Truss trolley type automatic feeding device and method for plate stamping

An automatic feeding, trolley-type technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unsuitable for wide and heavy-duty plates, complex control system, poor matching ability, etc., and achieve small footprint , excellent economy and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

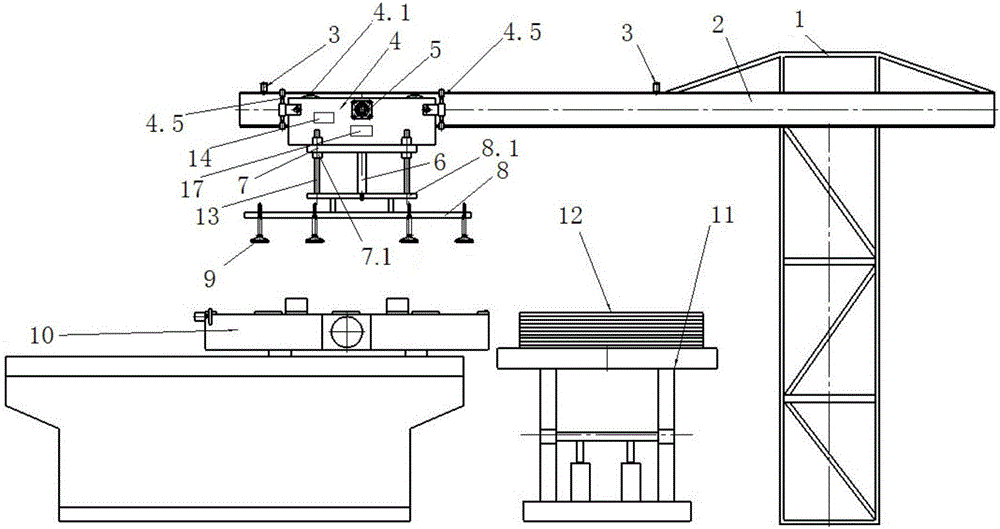

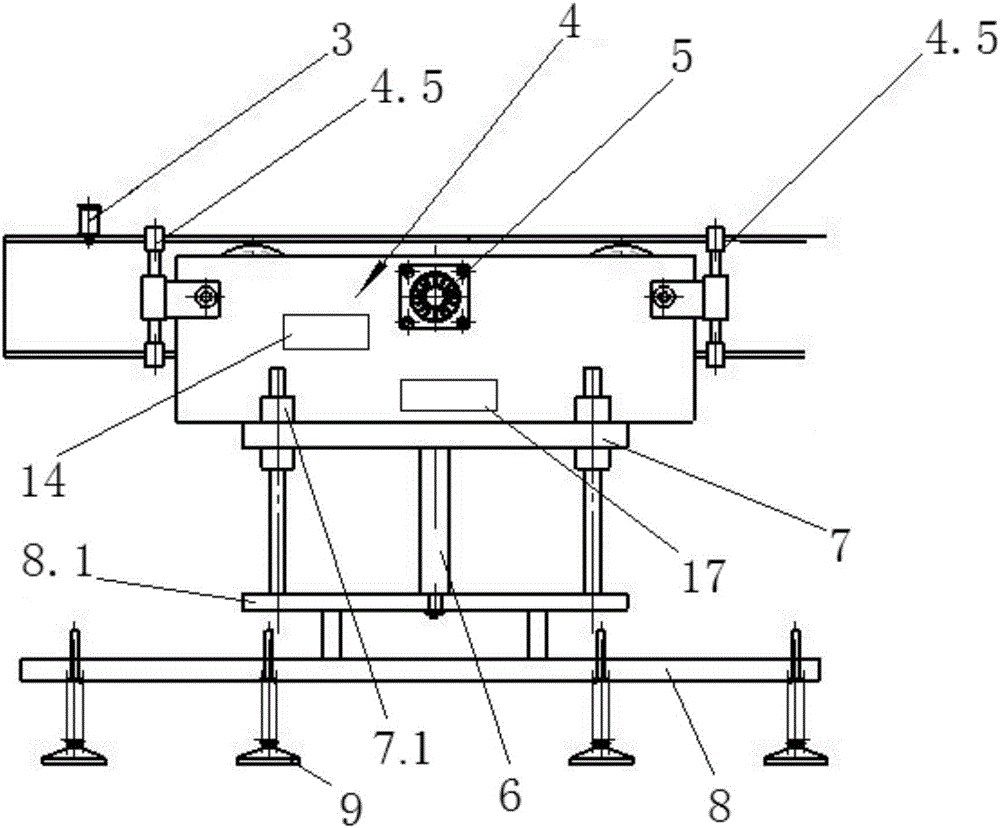

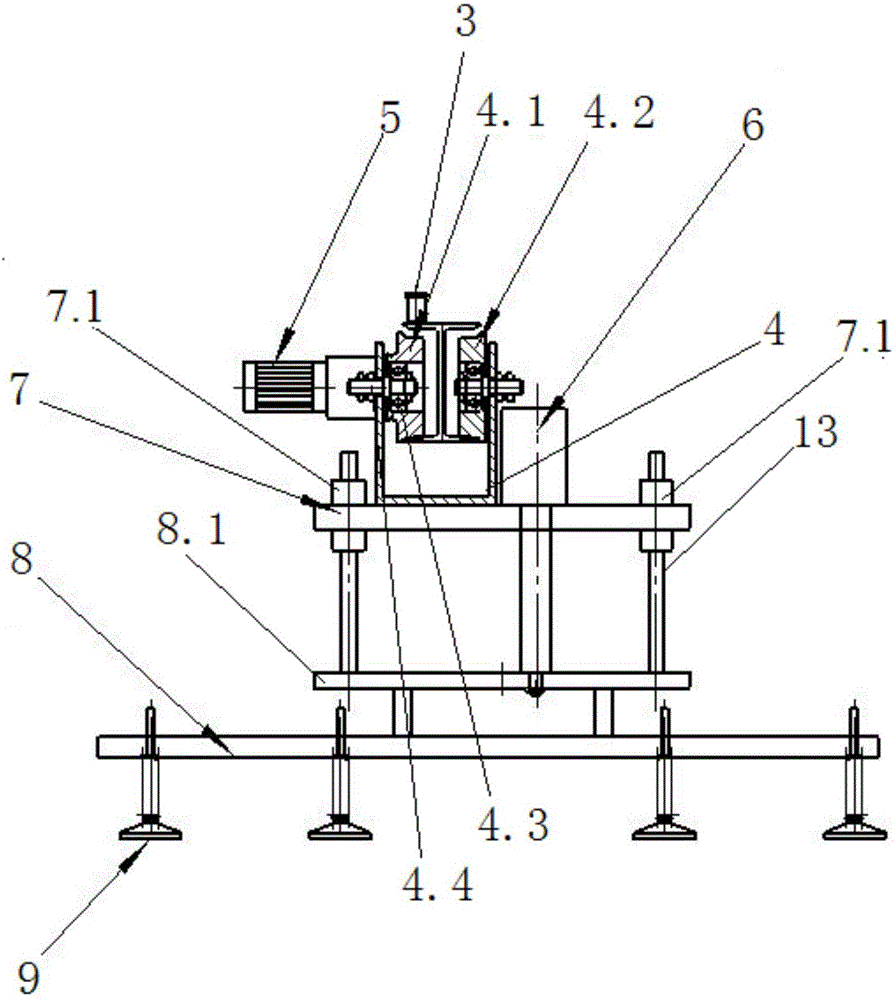

[0018] The truss trolley type plate stamping automatic feeding device of the present invention includes a suction cup frame 8, a vacuum suction cup 9, a suction cup charging and deflation device 14, a motor controller 15, a remote numerical control system 16, a cylinder charging and deflation device 17, a truss type Column 1, vertical guide rod 13, I-shaped beam 2 fixed on the truss-type column 1 (connected by welding, riveting, screw fixing), driven by the drive motor 5, it can roll on the I-shaped beam 2 through the roller group The transport vehicle 4, the fixed mount 7 fixed on the bottom of the transport cart 4, the suction cup frame lifting cylinder 6 arranged on the fixed mount 7, wherein, the cylinder block of the suction cup frame lifting cylinder 6 is fixed on the fixed mount 7, and the suction cup frame 8 The top is fixed with the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com