3D flame-retardant fabric and heat protection garment thereof

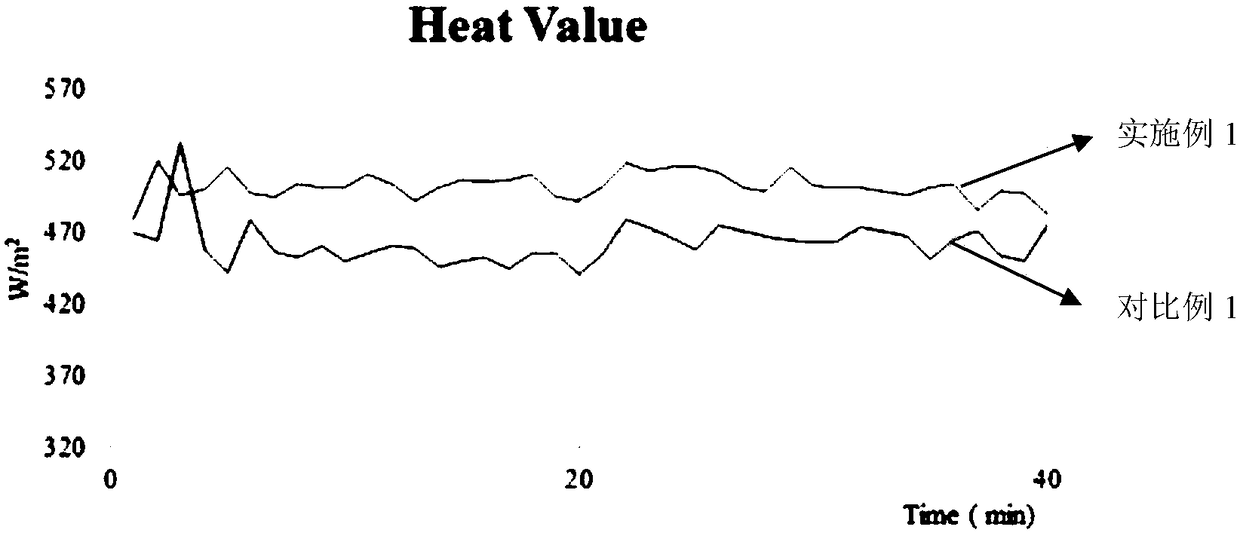

A kind of flame-retardant fabric, 3D technology, applied in the field of textile fabrics and clothing, can solve the problems of increased load and humidity and heat stress, not resistant to washing, easy to be damaged, etc., to improve thermal protection performance and comfort, and improve the resistance to radiant heat and convection Heat, reduce heat stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

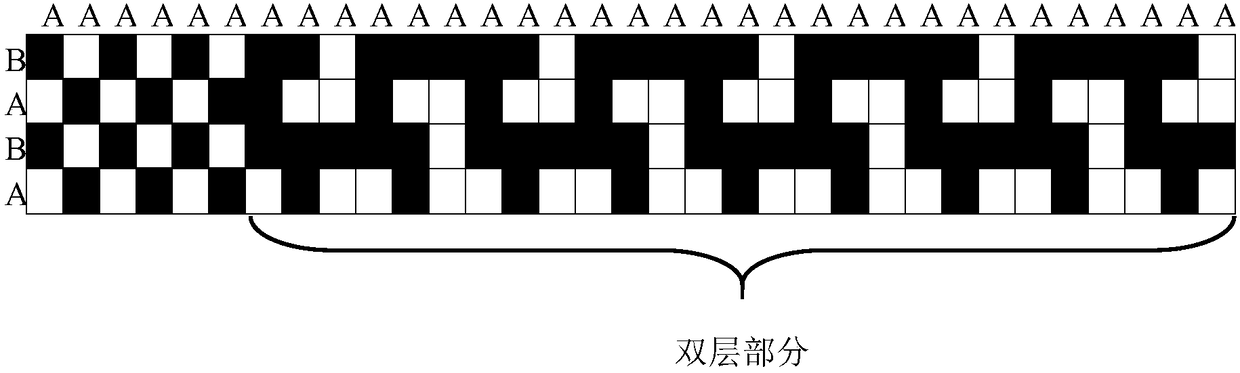

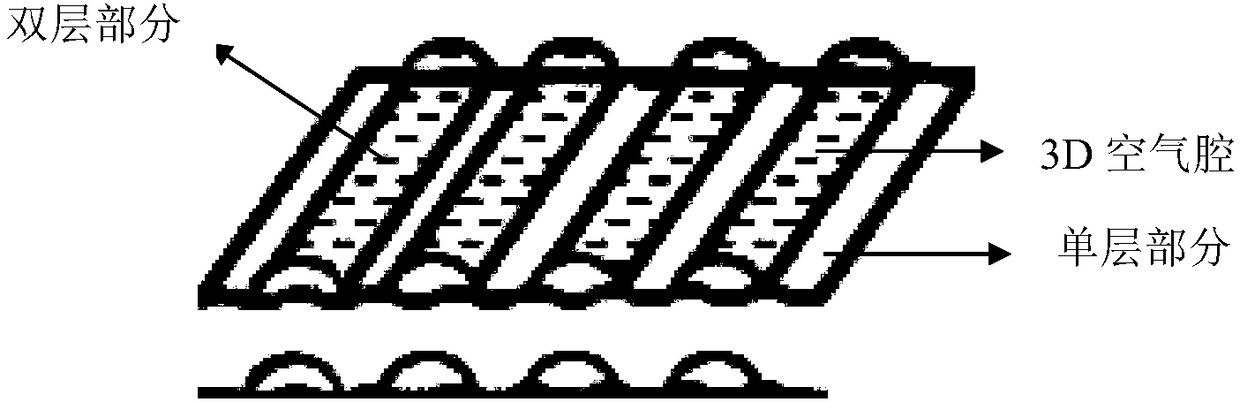

[0026] The high-performance flame-retardant yarn adopts meta-aramid and flame-retardant viscose, the mixing ratio is 50:50, and the yarn count is 40s / 1, forming raw material A. The flame-retardant elastic core-spun yarn includes leather yarn and core yarn, the leather yarn is meta-aramid, the core yarn is 20D / 24F spandex elastic yarn, and the raw material B is formed, the yarn count is 40s / 1, and the core yarn of flame-retardant elastic core-spun yarn The content is 6.5%.

[0027] (1) Design the weaving upper machine diagram, and carry out warping, sizing and weaving processing on the above-mentioned yarns. The technical parameters of each process are: warping in batches, the total number of warps is 6264, and the warping speed is 100-120m / min. The warping frame tension is 20-25gf; the sizing size is made of acrylic, wax and antistatic agent are added, the sizing rate is 8-10%, the temperature of the size tank is 60°C, and the temperature of the oven is 140-150°C;

[0028] (2...

Embodiment 2

[0040] The high-performance flame-retardant yarn adopts meta-aramid and flame-retardant viscose, the mixing ratio is 65:35, and the yarn count is 40s / 1 to form raw material C. The high-performance flame-retardant yarn is made of 100% meta-aramid, and the yarn count is 40s / 1, forming raw material E. The high-performance flame-retardant yarn adopts meta-aramid and flame-retardant viscose, the mixing ratio is 65:35, and the yarn count is 40s / 1, forming raw material F. The flame-retardant elastic core-spun yarn includes leather yarn and core yarn, the leather yarn is 100% aramid, the core yarn is 40D / 36F spandex elastic yarn, the yarn count is 40s / 1, and the raw material D is formed, and the core yarn of the flame-retardant elastic core-spun yarn The content of 12%.

[0041] (1) Design the weaving machine diagram, carry out warping, sizing and weaving processing on the above-mentioned yarns, the technical parameters of each process are: warping in batches, the total number of war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denier | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com