Patents

Literature

130results about How to "Obvious technological advancement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

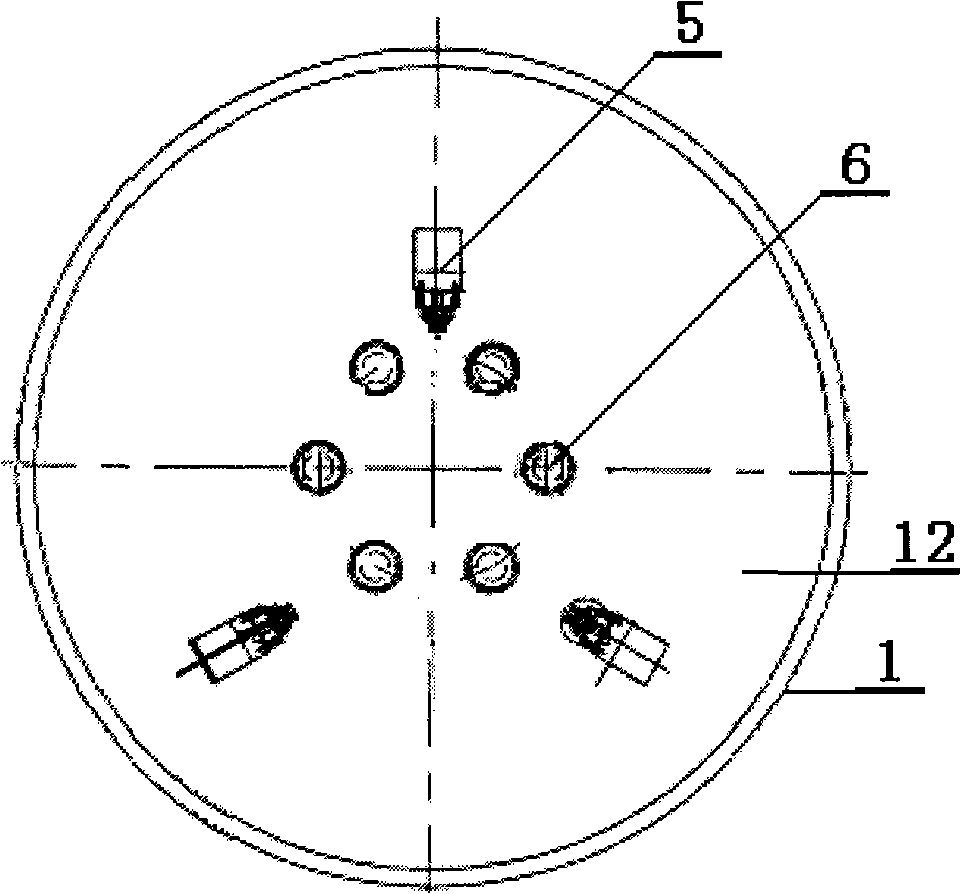

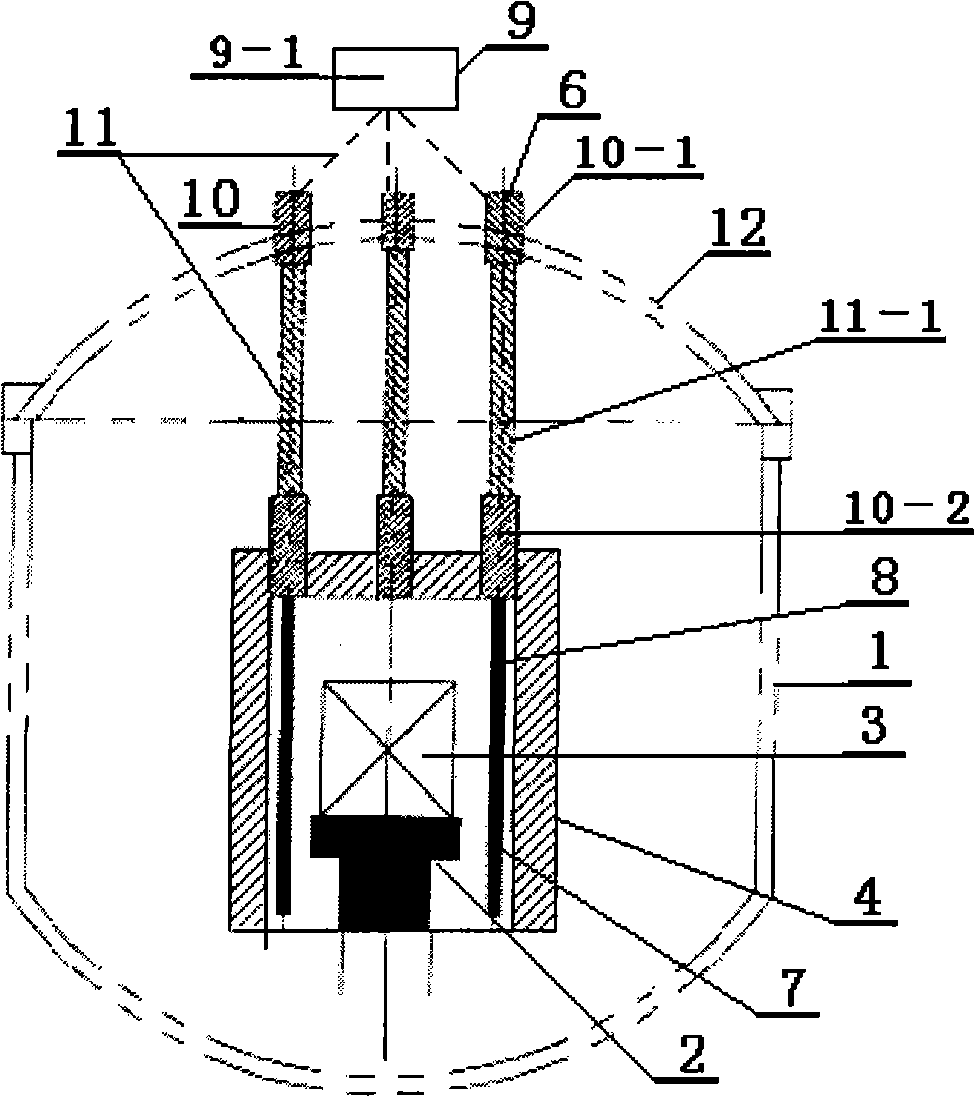

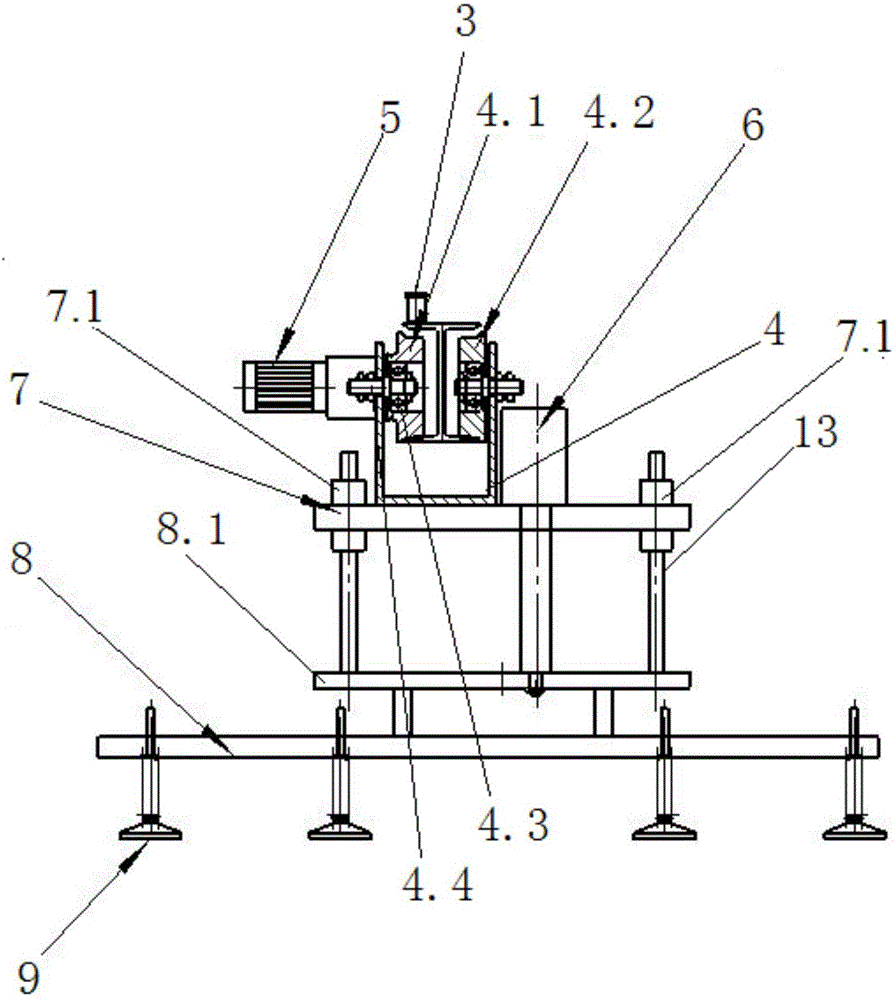

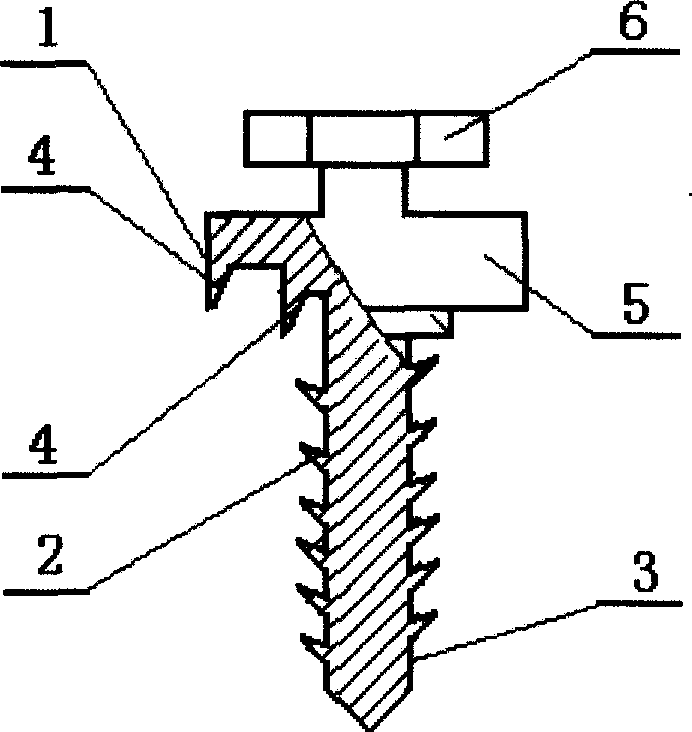

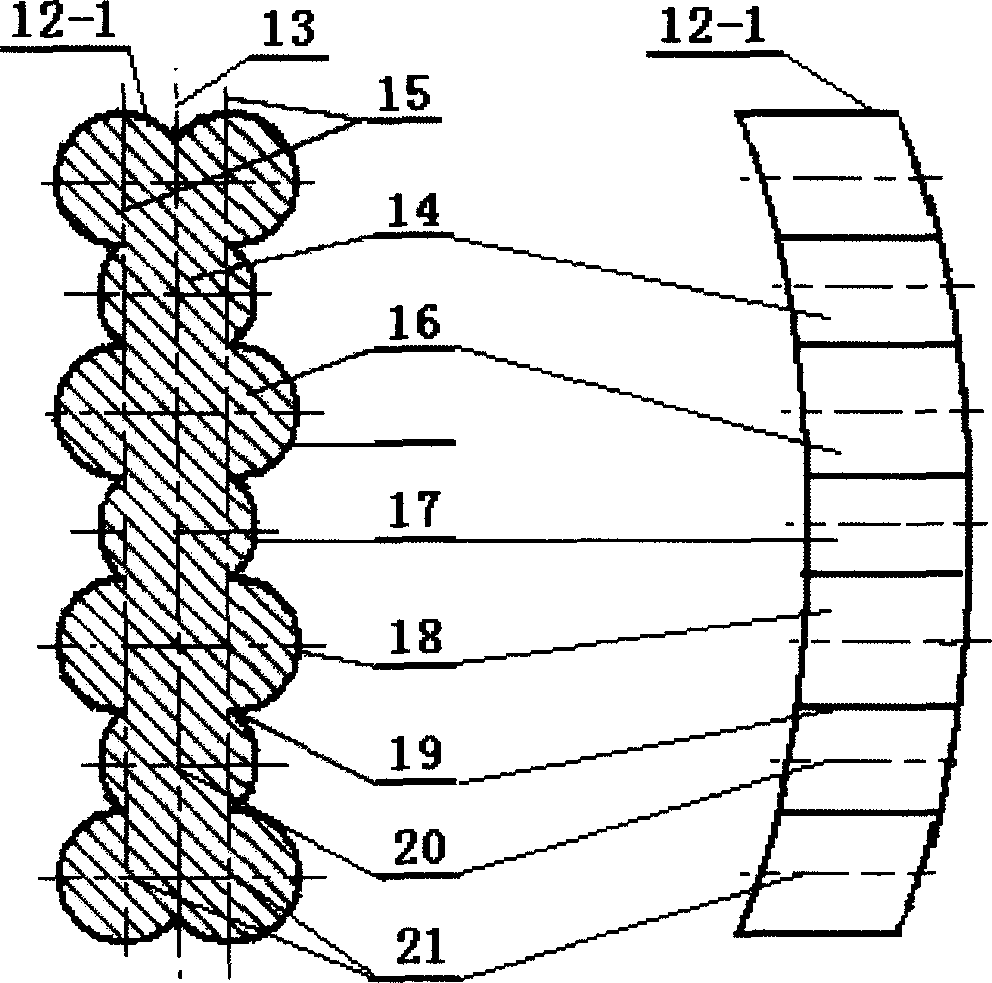

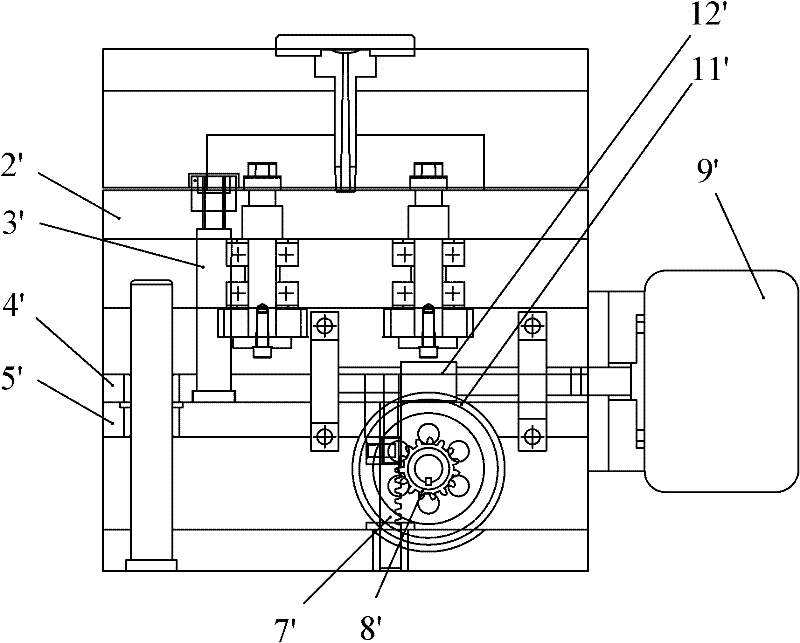

Injection mould servo synchronous automatic thread demoulding mechanism and control method thereof

ActiveCN101407103AObvious technological advancementGood application value and market prospectScrew-threads articlesPush outEngineering

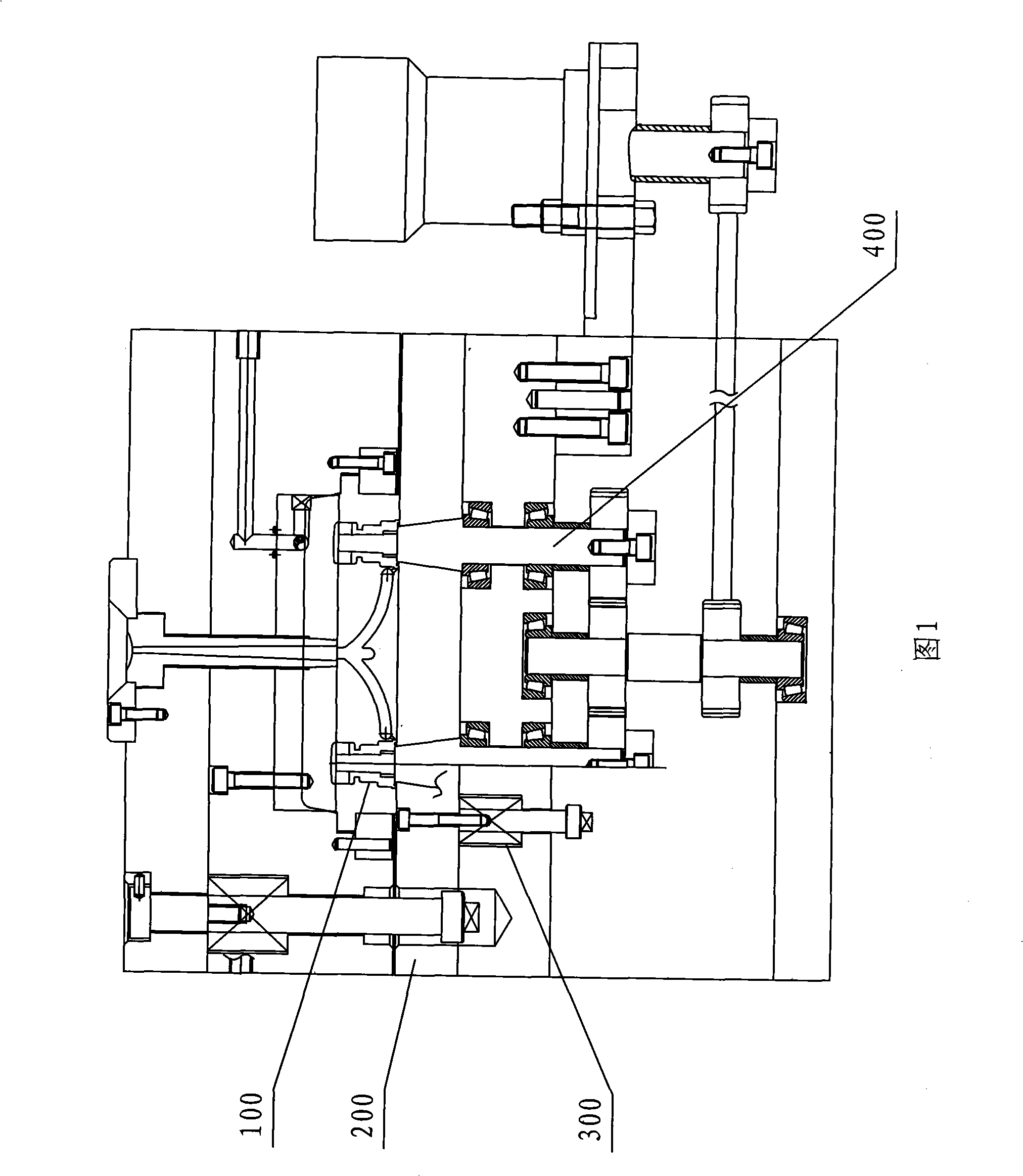

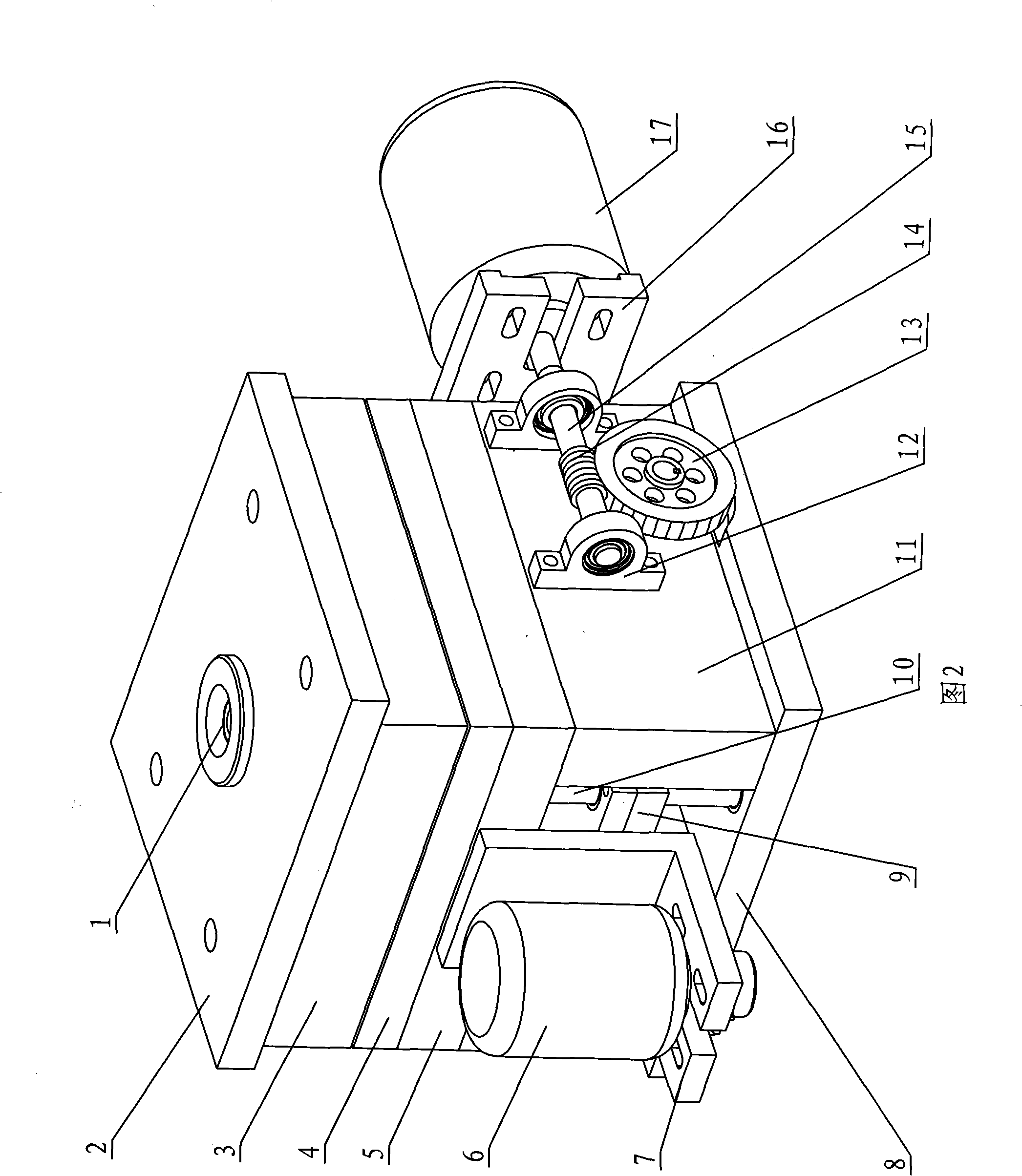

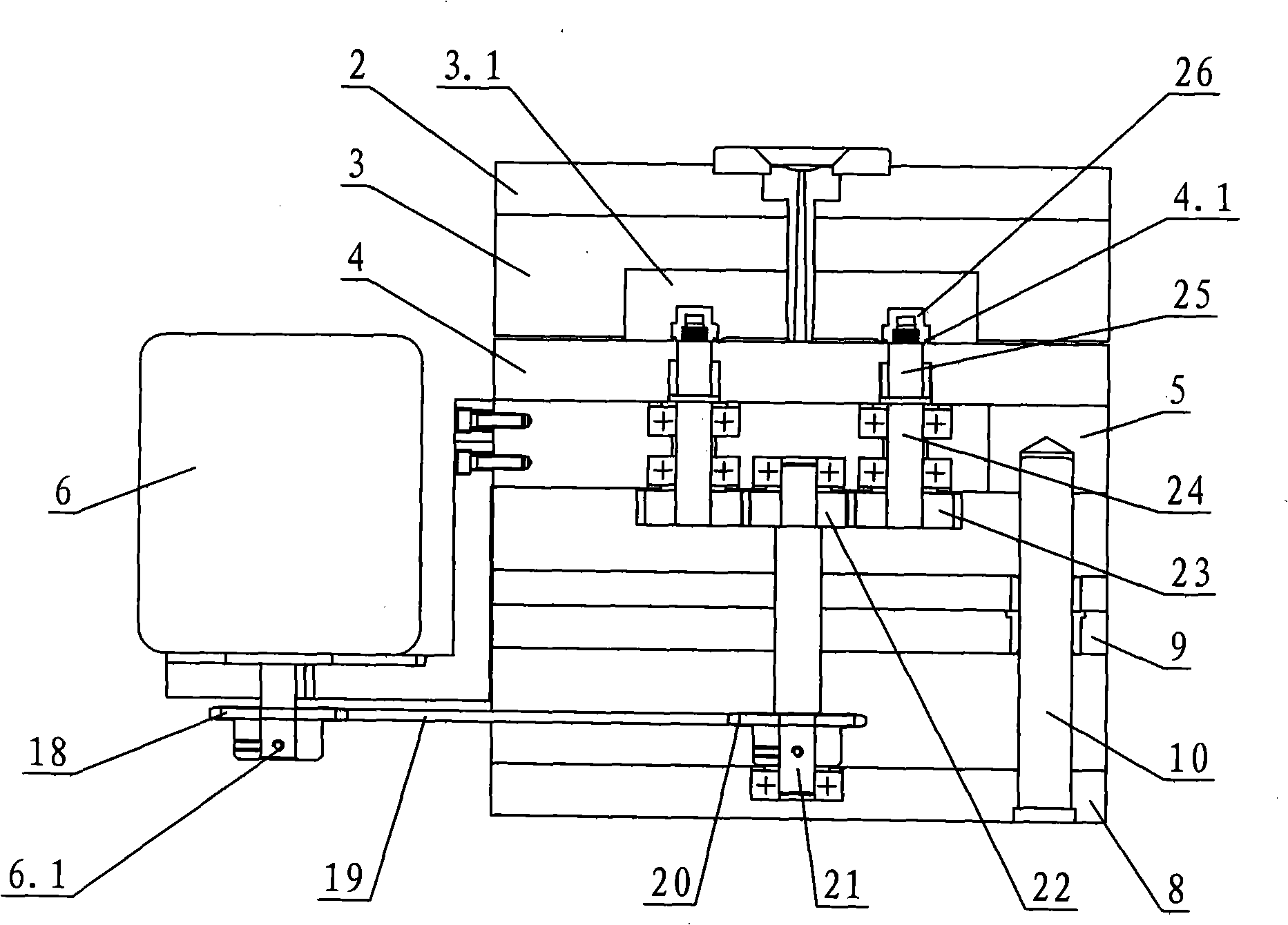

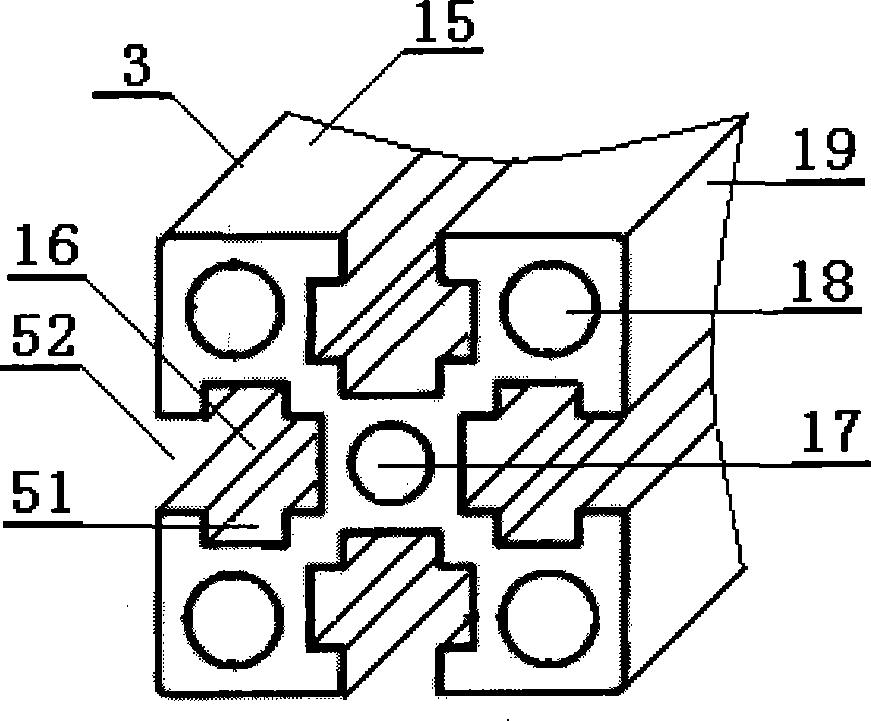

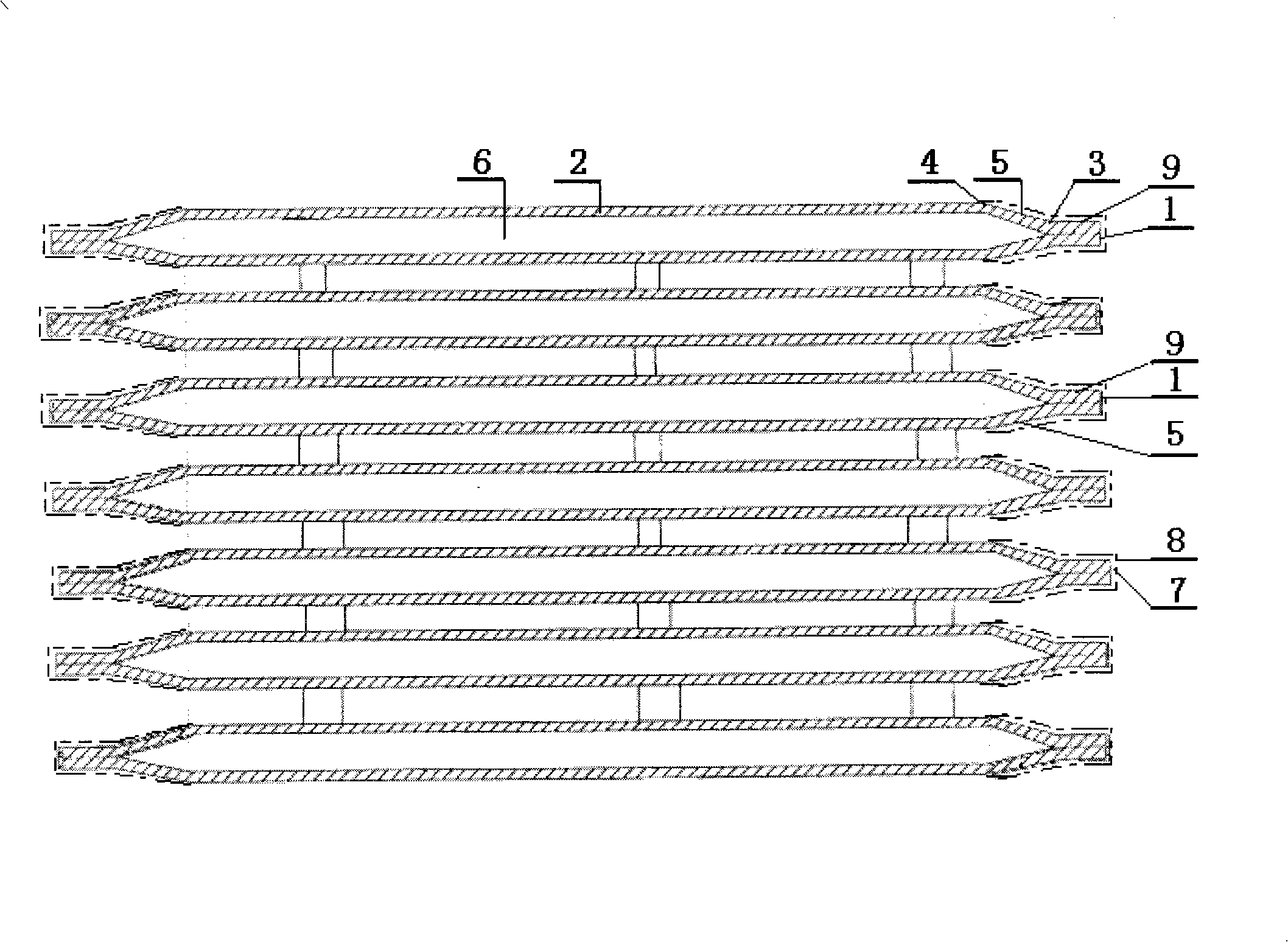

The invention discloses a servo synchronic automatic thread demoulding mechanism for an injection mould. The thread demoulding mechanism comprises a mould frame, a fixed molding board, a push board, a movable molding board, a threaded core and an injection molded part, wherein the threaded core and the push board are in transmission connection with a rotation mechanism and a lifting mechanism respectively. Under the control of a control system, the rotation mechanism screws out threads at an axial speed consistent with a speed at which the lifting mechanism pushes out the push board. The thread demoulding mechanism adopts a stepper motor for thread demoting and a novel mould thread demoulding synchronization mechanism under servocontrol to solve a current quality problem caused by lack of synchronization during thread demoulding. The thread demoulding mechanism is adaptive to different thread pitches and different plastic workpiece materials, overcomes the limitation on the prior mechanical thread demoulding mechanism and has obvious advantages in technology, good using value and market prospect. The thread demoulding mechanism has the advantages of simple and reasonable structure, high efficiency, high quality, convenient operation and wide application range.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

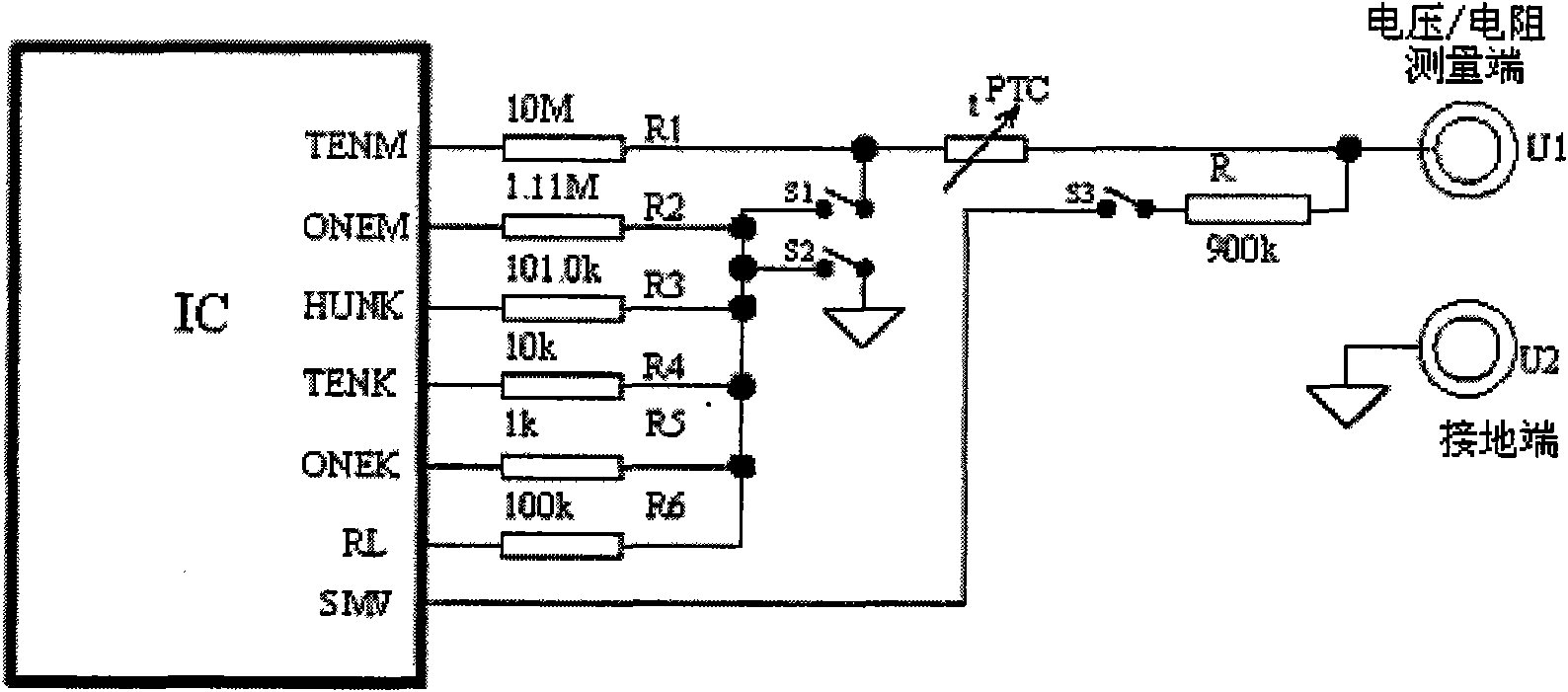

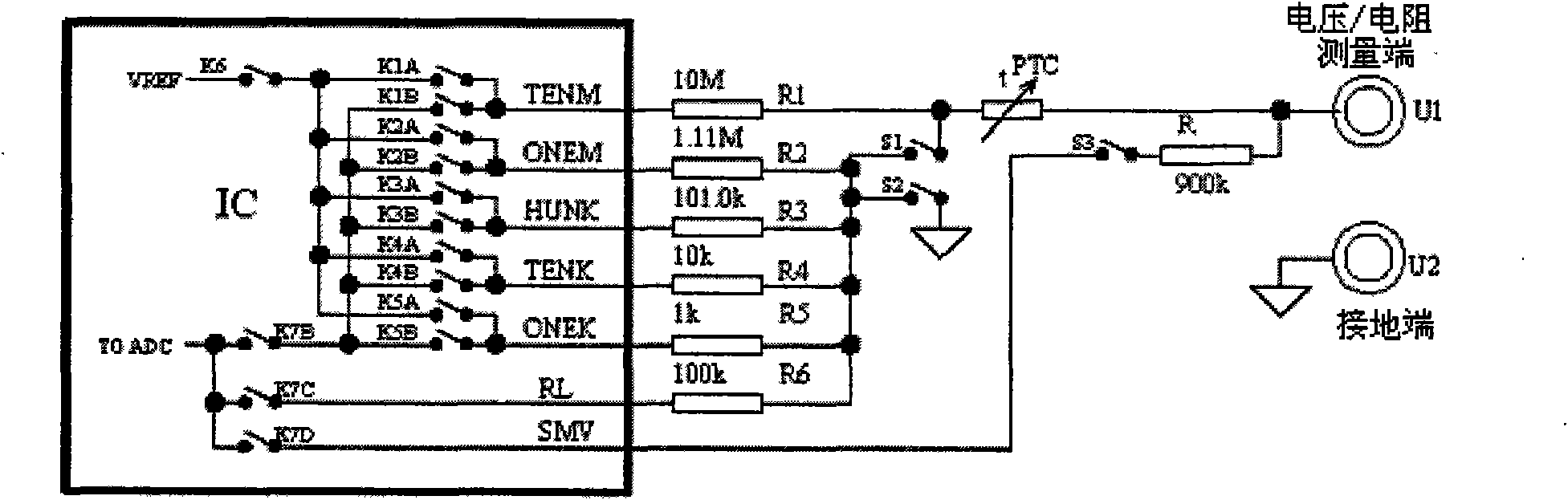

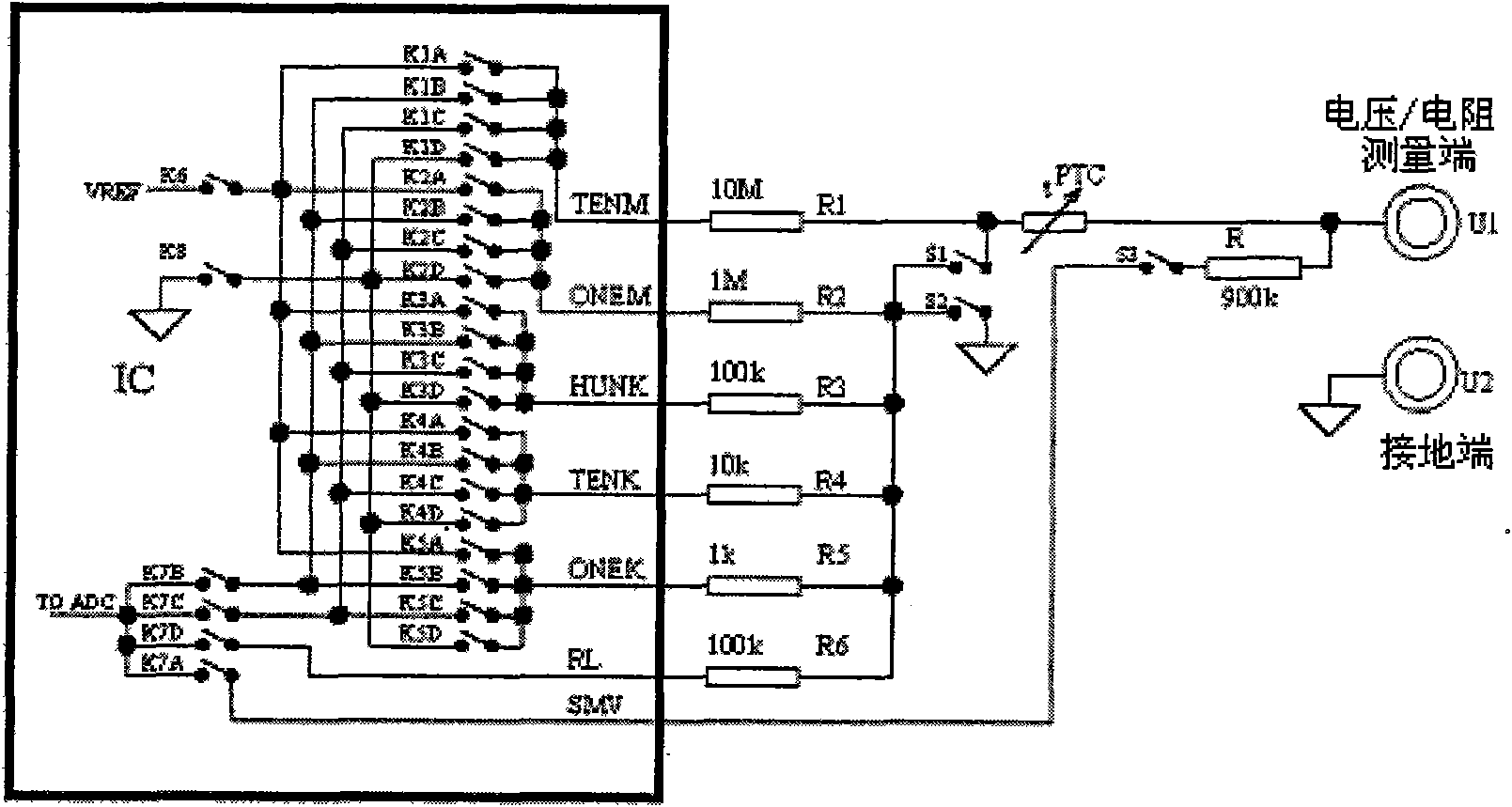

Self-calibrating method of internal reference resistors of multi-range digital electronic measuring instrument

InactiveCN101937066ASimple production processReduce indicator requirementsMulti-tester circuitsElectrical resistance and conductanceInternal memory

The invention relates to a self-calibrating method of internal reference resistors of a multi-range digital electronic measuring instrument, comprising the following steps of: on the basis of the design line of the traditional digital electronic measuring instrument, additionally setting an electronic switch and a self-calibrating program; setting a resistor with good long-term stability as an internal standard resistor in a set of internal reference resistors; when in a self-calibrating state, controlling the electronic switch by using the self-calibrating program to form different combinations so as to obtain comparing and measuring circuits among different reference resistors; and respectively and directly or indirectly comparing the reference resistors with the set internal standard resistor to measure respective actual resistance values and storing the actual resistance values in an internal storage for automatically correcting measuring results. Because only one standard resistor with good long-term stability needs to be adopted, other reference resistors are compared and calibrated with the standard resistor, and the method effectively reduces the requirements of other reference resistors, is beneficial to reducing the production cost and ensuring the measuring precision of each measuring process so that the calibration in the production process and the periodic calibration of users both are simpler and more effective and accurate.

Owner:臧佳菁

Porcelain granules containing carbon and preparation method thereof

InactiveCN101580349AReduce manufacturing costLight weightSolid waste disposalThermal insulationExpanded clay aggregate

The invention discloses a preparation method for porcelain granules containing carbon. According to the weight percentage, 5%-40% of carbon powder, 5%-25% of gold mine tailing powder and 35%-70% of fly ash make up main raw materials. The preparation method comprises the steps of: (1) the gold mine tailing powder is dipped in a HCl solution; (2) the carbon powder, the fly ash and the modified mine tailing powder are uniformly blended; and then water is added for wet mixing; (3) the wet material is prepared into spheric granules with the grain diameter of 5-20mm; (4) the spheric granules are dried and sintered to obtain the porcelain granules containing carbon. The porcelain granules containing carbon are multifunctional porcelain granules with the functions of adsorption, light weight, high strength, heat preservation, thermal insulation, etc.

Owner:ZHEJIANG UNIV

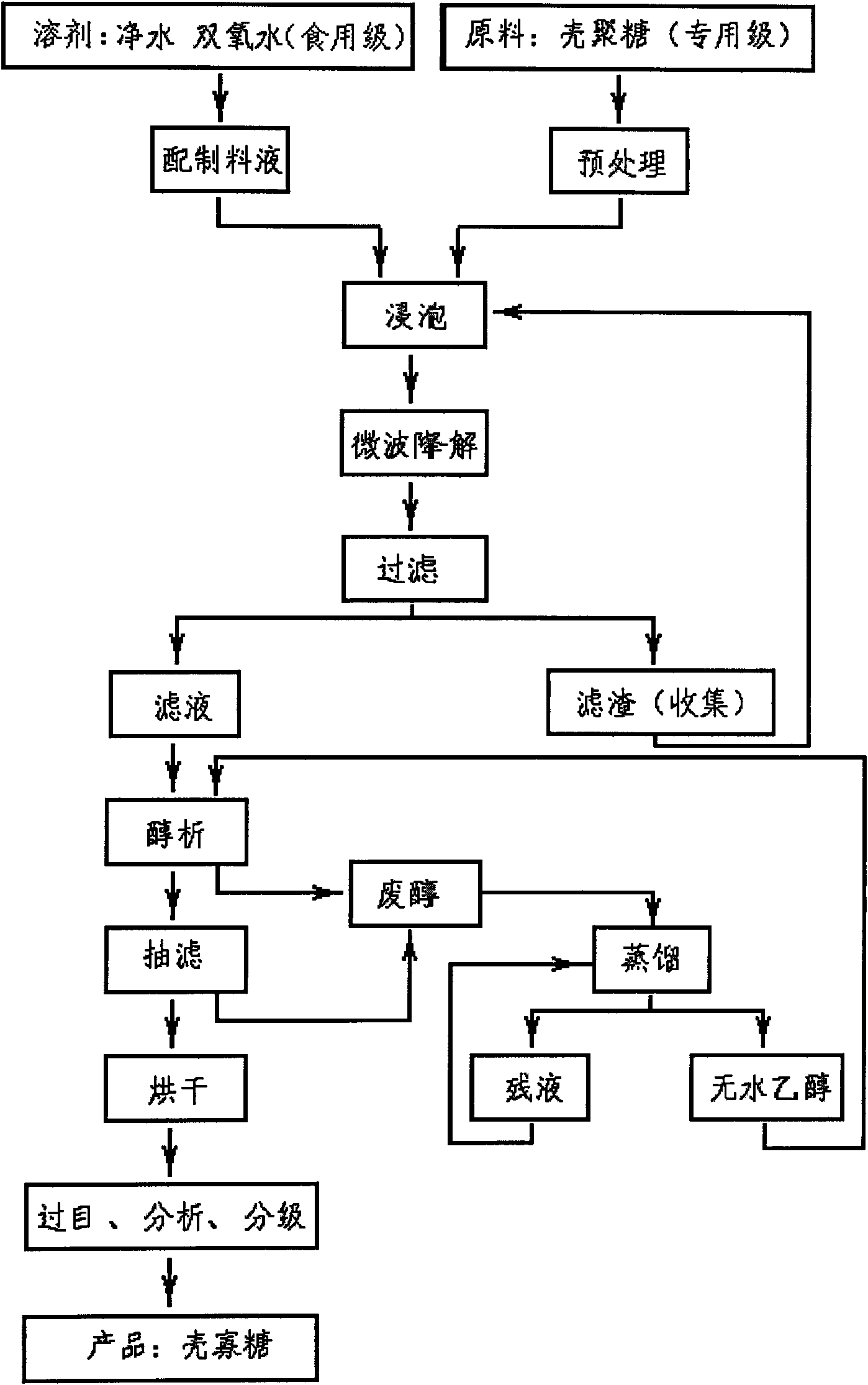

Method for preparing chitosan into water-soluble chitooligo saccharide

The invention relates to a method for preparing chitosan into water-soluble chitooligosaccharide, which comprises the following steps: using chitosan as a raw material, processing the chitosan by rinsing and drying technology, and immersing the chitosan in a material liquid prepared by purified water and edible hydrogen peroxide; carrying out the processing of microwave radiating degradation to form the mixed liquid of low-molecular chitooligo saccharide which can be dissolved in the material liquid and partial undegraded chitosan, and obtaining residual slag of chitosan and a chitooligo saccharide solution by filtration; and sending the chitooligo saccharide solution into absolute ethyl alcohol, and after alcohol precipitation, carrying out sucking filtration and drying to obtain a finished product of water-soluble chitooligo saccharide. The processing technology of microwave radiating degradation is used, and energy is mased by a physical method to degrade high-molecular chitosan into low-molecular water-soluble chitooligo saccharide with a stable structure, thus no other side product of reaction or pollutant is generated in the degrading process. Compared with the preparing method of the prior art, the invention has the advantages of advanced technology, simple procedures, low investment of production facilities, high product purity, stable quality and the like, and developsa wide market application prospect for the chitosan prepared by taking chitin as a raw material.

Owner:赵建发

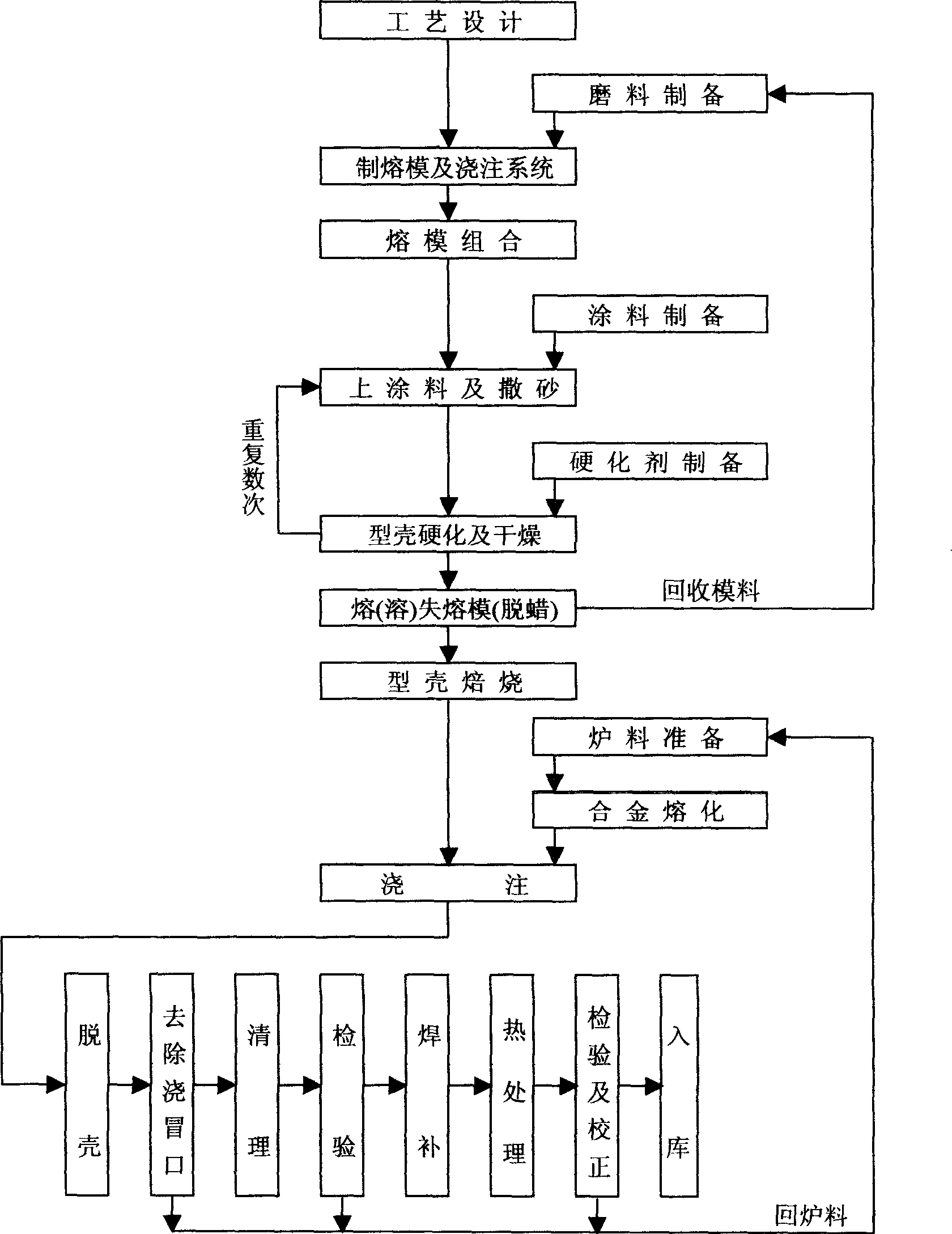

Technology method relating to component in manufacturing artificial limb knee-joint

InactiveCN101120894ASimplify production and processing proceduresImprove adaptabilityArtificial legsSolution treatmentTO-18

The invention discloses a process method for manufacturing related components in prosthetic knee joints. In the method, a silica sol precision casting process is used to replace the forging process. The relevant process steps and process parameters are as follows: a. Prepare high-strength aluminum alloy materials, except for the main components In addition to Al, it also includes: Cu: 4.6-5.3, Mn: 0.3-0.5, Si≤0.06, Fe≤0.30, and the total amount of other impurities≤0.60. b. Melting and pouring: melting temperature 680-720°C, pouring temperature 680-700°C; c. heat treatment process: solid solution treatment at 533-543°C for 10-18 hours, aging treatment at 170-180°C for 4-5 hours Hour. Adopting the process of the present invention obviously simplifies the processing procedure of the relevant parts in the prosthetic knee joint, and the product is formed by one-time casting, which avoids many cutting and forging processes, improves the production efficiency and the utilization rate of metal materials, and not only simplifies the equipment and process, It also reduces the production cost and facilitates the formation of large-scale production capacity.

Owner:上海市机械制造工艺研究所有限公司

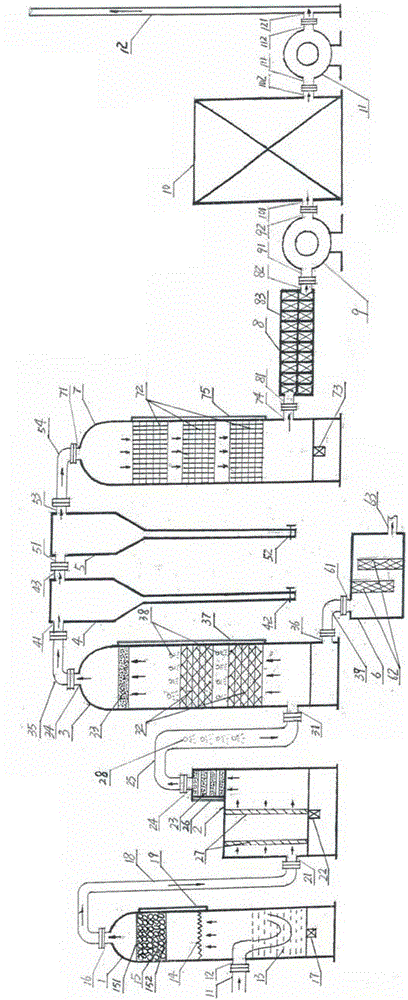

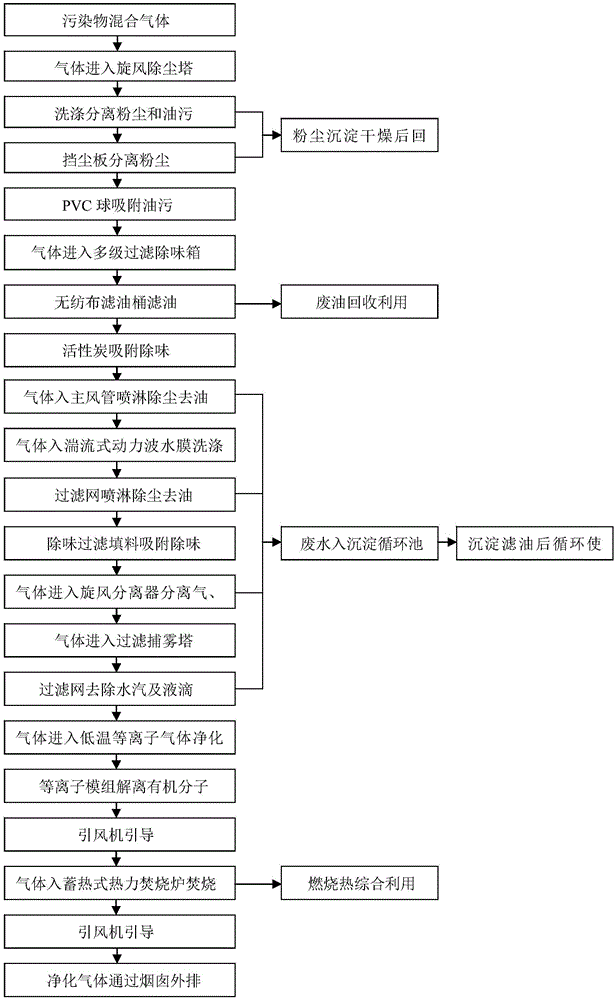

Asphalt smoke comprehensive environmental protection treatment system and applications thereof

InactiveCN105126515AOvercoming the drawbacks of simultaneous processingTake advantage ofCombination devicesIncinerator apparatusEngineeringLow temperature plasma

The invention relates to an asphalt smoke comprehensive environmental protection treatment system and applications thereof. The asphalt smoke comprehensive environmental protection treatment system comprises an environmental protection treatment facility, a gas transmission pipeline, an induced draft fan, and a chimney; the environmental protection treatment facility comprises a cyclone dust removal tower, a multistage filtering smell-removing box, a main air duct, a turbulent flow-type dynamitic wave water film washing tower, a cyclone separator, a precipitation circulation water basin, a filtering mist-capturing tower, a low-temperature plasma exhaust gas purifier, and a heat accumulating-type heating-power incinerator which are independent from each other; and the asphalt smoke comprehensive environmental protection treatment system is used for treating asphalt smoke generated in production. Compared with the prior art, the asphalt smoke comprehensive environmental protection treatment system is reasonable and scientific in structure design; operation is reliable; performance is stable; comprehensive utilization of generated wastes can be realized; no secondary pollution is caused; and the asphalt smoke comprehensive environmental protection treatment system is beneficial for full utilization of resources and energy saving.

Owner:SHANGHAI TAIAN BUILDING MATERIAL TECH CO LTD

Electric arc spraying process of chloride corrosion preventing alloy coating of garbage incinerator heating surface

InactiveCN102586714AImprove chlorine corrosion resistanceObvious technological advancementMolten spray coatingElectric arcCoated surface

The invention relates to an electric arc spraying process of a chloride corrosion preventing alloy coating of a garbage incinerator heating surface, which comprise the following steps: (1) cleaning and roughening the garbage incinerator heating surface; (2) adopting high-nickel alloy wire materials to perform electric arc spraying bottoming within 3-4 hours after abrasive blasting; (3) adopting a supersonic speed electric arc spraying technology to nickel-chromium-molybdenum alloy wire materials high in spraying hardness, excellent in corrosion resistance, good in abrasion resistance and high temperature resistance to manufacture the coating; and (4) using a high temperature, abrasion-resisting corrosion-preventing organosilicone sealant to seal holes on the coating surface. The protective coating is formed by adopting the spraying process on the heating surface, the effect of preventing high temperature corrosion can be achieved, the problem that the garbage incinerator heating surface is easily subjected to high temperature chloride corrosion to cause pipe explosion due to fuel containing high C1element in the working process is solved, and the service life and maintain period of garbage incinerator heating surface pipelines are greatly prolonged.

Owner:JIANGXI HENGDA HI TECH CO LTD +1

Non-curing waterproof glue with double character

ActiveCN102086349AImproves UV aging resistanceImprove high temperature performanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltravioletEngineering

The invention relates to non-curing waterproof glue with double character. The non-curing waterproof glue is mixed by asphalt used as main material and auxiliary materials which contain thermoplastic elastomer, modifier, tackifier, plasticizer, diluting additive and filler. As the modified asphalt sizing material uses high quality thermoplastic styrene-butadiene rubber as raw material to improve the high temperature performance, uses tackifying resin to increase the viscosity of asphalt, uses the plasticizer to improve the compatibility and processing performance between asphalt and the modifier and uses carbon black and calcium carbonate with stable chemical properties as filler, the ultraviolet ray aging resistance of the non-curing waterproof glue of the invention can be improved, the reinforcing effect can be realized and the production cost can be reduced; and the non-curing waterproof glue product can remain solid at the room temperature and can be in a flexible glue state and be not cured in a sealing state.

Owner:上海北新月皇新材料集团有限公司 +1

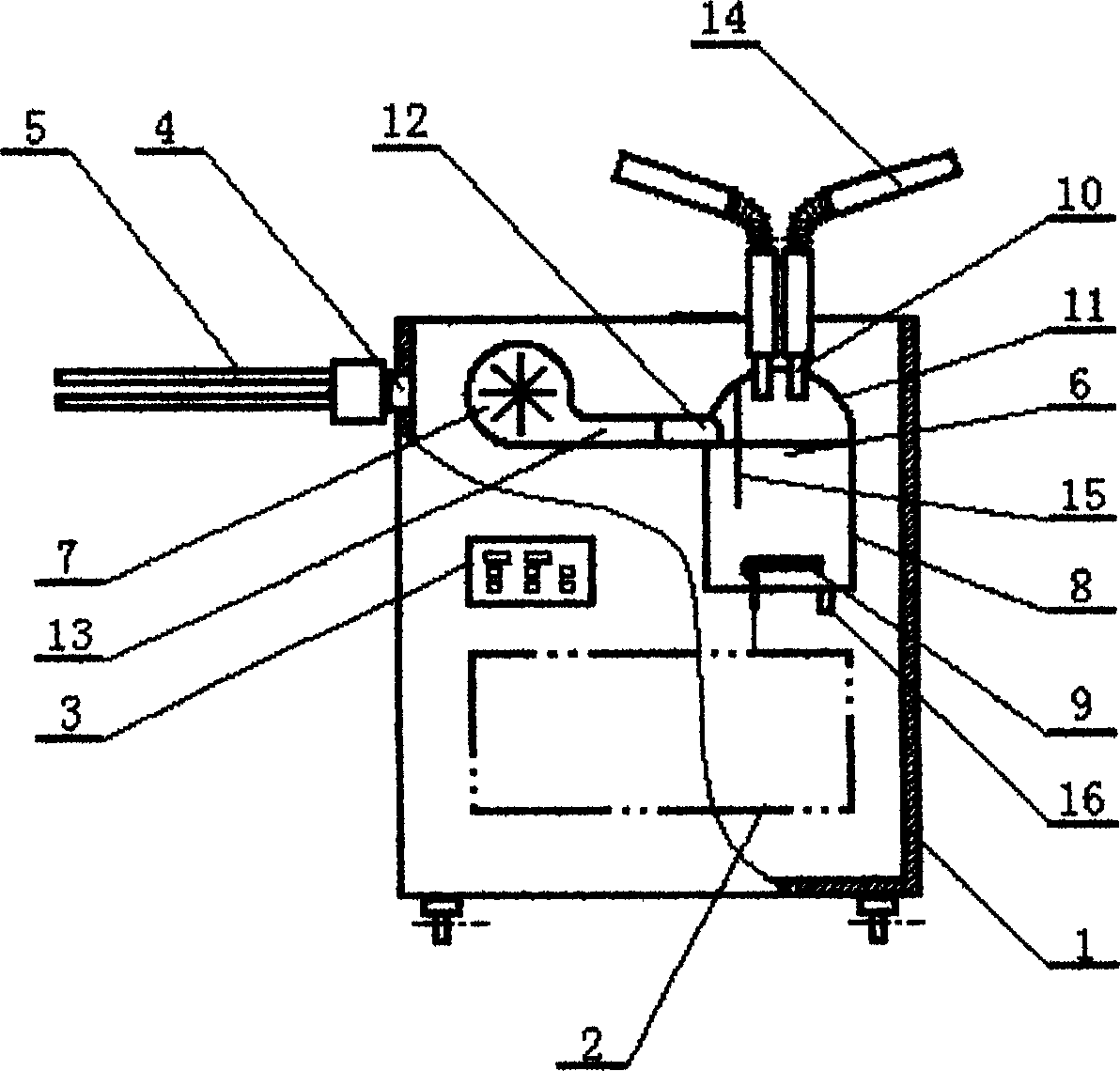

Method and apparatus for purifying indoor air

InactiveCN1763446AImprove purification effectIncrease the specific surface area of contactLighting and heating apparatusDispersed particle separationOxygen ionsAir cleaning

The invention relates to an indoor air purifying method and device, which comprises the following steps: adapting air purifying disposing liquid within photocatalytic agent; atomizing the disposing liquid into tiny particle mist material; spreading the mist disposing liquid into the polluted space through fan; activating the photocatalytic agent to catalyze the water and oxygen in the air into large amount of oxyhydrogen free radical and negative oxygen-ion. The device contains box, fan, operation panel, electric control pod, ultraviolet radiation lamp and ultrasonic atomizing device, wherein the electric control component is composed of power control mode, atomizing strength control mode and atomizing time control mode. The invention can finish air purifying disposal in a short time, which sustains the air purifying function for a long time.

Owner:黄志军

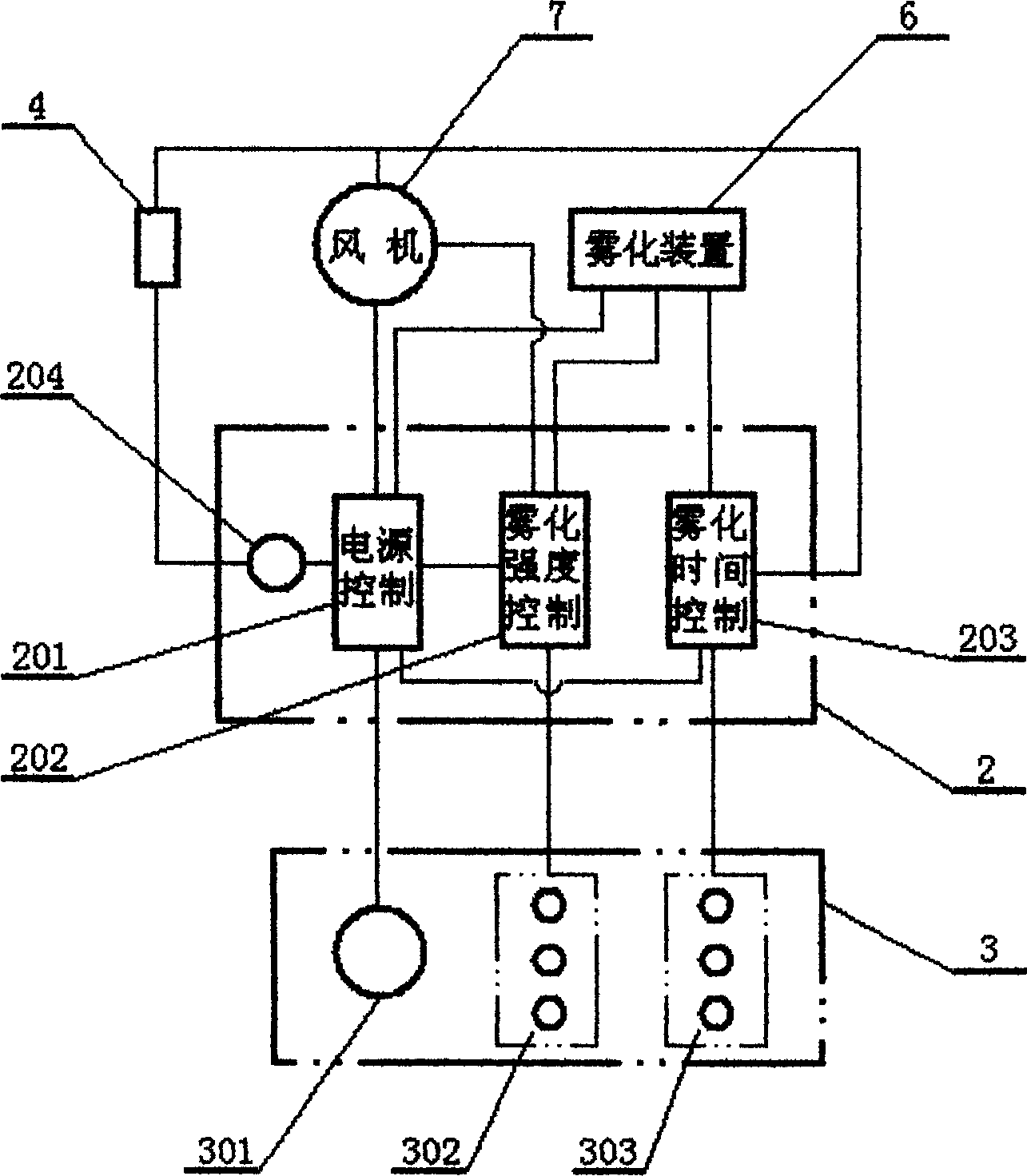

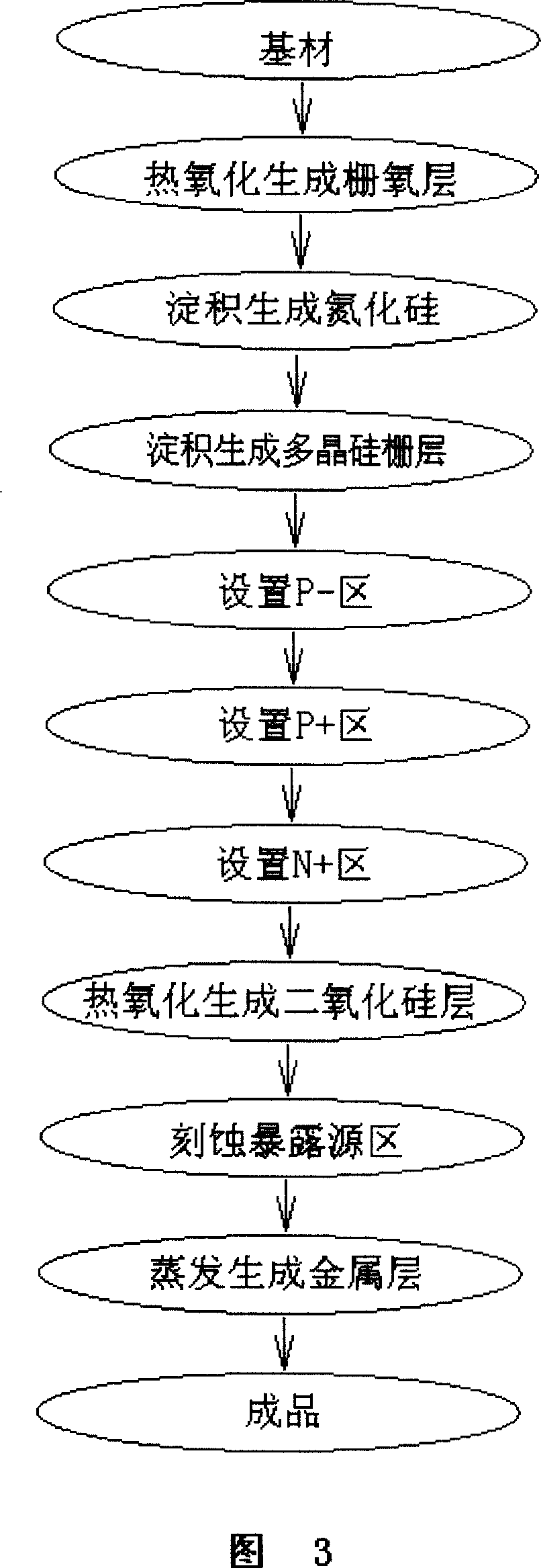

Method and device for treating fluorine-containing waste water using limestone

InactiveCN1962475ALow costReduce auxiliary workloadWater contaminantsMultistage water/sewage treatmentWater useDielectric

The invention discloses a disposing method and device of fluorine waste water through limestone, which comprises the following steps: adopting natural limestone as raw material; proceeding biochemical reaction to produce soluble calcium salt acid as middle dielectric; reacting soluble calcium salt acid and fluorine ion in the fluorine waste water to form indissolvable calcium fluoride and acid middle dielectric; reacting acid middle dielectric and limestone to produce soluble calcium salt; reacting soluble calcium salt acid and fluorine ion in the fluorine waste water to form indissolvable calcium fluoride and acid middle dielectric; circulating; disposing fluorine waste water until reaching standard. The corresponding disposing device contains reacting pond, circulating pump, neutralizing tower, sediment pond and sludge pond.

Owner:谢发达

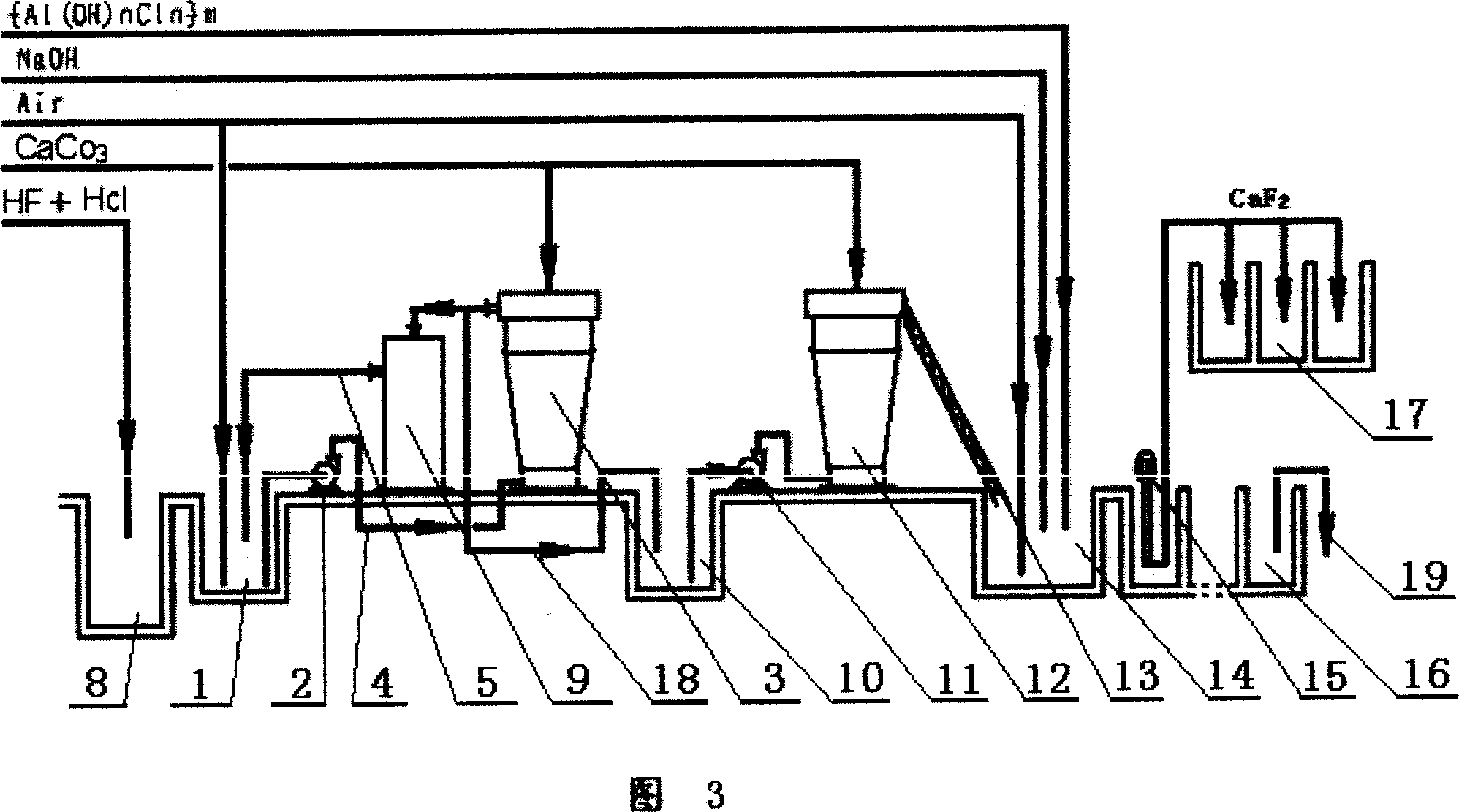

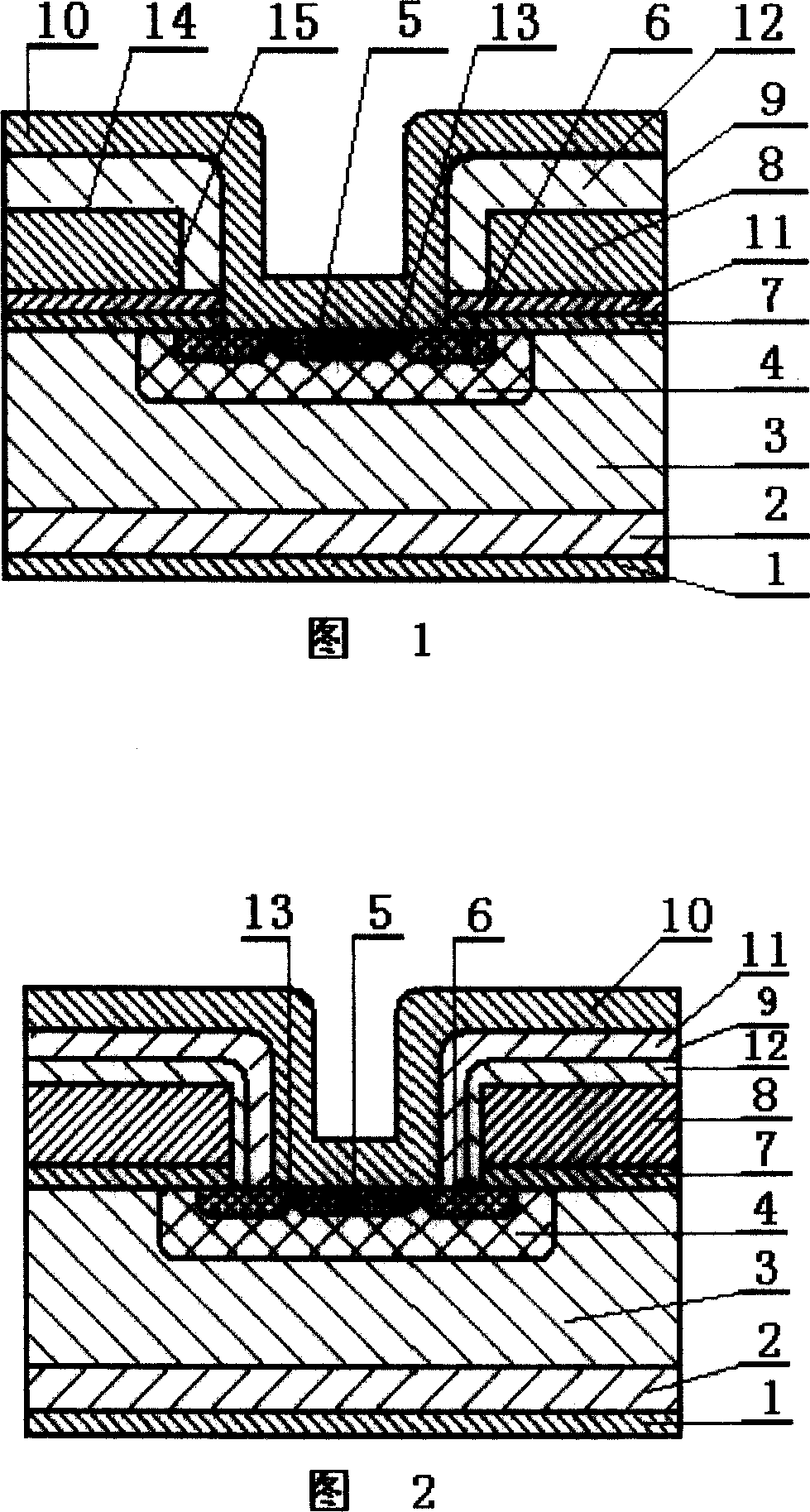

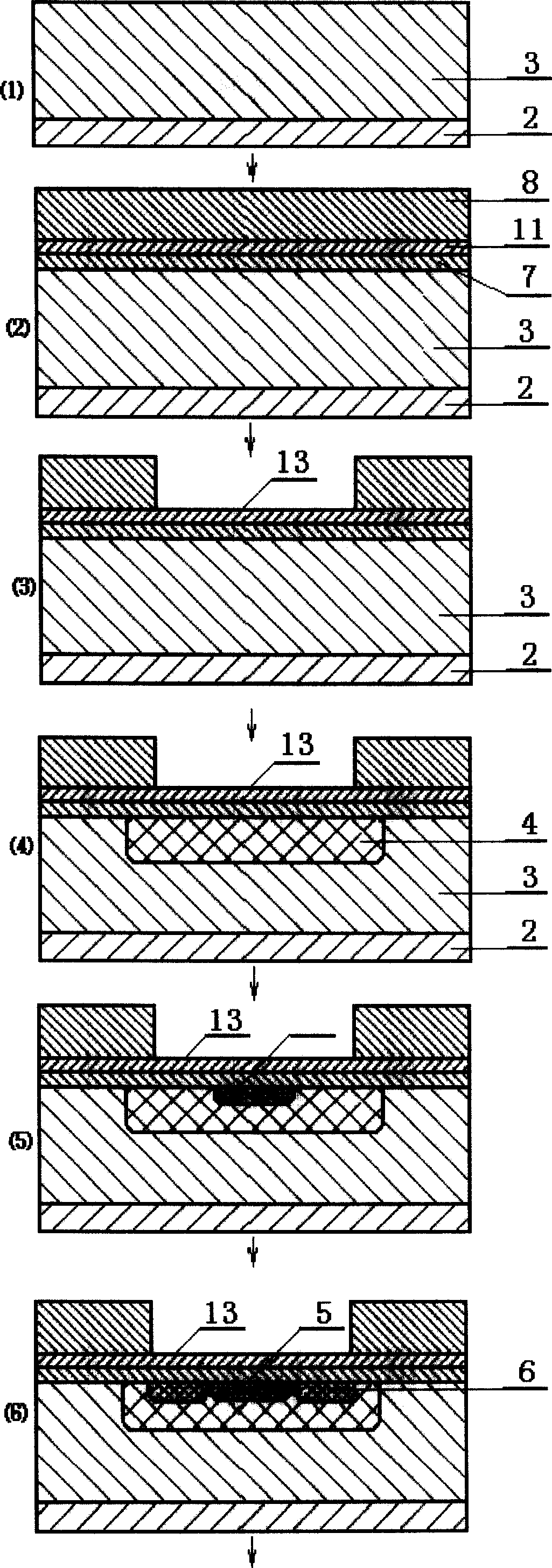

A compound bar, bar source self-separating VDMOS, 1GBT power unit and its making technology

InactiveCN101017849AQuick ShieldSimple manufacturing processSemiconductor/solid-state device manufacturingSemiconductor devicesState of artManufacturing technology

The invention relates to VDMOS and IGBT power device with composite grid and self-isolated grid-source. Wherein, it sets a thermal-oxidized SiO2 grid between source and multicrystal Si grid, and adds a Si3N4 layer to form a composite grid together with last grid to increase grid yield. Compared with prior art, this invention increase can fast shield grid window and generate only -very-thin oxidation layer to simplify manufacture technology, and needs low cost.

Owner:上海富华微电子有限公司 +1

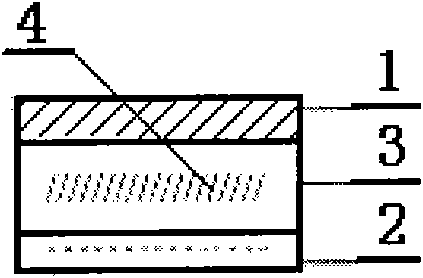

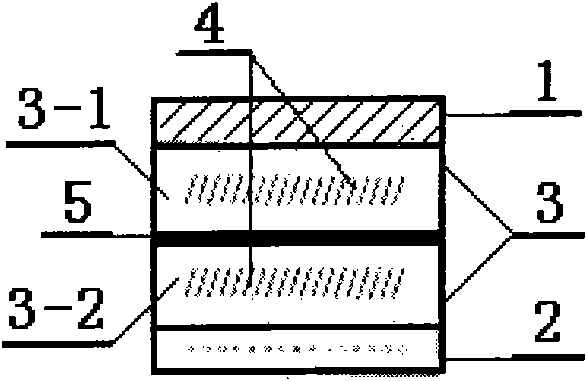

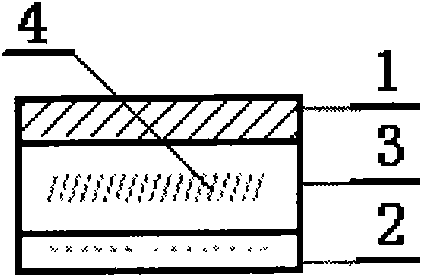

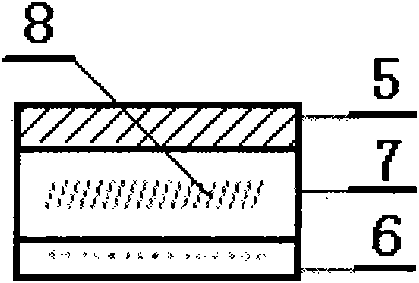

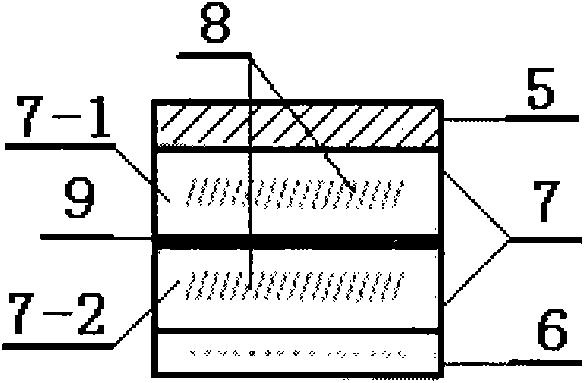

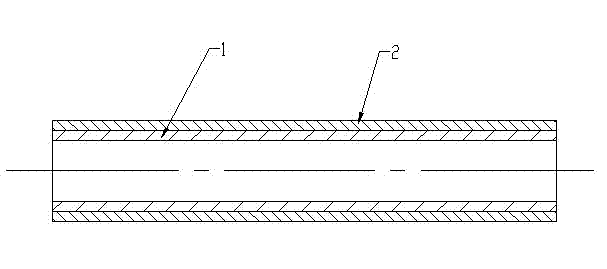

High-performance synthetic rubber asphalt waterproof coiled material

ActiveCN102031833AImprove tensile propertiesGood flexibilityRoof covering using flexible materialsBuilding insulationsPolyesterWater leakage

The invention relates to a high-performance synthetic rubber asphalt waterproof coiled material with good high and low temperature resistance, high bonding strength, good air permeability, high surface tensile strength and capability of meeting the long-term water leakage-proof use requirement in a 'composite waterproof system'. The coiled material consists of an upper coverage layer, a lower coverage layer and a middle waterproof layer, wherein the upper coverage layer is made of polyethylene polypropylene fibers, a polyethylene film or a metal aluminum foil; the lower coverage layer is made of needled polyester non-woven fabric; and the middle waterproof layer is made of modified asphalt glue layer prepared from modified asphalt glue. The performance of the coiled material is improved by organically and comprehensively utilizing special functional materials, multiple macromolecules and inorganic materials, the waterproof performance of the coiled material is greatly improved, the cost of the coiled material is effectively reduced, the service life of the coiled material is reliably guaranteed, and the coiled material used with non-curing glue can make a substantial contribution to construction of a complete composite waterproof system, so the coiled material has obvious technical advancement and strong practicability.

Owner:上海北新月皇新材料集团有限公司 +1

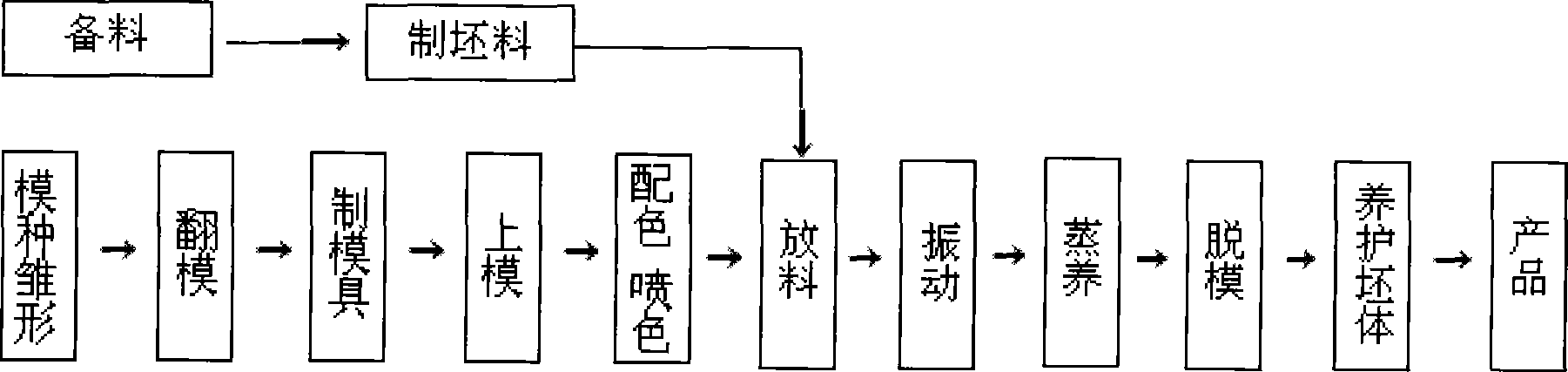

Method for manufacturing imitating natural cultural stone

InactiveCN101100090AReduce weightNon-toxicMixing operation control apparatusCeramic shaping plantsHigh volume manufacturingPortland cement

The present invention is imitation culture stone making process, which includes compounding paste material with Portland cement, float stone, ferric oxide, etc as main materials; molding in a mold made via copying natural culture stone; steam curing; demolding and further curing. The imitation culture stone has simple making process, low cost, capacity of batch producing and other advantages, and possesses broad marketing foreground.

Owner:SHANGHAI APE STONE

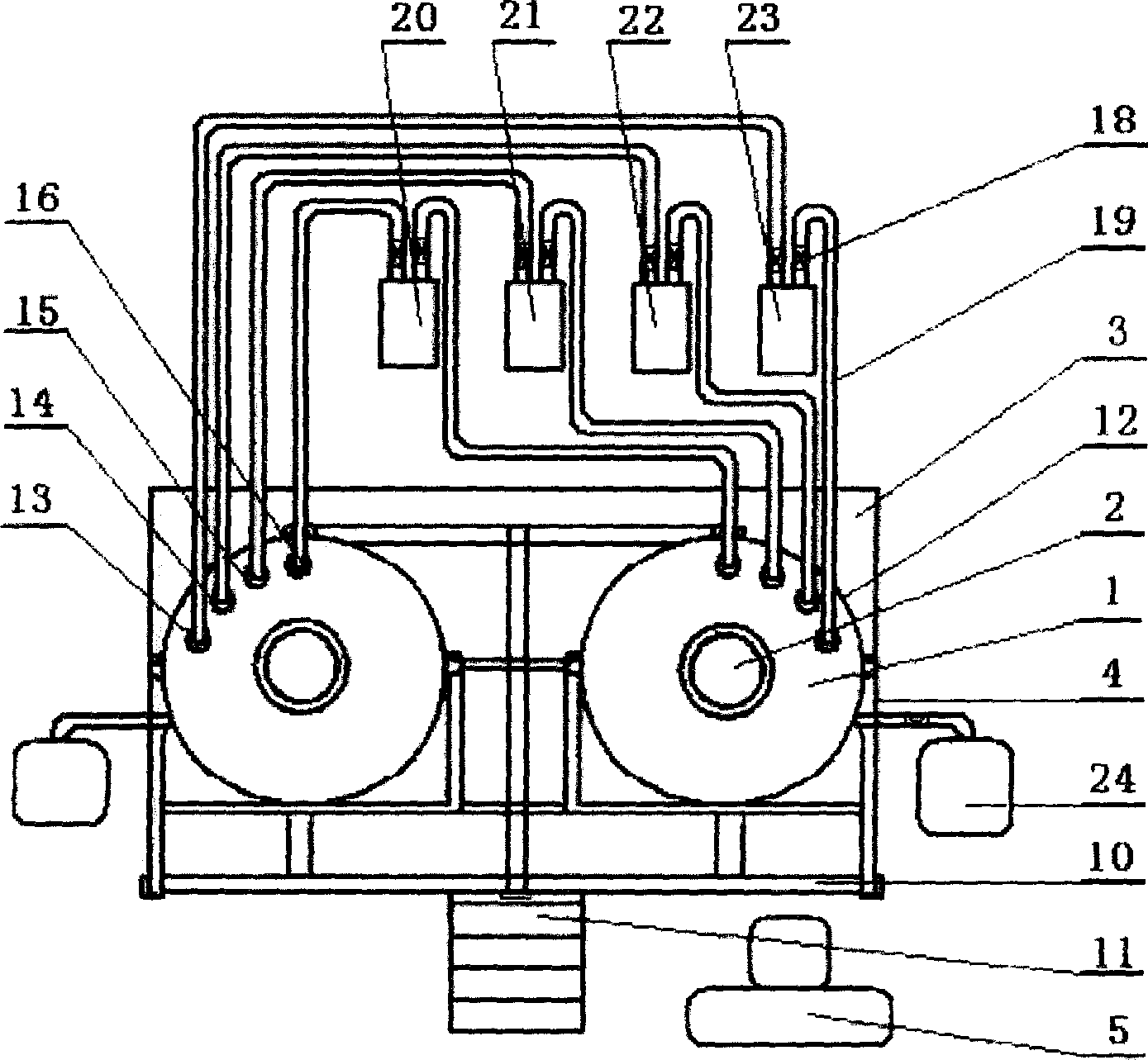

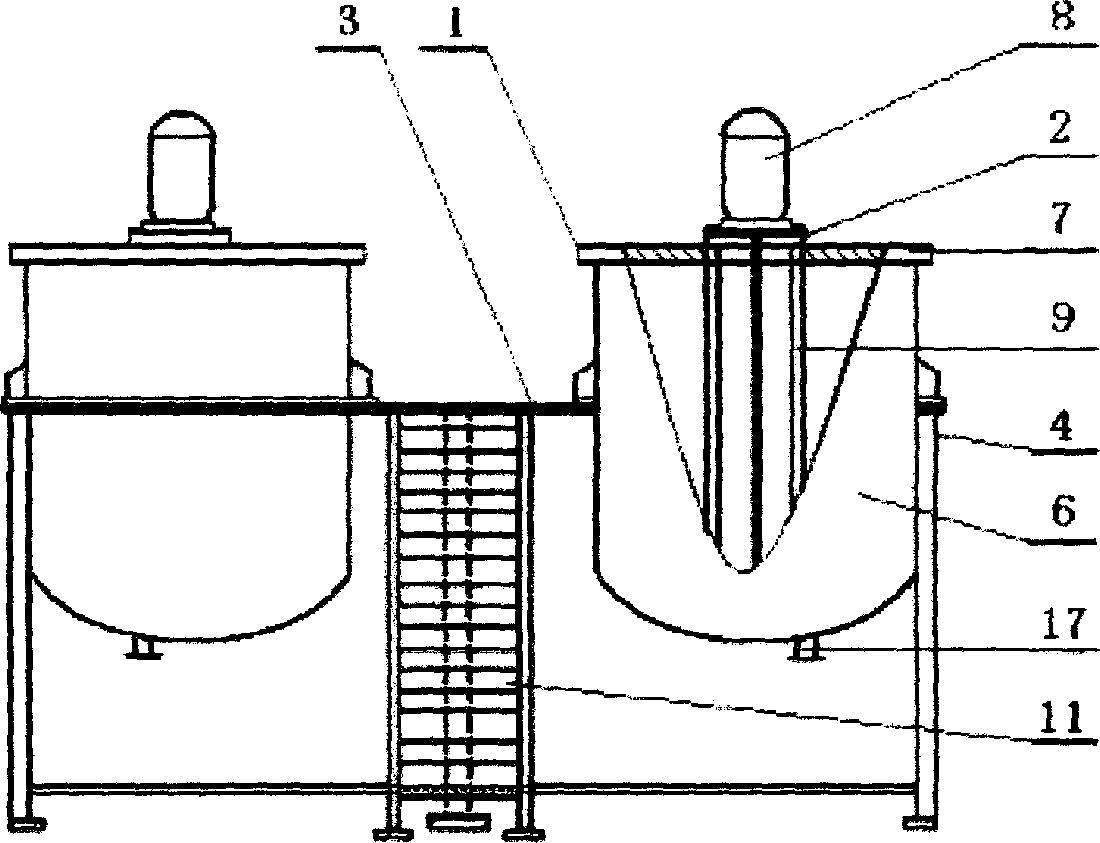

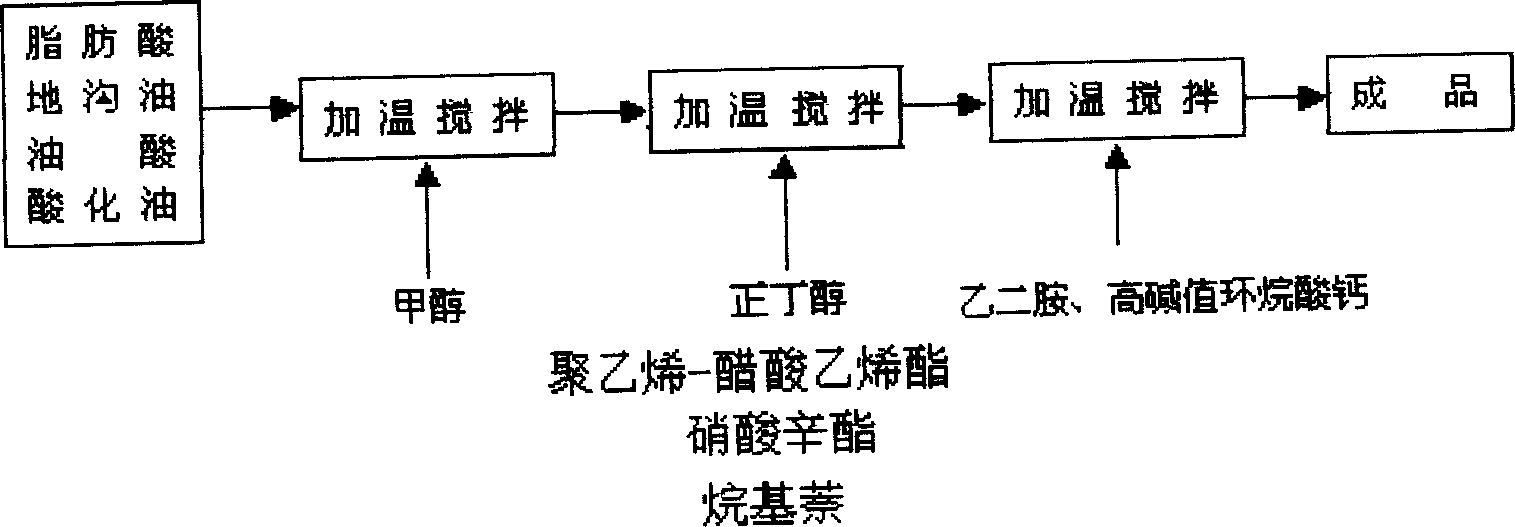

Method and device for producing biological diesel oil

InactiveCN1821348AReduce work intensitySimple processBiofuelsLiquid hydrocarbon mixture productionEthylenediamineBiodiesel

The biological diesel oil is produced with fatty acid, oleic acid, acidified oil and / or sewage oil as main material, and through adding methanol in 5-10 wt%, n-butanol in 5-10 wt%, ethylene-vinyl acetate copolymer in 0.1 wt%, octyl nitrate in 0.1 wt%, alkyl naphthalene in 0.05 wt%, and ethylenediamine and high base number calcium naphthenate successively white stirring in a reactor. The production apparatus consists of reacting tank, high speed stirrer, operating platform, rack and PLC control system. The present invention provides environment friendly biological diesel oil.

Owner:杨慈闵 +1

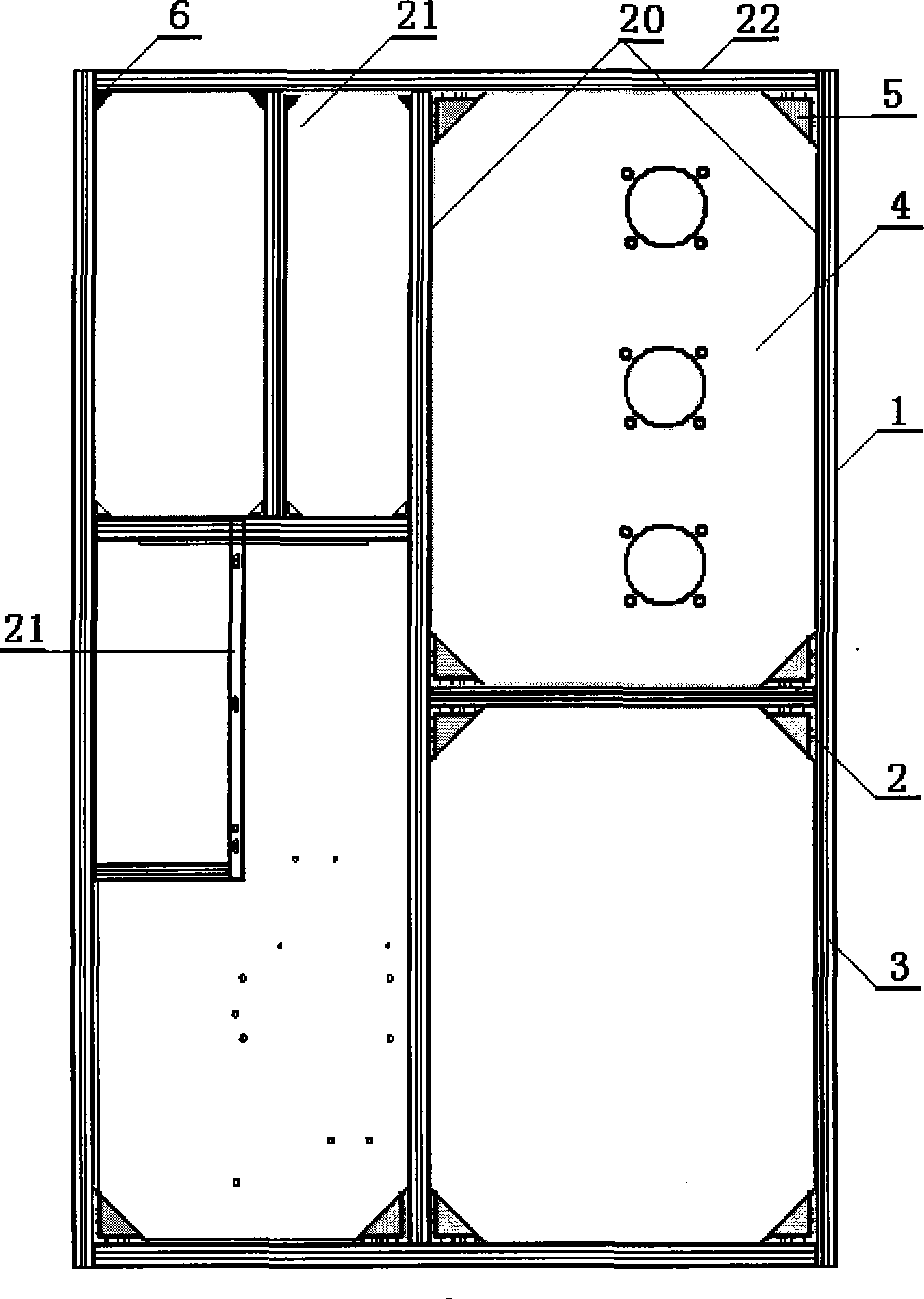

Method for manufacturing split mounting type regulator cubicle and components thereof

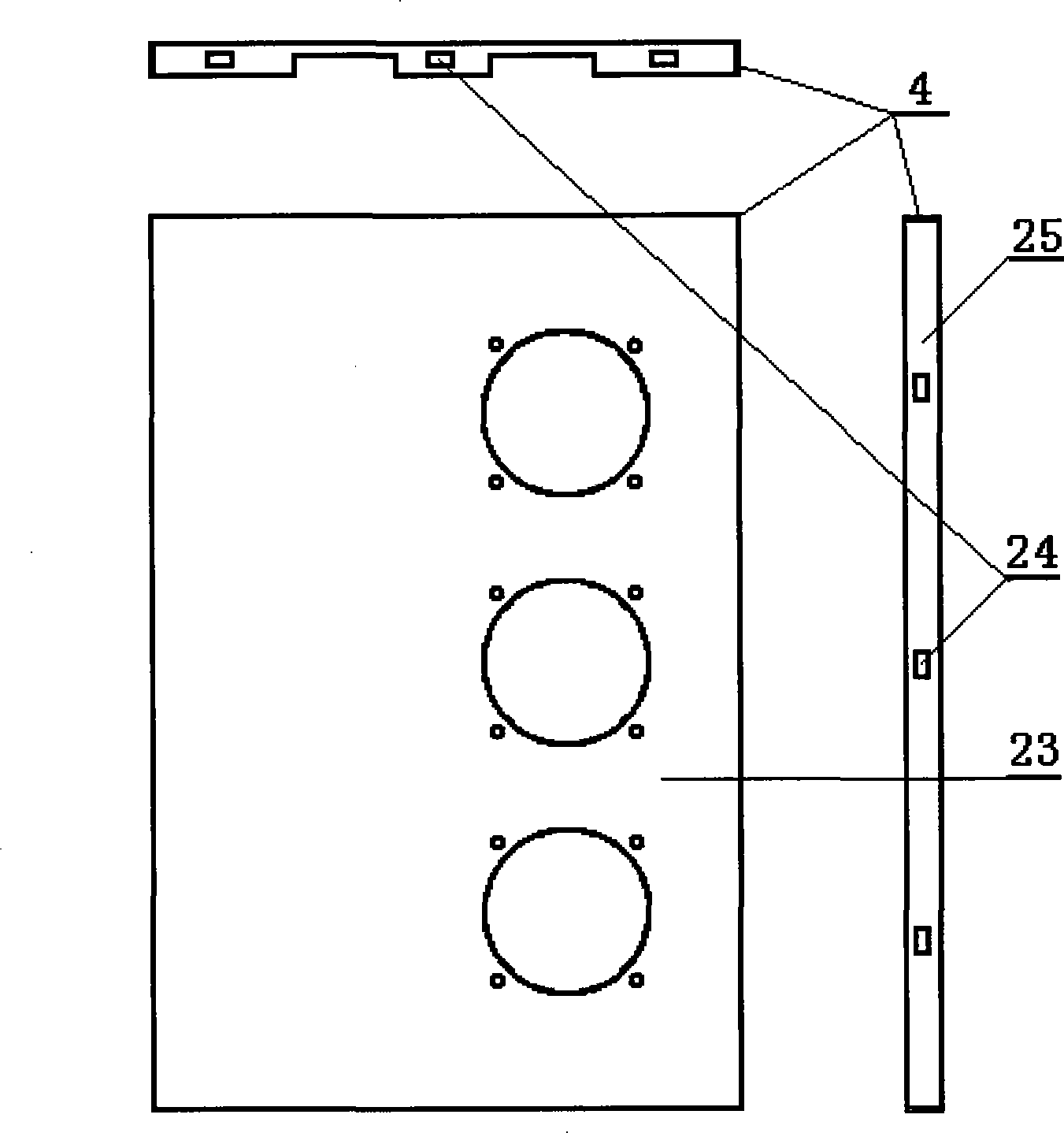

InactiveCN101252261AReliable Assembly Interconnect FunctionsReliable electrical groundingSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksEngineeringMechanical engineering

The invention relates to a method to manufacture a sectional electrical cabinet and the components thereof. The invention adopts a set of main member composed of a frame main piece and functional boards, and a combined assembly unit which consists of the auxiliary parts of a right-angle connecting base, a T-shaped bolt, a hexagon socket head bolt, a nut block, a right-angle diagonal block, a slot connecting piece, a right-angle slot base, a T-shaped connecting plate and a cross-shaped connecting plate. Installation holes are arranged on the frame main piece according to needs by making use of the central holes and the internal T-shaped slots on the frame main piece under the assistance of appropriate auxiliary parts and functional boards. Metal profiles are connected into a frame through enchasing, assembling, locking or towing and then the functional boards are installed; in this way, a target electrical cabinet with nice-looking appearance can be spliced up. The components are small in size and not multiple in variety, and require few auxiliary tools during splicing; therefore the sectional electrical cabinet is convenient for encased transport and site installation.

Owner:HUASHENG ELECTRICAL EQUIP INST SHANGHAI

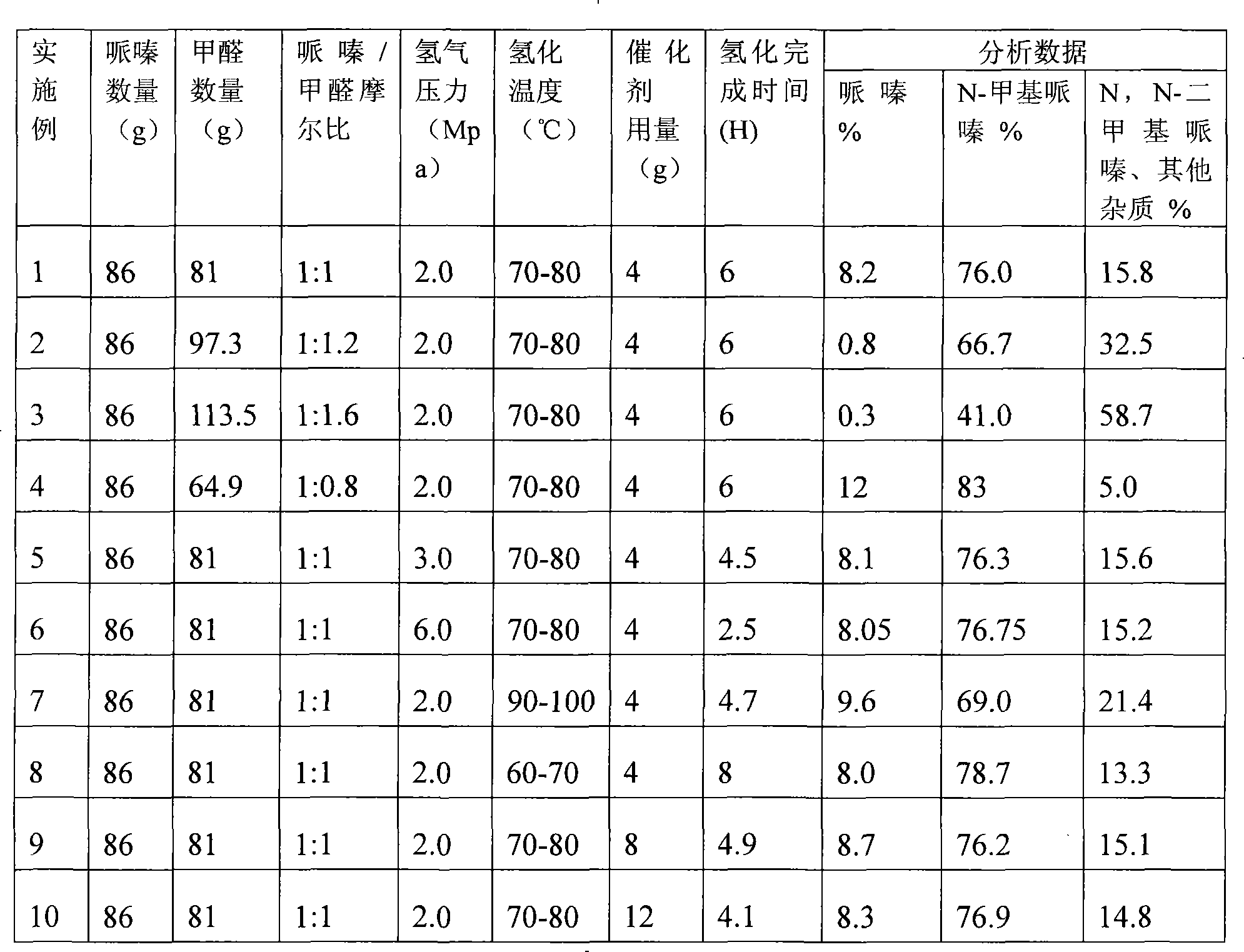

Method for synthesizing N-methylpiperazine

ActiveCN101239957AReduce consumptionReduce manufacturing costOrganic chemistryChemical recyclingChemical synthesisHydrogen

The invention relates to a synthesis method of N-methylpiperazine and chemical synthesis methods of chemical products, particularly to a synthesis process of N-methylpiperazine using vermex, formaldehyde and hydrogen as materials. Vermex is reacted with formaldehyde under atmosphere pressure to generate a condensate, and then the condensate is reacted with hydrogen in a same reaction container and under catalysis of Raney nickel catalyst to obtain N-methylpiperazine, wherein, the hydrogenation pressure is 1.0-6.0 MPa, the hydrogenation temperature is 70-100 DEG C, the catalyst dosage is 4%-12% of vermex dosage, the reaction solvent is methanol. The method has advantages of short process, low investment, high efficiency, etc.

Owner:安徽长华化工有限公司

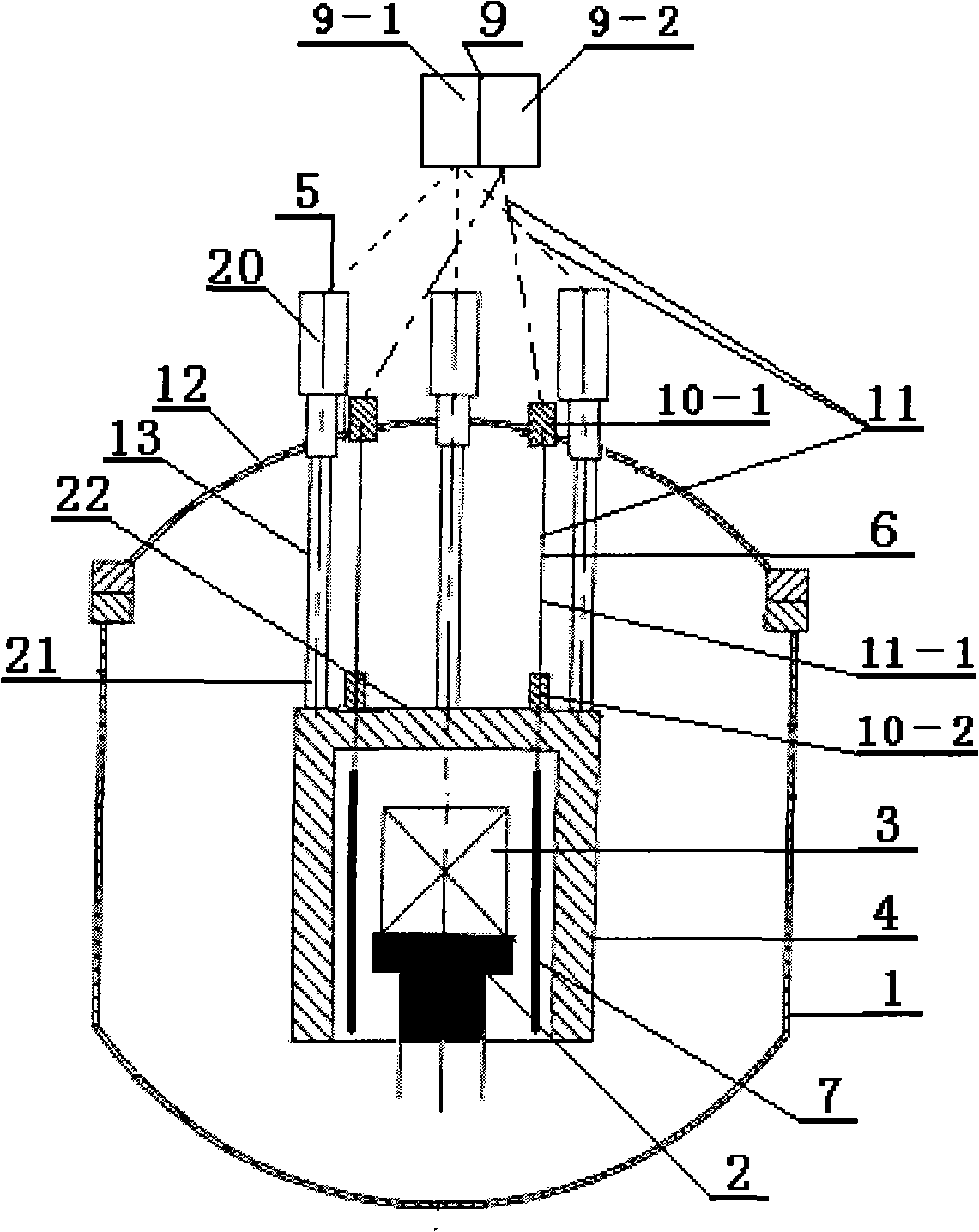

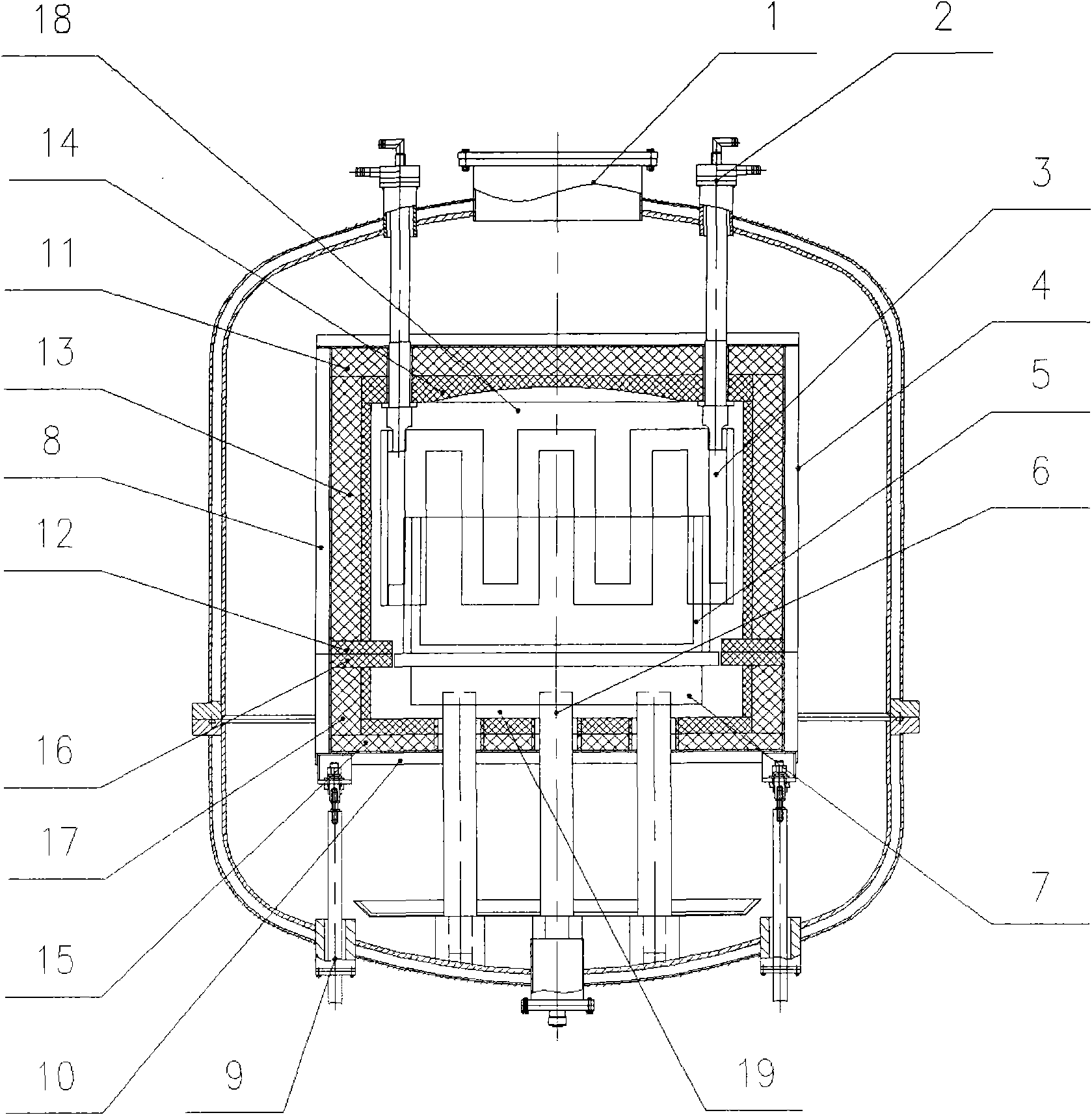

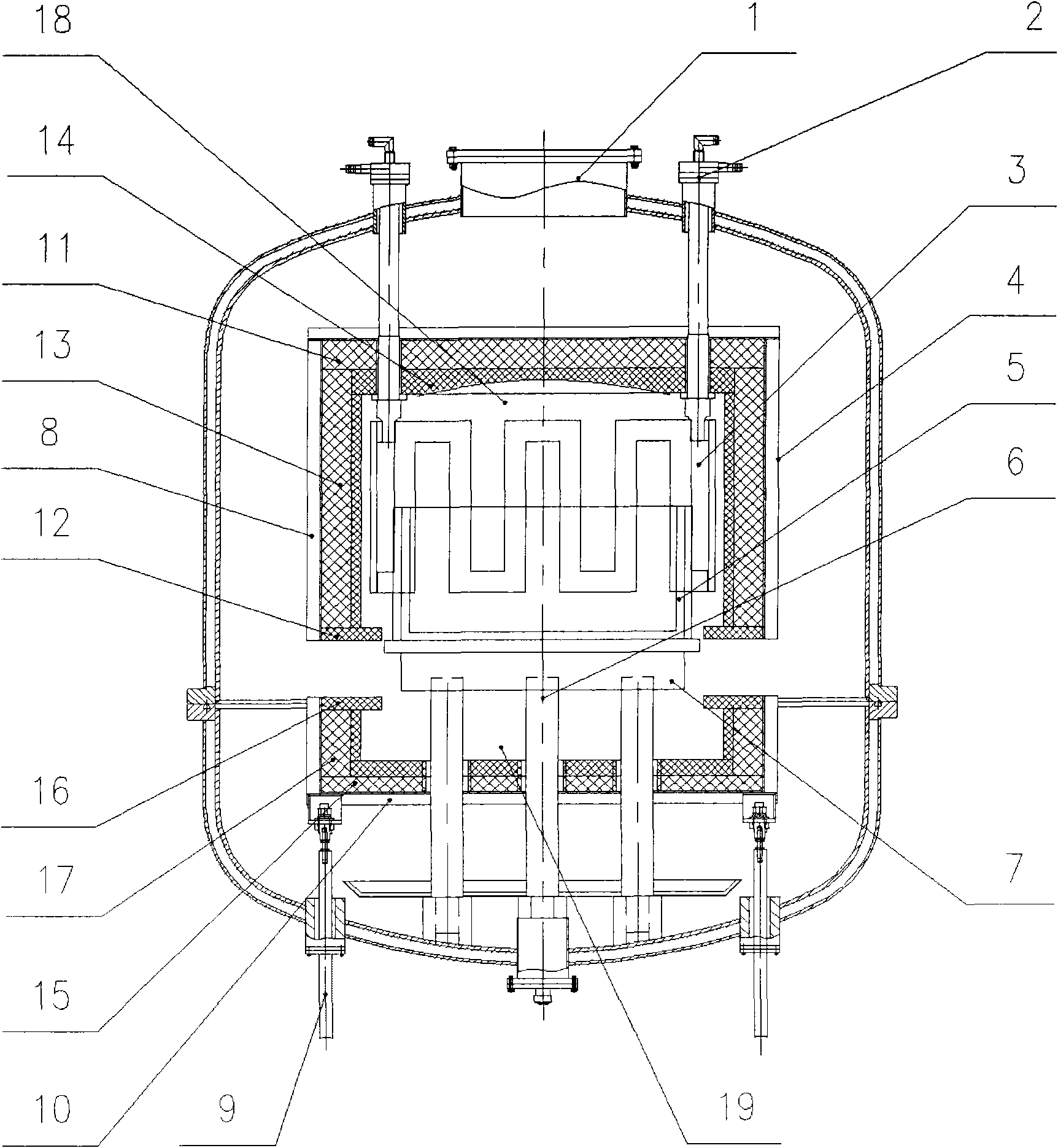

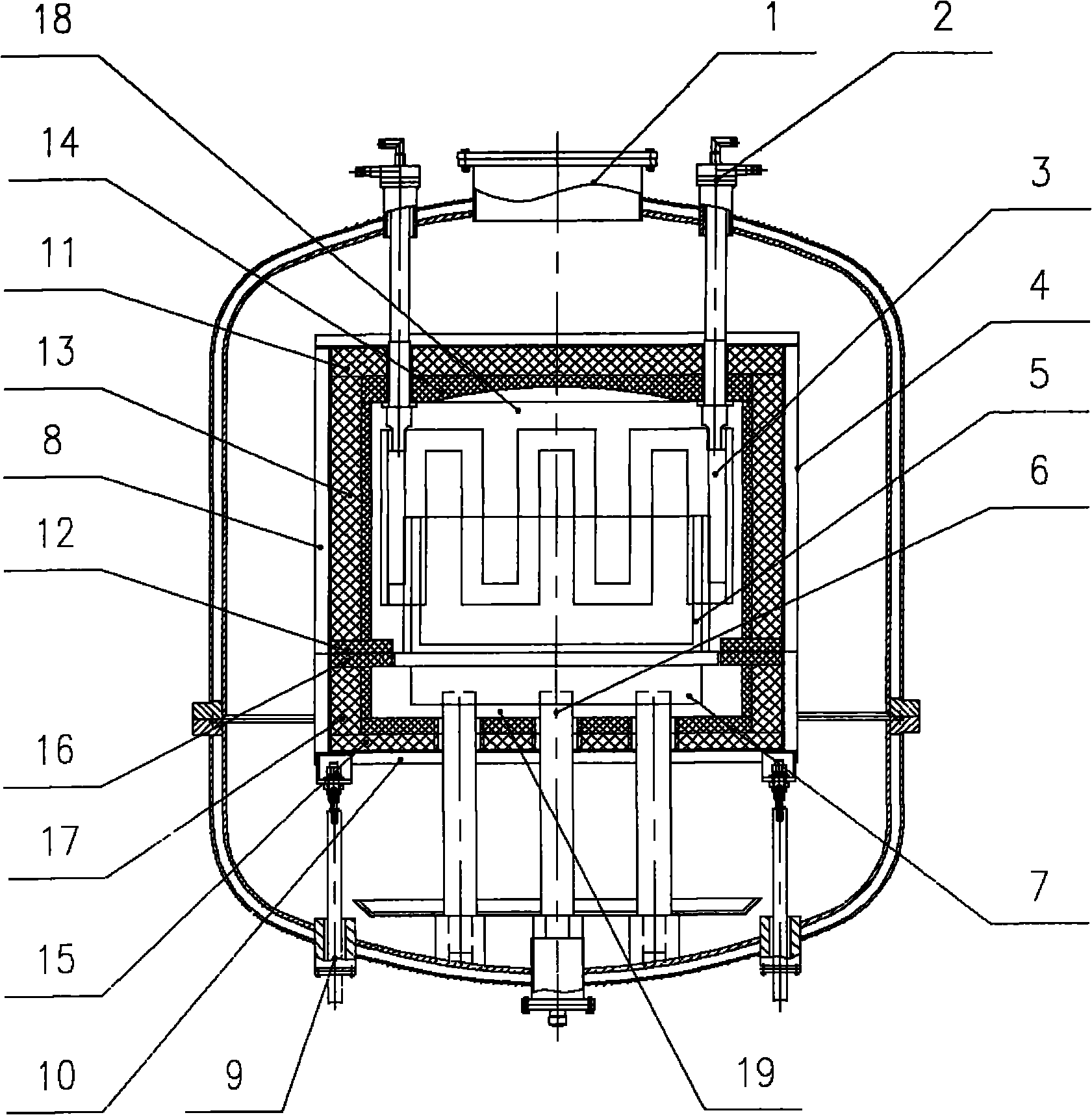

Vacuum furnace suitable for preparing large-diameter high-purity polysilicon ingot

InactiveCN101311343AScientific and reasonable structureImprove product qualityPolycrystalline material growthFrom frozen solutionsEngineeringWorking interference

The invention relates to an ingot vacuum furnace which is suitable for making polysilicon with large size and high purity. An insulating cover is designed to be a lifting type. A main body of a lifting mechanism consisting of a servo linear motion mechanism and a continuous-motion bar is arranged on a furnace cover, wherein, one end of the continuous-motion bar is fixedly arranged on the top of the insulating cover. An electrode of a power supply part is a water cooling type. A transmission cable in the furnace is a flexibility water cooling type. As a material platform and a crucible are free from the working interference of the lifting mechanism, a fixed type of the crystallization quality is beneficial to being ensured. The volume size in the crucible is only related to the bearing ability of the material platform; therefore, the crucible with large capacity is easy to be arranged. Furthermore, the water cooling type of the upper and lower electrodes and the water cooling type of the flexibility cable are adopted to ensure the reliable service life, thus ensuring the free lifting of the insulating cover. The ingot vacuum furnace has the advantages of scientific and reasonable structure, reliable working, long service life, stable product quality and high purity, which is suitable for producing polysilicon with large size and high purity and has strong practicability.

Owner:SHANGHAI CHEN HUA ELECTRIC FURNACE CORP

Method for hardening sand mold by CO2 blowing

InactiveCN1701875AEfficient and uniform hardeningReduce gas usageFoundry mouldsFoundry coresProduct gasLayer thickness

This invention relates to blowing with CO2 and hardening sand mould method. on one side wall of casting box or casting frame, set location holes according to given certain size and amount; when preparing sand mould, for different mould shapes, insert round bars crossed horizontally mould top to nearby of another side wall to wall holes accorded with blowing hole diameter and amount; on the base that ensures keep certain sand layer thickness between bar and mould surface and certain distance between its top and another side of sand box, fall moulding sand, ram and locate; after forming, draw out bar, form blowing air hole; cover plant plate on sand box top, blow CO2 till sand mould change to hard. This invention can fit to all cavities variety request; the product has advantages of well quality, even harden, easy to demould and convenient to convey.

Owner:鑫工艺(上海)材料科技有限公司

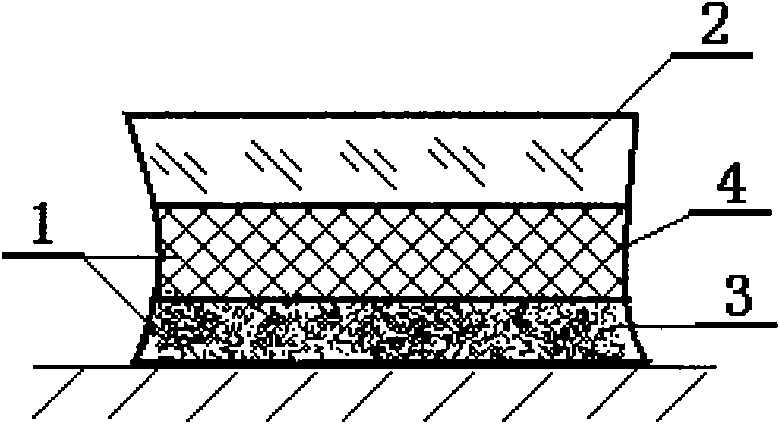

Compound waterproof system and construction technology thereof

ActiveCN102031834AImprove sealingAvoid Water Leakage SituationsRoof covering using flexible materialsBuilding material handlingWoven fabricSolid-state

The invention relates to a compound waterproof system and a construction technology thereof. The compound waterproof system comprises an inner base layer, a compound waterproof layer and an outside protective layer, wherein the inner base layer is formed by a non-solidifying waterproof gluing which has double features that the non-solidifying waterproof gluing is in a solid state after contacting with air at normal temperature and a flexible glue bonding state can be kept under sealed anaerobic conditions, the compound waterproof layer is formed by an outer strengthening layer formed by a high-performance synthetic rubber asphalt waterproof roll material composed of an upper covering layer, a lower covering layer and a middle modified asphalt gluing layer, and the outside protective layer is composed of polyethylene film or non-woven fabrics and fine stone concrete and steel bar mesh. The non-solidifying waterproof gluing is directly coated on a base surface, the waterproof roll material is covered and glued on the outer surface of the inner base layer, and the edge contacting parts and the surrounding edge parts of the waterproof roll material are all coated and sealed by the non-solidifying waterproof gluing so that the whole inner of the compound waterproof layer is in a sealed state. Adopting the setup of clod construction, the compound waterproof system has the advantages of reasonable components, scientific structure and reliable construction technology, reaches active technique effects of long-time no leakage for buildings, and has very strong practical applicability and commendable market application prospect.

Owner:上海北新月皇新材料集团有限公司 +1

Technology for manufacturing hard alloy thin-wall shaft sleeve

The invention relates to a technology for manufacturing a hard alloy thin-wall shaft sleeve, which comprises the following processes of: A, parison machining: taking a circular steel tube or a taper steel tube as a shaft sleeve parison and trimming a size of an excircle; B, spray-welding: spray-welding a hard alloy material on the external surface of the shaft sleeve parison to form an even spray-welded layer; C, external surface machining: turning or grinding a size of an excircle of the spray-welded layer; and D, internal surface machining: cutting to remove the shaft sleeve parison by using a turning or grinding method, so as to form the hard alloy shaft sleeve. The technology for manufacturing the hard alloy thin-wall shaft sleeve, provided by the invention, is a manufacturing method which comprises the following steps of: firstly spray-welding the hard alloy material on the external surface of the shaft sleeve parison and then cutting to remove the shaft sleeve parison, so as to form the hard alloy shaft sleeve, so that the molding of small-bore thin-wall hard alloy shaft sleeves is realized, and the technical difficult problem that the small-bore thin-wall hard alloy shaft sleeves are difficult to be manufactured through a powder metallurgy molding and double-surface spray-welding method currently is solved.

Owner:自贡市巨光硬面材料科技有限公司

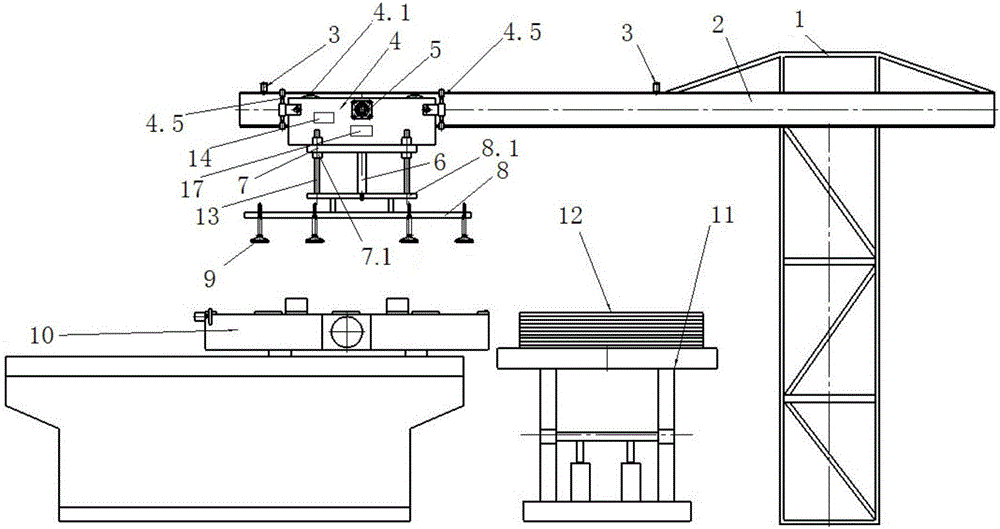

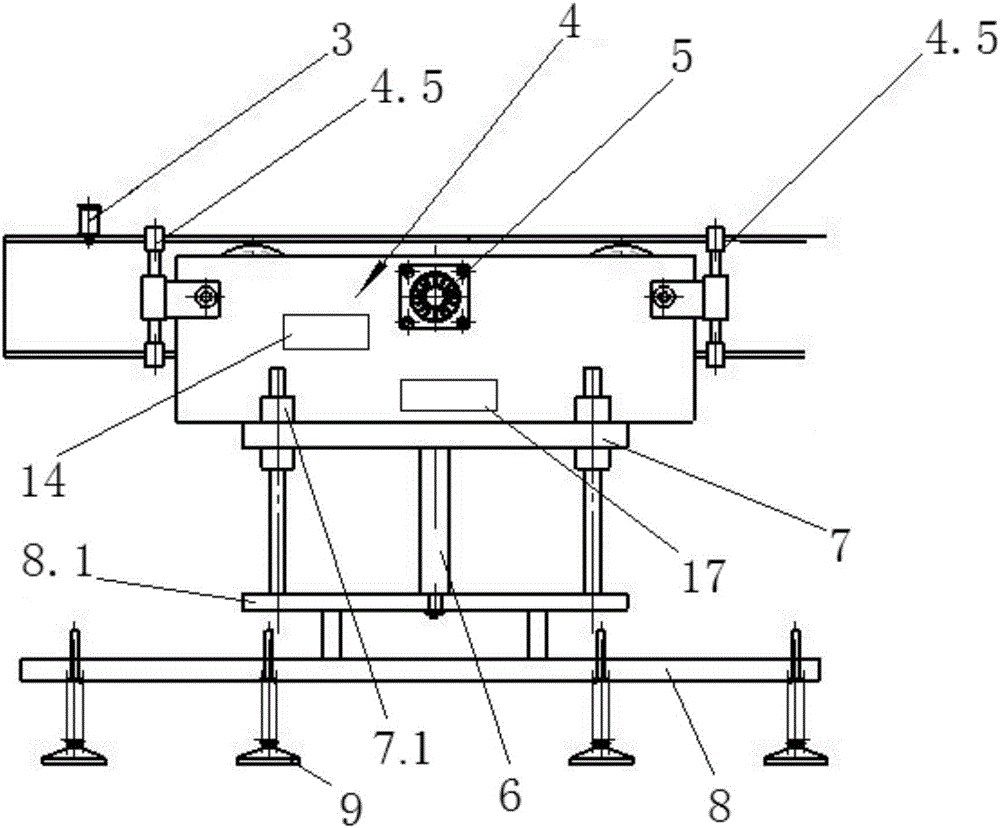

Truss trolley type automatic feeding device and method for plate stamping

InactiveCN106475485ACompact structurePracticalMetal-working feeding devicesPositioning devicesFixed frameEngineering

The invention relates to a truss trolley type automatic feeding device for plate stamping. The truss trolley type automatic feeding device for plate stamping comprises a suction disc frame, vacuum suction cups, a suction cup inflation and deflation device, a motor controller, a far-end numerical-control system, an air cylinder inflation and deflation device, a truss type stand column, vertical guide rods, an I-shaped cross beam which is fixed to the truss type stand column, a transport trolley which can be driven by a driving motor to roll on the I-shaped cross beam through a wheel set, a fixed frame fixed to the bottom of the transport trolley, and a suction cup frame lifting cylinder fixed to the fixed frame. The truss trolley type automatic feeding device for plate stamping is simple and compact in structure, high in practicability, broad in coverage and high in bearing capacity and can conveniently adapt to machining equipment of various models and plates of various types. Only one motor system for control is arranged, other components are all universal and economical profiles and parts, the occupied area is small (only the area of one stand column is required on the ground), and the technical advancement, manufacturability and economical efficiency of the automatic feeding device are all excellent.

Owner:WUHAN ENG SCI & TECH RESINST +1

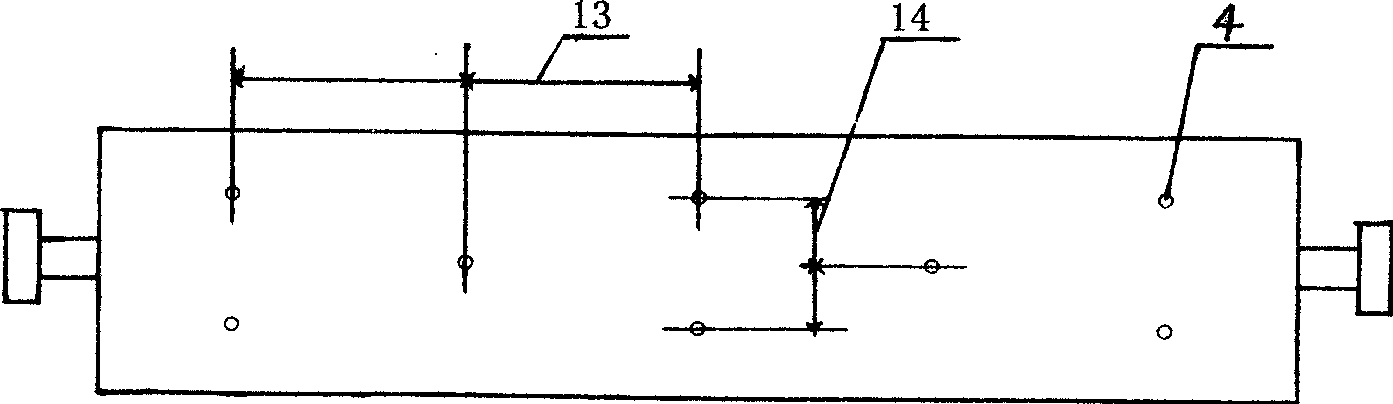

Method for repairing cracks on arcwall face of metalwork

A method for repairing the crack on arc surface of metallic object features that an arc profile plate with the copied crack line, temporary installation holes and the central locating holes arranged at intervals, several repairing screw bolts and nuts, and the arc inserts for preventing the extension of crack are used.

Owner:上海博士高环保科技有限公司

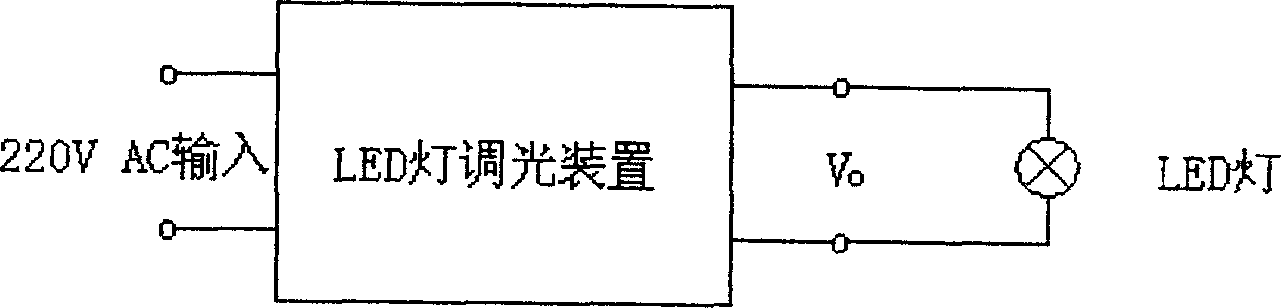

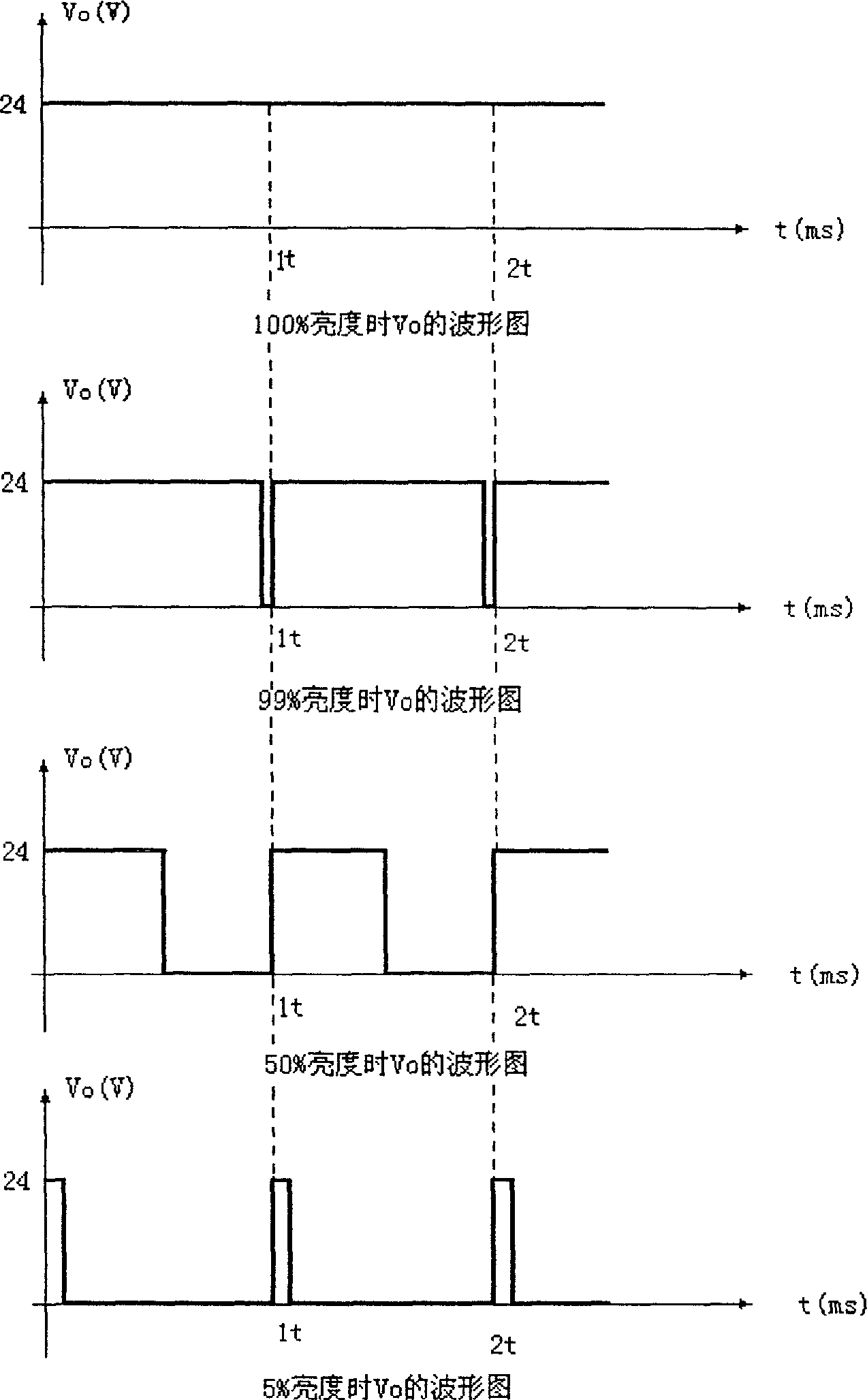

Method for regulating and controlling LED lamp lightness

InactiveCN1678157ARealize Regulatory ControlExtend working lifeElectric light circuit arrangementEnergy saving control techniquesSubjective sensationEngineering

Based on visual persistence of human eye, brightness theory of subjective sensation and characteristic of quick response of LED, controlling ducting pulse width of LED operating voltage realizes control for LED brightness when basic frequency of operational power supply is adjusted at 60Hz to 180Hz. Moreover, it is ensured that LED keeps pure white light within range of changing light brightness. The method described above is also applicable to LED in other color, that is to say brightness is adjusted while color is not changed basically. The invention solves difficult problem in brightness adjustment for LED, playing active effectiveness for using LED with advantages of energy saving, long service life, and no pollution etc.

Owner:项珏 +1

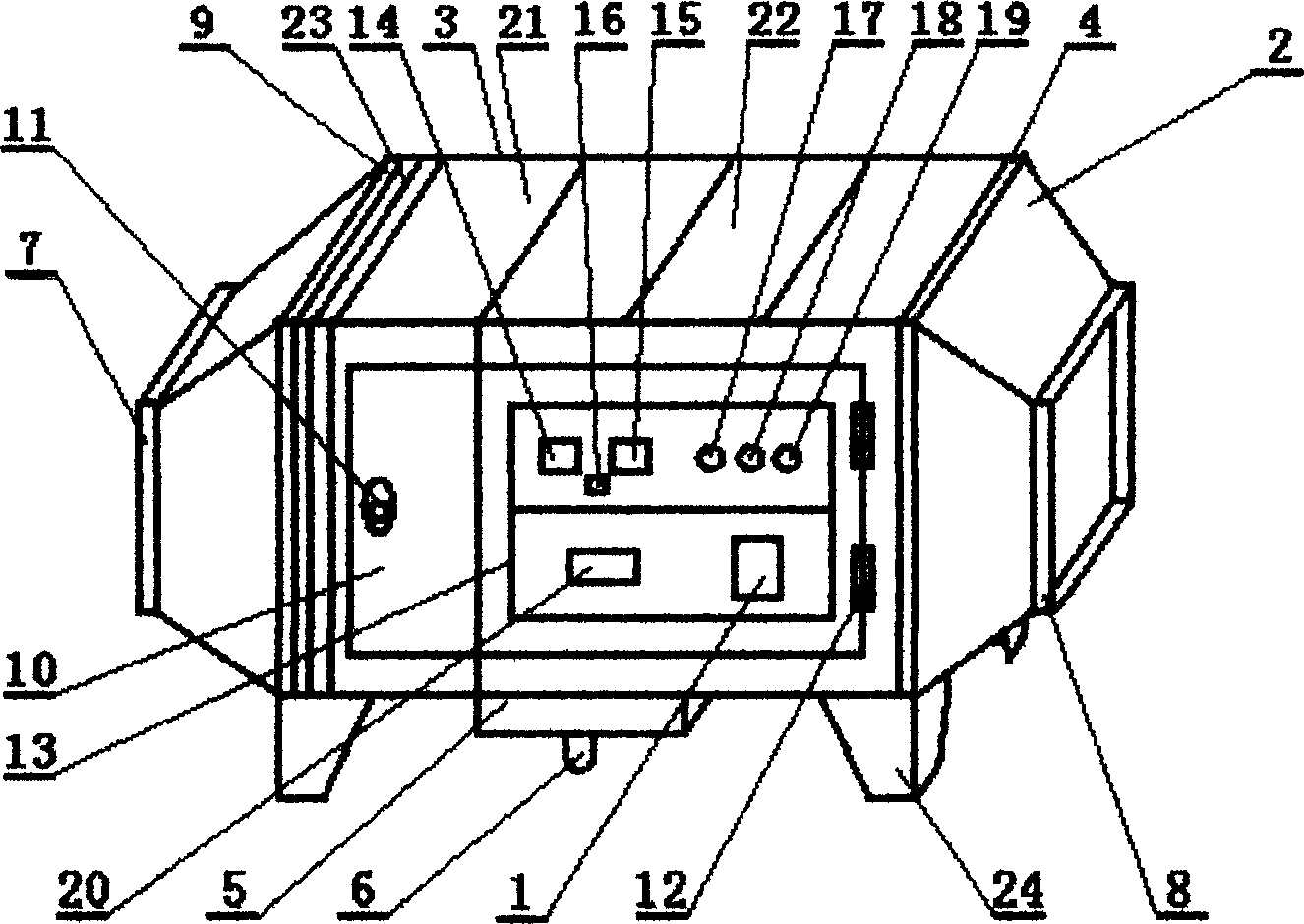

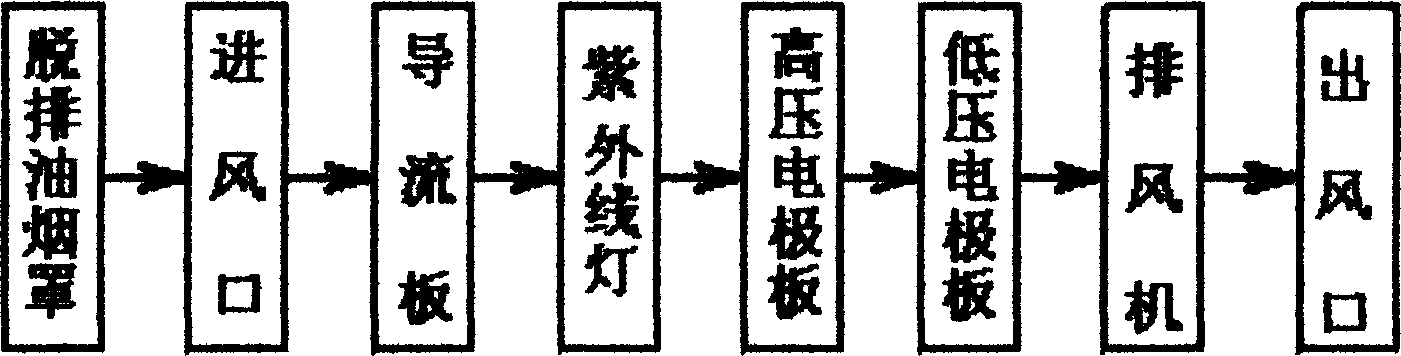

Cleaning-free smoke purifier

InactiveCN1763438AWeaken the carbon-hydrogen bondEliminate odorDomestic stoves or rangesLighting and heating apparatusTransformerUltraviolet

The invention relates to a cleaning-free smoke purifier, which comprises the following parts: cabinet, case, inner container, oil net, drip tray and valve, wherein the canned, mode built-up high-frequency and high-pressure impulse private power is set in the cabinet; the relay, delayer, transformer, overpressure and current foldback device, private controlling button switch of current and frequency adjustment are set on the cabinet; the case is made of stainless steel plate; the splitter and private ultraviolet lamp are set in the air inlet sequently; the oil web is set in the air outlet; the opening door is set on the front side of case with lock, hinge and cabinet operating panel; the inner container is oil-proof plate, which is composed of stainless steel plate and surface terphulone. The device lengthens the utility lifetime of purifier, which can work continually.

Owner:林启锋

Broad passage plate heat exchanger heat radiation board and its surface intensifying process

InactiveCN101261098AImprove product qualityImprove job stabilityMolten spray coatingStationary conduit assembliesPlate heat exchangerWater flow

The invention relates to a heating panel of a wide channel plate type heat exchanger and a surface strengthening technique thereof. The heating panel with two plates which are combined together consists of a flat section at the two ends, a middle expanding section and an inclined radiating section, wherein, the inside of the middle expanding section is provided with a water flow channel, the outside surfaces of the flat section at the two ends and the inclined radiating section are provided with an erosion-resistance reinforced layer consisting of a layered high hardness alloy powder spraying layer and a high strength resin plugging layer. The surface strengthening technique adopts the supersonic spraying technique and the oxyacetylene spraying technique in the flame spraying technique; the erosion-resistance reinforced layer consisting of the layered high hardness alloy powder spraying layer and the high strength resin plugging layer is sprayed on the erosion working surface of the heating panel, thereby improving the surface hardness and the abrasion resistance of a stainless steel plate and contributing to improving the product quality of the heat exchanger, prolonging the service life and improving the working stability.

Owner:上海富珉喷涂有限公司

Method for manufacturing lock shaft parts for container

InactiveCN1710227ASimplify production and processing proceduresIncrease productivityBuilding locksEngineeringHigh intensity

The invention discloses a center shaft component for locks of cargo container production technique with investment moulding. The invention provides with a set of rational technique from material selecting, shell making, melting, and heat processing, resolving the many technique problems in center shaft component for locks of cargo container production with investment moulding, simplifying the production procedure and lowering the cost, enhancing productivity so to be more adaptive to mass production.

Owner:上海市机械制造工艺研究所有限公司

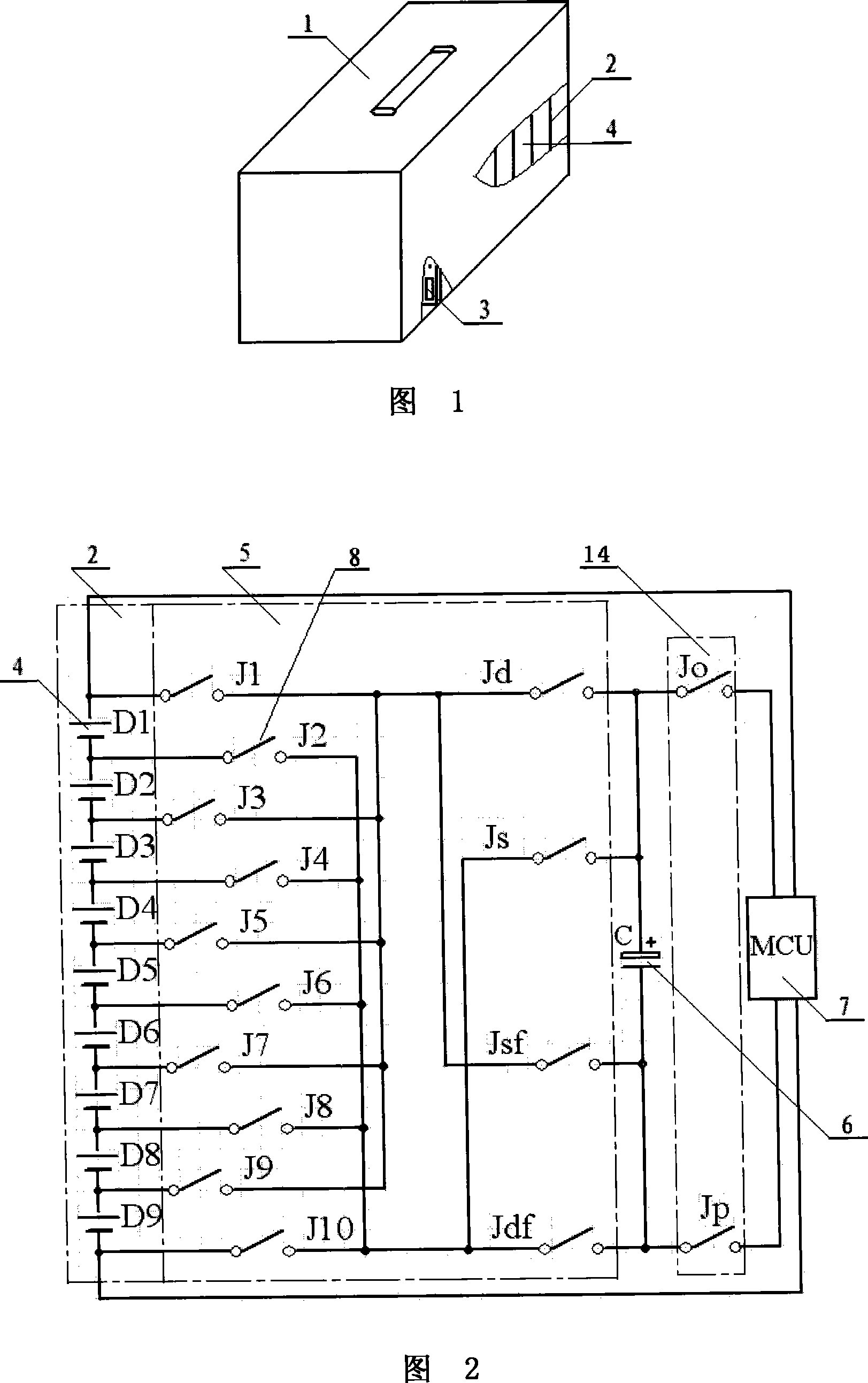

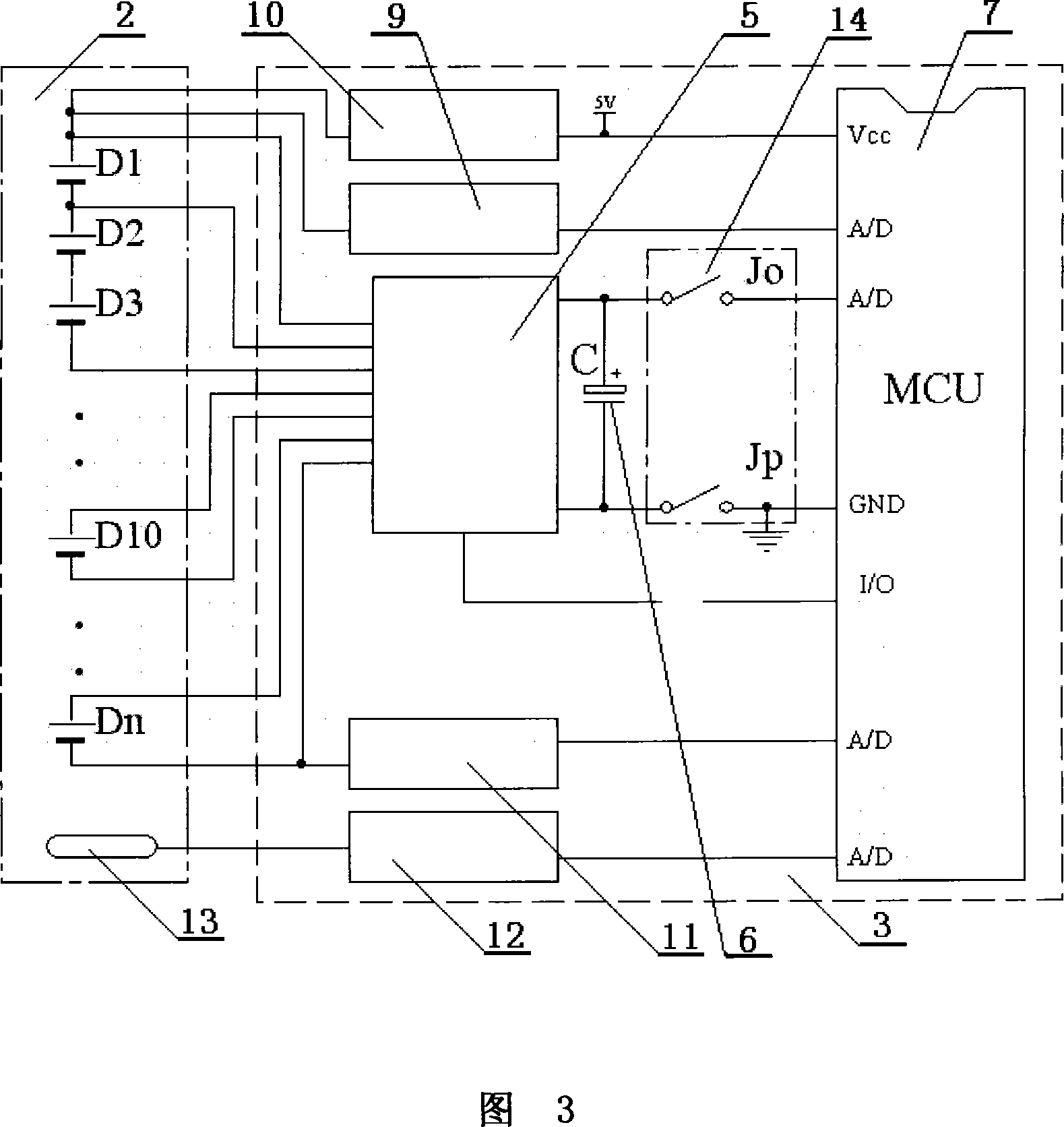

Apparatus and method for voltage equalizing of monomer battery voltage in lithium batteries

InactiveCN101207295AAvoid the disadvantages of shorter actual service lifeOvercome the disadvantages of short actual service lifeBatteries circuit arrangementsSecondary cells charging/dischargingMicrocontrollerAutomatic control

The invention relates to a voltage-equalizing method of the voltage of all single cells in the lithium-cell group and a device thereof, the device comprises a box body, a lithium-cell group and an electrical circuit board that is provided with an electronic switch component, an energy-storing element, a sampling electronic switch and a single chip. The electronic switch component consists of a group of electronic switches with one end respectively communicated with an electrode leading pin that is formed by the serial connection of the single cells, and with the other end communicated with a leading pin of a power-storage element and a signal input / output pin of the single chip. The single chip controls the on-off of the electronic switches, executes the voltage sampling of all single cells, closes the corresponding electronic switches as required, takes out and stores the surplus electric power from the single cell with higher voltage into the power-storage element so as to decrease the voltage of the single cell, and transmits the electric power stored in the power-storage element to the single cell with lower voltage so as to increase the voltage of the single cell; under the automatic control of the single chip, the electric power is automatically transferred as required, the voltage of all single cells in the lithium-cell group becomes equal to realize the voltage equalizing, thereby favoring the energy conversation and improving the service life of the lithium-cell group.

Owner:马仁源

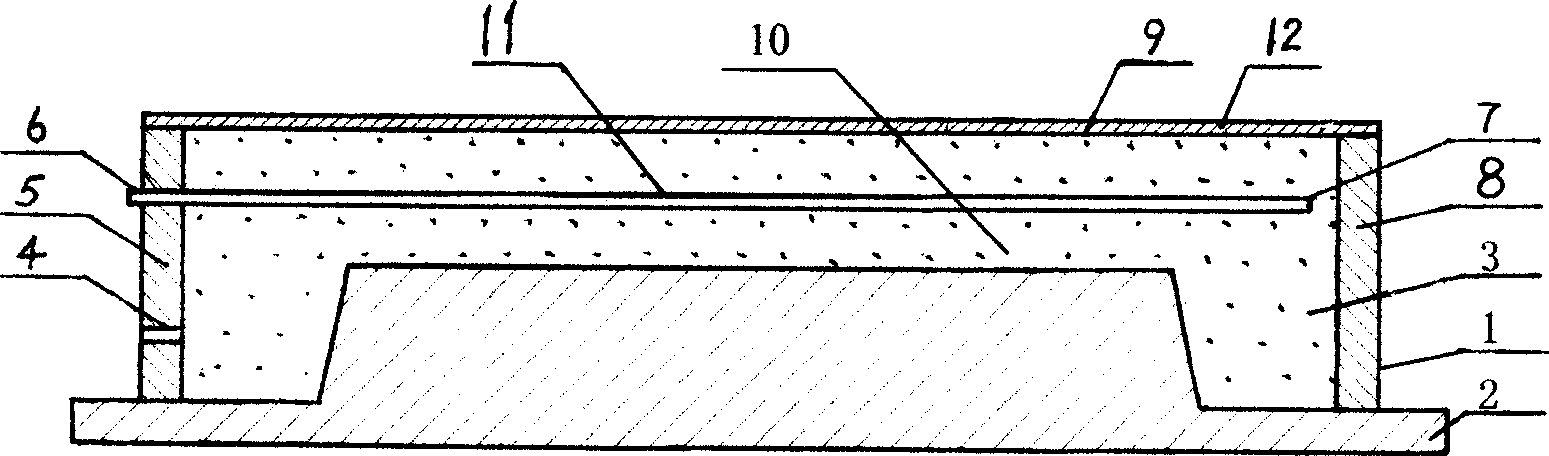

Crystalline silicon ingot furnace thermal field structure with two-stage thermal insulation cage

InactiveCN102002755ASmall deformation at high temperatureReduce Silicon LeakagePolycrystalline material growthSingle crystal growth detailsThermal insulationEngineering

The invention relates to a crystalline silicon ingot furnace thermal field structure with a two-stage thermal insulation cage. The thermal insulation cage has a two-stage structure, and consists of an upper thermal insulation cage fixed on the top of the furnace and a lower thermal insulation cage fixed on a lifting device at the bottom of the furnace; the upper thermal insulation cage is an inverted bucket, and consists of a top insulation board and an upper insulation cylinder of which the lower edge is provided with an L-shaped inner-turned upper insulation ring, wherein the top insulation board and the upper insulation cylinder are connected with each other into a whole and the inner surface of the top insulation board is provided with a concave arc reflector; the lower thermal insulation cage is an upright bucket, consists of a bottom insulation board and a lower insulation cylinder of which the upper edge is provided with an L-shaped inner-turned lower insulation ring, and is fixed on the lifting device controlled externally at the bottom of the furnace, wherein the bottom insulation board and the lower insulation cylinder are connected with each other into a whole; and the upper and lower insulating rings separate the inner cavity of the thermal insulation cage into an upper high-temperature area and a lower high-temperature area. The thermal field required by the production of the crystalline silicon is realized by adjusting the lift opening of the lower insulation cage through the lifting device; and the structure has the advantages that: the structure is simple and reasonable and obviously saves energy, the established thermal field has high stability and repeatability, the temperature is difficultly interfered by air disturbance and the structure has high practicability.

Owner:SHANGHAI CHEN HUA ELECTRIC FURNACE CORP

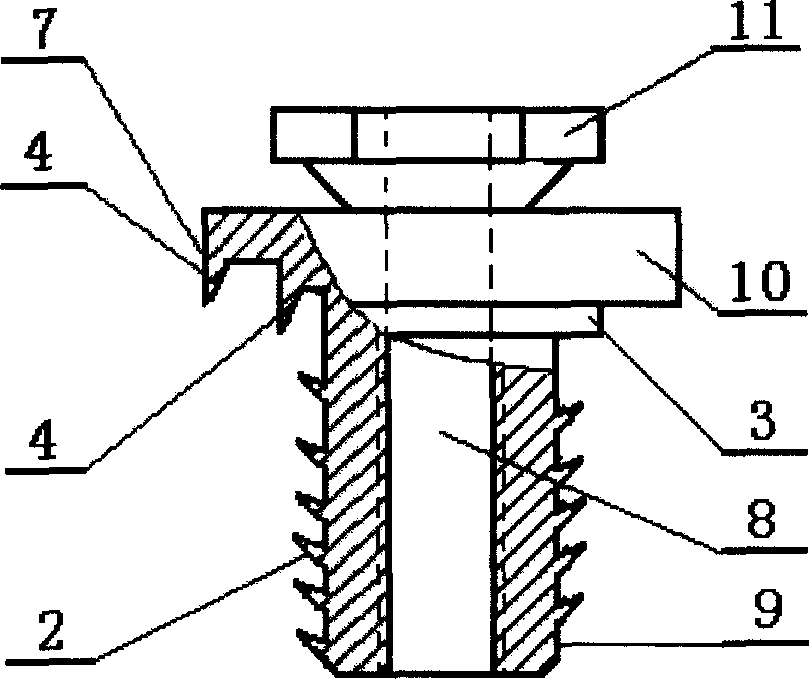

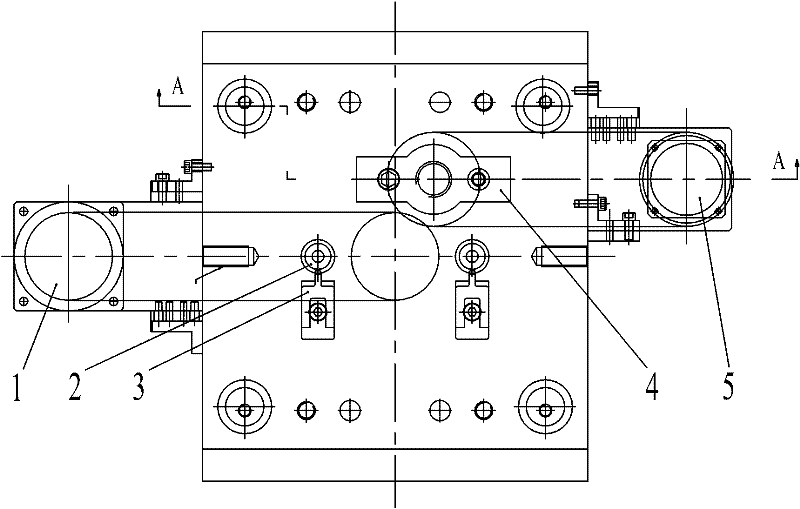

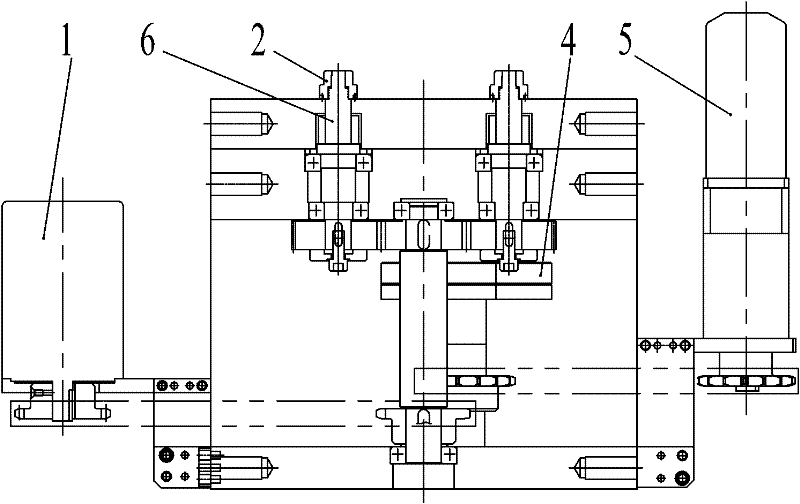

Injection mold screw thread core pulling mechanism

InactiveCN102358009AEasy to install and disassemblePlenty of spaceScrew-threads articlesControl systemSprocket

The present invention provides an injection mold screw thread core pulling mechanism. The mechanism comprises a mold cavity, an injection part, a screw thread type core inside the injection part, and a pushing plate arranged below the injection part. The screw thread type core is connected with a rotating core pulling mechanism. The pushing plate is connected with an ejection mechanism, and further comprises a PLC synchronization control system, wherein the screw thread type core pulling and the pushing plate have synchronous ejection travel through the PLC synchronization control system. The ejection mechanism comprises a servo motor, a sprocket pair and a screw rod nut pair, wherein the servo motor is connected with the sprocket pair, the sprocket pair is connected with the screw rod nut pair, the screw rod nut pair is connected with the pushing plate. The injection mold screw thread core pulling mechanism provided by the present invention has a reasonable and compact structure, and adopts the screw rod nut, such that the rotation movement is directly transformed into the linear movement, the ejection mechanism further becomes the labor-saving mechanism so as to reduce the torsional moment of the servo motor, conveniently install the mechanism. In addition, the injection mold screw thread core pulling mechanism provided by the present invention has significantly technical advancement.

Owner:SHUNDE POLYTECHNIC

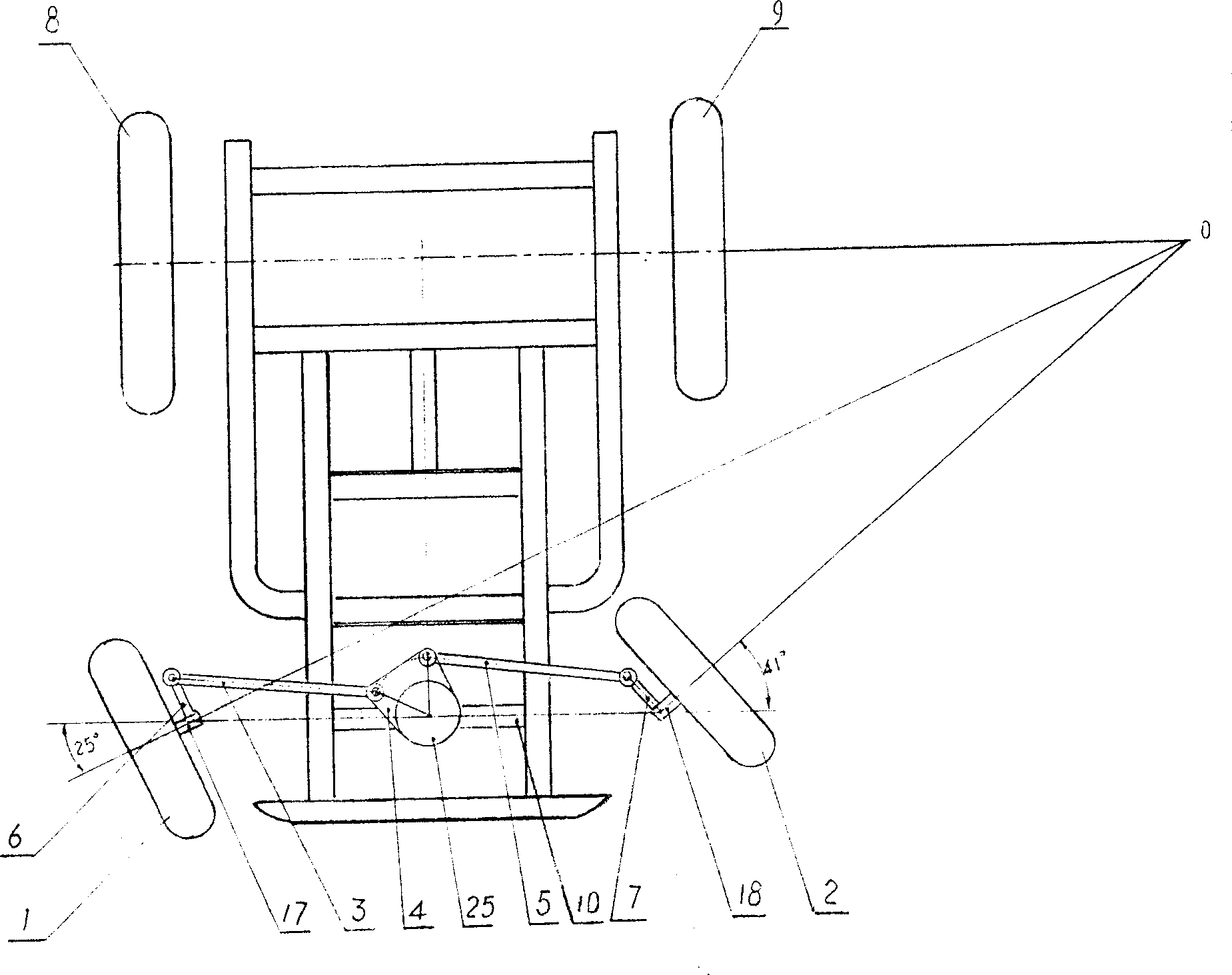

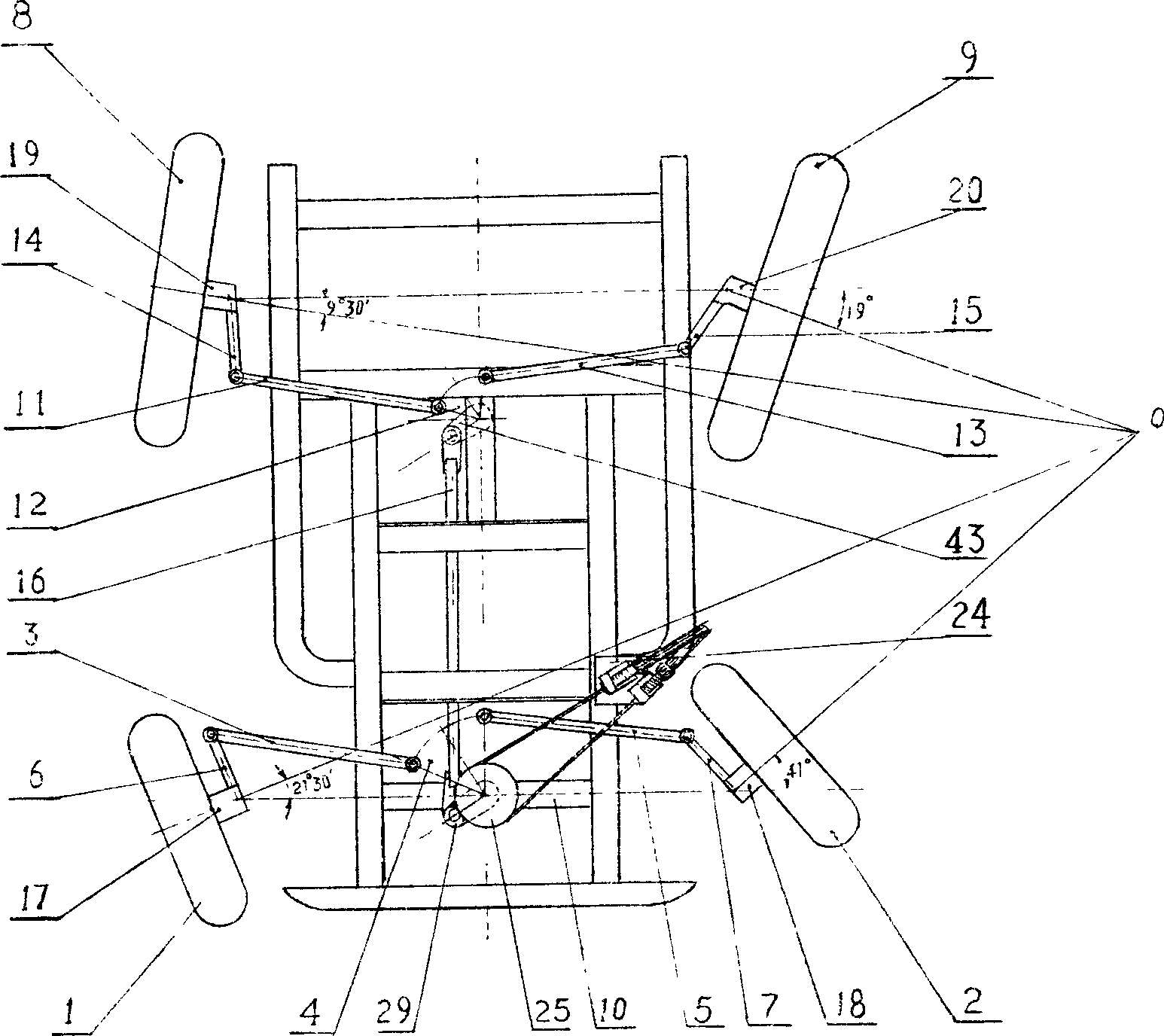

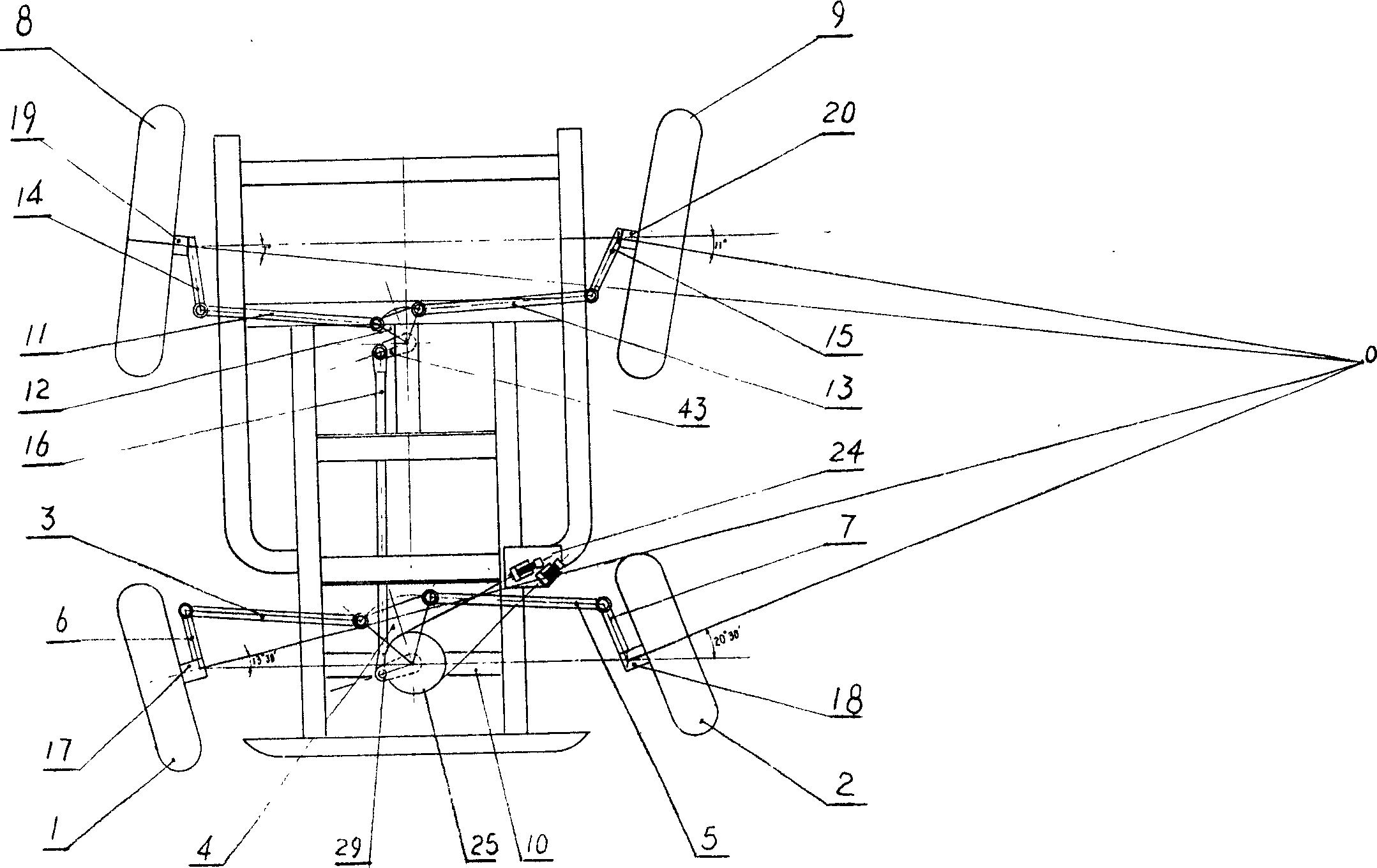

Four-wheel steering electric walk instead vehicle

InactiveCN1698563AObvious technological advancementPracticalWheelchairs/patient conveyanceWheelchairSynchronous control

The invention provides a four-wheel steering electric walk instead vehicle, wherein a front and a rear fork devices are arranged on the frame, the fork devices are driven by a front and a rear connecting rod connected with a front and a rear fork rocker arms for synchronous movement, and corresponding wheel diversion movements are realized through the synchronous control by each fork boards, thus the four wheels are steered simultaneously under control, and the minimum turning radius is determined by the point of intersection of the four wheel axis. The minimum turning radius can be reduced by around 30%.

Owner:葛家莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com