing the differential lock control device which is simple in structure, safe, reliable and convenient to install and the vehicle. Through the differential lock control device, locking and separation of a differential mechanism can be achieved in various states, and torque distribution between wheels can be effectively achieved, so that the vehicle adapts to various bad road conditions. According to the technical scheme, the differential lock control device is used for enabling a sliding engagement sleeveand a fixed engagement sleeve to be engaged or disengaged, wherein the sliding engagement sleeve is used for being connected with a half axle through a spline and can move in the axial direction of the half axle; the fixed engagement sleeve is used for being connected with a differential mechanism shell. The differential lock control device is provided with an action mechanism, a buffer energy accumulator and a transmission mechanism; the action end of the action mechanism is connected with the sliding engagement sleeve through the buffer energy accumulator and the transmission mechanism in sequence; the action mechanism drives the sliding engagement sleeve to move in the axial direction of the half axle through the buffer energy accumulator and the transmission mechanism to achieve engagement and disengagement of the sliding engagement sleeve and the fixed engagement sleeve. The differential lock control device is applicable to the field of differential locks.

Owner:HANGCHA GRP +1

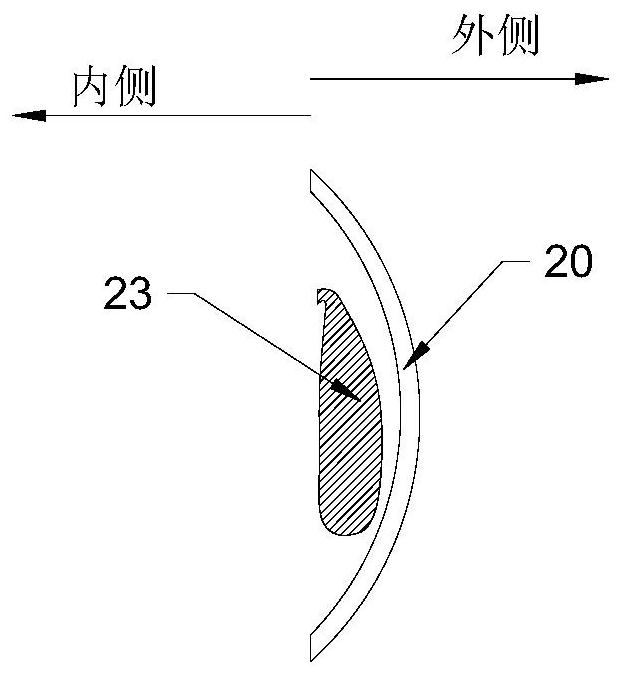

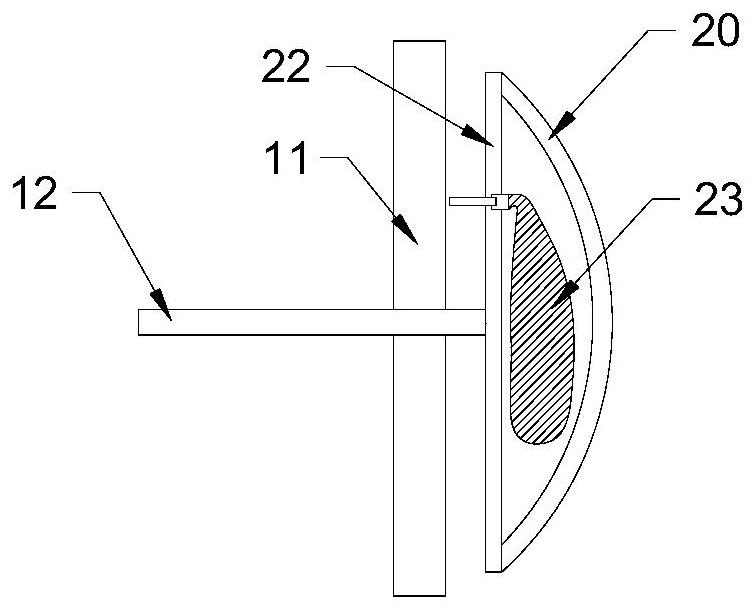

Escape device and underwater robot

PendingCN111645050AImprove the ability to get out of troubleIncrease buoyancyManipulatorUnderwater equipmentEngineeringClassical mechanics

The invention provides an escape device and an underwater robot. The escape device comprises an escape tray and an air bag. The escape tray is arranged on a driving shaft on the outer side of a buoyancy tank and rotates along with the driving shaft. The escape tray is provided with a convex outer wall protruding outwards, the air bag is arranged between the escape tray and the buoyancy tank, and an opening is arranged on the convex outer wall. When the air bag is inflated, a bag body of the air bag fills the inside of the escape tray and protrudes outwardly from the opening in the convex outerwall. The escape performance is improved by assembling the escape tray at the front end of the buoyancy tank which is most prone to being trapped and sunk, namely at the position where the driving shaft is arranged.

Owner:泰华智业(天津)科技有限责任公司 +1

Dual-motor driving system assembly and vehicle

PendingCN112721620AIncrease the center distanceMeet the needs of large center distanceControl devicesElectric propulsion mountingGear wheelElectric machinery

The invention discloses a dual-motor driving system assembly and a vehicle. The dual-motor driving system assembly comprises a first motor and a second motor which are coaxially arranged, a first gear transmission, a second gear transmission and a plurality of idle wheel pairs, the first gear transmission is driven by the first motor, the second gear transmission is driven by the second motor, and the idler wheel pairs are arranged in the first gear transmission and the second gear transmission respectively and used for increasing the distance between an output shaft of the first motor and a tail end shaft of the first gear transmission. According to the scheme, due to the fact that the idle wheels are additionally arranged, the center distance between the input shaft and the output shaft in the assembly can be adjusted more flexibly by adjusting the size of the idle wheels, large-center-distance design is achieved, structural space brought by the large center distance is fully utilized for installing other components, and adjustment can be conducted according to space arrangement requirements and performance requirements of different clients.

Owner:JING JIN ELECTRIC TECH CO LTD

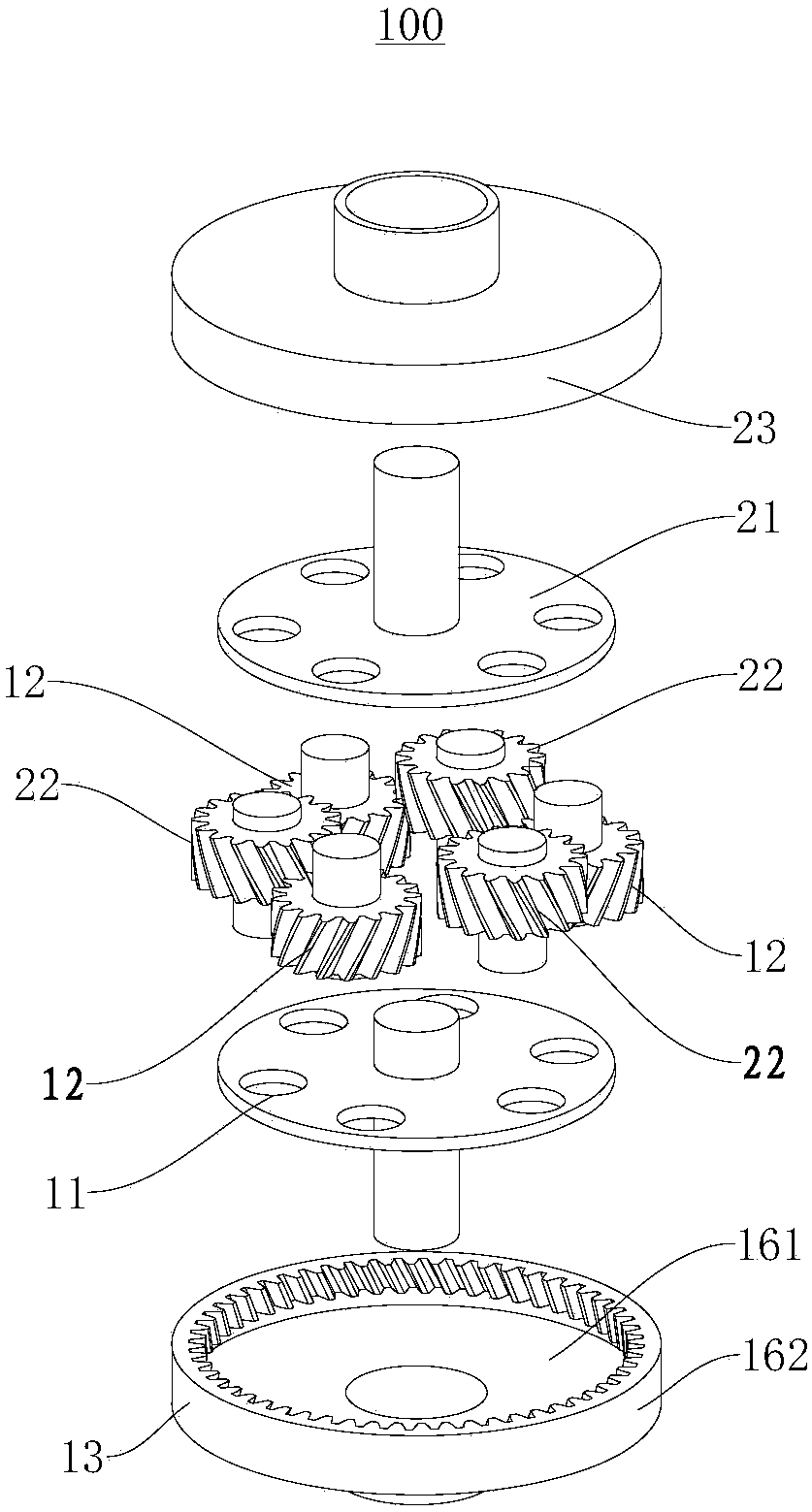

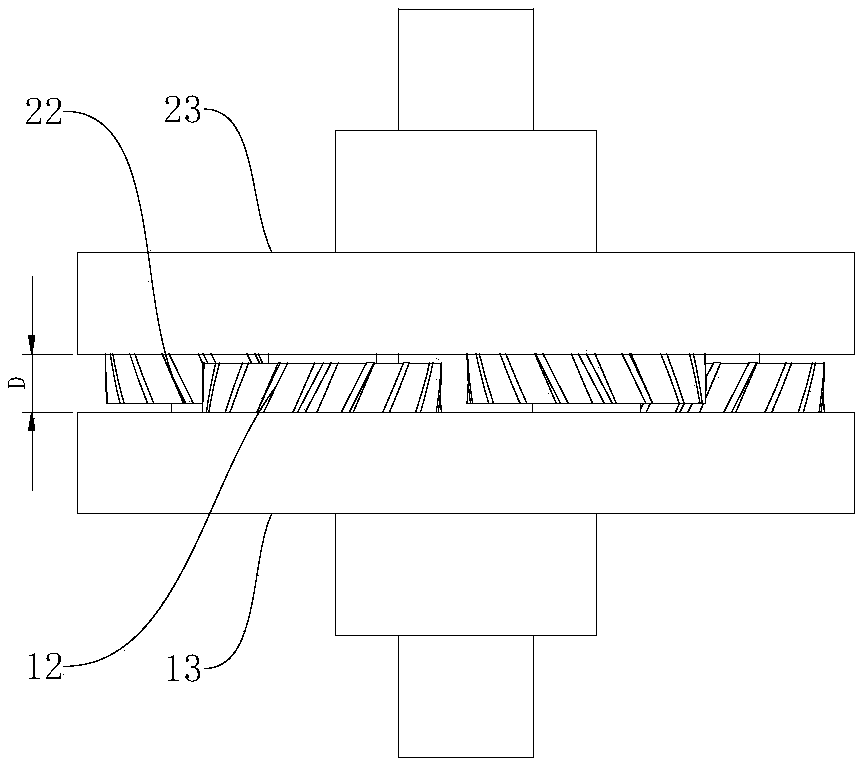

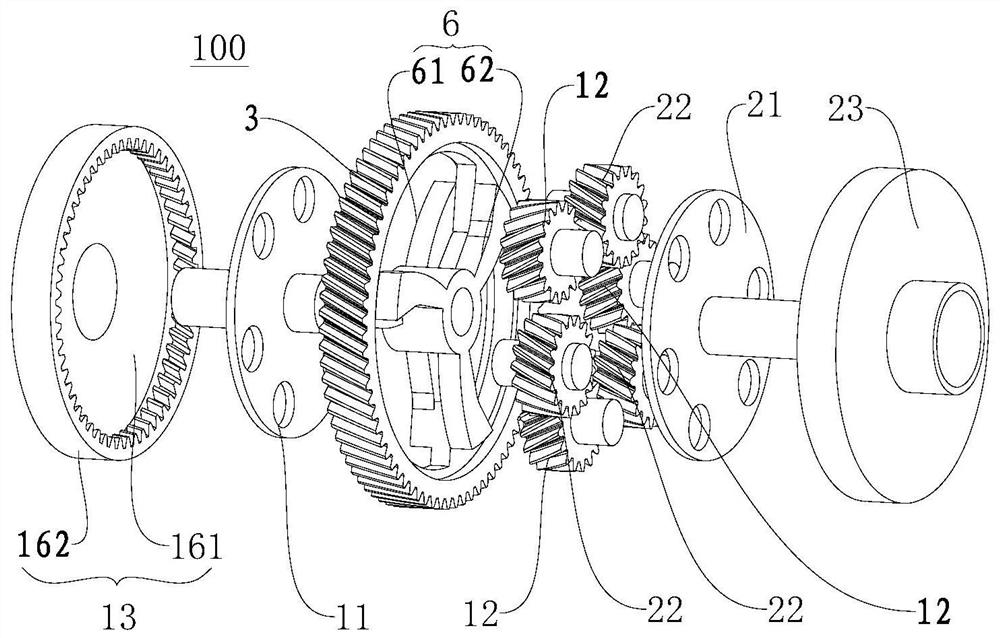

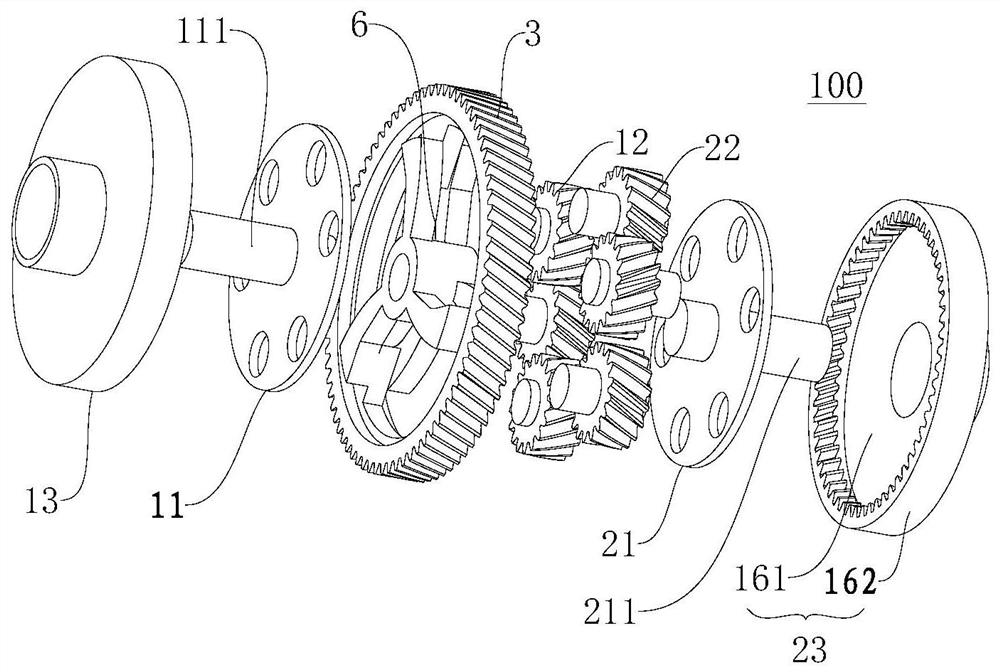

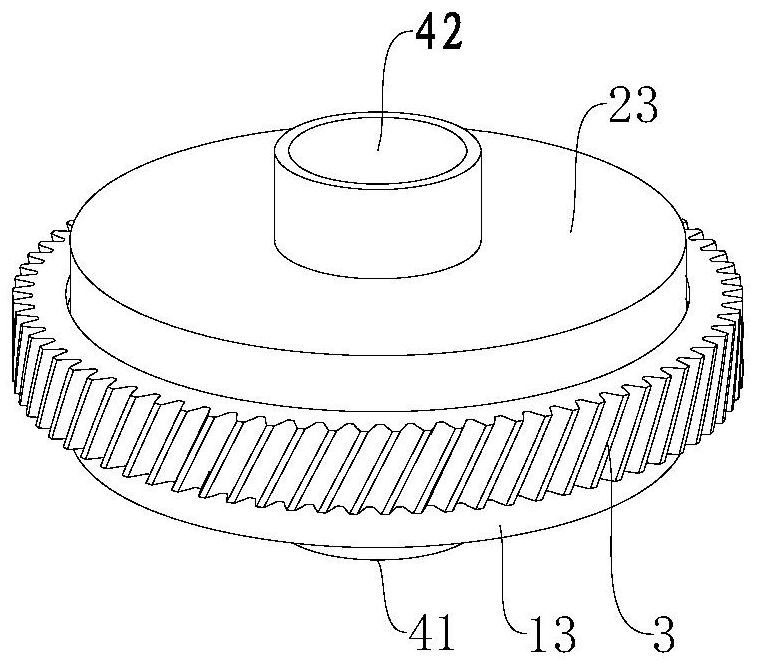

Differential and vehicle

The invention discloses a differential and a vehicle. The differential comprises two planet gear mechanisms, a power joint device and a joint part driving device, wherein gear rings are power output ends and input parts; the input parts and two planet carriers are coaxially arranged; the input parts are respectively linked with the two planet carriers; the power joint device comprises first and second joint parts; the first joint part is connected with one of the two gear rings; the second joint part is synchronously rotated with the two planet carriers; the two planet carriers form a power input end of the differential; the joint part driving device comprises a driving needle and a driving part; and the driving part is configured to drive the driving needle to drive the second join part to move in a direction near the first joint part in the axial direction, so that the second joint part is joined with the first joint part. The differential can lock two half shafts, and can improve the vehicle recovery capacity.

Owner:BYD CO LTD

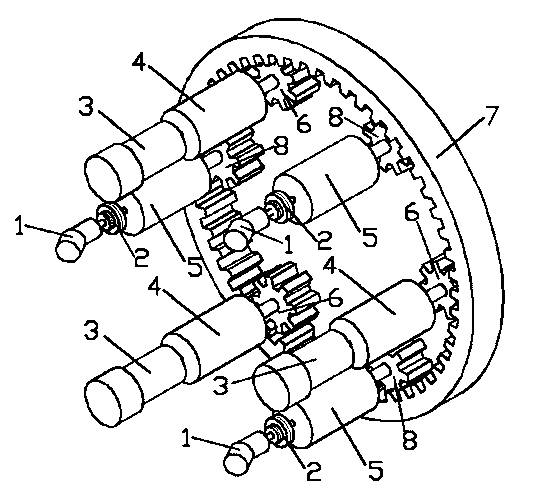

Wheel edge driving structure, wheel edge driving assembly and vehicle

PendingCN114571989AImprove escape performanceImprove efficiencyMotor depositionElectric energy managementDrive wheelGear wheel

The invention discloses a wheel-side driving structure, a wheel-side driving assembly and a vehicle, the wheel-side driving structure comprises a planetary gear train, a driving motor unit and an adjustable-speed motor unit, the planetary gear train comprises a sun gear, a gear ring and a planet carrier for driving wheels, and the adjustable-speed motor unit is in transmission connection with the sun gear; the driving motor unit is in transmission connection with the gear ring; or the planetary gear train comprises double planet carriers for driving the wheels, and a small sun gear and a large sun gear of which the rotating axes coincide, the speed regulating motor unit is in transmission connection with the small sun gear, and the driving motor unit is in transmission connection with the large sun gear. The wheel-side driving assembly and the vehicle comprise a left wheel-side driving structure and a right wheel-side driving structure which share the driving motor unit, and the left wheel-side driving structure and the right wheel-side driving structure both comprise the wheel-side driving structure. The wheel edge driving structure is simple and compact in structure and good in installation performance, the average efficiency of the wheel edge driving assembly and the vehicle is high, and the cost is relatively low.

Owner:BYD CO LTD

Coaxial electric drive axle with differential lock

PendingCN112918189ARealize deadlockUniform outputAxle unitsControl devicesReduction driveElectric machine

The invention discloses a coaxial electric drive axle with a differential lock, which enables a motor to transmit power of the motor to a differential mechanism through a planetary reducer and transmit the power to wheels on two sides. The drive axle is characterized in that the drive axle motor is fixed with a sun gear of the planetary reducer through a spline, power is transmitted to the planetary reducer and then transmitted to the differential mechanism, and the differential mechanism outputs the power to wheels at the two ends through half shafts; a differential lock and a planet carrier are both provided with end face teeth, the differential lock is inserted into a half axle wheel carrier, when a vehicle runs normally, an electromagnetic controller attracts the differential lock to be recovered, and the differential lock is separated from the end face teeth of the planet carrier; when a vehicle slips, the differential lock end face teeth are combined with the planet carrier end face teeth, the planet carrier and the differential lock are fixed into a whole, then the planet carrier and the half axle wheel carrier are combined into a whole, the differential mechanism is locked, and power is evenly output to the two sides.

Owner:SHANDONG PENGXIANG AUTOMOBILE

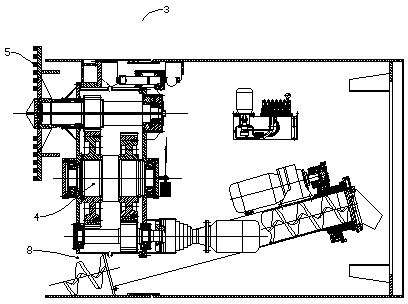

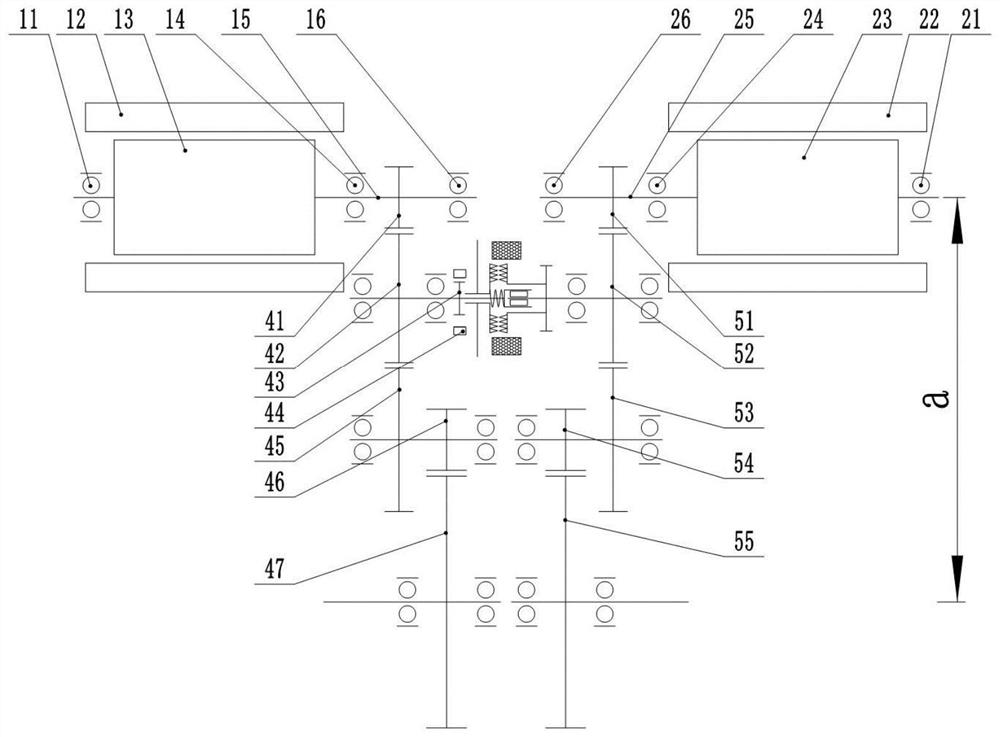

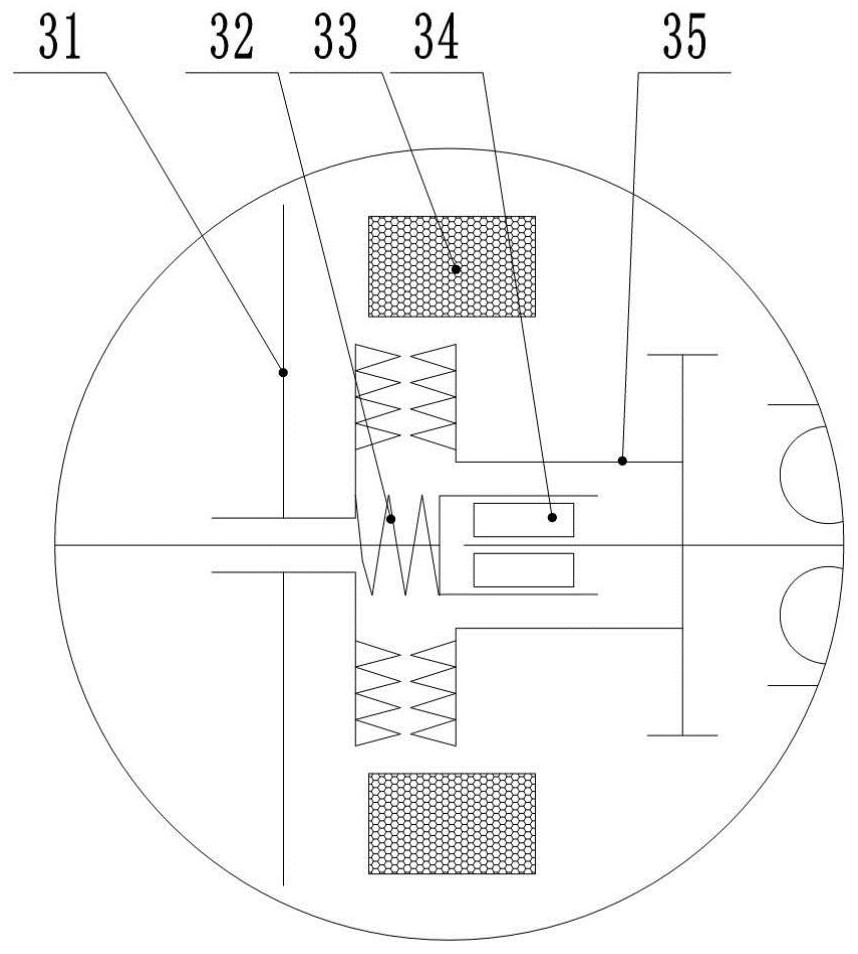

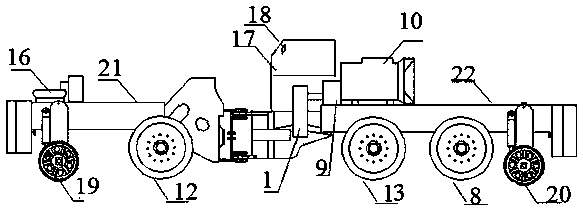

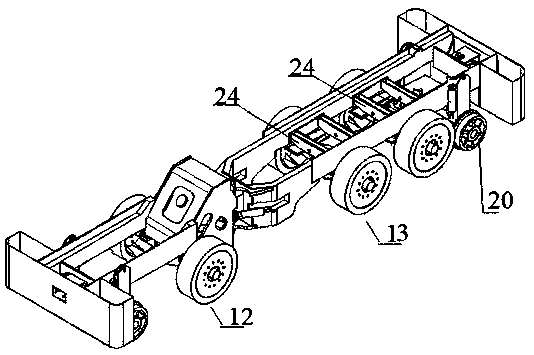

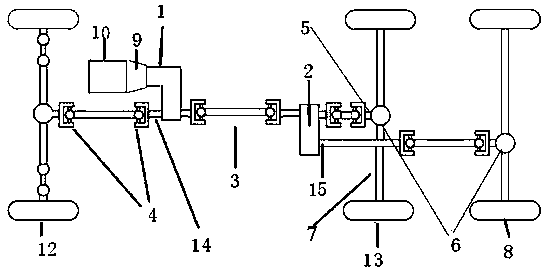

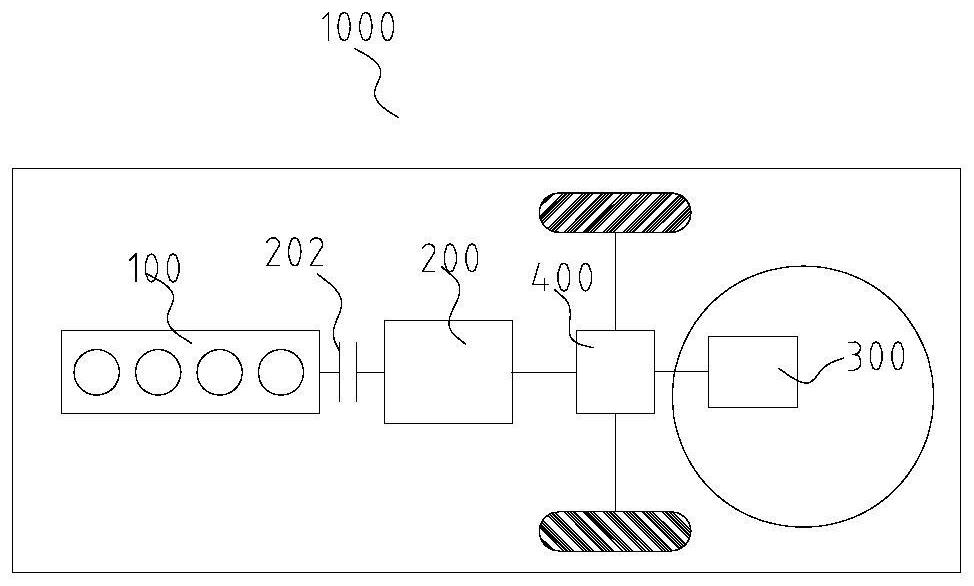

Highway-railway dual-purpose six-wheel drive traction locomotive and traction method

PendingCN111546882AImprove passabilityImprove escape performanceRail and road vehiclesClosed circuit television systemsRoad surfaceControl theory

The invention belongs to the technical field of highway-railway dual-purpose traction locomotives, and in particular to a highway-railway dual-purpose six-wheel-drive traction locomotive and a traction method. The highway-railway dual-purpose six-wheel-drive traction locomotive comprises a six-wheel drive transmission device, a brake device, a balancing device, a guide wheel lifting device and a working video system, according to the highway-railway dual-purpose six-wheel drive traction locomotive, six-wheel drive of the highway-railway dual-purpose traction locomotive can be achieved, the friction area between the highway-railway dual-purpose traction locomotive and steel rails and the ground is increased, the friction force between the highway-railway dual-purpose traction locomotive andthe steel rails and the ground is increased, and the traction capacity is improved under the condition that the engine power is not changed; the trafficability of the highway-railway dual-purpose traction locomotive on a severe road surface can be improved, and the escape capacity, the climbing capacity and the stability on a slippery road surface are enhanced, so that a better traction effect isachieved.

Owner:山东智捷专用车制造有限公司

Movement control method of cleaning machine

PendingCN114468873ASimple structureEasy to cleanAutomatic obstacle detectionTravelling automatic controlControl engineeringMachine

According to the movement control method of the cleaning machine, the cleaning machine comprises a machine body, the machine body is provided with two pieces of mop cloth distributed in a parallel structure, and the mop cloth is arranged to be of a structure capable of being attached to the ground to horizontally rotate; the two mops are controlled to horizontally rotate to serve as a power source to drive the cleaning machine to move on the ground to execute a cleaning mode; in the cleaning mode, if it is detected that the posture of the cleaning machine is inclined in the state that the horizontal rotating speed of the two mops is not reduced and the horizontal rotating direction of the two mops is not changed, and the inclination angle F is larger than or equal to E degrees, the posture of the cleaning machine is controlled and adjusted so that the cleaning machine can be separated from the current position. According to the scheme, the problem that an existing cleaning machine cannot timely and effectively escape or bypass obstacles in the process of moving on the ground is solved.

Owner:QUFU SINODOD INTELLIGENT TECH CO LTD

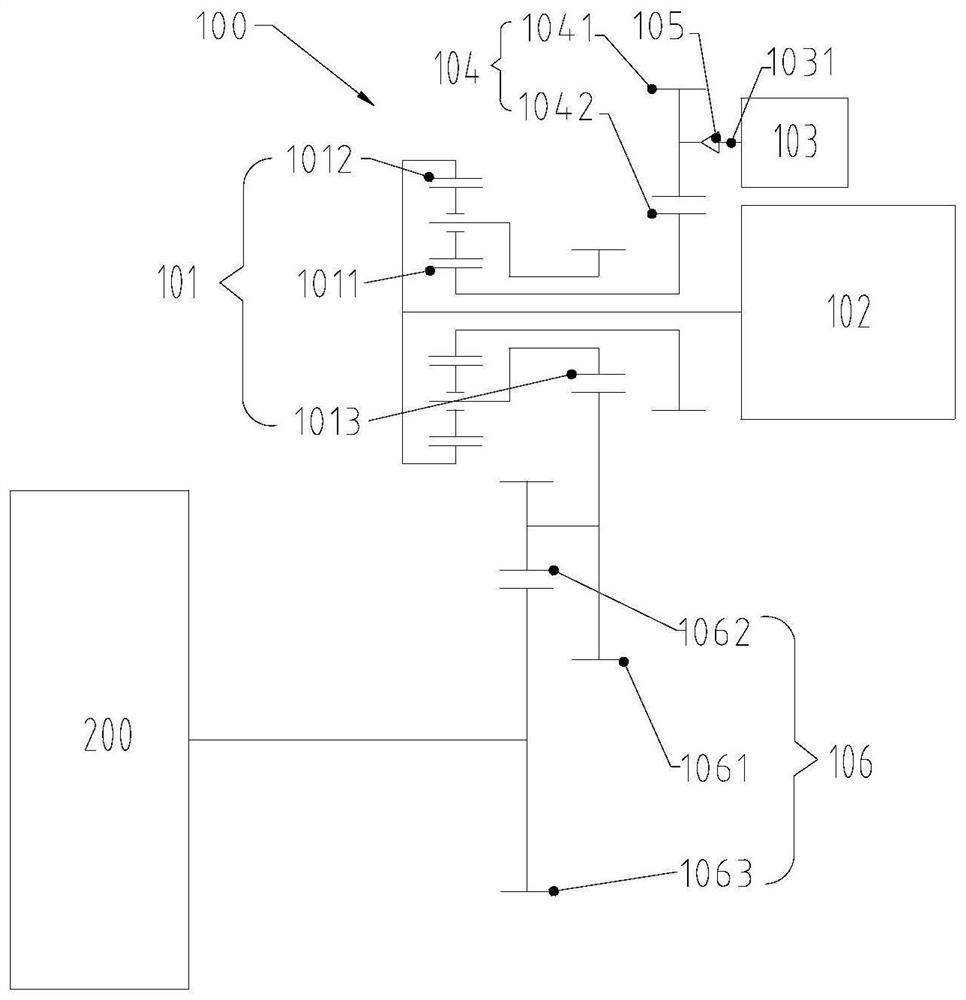

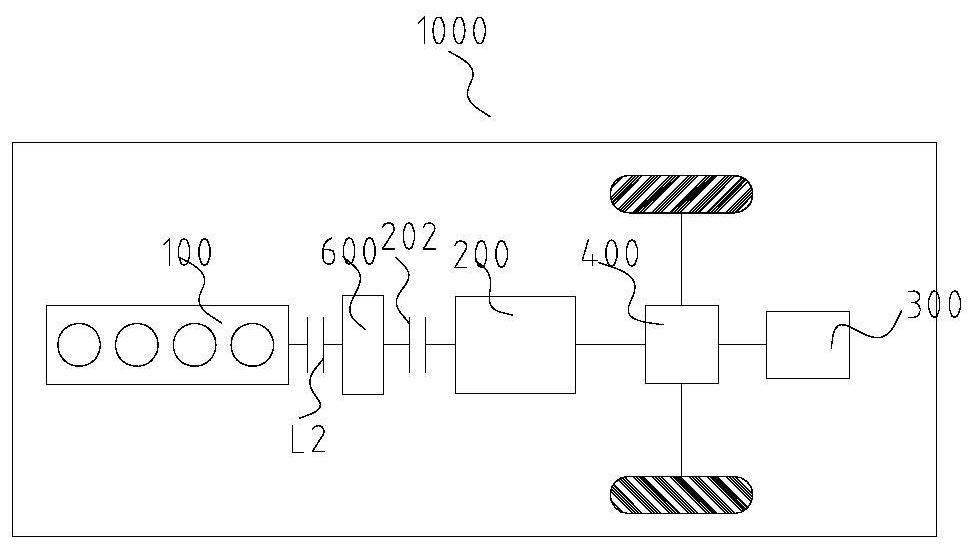

Powertrain and vehicle having same

ActiveCN108016280BImprove economyImprove powerPropulsion using engine-driven generatorsGas pressure propulsion mountingDrivetrainGear wheel

Owner:BYD CO LTD

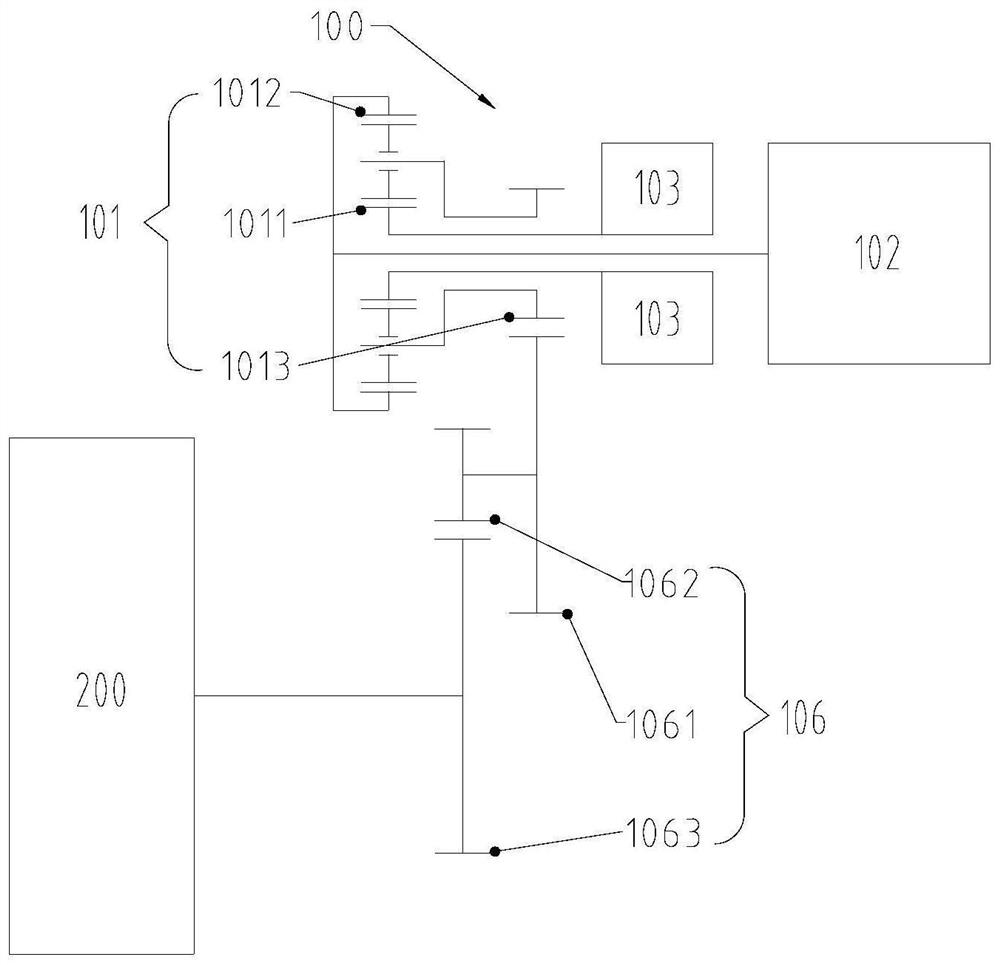

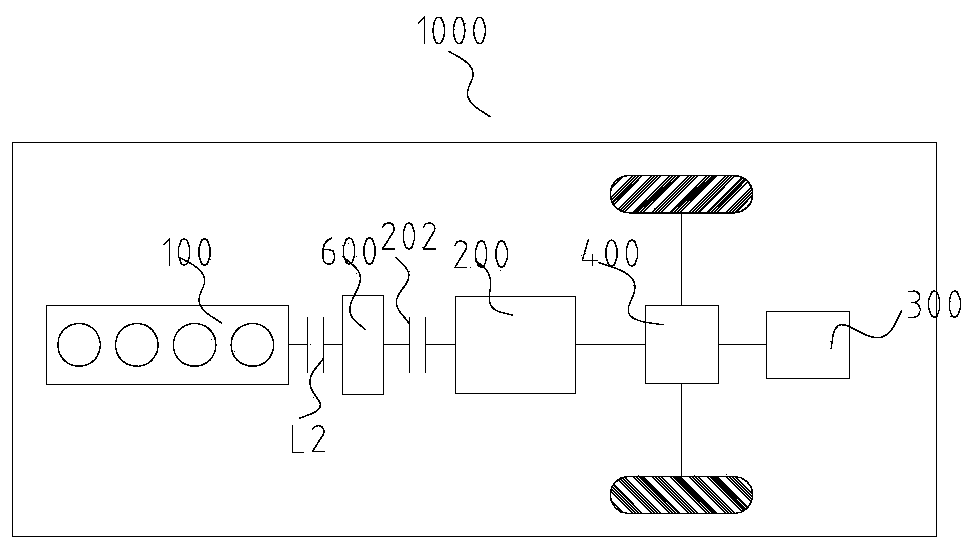

Powertrain and vehicle having same

ActiveCN108001192BImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingPower couplingDrivetrain

The invention discloses a power transmission system and a vehicle with the same. The power transmission system includes a power source, a speed change unit, a first motor generator unit, a switching module, a second motor generator, a system power output part and a mode conversion device; the first motor generator unit comprises a first motor generator and a unit coupling part; the first motor generator is selectively in dynamic coupled connection with the speed change unit or the unit coupling part through the switching module; the second motor generator is directly or selectively in dynamiccoupled connection with an engine; the mode conversion device comprises an input part and an output part, the conversion device input part is in dynamic coupled connection with the speed change unit and the unit coupling part separately, the output part is connected with the system power output part, and the input part is selectively connected with the output part; when the input part is in dynamic coupled connection with the output part, the rotational speed of the input part is greater than or equal to that of the output part. In this way, the driving modes of the vehicle can be enriched, and the vehicle can adapt to different road conditions.

Owner:BYD CO LTD

Powertrain and vehicle having the same

ActiveCN108001186BImprove economyImprove powerHybrid vehiclesElectric propulsion mountingPower couplingDriver/operator

Owner:BYD CO LTD

Powertrain and vehicle having same

ActiveCN108016277BImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingDrivetrainControl theory

The invention discloses a power transmission system and a vehicle thereof. The power transmission system includes: a power source; a first motor generator unit; a system power output part; part, a second conversion part and an output part, the output part is connected to the input end of the system power output part, the input part is suitable for outputting power from at least one of the power source and the first motor generator unit, and the input part is selectively connected with One of the first conversion part and the second conversion part is engaged, the first conversion part and the second conversion part cooperate with the output part for transmission, and the input part is engaged with the second conversion part, so that it is suitable for reducing the output speed of the input part Output to the input end of the power output part of the system. In this way, the driving modes of the vehicle can be enriched, and the vehicle can adapt to different road conditions.

Owner:BYD CO LTD

A hexapod bionic robot

The invention relates to a hexapod bionic robot which comprises a body frame, a controller mounted in the body frame and a power source. Compared with the prior art, the hexapod bionic robot further comprises six sets of walking devices driving the robot to walk; the walking devices are of an integrally-assembled type structure and can be integrally mounted into the body frame or integrally detached out of the body frame; the six sets of walking devices are fixed to the two sides of the front, the two sides of the middle and the two sides of the rear portion of the body frame respectively, and the walking devices on the two sides of the front, the two sides of the middle and the two sides of the rear portion of the body frame are arranged in a staggered mode. The robot is more reasonable in structure and convenient to disassemble and assemble, and meanwhile precise control is achieved easily.

Owner:原粒(北京)半导体技术有限公司

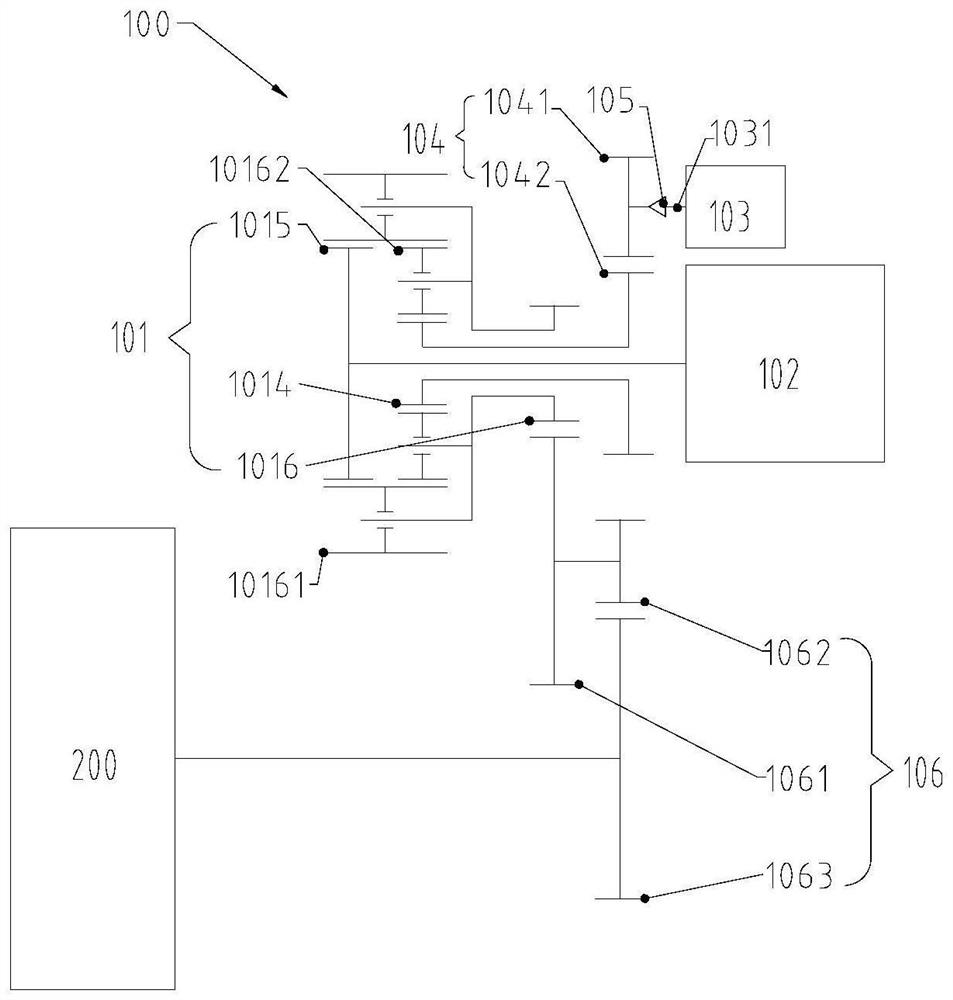

Power transmission system and vehicle with power transmission system

ActiveCN108016286AImprove economyImprove powerHybrid vehiclesGas pressure propulsion mountingPower couplingElectric power transmission

The invention discloses a power transmission system and a vehicle. The power transmission system comprises a system power output part, a power source, a variable speed unit, a first motor generator unit and a mode conversion device, wherein the power source and the system power output part are in selective power coupling connection; the variable speed unit is selectively connected with the power source and connected with the system power output part; the first motor generator unit comprises a first motor generator and a unit coupling part, the unit coupling part is connected with the system power output part, and the first motor generator is selectively connected with the unit coupling part; and the mode conversion device is used for selectively connecting the variable speed unit with theunit coupling part and is in power coupling connection with the variable speed unit and the unit coupling part, so that power from the power source sequentially passes through the variable speed unitand the mode conversion device to be secondarily decelerated and then is output to the unit coupling part. Therefore, drive modes of the vehicle can be enriched, and the vehicle can adapt to differentroad conditions.

Owner:BYD CO LTD

Powertrains and Vehicles

ActiveCN108237907BImprove escape performanceBraking element arrangementsControl devicesGear wheelMotronic

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com