Technology method relating to component in manufacturing artificial limb knee-joint

A process method and knee joint technology, applied in the field of prosthesis manufacturing, to achieve the effect of adapting to large-scale production, simplifying equipment, and significantly advancing technology

Inactive Publication Date: 2010-05-12

上海市机械制造工艺研究所有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with the manufacture of related components in prosthetic knee joints with complex shapes and high strength requirements, due to the limitations of traditional techniques, there is no such method yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiment:

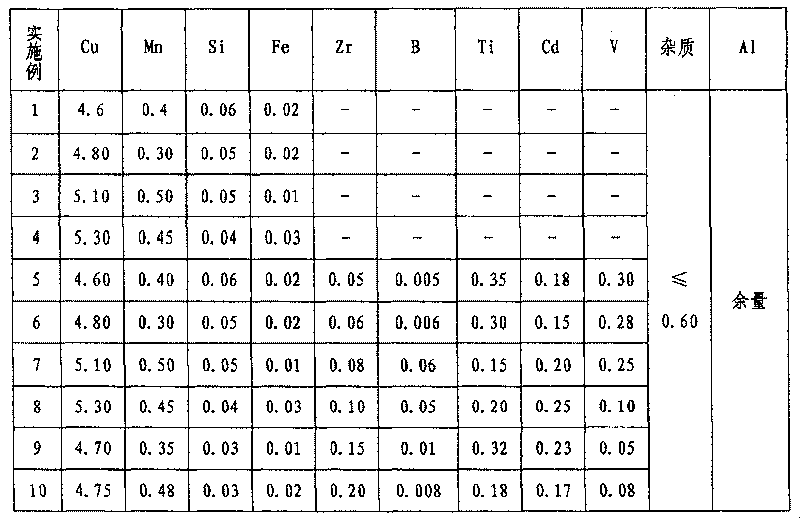

[0031] The following table is the element content and process parameter value of each embodiment

[0032]

[0033] The following table is the value of the melting and heat treatment process parameters and the corresponding mechanical properties of each embodiment

[0034] Reality

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The present invention discloses a technology method about manufacture of the related components in a prosthetic knee. In the method, forging process is replaced by precise casting technology of the silica sol. The relative art procedure and the art parameter are as follows. Step a comprises preparation of aluminum alloy material with high intensity, which comprises 4.6 to 5.3 Cu, 0.3 to 0.5 Mn, nomore than 0.06 Si, no more than 0.30 Fe and no more than 0.60 other impurity amount, besides the main element A1. Step B comprises melting and casting with the melting temperature of 680 DEG C to 720DEG C and the casting temperature of 680 DEG C to 700 DEG C. Step c, the heat treatment process comprises a solution treatment at 533 DEG C to 543 DEG C for 10 hours to 18 hours and an aging treatment at 170 DEG C to 180 DEG C for 4 hours to 5 hours. Technology in the present invention greatly simplifies processing procedure of the related components in a prosthetic knee. The product is molded byone time injection, which eliminated a plurality of cutting procedure and hammering procedure. Therefore working efficiency and utilization ratio of the metal material are improved, which not only simplifies the device and the procedure, but also reduces the production cost. The present invention is convenient for forming production capacity with massive size.

Description

technical field [0001] The invention relates to a manufacturing method of an artificial limb, in particular to a manufacturing method of related components in the knee joint of the artificial limb. Background technique [0002] The existing production process of the relevant parts in the knee joint is to forge the blank shape for many times, and then from preliminary processing to finishing processing. Costs remain high. The annual demand for such parts is very large, and currently basically depends on imports, and the price in the domestic market is relatively high, but the majority of disabled people with middle and low incomes cannot afford it at all. [0003] Silica sol precision casting This method is to inject fusible molding material into the mold (in the mold) to make an investment pattern, assemble it into a module, and then coat the surface of the module with a refractory material and a silica sol binder. The finished liquid paint is then sprinkled with refractor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A61F2/64C22C21/12C22C1/02C22F1/057B22D21/04

Inventor 毛军王峥李佳和王爱根杨正道金刚周耀忠钱宏生

Owner 上海市机械制造工艺研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com