Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

A technology for absorbing moisture and heating fabrics, applied in the field of knitted garment fabrics, can solve the problems of poor elasticity, affecting the appearance and wearing performance of underwear, pilling, etc., and achieve the effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

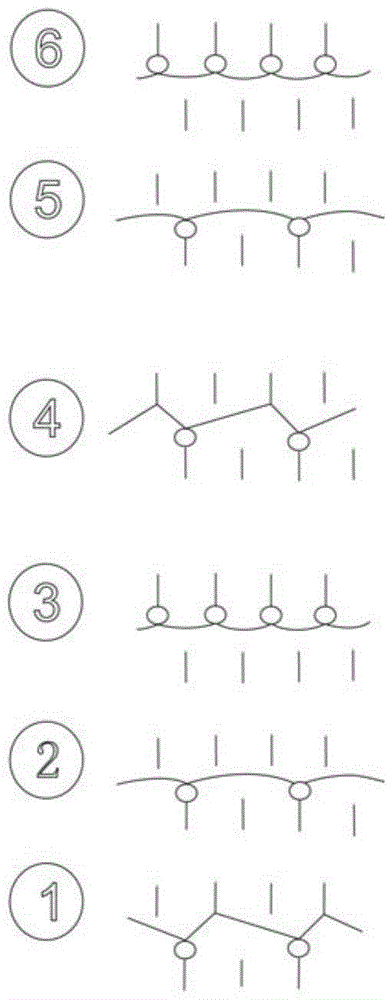

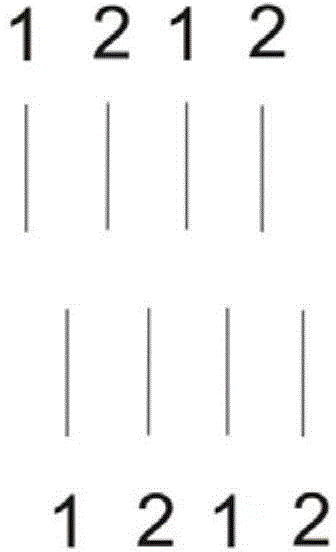

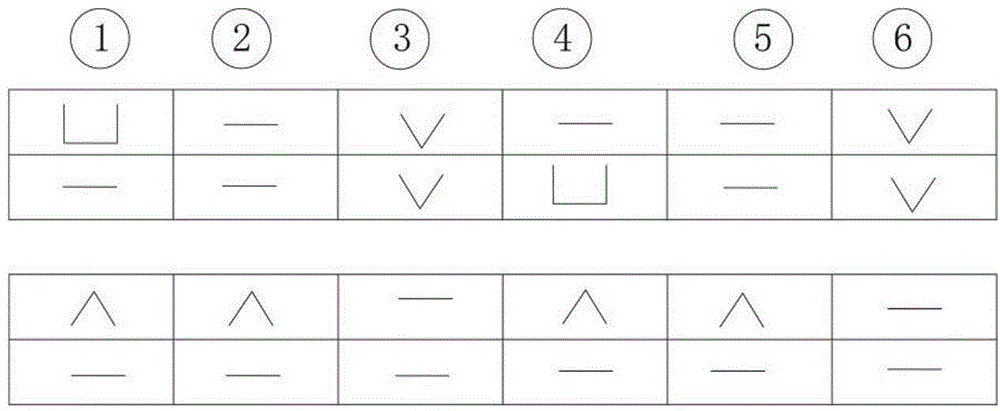

Method used

Image

Examples

Embodiment 1

[0060] A moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric, woven by four kinds of yarns, the first yarn is regenerated cellulose fiber blended yarn J40S Lenzing Modal / Cotton 50 / 50 blended with cotton fiber and regenerated cellulose fiber Blended yarn, wherein the weight percentage of regenerated cellulose fiber accounts for 50%; the second yarn is the cross-section modified polyester fiber yarn COOLDRY75D / 72F produced by Shanghai Haitian Yingjie Textile Technology Co., Ltd.; the third yarn is 20S cotton high-grade carded yarn; the fourth yarn is 30D polyurethane fiber yarn produced by Hangzhou Asahi Kasei Spandex Co., Ltd.

[0061] The preparation method of the moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric comprises the following steps in sequence:

[0062] 1) Select the above-mentioned four kinds of yarn raw materials according to the designed fabric, and prepare the necessary number of raw mater...

Embodiment 2

[0089] A moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric, which is interwoven with four kinds of yarns. The first yarn is a regenerated cellulose spun yarn J45S100% Lenzing Modal, and the second yarn is Shanghai Xingnuo Kanglun Fiber Technology Co., Ltd. The cross-section modified polyester yarn 75D / 72F imported from the Co., Ltd. with nano-silver ions is a low elastic fiber of Conlon fiber. The third yarn is 20S cotton high-end carded yarn, and the fourth yarn is Korean Hyosung Spandex (Jiaxing) Co., Ltd. produces 20D and 40D polyurethane fiber yarns.

[0090] The preparation method of the moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric comprises the following steps in sequence:

[0091] 1) Select the above-mentioned four kinds of yarn raw materials according to the designed fabric, and prepare the necessary number of raw material tubes for the above four kinds of raw materials when going on the m...

Embodiment 3

[0118] A moisture-absorbing, heat-generating, quick-drying, moisturizing and warm-keeping fabric, woven from four kinds of yarns. The first yarn is wool, flax and regenerated cellulose fiber blended regenerated cellulose fiber blended yarn J40S80S wool 30 / bleached degummed linen 20 / Superfine Lenzing Modal 50 compact blended yarn, in which regenerated cellulose fiber accounts for 50% by weight, and the second yarn is a cross-section imported with nano-silver ions provided by Shanghai Xinnuo Kanglun Fiber Technology Co., Ltd. Modified polyester yarn 75D / 72F Conlon fiber low elastic yarn, the third yarn is polyacrylonitrile fiber and cotton fiber blended cotton fiber blended yarn J40S milk protein fiber 30 / combed cotton 70 siro Compact blended yarn, wherein cotton fiber accounts for 70% by weight, and the fourth yarn is 30D and 40D polyurethane fiber yarn produced by INVISTA Fiber (Shanghai) Co., Ltd.

[0119] The preparation method of the moisture-absorbing, heat-generating, qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com