Patents

Literature

52results about How to "Avoid swimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

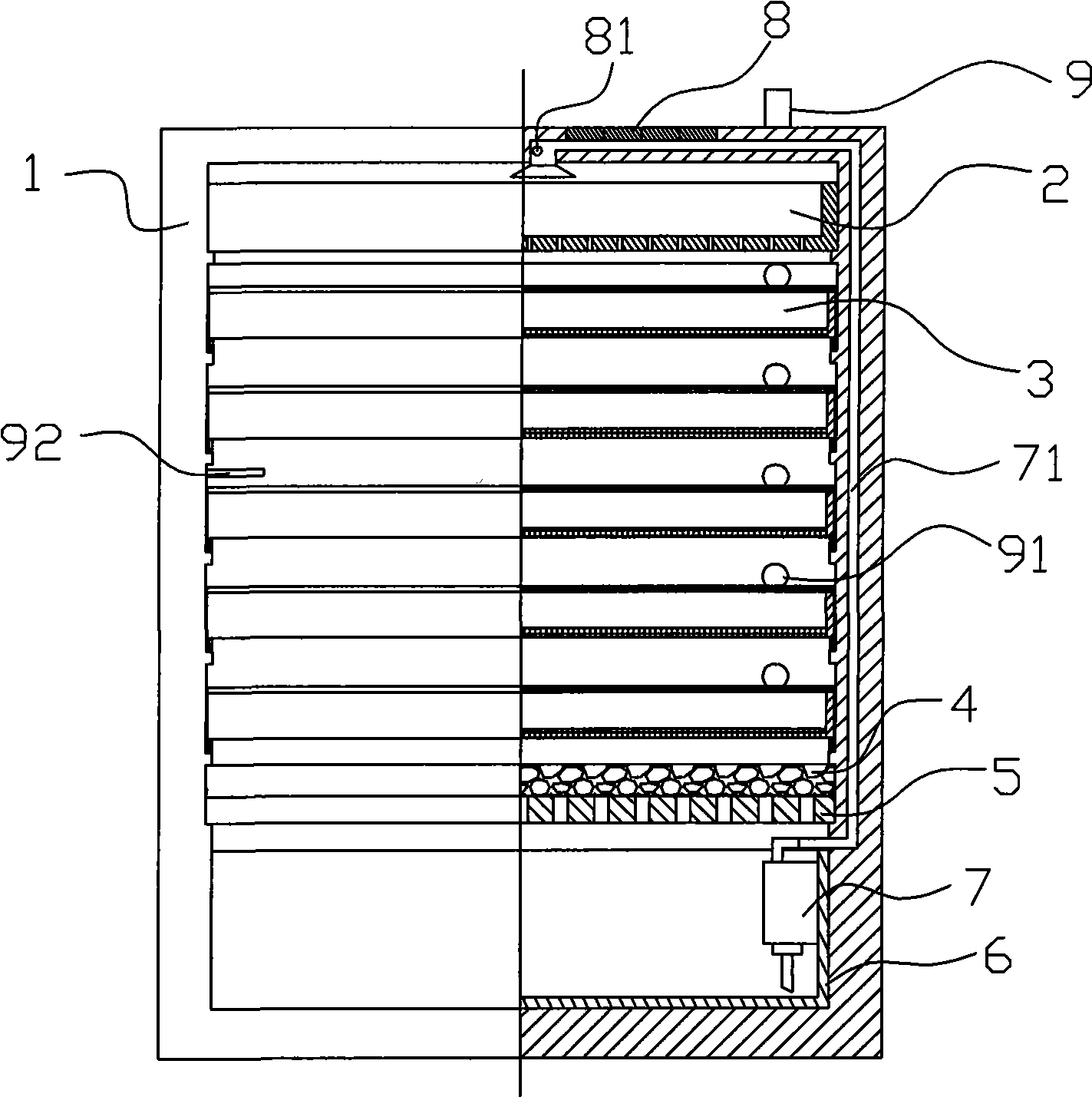

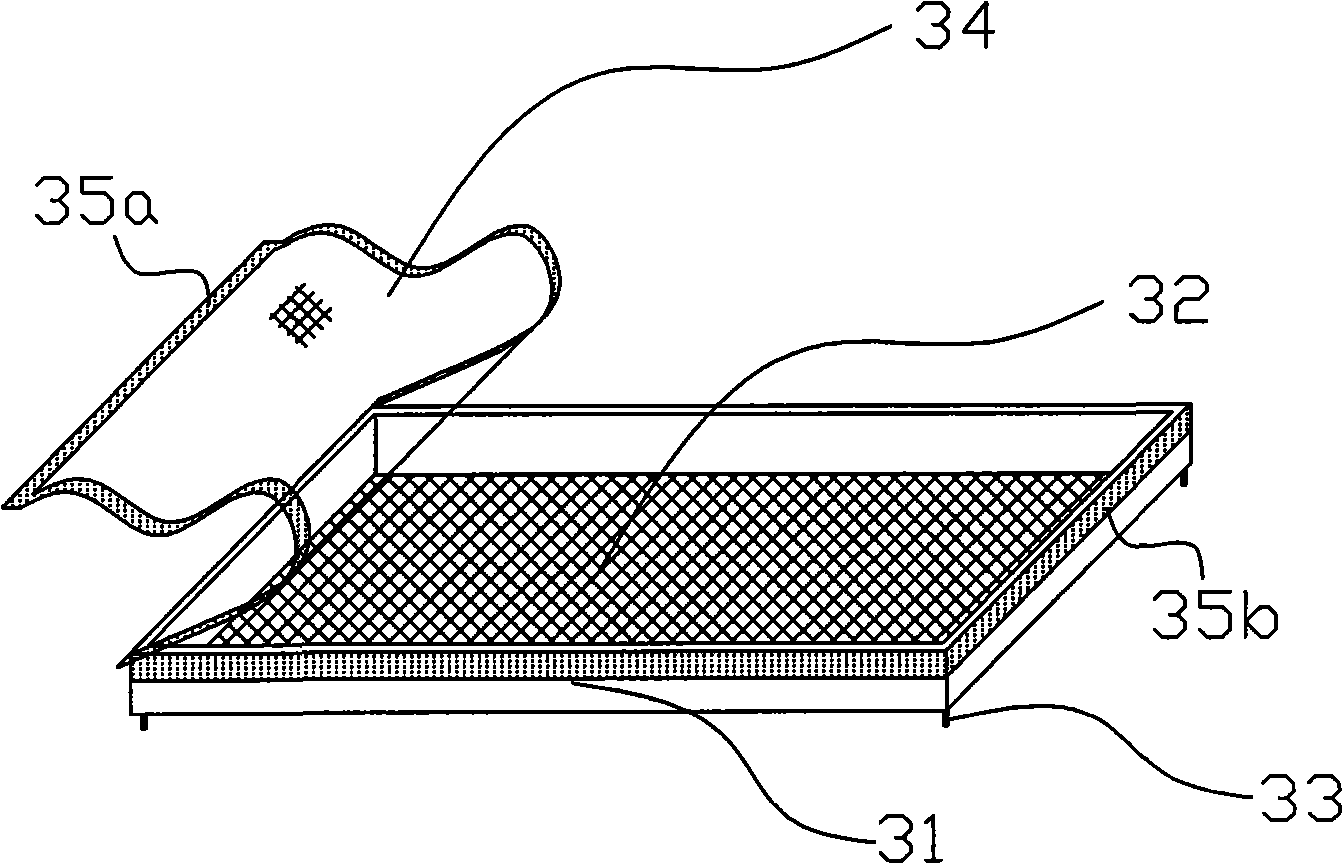

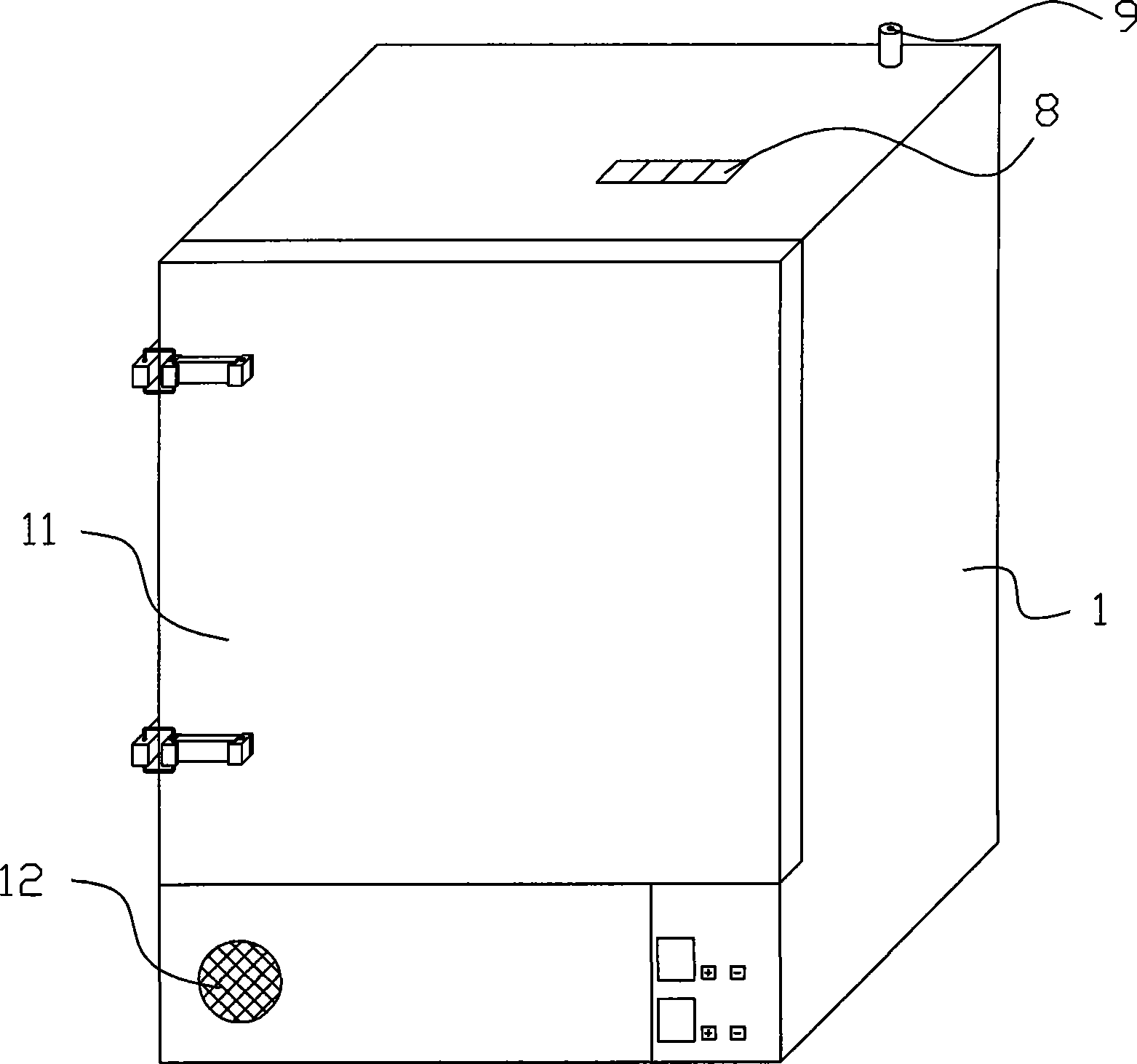

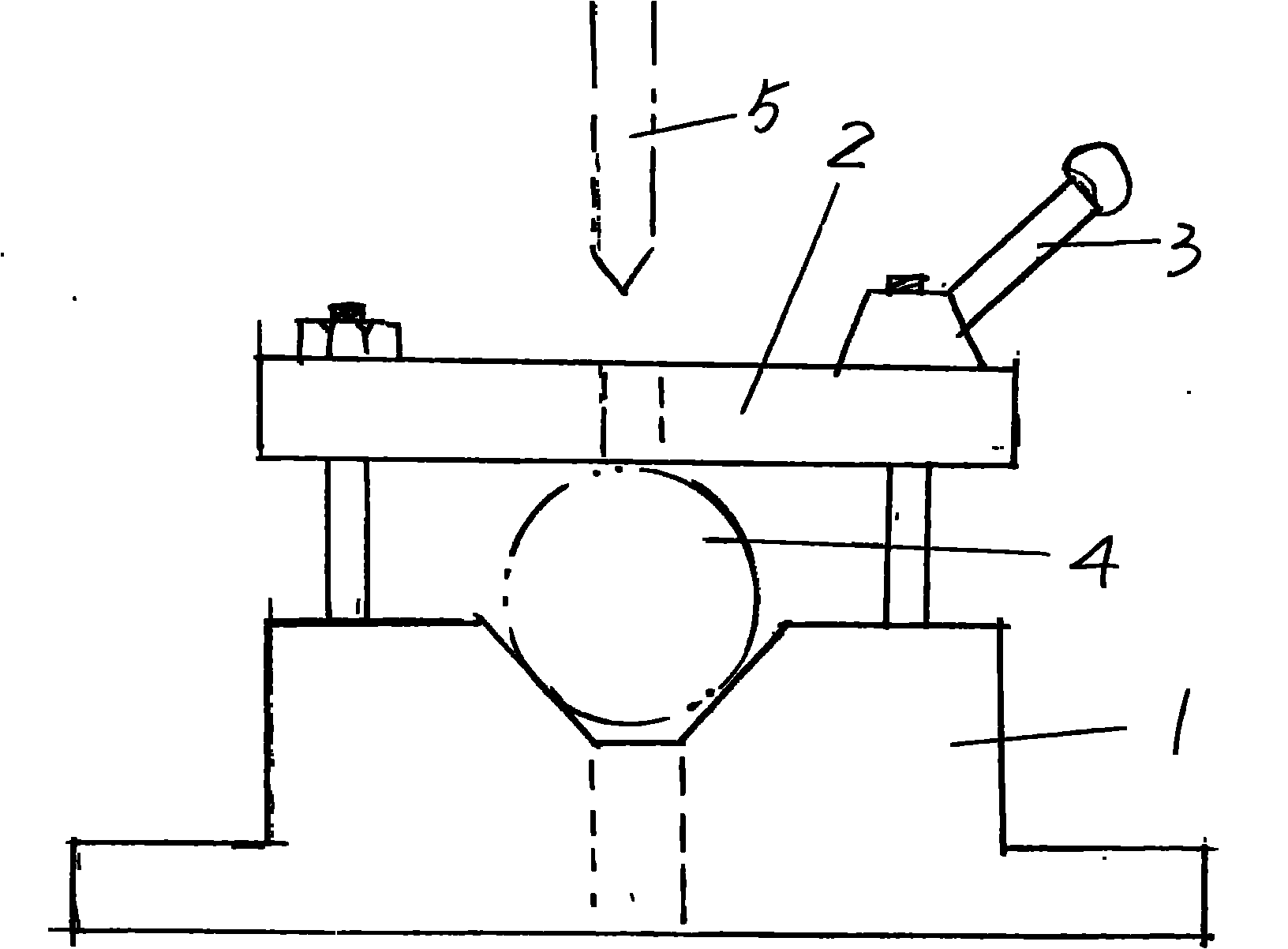

Method for transporting living body of shrimp and special equipment thereof

InactiveCN101480172AAvoid swimmingGuaranteed survivalPisciculture and aquariaAutomatic controlBiological filter

The invention discloses a method and a special device for live shrimp transportation. The method adopts cooling water to spray shrimps so as to finish transportation. In the special device, a flow separation device is mounted at the upper part of the inner side of an insulation casing, a plurality of trays, a biological filter element, a support plate with uniformly distributed through holes and a water tank are sequentially arranged at the lower side of the flow separation device, and a water pump is arranged in the water tank and can feed water in the water tank to the flow separation device by a water pipe; an oxygen-transmitting hole is arranged at the inner side wall of the insulation casing, and an oxygen-transmitting electric valve tube is communicated with an oxygen-transmitting hole pipeline; a semiconductor refrigeration device penetrates through the insulation casing, and the water pump, the semiconductor refrigeration device, and a temperature probe and an oxygen sensor in the insulation casing are electrically connected with an automatic control device for controlling temperature and oxygen. The invention has the advantages of reasonable structure, space conservation and small consumption of water for transportation, avoids the drug anesthesia of the shrimps, can prevent the shrimps from pricking each other to death due to scare in a transportation process, and the like.

Owner:ZHEJIANG OCEAN UNIV

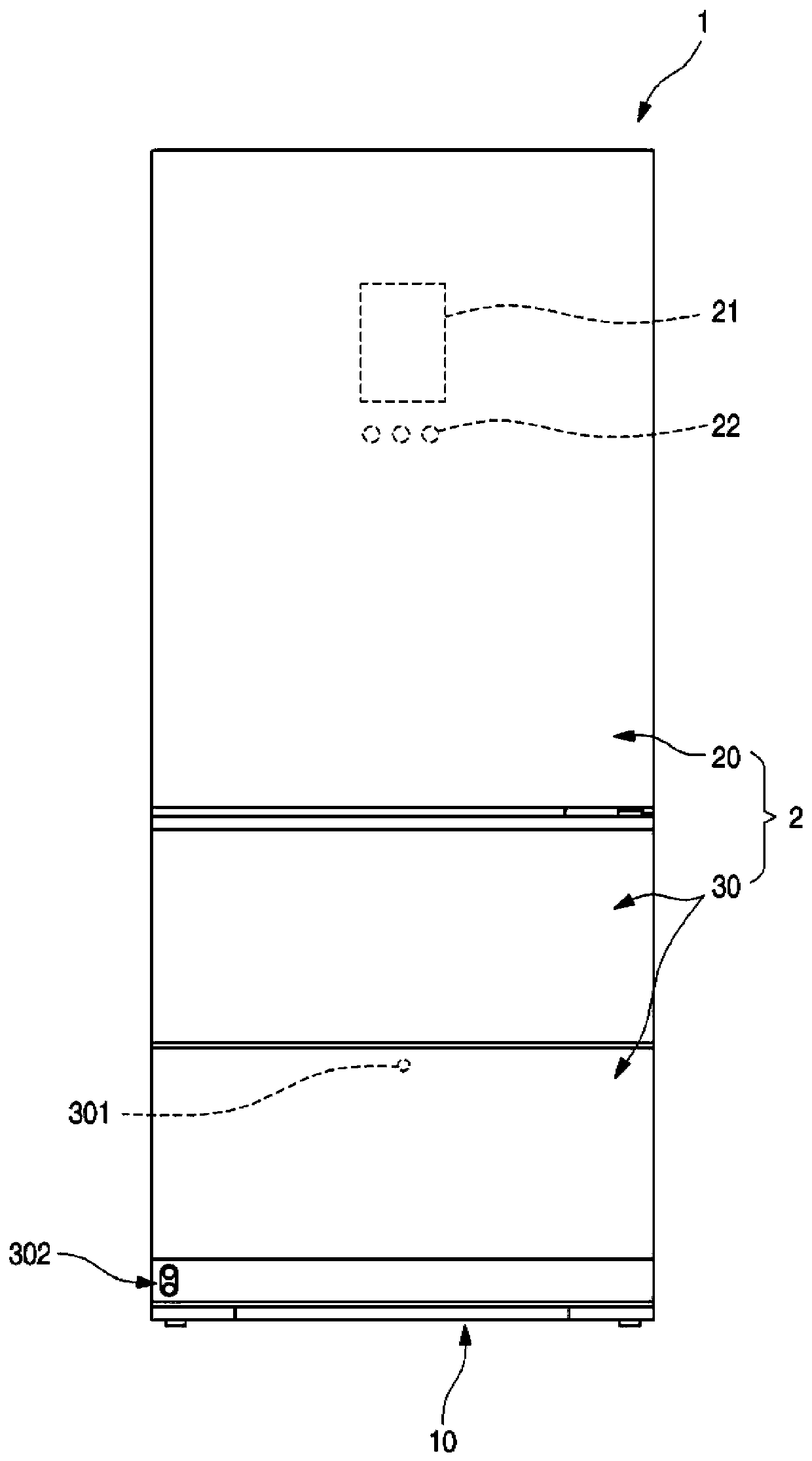

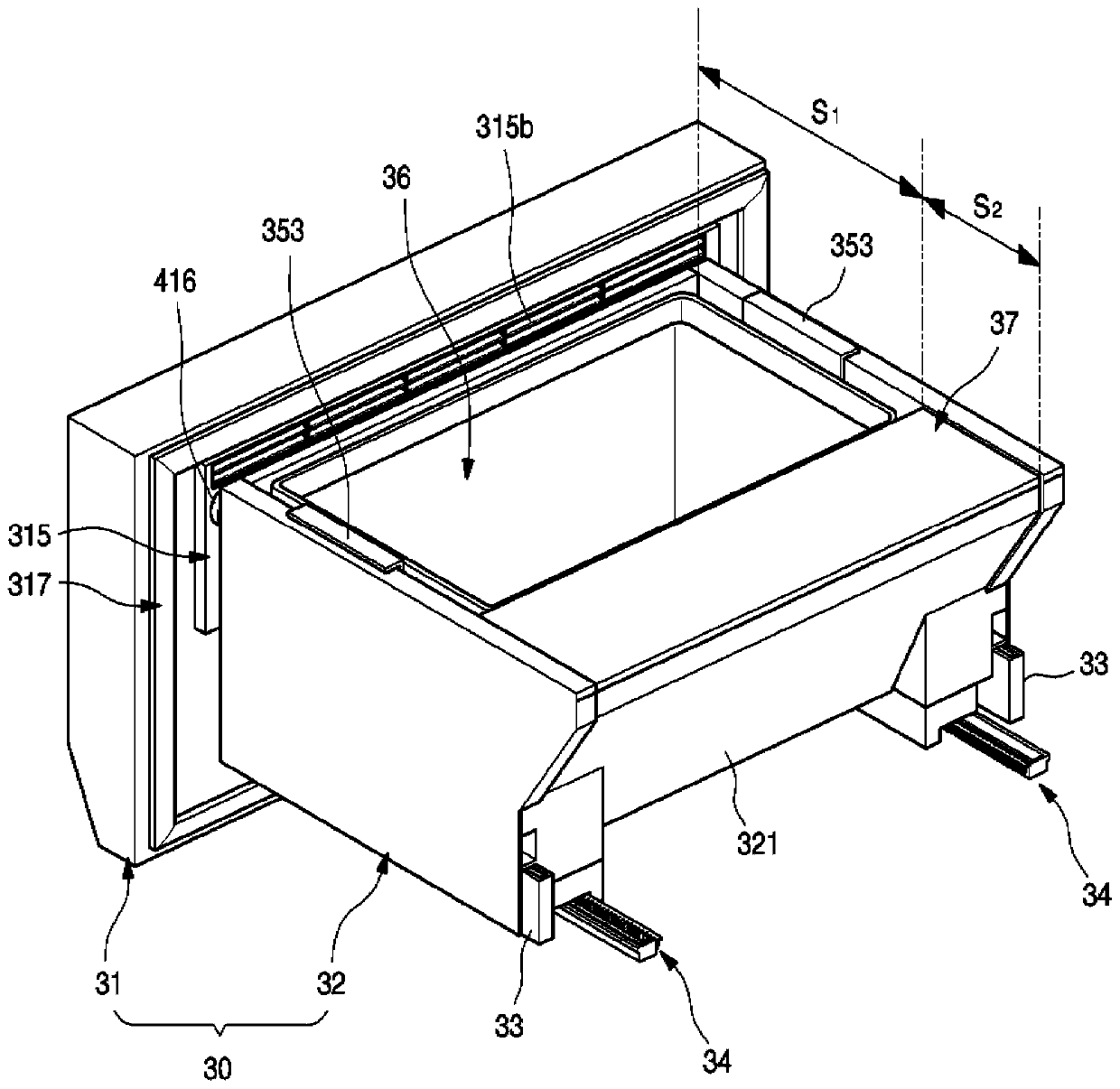

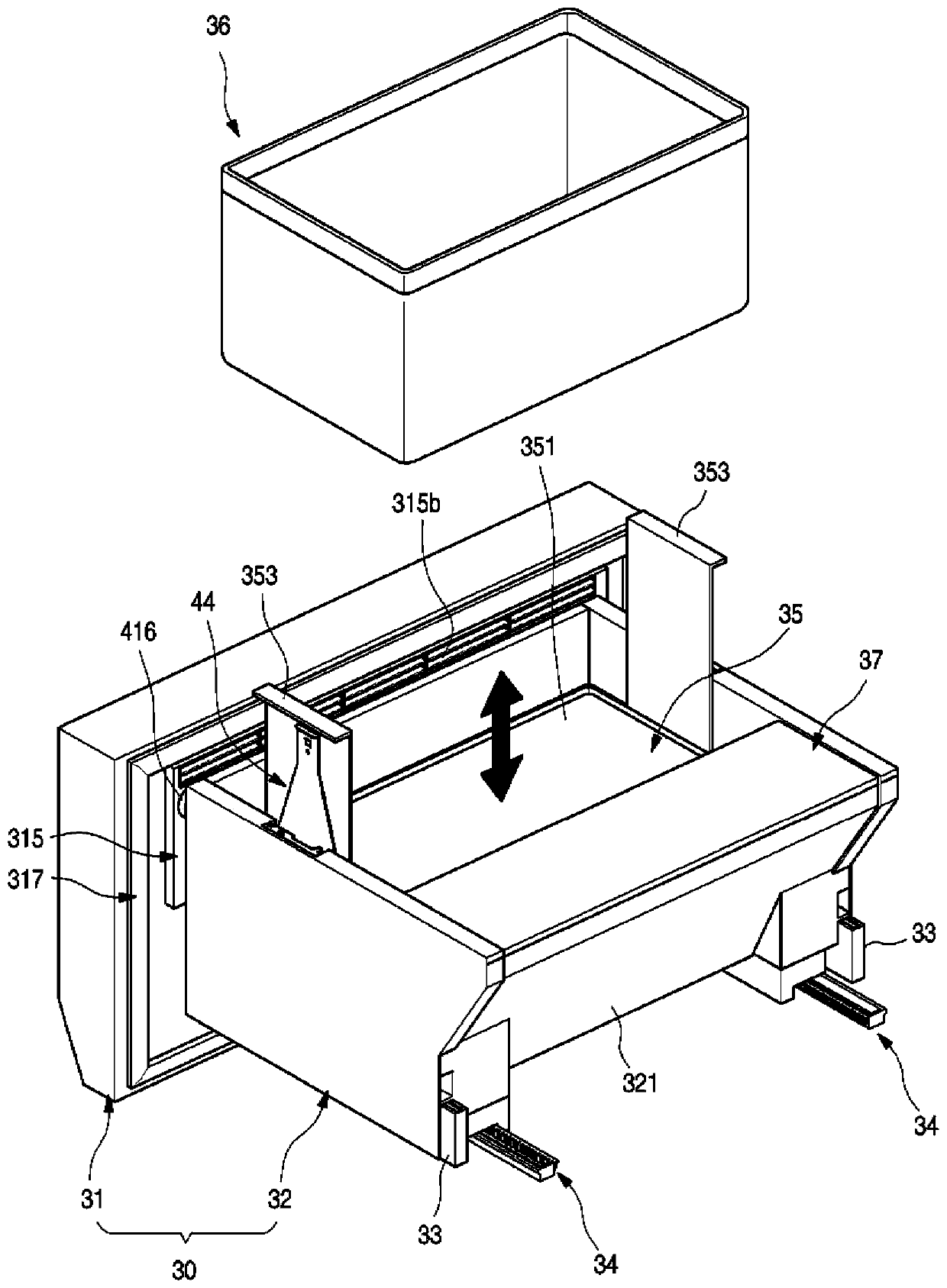

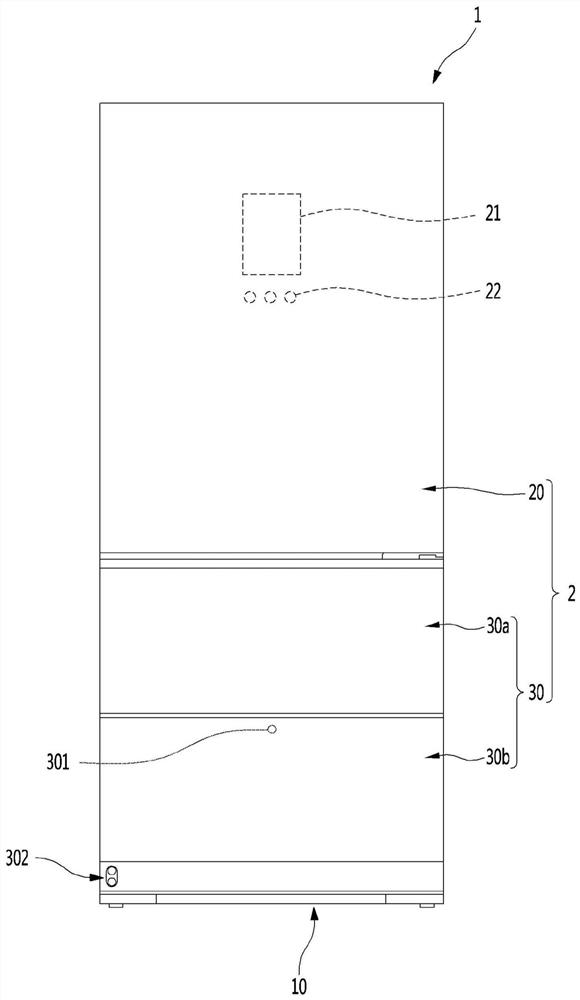

Refrigerator

ActiveCN109990557AImprove ease of useMinimize the loss of storage spaceLighting and heating apparatusSupportStructural engineeringElectrical and Electronics engineering

Owner:LG ELECTRONICS INC

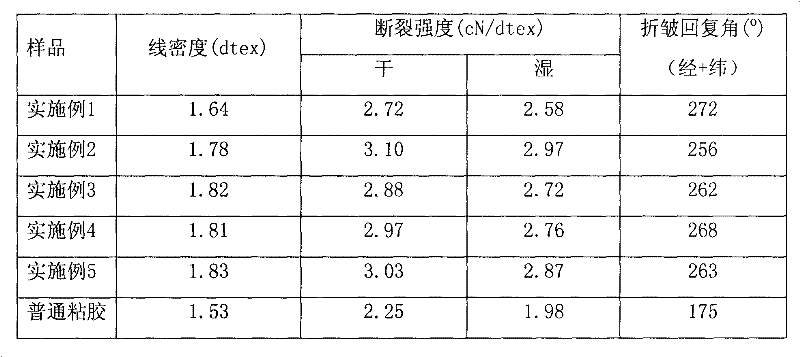

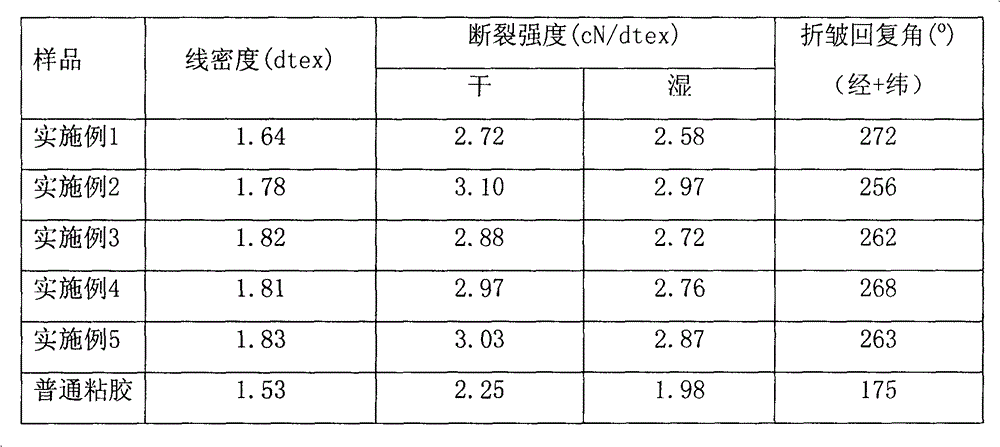

High elastic non-ironing cellulose fiber and preparation method thereof

ActiveCN102199803AGood mechanical propertiesComfortable elasticArtificial filaments from cellulose derivativesCross-linkChemical reaction

The invention relates to a high elastic non-ironing cellulose fiber and a preparation method thereof, and belongs to the technical field of weaving. The high elastic non-ironing cellulose fiber is prepared from cellulose, a finishing agent and a catalyst through a cross linking reaction, and comprises, by mass, 85%-91% of the cellulose, 6%-10% of the finishing agent and 3%-5% of the catalyst. Thehigh elastic non-ironing cellulose fiber provided by the present invention has advantages of excellent mechanical property, natural tactility, comfortable elasticity and good wrinkle resistance, can suffer a plurality of slashing washing technologies and finishing technologies, and can be widely applicable for products such as non-ironing shirts, trousers and suits so as to satisfy consumer demands of easy-care clothing and easy-care fabric. Due to the fiber with high elasticity, textile produced from the fiber provided by the present invention has excellent wrinkle resistance without ironingand finishing. With the present invention, processing enterprises of fabric and clothing can save cost and energy.

Owner:QINGDAO TIANYI GROUP

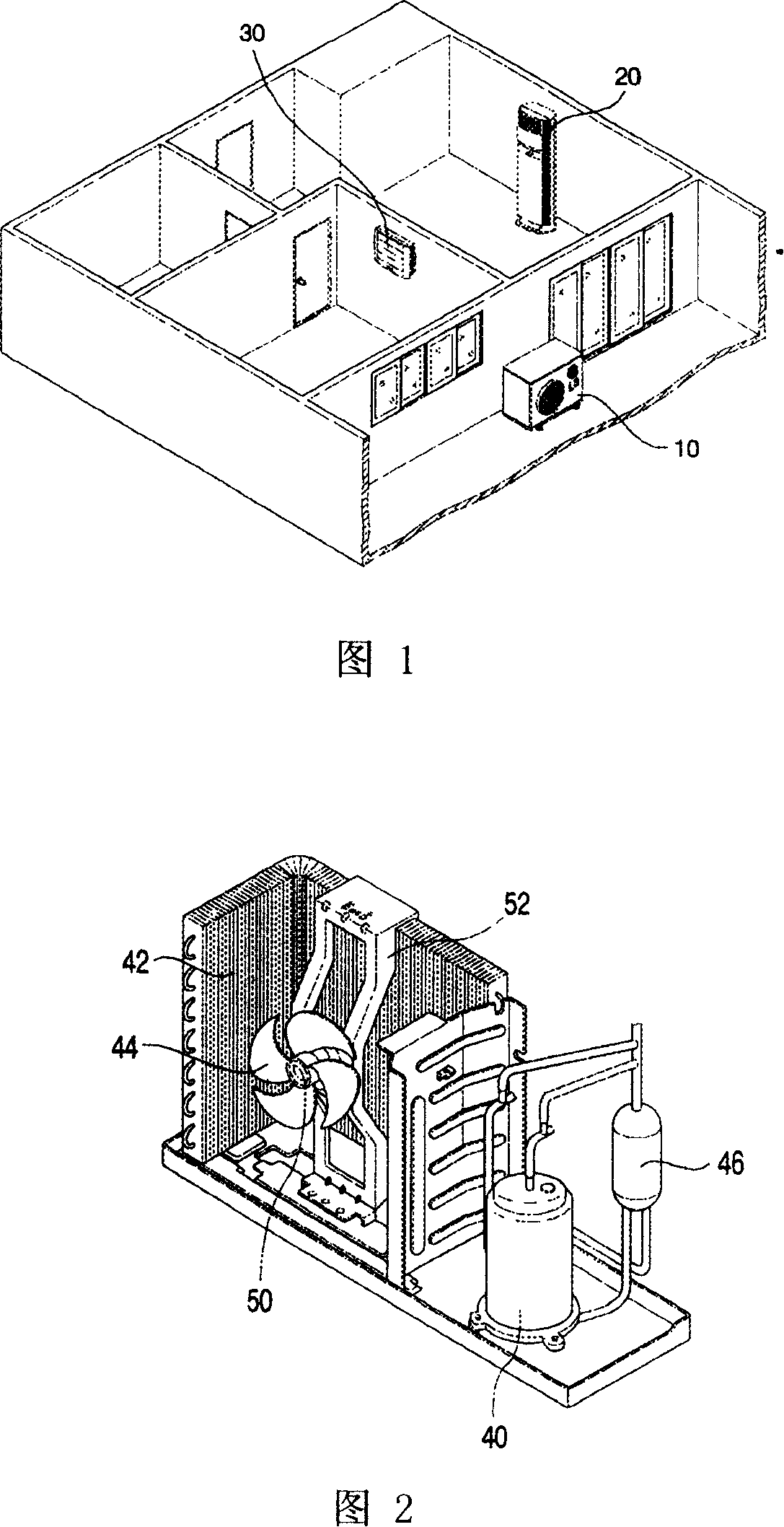

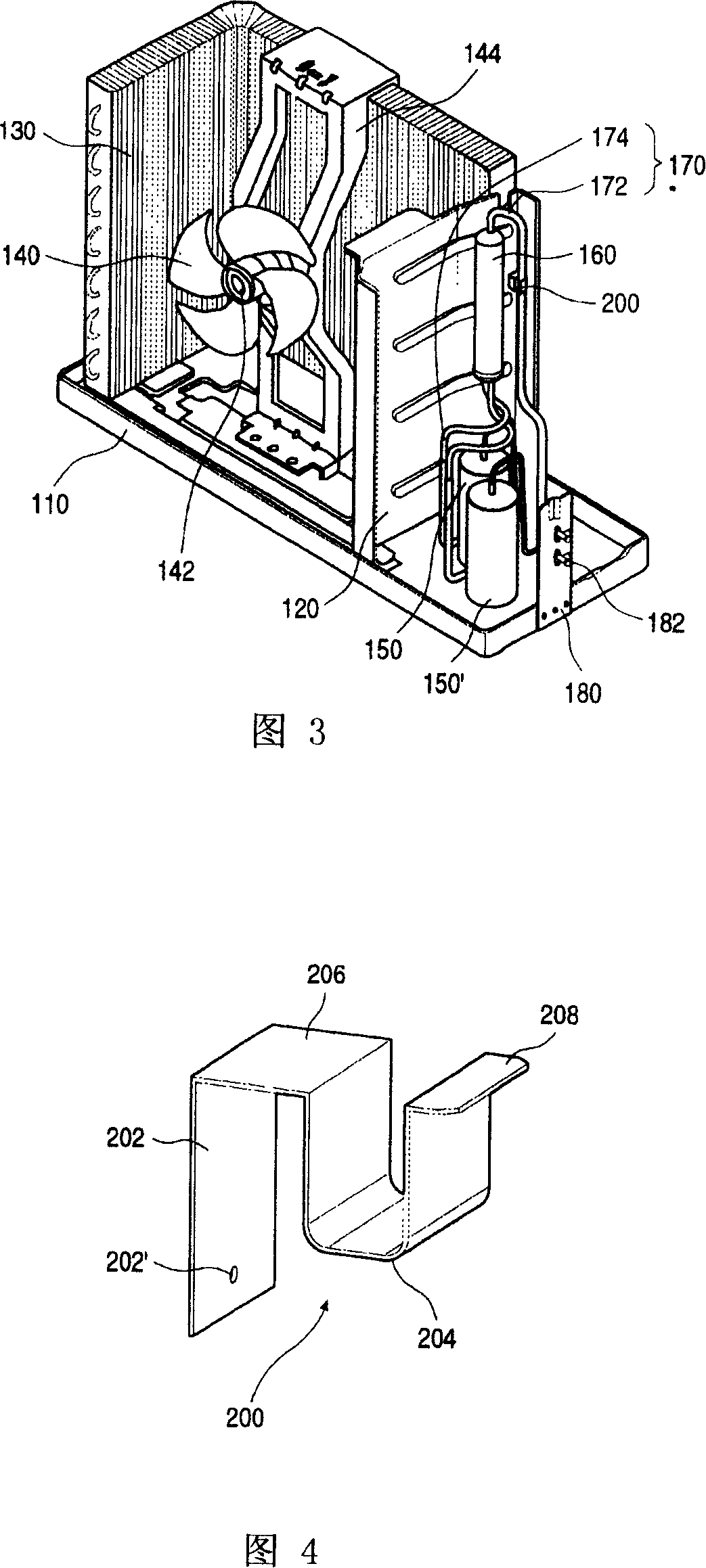

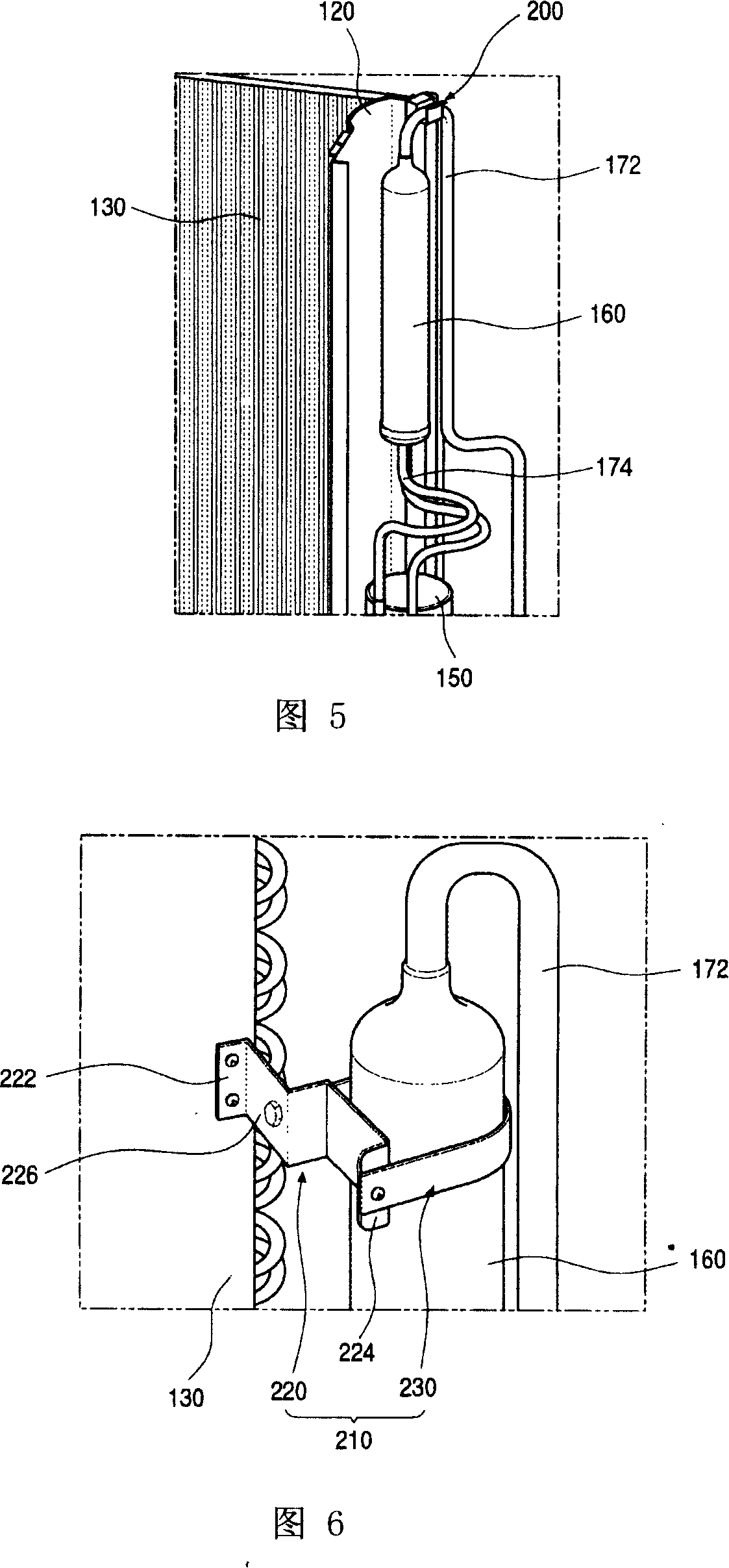

Outdoor machine of air regulator

InactiveCN101086349AAvoid damageAvoid swimmingLighting and heating apparatusAir conditioning systemsVapor–liquid separatorPlate heat exchanger

The invention discloses an outdoor machine of air-conditioning which belongs to the installation of the gas or liquid separation or purification device. The invention includes the baffle which divides the left and right inner space, the heat exchanger which is installed at one side of baffle and heat-exchanges between coolant and air, the air supply fan which is installed at one side of heat exchanger and is used for flowing air, the compressor which is installed at one side of baffle and is used for compressing coolant, and the gas and liquid separator which is installed at one side of compressor and is used for filtering out the liquid coolant in the coolant flowing into compressor; and it is also equipped with the fixing structure which is used for fixing gas and liquid separator. The outdoor machine of air-conditioning in the invention can prevent the damage of connecting part of gas and liquid separator two ends caused by vibration, and it has the advantages of improving products reliability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

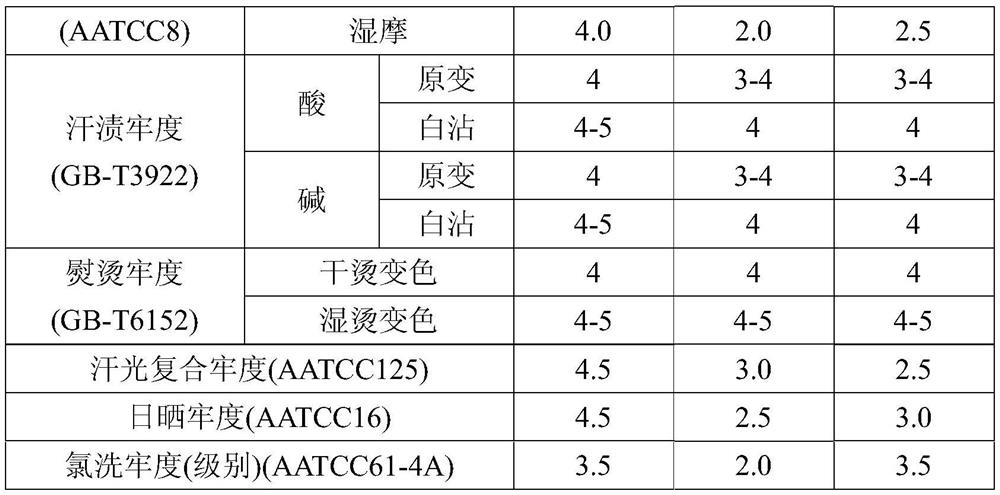

Method for distressed rapid dyeing of wool sweater

The invention relates to a method for distressed rapid dyeing of a wool sweater. The method comprises the following steps: (1) wax-dipping: weighing liquid Evo wax with the amount of 1.05-1.15 times of the wool sweater fabric weight, at the room temperature, soaking the wool sweater in the wax liquid, and repeatedly kneading and pressing until being uniform; and carrying out low temperature drying or natural drying; (2) dyeing: putting the wool sweater fabric after wax-dipping pretreatment and drying into a prepared dyeing bath; heating up to 75-80 DEG C at a speed of 3 DEG C / min, and holding for 5-10 min to achieve dyeing; (3) carrying out color fixation: after dyeing, adding a cationic color-fixing agent for color fixation for 5 min, and then taking out the fabric; (4) cleaning: washing with a non-ionic surfactant for 15 min at the temperature of 70 DEG C; and (5) drying. After the wool sweater is dyed by the rapid dyeing process, a distressed effect of distinct depth levels and uniform overall appearance appears. In addition, compared with a conventional dyeing process, the dyeing time is shortened by 60%-70%, and the color fastness is at the level of 2.5 or above.

Owner:嘉兴俊雅服饰股份有限公司

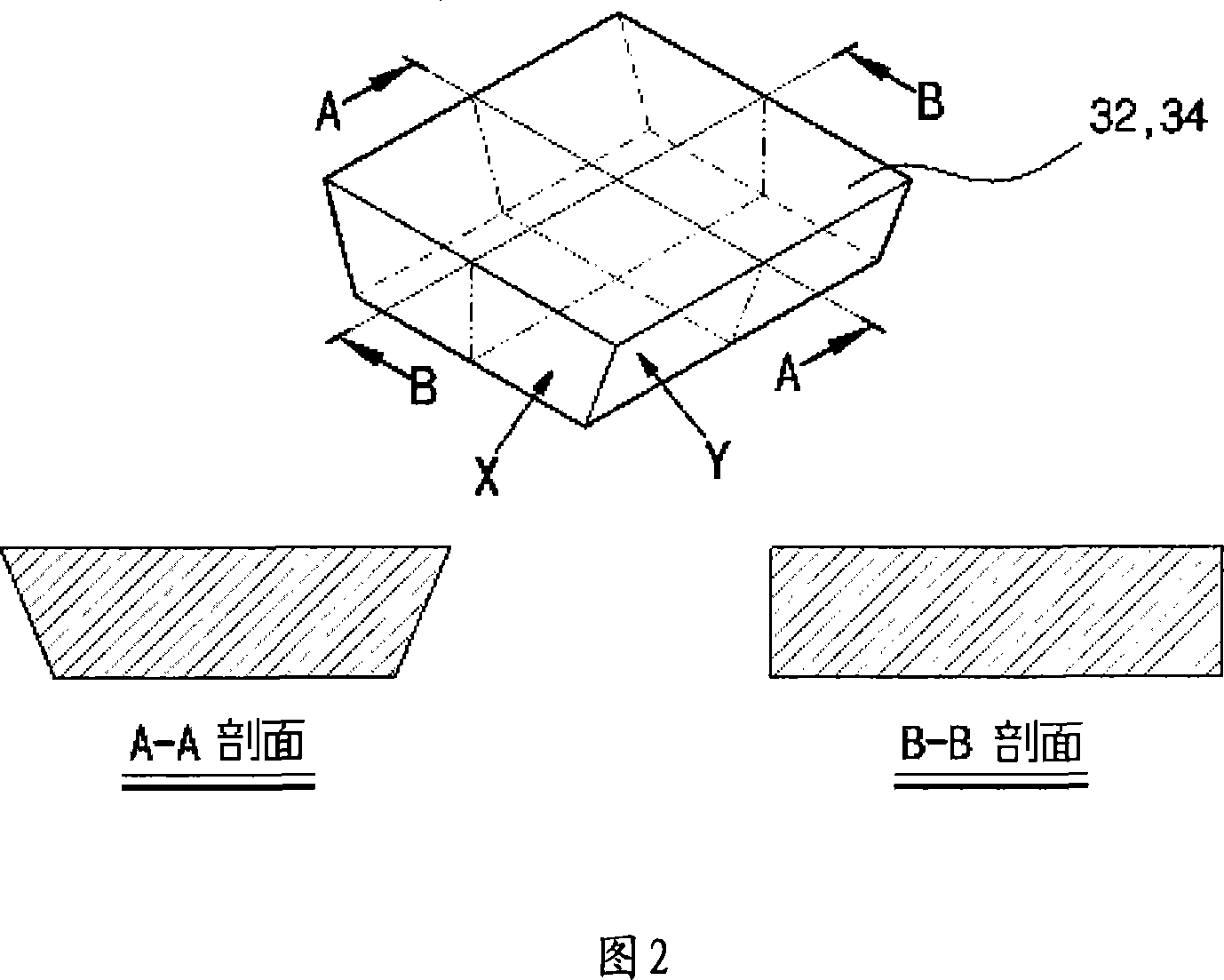

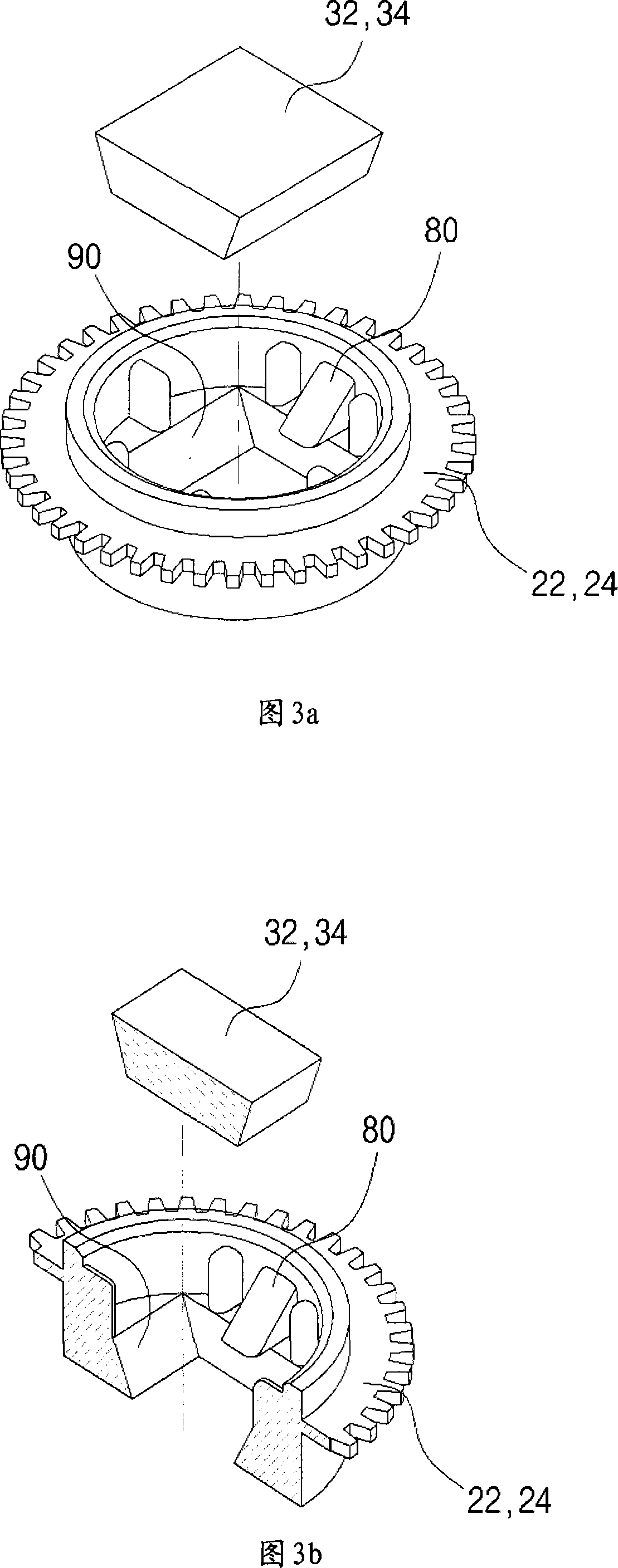

Vehicle's steering wheel rotation angle sensing device

ActiveCN101182988AAvoid swimmingAngles/taper measurementsUsing electrical meansSteering wheelElectrical polarity

The invention relates to a vehicle steering wheel angle detection device, which comprises: a rotor connected to a steering shaft capable of transmitting an operating force to the wheels and rotating; a main gear fixed on the rotor and integrated into one body and rotating; a first The rotating gear and the second rotating gear rotate together with the above-mentioned main gear; the first magnetic body and the second magnetic body are in the shape of a hexahedron and the area of the top surface is larger than the area of the bottom surface as the opposite surface, and are respectively fixed on the above-mentioned first magnetic body. The first rotating gear and the second rotating gear rotate according to the same rotation ratio as the first rotating gear and the second rotating gear; the first detecting part and the second detecting part can respectively detect and the phase change of polarity (N pole, S pole) caused by the rotational movement of the second magnetic body; the PCB substrate has various terminals and pins, including the above-mentioned first detection part and second detection part; and the casing.

Owner:LS AUTOMOTIVE TECH CO LTD

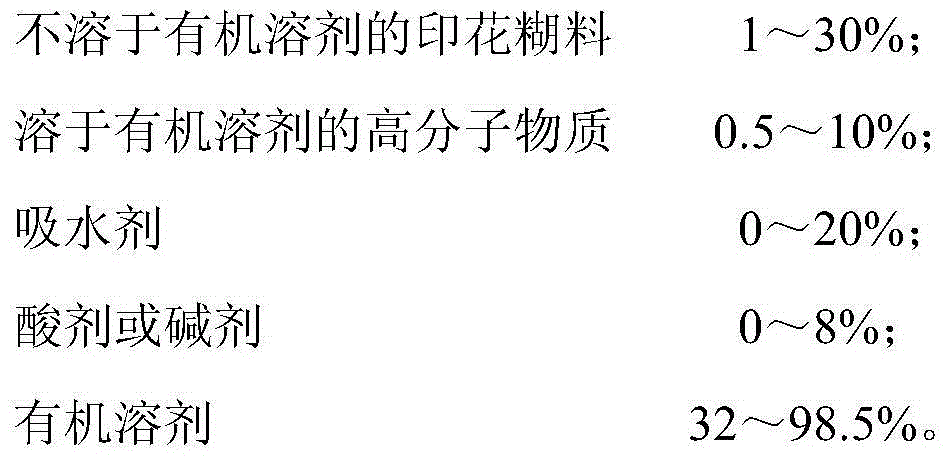

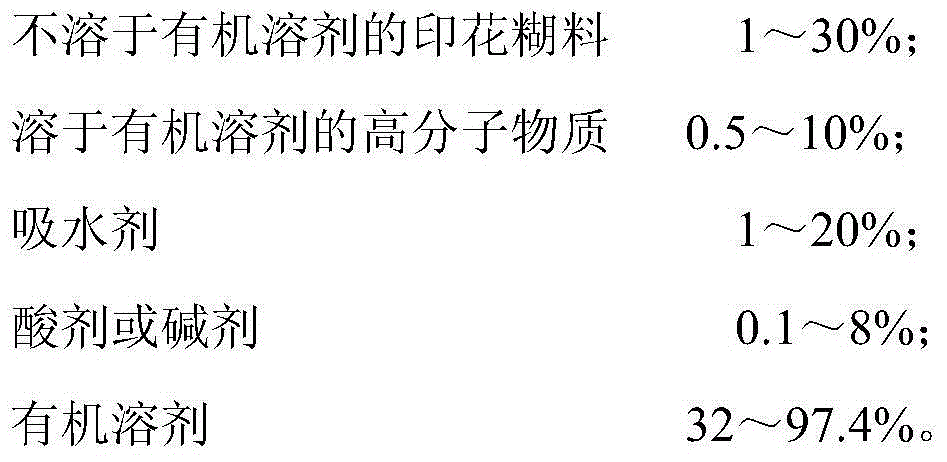

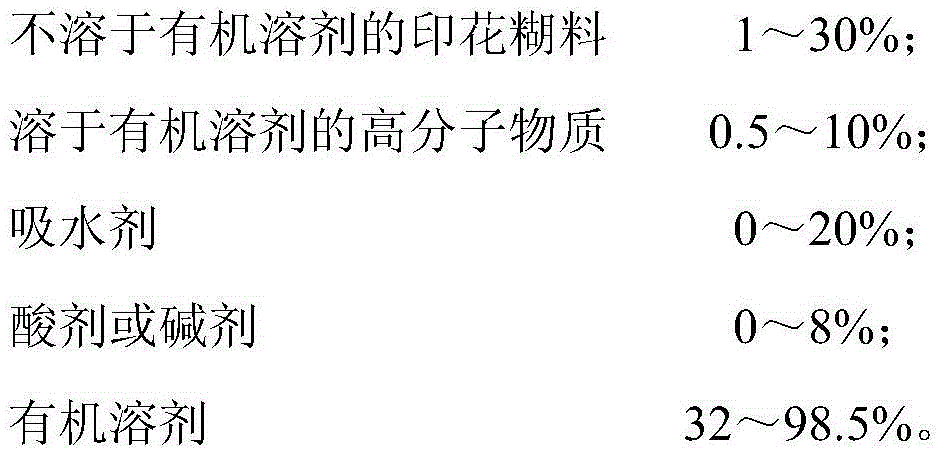

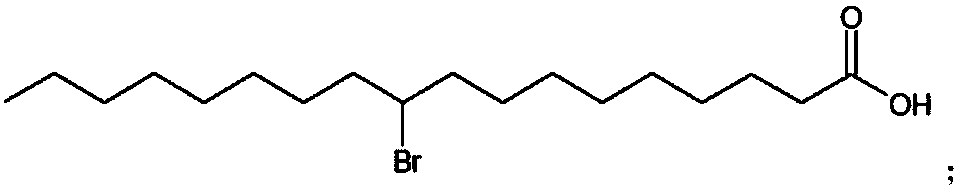

Printing pre-treatment thickener and preparation method thereof

The invention discloses a printing pre-treatment thickener. The pre-treatment thickener comprises the following components in percentage by weight: 1%-30% of printing past which is not dissolved into an organic solvent, 0.5%-10% of macromolecular substances which are dissolved into the organic solvent, 1%-20% of a water absorbent, 0.1%-8% of an acidic agent and 32%-97.4% of the organic solvent. The invention further discloses a preparation method of the thickener. According to the thickener and the method disclosed by the invention, the disadvantages in the prior art that the sizing amount of hydrophilic fiber textiles is great and the discharging amount of wastewater in an later water washing process is not enough are overcome; and furthermore, the disadvantages that hydrophobic textiles can be only printed with shallow colors but not medium and deep colors in a direct injection printing process are overcome.

Owner:苏州汇万色纺织有限公司

Unloading and locating method for ultra-high-voltage transformer

ActiveCN104143423ASuitable for unloading in placeAvoid swimmingInductances/transformers/magnets manufactureChinese charactersUltra high voltage

The invention relates to an unloading and locating technology for large electrical equipment, in particular to an unloading and locating method for an ultra-high-voltage transformer. According to the method, a slipper pillar shaped like a Chinese character tian is used as a support for transfer, the transformer is firstly transferred onto the slipper pillar from a flat car by jacking four ends of the transformer by a hydraulic oil pump, then the ground clearance of the transformer is adjusted, and finally, the transformer is moved to an specified position through steel rails. According to the unloading and locating method for the ultra-high-voltage transformer, in combination of accurate operation data, the slipper pillar shaped like a Chinese character tian is stable, safe and reliable, and positions of a hoisting point and jacking points are selected reasonably in an unloading and locating process, so that equipment is not deformed under stress; when the transformer is hoisted, underlay is used for protection timely, moving or inclination of the transformer due to a crane fault is prevented, and the equipment safety is guaranteed; and the transformer maintains stable without shaking or bumping, the requirement that three-dimensional impact on the transformer is not larger than 3 g is met, the process is simple, time and labor are saved, and the method is convenient and simple.

Owner:STATE GRID CORP OF CHINA +2

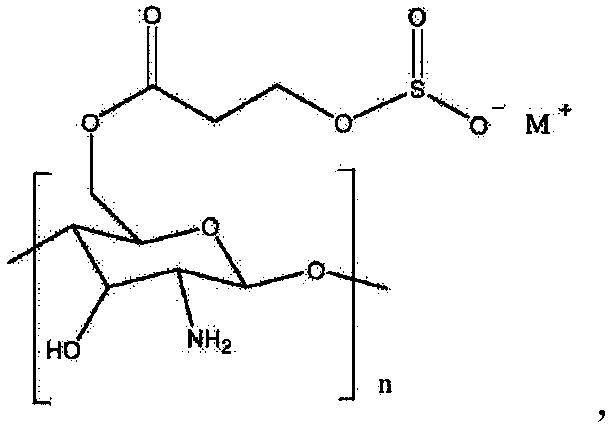

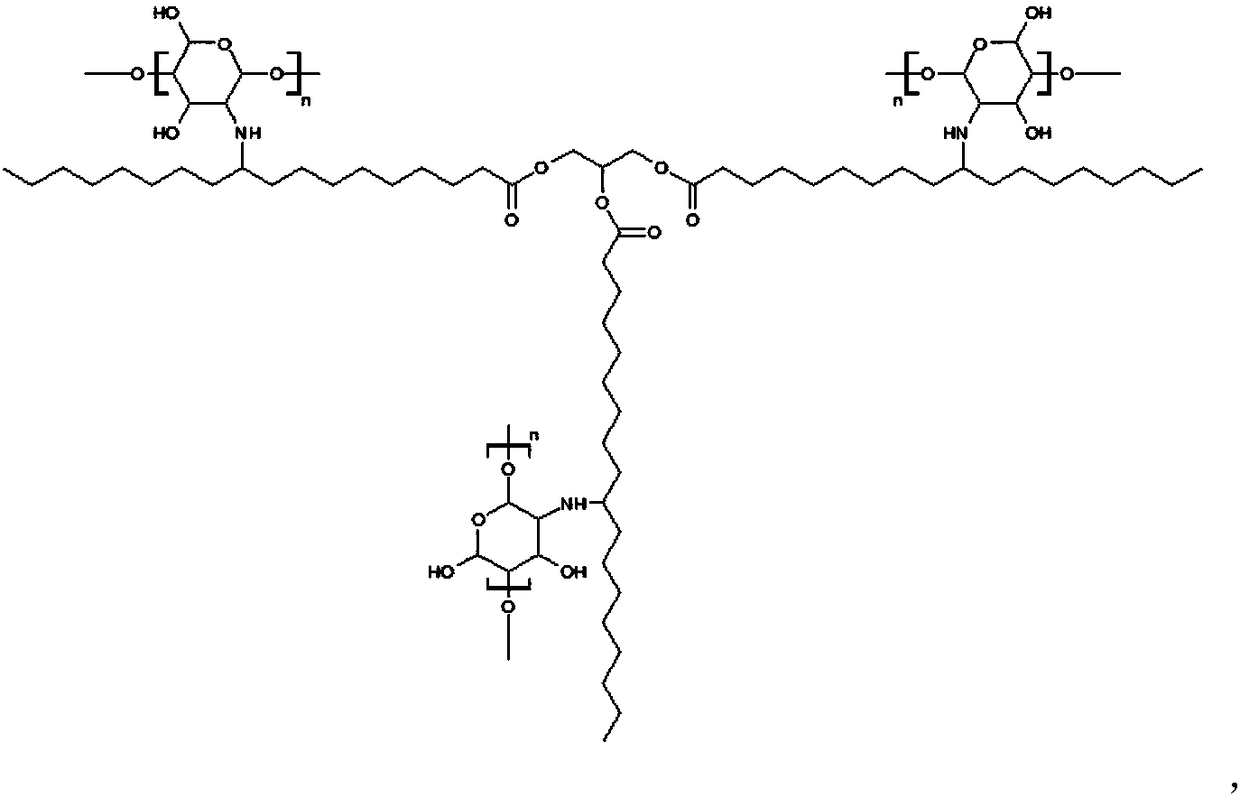

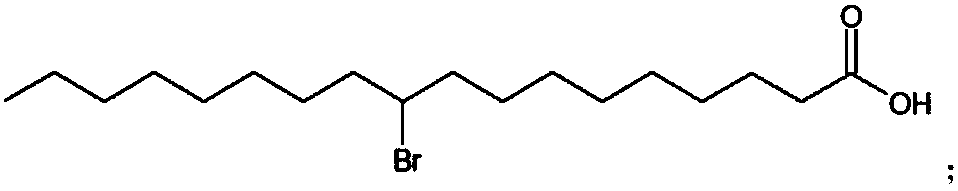

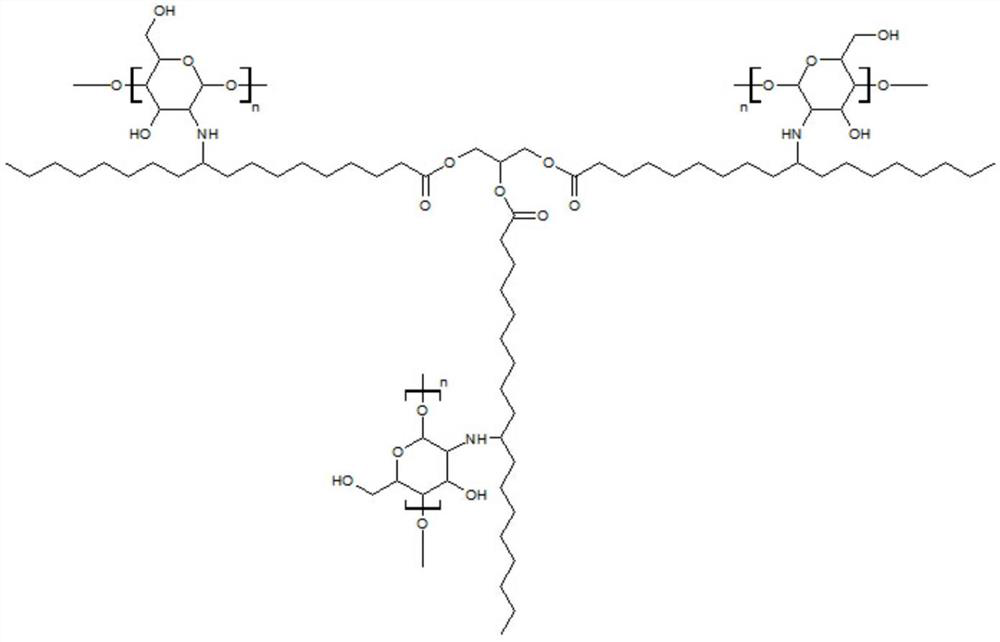

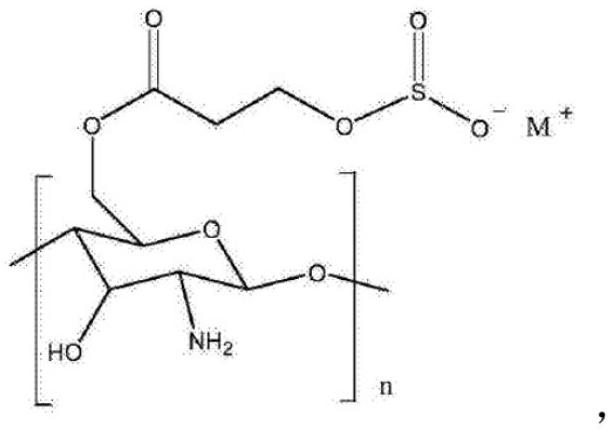

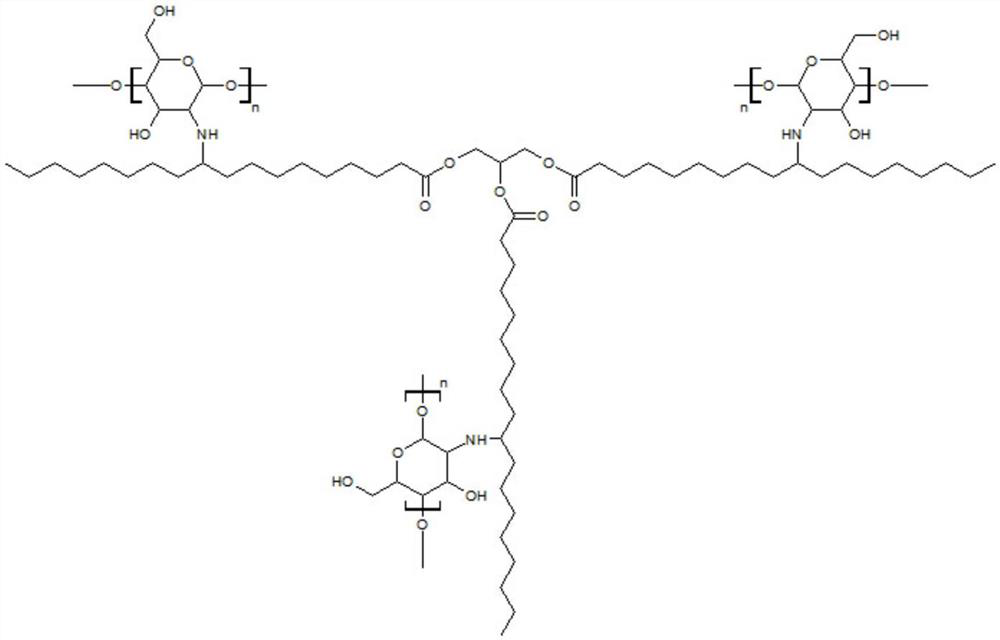

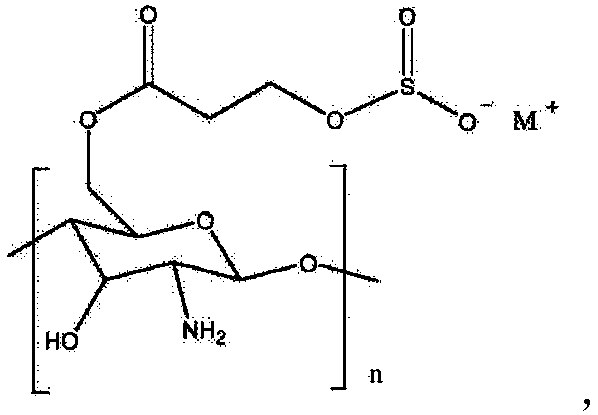

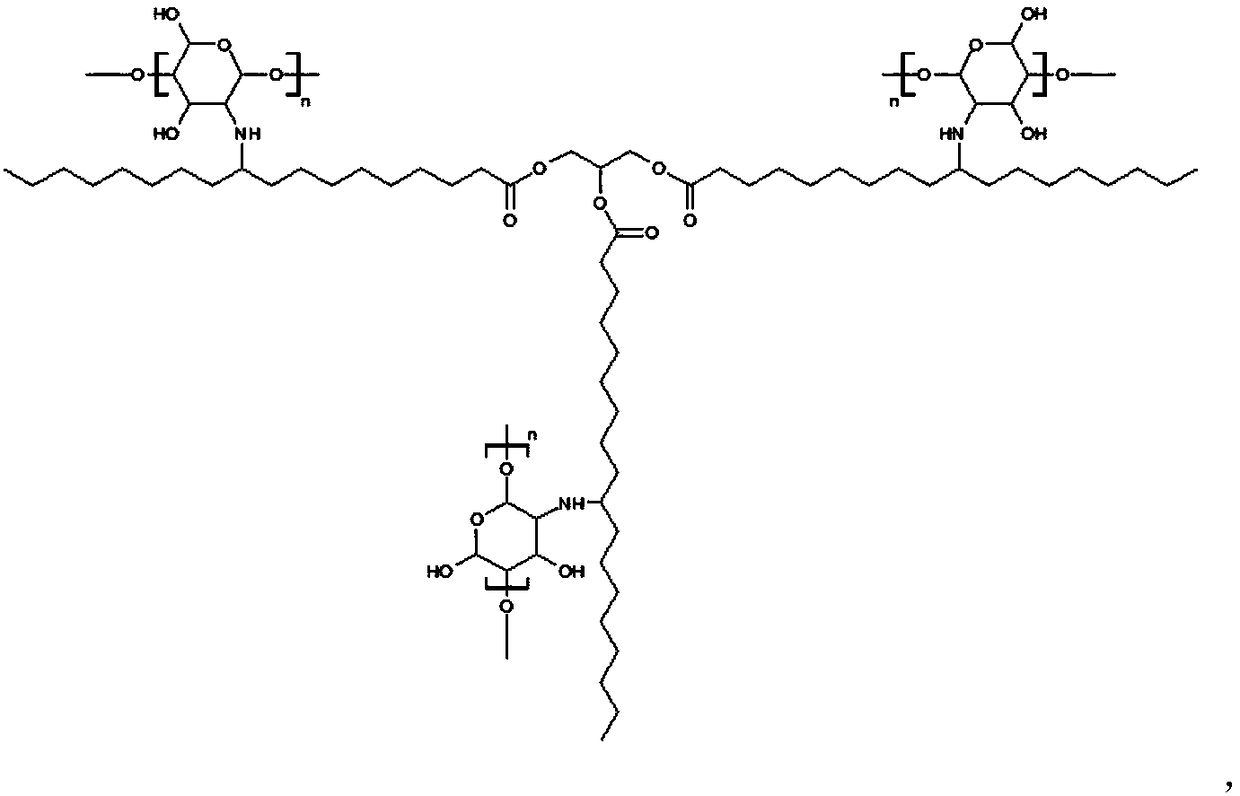

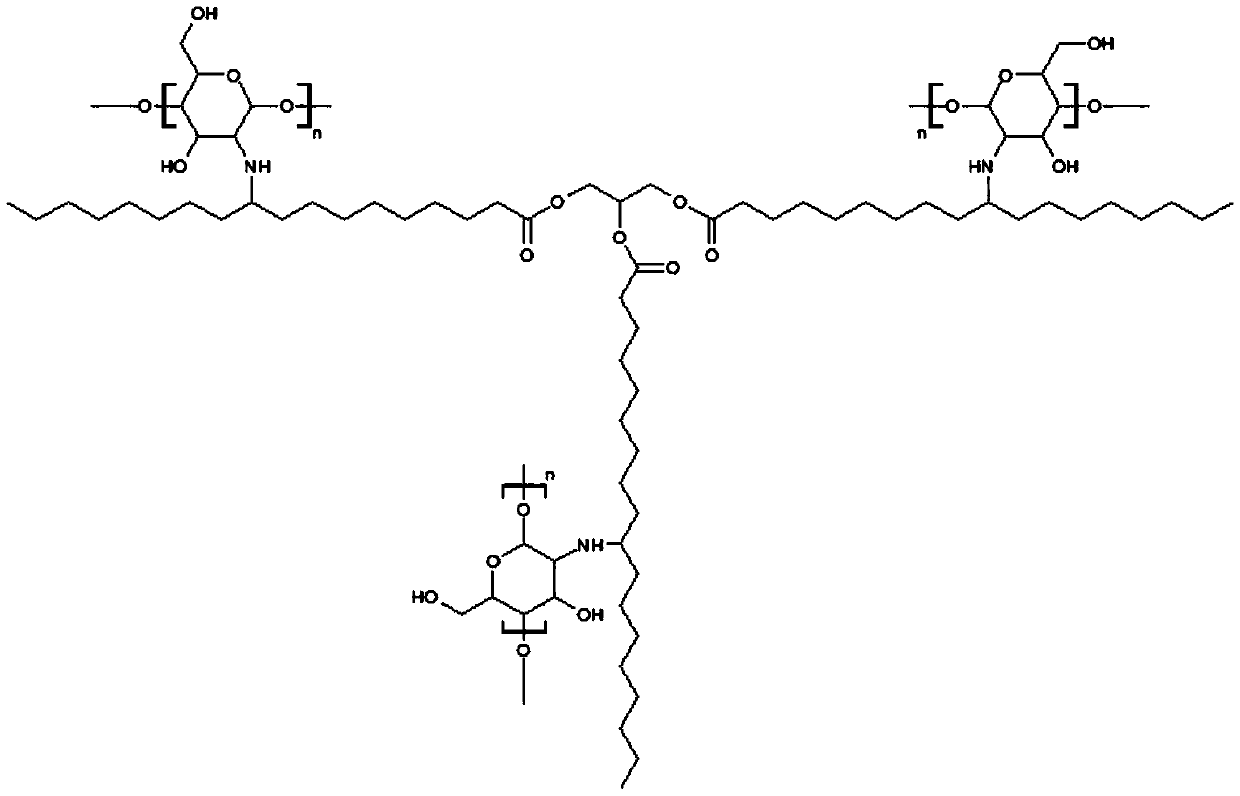

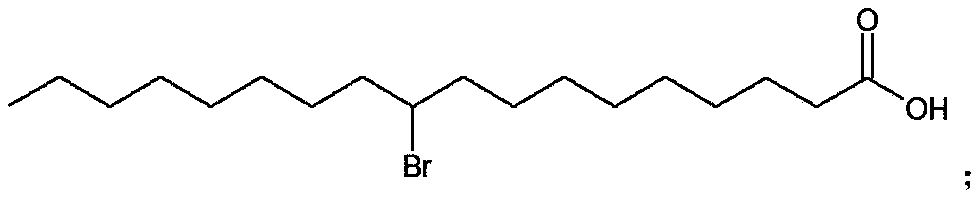

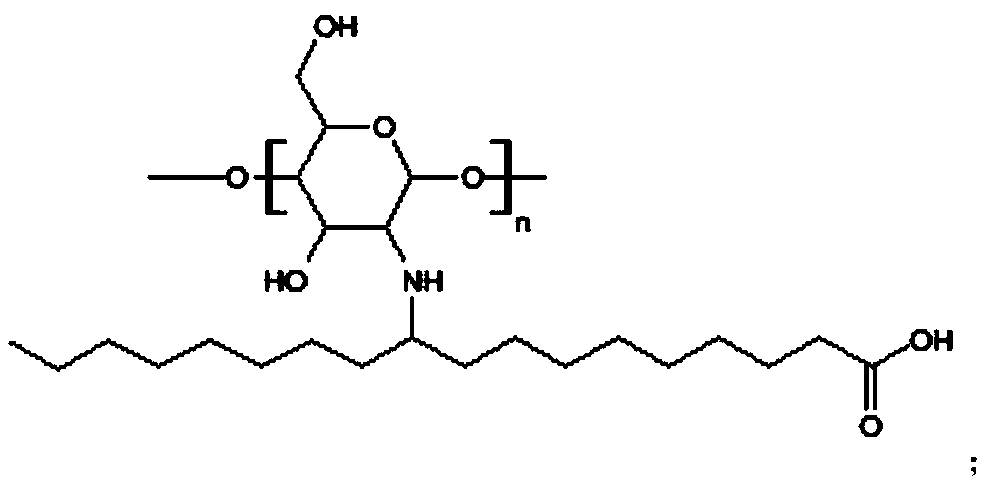

Levelling agent and preparation method and application thereof

The invention relates to a levelling agent and a preparation method and an application thereof. A structural formula of the levelling agent is as shown in the following specification, wherein n is a number between 5 and 10. The levelling agent has the good film-forming property, and contains abundant ester groups, and is capable of combining with dye through a hydrogen bond, thereby uniformly carrying the dye to the surface of fabric and forming a film in uniform thickness, enabling the dye to be uniformly adhered to the fabric, and preventing the non-uniform dispersion because of the short contact time of the dye and the fabric. In addition, the film can also prevent migration and sublimation of the dye in a drying and color development process, and the chromatic aberration of a warp direction, a weft direction and positive and negative faces of the fabric is prevented. The levelling agent is suitable for continuous padding-type dyeing and coating-type dyeing. Compared with vat dyeingin high-temperature and high-pressure, the energy consumption can be reduced, the dyeing efficiency is improved, and the product quality is improved, the color fastness of the fabric and the color uniformity reach a A-grade level stated by a national standard, so the vat dyeing in high-temperature and high-pressure can be possibly replaced by the continuous dyeing in normal pressure and temperature.

Owner:SUZHOU TANGHUA NANO TECH

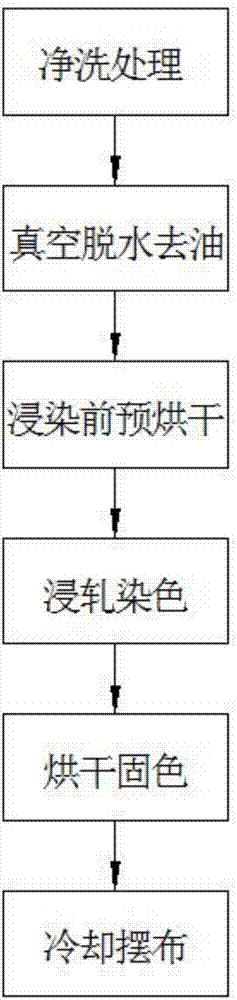

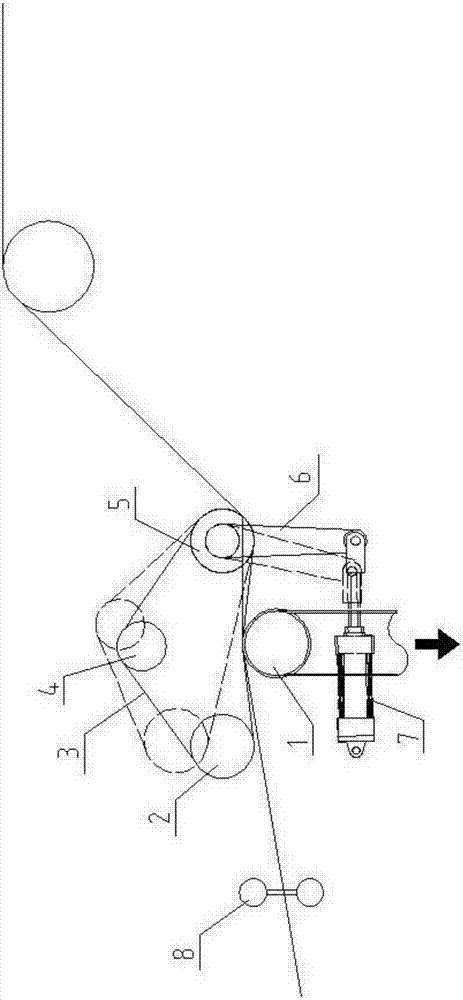

Energy-saving, environment-friendly and continuous fabric washing, dyeing, baking and fixation method

ActiveCN106894223AReduce consumptionEmission reductionSucessive textile treatmentsTwo or more solvent application treatmentEngineeringDyeing wastewater

An energy-saving, environment-friendly and continuous fabric washing, dyeing, baking and fixation method is characterized by comprising the following steps that 1, dirt and oil stains on the surface of a fabric are removed; 2, the cleaned fabric is dehydrated and de-oiled, the liquor detention rate of the dehydrated fabric is controlled to be 15%-40%; 3, the dehydrated fabric is fed into a drying box for pre-baking processing, and the moisture content of the baked fabric is controlled to be 15% or below; 4, the pre-baked fabric is dip-dyed through a pad dyeing unit, and the liquor detention rate of the dyed fabric is controlled to be 30-70%; 5, drying and color fixation processing is conducted on the dyed fabric; 6, the fabric obtained after drying and color fixation are completed is fed into a cooling unit for cooing, then repeated zigzagging and winding are performed, and finally a finished fabric product is obtained through fabric swing. The energy-saving, environment-friendly and continuous fabric washing, dyeing, baking and fixation method is high in intelligence, saves energy, reduces emissions, is simple and easy to operate, high in yield, stable in quality, achieves continuous production, reduces energy consumption, meanwhile decreases water consumption and accordingly reduces dyeing wastewater discharge greatly.

Owner:连云港鹰游工程技术研究院有限公司 +1

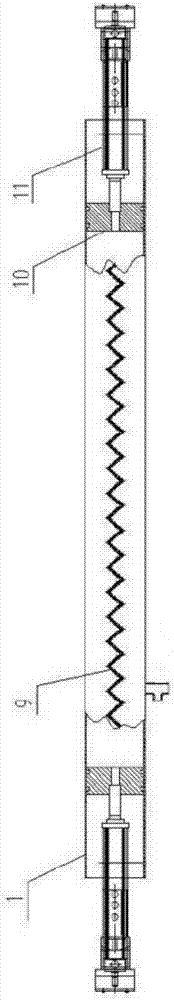

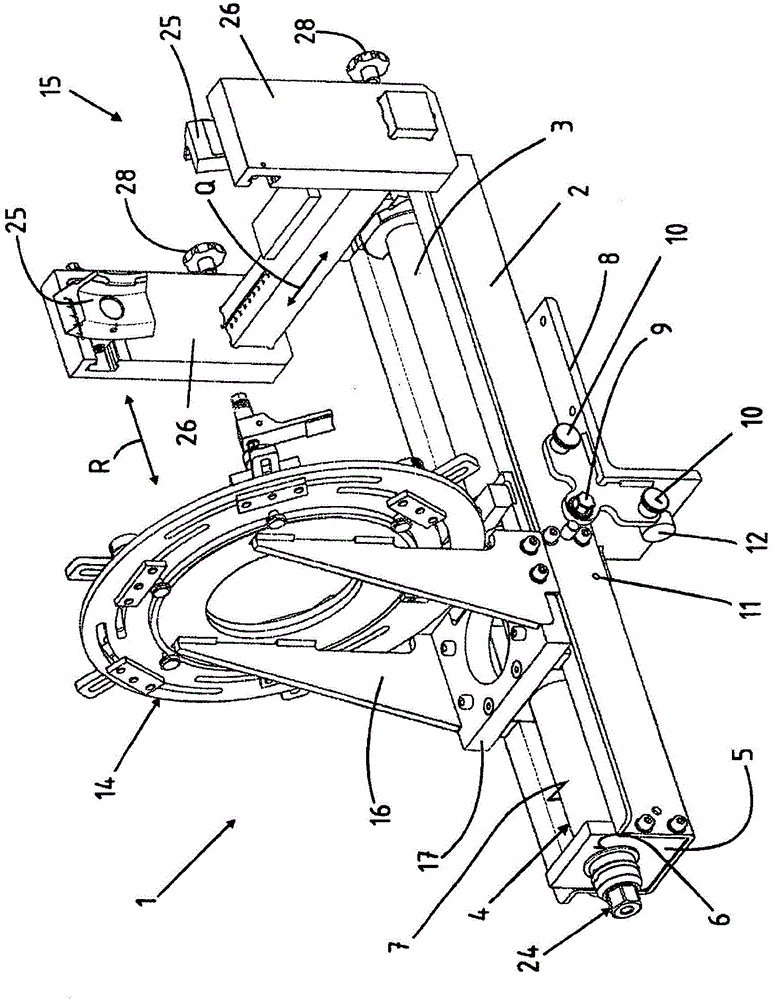

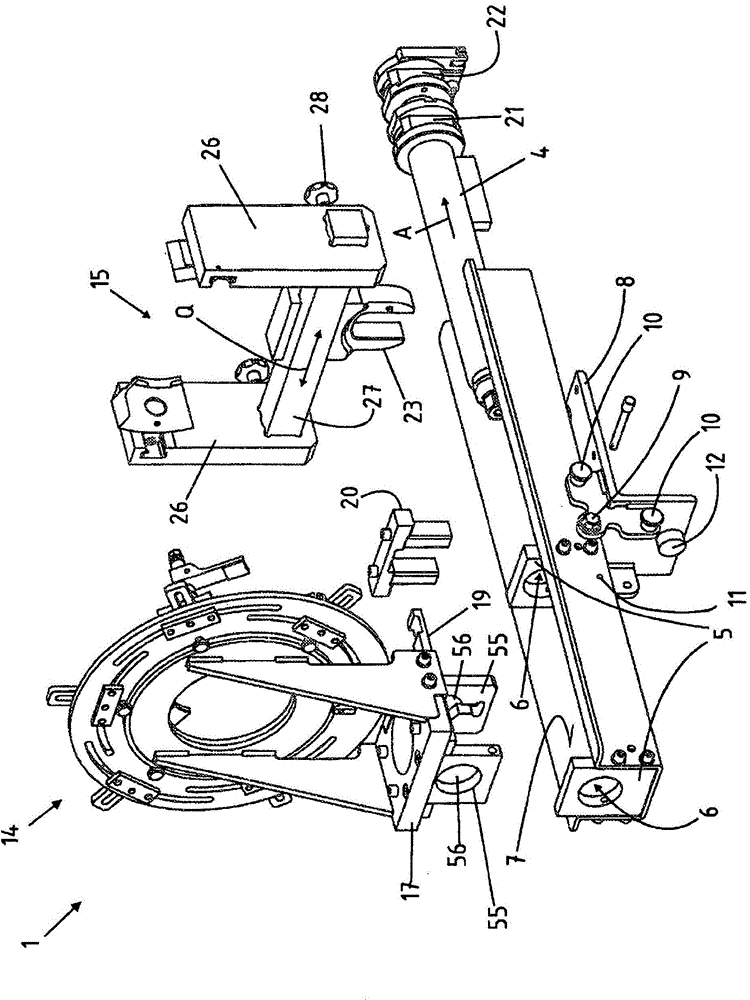

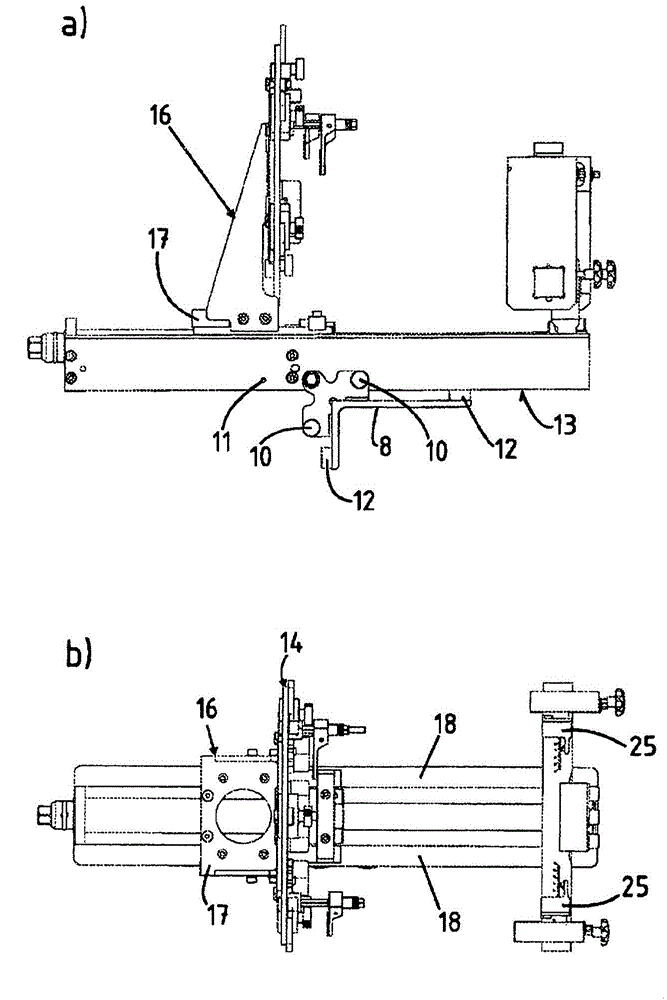

Spring tensioning device comprising a universal tension table

ActiveCN104411462AGuaranteed fixed effectLimit exercise possibilitiesMetal-working hand toolsControl theory

The invention relates to a spring tensioning device (10) for mounting and / or removing helical compression springs on / from spring damper struts (57) for motor vehicles. According to the invention the spring tensioning device (1) comprises a universal tension table (14), wherein the spring damper strut (57) can be arranged such that the head plate (58) of the spring damper strut (57) is on the universal tension table (14) and the head plate (58) can be fixed in position by means of clamping shoes and brake arms (46).

Owner:HAZET WERK HERMANN ZERVER

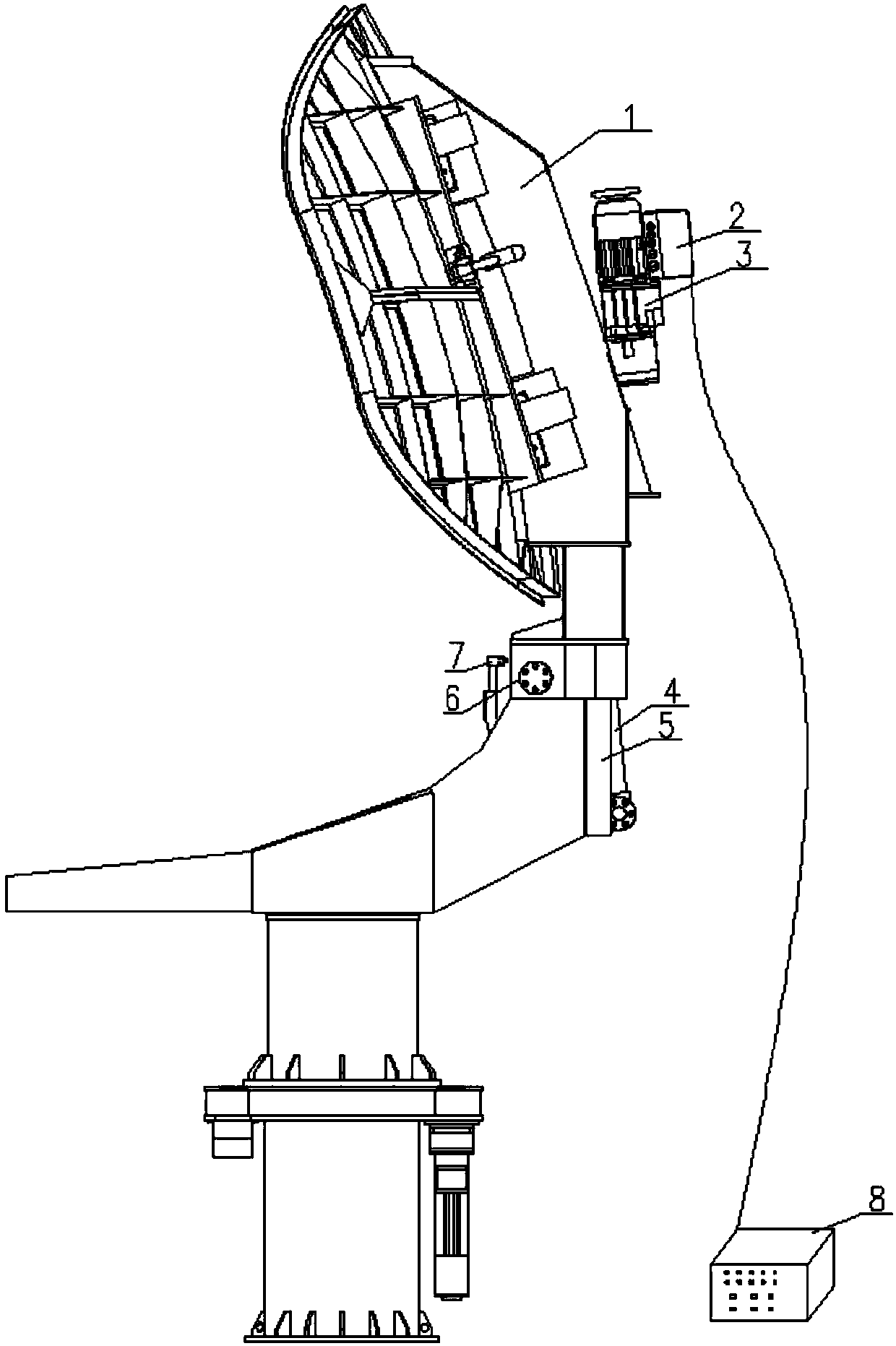

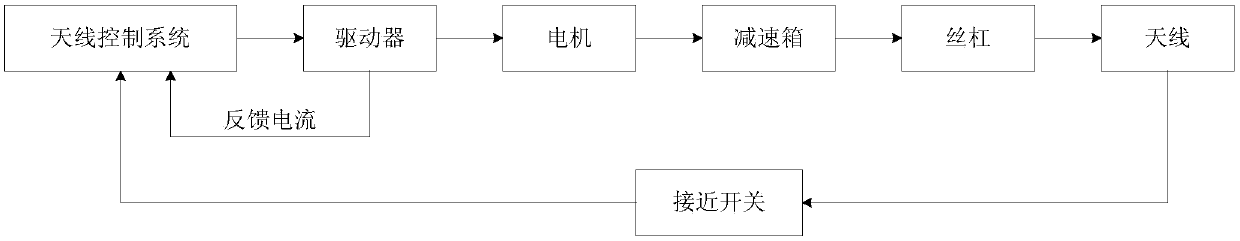

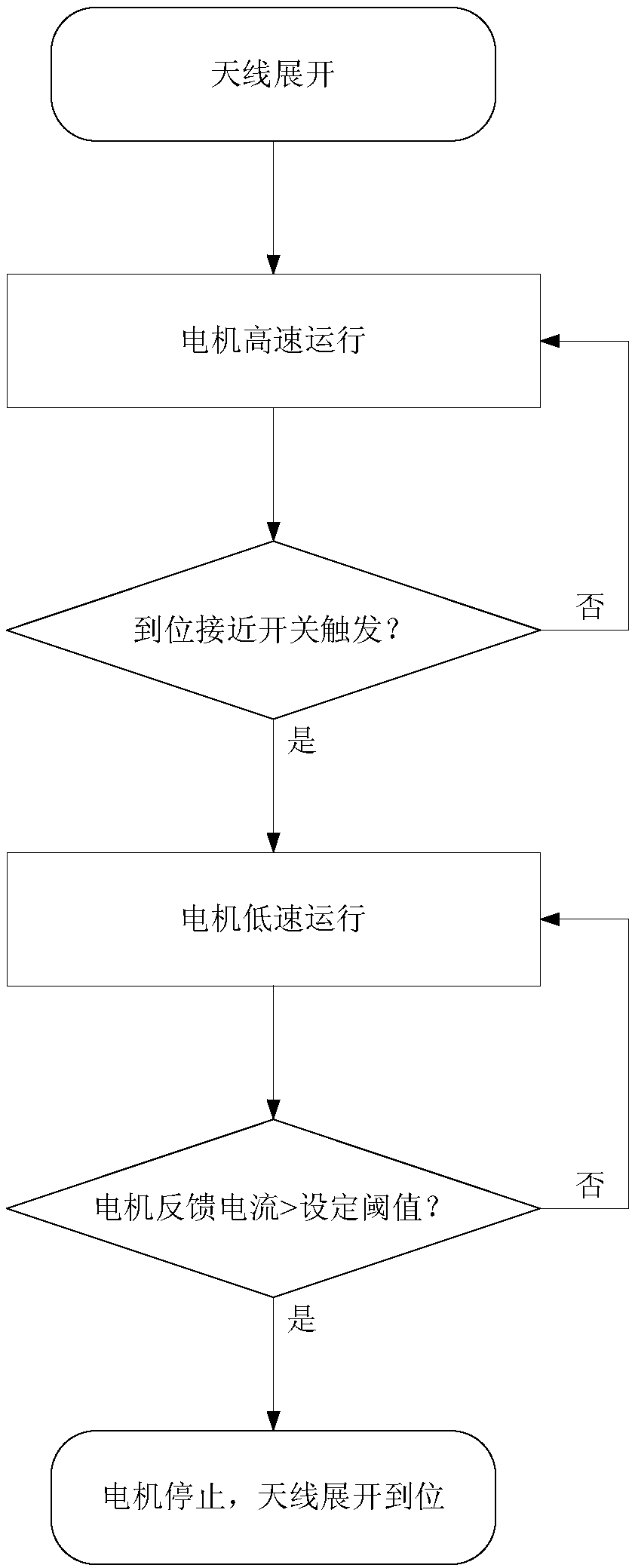

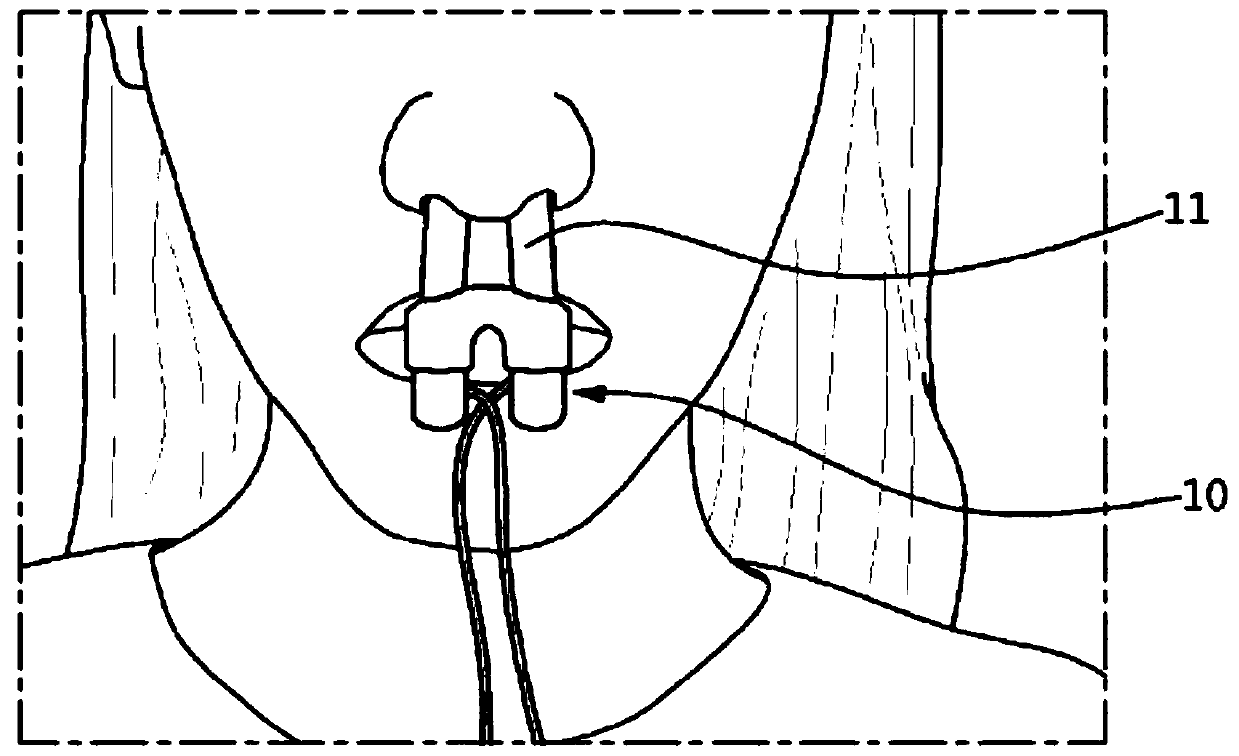

Folding antenna high-precision deployment control method based on motor current feedback

InactiveCN107561500AGuaranteed stiffnessGuaranteed StrengthWave based measurement systemsMechanical energy handlingMotor speedLow speed

The invention relates to a folding antenna high-precision deployment control method based on motor current feedback, which belongs to the field of electromechanical integrated control. The method is designed to solve the problem that the precision of automatic deployment of the folding antenna is low and the folding antenna is of poor rigidity. In view of the problem, the control method as followsis adopted: a proximity switch is designed and installed in a position where an antenna is about to be deployed in place; a mechanical block with high strength and stiffness is set in the precise position; after a control system receives an antenna deployment operation instruction, a motor runs at high speed, and a reducer box drives a trapezoidal screw to drive an antenna block to be deployed; after the in-place proximity switch is triggered, the running speed of the motor is reduced, the motor continues to run at low speed after contacting the mechanical block, and thus, the structure gap is eliminated; and a pre-tightening force is applied to the antenna structure, the feedback current of the motor is detected, and when the feedback current of the motor rises sharply and exceeds a setthreshold, that the antenna is deployed in place is determined, and the motor is immediately disabled. Through the method, antennas can be precisely deployed in place, and the rigidity of antennas isimproved.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

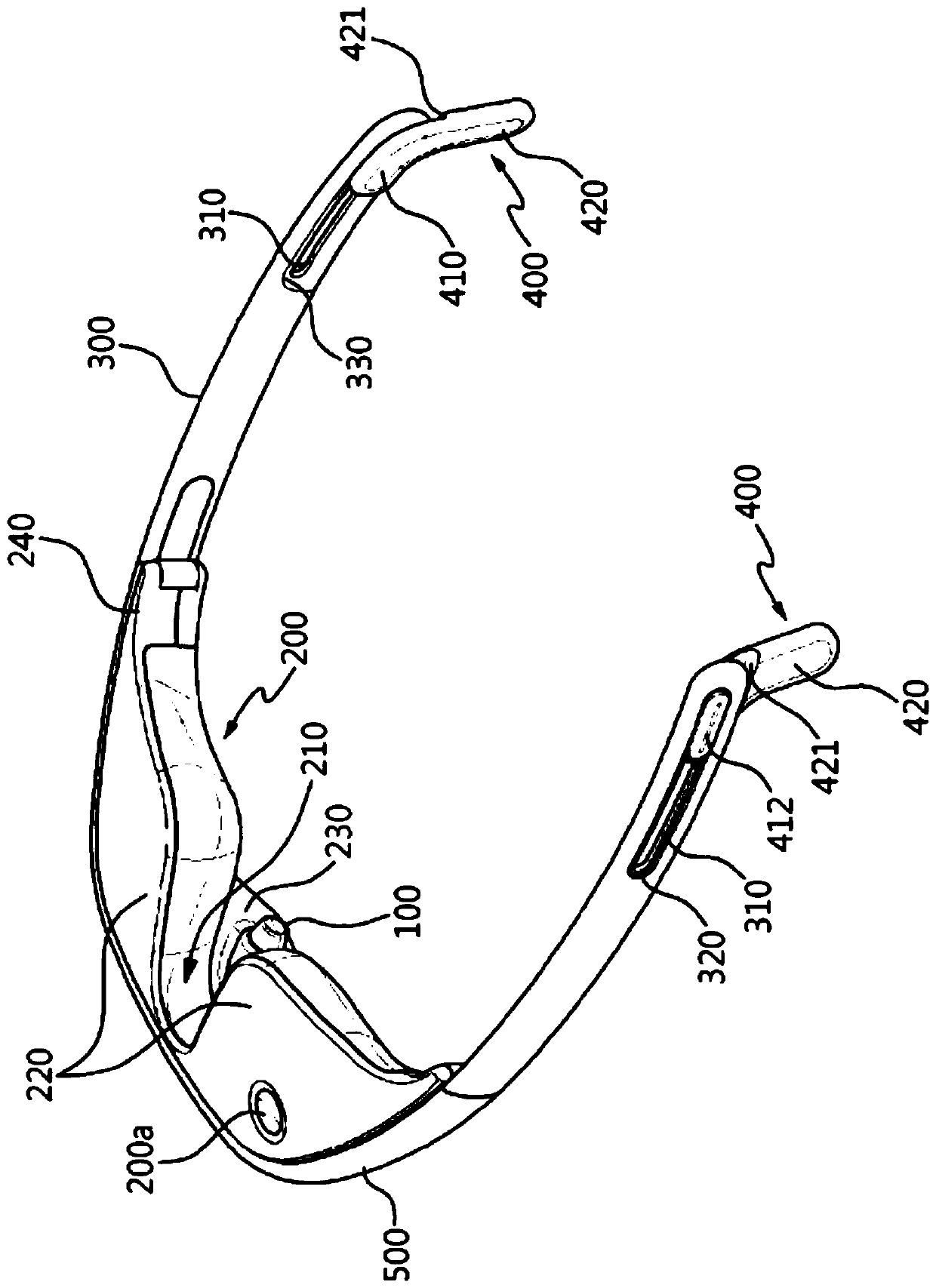

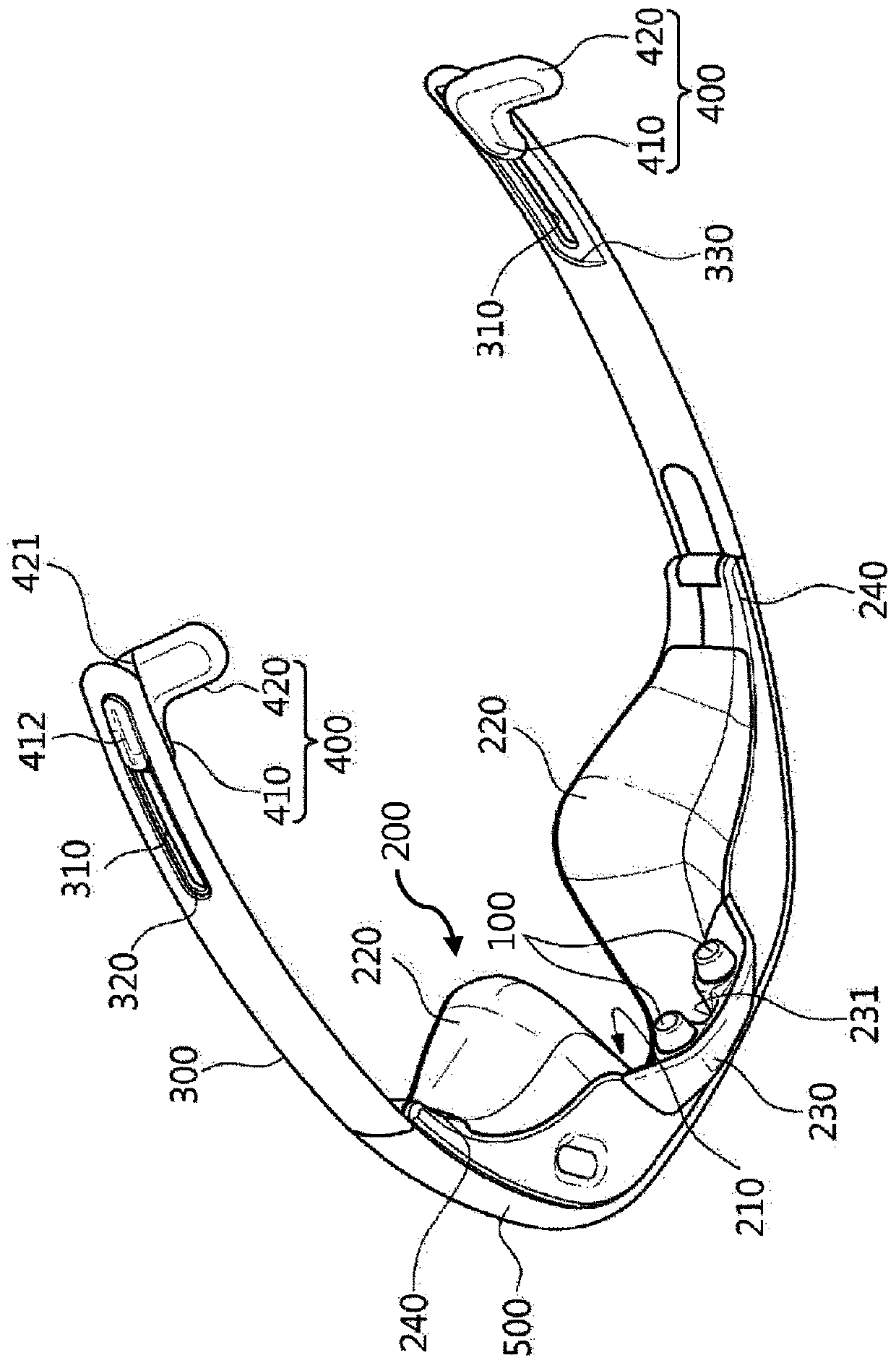

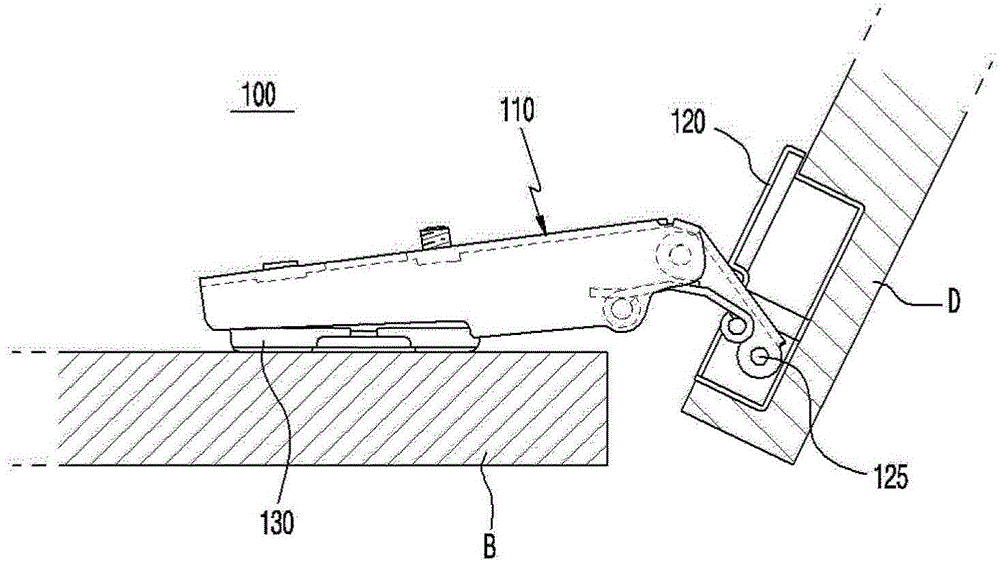

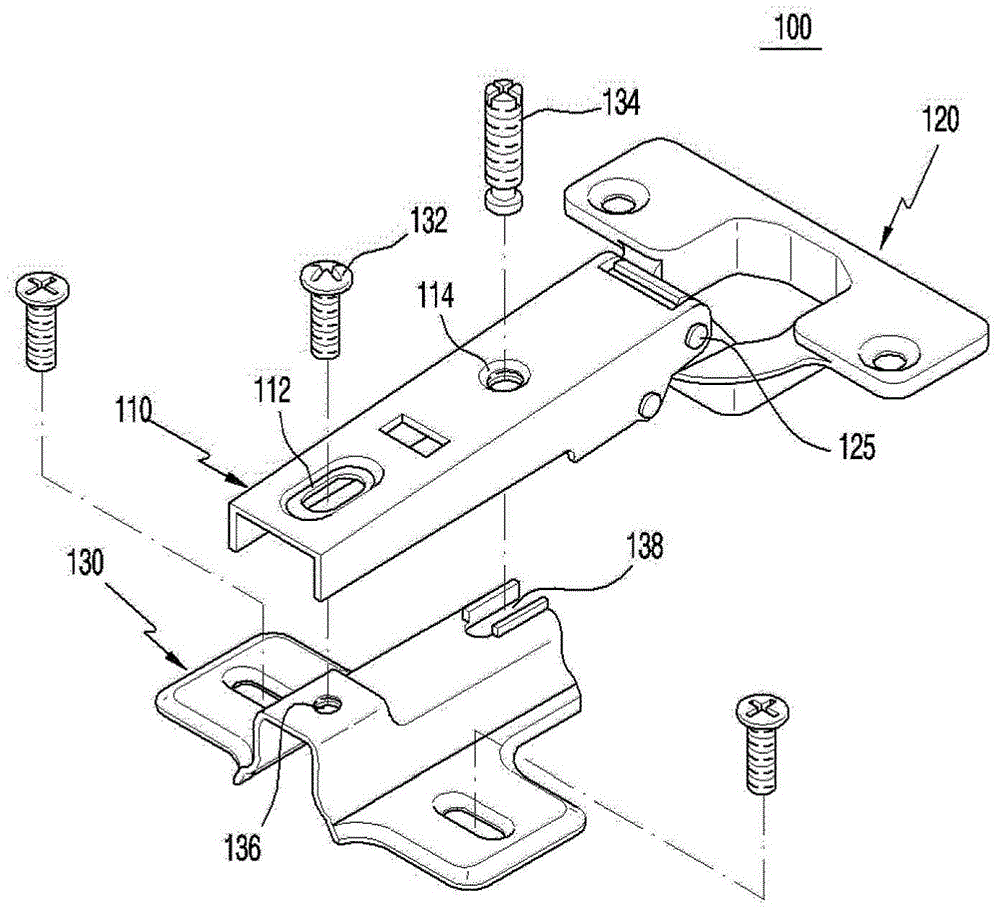

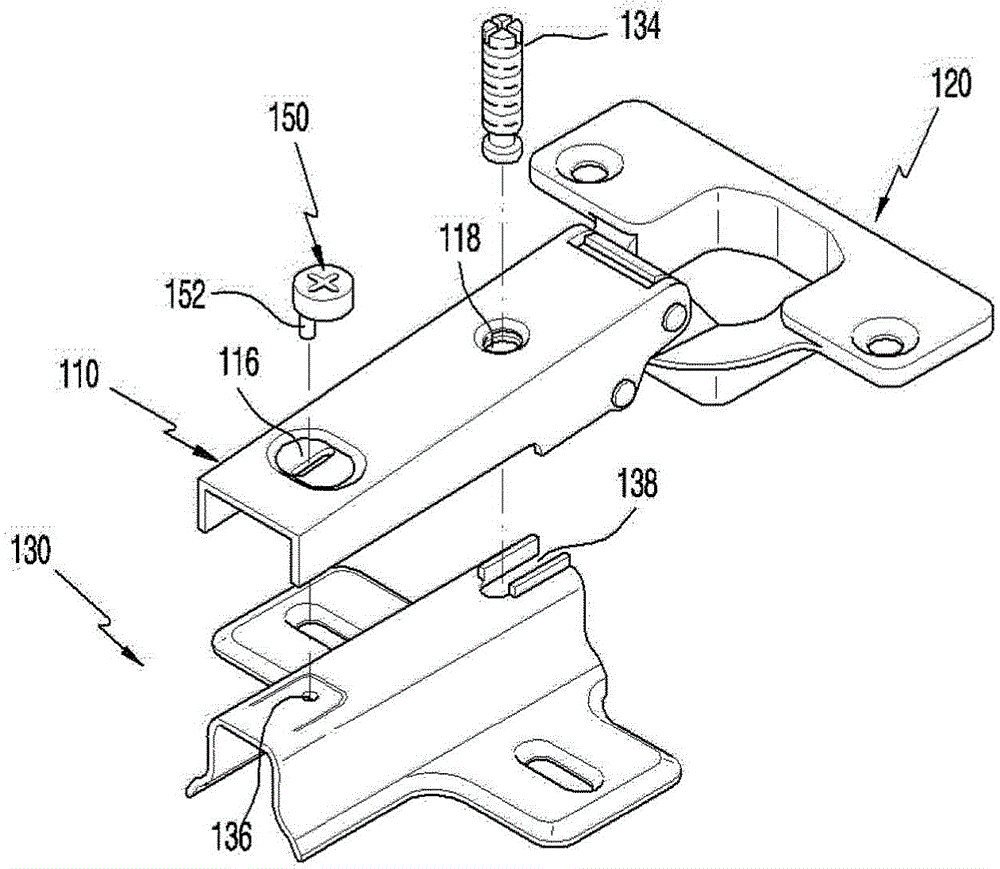

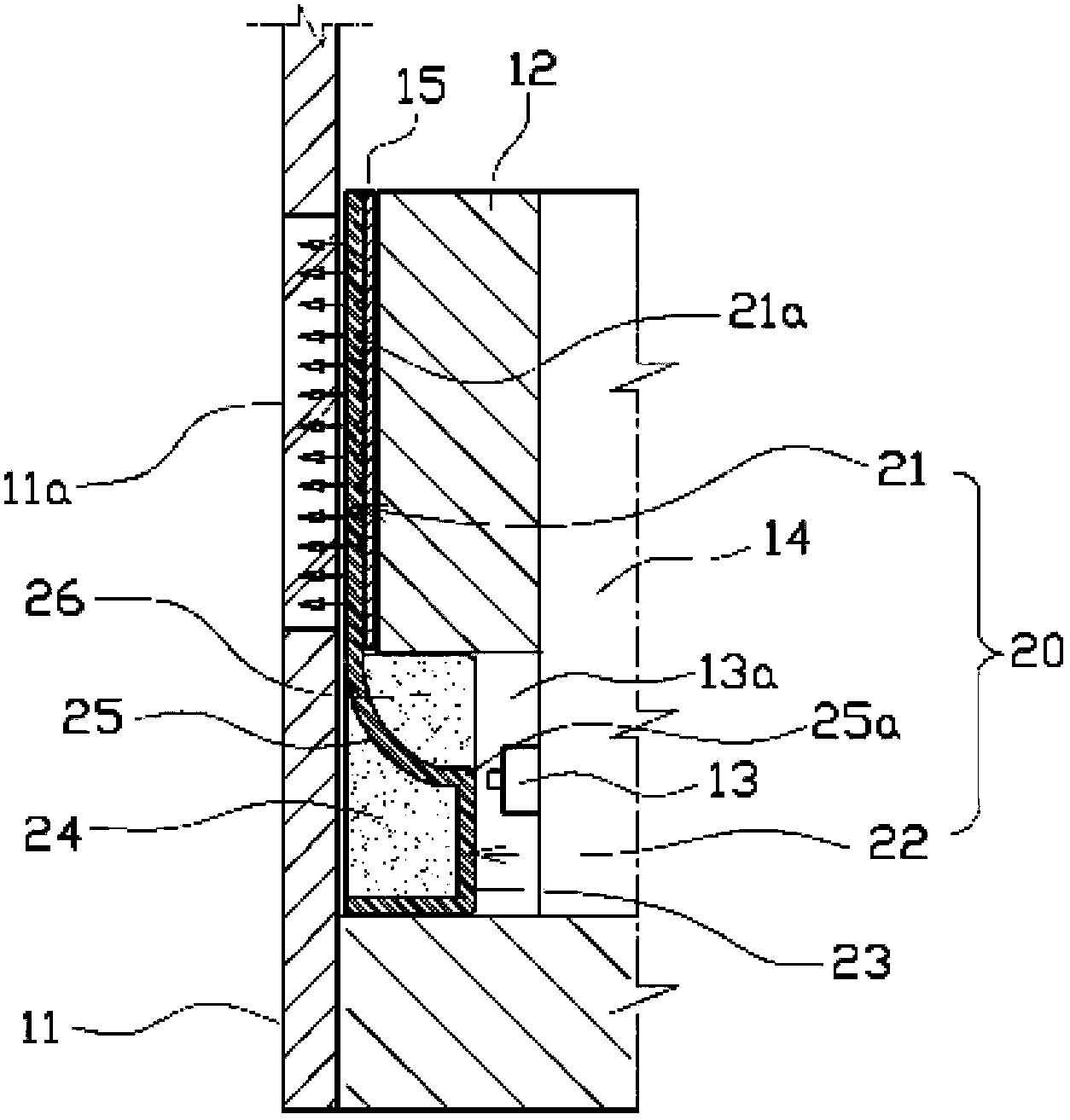

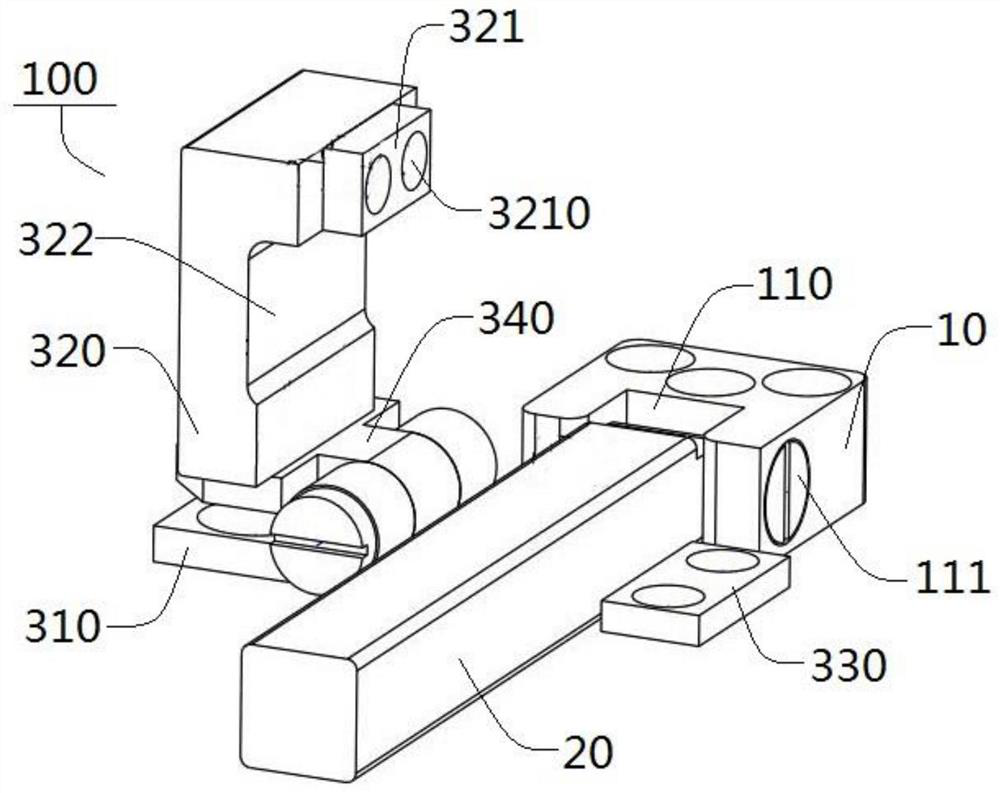

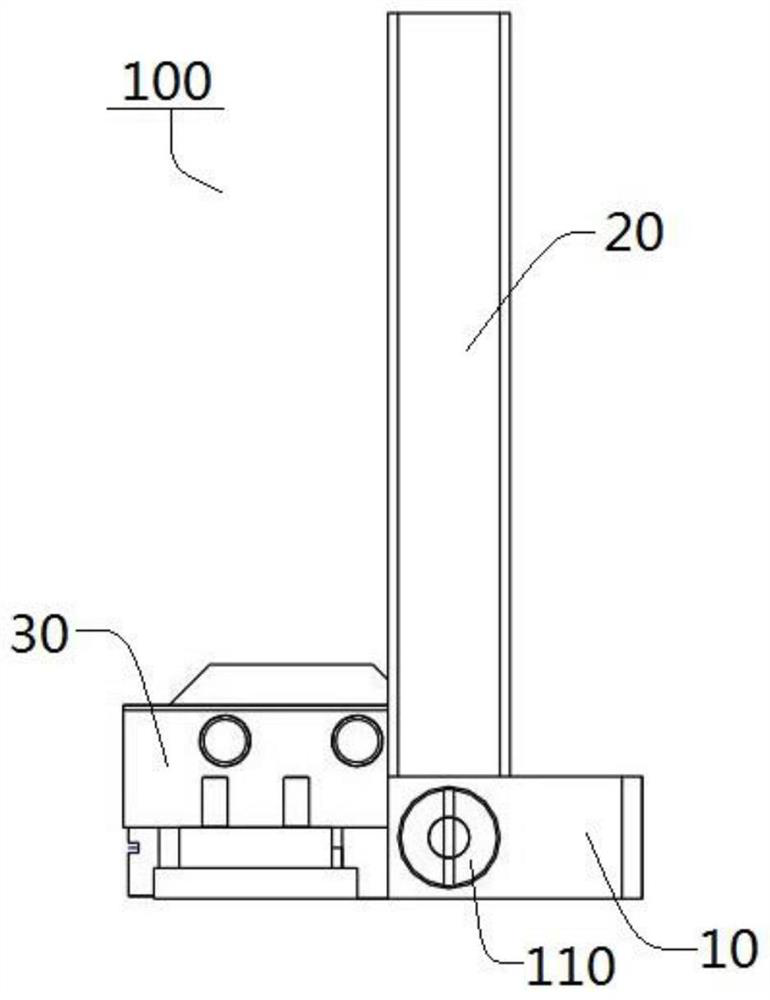

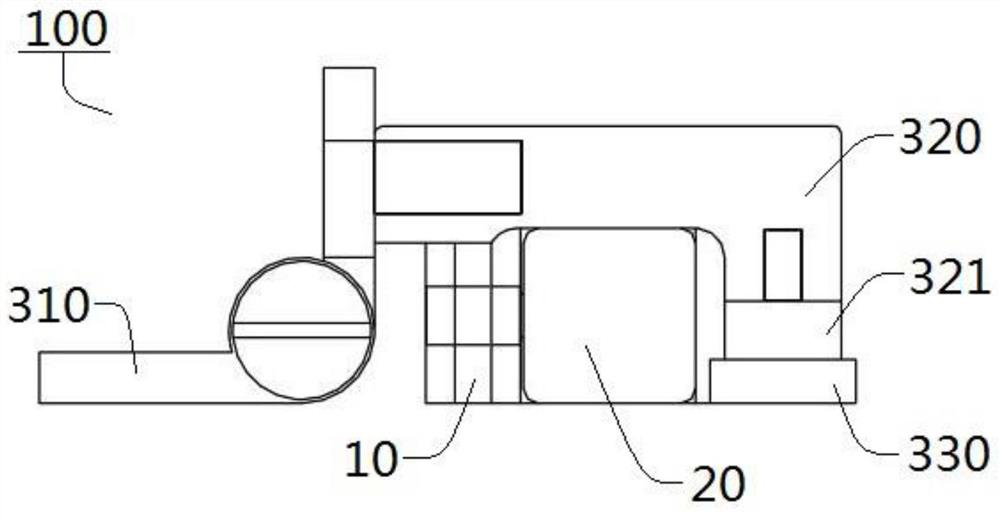

Furniture door position adjustment device for furniture hinge

ActiveCN104411907AAvoid swimmingImprove reliabilityFurniture joining partsPin hingesMechanical engineeringHinge angle

The present invention relates to a furniture hinge that is mounted between a furniture wall body and a furniture door so as to be used as an opening and closing means for the furniture door. The present invention includes: a long concave hole (50) that is formed in a main body portion (110); an elastic piece (10) that is formed in a middle plate (140) so as to perform a buffering function in the vertical direction; an oblong hole (20) that is formed in the elastic piece (10); a rotor (30) which is accommodated in the oblong hole (20) and which has a step protrusion (32) that is formed in one side portion on the outer circumference surface thereof; and an eccentric bolt (40) that rotates while being inserted into the long concave hole (50) and is coupled to the rotor (30) through a leg portion (42) for the regular / reverse rotation. The furniture hinge can be finely adjusted and the position of the door can be discerned with the naked eye.

Owner:SAMSUNG PRECISION IND

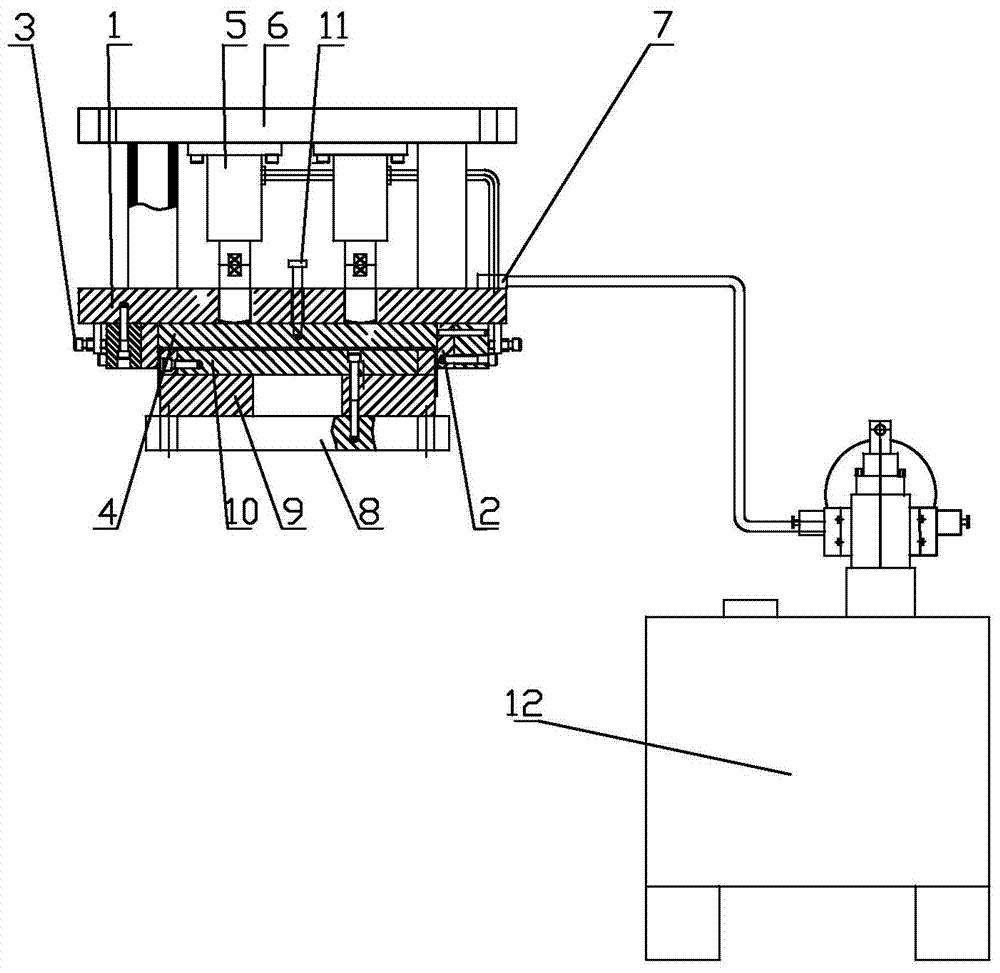

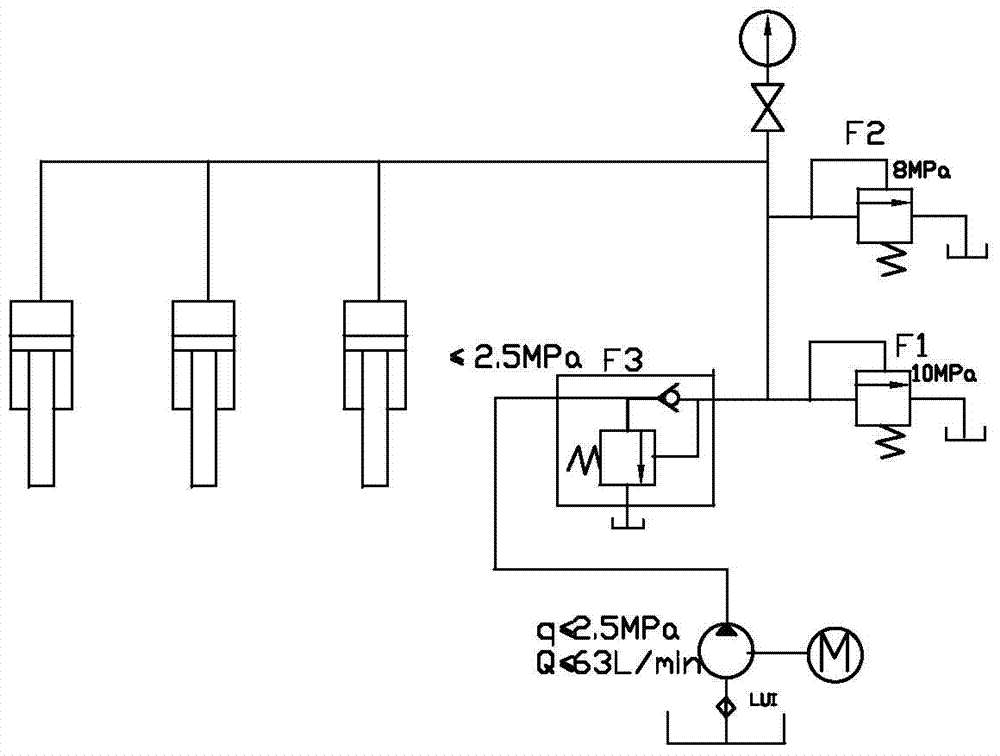

Hydraulic side pressing die

InactiveCN103658281AAvoid swimmingReduce power consumptionShaping toolsHydraulic cylinderEngineering

The invention relates to a hydraulic side pressing die which is characterized by comprising a die-set. A female die plate component is installed below the die-set. The two sides of the female die plate component are provided with adjusting screws. A side pressing material returning plate is installed inside the female die plate component and moves up and down inside the female die plate component. The side pressing material returning plate is connected with hydraulic cylinders. The multiple hydraulic cylinders are fixed to an upper plate of the die-set and connected with distributors through oil tubes respectively. The distributors are connected with a hydraulic system through oil pipes at the same time. A subplate is installed at the upper portion of a lower die base of the die-set. A male die fixing plate is installed at the upper portion of the subplate. A male die is fixed to the male die fixing plate. A positioning pin is arranged on the surface of the male die fixing plate. Due to enough pressing force, moving displacement of a workpiece in the bending process is avoided, plane wrinkles and deformation are avoided, the product quality is stable, the production efficiency is improved by more than 4 times, and the hydraulic side pressing die has the advantages of being simple in structure, high in automation degree, constant in side pressing force and the like.

Owner:SHANDONG SPECIAL INDUSTRY GROUP CO LTD

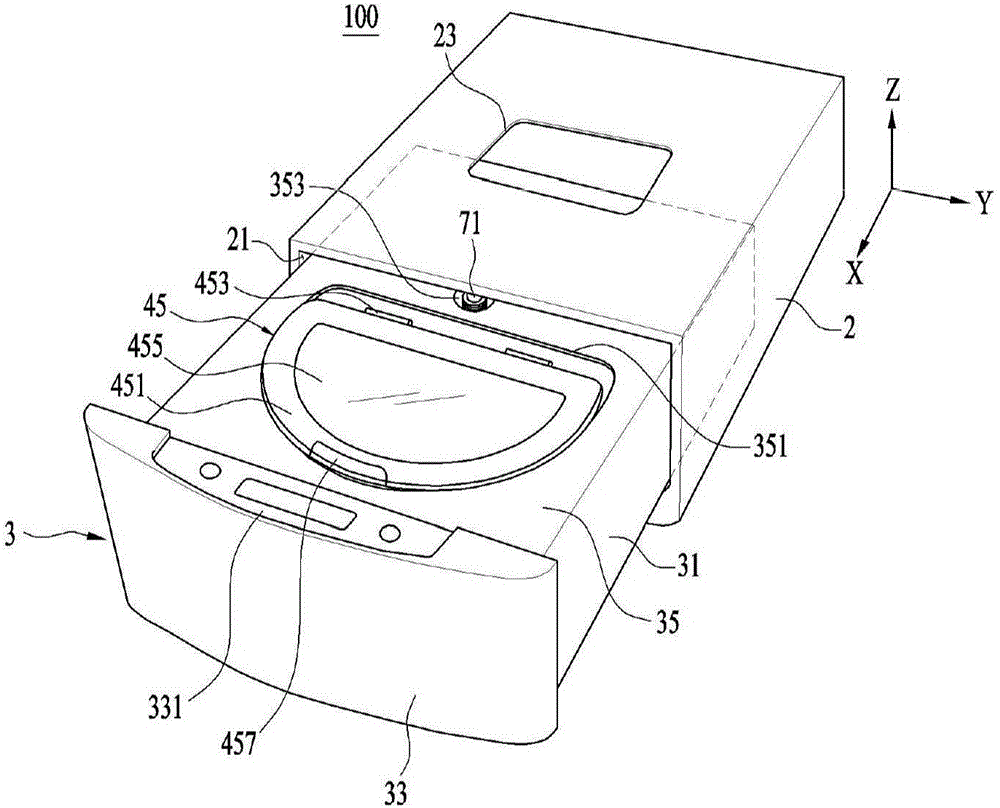

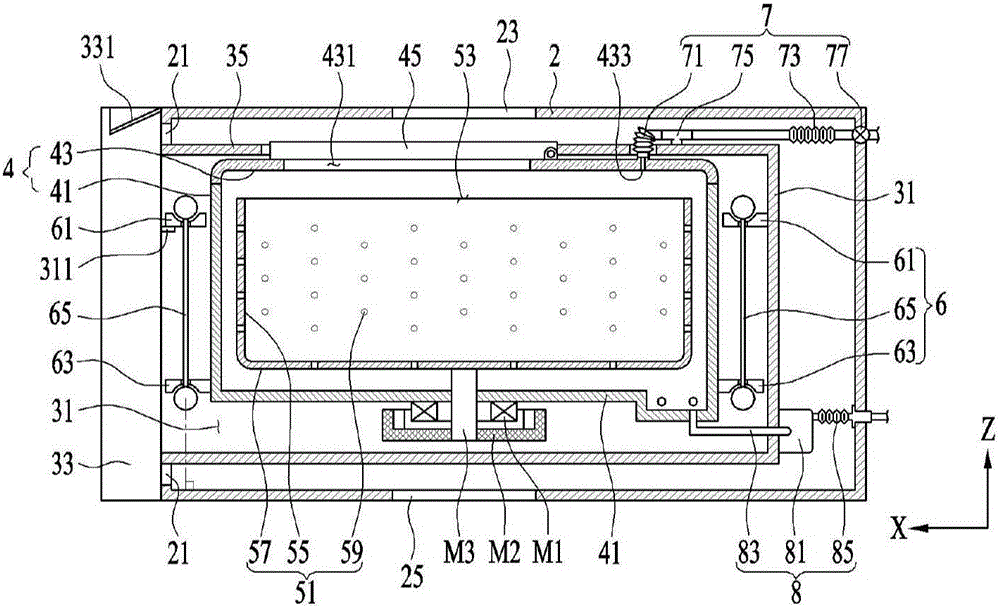

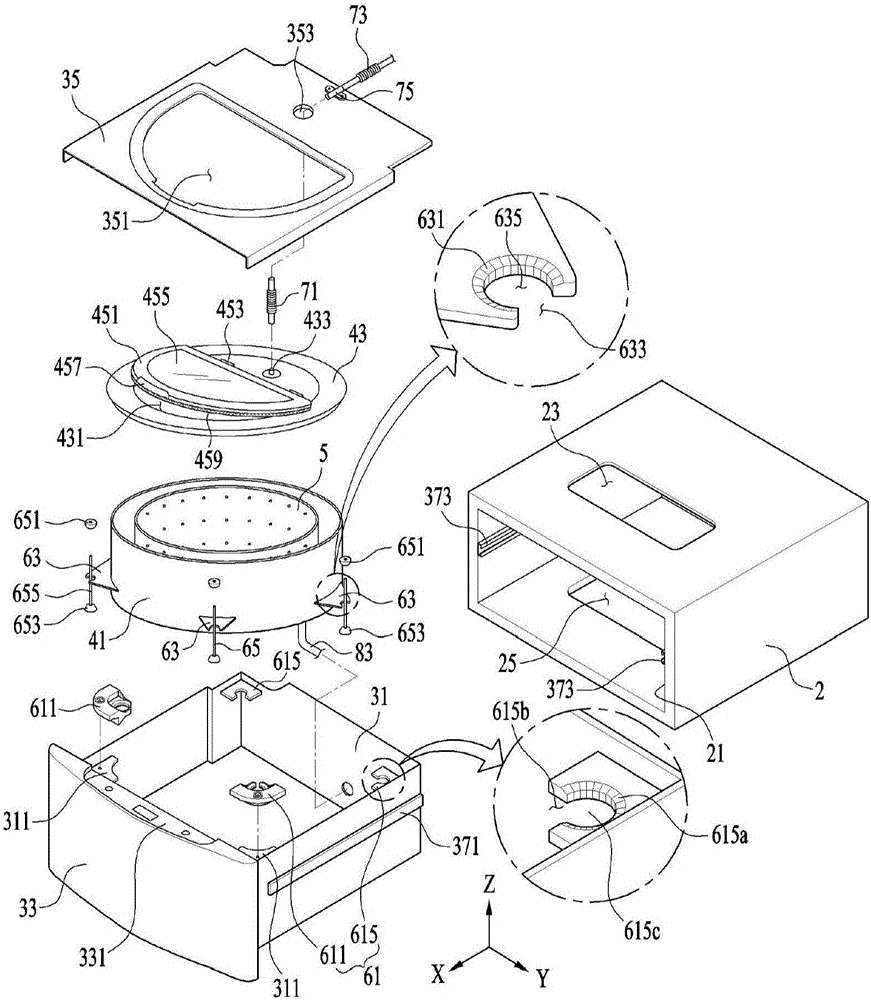

Laundry treatment apparatus

ActiveCN106319820AAvoid collisionPrevent extractionOther washing machinesWashing machine with receptaclesEngineeringLaundry

The invention relates to a laundry treatment apparatus which includes a drawer. The laundry treatment apparatus further includes a cabinet that is configured to receive the drawer. The laundry treatment apparatus further includes a tub that is located in the drawer and that defines a space that is configured to receive water. The laundry treatment apparatus further includes a drum that is located in the tub, that is configured to rotate, and that defines a space configured to receive laundry. The laundry treatment apparatus further includes a spacer that is configured to maintain separation between the drawer and the cabinet, that is configured to prevent the drawer from discharging from the cabinet, and that is removable by a user from outside the cabinet while the drawer is in the cabinet.

Owner:LG ELECTRONICS INC

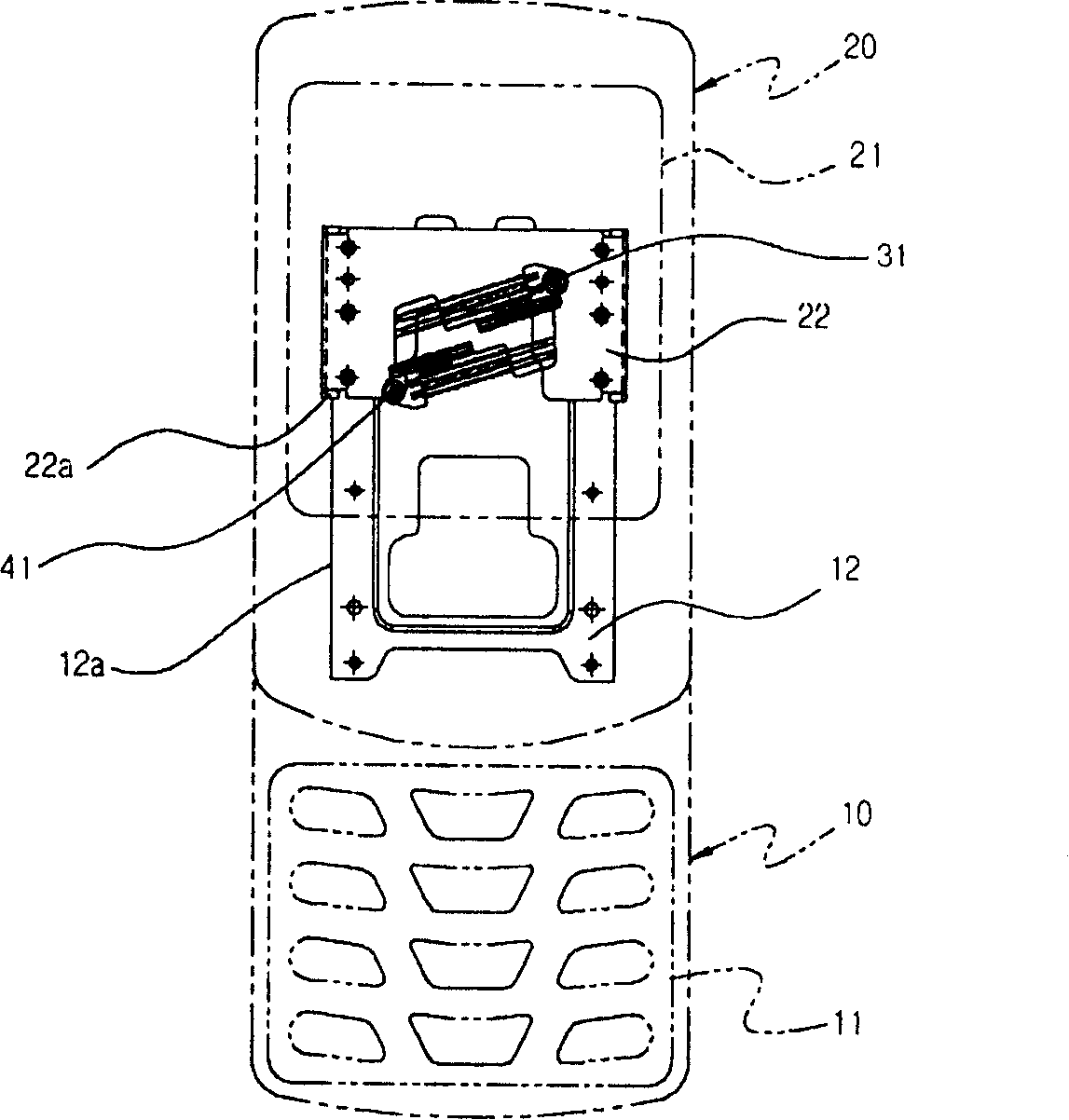

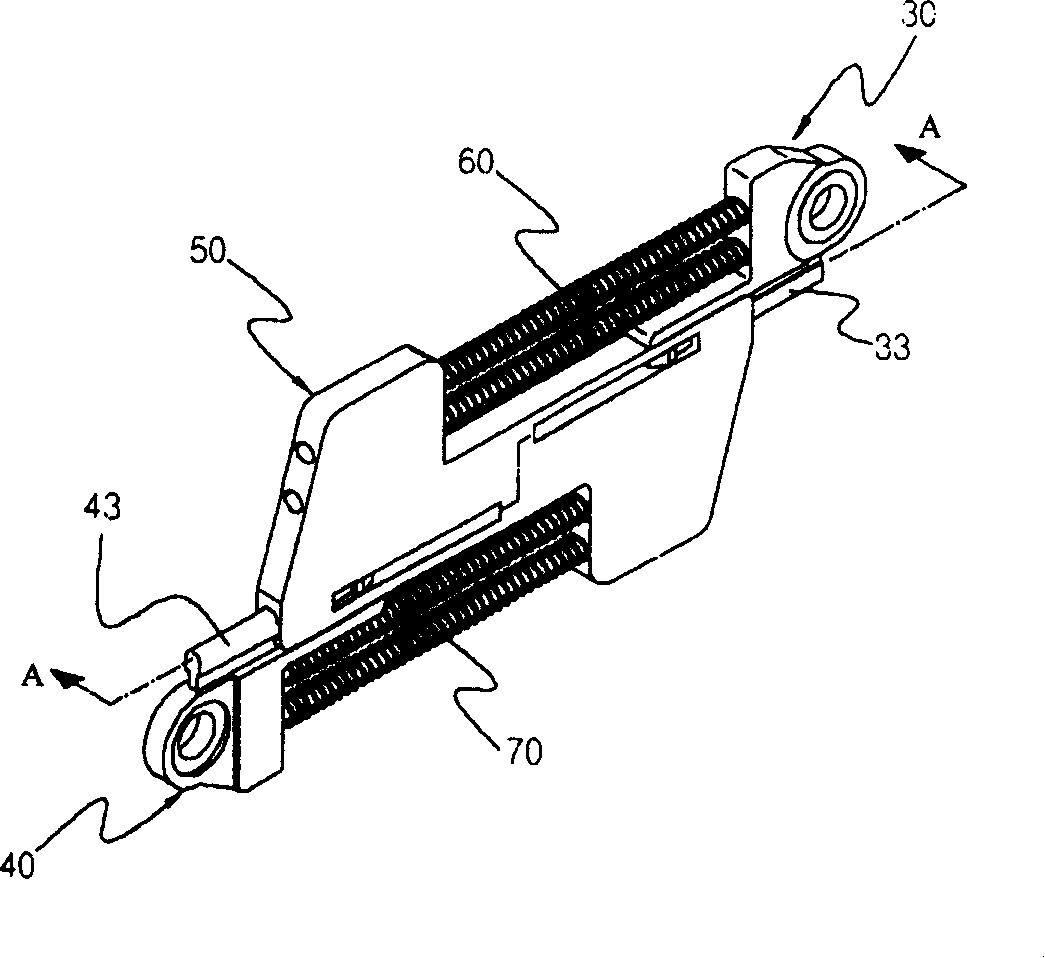

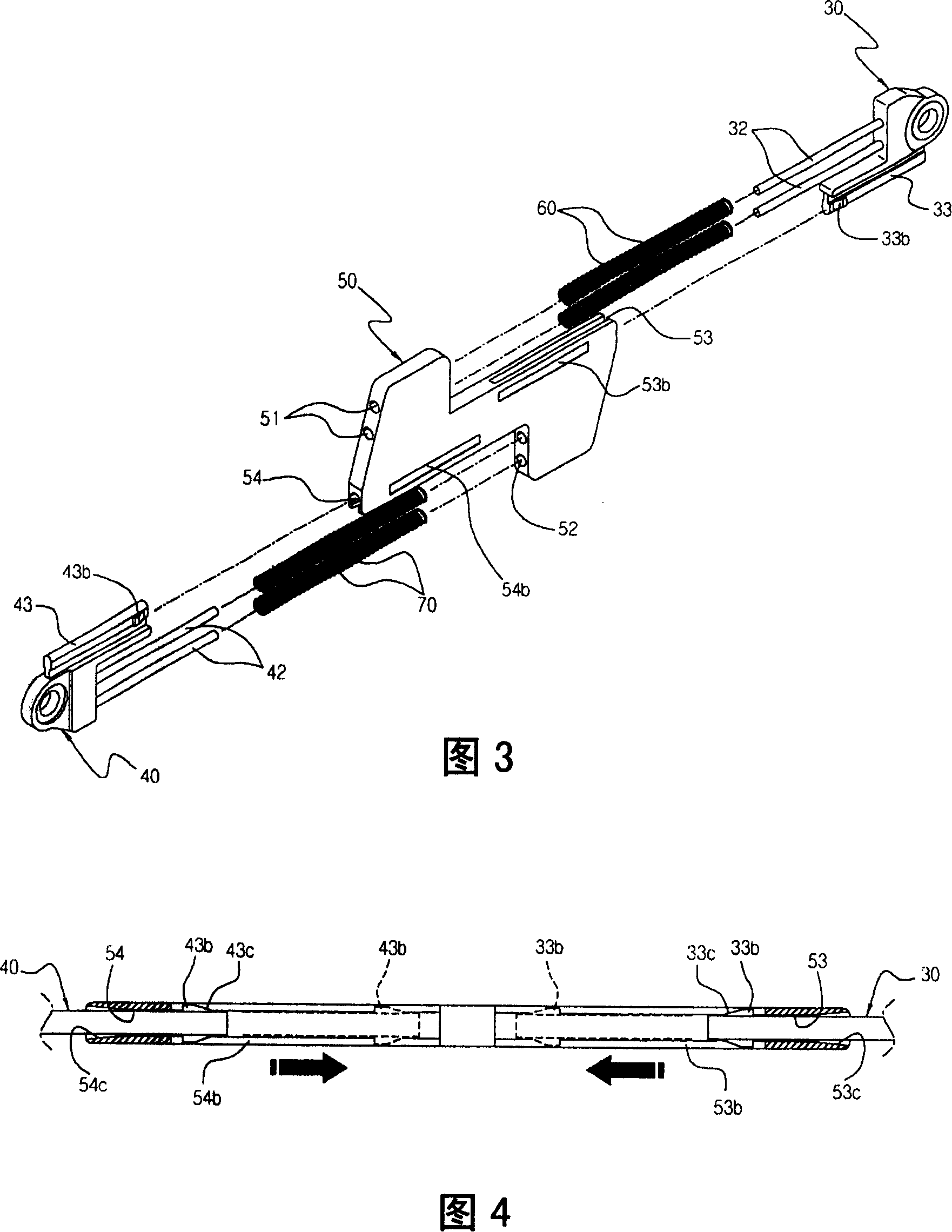

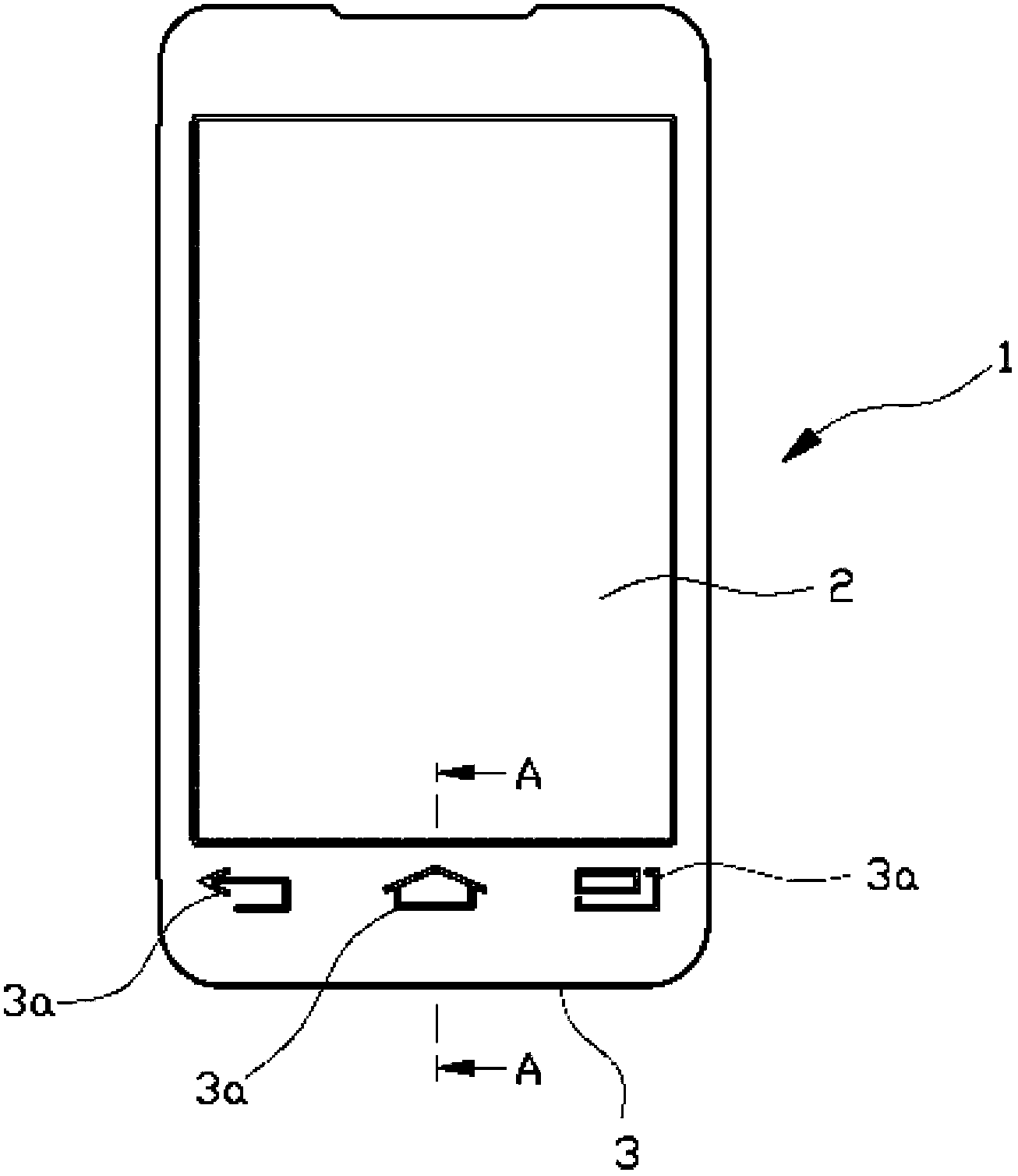

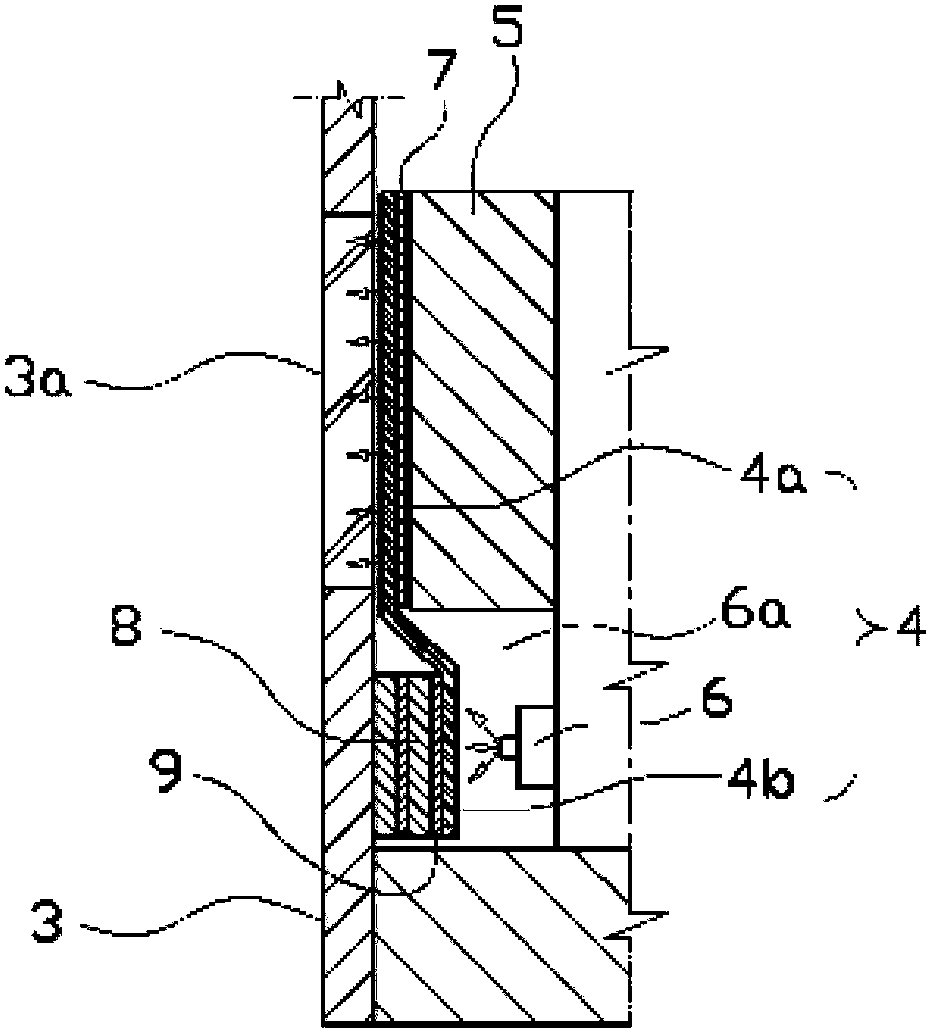

Sliding cover open-close device for sliding cover mobile phone

InactiveCN101166200AImprove reliabilityReduce frictionTransmissionTelephone set constructionsFixed frameMobile phone

The present invention relates to sliding cover opening / closing device for sliding cover mobile phone, it comprises: a first chain plate having a first shaft parallel arranged on the fixing frame and sliding frame and fixed on the fixing frame by a first shaft pin with rotatably mode; a second chain plate having a second shaft corresponding to the first shaft and fixed on the fixing frame by the first shaft pin with rotatably mode; a connecting plate having a first and a second pilot holes on its two ends so as to guide the first and the second shafts to slide action; a first and a second compression ring shape spring separately mounted on external diameters of the first and the second shafts, leading the sliding frame to elastic slide action along the fixing frame after bearing some outside force and leading the mobile phone cover to open / close small keyboard; and a traveling proof mechanism for preventing the first and the second chain plates from traveling phenomenon when sliding between two ends of the connecting plate.

Owner:郑英照

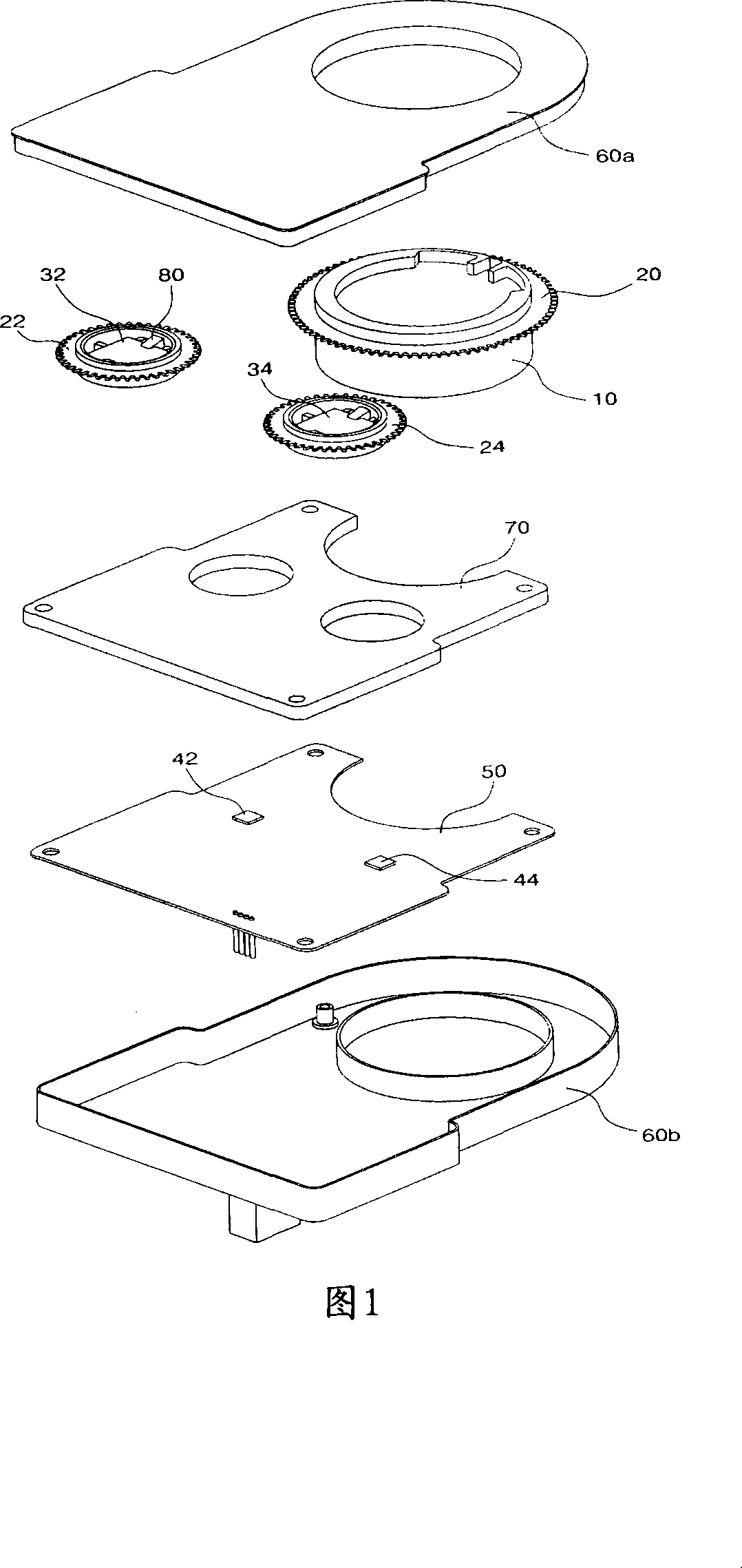

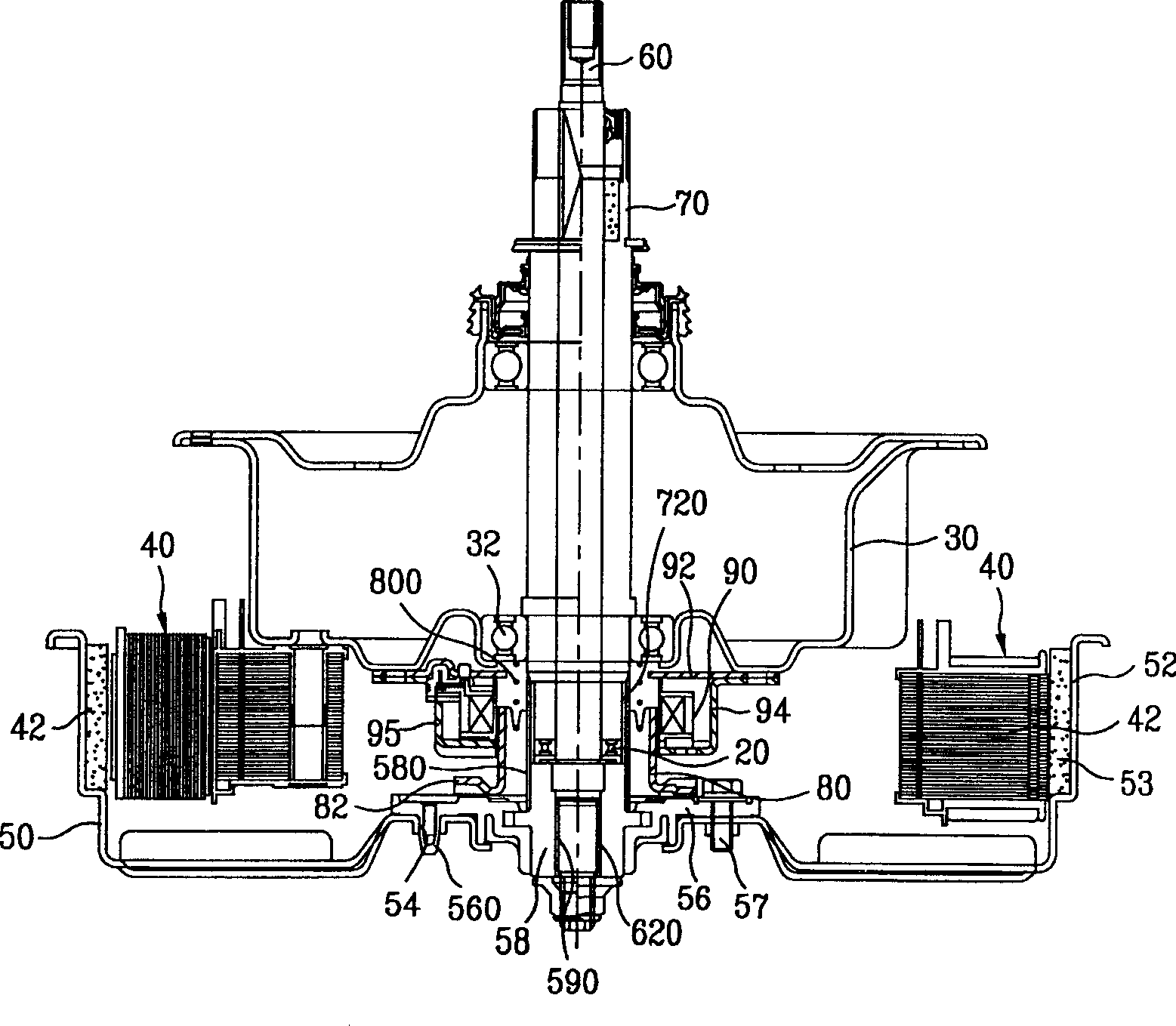

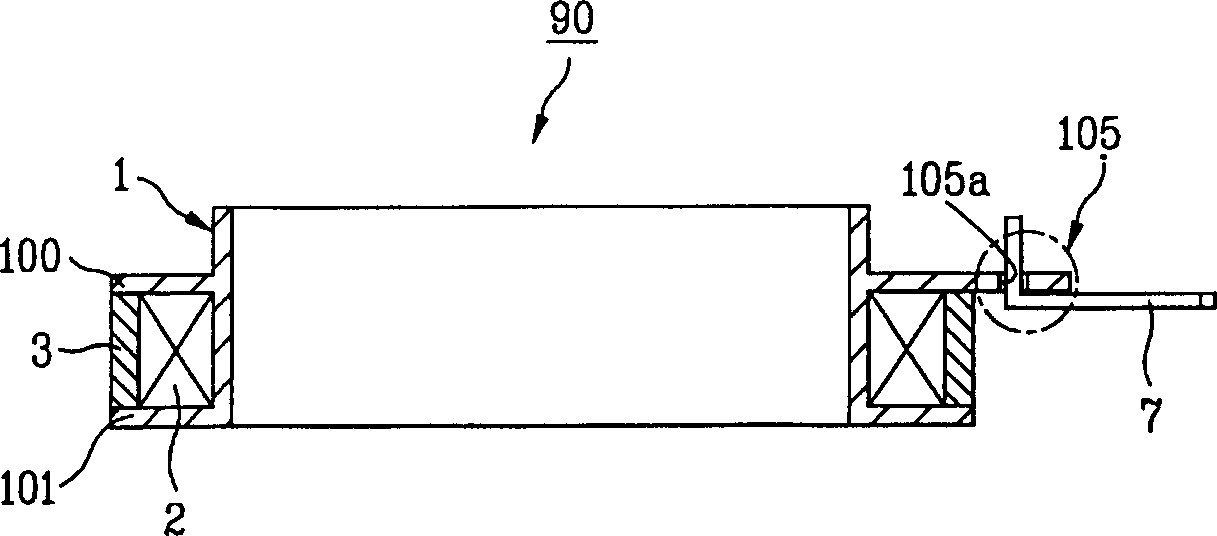

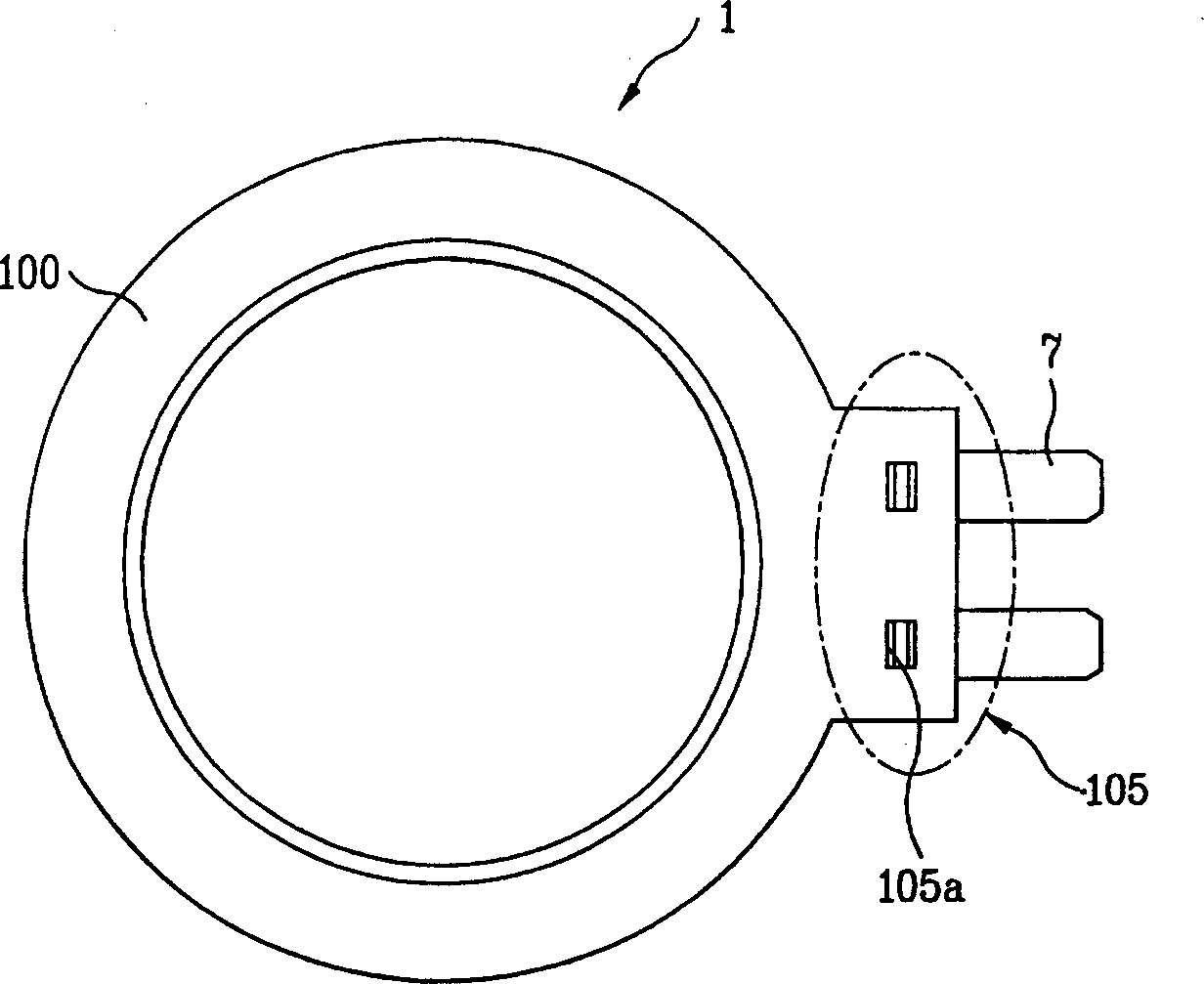

Electromagnetic coil spool and terminal assembling structure of clutch for washing machine

InactiveCN1508341AAvoid swimmingOther washing machinesMagnetically actuated clutchesEngineeringClutch

The invention is a spool and terminal assembly construction for the electromagnetic coil of the washer clutch, including spool, terminal, coil and package; the terminal part of the spool includes support wall, and the first and second fixing holes, the support wall formed behind the terminal part, the first fixing holes formed on two sides of and in front of the support wall, respectively, directly contacting the front of the support wall, and the second ones formed in front of the first ones; the terminal including underpan, coil linking piece and terminal linking piece, the underpan plated shaped; the coil linking piece perpendicular to the underpan surface, formed by extending from one side behind the underpan and penetrating through the first fixing hole to project to the top of the terminal part, and the terminal linking piece perpendicular to the underpan surface, formed by extending from the other side and projecting to the top of the terminal part in front of the coil linking piece.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

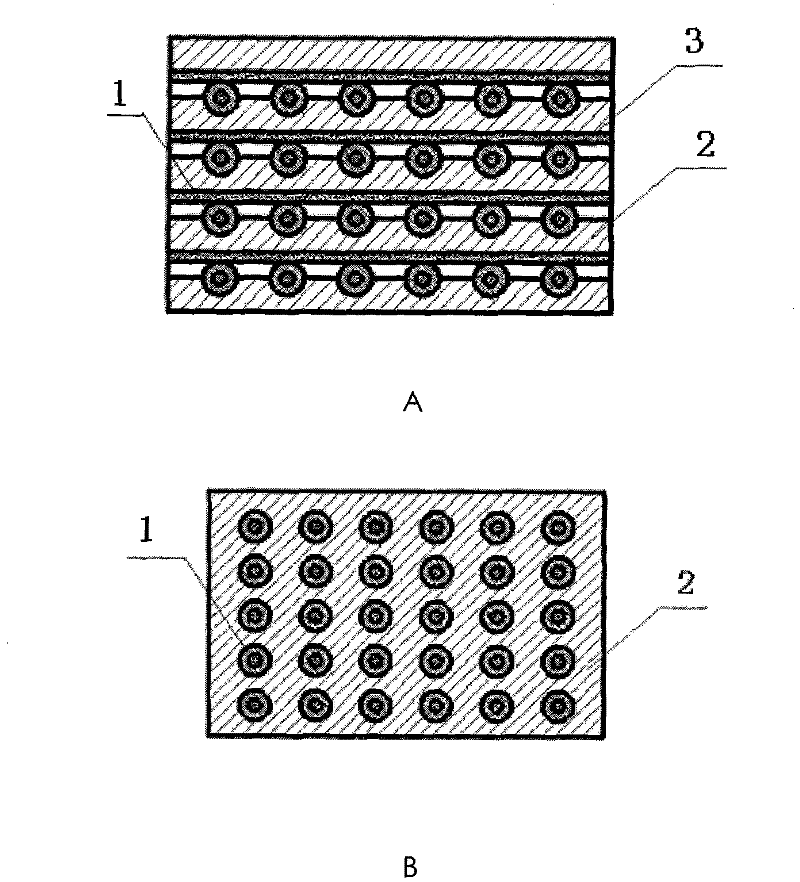

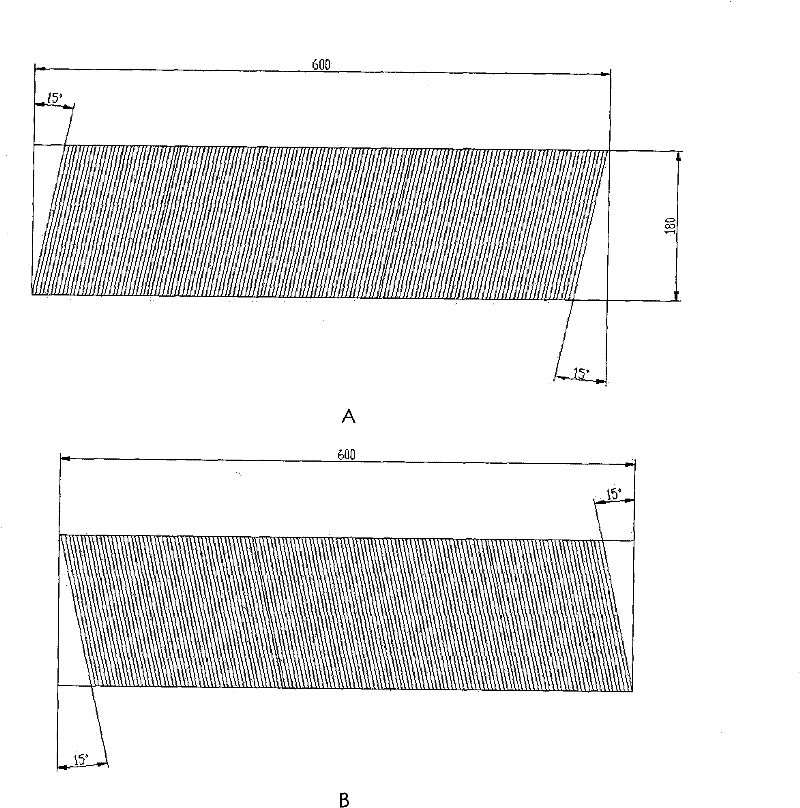

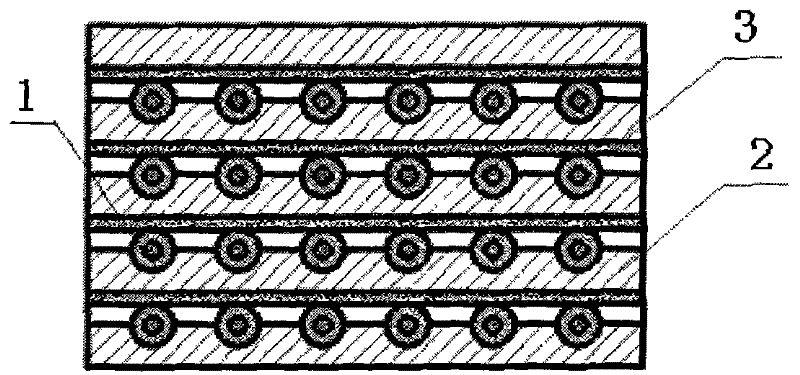

A kind of preparation method of continuous fiber reinforced titanium matrix composite material

The invention belongs to the preparation technology of metal-based composite materials, and relates to a method for preparing continuous fiber-reinforced titanium-based composite materials. In the compounding process, the present invention adopts the method of notching grooves on the surface and bonding temporary adhesive tapes, which can prevent fibers from swimming during the compounding process, thereby obtaining a composite material with uniform fiber arrangement. While fixing the fiber cloth, the temporary adhesive can also well realize the fixing and positioning of the adjacent foil and fiber cloth, preventing them from shifting during the preparation process, so as to prepare a composite material with excellent performance; the foil material Many grooves are etched on the surface of the surface by chemical milling. Compared with the traditional foil-fiber-foil method, the content of matrix metal is further reduced, thereby increasing the percentage of fibers; for the manufacture of locally fiber-reinforced titanium matrix composite components, it can be Using the method of selected area photochemical milling, the local grooves are carved in the foil, and it is easy to realize the laying and fixing of the fiber cloth on the surface of the foil.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Preparation method of dye composition

The invention relates to a preparation method of a dye composition. The preparation method comprises the following steps of preparing disperse dye, lauryl sodium sulfate, glycerol, a dispersant and water into turbid liquid, grinding trough the turbid liquid until the particle size of the disperse dye is 30-50nm, and adding a leveling agent and acetic acid to obtain the dye composition. The dye composition disclosed by the invention is suitable for continuous padding type dyeing and coating type dyeing, and can reduce energy consumption, improve dyeing efficiency and improve product quality compared with dye vat dyeing at high temperature and high pressure, so that the color fastness and color uniformity of the fabric can reach the grade A specified by the national standard, and continuousdyeing at normal temperature and normal pressure can replace high-temperature and high-pressure dye vat dyeing.

Owner:SUZHOU TANGHUA NANO TECH

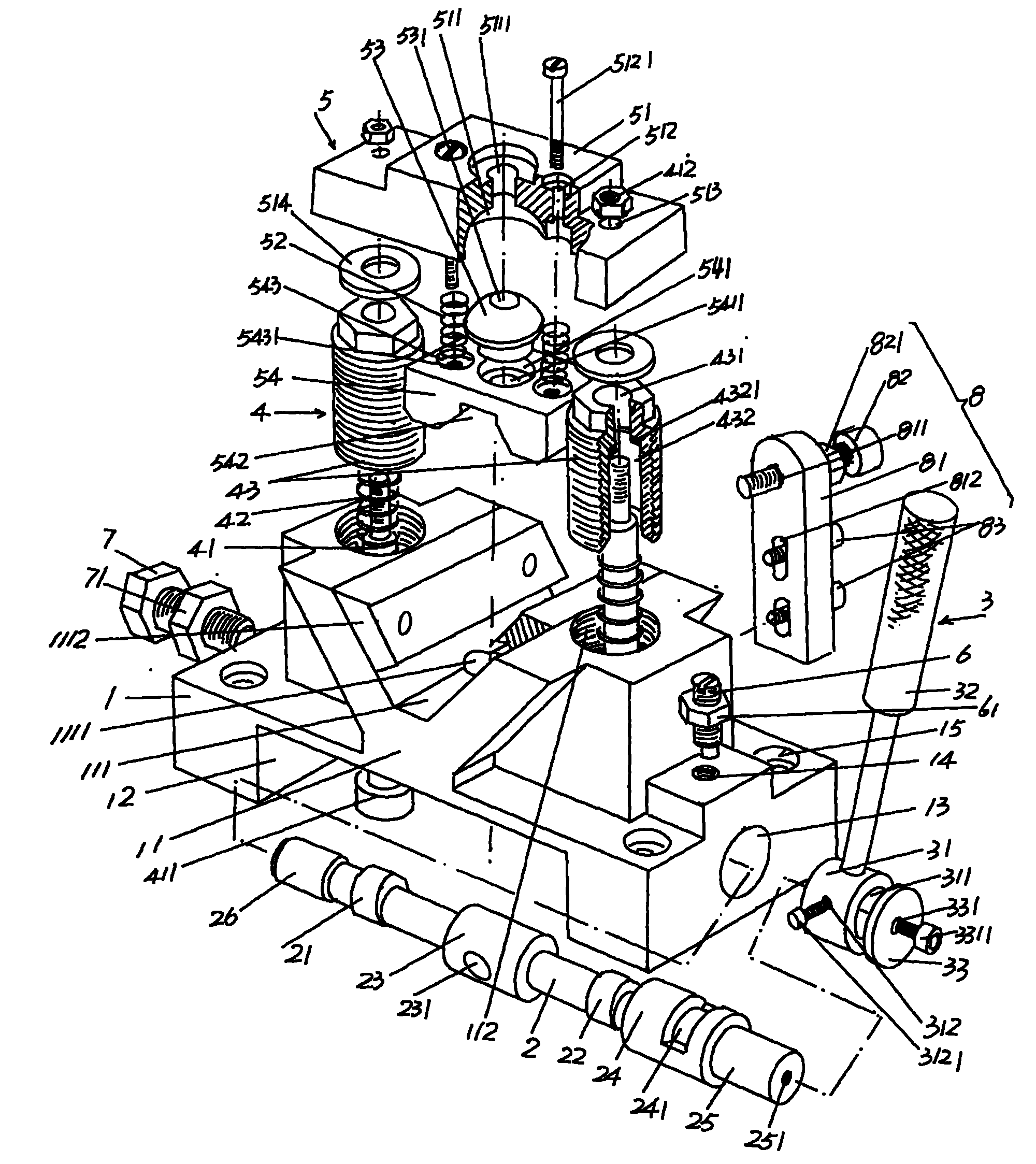

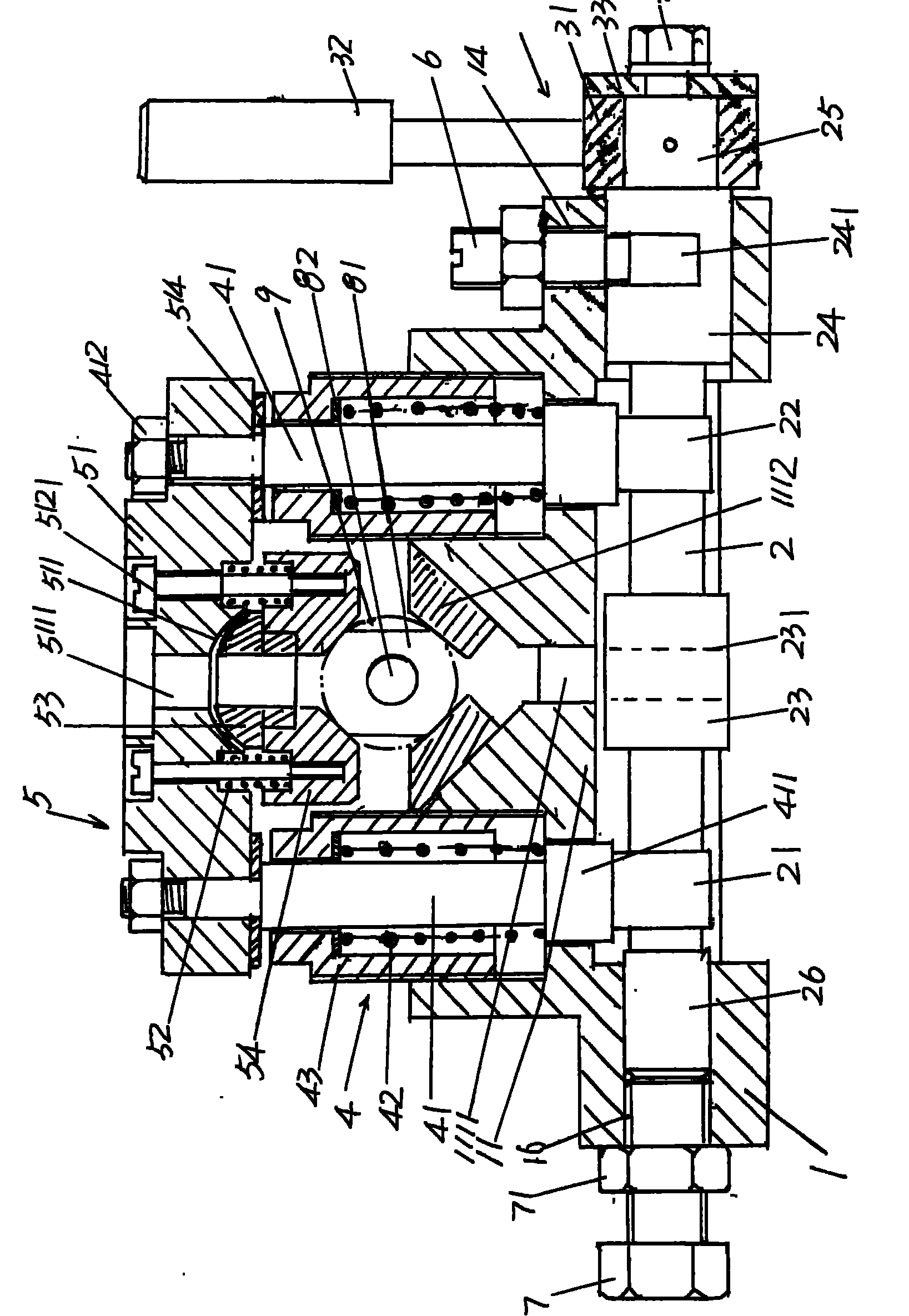

Clamp mechanism for processing piston pin hole of compressor

InactiveCN101695815BAvoid out of toleranceReliable clampingPositioning apparatusMetal-working holdersEngineeringCam

The invention relates to a clamp mechanism for processing a piston pin hole of a compressor, and belongs to the technical field of frock clamps. The clamp mechanism comprises a substrate, a cam shaft, a cam shaft control device, a pair of spherical pair lifting gears and a spherical pair hold-down gear, wherein the bottom of the substrate is provided with a cam cavity; the upper part of the substrate is provided with a workpiece seat; the workpiece seat is provided with a workpiece cavity; the bottom of the workpiece cavity is provided with a cutter through hole; both ends of the cam shaft are rotationally arranged on the substrate; the middle part of the cam shaft corresponds to the inside of the cam cavity; the cam shaft control device is linked with an end part of the cam shaft; the pair of spherical pair lifting gears corresponding to each other is arranged on the workpiece seat of the substrate and corresponds to both sides of the workpiece cavity; lower parts of the pair of spherical pair lifting gears extend into the cam cavity, are in contact with the cam shaft and are actuated by the cam shaft; and the spherical pair hold-down gear is linked with upper parts of the spherical pair lifting gears. The clamp mechanism for processing the piston pin hole of the compressor not only guarantees to reliably clamp a piston to avoid the piston moving about, but also avoids damaging the piston and avoids the deformation of a clamped position of the piston, and has convenient operation.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Dyeing method

The invention relates to a dyeing method. The dyeing method comprises the following steps: continuously dyeing at normal temperature and normal pressure; importing a desized texture into a dye tank, making the texture with a dye composition, and then carrying out drying and coloring treatment to finish dyeing, wherein the operation speed of the texture is controlled to 500 to 100m / min; or coatingthe foamed dye composition to the surface of the desized texture, and then carrying out drying and coloring treatment to finish dyeing, wherein the operation speed of the texture is controlled to 80 to 120m / min; the coating speed of the dye composition is 0.30 to 0.45m<3> / min; the dye composition comprises a dye leveler; the structural formula of the dye leveler is shown in the description; n is anumber of 5 to 10. The dyeing method disclosed by the invention has the advantages of high dyeing speed, low dyeing consumption, low energy consumption and uniform color without color difference; a product can reach the level of grade A product meeting state-specified standards.

Owner:SUZHOU TANGHUA NANO TECH

Acrylic fabric cationic dyeing pad dyeing process

The invention relates to the technical field of acrylic fabric dyeing, in particular to an acrylic fabric cationic dyeing pad dyeing process. The acrylic fabric cationic dyeing pad dyeing process comprises the following steps of (1) padding a fabric in a heated dye liquor, wherein the dye liquor is a cationic dye solution with the concentration of 1-130 g / L, the pH value of the dye liquor is 4-5, and the amount of liquid carried by the fabric after padding is 30%-80%; (2) directly steaming the fabric padded with the dye liquor, wherein the steaming temperature is 100-102 DEG C; (3) washing; and (4) drying. According to the process, continuous dyeing processing is adopted, the production efficiency is high, the production period can be shortened, the process is suitable for dyeing of large-batch fabrics, and acrylic fabric products which are consistent in colored light, full in cloth cover and excellent in color fastness index can be obtained through the process. In addition, the process does not affect the dye uptake and color fastness of other fibers in the blended fabric.

Owner:HUAFANG +1

High elastic non-ironing cellulose fiber and preparation method thereof

ActiveCN102199803BEvenly dispersedAvoid failureArtificial filaments from cellulose derivativesCross-linkPolymer science

Owner:QINGDAO TIANYI GROUP

Keyboard light guide film and manufacturing method thereof

InactiveCN103672739AMaintain curved shapePrevent shape deformationMechanical apparatusElectric switchesLight guideAdhesive

The invention aims to provide a keyboard light guide film and a manufacturing method thereof. Even if a thick reflection board is not used or double-sided adhesives enabling the reflection board to adhere to a light leading-in portion are not used, the distance between the light leading-in portion and a light source can be shortened to the maximum, shape deformation or movement of the light leading-in portion can be avoided and the light leading-in efficiency of the light leading-in portion can be further improved. According to the light guide film, a bent shape portion is formed on the light leading-in portion, and therefore the distance between the light source and the light leading-in portion is shortened; the inner portion of the bent shape portion is filled with shape maintaining bodies, and therefore the shape of the bent shape portion is maintained firmly. In addition, the light guide film is manufactured through a manufacturing procedure of a light guide raw sheet, a cutting procedure of the light guide raw sheet and a separating procedure of the light guide raw sheet.

Owner:MAGMA

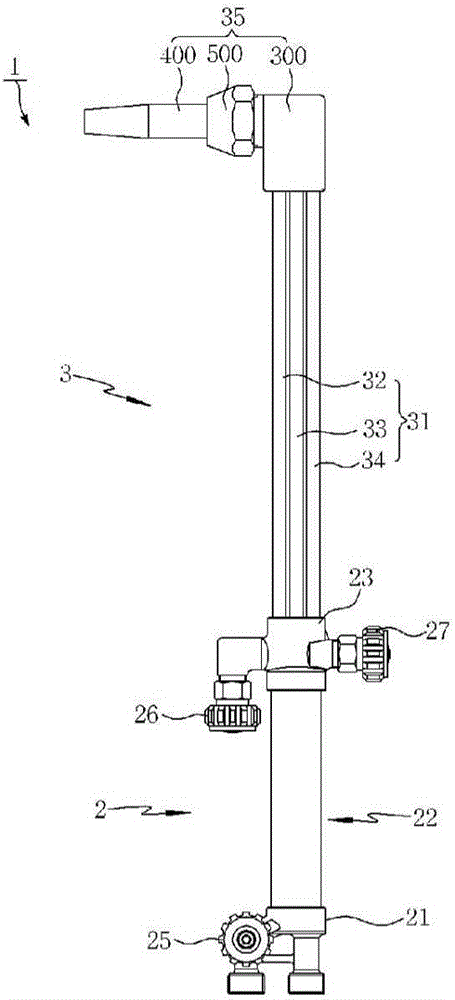

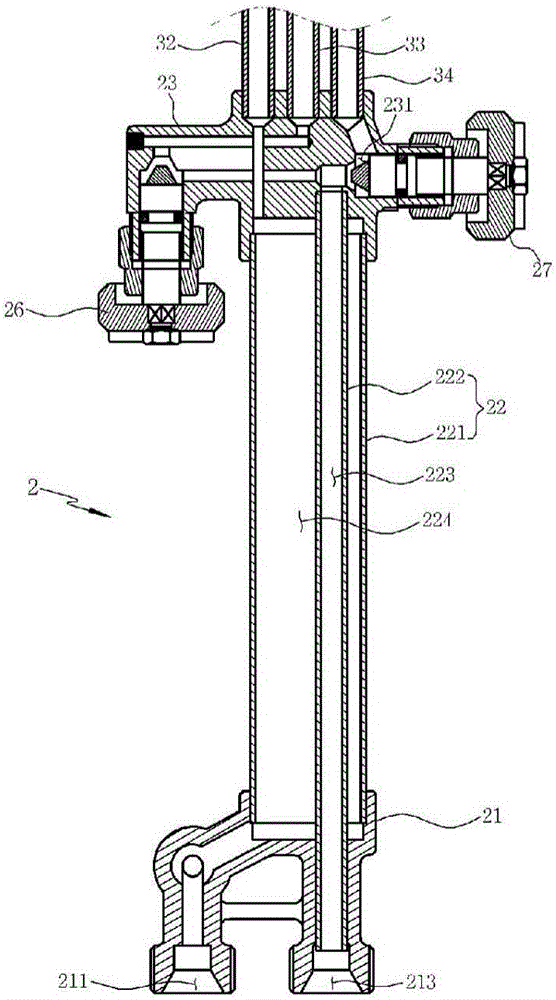

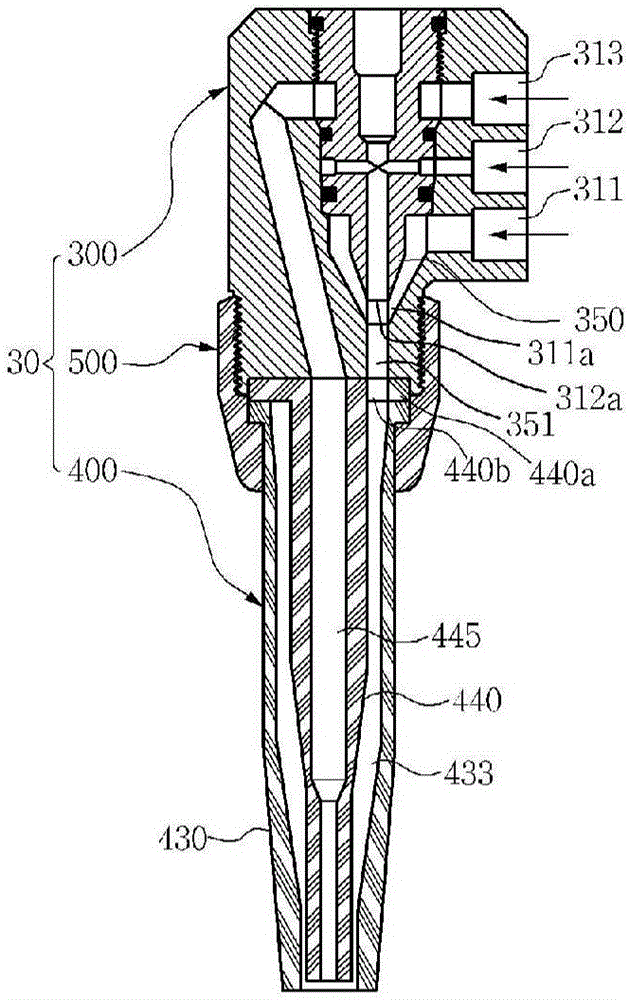

Gas cutter

InactiveCN105682843APressure changes are minimizedSmall pressure changeGas flame welding apparatusBack-fireProduct gas

The purpose of the present invention is to provide a head for a gas cutter which, due to minimizing a pressure change occurrence caused by a pressure difference in a mixed gas passageway, is capable of maintaining preheating performance by smoothly spraying mixed gas and stably forming a flame, and which is capable of maximally inhibiting backfire occurrence caused by a mixed gas pressure difference within the head. In addition, the purpose of the present invention is to provide a head for a gas cutter which allows even an unskilled person to very promptly and conveniently combine a head frame and a tip, which constitute the head, in such a manner that an injecting flow path provided to the head frame and the mixed gas passageway provided to the tip are in communication with each other, simultaneously allowing the laminar flow movement of preheated oxygen and fuel gas by efficiently configuring the injecting flow path of an injecting part, which is capable of preventing backfire by minimizing the pressure difference within the mixed gas passageway after the preheated oxygen and the fuel gas are mixed, and which is capable of extending the life span by minimizing the heating of the head as well as being capable of increasing heat efficiency by improving the mixing ratio of the mixed gas, without allowing the flame to reach the head even if a backfire occurs.

Owner:(株)火火 +1

A kind of leveling agent and its preparation method and application

ActiveCN108411650BUniform active siteGood film formingDyeing processColour fastnessMaterials science

The invention relates to a leveling agent, a preparation method and an application thereof. The structural formula of the leveling agent is: n is a number between 5 and 10. The leveling agent of the present invention has good film-forming properties, and contains abundant ester groups, which can be combined with dyes through hydrogen bonds, and then can carry the dyes to the surface of the fabric evenly and form a film with uniform thickness, so that the dyes can be evenly Adhesion to the fabric to prevent uneven dispersion caused by the short contact time between the dye and the fabric. At the same time, the film can also prevent the migration and sublimation of the dye during the drying and color development process, and prevent the color difference between the warp direction, weft direction and front and back of the fabric . The leveling agent of the present invention is suitable for continuous pad dyeing and coating dyeing. Compared with dyeing vat dyeing under high temperature and high pressure, it can reduce energy consumption, improve dyeing efficiency, improve product quality, and improve fabric color fastness and color. The uniformity of the product reaches the grade A grade stipulated by the national standard, making it possible to replace the high-temperature and high-pressure dyeing vat dyeing with continuous dyeing under normal temperature and pressure.

Owner:SUZHOU TANGHUA NANO TECH

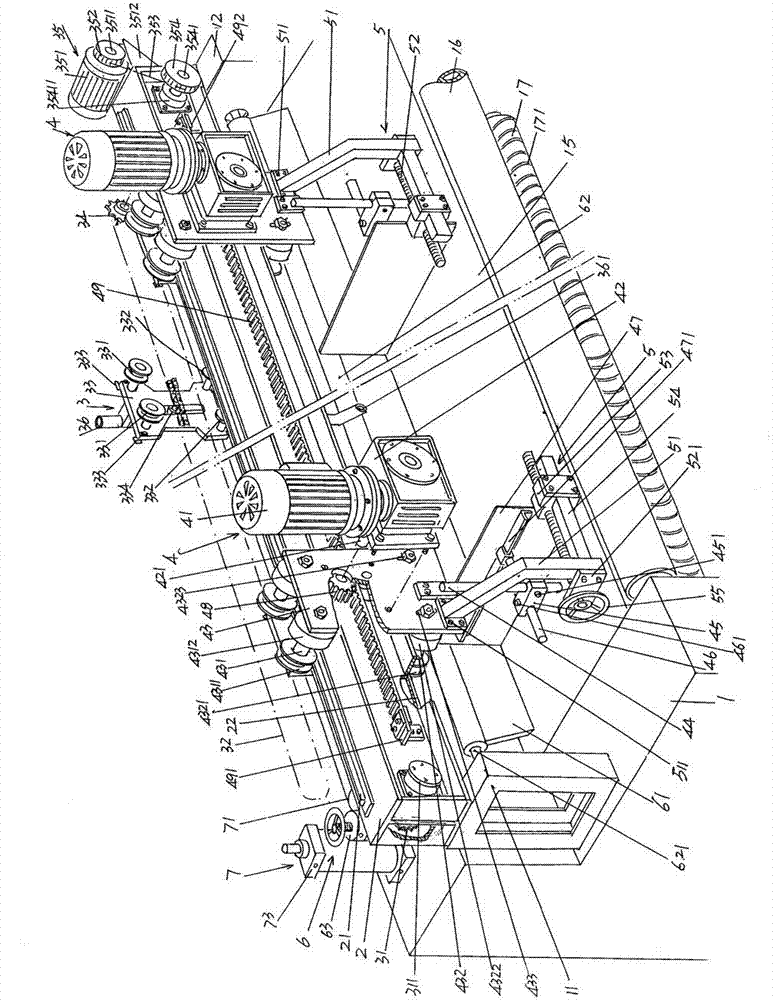

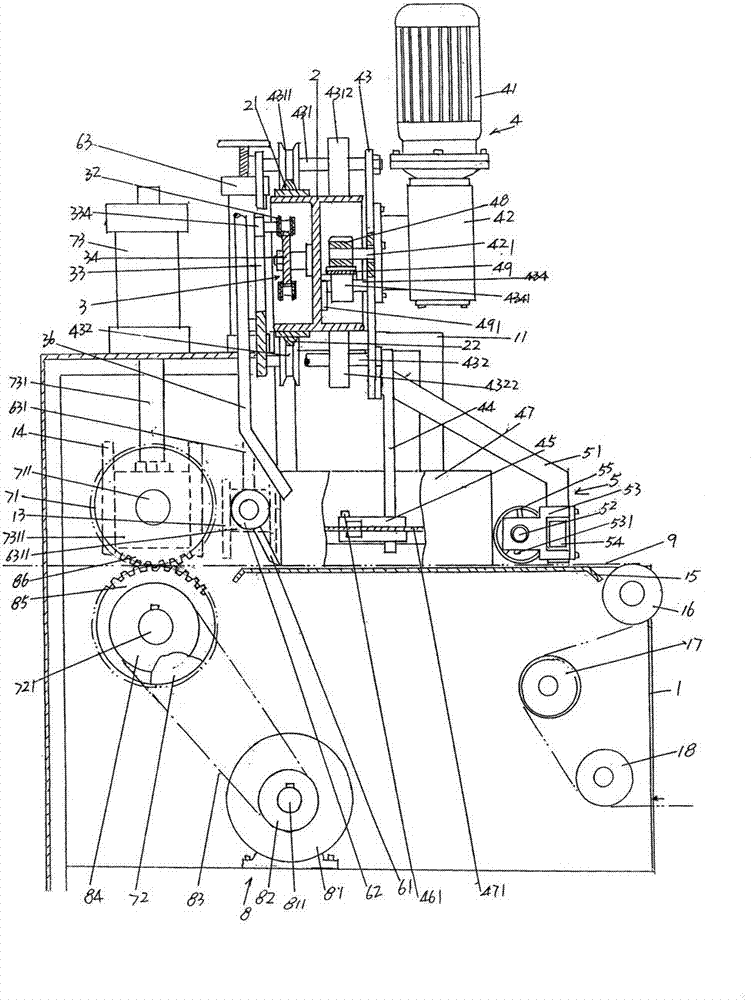

Gluing machine for non-woven fabrics

ActiveCN102962165BPrevent disengagementAvoid wastingLiquid surface applicatorsCoatingsStructural engineeringNonwoven fabric

The invention discloses a gluing machine for non-woven fabrics, belonging to the technical field of gluing machinery for non-woven fabrics. The gluing machine comprises a rack, a beam, a glue feeding mechanism, a pair of glue blocking mechanisms, a pair of edge detecting mechanisms, a glue scraping mechanism and a glue squeezing mechanism, wherein a first beam support is fixed at the upper part of one end of the rack, and a second beam support is fixed at the upper part of the other end of the rack; the upper part of the rack is fixedly provided with a fabric guide platform, and one side of the rack is provided with a fabric guide roller, a fabric spreading roller and a transition roller; the beam is fixed on the first beam support and the second beam support, an upper guide rail is fixed on the upward side of the beam, and a lower guide rail is fixed on the downward side of the beam; the glue feeding mechanism is arranged on the beam; the pair of glue blocking mechanisms are matched with the upper and lower guide rails in a moving manner; the pair of edge detecting mechanisms are arranged on the pair of glue blocking mechanisms; the glue scraping mechanism is arranged on the rack; and the glue squeezing mechanism is arranged on the rack and corresponds to a space between the pair of glue blocking mechanisms and the glue squeezing mechanism. The gluing machine has the advantages of guaranteeing a uniform glue coating effect, preventing the two side edges of the non-woven fabrics from being separated from a glue feeding area of the glue feeding mechanism, avoiding the escape of glue, allowing the selvages of the non-woven fabrics to be stripped and spread, and preventing the non-woven fabrics from moving to two sides and the middle.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

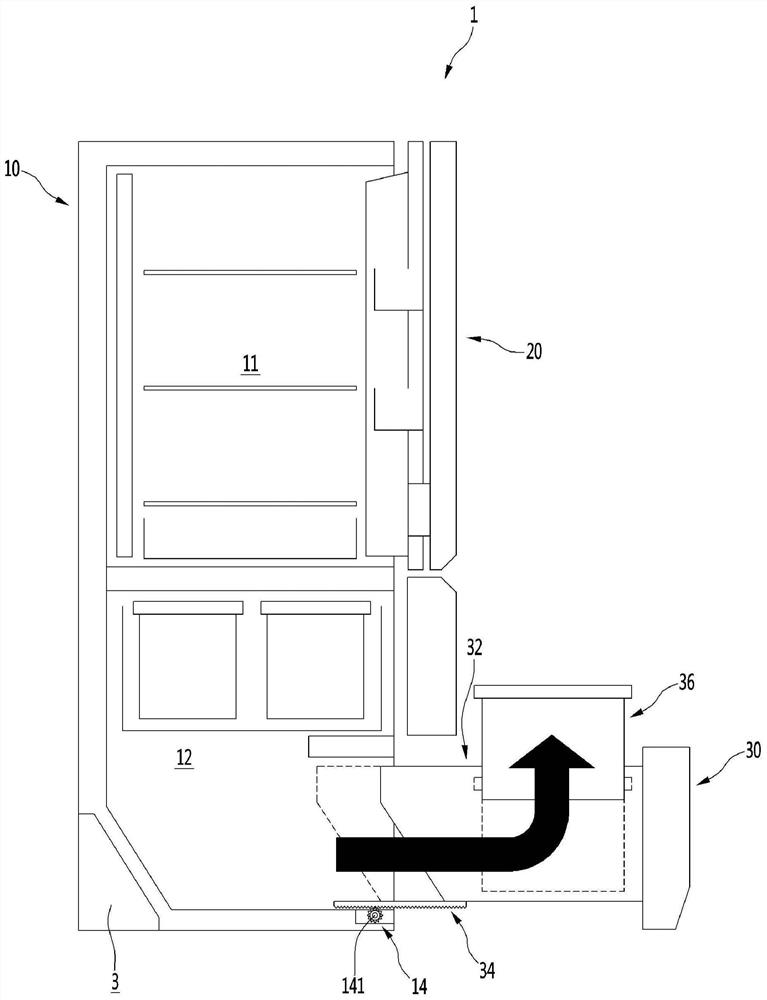

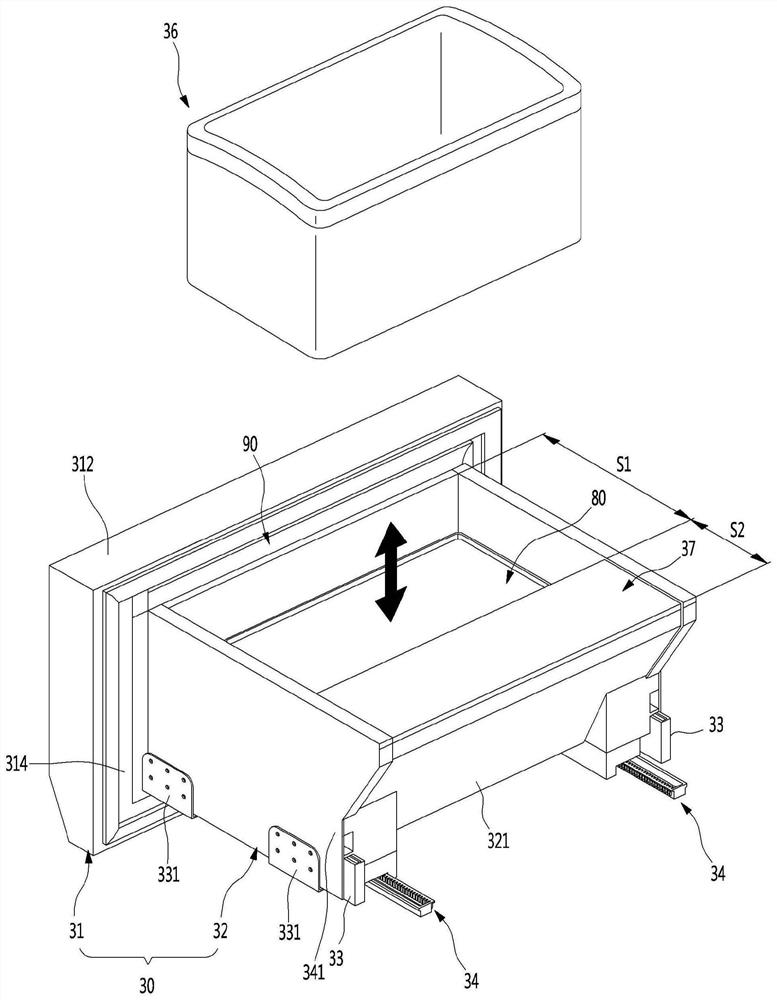

refrigerator

ActiveCN110873498BImprove ease of useAvoid injuryLighting and heating apparatusDomestic refrigeratorsIceboxGear wheel

A refrigerator comprising: a box body forming a storage space; a door having a door portion for opening and closing the storage space and a drawer portion providing a storage space; a track connecting the door and the box body and leading in / out the door; a driving device arranged on the door part, providing power; and a lifting device, which is arranged on the drawer part, and is connected with the driving device to move a part of the drawer part up and down. The driving device includes: a motor assembly; The motor components are connected and act at the same time; and the connecting rod is rotated by the screw unit and connected with the lifting device to provide power for the lifting device to rise and fall. The screw unit includes: a cover body; The gears are combined and rotated; the screw holder is penetrated by the screw, and the thread corresponding to the screw is formed to move along the screw; and the guide bar is arranged in parallel with the screw inside the cover body, and guides the screw through the screw holder. move.

Owner:LG ELECTRONICS INC

Debugging support leg assembly used for photoelectric rotary table and photoelectric rotary table

The invention provides a debugging support leg assembly used for a photoelectric rotary table and the photoelectric rotary table. The debugging support leg assembly comprises a fixing seat, a support leg and a locking assembly, wherein the fixing seat is arranged on a rotary table azimuth seat of the photoelectric rotary table; the support leg is pivotally connected with the fixing seat so that the support leg can be switched between an unfolded state and a stored state; the locking assembly is arranged on the rotary table azimuth seat, and is adjacent to the fixing seat; the locking assembly has a locking state and an opened state, and when the locking assembly is in the opened state, the support leg can rotate relative to the fixing base; and when the locking assembly is in the locking state, the locking assembly matches the support leg in a locking and abutting mode, so that the support leg is fixed in the unfolded state or the stored state. Therefore, the support leg can be fixed in the unfolded state through the locking assembly, and a pitching assembly of the photoelectric rotary table is supported through the support leg, so that debugging and maintenance of the photoelectric rotary table are facilitated; and after debugging or maintenance is completed, the support leg can be switched to the stored state and fixed through the locking assembly, the structure is simple, and operation is convenient.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com