High elastic non-ironing cellulose fiber and preparation method thereof

A technology of cellulose fiber and high elasticity, which is applied in the field of cellulose fiber and its preparation to achieve excellent mechanical properties, cost and energy savings, and comfortable elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

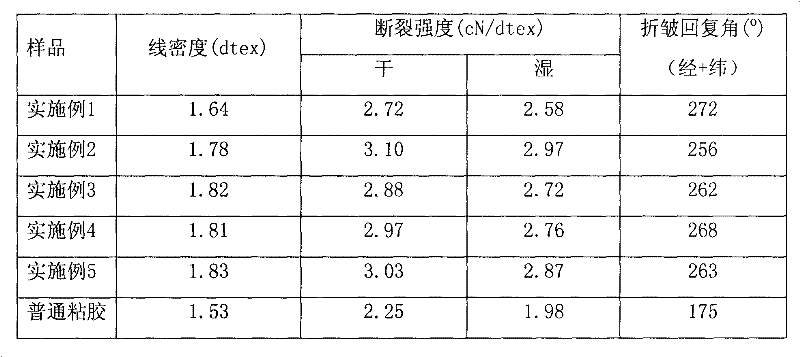

Examples

preparation example Construction

[0036] A preparation method of highly elastic non-ironing cellulose fibers, the preparation method comprising the steps of:

[0037] a. Vacuum-dry the selected cellulose at 60-100°C for 2-5 hours for later use. The cellulose can be one of cotton pulp cellulose, wood pulp cellulose or bamboo pulp cellulose;

[0038] b Weigh the finishing agent according to 6.6% to 11.6% of the mass of the selected cellulose, weigh the catalyst according to 3.3% to 5.8% of the mass of the selected cellulose, and weigh the ionic liquid according to 10 to 50 times the mass of the selected cellulose, Then, mix the weighed finishing agent, catalyst and ionic liquid, heat to 30° C. to 40° C., stir to dissolve, and obtain a modified solution. The finishing agent can be one of 1,2,3,4-cyclopentadinic acid or citric acid or 1,2,3,4-butane tetracarboxylic acid, and the catalyst can be sodium hypophosphite or sodium phosphite or sodium nitrate, and the ionic liquid can be 1-allyl-3-methylimidazole acetat...

Embodiment 1

[0047] Vacuum dry the cotton pulp cellulose at 100°C for 2 hours, weigh 20g for later use; add 2.32g of 1,2,3,4-cyclopentadinic acid and 1.16g of sodium hypophosphite to 1000g of 1-allyl-3 - Methylimidazolium acetate ionic liquid, the solution is heated to 30°C, then stirred to dissolve to obtain a modified solution; 20g of spare dry cotton pulp cellulose is added to the above modified solution, and the solution is heated to 80°C , then stirred to dissolve it, and then degassed under reduced pressure for 20 hours to obtain a modified spinning solution; prepare a sulfuric acid solution with a mass percentage concentration of 1%, and heat it to 50°C for later use; the modified spinning solution is sprayed under pressure into the acid solution prepared above, solidified for 30s, and then stretched in three stages, each stretching ratio was 1.5 times, to obtain shaped fibers; put the shaped fibers into an oven, pre-baked at 80°C for 5min, and then 160°C ℃ for 2 minutes; the baked ...

Embodiment 2

[0049] The wood pulp cellulose was vacuum-dried at 60°C for 5 hours, and 100 g was weighed for later use; 6.6 g of citric acid and 3.3 g of sodium phosphite were sequentially added to 1000 g of 1-allyl-3-methylimidazolium chloride salt ionic liquid, The solution was heated to 40°C, and then stirred to dissolve it to obtain a modified solution; 100g of spare dry wood pulp cellulose was added to the above modified solution, the solution was heated to 80°C, stirred again to dissolve it, and then decompressed to remove Soak for 20 hours to obtain a modified spinning solution; prepare a phosphoric acid solution with a mass percentage concentration of 3%, and heat it to 30°C for use; under pressure, the modified spinning solution passes through the spinneret and enters the above-mentioned prepared acid solution , solidified for 30s, and then carried out three stages of drawing, and the drafting ratio of each stage was 2.0 times to obtain shaped fibers; put the shaped fibers into an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com