Method for manufacturing lock shaft parts for container

A technology for containers and locks, applied in building locks, building structures, buildings, etc., to achieve the effects of adapting to large-scale production, significant technological advancement, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

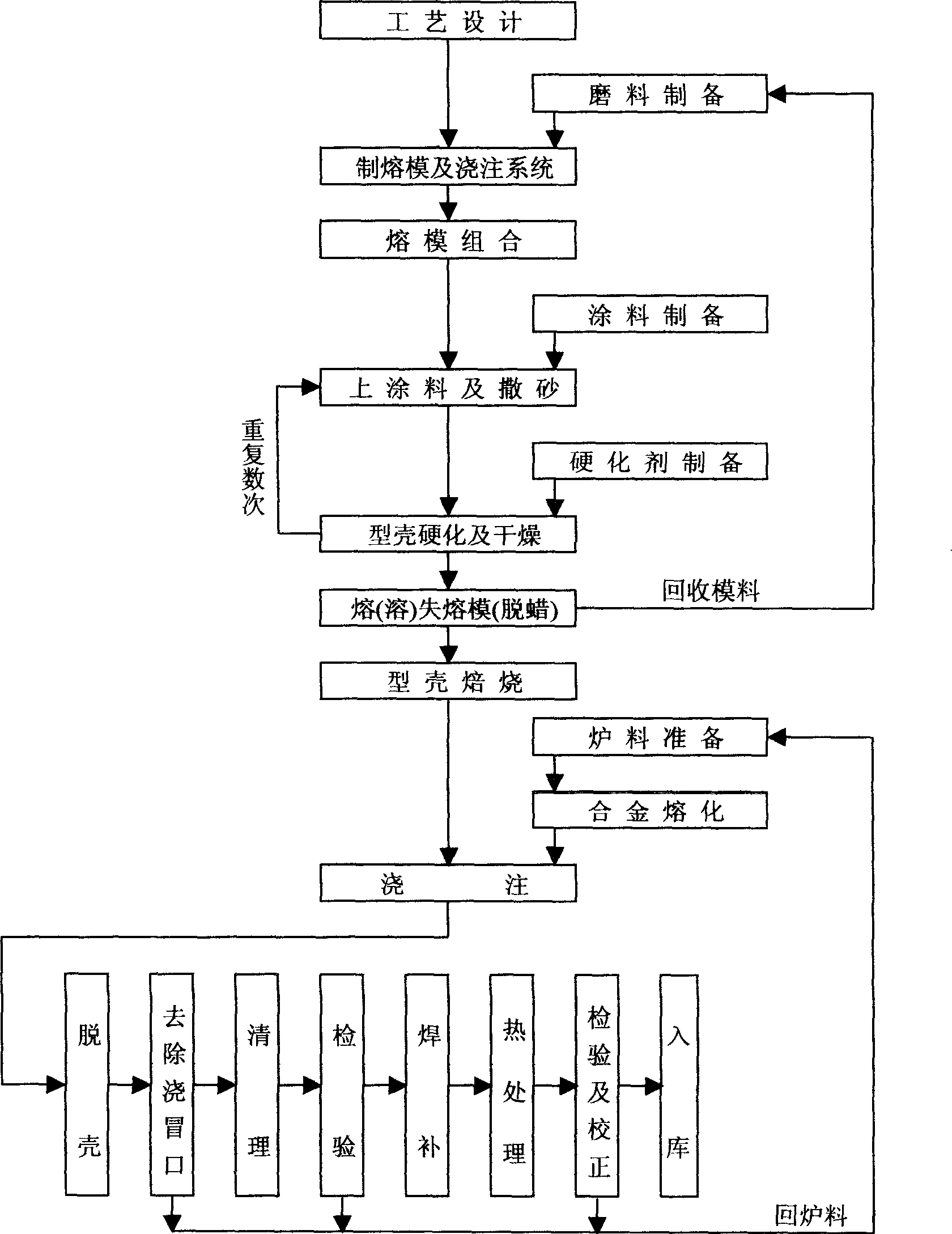

Method used

Image

Examples

Embodiment 1

[0050] a. Wax model making;

[0051] According to the structure of casting parts, design the pouring riser system. The wax mold has a reasonable pouring system design, which can ensure the sequential solidification of the castings; it can be poured in multiple layers with columnar risers. It can also be poured in a single layer with a spherical riser. The gate can be single gate or double gate.

[0052] b. Shell molding;

[0053] Using water glass as a binder to make the shell mold, including hardening, dewaxing and roasting of the shell mold.

[0054] c. Prepare a high-strength alloy material whose composition is:

[0055] C: 0.38 Si: 0.33 Mn: 0.94

[0056] Cr: 1.09 Mo: 0.27 S, P≤0.025;

[0057] d. Melting and pouring of alloy materials:

[0058] It adopts intermediate frequency furnace melting, adopts non-oxidizing steelmaking process, and selects rare earth ferrosilicon (FeSiRe45) for deoxidation,

[0059] Melting temperature: 1590°C; casting pouring, pouring temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com