Patents

Literature

40results about How to "Comfortable elastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

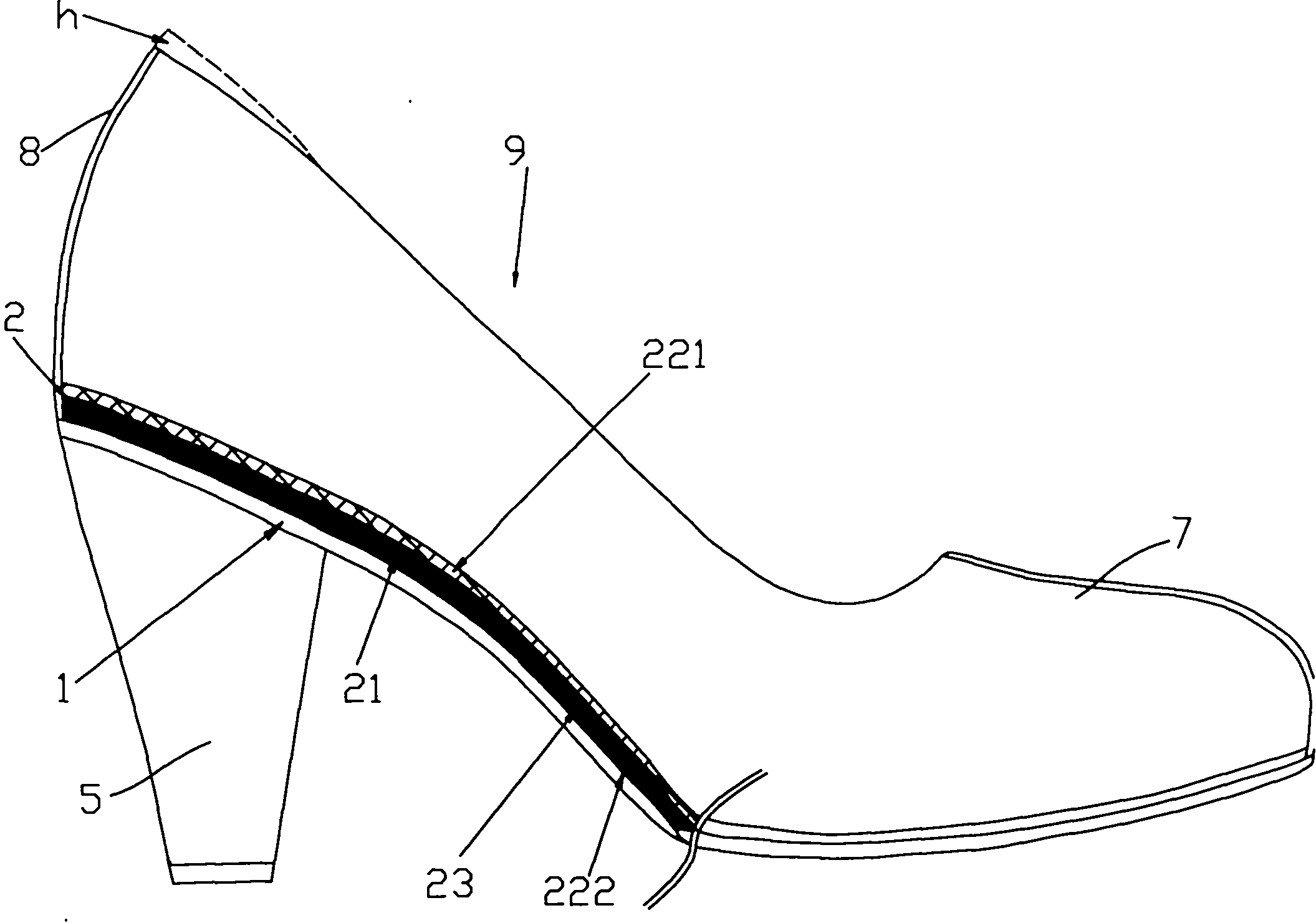

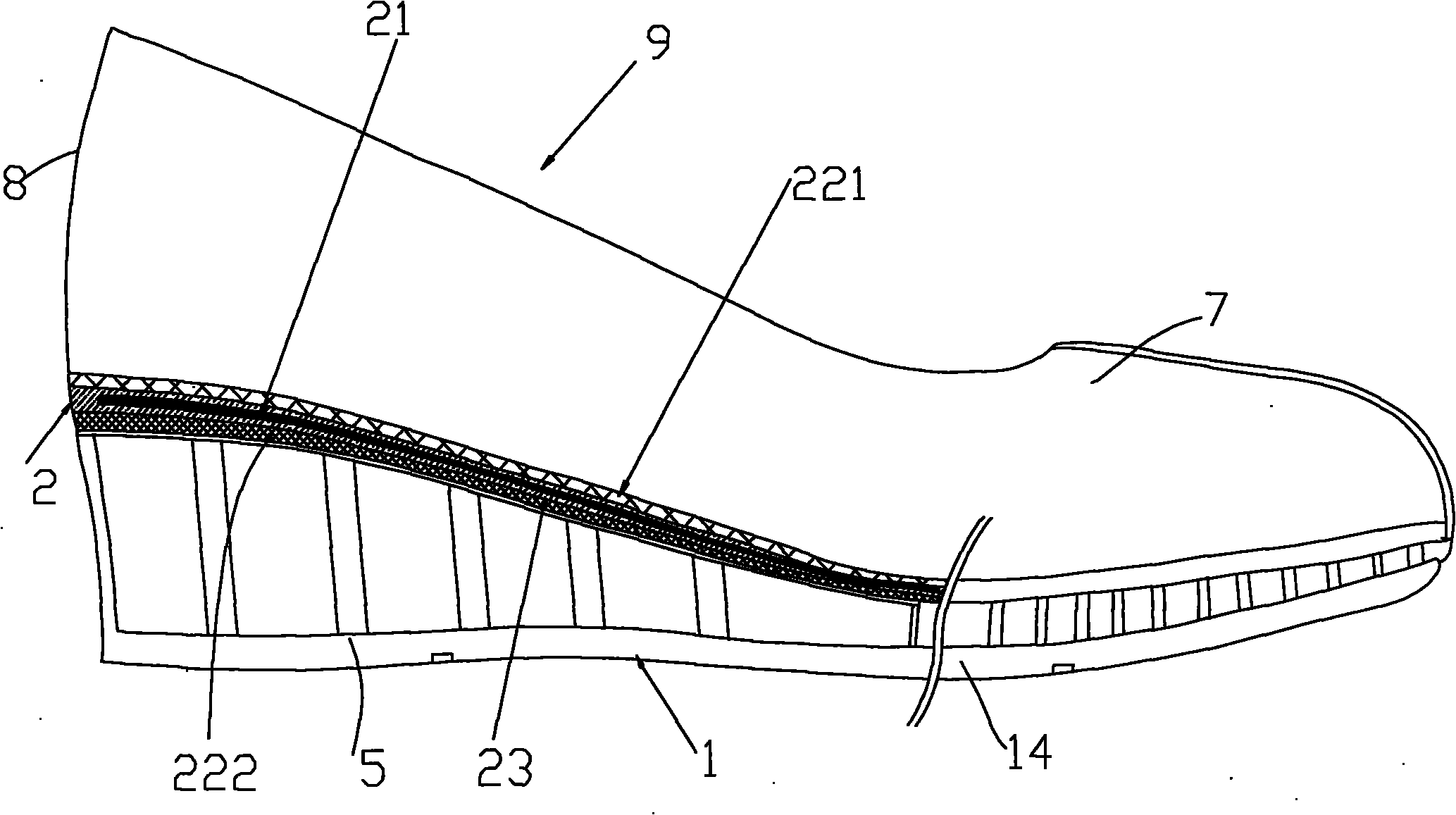

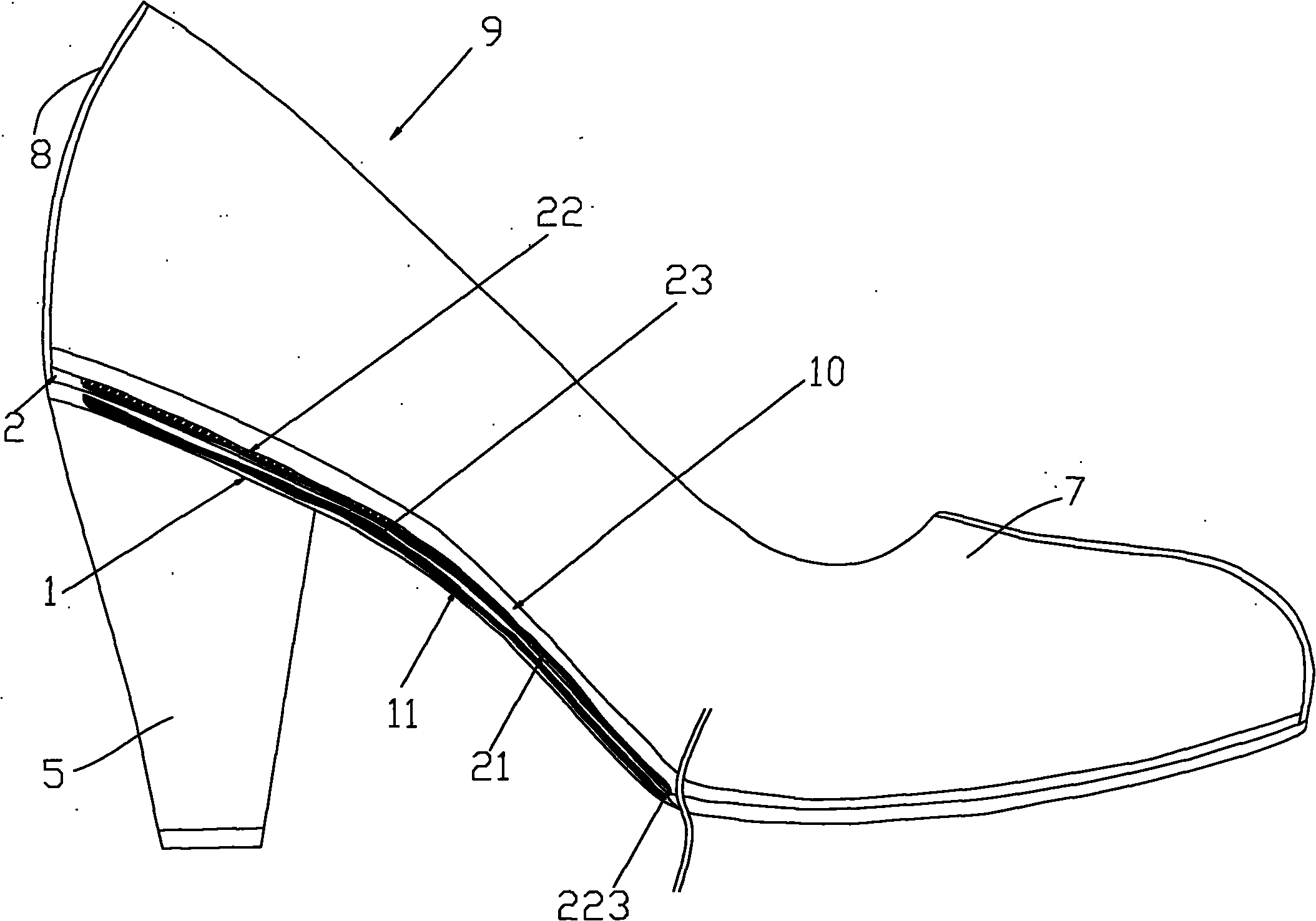

Comfortable shoe with waist iron blocks respectively arranged at outsole and midsole

The invention discloses a comfortable shoe with waist iron blocks respectively arranged at an outsole and a midsole. The comfortable shoe comprises a shoe main body. The shoe main body comprises the outsole and the midsole. A midsole plate and a midsole waist iron block are arranged in the midsole. A single midsole insert is arranged in the midsole. The midsole waist iron block is arranged at a position above the midsole plate. The single midsole insert is arranged at a position above the midsole waist iron block. The midsole waist iron block, the single midsole insert and the midsole plate are integrally arranged. An outsole waist iron block is arranged in the outsole. Since the hardness of the part of the traditional midsole in contact with a foot is high and the part has certain thickness, people wearing the shoe with the traditional midsole feel uncomfortable. Through thinning the midsole, arranging the outsole waist iron block in the outsole and reinforcing the structure of the outsole, the appearance of an original leather shoe is not required to be changed and the height of the back part of the shoe is not required to be increased. Moreover, since a 6mm-thick foot bed type foot pad made of elastic PU or high-foaming material and matched with the shape of the bottom of the foot is arranged in the shoe main body, people wearing the shoe can feel comfortable and the stability is better.

Owner:黎田建

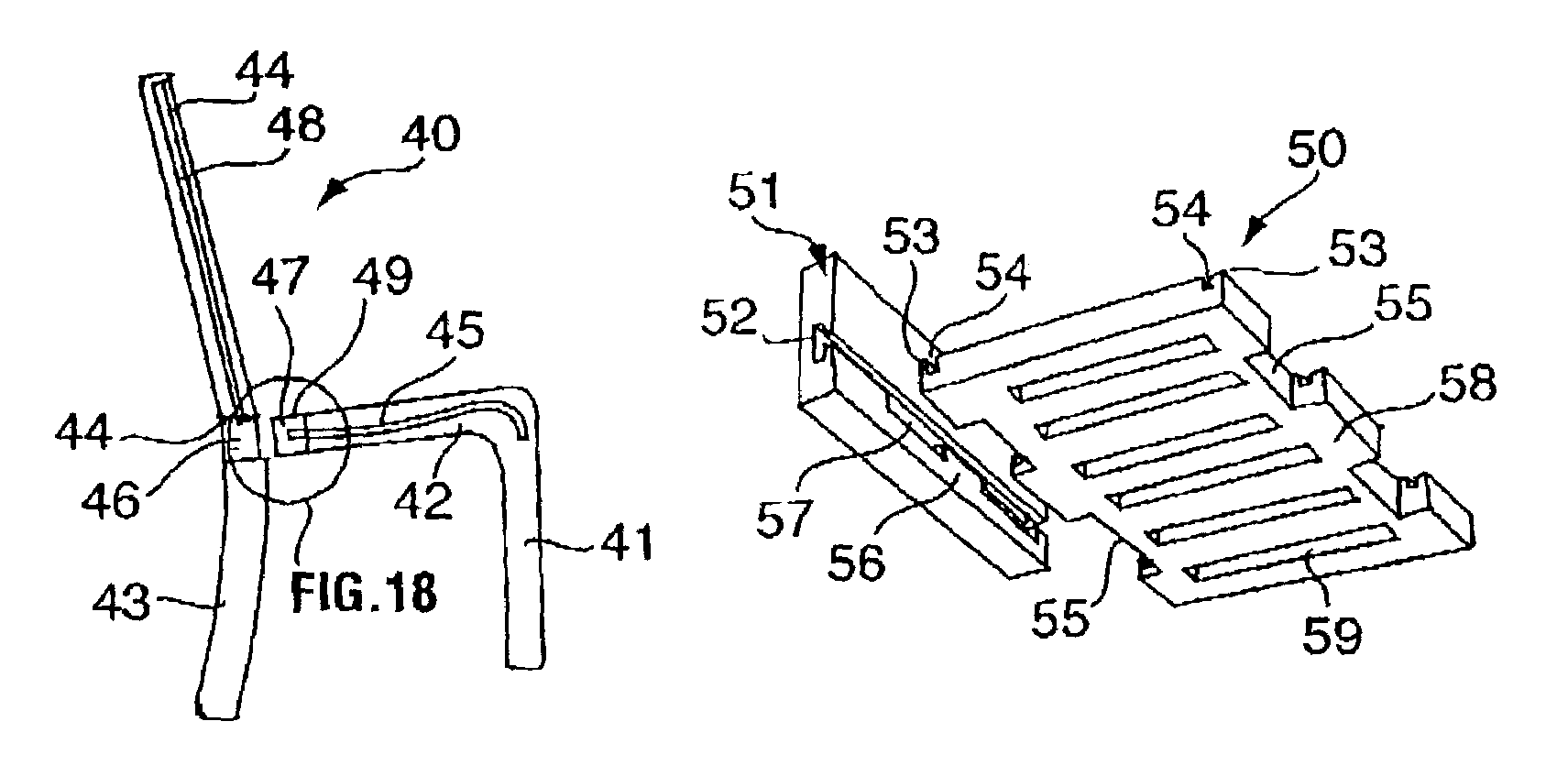

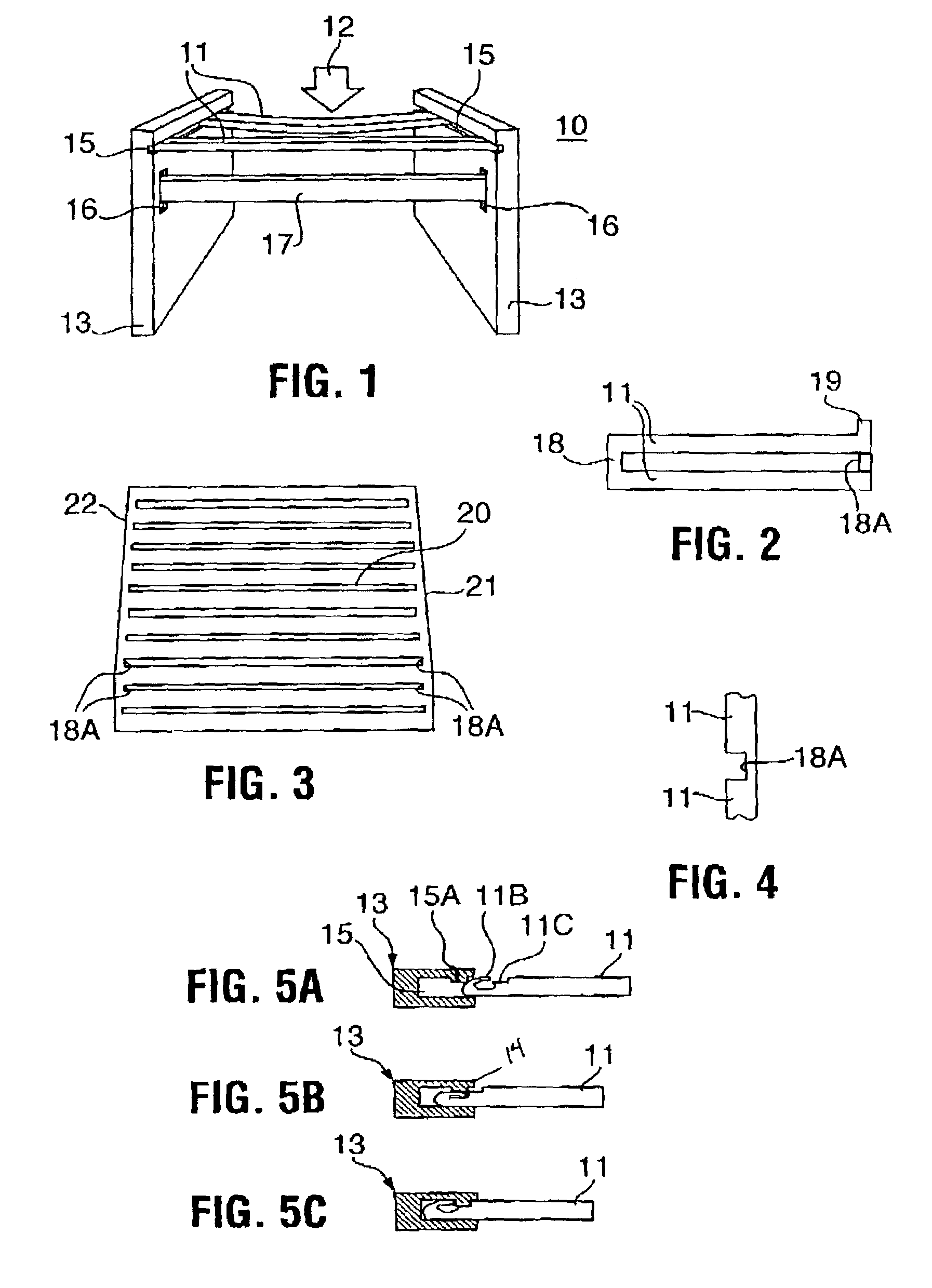

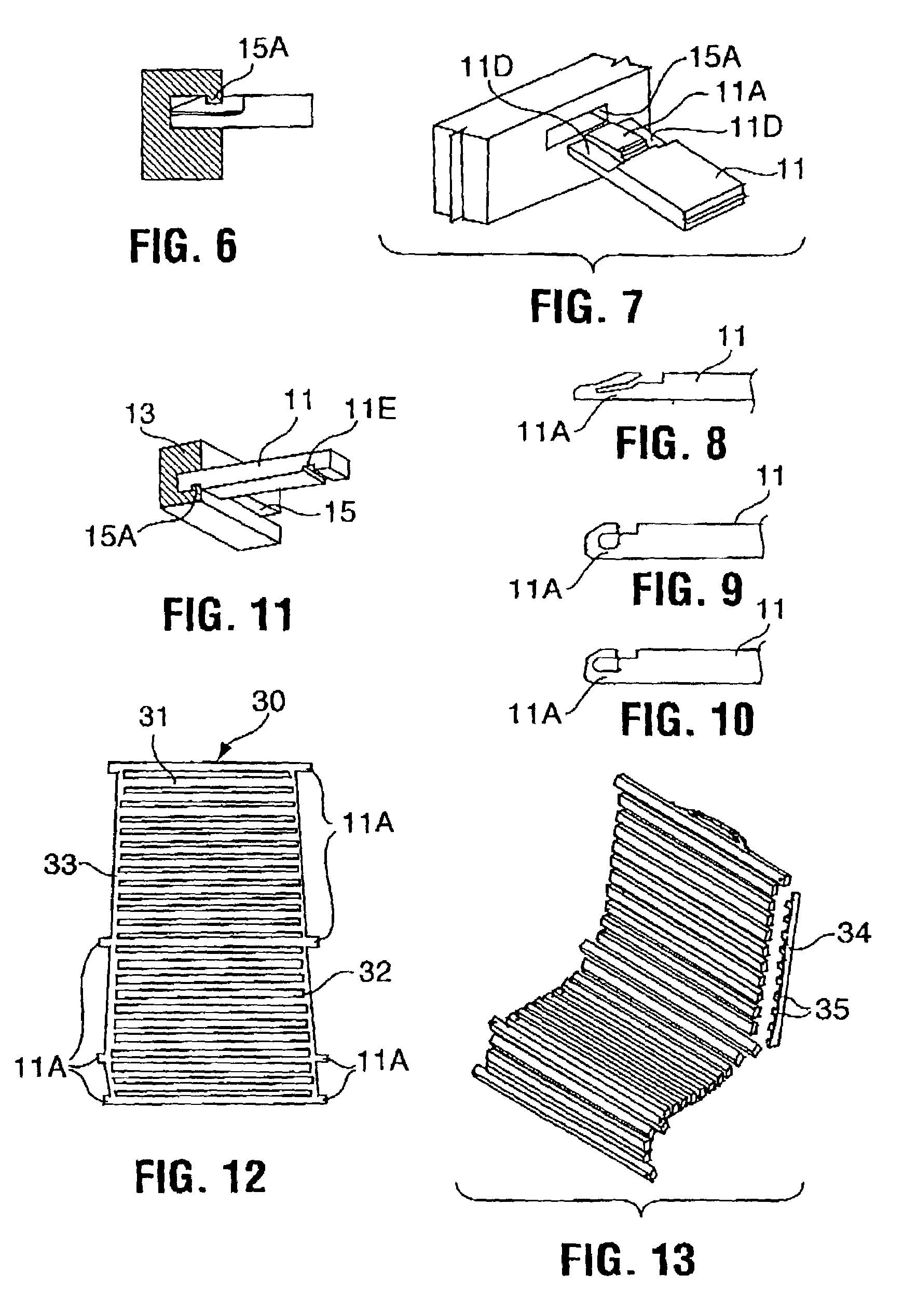

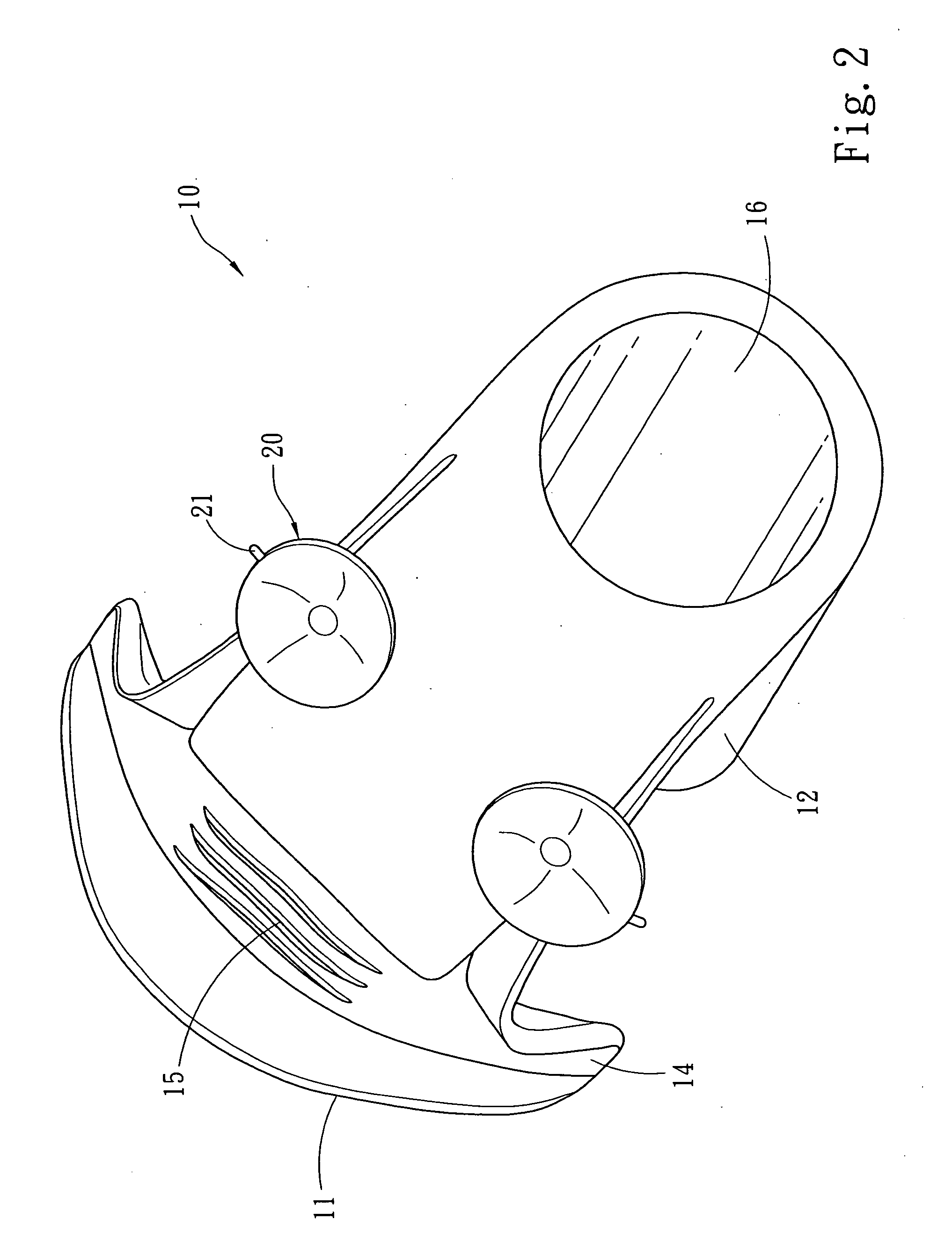

Furniture structure

InactiveUS7066553B2Improve comfortIncreased durabilitySpring mattressesStoolsEngineeringMechanical engineering

Owner:FINCASTLE COUNTY CHAIRWORKS

Preparation method of cut resistant yarn

The invention provides a preparation method of anti-cutting yarn. Two high-strength polyester filaments or ordinary polyester filaments are plyed and twisted, and then twisted and coated with ordinary glass fiber filaments or basalt fibers to form a core yarn. , On the basis of the above core fiber, the outer layer is covered with high-strength nylon or high-strength polyester filament or high-strength nylon and spandex as the outsourcing fiber to make a cut-resistant yarn. The core yarn provides the skeleton of the cut-resistant yarn, the spandex provides comfortable elasticity, and the outer covering yarn provides toughness resistant to direct cutting, which can be used in textiles including fabrics, gloves, sheaths, aprons and other fields. The present invention adopts conventional fiber varieties as the core yarn, rationally configures the twist of the yarn and the distribution and proportion of fibers, so that the yarn or textiles can reach different anti-cutting levels and the highest anti-cutting level, greatly reducing the production cost, and the cutting resistance is stable. And the yarn feels comfortable.

Owner:SHANGHAI SHUQUE TRADING CO LTD

Bombax cotton thermal shell fabric and its manufacturing method

The invention discloses a kapok warm face material. The fiber ingredients and the ratio are: natural kapok fiber 10-100%, cotton or other fiber 0-90%, urethane elastic fiber and other elastic fiber 0-50%. The invention also discloses the manufacture method including the following steps: selecting the fiber ingredients; spinning after mixing the raw material; weaving on the knitting great circle machine; dyeing and after processing. The advantage of the invention is good warm effect, soft tactility and comfort.

Owner:DONGHUA UNIV

Underclothing fabric and processing technique thereof

InactiveCN102031624AGood warmth retentionGood skin affinityWeft knittingDyeing processYarnAcrylic fibre

The invention relates to an underclothing fabric which comprises the following raw materials in percentage by weight: 4-18% of heating fiber, 30-52% of anti-pilling acrylic fiber, 35-40% of Lenzing Modal fiber, 4-6% of nylon fiber and 3-5% of Lycra elastic fiber. The processing technique comprises the following steps: spinning the heating fiber, the anti-pilling acrylic fiber and the Lenzing Modal fiber into sirospun yarns, coating the Lycra elastic fiber with the sirospun yarns and the nylon fiber, weaving with a circular weft knitting machine, carrying out dyeing pretreatment, dyeing, cleaning, neutralizing, fixing, soaping, softening, drying, scutching, sanding, shaping and the like. The underclothing fabric has favorable warm-keeping effect, has the advantages of good skin friendliness, low pilling possibility, easeful elasticity and high air permeability and is comfortable to wear.

Owner:格来德服饰贸易(上海)有限公司 +1

Underwear fabric and production method thereof

InactiveCN102454025AChic appearanceIn line with the development trendWeft knittingBiochemical fibre treatmentYarnEngineering

The invention relates to underwear fabric and a production method thereof. The underwear fabric comprises blended fiber, cotton fiber and elastic spandex fiber. The blended fiber comprises 3-30% by weight of heating fiber, 20-40% by weight of acrylic fiber and 35-40% by weight of modal fiber. The cotton fiber accounts to 4-20% by weight, and the elastic spandex fiber accounts to 5-10% by weight. The underwear fabric is formed by spinning yarn, weaving and post-processing. The underwear fabric disclosed by the invention has strong anti-pilling performance and skin friendliness, comfortable elasticity and good warm keeping effect, contains five kinds of different fibers, has unique structure, style and appearance and complies with the fabric development trend.

Owner:CHANGSHU XINTEDU GARMENTS

Preparation method of biological type elastic fabric made of silk floss

InactiveCN103382597AFlat surfaceSoft touchBiochemical fibre treatmentHeating/cooling textile fabricsYarnEngineering

The invention relates to an elastic fabric made of silk floss, in particular to a preparation method of a biological type elastic fabric made of silk floss. The preparation method comprises the following steps: weaving yarns, preparing and weaving warp beams, carrying out pretreatment, carrying out dyeing treatment, and shaping. The elastic fabric made of silk floss prepared by adopting the preparation method has the advantages that the surface is smooth, the hand feeling is soft, the anti-pilling tendency, washability and hygroscopicity are good, the elasticity and elasticity recovering performance are comfortable, meanwhile, the cloth cover has unique appearance effects like clouds and running water due to a special drawing technology.

Owner:富丽达集团控股有限公司

Newdal fibre inner wear face fabric and processing technique thereof

The present invention relates to Newdal fiber underwear fabric, and is characterized in that the present invention is composed of raw materials having the following weight percentages: 45 percent to 52 percent of Newdal fiber, 45 percent to 52 percent of cotton fiber, and 3 percent to 8 percent of Lycra elastic fiber. The processing craft is that the Newdal fiber and the cotton fiber are firstly blended for spinning, and then are interwoven with the Lycra elastic fiber, so as to make the underwear fabric. The present invention has the advantages of better gloss, skin-friendly property, smooth hand feeling and comfortable flexibility.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

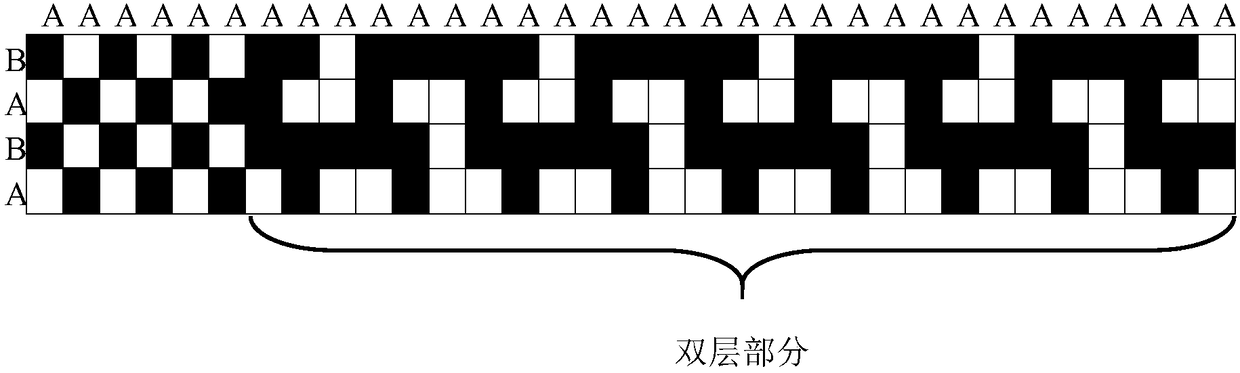

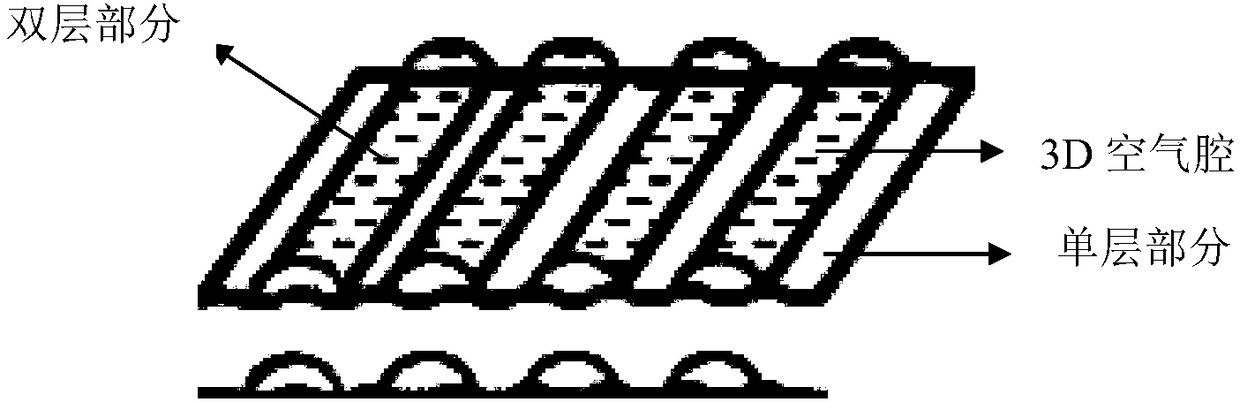

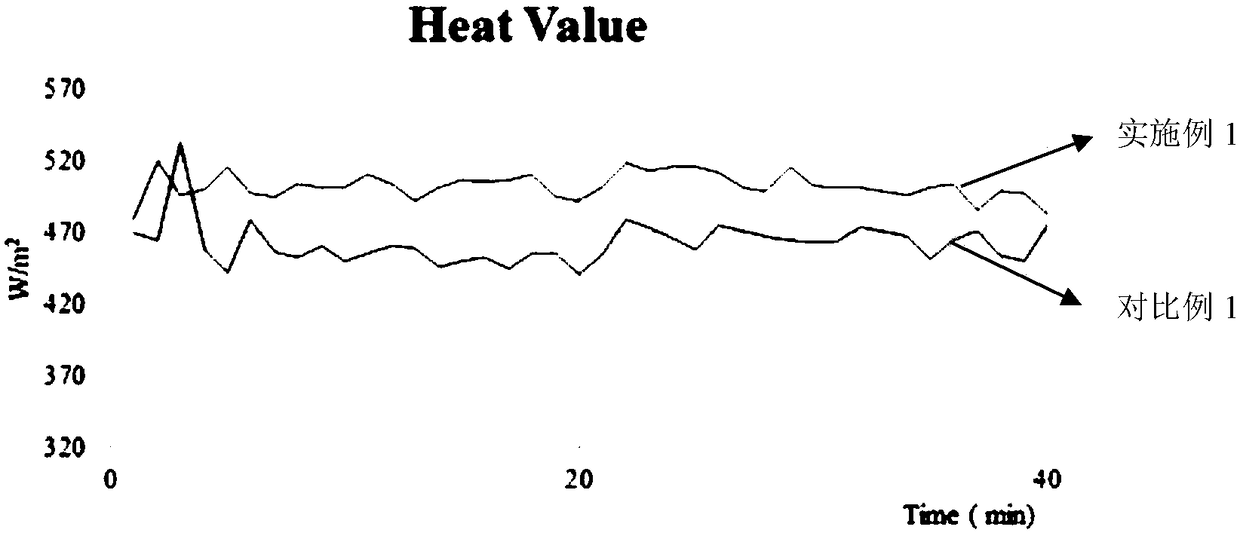

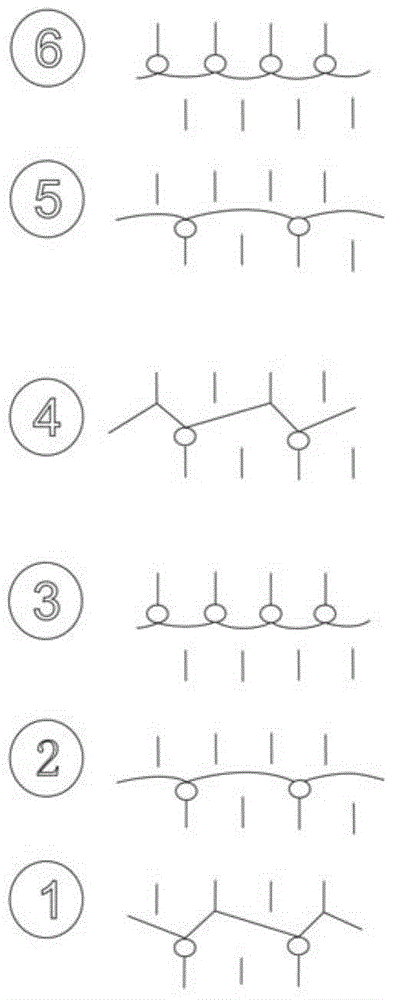

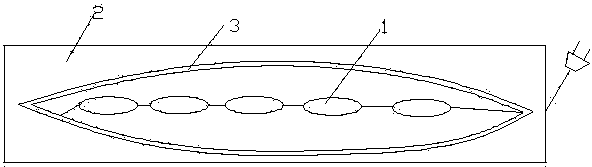

3D flame-retardant fabric and heat protection garment thereof

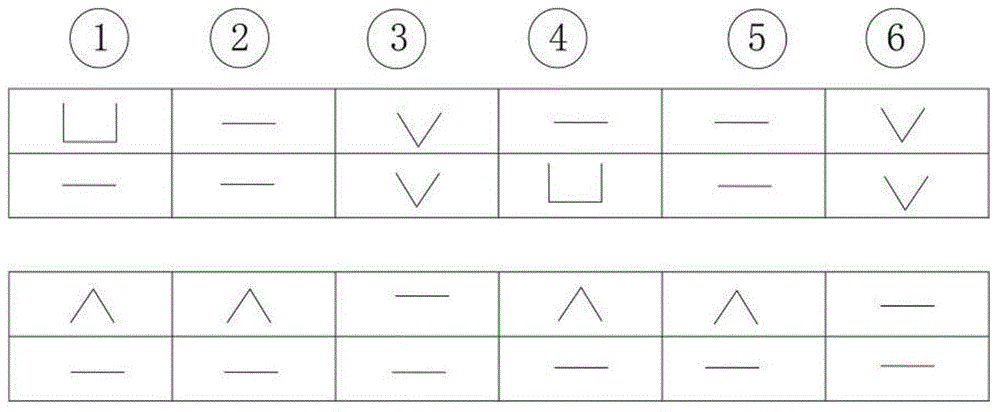

PendingCN108385241AImprove barrier propertiesEnhanced convective heatWarp knittingWoven fabricsSurface layerEngineering

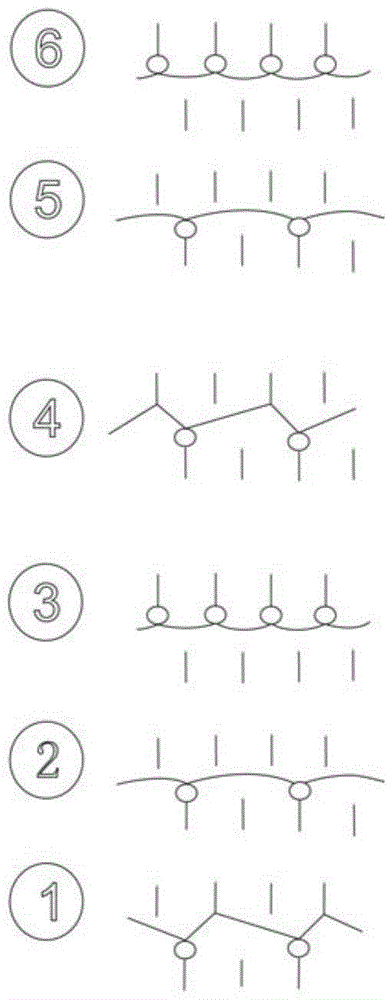

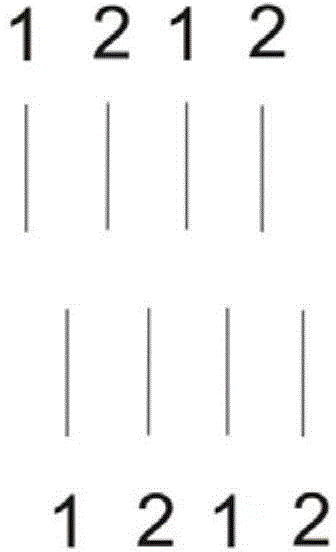

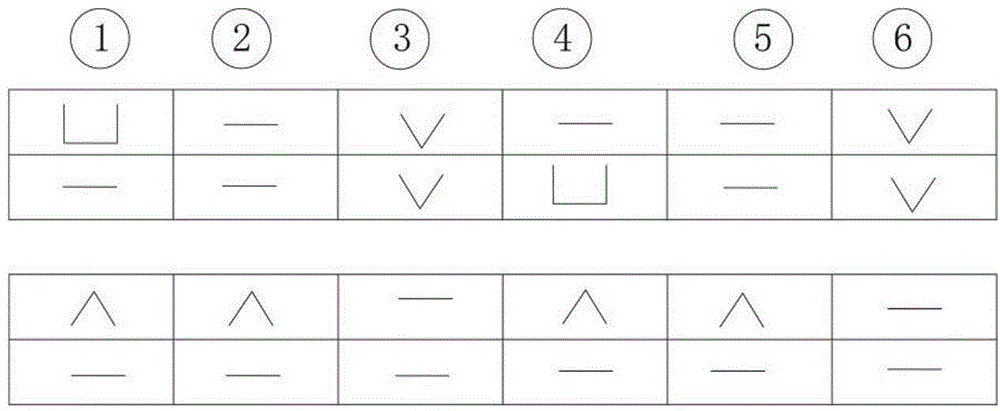

The invention discloses 3D flame-retardant fabric and a heat protection garment thereof. The fabric comprises a single-layer portion and a double-layer portion which are in parallel and alternate arrangement. The fabric is made of high-performance flame-retardant yarns and flame-retardant elastic covering yarns, and is formed through interweaving of the yarns by a weaving or warp knitting technology according to a weave diagram. The double-layer portion comprises a surface layer and an inner layer which are completely separated from each other. The inner layer is made of the high-performance flame-retardant yarns and the flame-retardant elastic covering yarns. The surface layer is made of the high-performance flame-retardant yarns. Through arraying of connection joints of the single-layerportion and the double-layer portion under the action of the flame-retardant elastic covering yarns, the surface layer and the inner layer are different in stress rebound resilience of raw materials,and are separated from each other, so that a 3D air cavity protrusion structure is formed at the separation position. The heat protection garment comprises the 3D flame-retardant fabric, or comprisesa heat-insulating comfort layer, a waterproof breathable layer and a flame-retardant outer layer from inside to outside sequentially. The heat-insulating comfort layer, the waterproof breathable layerand the flame-retardant outer layer are made of the 3D flame-retardant fabric.

Owner:北京邦维普泰防护纺织有限公司

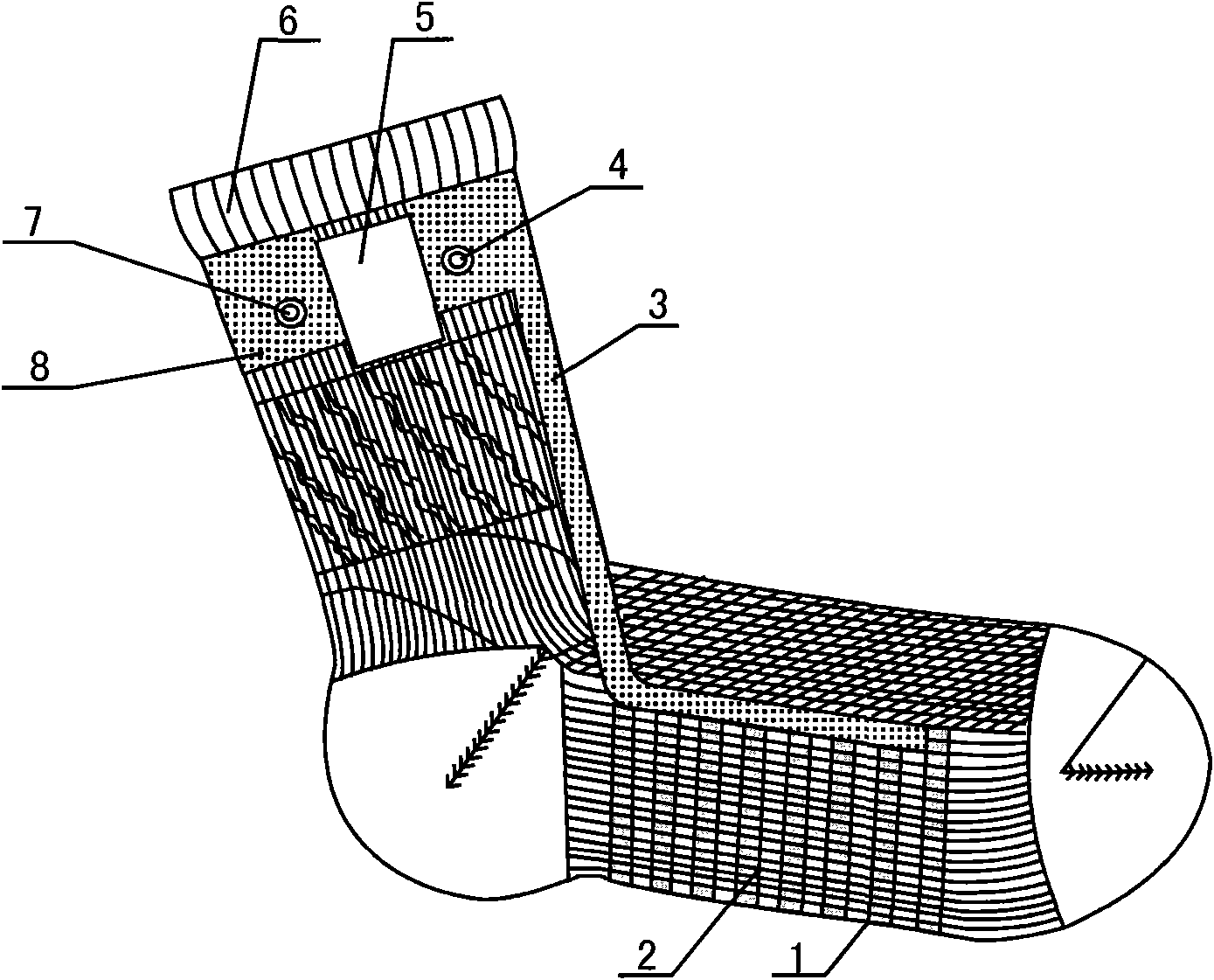

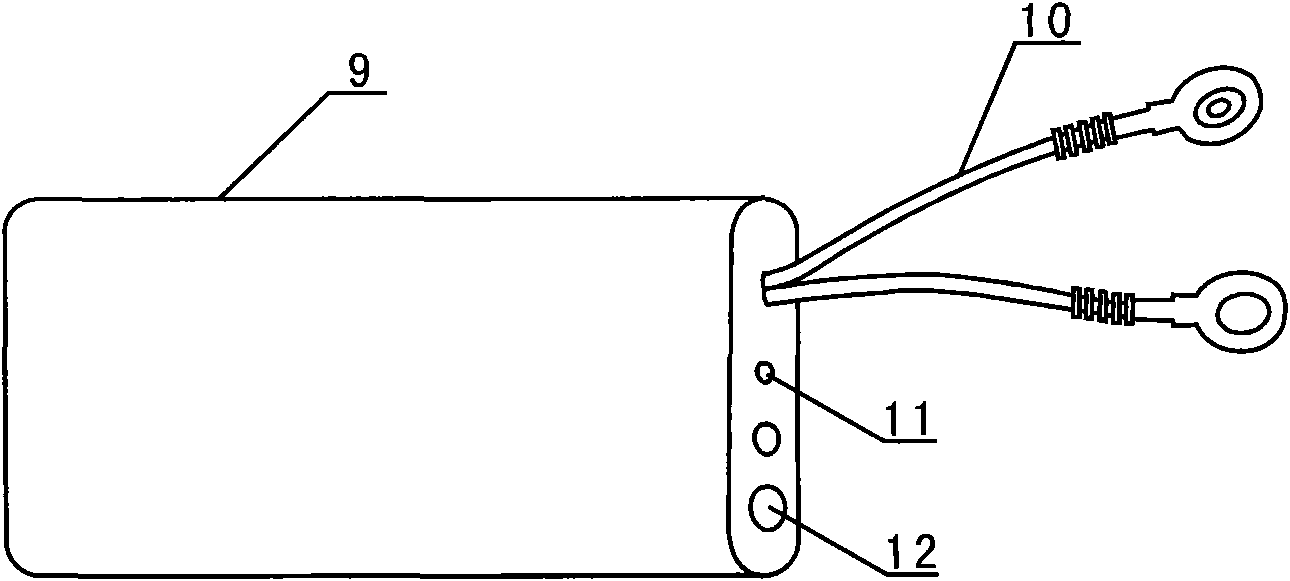

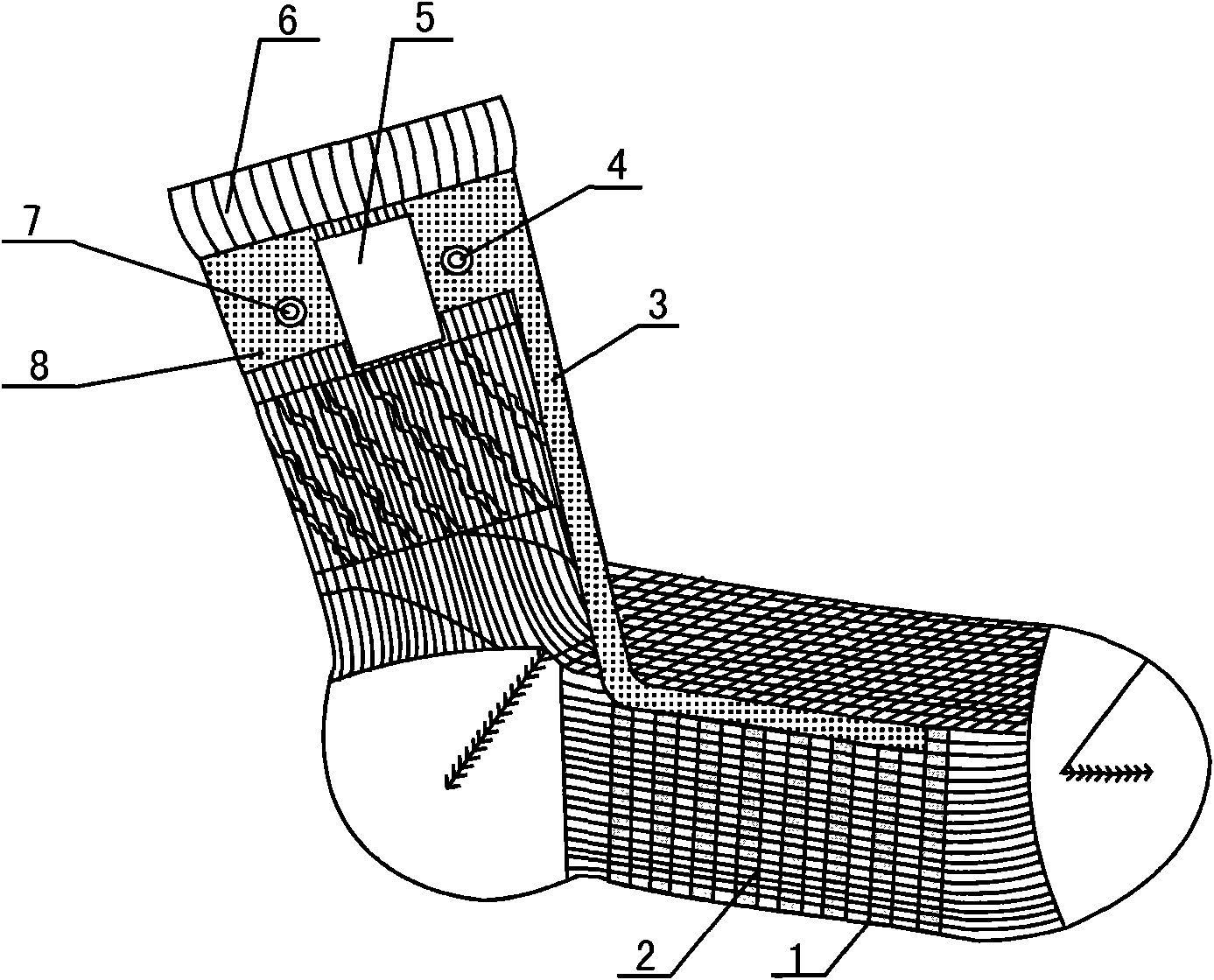

Heating health care socks and processing method thereof

InactiveCN101878961ASoft touchComfortable elasticPanty-hoseHosieryConductive yarnElectrically conductive

The invention relates to heating health care socks and a processing method thereof. The sock consists of a sock boy and a power supply configuration. Conventional sock material and electric conductive yarns are woven into the sock body and a heating body is formed at a vola part through a jacquard technology. An electric conductive belt is respectively formed along the two side edges of the heating body to a sock leg. The electric energy input ends of the two electric conductive belts are respectively provided with a terminal. The space of the two terminals is provided with a bag for placing the power supply configuration. A connecting line extending out of the power supply configuration and is buckled with the terminal to form a heating control system. The heating health care socks based on the invention keep the original knitting performance of the socks, which are comfortable, have no foreign body sensation and can be heated actively, i.e. the heating, moisture transmitting, ventilation, warming and comfortable property is harmonious with the heat of feet and has health care heat treatment extension effect which is favorable to human body health. The invention has strong practicality, good popularization value and market foreground.

Owner:陆思烨

Preparation method of gelatin/plant polysaccharide composite hemostatic sponge

ActiveCN107349458AImprove suctionGood hemostatic effectSurgical adhesivesChemistryNormal platelet morphology

The invention discloses a preparation method of gelatin / plant polysaccharide composite hemostatic sponge. The preparation method of the gelatin / plant polysaccharide composite hemostatic sponge is characterized by comprising the following steps: S1, dissolving gelatin in hot water, adding plant polysaccharide solution into the gelatin solution, and carrying out mixing and stirring reaction; and S2, transferring the reaction liquid after the mixing and stirring reaction into a mould, carrying out low-temperature freeze drying, and carrying out heat treatment, thus obtaining the gelatin / plant polysaccharide composite hemostatic sponge. The sponge prepared by adopting the preparation method disclosed by the invention has excellent hemostatic property, and can rapidly absorb liquid when contacting a wound, the aggregation of blood platelets and hemoglobin is accelerated, bleeding is stopped rapidly, and the bleeding stopping time is less than or equal to 60 seconds.

Owner:沈阳米尔生物科技有限公司

Novel elastic yarn

The invention discloses novel elastic yarn which comprises an elastic yarn core and external wrapping yarn. The external wrapping yarn is wound around the elastic yarn core, the elastic yarn core is elastic yarn made of spandex fibers, the elastic yarn core is provided with a plurality of pieces of the elastic yarn, and the external wrapping yarn is a silk thread formed by blending dacron high stretch yarn and cotton fibers. Through the mode, according to the novel elastic yarn, the elastic yarn core is provided with the elastic yarn, high safety performance is achieved, the dacron high stretch yarn is included in the external wrapping yarn, remaining yarn is still kept elastic when part of the yarn is broken, and silk stockings or elastic trousers made of the novel elastic yarn are good in breaking resistance, comfortable in elasticity, long in service life and high in cost performance.

Owner:WUJIANG BEISHENG TEXTILE

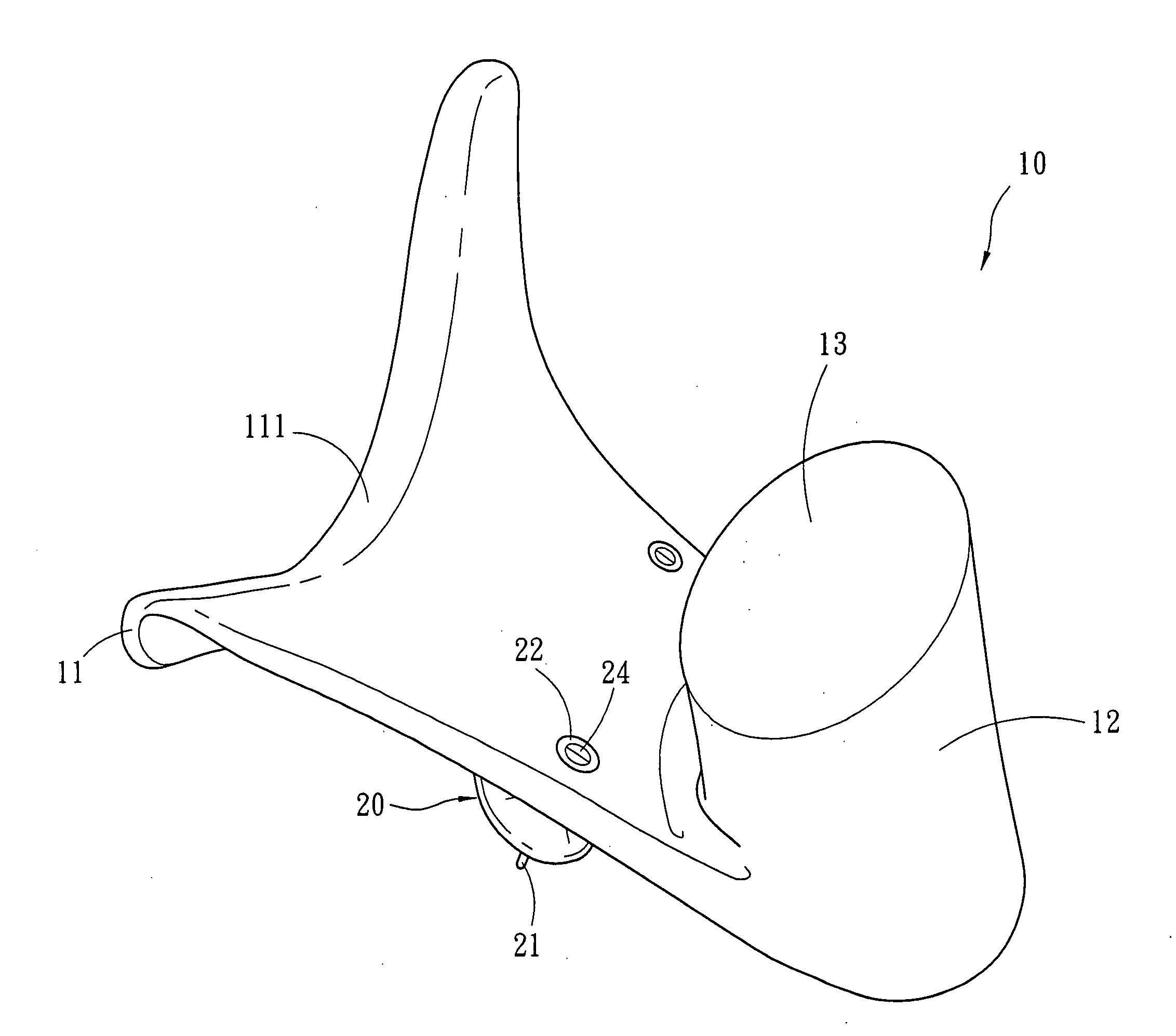

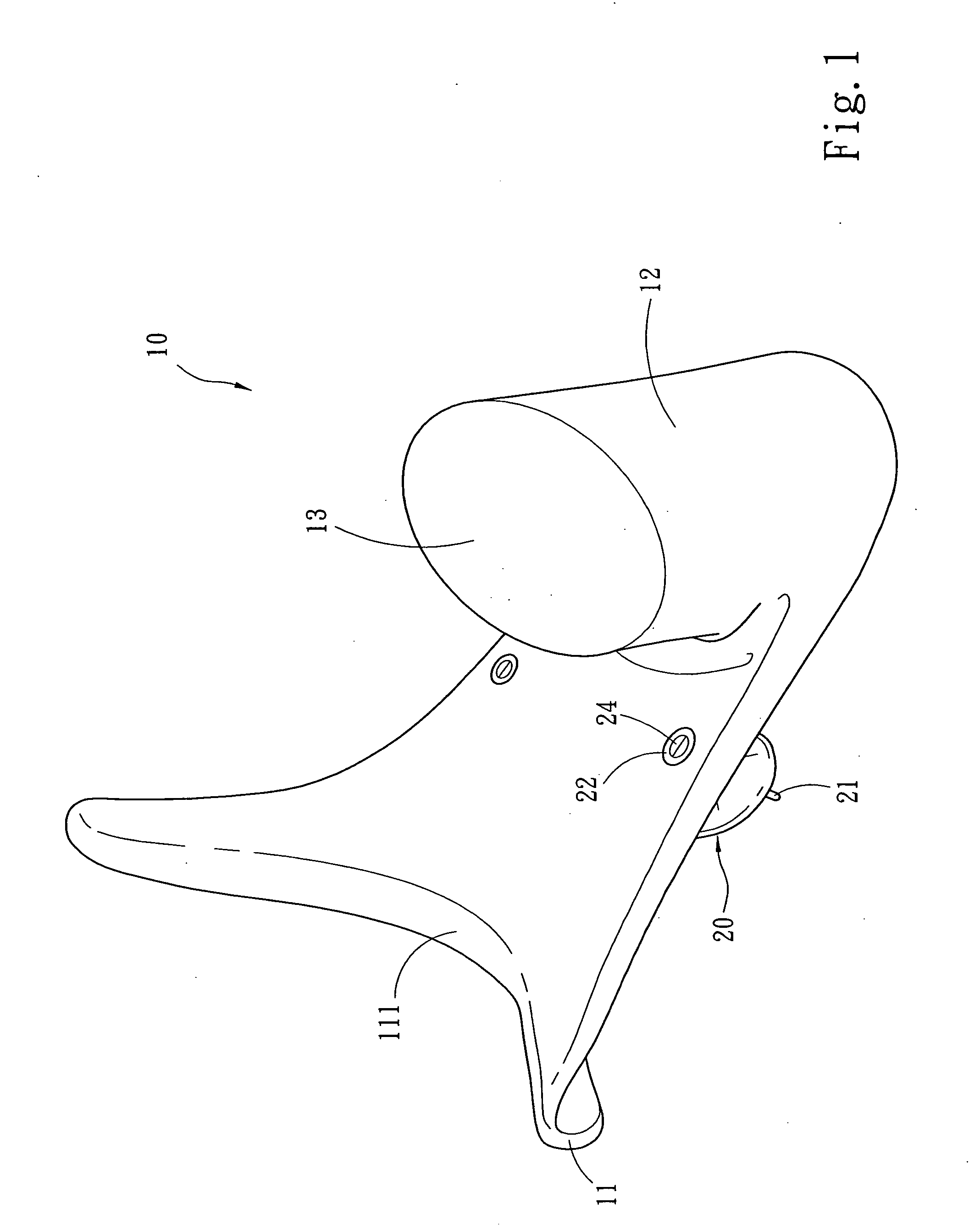

Support base of shampoo basin

InactiveUS20050283901A1Comfortable support base designComfortable elasticPackaging toiletriesPackaging cosmeticsEngineeringErgonomics in Canada

The present invention discloses an improved support base of a shampoo basin, and the support base is made of a silicon gel material to further comply with the comfort pursued by ergonomics by taking an evacuation measure for the internal structure of the support base to achieve a more comfortable elasticity of the support base. The support base comprises a saddle section and a support section; wherein the saddle section comprises a latch groove for being latched to the edge of the shampoo basin and the surface of the latch groove having a plurality of gaps, and an evacuated space disposed inside the support section, so that the design of the gaps and evacuated space produces a comfortable elasticity when our neck and head rest on the saddle section and the support section.

Owner:CHENG HSIEN YANG

Wear-resisting anti-bacteria stretch yarn

The invention discloses a wear-resisting anti-bacteria stretch yarn. The wear-resisting anti-bacteria stretch yarn is formed by proportionally mixing polyethylene glycol terephthalate, polyurethane, nano-silver and additives. The additives include an antioxidant, an ultraviolet light absorber and a slipping agent. The wear-resisting anti-bacteria stretch yarn comprises, by weight, 85 parts to 100 parts of polyethylene glycol terephthalate, 15 parts to 25 parts of polyurethane, 0.3 part to 0.5 part of nano-silver and 5 parts to 8 parts of additives. In this way, according to the wear-resisting anti-bacteria stretch yarn, the antibacterial activity and the wear resistance of the stretch yarn are improved by adding the nano-silver particularly, the manufactured stretch yarn is elastic and comfortable, the anti-bacteria and odor-resistant effects are achieved, and the manufactured silk stockings are good in wear resistance and long in service life.

Owner:TAICANG TIANLONG CHEM FIBER

Moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric and preparation method thereof

ActiveCN103952845BDoes not affect hydrophilicityGood moisture permeabilitySucessive textile treatmentsWeft knittingYarnPolyester

A moisture-absorbing heat-generating quick-drying moisture-retaining thermal fabric and manufacturing method thereof; the fabric is woven by a first yarn, a second yarn, a third yarn and a fourth yarn; the first yarn is regenerated cellulose fiber-type blended yarn made by blending regenerated cellulose fiber with one or more of linen, wool or cashmere, and cotton fiber, or is regenerated cellulose long fiber yarn or regenerated cellulose staple fiber yarn; the second yarn is modified polyester fiber yarn having a non-circular cross section; the third yarn is cotton fiber-type blended yarn made by blending cotton fiber with one or two of polyester staple fiber or polyacrylonitrile fiber, or is all-cotton yarn; and the fourth yarn is polyurethane fiber yarn. The fabric has a moisture-absorption heat-generation value above the national standard, and good moisture-absorption and quick-drying properties, and a thermal value meeting the national standard, and also has comfortable resilience, and a soft, smooth feel of the surface contacting the skin. In addition, the manufacturing method has a simple process and is easy to operate.

Owner:武汉爱帝针纺实业有限公司

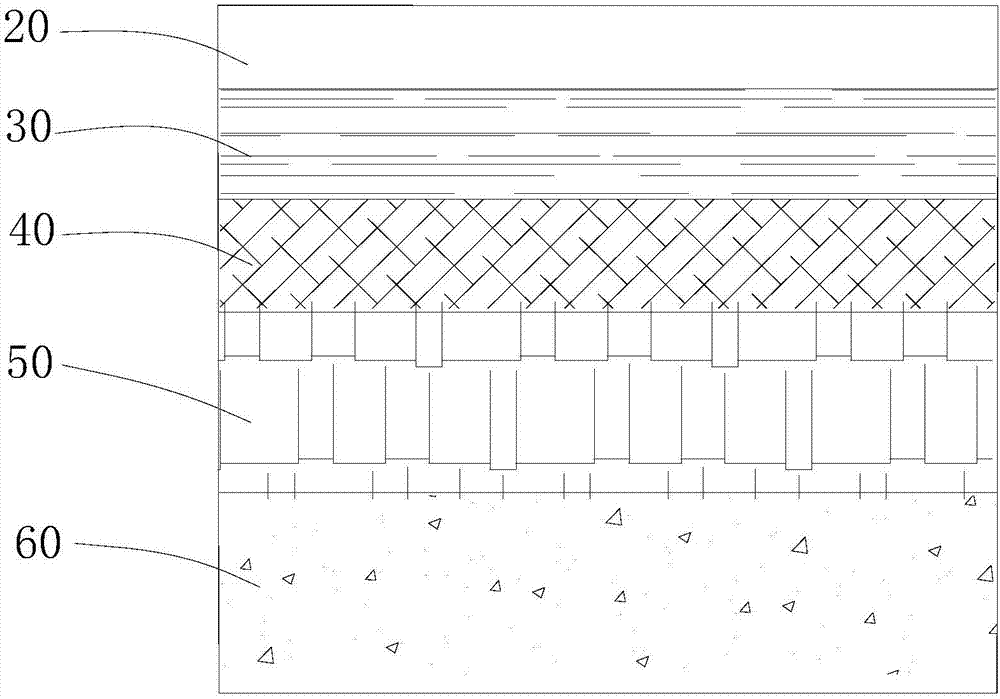

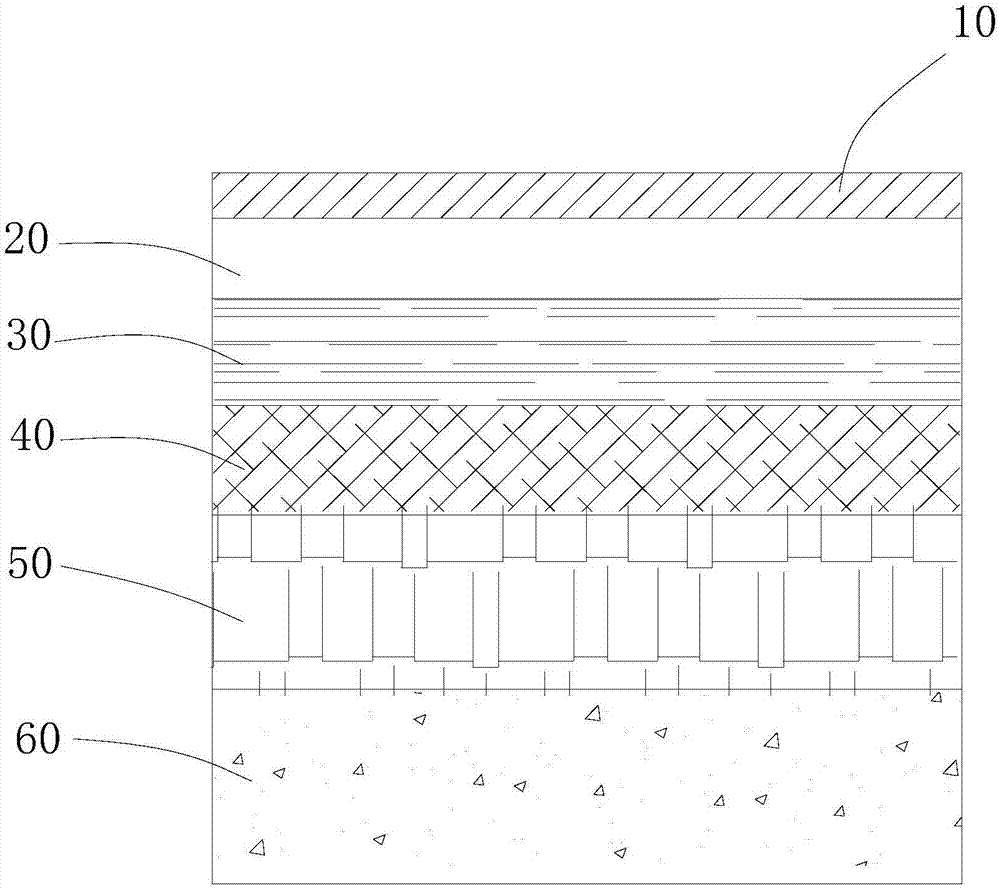

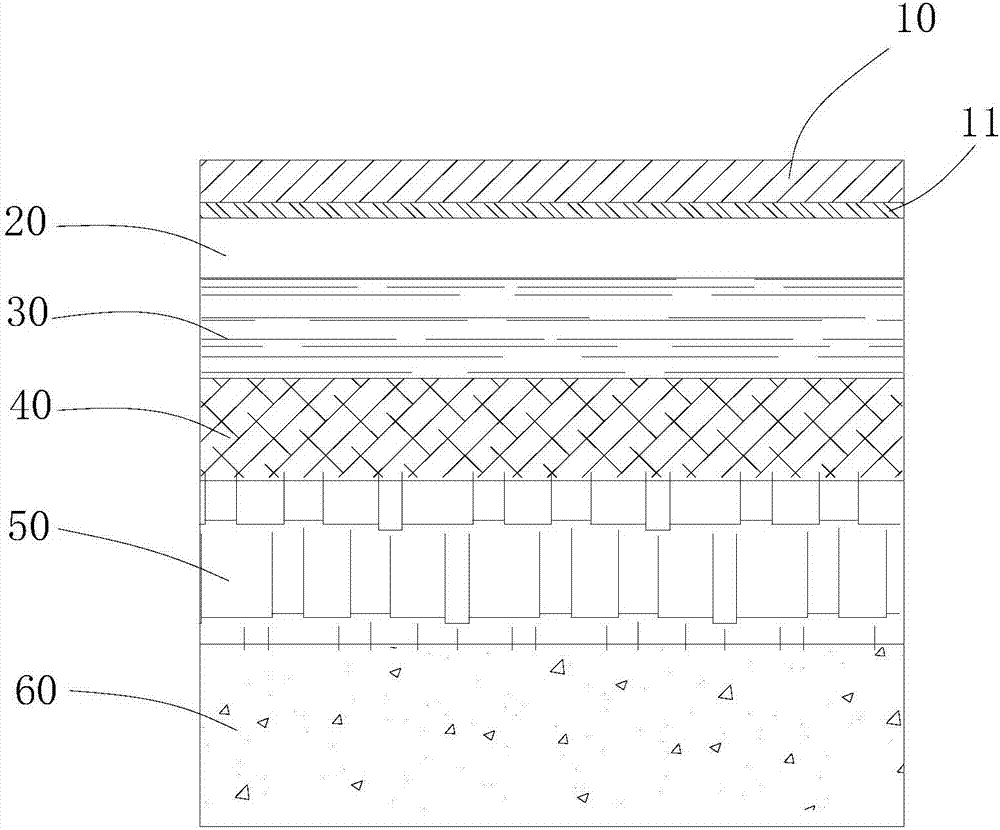

Environment-friendly road surface and construction method thereof

PendingCN107974892APrevent leakageReduce air pollutionIn situ pavingsEnvironmental resistanceEngineering

The invention discloses an environment-friendly road surface and meanwhile discloses a construction method of the environment-friendly road surface. The pitch road surface comprises a bottom base layer (60), a base layer (50), a pitch lower layer (40), a pitch middle layer (30) and a pitch upper layer (20) from bottom to top. The pitch upper layer (20) is further covered with a concrete sealing layer (10) with the thickness being smaller than or equal to 3 cm and for preventing harmful gas of the pitch road surface from leaking in a bonded mode. The harmful gas volatilized by the pitch road surface is sealed below the concrete sealing layer, leaking of the harmful gas is prevented, air pollution is reduced, and body health is facilitated. Through the elasticity of the pitch road surface, the problems that in the prior art, a concrete road surface is large in hardness and poor in driving comfort are solved.

Owner:唐华国

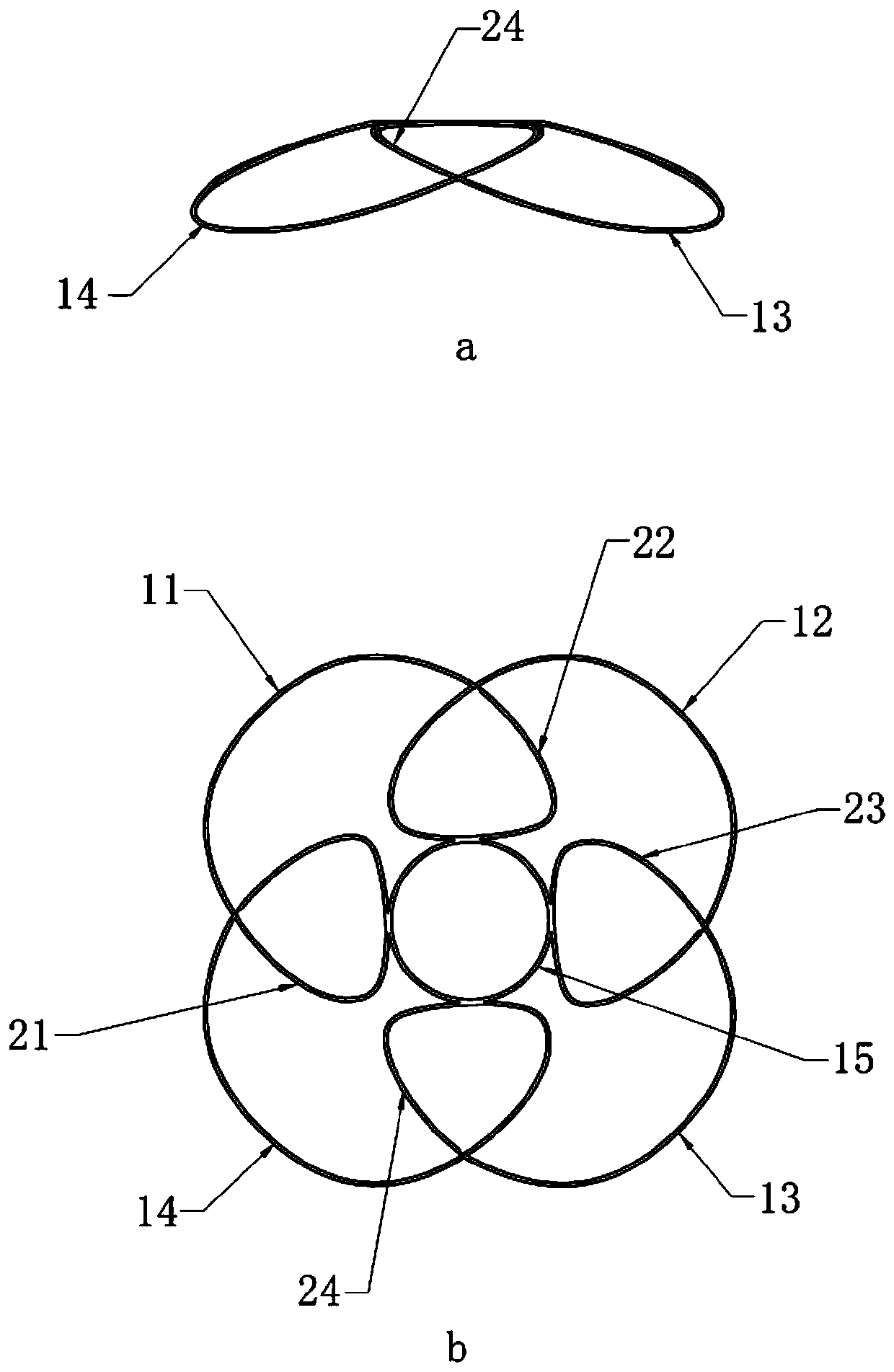

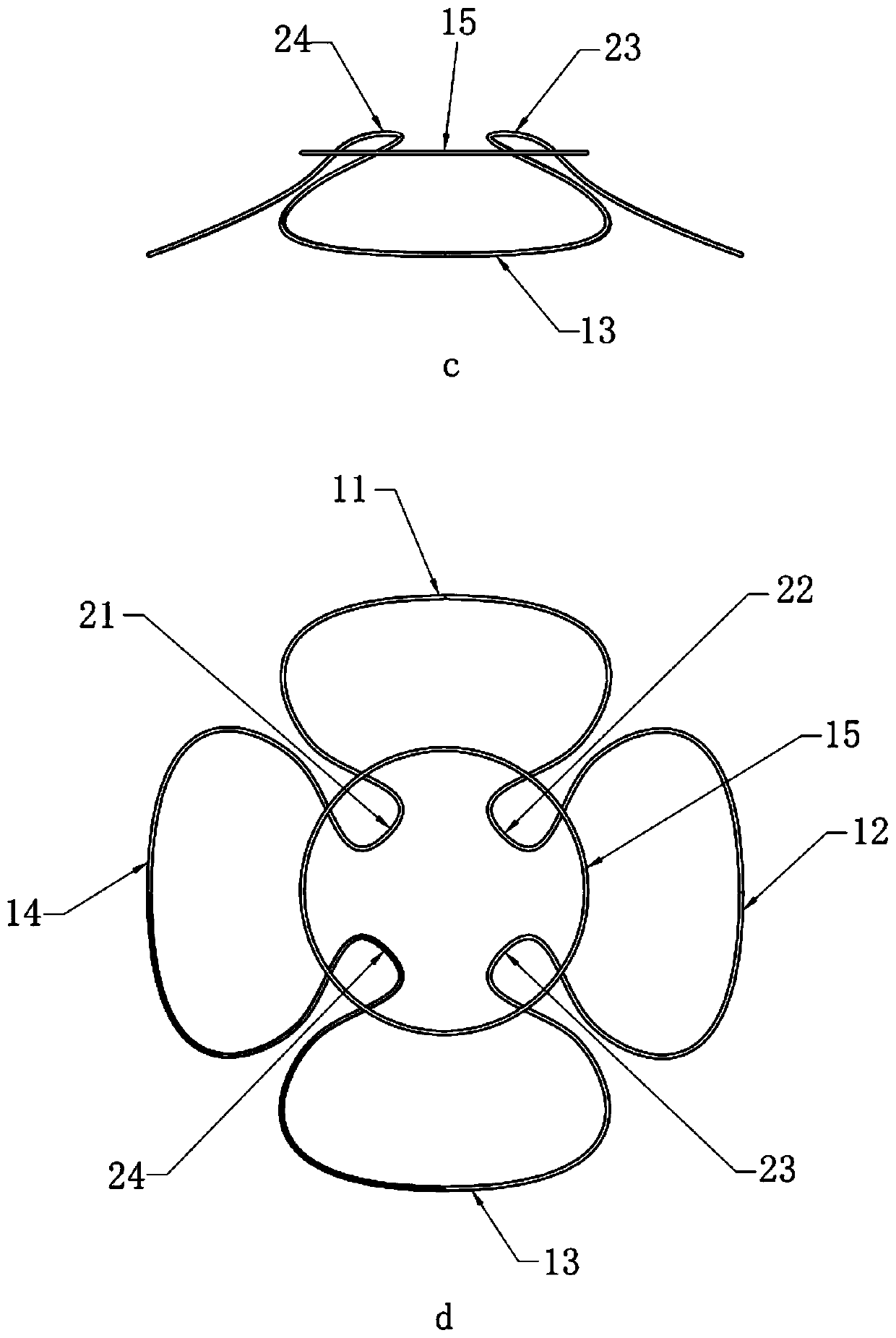

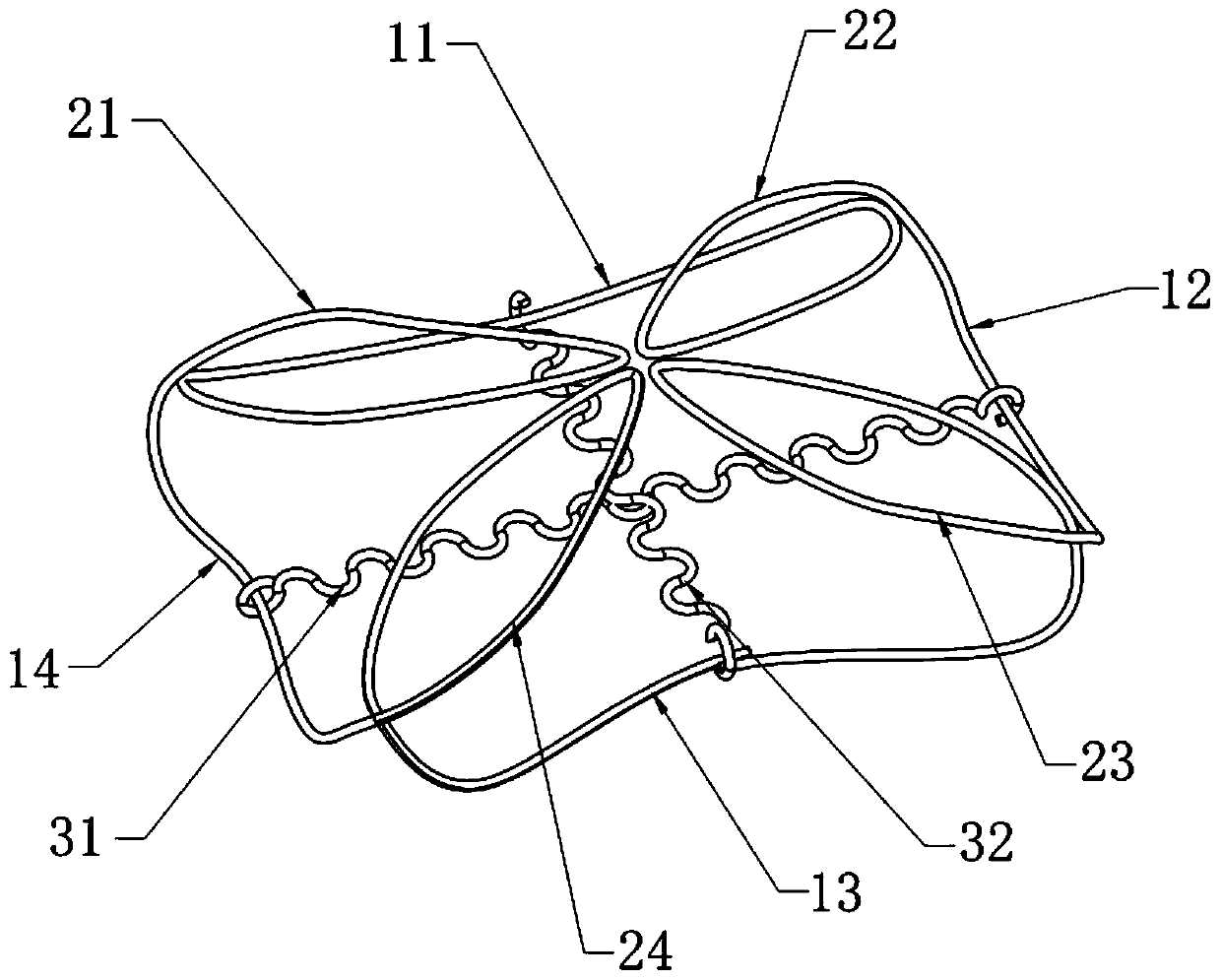

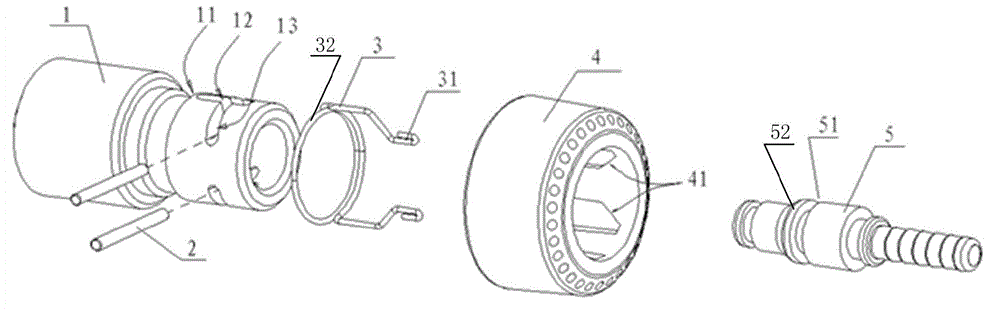

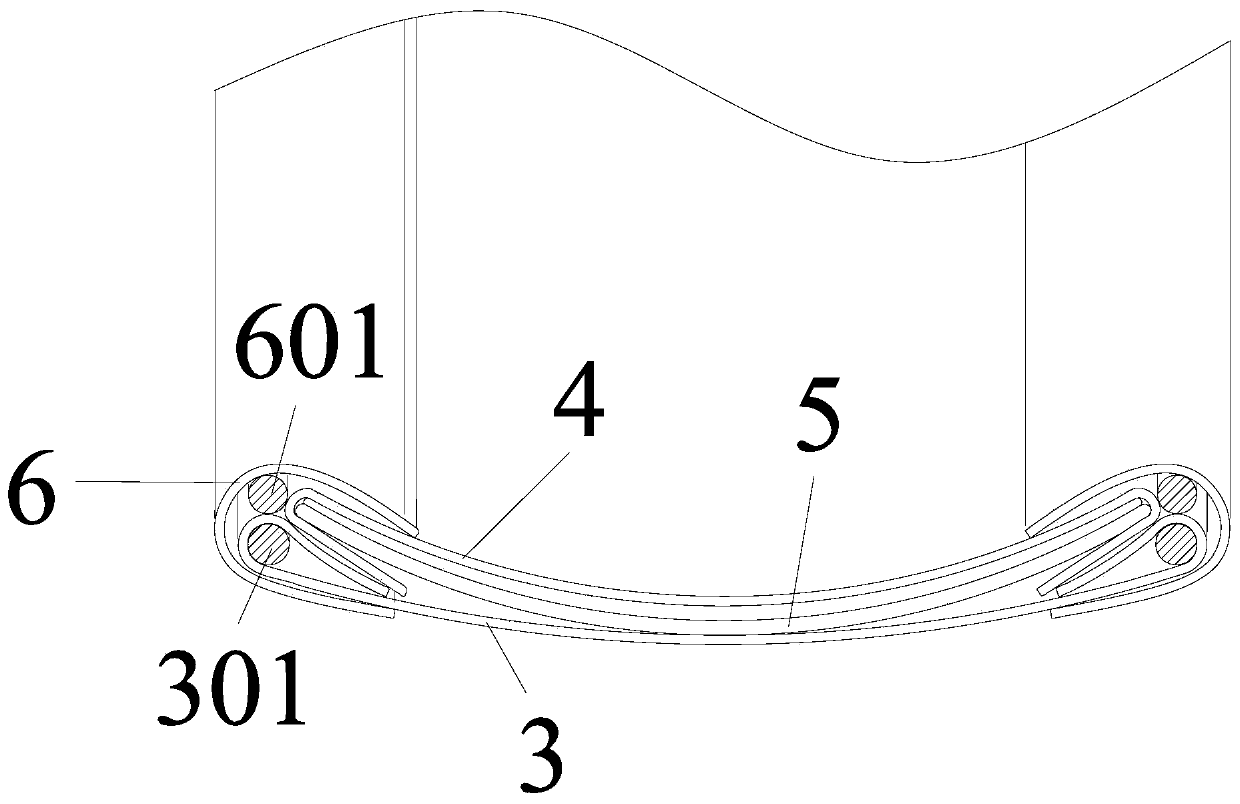

Three-dimensional elastic part

The invention relates to the technical field of furniture accessories and particularly relates to a three-dimensional elastic part, which comprises a first connecting part, a second connecting part, athird connecting part, a fourth connecting part, a first arc-shaped supporting part, a second arc-shaped supporting part, a third arc-shaped supporting part and a fourth arc-shaped supporting part, the bent end of the first arc-shaped supporting part, the bent end of the second arc-shaped supporting part, the bent end of the third arc-shaped supporting part and the bent end of the fourth arc-shaped supporting part are all arranged in an upward inclined mode. According to the invention, curve overlapping deformation is carried out on the steel part after heat treatment; therefore, the four arc-shaped supporting parts have flexible deformation; the four arc-shaped supporting parts can correspondingly and irregularly deform according to the curve contact surface of a human body; therefore, it is ensured that all parts of the human body can make contact with the arc-shaped supporting parts in an attached mode, the four arc-shaped supporting parts can provide more flexible elastic supporting for the human body and quickly disperse the gravity of the human body, and therefore more comfortable contact feeling is provided for the human body.

Owner:刘长权

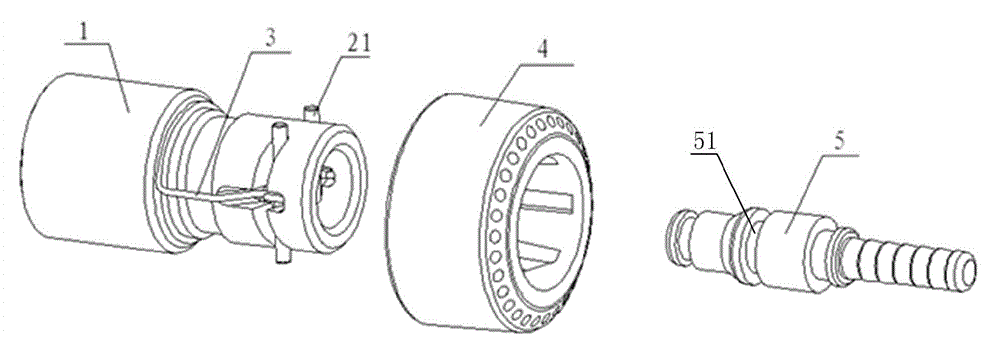

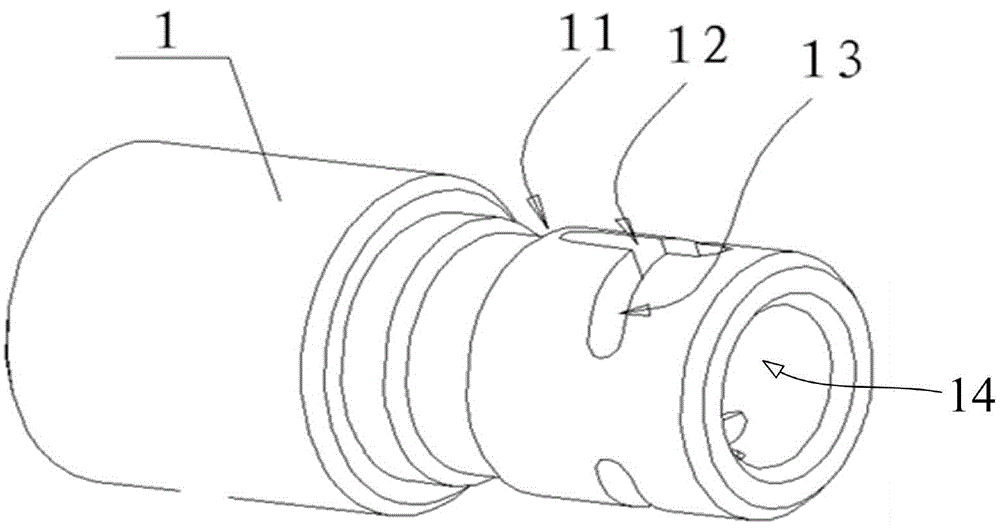

Fast-inserting connecting device and assembling method thereof

Owner:SHANGHAI YILI ELECTRIC

Shell fabric for energized massage

The invention discloses a shell fabric for energized massage. The shell fabric comprises a shell fabric body and massager arranged inside the shell fabric body, wherein one end of the massager is connected with a socket, the shell fabric body comprises an elastic comfortable shell fabric layer at an upper surface, an elastic comfortable shell fabric layer at a lower surface and an insulating electricity preventing layer which wraps the surfaces of the massagers, the elastic comfortable shell fabric layers are formed through blending and weaving mohair fibers and bast fibers, the insulating electricity preventing layer is made from polystyrene plastics, and the massagers are formed by a plurality of series-connected shaking rods. Through blending and weaving the mohair fibers and the bast fibers, the formed shell fabric has the functions of static electricity prevention and comfortable elasticity; due to the adoption of the insulating electricity preventing layer which is made from the polystyrene plastics, the shell fabric has the functions of static electricity insulation and prevention; the massagers are mounted inside the shell fabric, so that the shell fabric can help people to massage bodies and relieve stress, thereby playing a health caring effect on the bodies.

Owner:WUJIANG FENGYI TEXTILE

Swimsuit fabric

InactiveCN103300518AGood skin affinityGood moisture-wicking effectLayered productsWoven fabricsFiberBiochemical engineering

The invention discloses a swimsuit fabric which comprises a fabric base layer; the fabric base layer comprises warps and wefts; an air permeable layer is arranged on the surface of the fabric base layer; the fabric base layer and the air permeable layer are compounded together through an environmental-friendly adhesive; the warps are formed by blending mulberry silk and soybean fibers; the wefts are PTT fibers; and the air permeable layer is formed by blending milk fibers and bamboo fibers. The swimsuit fabric is reasonable in structure, and is simple in manufacturing process; the air permeable layer has stronger wet permeability and excellent air permeability; in high-temperature bright light, steam on the surface of the skin is convenient to give off; and the fabric base layer has comfortable elasticity, is soft and cool, has excellent anti-pollution performance, and is higher in light fastness.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

Low-shrinkage-rate blend fiber

The invention discloses a low-shrinkage-rate blend fiber. The low-shrinkage-rate blend fiber is formed by blend weaving of a first fiber and a second fiber; the first fiber is made by blend weaving of polynosic, viscose, a polypropylene fiber and a polyamide fiber; the second fiber is made by blend weaving of a polyvinyl formal fiber and a polyacrylonitrile fiber. The low-shrinkage-rate blend fiber has advantages of low shrinkage rate, elasticity, comfort, crease resistance, high wear resistance and high strength.

Owner:太仓市天茂化纤有限公司

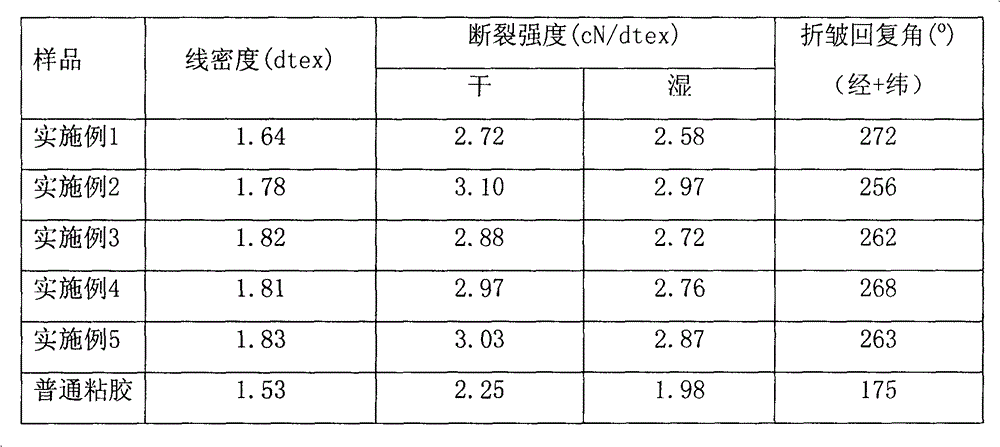

High elastic non-ironing cellulose fiber and preparation method thereof

ActiveCN102199803BEvenly dispersedAvoid failureArtificial filaments from cellulose derivativesCross-linkPolymer science

Owner:QINGDAO TIANYI GROUP

Manufacturing process of bamboo charcoal fiber fabrics

InactiveCN110499571AGood development prospectsWeaken uneven stainingWeft knittingOrnamental textile articlesWater contentTitanium dioxide

The invention discloses a manufacturing process of bamboo charcoal fiber fabrics. The manufacturing process specifically includes the following steps of 1, obtaining an appropriate number of old bamboo materials at the age of 5 or above for drying to make the water content of the bamboo materials reach 20-25%; 2, putting the bamboo materials pre-dried in step 1 into an external-heating type vertical retort for firing for 48-72 hours to obtain bamboo charcoal; 3, utilizing a nano grinder to grind the bamboo charcoal obtained in step 2 into nano-scale particles, and putting the nano-scale bamboocharcoal and nano-scale titanium dioxide into a viscose spinning solution to obtaining bamboo charcoal fiber through spinning; 4, blending the bamboo charcoal fiber obtained in step 3 and cotton fiber to obtain yarn serving as base yarn; 5, utilizing blending of the cotton fiber and regenerated cellulose fiber to obtain yarn serving as veil. The manufacturing process is simple, the cost is low, the production quality is high, and compared with traditional bamboo charcoal fiber fabrics, the bamboo charcoal fiber fabrics manufactured by means of the process is more comfortable and easier to use.

Owner:无锡市奥菲超细织物有限公司

A kind of preparation method of gelatin/plant polysaccharide composite hemostatic sponge

ActiveCN107349458BGood hemostatic effectGood biocompatibilitySurgical adhesivesFreeze-dryingPlatelet

The invention discloses a preparation method of gelatin / plant polysaccharide composite hemostatic sponge. The preparation method of the gelatin / plant polysaccharide composite hemostatic sponge is characterized by comprising the following steps: S1, dissolving gelatin in hot water, adding plant polysaccharide solution into the gelatin solution, and carrying out mixing and stirring reaction; and S2, transferring the reaction liquid after the mixing and stirring reaction into a mould, carrying out low-temperature freeze drying, and carrying out heat treatment, thus obtaining the gelatin / plant polysaccharide composite hemostatic sponge. The sponge prepared by adopting the preparation method disclosed by the invention has excellent hemostatic property, and can rapidly absorb liquid when contacting a wound, the aggregation of blood platelets and hemoglobin is accelerated, bleeding is stopped rapidly, and the bleeding stopping time is less than or equal to 60 seconds.

Owner:稳得希林(杭州)生物科技有限公司

A kind of preparation method of biological type silk cotton elastic fabric

InactiveCN103382597BFlat surfaceSoft touchBiochemical fibre treatmentHeating/cooling textile fabricsYarnPolymer science

The invention relates to an elastic fabric made of silk floss, in particular to a preparation method of a biological type elastic fabric made of silk floss. The preparation method comprises the following steps: weaving yarns, preparing and weaving warp beams, carrying out pretreatment, carrying out dyeing treatment, and shaping. The elastic fabric made of silk floss prepared by adopting the preparation method has the advantages that the surface is smooth, the hand feeling is soft, the anti-pilling tendency, washability and hygroscopicity are good, the elasticity and elasticity recovering performance are comfortable, meanwhile, the cloth cover has unique appearance effects like clouds and running water due to a special drawing technology.

Owner:富丽达集团控股有限公司

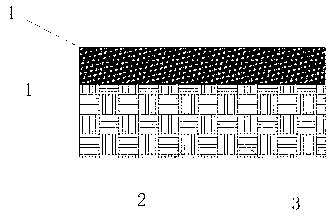

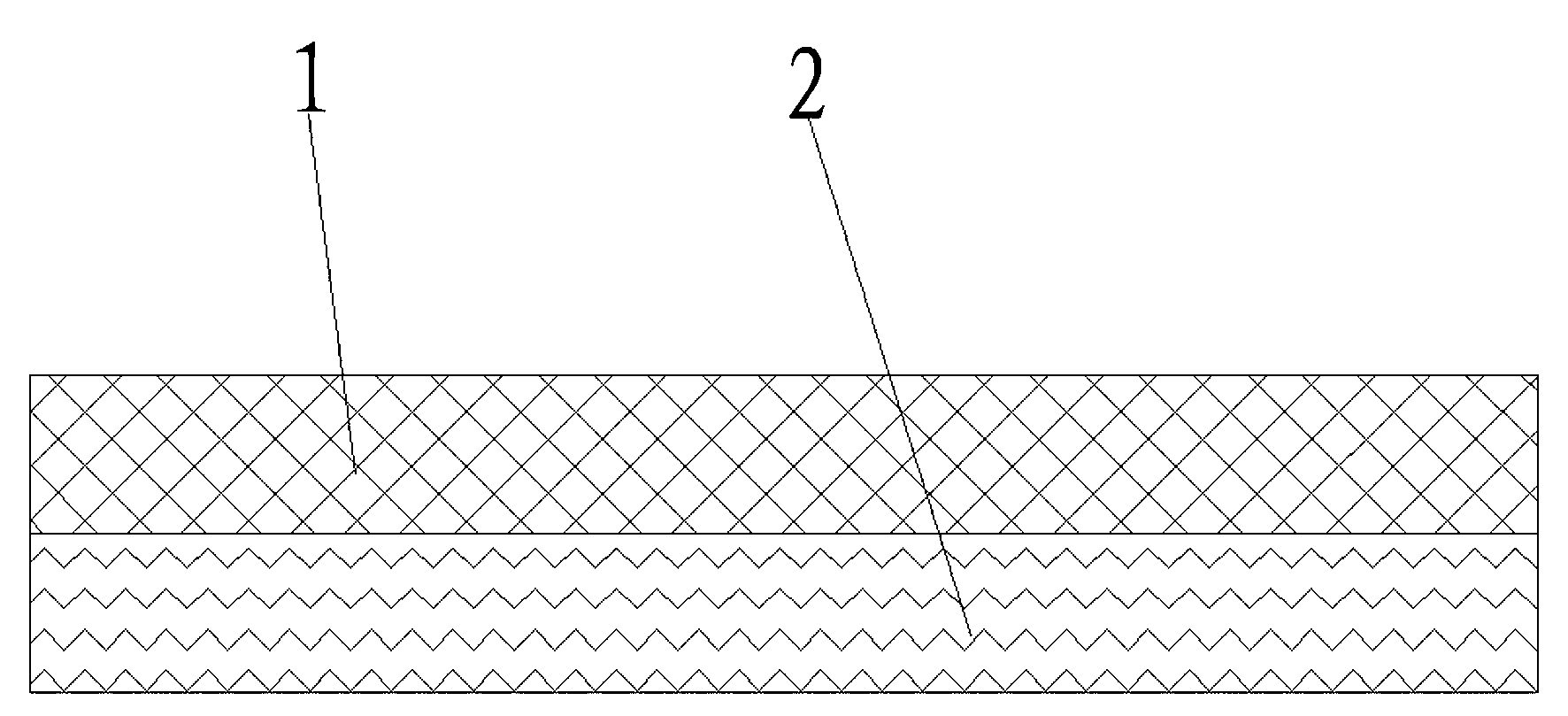

Superfine fiber mesh structure

InactiveCN102837457AWaterproof, windproof and breathableComfortable elasticLayered productsProtective garmentTextile printerEngineering

The invention discloses a superfine fiber mesh structure which comprises an upper mesh structure layer and a lower mesh structure layer, wherein the upper mesh structure layer is compounded on the surface of the lower mesh structure layer, and the upper mesh structure layer and the lower mesh structure layer are respectively weaved in a warp knitting mode. According to the technology, the superfine fiber mesh structure has the advantages of weaved tatting-simulated style, comfortable elasticity, exquisite style, waterproof wind-proof ventilating function, suitability for down-filled coat, outdoor functional fabric, various printed and knurled styles, and cloud style.

Owner:泉州维林森体育用品有限公司

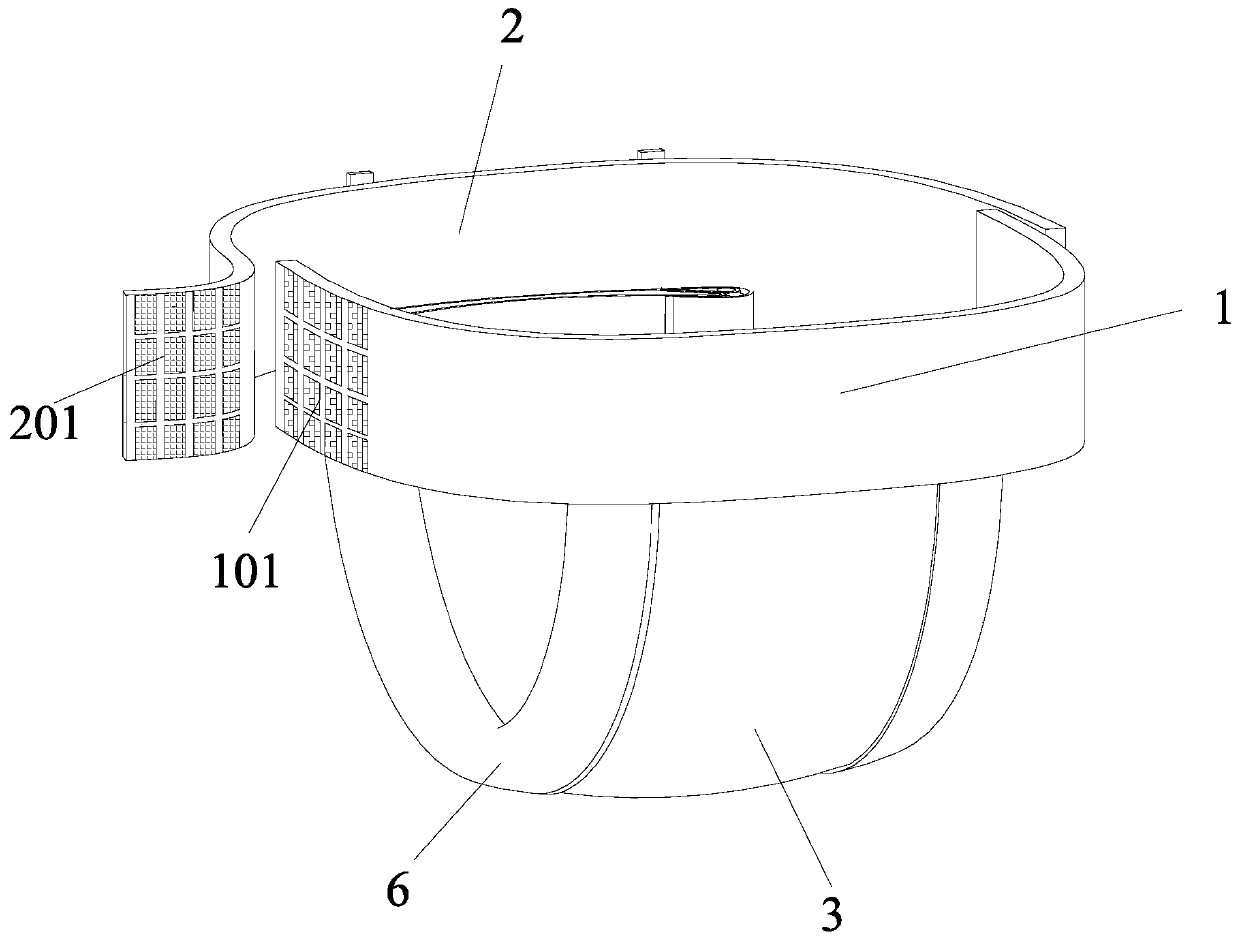

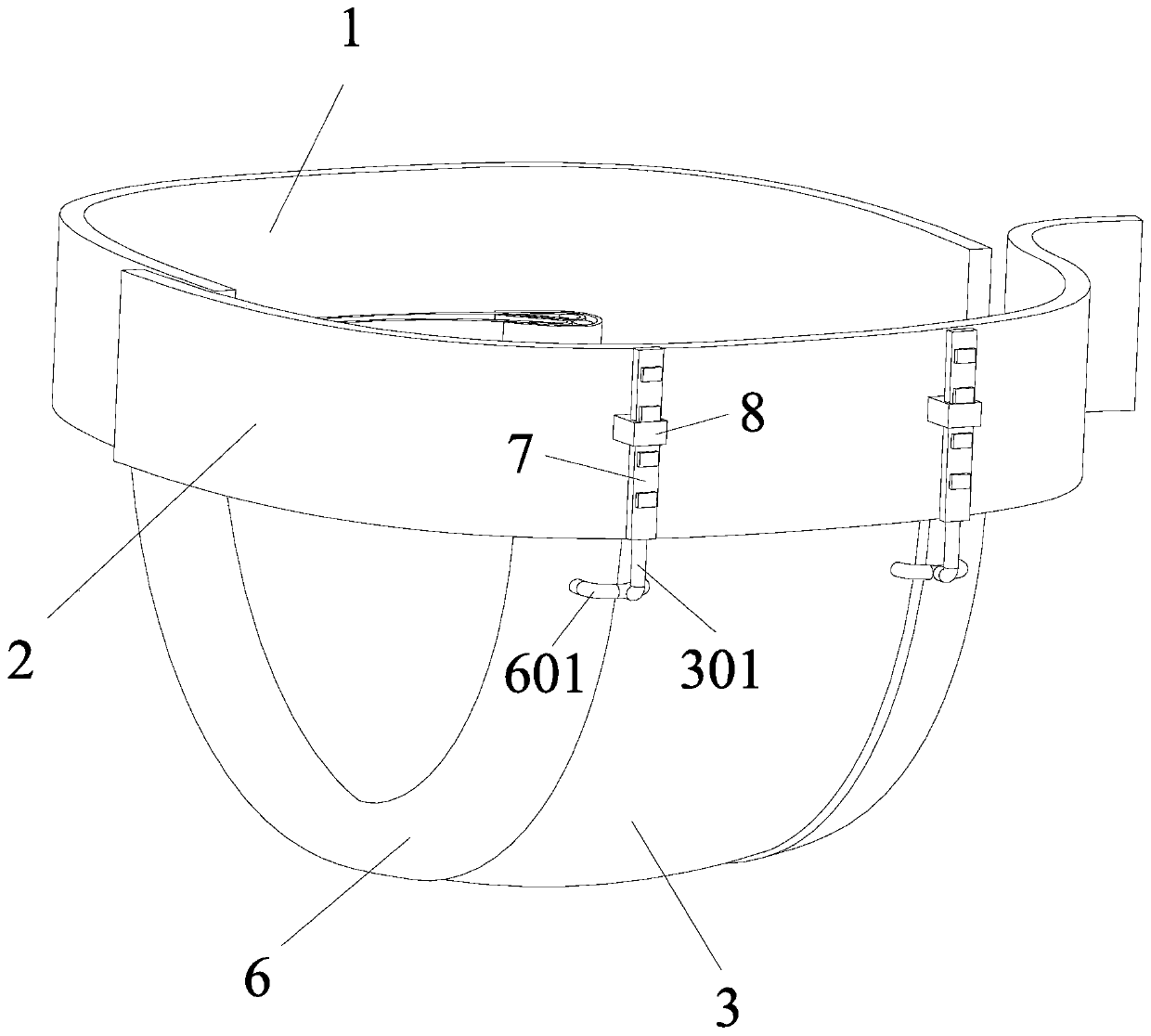

Paper diaper with openable and closable side waist

PendingCN110279524AImprove bindingEasy to wearAbsorbent padsBaby linensPulp and paper industryCrotch

The invention relates to the technical field of diapers, in particular to a paper diaper with an openable and closable side waist. The paper diaper comprises a side waist part and a crotch part, wherein the side waist part comprises a front side waist and a rear side waist which are both made of elastic non-woven fabric, hook pieces are arranged on two sides of the front side waist, fabric patches are arranged on two sides of the rear side waist, and the hook pieces on the front side waist and the fabric patches on the rear side waist are attached to form the annular side waist part. The side waist part has a 360-degree elastic waistline and also comprises the hook pieces and the fabric patches which can be firmly combined and easily separated, and wearing and replacement of the paper diaper are facilitated; the elastic non-woven fabric is adopted at the side waist part, a conventional non-woven fabric and rubber string combined process is replaced, and the production is simpler; the side waist part has a large area and does not require glue, the elasticity is uniform, and the paper diaper is more comfortable to wear; the attachment degree of the crotch part can be adjusted by straps, and side leakage caused by misfit of the paper diaper is avoided.

Owner:DADDY BABY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com