Comfortable shoe with waist iron blocks respectively arranged at outsole and midsole

A technology of comfortable shoes and waist irons, which is applied in the field of men's and women's shoe structures, can solve the problems of uncomfortable wearing, high hardness, and lowering, and achieve the effect of comfortable wearing and stable shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

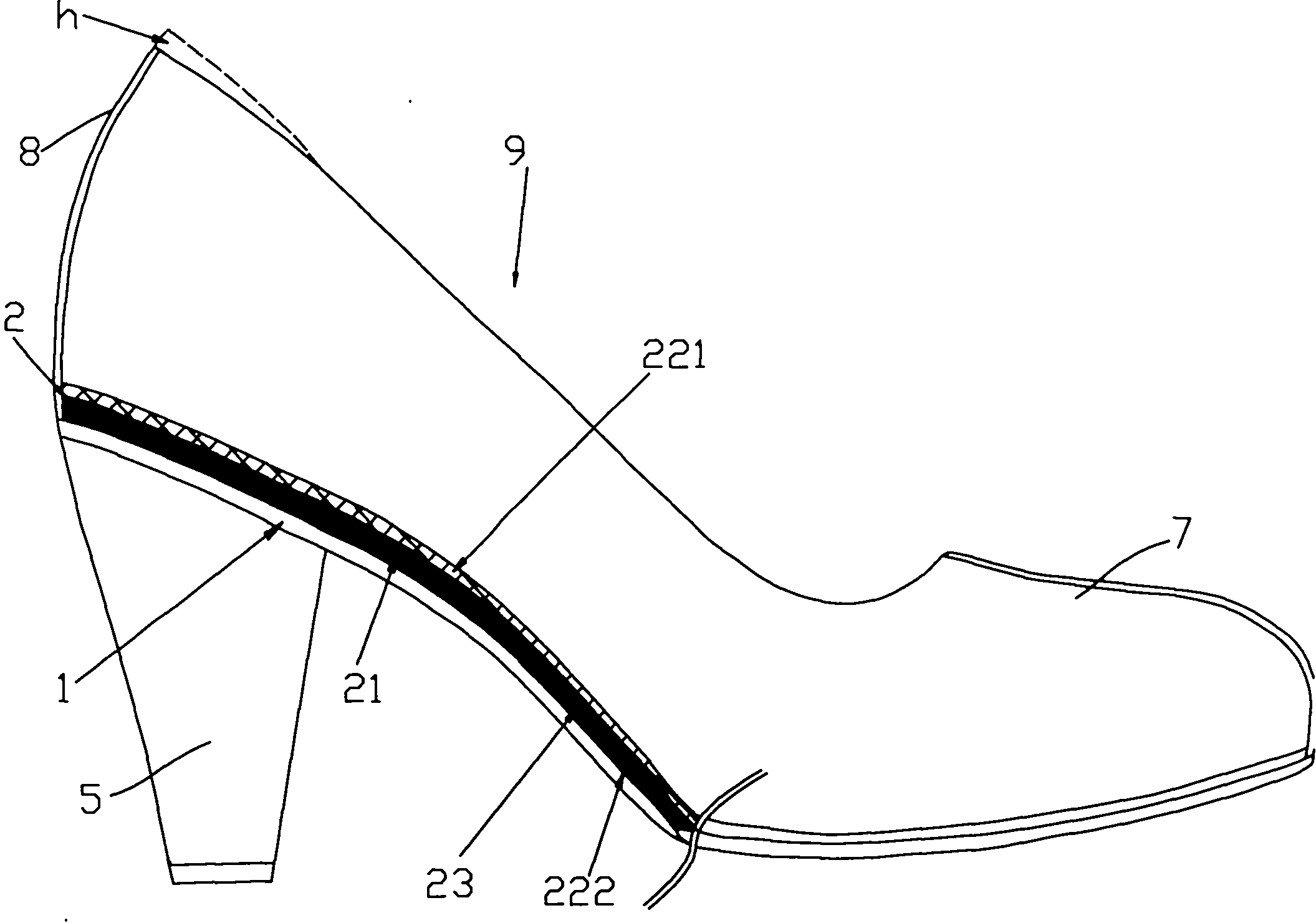

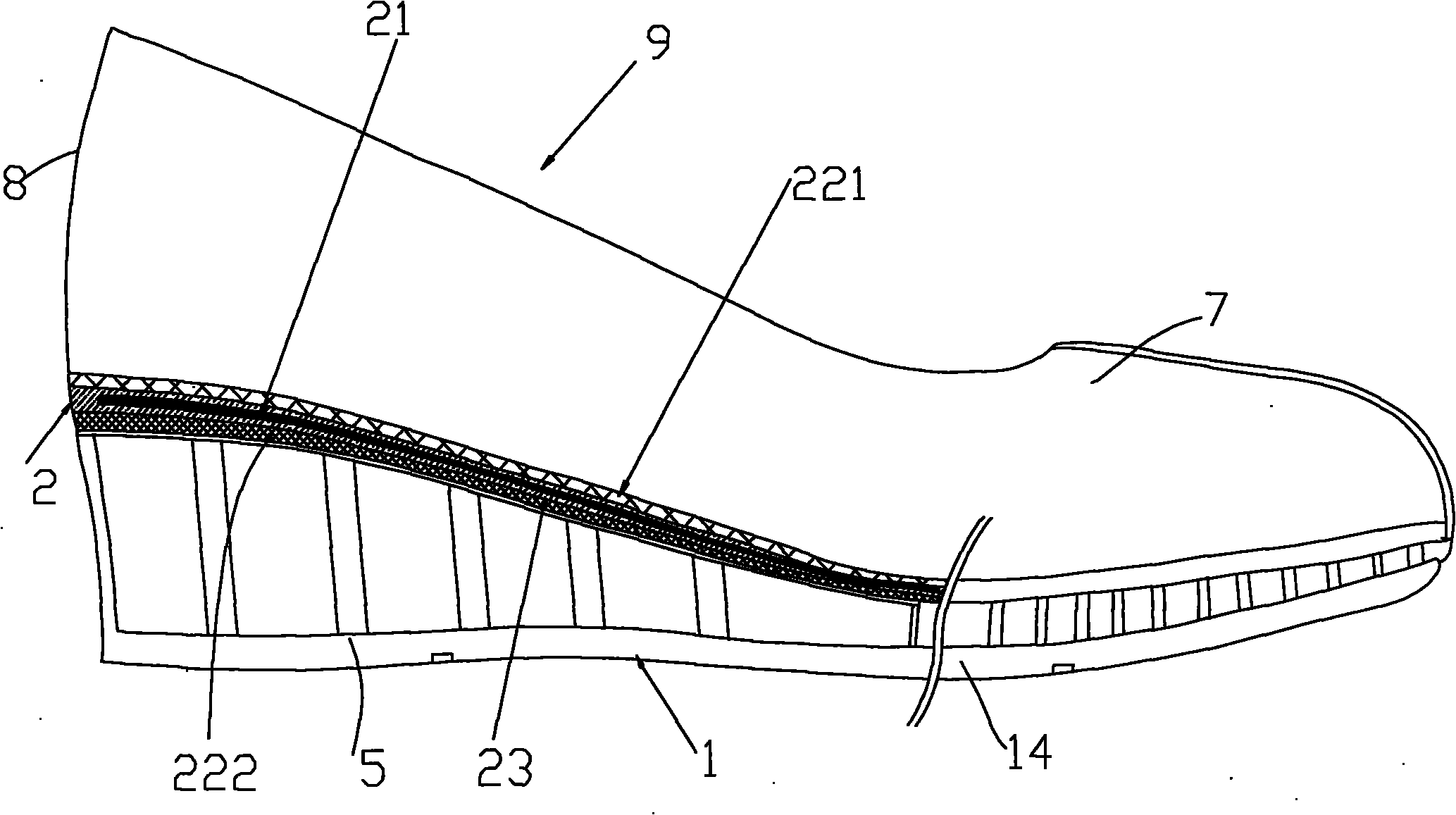

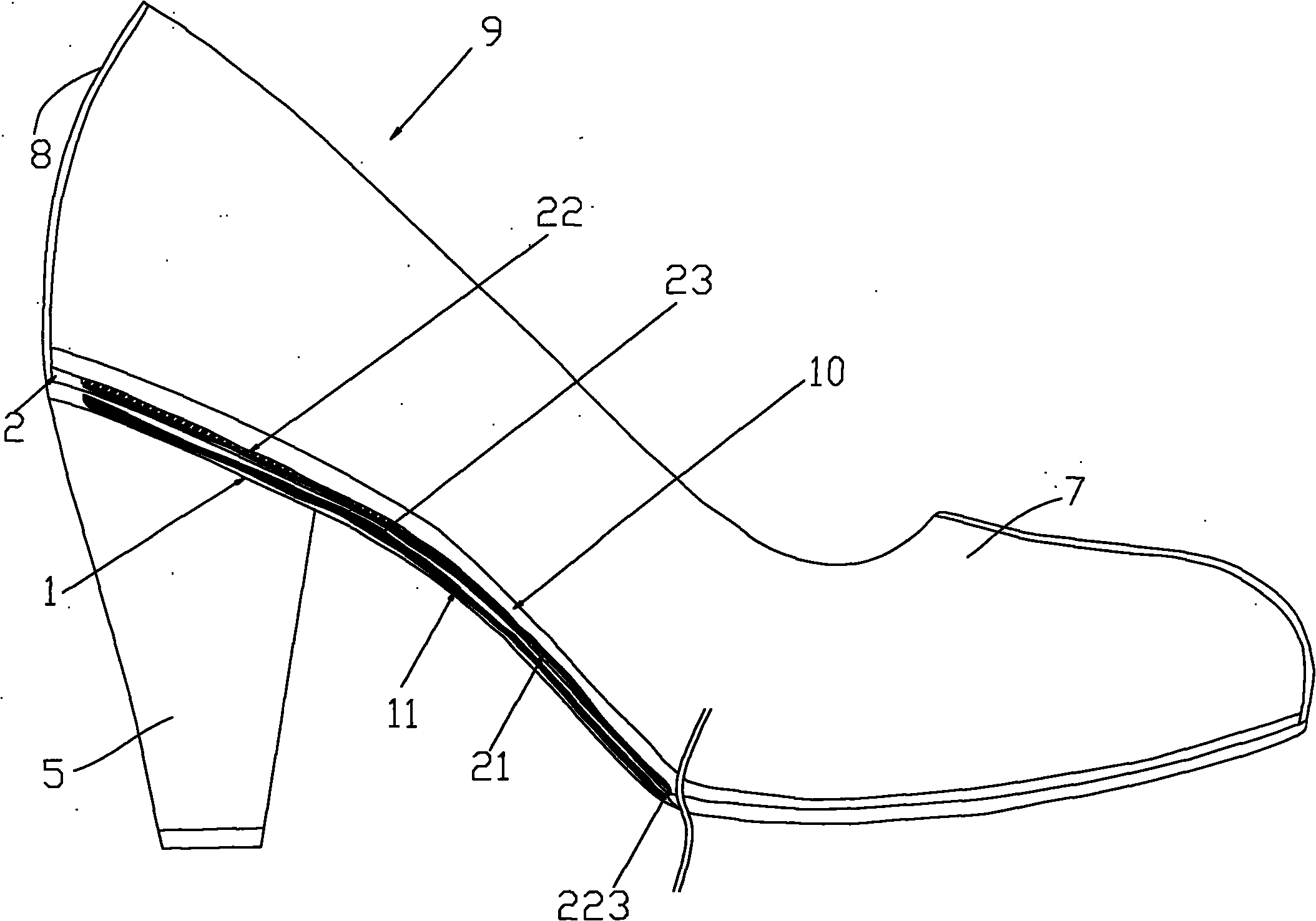

[0037] see image 3 and Figure 14 As shown, a comfortable shoe with waist iron in the outsole and midsole respectively includes a shoe body 9, the shoe body 9 includes a outsole 1 and a midsole 2, and the midsole 2 includes a midsole plate 23 and a midsole The bottom waist iron 21, the midsole waist iron 21 is arranged at the upper position of the midsole plate 23, the single-piece midsole insert 22 is arranged at the upper position of the midsole waist iron 21, the midsole waist iron 21 and the single-piece midsole insert 22 It is integrated with the middle bottom plate 23, and the big bottom waist iron 11 is arranged in the big bottom 1. The thickness of the single-piece midsole insert 22 is 1.5-2 mm; the end 223 of the single-piece mid-sole insert 22 near the landing point 14 is thinned with a slope of 10-15 mm wide; the single-piece mid-sole insert 22 and the midsole The thickness of the midsole 2 after the waist iron 21 is arranged in the midsole 2 is 1.2-1.6mm.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com