Dual-motor driving system assembly and vehicle

A dual-motor drive and motor-driven technology, which is applied to vehicle components, transportation and packaging, and control devices, can solve the problems of enlarging the envelope of the powertrain, increasing the axial width of the powertrain, and increasing the cost. Improve the ability to get out of trouble, improve the overall benefit, and improve the effect of parking safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

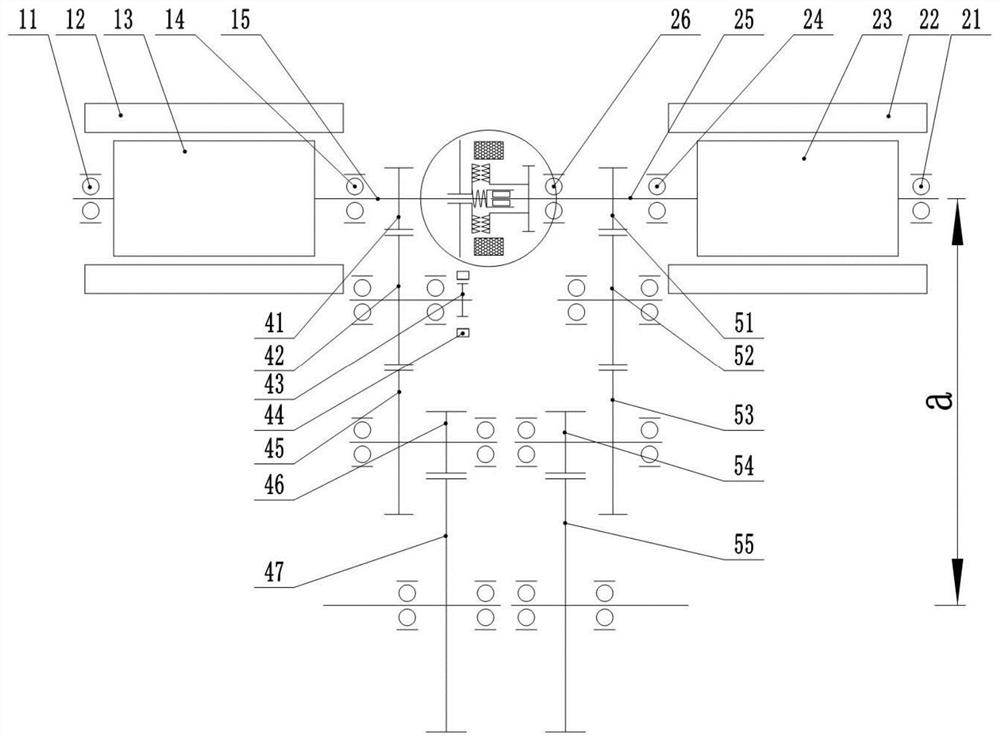

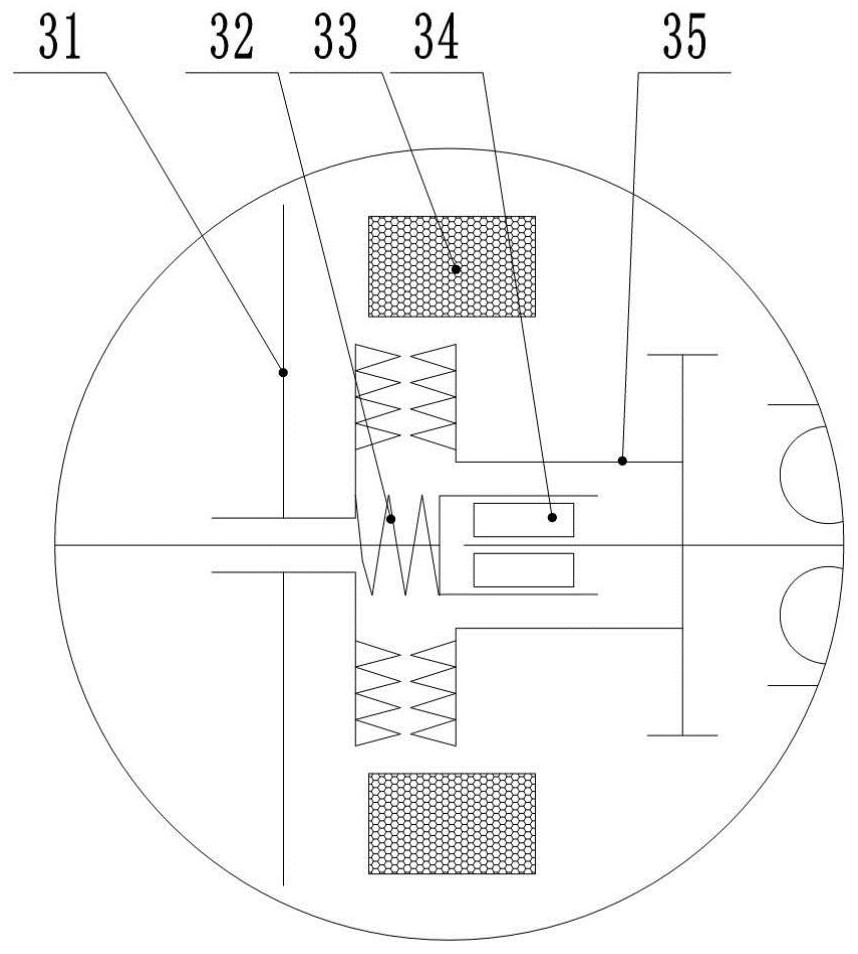

[0051] For the dual-motor drive system assembly in Embodiment 1, see figure 1 and the aforementioned description. It should be pointed out that, figure 1 The differential lock mechanism can be realized by locking the output shaft 15 of the first motor and the output shaft 25 of the second motor through an electromagnetic clutch; specifically, the following scheme can be used: the movable chain plate assembly 31 and the output shaft 15 of the first motor pass through The spline sliding connection, the fixed gear plate assembly 35 and the output shaft 25 of the second motor are fixedly connected by splines and other connection methods; the parking gear is integrated on the fixed gear plate, which can effectively reduce the number of parts and the assembly shaft The fixed electromagnetic coil 33 is energized to generate electromagnetic force, so that the movable toothed plate assembly 31 moves in the direction of the fixed toothed plate assembly 35, and the end face teeth on the...

Embodiment 2

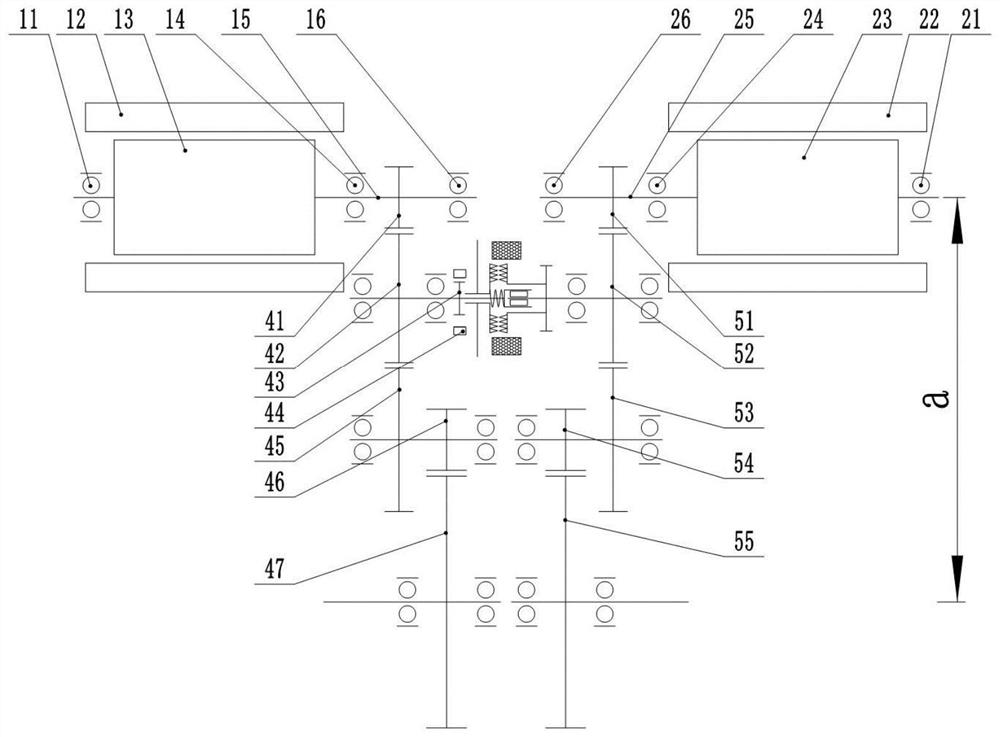

[0054] For the dual-motor drive system assembly in Embodiment 2, see figure 2 and the aforementioned description. It should be pointed out that the differential lock mechanism can be realized by the idler gear I42 and the idler gear II52; specifically, the following scheme can be used: the movable chainring assembly 31 and the idler gear I42 are slidably connected by a spline, and the fixed chainring assembly 35 and the idler gear are slidably connected. II52 is fixedly connected by splines and other connection methods; the parking gear is integrated on the fixed gear plate, which can effectively reduce the number of parts and the axial size of the assembly; the fixed electromagnetic coil 33 is energized to generate electromagnetic force, which makes the movable tooth The disc assembly 31 moves towards the fixed toothed disc assembly 35, and achieves mutual meshing and locking through the end face teeth on the toothed disc, reaching the function of locking the idler gear I an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com