Heating health care socks and processing method thereof

A technology of health care socks and heating elements, applied in the field of heat generation health care socks and their processing, can solve the problems of no practical value, intolerance to bending, short service life, etc., achieve good promotion value and market prospect, good electrical and thermal conductivity , the effect of inhibiting bacteria and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

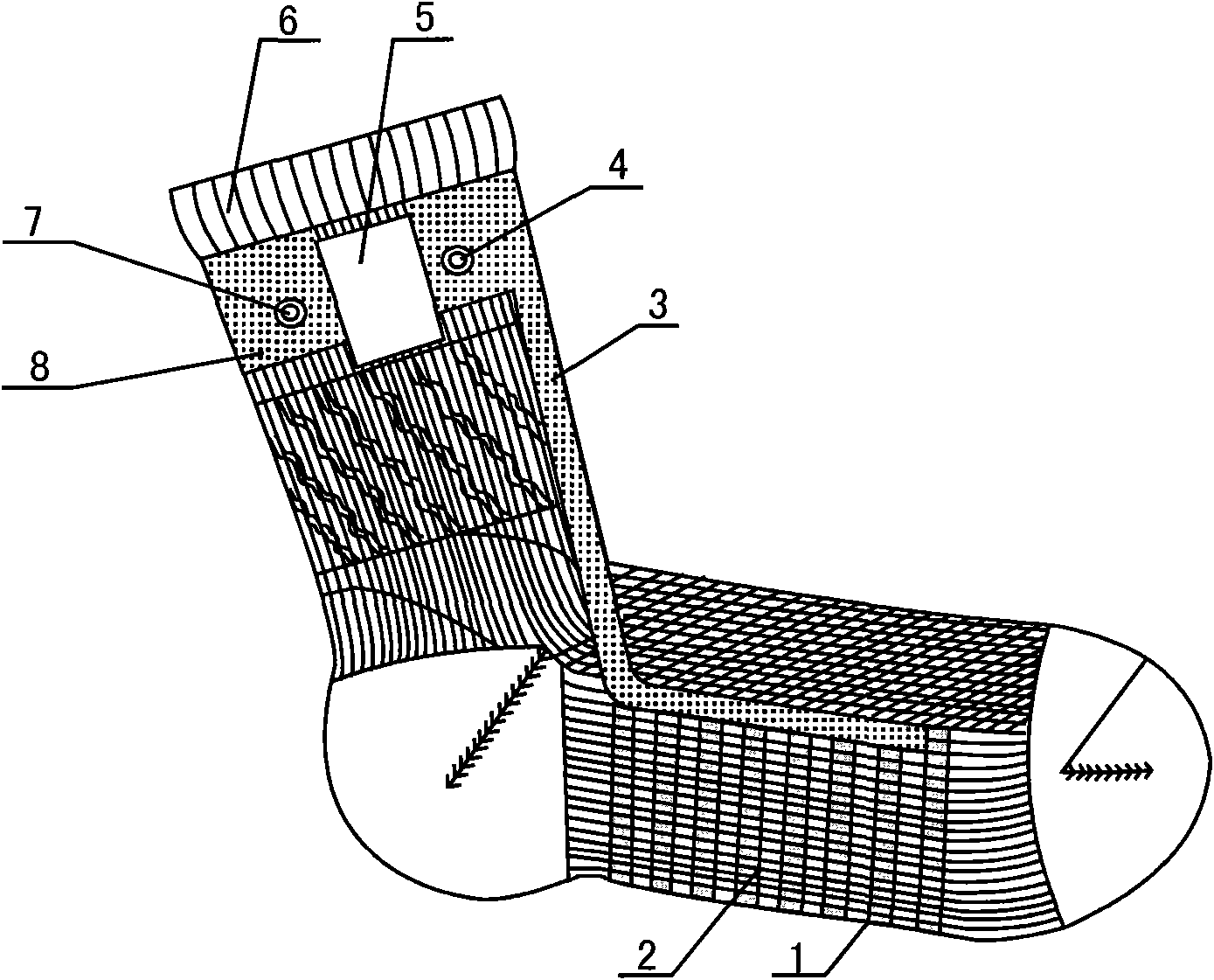

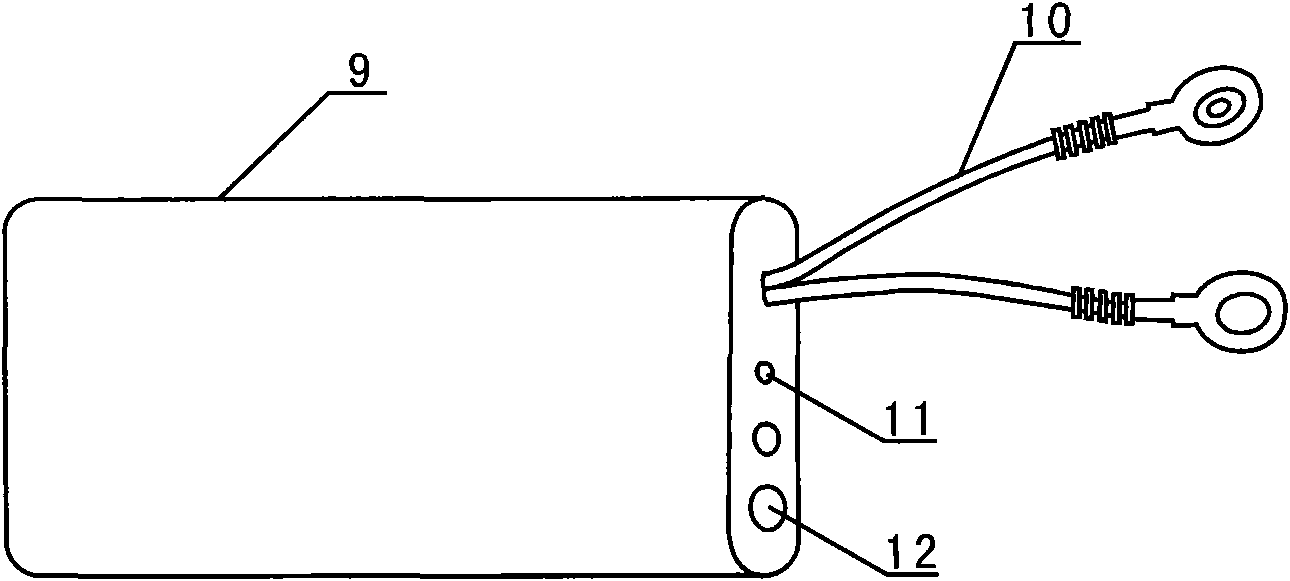

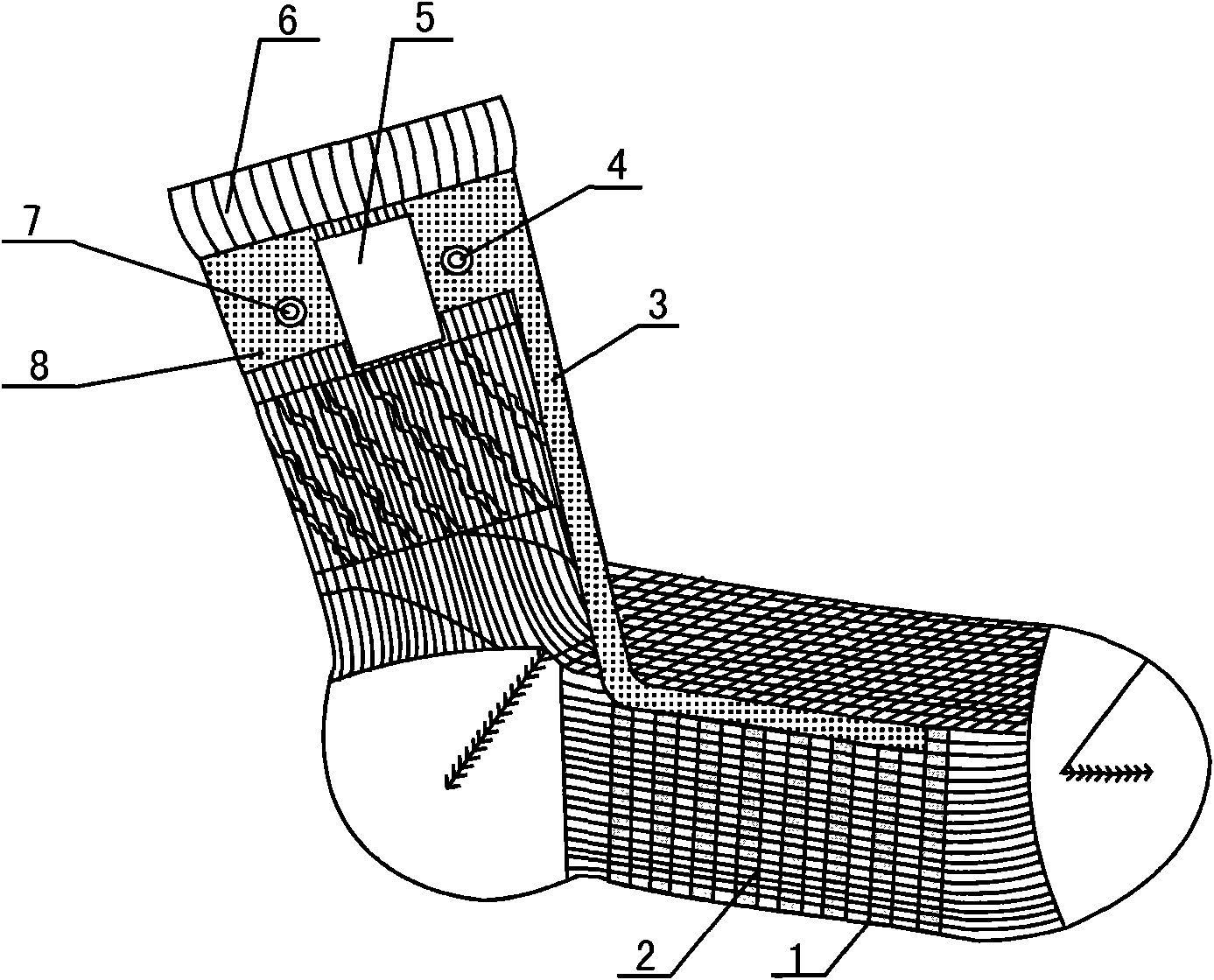

[0022] exist figure 1 with figure 2 Among them, the heat-generating health care socks of the present invention are mainly composed of a sock body and a power supply configuration (9). Conventional socks and conductive yarns are woven into the sock body to form a heating element (2) on the bottom of the foot (1) through a jacquard process. The bottom (1) is made of a double-sided fabric structure, the conductive yarn constituting the heating element (2) is woven on the inner surface of the sole (1), and conventional socks are woven on the outside of the sole (1), and the conductive yarn is selected from the following: 150D nylon filament is silver-plated filament as the base material, and its linear resistance is 0.05Ω / cm. The heating element (2) is continuously knitted between the bottom of the foot (1) and the width of the bottom of the foot along the lateral direction of the sock body by conductive yarn. , between every adjacent conductive yarns, there are conventional hos...

Embodiment 2

[0025] The conductive yarn is changed to polypropylene fiber containing 6%-7% silver powder blending based on the total dry weight of the fiber. In high-speed spinning equipment, it is spun and wound according to the conventional process to obtain 150D filaments. The linear resistance is in 0.09Ω / cm-0.15Ω / cm, the heating element (2) is continuously knitted between the bottom of the foot (1) and the width of the sole of the foot along the horizontal direction of the sock body, and knits between each adjacent conductive yarn Change to a conventional sock with 12-15 coils in the longitudinal length of the sole, and the conductive yarn is connected back and forth in series at the two ends of the width of the sole in the form of folded edges to produce a resistance between the first and second points and the two ends. Change the value between 2.5Ω-3Ω. The coils at the first and second end points along the two folded edges of the heating element (2) are knitted in series with each o...

Embodiment 3

[0027]The conductive yarn is changed to polyester fiber containing 7%-9% copper powder blending based on the total dry weight of the fiber, spinning and winding in high-speed spinning equipment according to conventional processes to obtain 150D filaments, and its linear resistance is in 0.1Ω / cm-0.2Ω / cm, the heating element (2) is continuously knitted between the bottom of the foot (1) and the width of the bottom of the foot along the horizontal direction of the sock body, and knits between each adjacent conductive yarn Change to a conventional sock with 12-15 coils in the longitudinal length of the sole, and the conductive yarn is connected back and forth in series at the two ends of the width of the sole in the form of folded edges to produce a resistance between the first and second points and the two ends. Change the value between 2.8Ω-3.8Ω. The coils at the first and second end points along the two folded edges of the heating element (2) are knitted in series with each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com