A high-efficiency polishing cleaning machine based on button production

A high-efficiency cleaning machine technology, which is applied to surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, grinding/polishing equipment, etc., can solve problems such as cumbersome procedures, simplify procedures, facilitate cleaning, and improve bearing capacity. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

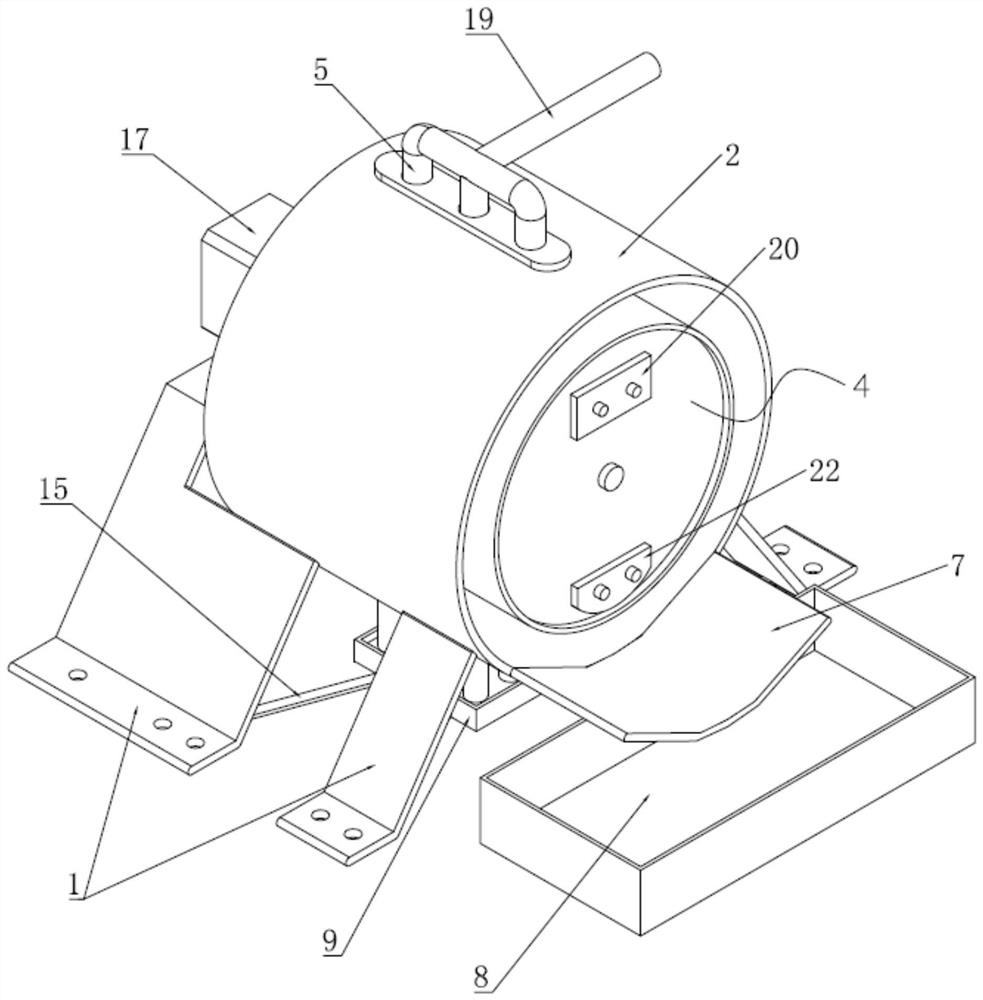

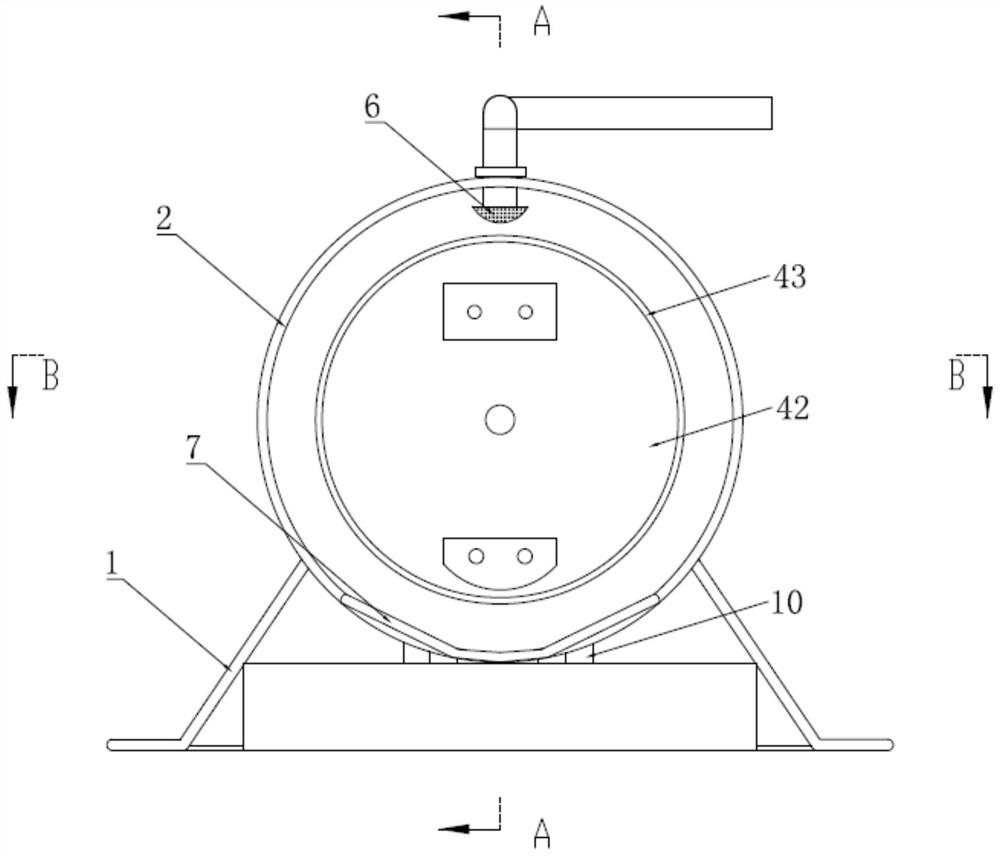

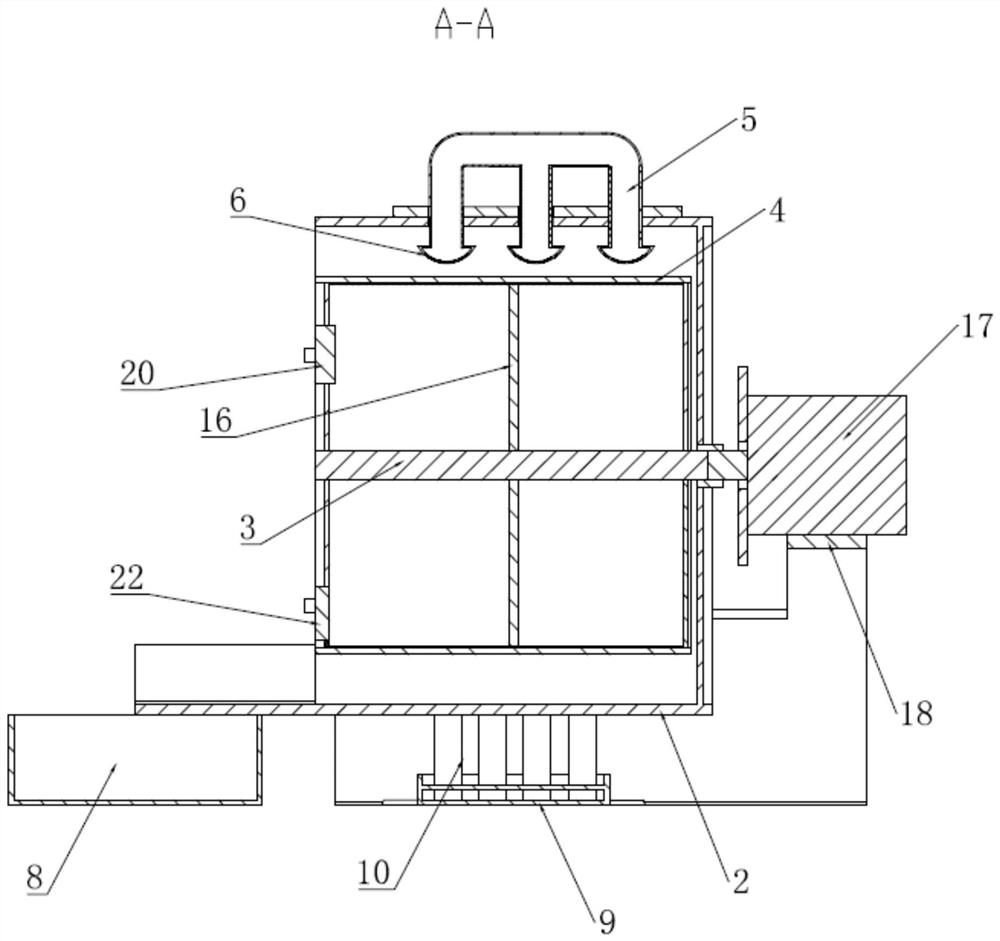

[0026] see Figure 1-Figure 5 As shown, the present invention provides a high-efficiency polishing cleaning machine based on button production, including a support frame 1, an outer cylinder 2 is installed on the support frame 1, and a rotating shaft 3 is movable in the outer cylinder 2, and a rotating shaft 3 is installed There is a polishing cylinder 4 located in the outer cylinder body 2, the polishing cylinder 4 is rotated relative to the outer cylinder body 2, the polishing cylinder 4 includes an annular filter 41, and the two ends of the annular filter 41 are respectively provided with sleeves installed on the rotating shaft 3 The sealing plate 42, the annular filter screen 41 is provided with an annular baffle 43, the distance between the annular baffle 43 and the outer cylinder 2 is set, the annular baffle 43 and the sealing plate 42 are slidably connected and sealed, and the outer cylinder 2 There is a water inlet pipe 5 connected to the external water supply equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com