Patents

Literature

53results about How to "Guaranteed strength performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of thick-walled titanium tube

ActiveCN102240890AEasy to prepareReduce manufacturing costRoll force/gap control deviceIngotTitanium

The invention discloses a manufacturing method of a thick-walled titanium tube. The method comprises the following steps: firstly preparing a cast ingot; forging the cast ingot, processing, then extruding to form a tube blank, and further performing acid cleaning; rolling the tube blank after acid cleaning, and sequentially performing deoiling treatment and recrystallization annealing treatment on the rolled tube blank after rolling every time; after rolling, further rolling the rolled tube blank again to obtain a finished tube product; and finally performing annealing treatment on the finished tube product, and performing acid cleaning to remove oxide skins on the inner surface and the outer surface so as to obtain the Gr.3 thick-walled titanium tube. The Gr.3 thick-walled titanium tube manufactured by adopting the method is excellent in performance, the tensile strength is not less than 500MPa, the yield strength is 380-550MPa, the elongation rate is not less than 20%, the ratio of the outer diameter of the tube to the wall thickness is 5-10, and the inner surface and the outer surface are better in quality and can meet the requirements of ASTM (American society for testing and materials) B 338, thereby meeting the requirements of tubes for industrial fields such as pressure vessels, condensers, heat exchangers and the like.

Owner:WESTERN TITANIUM TECH

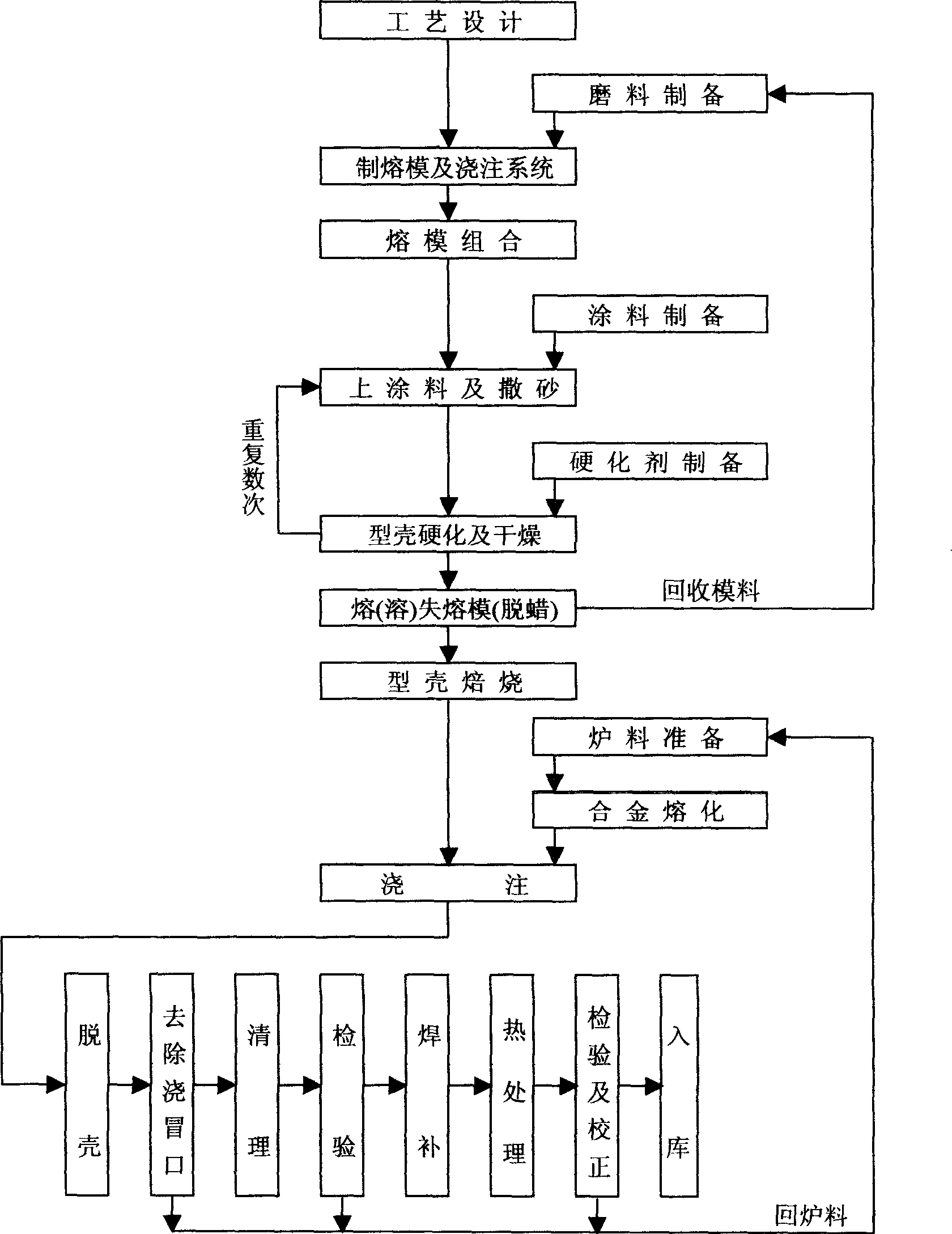

Technology method relating to component in manufacturing artificial limb knee-joint

InactiveCN101120894ASimplify production and processing proceduresImprove adaptabilityArtificial legsSolution treatmentTO-18

The invention discloses a process method for manufacturing related components in prosthetic knee joints. In the method, a silica sol precision casting process is used to replace the forging process. The relevant process steps and process parameters are as follows: a. Prepare high-strength aluminum alloy materials, except for the main components In addition to Al, it also includes: Cu: 4.6-5.3, Mn: 0.3-0.5, Si≤0.06, Fe≤0.30, and the total amount of other impurities≤0.60. b. Melting and pouring: melting temperature 680-720°C, pouring temperature 680-700°C; c. heat treatment process: solid solution treatment at 533-543°C for 10-18 hours, aging treatment at 170-180°C for 4-5 hours Hour. Adopting the process of the present invention obviously simplifies the processing procedure of the relevant parts in the prosthetic knee joint, and the product is formed by one-time casting, which avoids many cutting and forging processes, improves the production efficiency and the utilization rate of metal materials, and not only simplifies the equipment and process, It also reduces the production cost and facilitates the formation of large-scale production capacity.

Owner:上海市机械制造工艺研究所有限公司

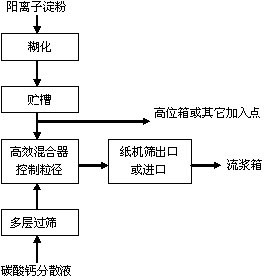

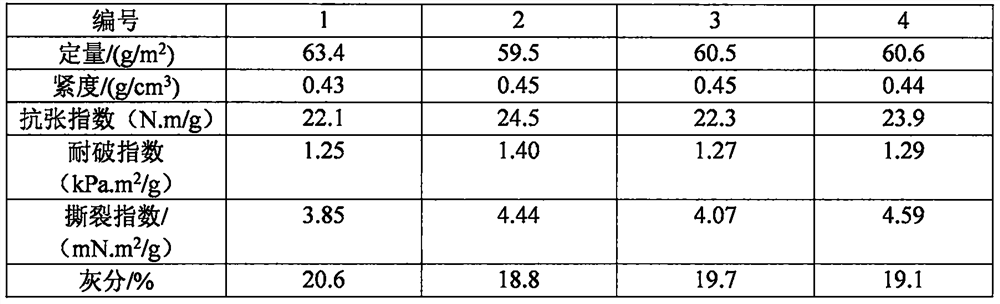

Method for fill feeding in papermaking

ActiveCN102677543AImprove stabilityFine granularityPulp material addition processesFiberFlocculation

The invention discloses a method for fill feeding in papermaking, which is characterized by comprising the following steps of: (1) firstly gelatinizing quaternary ammonium type cation starch, diluting to 1-3 percent concentration, conveying to a high-efficient mixer by a piston pump; conveying calcium carbonate with 10-30 percent concentration to the high-efficient mixer by a centrifugal pump; and (2) completing pre-flocculation of the quaternary ammonium type cation starch and the calcium carbonate in the high-efficient mixer, conducting multilayer filtering on the pre-flocculation bodies in the mixer, thus obtaining the pre-flocculation bodies with proper granules. With the adoption of the method, on the premise that the strength property of paper is guaranteed, the ash content can be effectively improved, the ash content of facial gummed paper can be improved from 25% to 35%, and the dry steam consumption can be reduced by 10%, moreover, the fiber materials can be greatly reduced, thus the method has wide application prospects.

Owner:YUEYANG FOREST & PAPER CO LTD +1

Manufacturing process of mold for manufacturing carbon fiber box

InactiveCN105500731AHigh thermal deformation coefficientImprove the finishSteel platesHigh intensity

The invention relates to a manufacturing process of a mold for manufacturing a carbon fiber box. In the process, a male mold is used. The manufacturing process comprises the following steps: step 1, spraying a gel coat on the outer surface of the male mold and curing to form a gel coat layer; step 2, coating the gel coat layer with surface felt to form a surface felt layer; step 3, gluing at least three layers of shortly-chopped felt on the surface felt layer to form a shortly-chopped felt layer, and curing the surface felt layer, resin and the shortly-chopped felt layer to form a glass fiber reinforced plastic layer; step 4, sequentially laying the shortly-chopped felt layer, a multi-axial cloth layer and a bordering cloth layer on the glass fiber reinforced plastic layer; step 5, filling in vacuum, namely sequentially laying de-molding cloth, a double-layered flow guide net, a flow guide belt, a flow guide pipe and a double-layered vacuum bag on the layer in the step 4, and after keeping pressure, filling to primarily form a female mold shell plate; step 6, gluing a steel frame and a steel plate; and step 7, after sticking the steel frame and the female mold shell plate for at least 48 hours, taking out the male mold from the female mold shell plate so as to manufacture the mold. The manufacturing process provided by the invention has the characteristics that the high-strength performance of the mold is guaranteed, the durability of the mold is improved, the service life of the mold is prolonged and the like.

Owner:NEWTRY COMPOSITE

Phase-change roof self-insulation ceramsite concrete

ActiveCN105036627AImprove energy storage performanceFix stability issuesSolid waste managementExpanded clay aggregatePhase change

The invention relates to phase-change roof self-insulation ceramsite concrete, and belongs to the technical field of building materials. The problems that existing ceramsite concrete is low in strength property and poor in energy storage effect can be solved. The phase-change roof self-insulation ceramsite concrete comprises, by mass, 30%-40% of cement, 20%-35% of pottery sand, 8.0%-13% of phase-change material, 10%-20% of ceramsite and 5.0%-8.0% of coal ash. The phase-change material uses the ceramsite as a loaded carrier. According to the concrete, the phase-change material is added and loaded onto the ceramsite, hence, a good energy storage effect can be achieved, and a large amount of heat can be stored or released when phase change happens; the phase-change latent heat range is wide, indoor temperature fluctuation is reduced, and cost is lowered; meanwhile, the strength property of the concrete can be guaranteed.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

High-strength anti-deformation corrugated paper box and production technology

InactiveCN110106733AImprove stress resistanceAvoid deformationMechanical working/deformationWrappersCartonPulp and paper industry

The invention discloses a high-strength anti-deformation corrugated paper box, and relates to technical fields related to corrugated paper boxes. The paper box comprises a bottom plate, side plates are fixedly connected on the bottom plate, a top plate is fixedly connected to the top ends of the side plates, a support is arranged between the bottom plate and the side plates, and the bottom plate and the side plates are fixedly connected through the support. First reinforcing ribs are fixedly connected between the bottom plate and the side plates, and second reinforcing ribs are fixedly connected between the side plates and the top plate. The invention further discloses a production technology of the high-strength anti-deformation corrugated paper box. The production technology comprises the following steps of A, raw material preprocessing; B, pulping; C, enzymolysis; D, paper preparation, E, heat treatment; F, gluing; G, corrugated paper board preparation; H, line pressing; I, printing; J, assembling. Through the arrangement of the support, the first reinforcing ribs and the second reinforcing ribs, the compression resistance of the eight corners of the corrugated paper box can beenhanced, the corrugated paper box is prevented from deforming, and the corrugated paper box is simple in structure, low in manufacturing cost and long in service life.

Owner:伟岸包装制品(苏州)有限公司

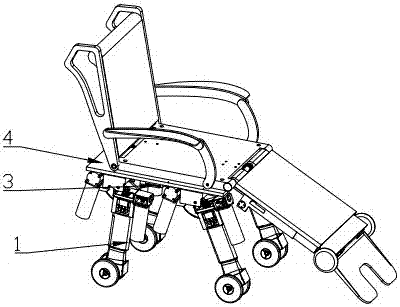

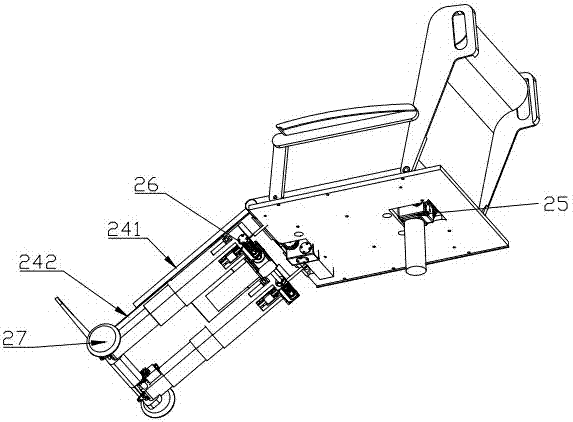

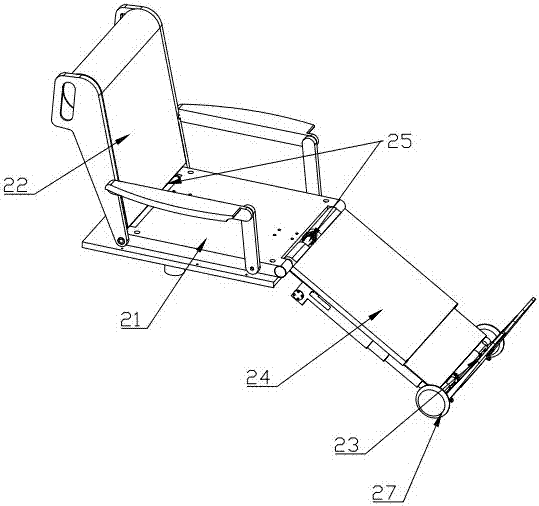

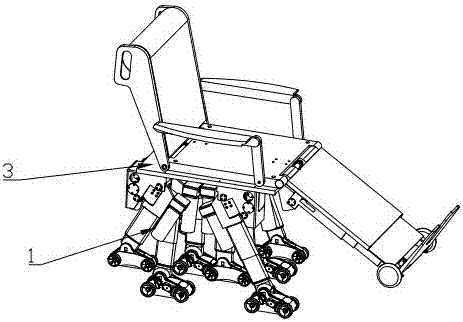

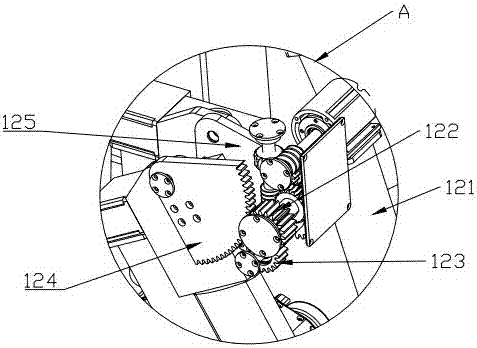

Wheeled obstacle-surmounting robot

PendingCN107307950AGuaranteed stretchGuaranteed Strength CapabilityWheelchairs/patient conveyanceMechanical engineeringRoboty

Provided is a wheeled obstacle-surmounting robot. A telescopic support cylinder comprises a plurality of sleeves which are sleeved with each other sequentially and slidably matched with each other, wherein the sleeves comprises an upper sleeve body, a plurality of middle sleeve bodies and a lower sleeve body, and a mounting frame is arranged at the upper end of the upper sleeve body; a scissor-fork linkage mechanism is arranged in the sleeves, and the lower end of the scissor-fork linkage mechanism is connected with the lower sleeve body; the upper end of the scissor-fork linkage mechanism extends out of the upper sleeve body and is connected with a first drive transmission mechanism which drives the scissor-fork linkage mechanism to expand and contract, and the first drive transmission mechanism is mounted at a mounting frame; the mounting frame is hinged to a connecting piece. According to the wheeled obstacle-surmounting robot, the scissor-fork linkage mechanism is better in telescopic adjustment ability and faster in telescopic adjustment speed, and meanwhile is also arranged in the sleeves which are sleeved with each other sequentially and slidably matched with each other; through the combination of the scissor-fork linkage mechanism and the sleeves, not only can the telescopic range and the telescopic speed be ensured, bu also the strength capability can be ensured; therefore, the support effect is more stable and tighter, the obstacle-surmounting ability of a ladder-climbing and obstacle-surmounting robot is stronger, and the obstacle-surmounting speed is faster.

Owner:嘉兴崎创精密零部件有限公司

Method for manufacturing lock shaft parts for container

InactiveCN1710227ASimplify production and processing proceduresIncrease productivityBuilding locksEngineeringHigh intensity

The invention discloses a center shaft component for locks of cargo container production technique with investment moulding. The invention provides with a set of rational technique from material selecting, shell making, melting, and heat processing, resolving the many technique problems in center shaft component for locks of cargo container production with investment moulding, simplifying the production procedure and lowering the cost, enhancing productivity so to be more adaptive to mass production.

Owner:上海市机械制造工艺研究所有限公司

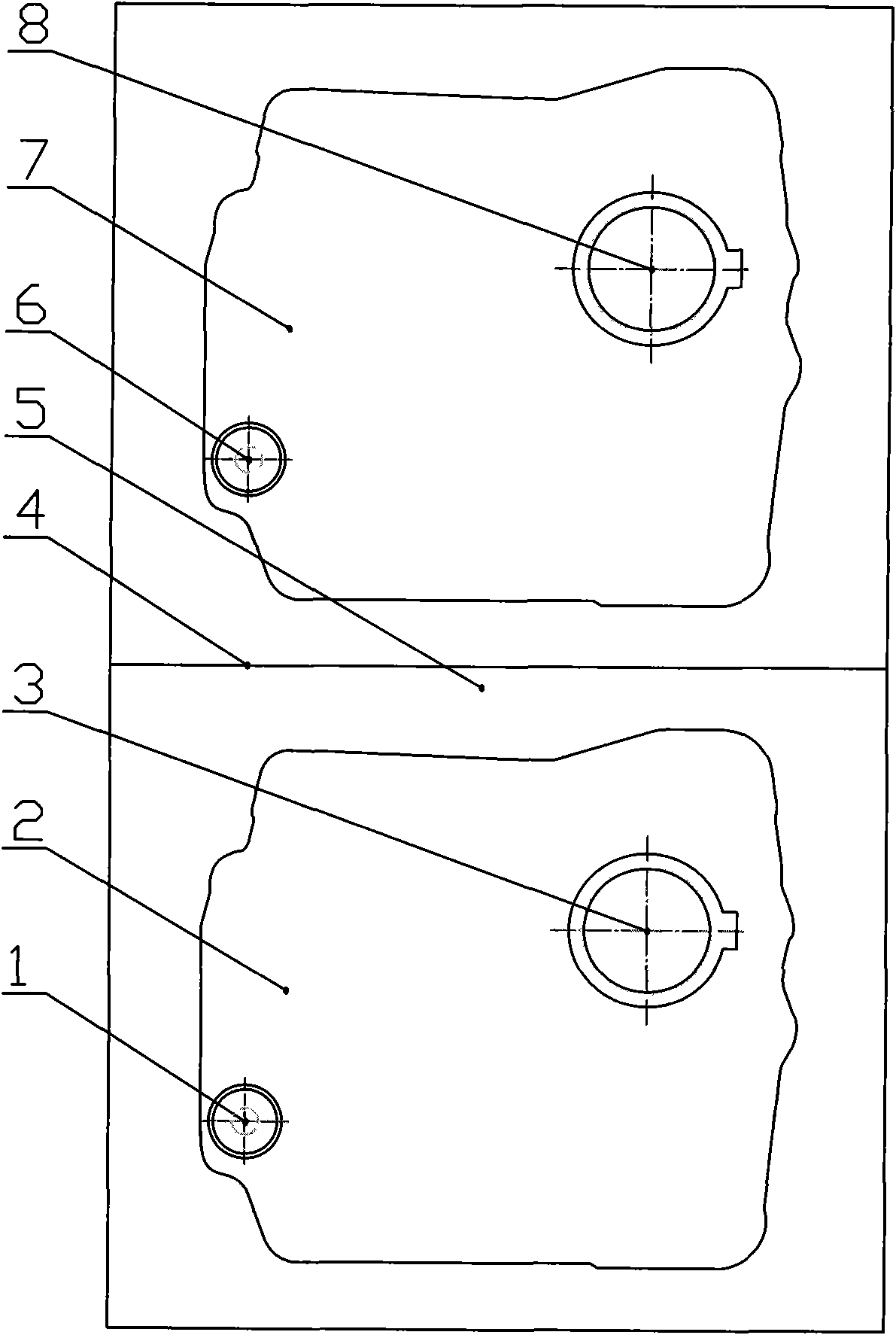

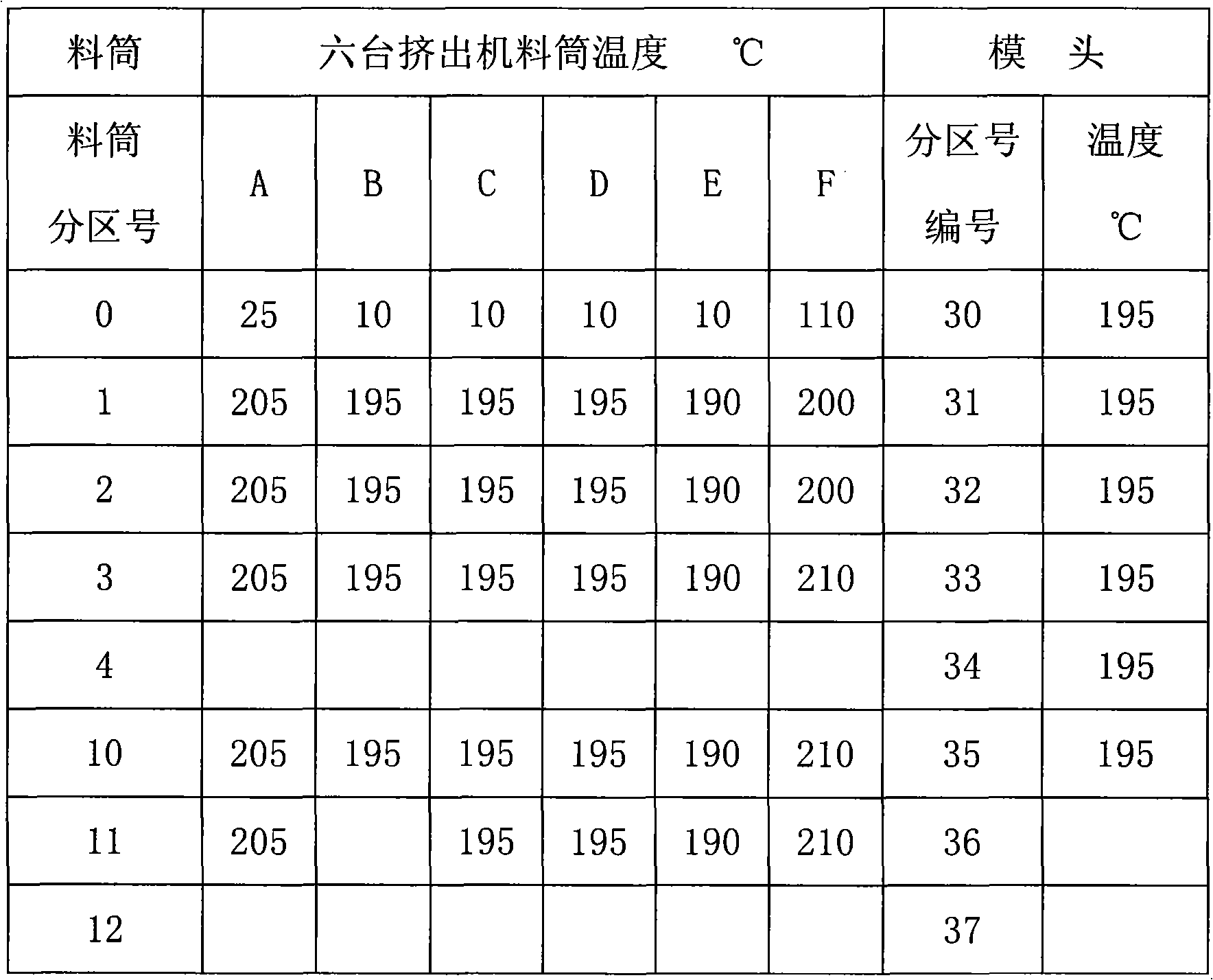

Manufacturing method of plastic fuel tank

The invention discloses a manufacturing method of a plastic fuel tank, which comprises the following steps: six special extruding machines with automatic weighing control are used to pump out qualitative and quantitative melting stocks and continuously extrude out a molding blank by a coextrusion mold head, the molding blank comprises six layers from inside to outside, and the ratio of the thicknesses of the six layers which are respectively high density polyethylene, sizing, barrier material, sizing, returns and high density polyethylene is 37:1.5:2:1.5:46:12; a blowing mold is internally provided with mold cavities of two fuel tanks, each mold cavity is respectively provided with an air inlet hole and an air return hole, a material overflow area is arranged between the two mold cavities, and the middle part of the material overflow area is provided with a split line. The manufacture method adopts a single-station blow molding machine and can manufacture two fuel tanks in one mold in a blow molding way once, thereby greatly enhancing the production efficiency, reducing the occupation of production space, lowering the investment and energy-consumption of the blow molding machine and also reducing the raw material consumption of single fuel tank.

Owner:YAPP AUTOMOTIVE PARTS

High-strength fiber oil-resistant thin layer paint

The invention discloses a high-strength fiber oil-resistant thin layer paint. The formula of the paint comprises the following components: 20-25 parts of acrylate resin, 1-3 parts of leveling agent, 4-7 parts of nano filler, 9-13 parts of fiber, 1-3 parts of oil resistance agent, 0.1-0.6 part of drying promoter, 0.9-1.7 parts of weather resistance agent and 1-3 parts of curing agent. The invention also provides a preparation method of the paint. According to the invention, the preparation method is simple, and a three-stage reaction process is adopted, thus ensuring thorough reaction of resins, and uniformly stirring and distributing the fibers and nano fillers to obtain a high strength effect; and meanwhile, the oil resistance agent reacts with the weather resistance agent, grafting to polyacrylate is realized, and the oil resistance and weather resistance stability is achieved..

Owner:黄远明

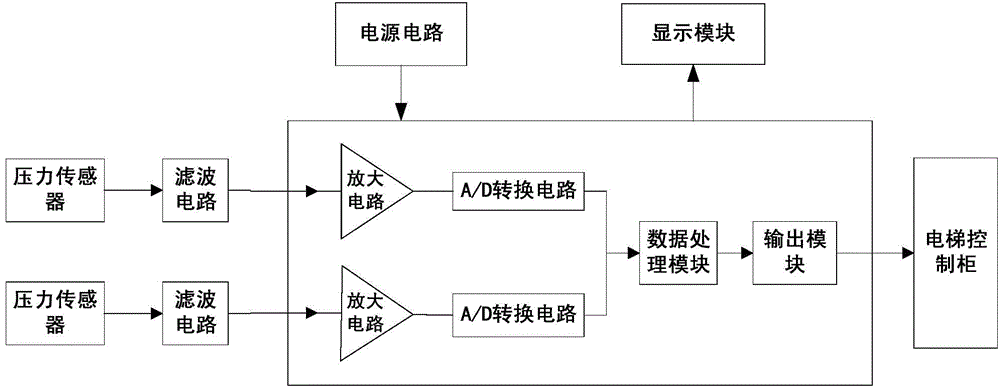

Drum-type tractor band-type brake monitoring device

InactiveCN104609275AImprove securityDimensions influenceBrake typesElevatorsBrake torqueComputer module

The invention discloses a drum-type tractor band-type brake monitoring device. The device comprises a power circuit, a pressure sensor, a signal processor and a display module, wherein the pressure sensor, the signal processor and the display module are connected with the power circuit, the pressure sensor is arranged on a brake arm to be used for acquiring a brake arm stress change signal, the acquired stress change signal is input into the signal processor by the pressure sensor for data processing to obtain a tractor braking torque monitoring signal, and the monitoring signal is input into the display module to be displayed. According to the device, a stress gauge is adopted to acquire brake arm stress change data, and then whether tractor braking torque meets using requirements is judged according to stress change. The device can be used for indirectly monitoring tractor braking torque and is convenient to install, reliable in use and easy to maintain. The safety performance of a tractor is improved, the dimension of the tractor is not affected at all, and the strength performance of the whole tractor is guaranteed.

Owner:宁波申菱机电科技股份有限公司

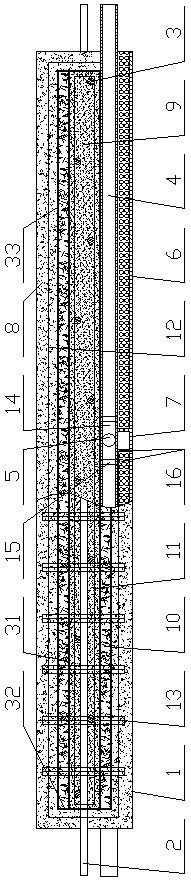

High-intensity hydraulic support pipe with wall thickness of 60mm-70mm

ActiveCN101566066AIncrease the depth of hardeningImprove welding qualityFurnace typesProps/chocksHeat-affected zoneHigh intensity

The invention discloses a high-intensity hydraulic support pipe wall thickness of 60mm-70mm, which includes the components with mixture ratios as follows: C: 0.19-0.32 percent, Si: 0.2-0.8 percent, Mn:1.1-2.1 percent, Ti: 0.001-0.032 percent, V: 0.02-0.16 percent, B: 0.0001-0.0038 percent and the balance of Fe. The hydraulic support pipe after quenched has mechanical performances for the central section as follows: yield strength between 850-1110MPa, tensile strength between 980-1210MPa, longitudinal impact between 39-110 joule, and lateral impact between 33-90 joule; and metallurgical structure after modulation is tempered sorbite and weld crack has sensitivity coefficient that Pcm is equal to 0.356-0.379. The method has the advantages that the technique of the hydraulic support pipe adopts the mode of introduction of element B and element Mn, and quenched depth after elements B and Mn introduced is apparently enhanced, thus ensuring the final strength performance. V and Ti are grain refining elements that can effectively decrease the cold crack trend in weld metal. The precipitation of V and Ti elements plays an active role in inhibiting the growth of grain in heat affected zone, thus improving welding quality.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Slow recovery foam

InactiveCN106117505AImprove folding resistanceLow springback deformation ratePolyesterFolding endurance

The invention relates to slow recovery foam, belongs to the technical field of high polymer materials, and aims to solve the problems of poor folding endurance and high recovery deformation rate in the prior art. The slow recovery foam is mainly prepared from the following raw materials in parts by weight: 51 to 55 parts of polyether polyol, 55 to 60 parts of a hardening agent, 40 to 45 parts of slow recovery polyester, 70 to 80 parts of slow polyester, 20 to 23 parts of melamine, 30 to 35 parts of toluene diisocyanate, 5 to 8 parts of dichloromethane, 2 to 3 parts of water, 0.3 to 0.5 part of a first catalyst, 0.2 to 0.5 part of a second catalyst, 0.06 to 0.08 part of a foam stabilizer and 0 to 0.08 part of a coloring agent. The slow recovery foam has the effects of high folding endurance and low recovery deformation rate.

Owner:海宁兄弟家具有限公司

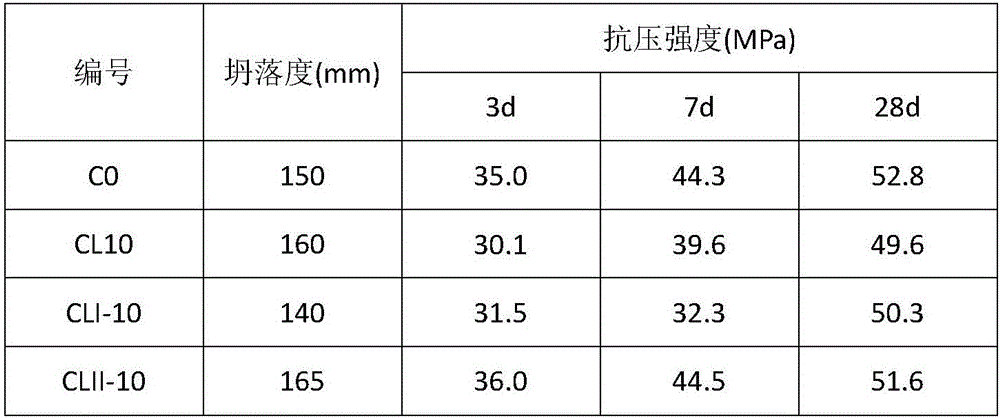

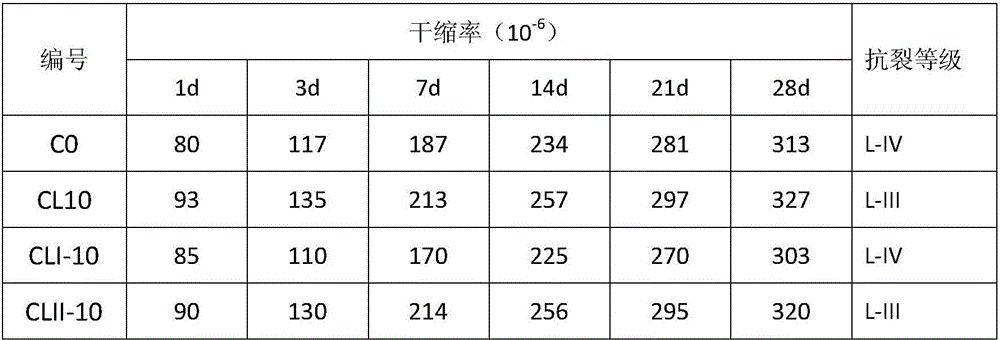

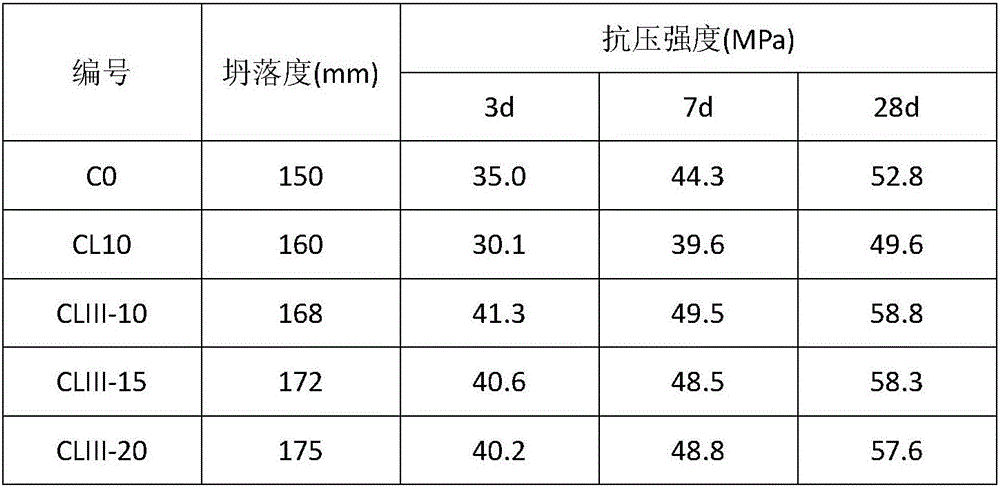

Compound admixture for anti-crack limestone powder and preparation method of compound admixture

The invention provides a compound admixture for anti-crack limestone powder and a preparation method of the compound admixture. The compound admixture comprises, by mass, 60-70 parts of limestone powder, 28-40 parts of coal ash, 1-2 parts of polypropylene fibers and 0.1-0.2 part of triethanolamine. By the compound admixture for the anti-crack limestone powder, concrete contraction can be reduced and concrete anti-crack performance can be improved while working performance and mechanical performance of concrete are guaranteed, so that durability of limestone powder concrete is improved, and application of the limestone powder to the concrete is widened.

Owner:CENT SOUTH UNIV

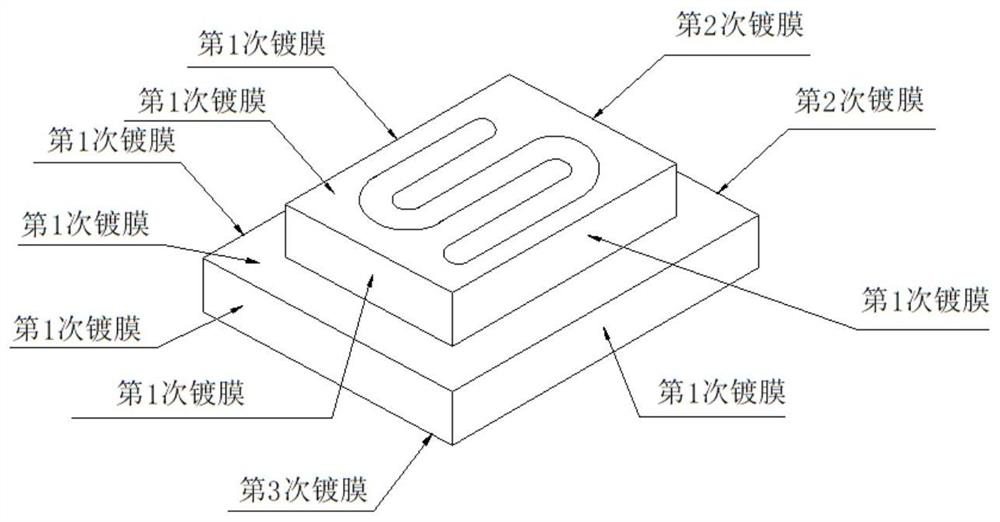

Splicing coating method for semiconductor part

ActiveCN112063972AEnsure consistencyMeet the requirements of the subsequent welding processVacuum evaporation coatingSputtering coatingCoated surfaceSemiconductor

The invention provides a splicing coating method for a semiconductor part. The method comprises the following steps: shielding the surface, making contact with a clamp in coating equipment, of the semiconductor part by adopting a protective film; coating the treated semiconductor part, and controlling the coating temperature and power to finish the coating of the non-shielding surface; attaching the protective film to the coated surface, and removing the original shielding protective film; and repeating the coating of the non-shielding surface, and removing the protective film on the coated surface after the coating is completed until the semiconductor part with the fully-coated surface is obtained. According to the method, the whole surface of the semiconductor part can be coated in a splicing coating manner, and particularly, the non-coating surface is shielded firstly, so that the consistency of coating in different sequences can be ensured, and the requirements of a subsequent welding process are met; and coating parameters are correspondingly adjusted according to selected semiconductor part materials, crystal grain change can be avoided, the strength performance of the part is guaranteed, and the method is suitable for different kinds of products and wide in application range.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Brick making mortar

InactiveCN105837140AEasing the conundrum of reduced supplyGuaranteed strength performanceSolid waste managementBrickSlag

The invention discloses a brick making mortar which comprises the following components in percentage by mass: combined cement, casting waste sand, yellow sand, fly ash, slag powder, attapulgite, crushed calcite, cellulose ether, redispersible polymers and polysiloxane powder. Compared with the prior art, the addition proportion of the combined cement is properly added into the brick making mortar, and the casting waste slag and attapulgite are used instead of part of yellow sand, thereby relieving the problem of reduced supply of yellow sand and lowering the manufacturing cost.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

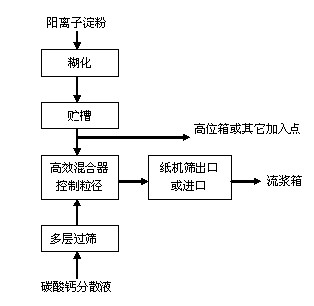

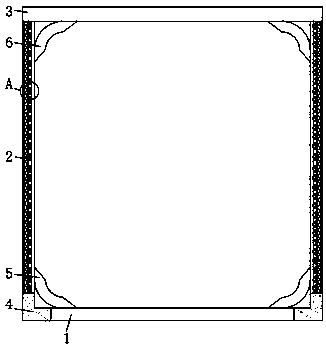

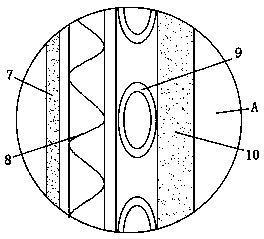

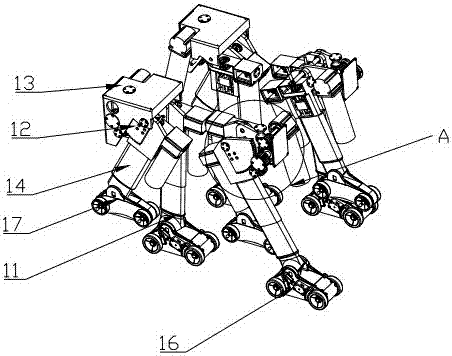

Stair-climbing and obstacle-crossing robot

PendingCN107307951AGuaranteed stretchGuaranteed Strength CapabilityWheelchairs/patient conveyanceManipulatorStructural engineeringMechanical engineering

The invention provides a stair-climbing and obstacle-crossing robot. The stair-climbing and obstacle-crossing robot is characterized in that the structures of second telescoping support cylinders are same as those of first telescoping support cylinders, each first telescoping support cylinder comprises a plurality of sleeves, wherein the sleeves are arranged in a sleeved mode in sequence, and the sleeves are in slipping fit with each other. Each group of sleeves comprises the upper sleeve, the middle sleeves and the lower sleeve, wherein an installation frame is installed at the upper end of the upper sleeve. A scissor-fork type connecting rod mechanism is arranged in each group of sleeves, the lower ends of the scissor-fork type connecting rod mechanisms are connected with the lower sleeves respectively, the upper ends of the scissor-fork type connecting rod mechanisms extend out of the upper sleeves respectively, the scissor-fork type connecting rod mechanisms are connected with first drive transmission mechanisms driving the scissor-fork type connecting rod mechanisms to extend and retract respectively, the first drive transmission mechanisms are installed on the installation frames respectively, and the installation frames are hinged to connecting pieces respectively. The stair-climbing and obstacle-crossing robot has the advantages that the scissor-fork type connecting rod mechanisms have better telescopic adjustment capacity and higher telescopic adjustment speed, meanwhile, the strength capacity is ensured, the supporting is more stable and firmer, the stair-climbing and obstacle-crossing capacity of the stair-climbing and obstacle-crossing robot is higher, and the speed in the stair-climbing and obstacle-crossing processes is higher.

Owner:嘉兴崎创精密零部件有限公司

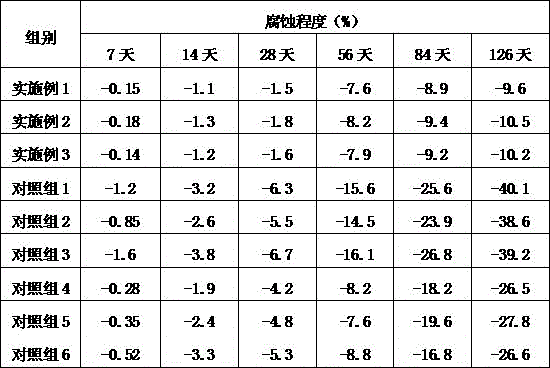

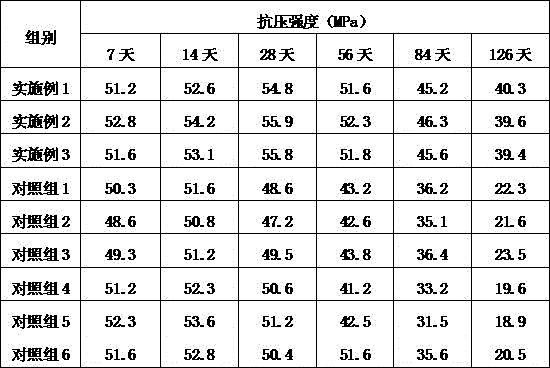

Acid-resistant dry-mixed mortar

InactiveCN105837141AEasing the conundrum of reduced supplyGuaranteed strength performanceSolid waste managementFiberErosion rate

The invention discloses acid-resistant dry-mixed mortar which comprises the following components in percentage by mass: combined cement, casting waste sand, yellow ground, coal ash, slag powder, lithium slag, wood fiber, cellulose ether, a redispersible polymer and polysiloxane powder. Compared with the prior art, the acid-resistant dry-mixed mortar has the following advantages that the addition ratio of the combined cement is appropriately increased; a part of the yellow ground is replaced by the casting waste slag and the lithium slag, so that the difficulty that the yellow ground is in supply shortage is alleviated, and the preparation cost is lowered; meanwhile, under the action of the polysiloxane powder and on premise that the strength of the dry-mixed mortar is ensured, the lithium slag and the combined cement can improve the acid resistance of the dry-mixed mortar, and after the dry-mixed mortar is used normally, the erosion rate of the dry-mixed mortar in an acid environment is less than 1% within two years, and the compressive strength of the dry-mixed mortar is reduced by about 8% after two years, being of relatively optimal levels.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

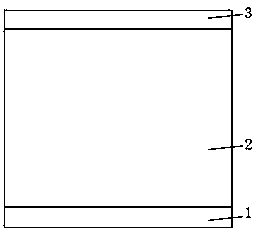

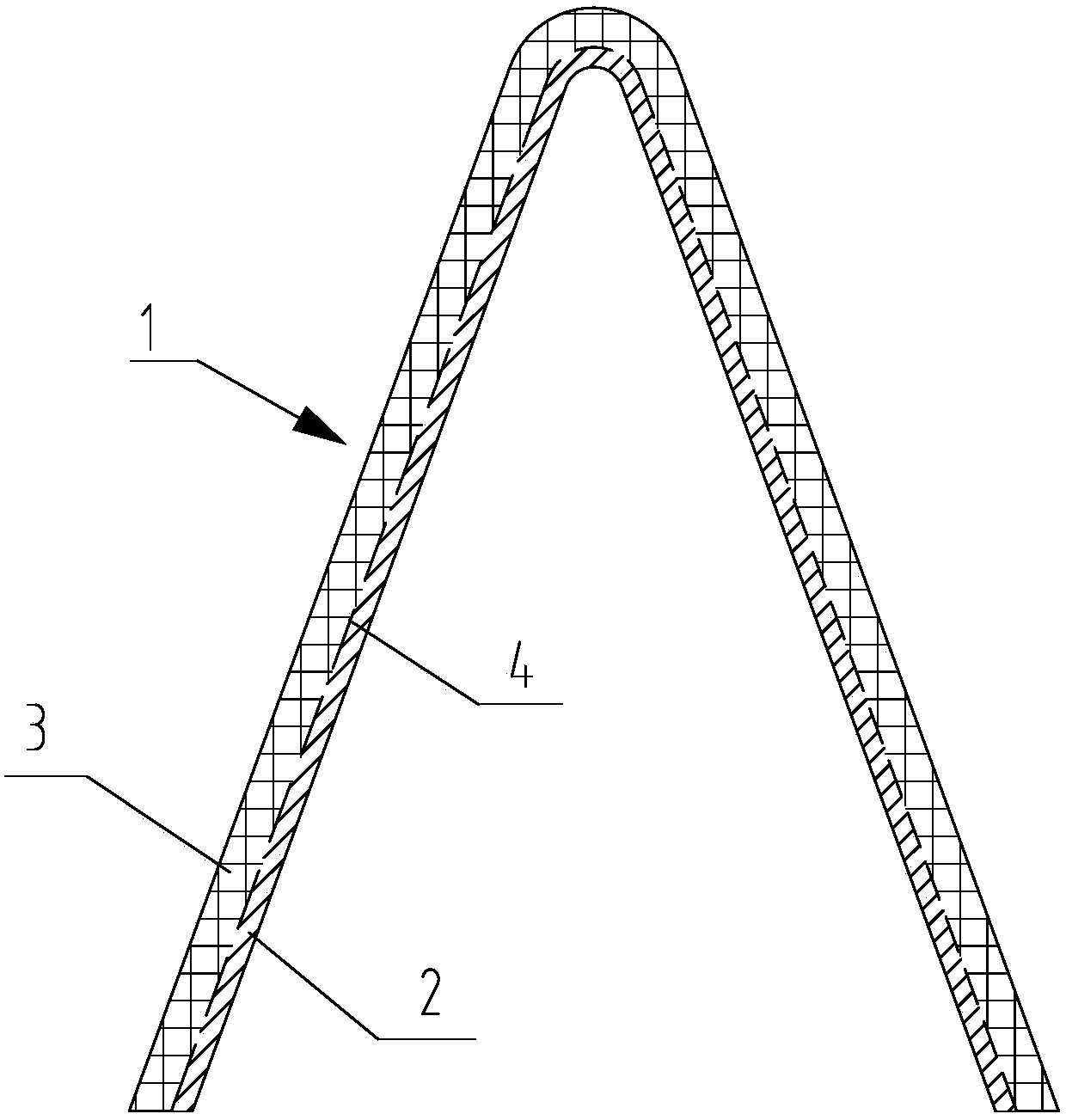

Broadband wave-transparent double-layer composite ceramic radome cover body and preparation method thereof

ActiveCN106129615BGuaranteed strength performanceGuaranteed electricityRadiating element housingsComposite ceramicBroadband

The invention discloses a cover body of a broadband wave-transmitting dual-layer composite ceramic antenna cover and a fabrication method for the cover body. The fabrication method for the cover body of the broadband wave-transmitting dual-layer composite ceramic antenna cover comprises the following steps of 1) weaving a shaped fabric; 2) pre-processing the shaped fabric; 3) impregnating an outer layer of the shaped fabric; 4) performing integral impregnation; 5) repeating to perform integral impregnation in the above step of 4) for two or three times; 6) sintering an intermediate blank; 7) roughly processing a cover body blank; 8) repeating to perform integral impregnation in the above step of 4) on the roughly-processed cover body blank for one time, and performing high-temperature sintering; and 9) finely processing an initial cover body. The shaped fabric of the cover body of the dual-substrate composite ceramic antenna cover is formed by laying and integratedly stitching a hollow quartz fiber fabric, a hollow quartz fiber felt and a solid quartz fiber fabric, the integral formation of the dual-layer composite ceramic antenna cover can be achieved, thus, the connection strength and the assembly accuracy of the cover body are improved, and the production cost is reduced.

Owner:湖北三江航天江北机械工程有限公司

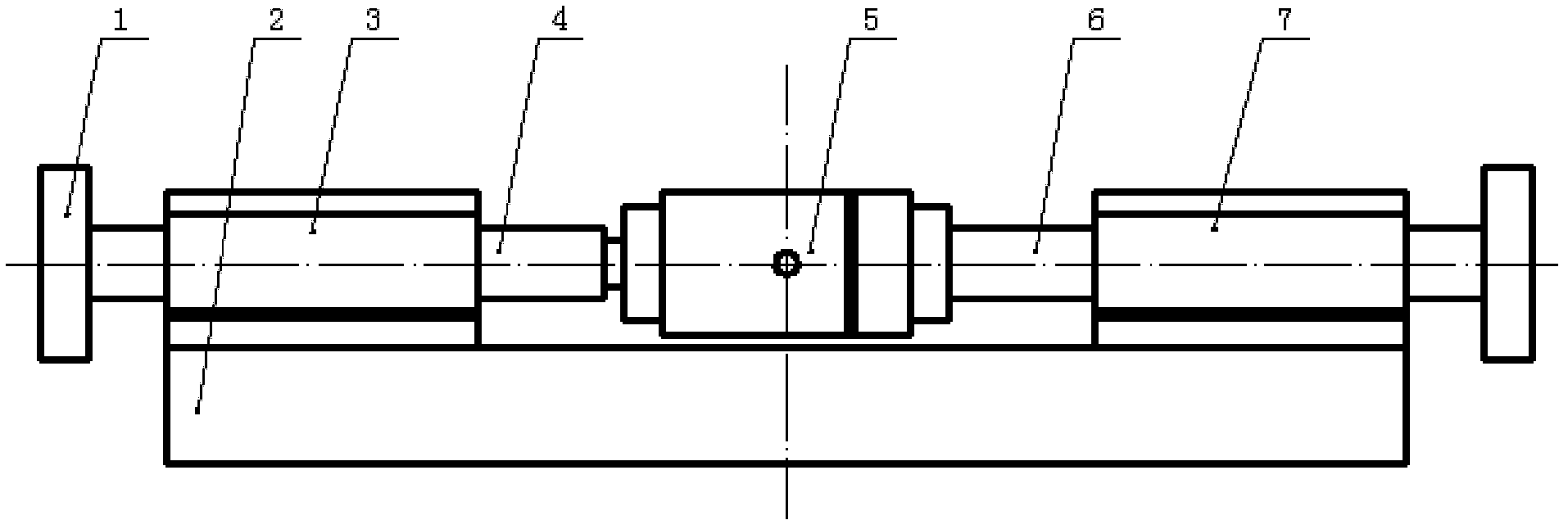

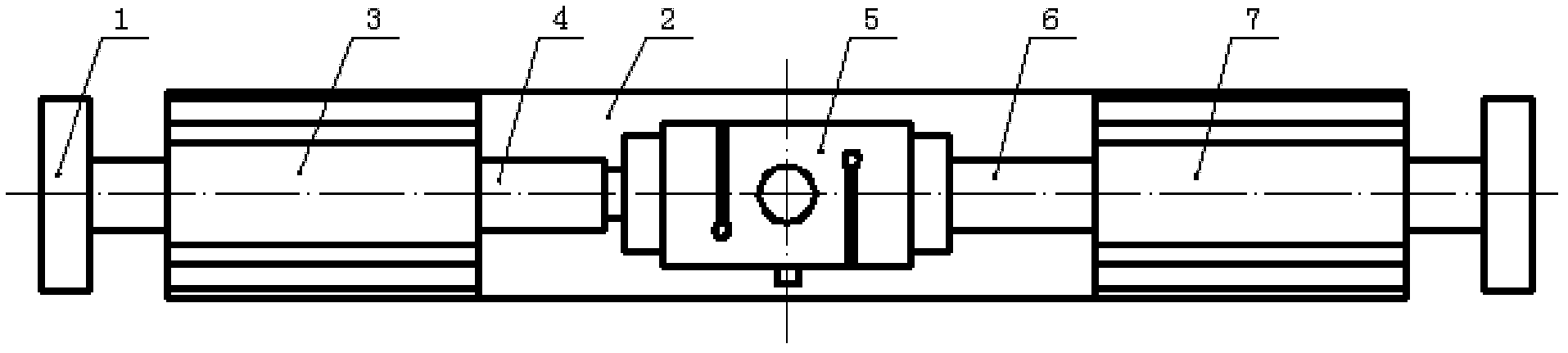

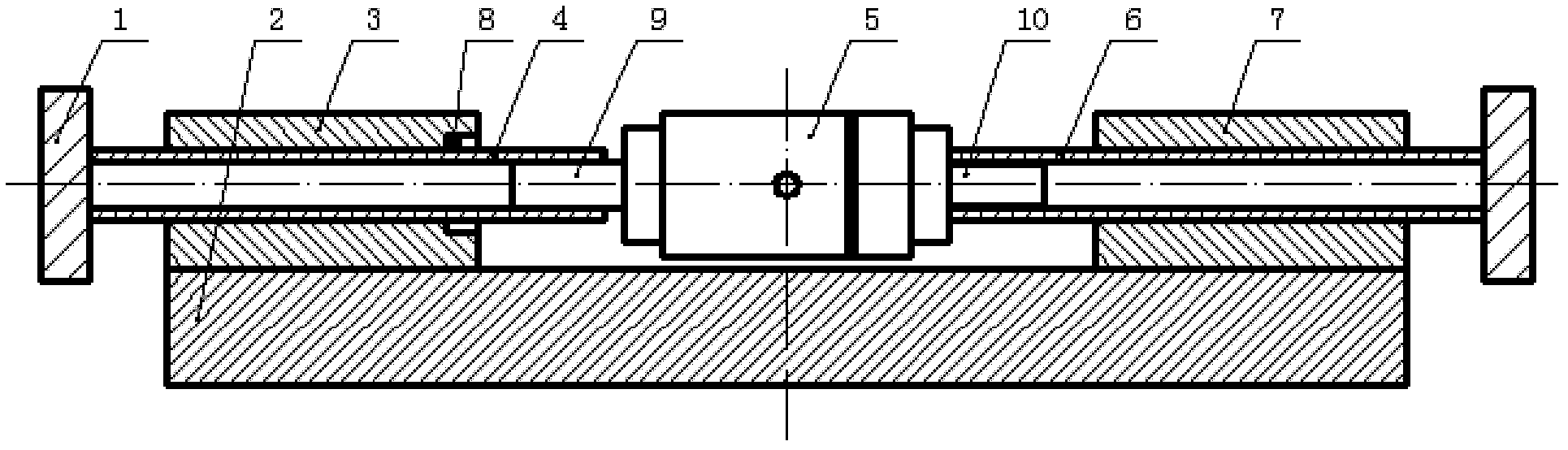

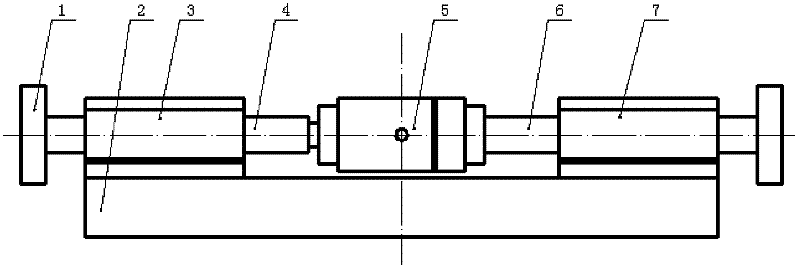

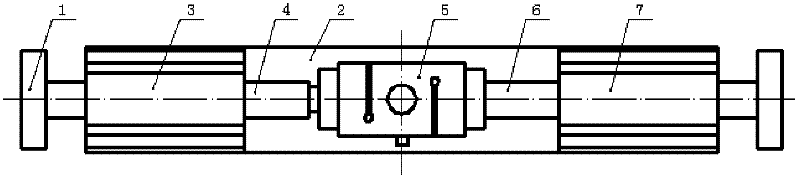

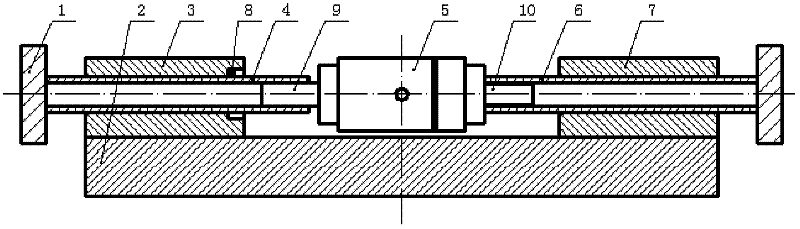

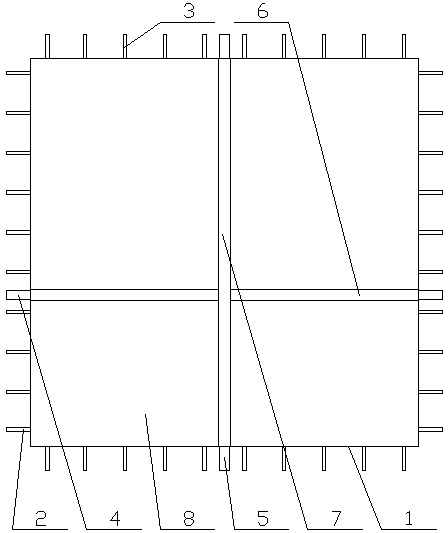

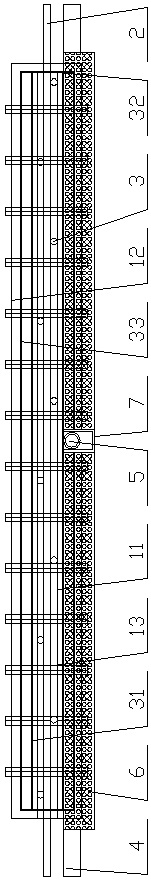

High-precision clamping force measuring apparatus

ActiveCN102519641BExtended service lifeImprove reliabilityApparatus for force/torque/work measurementTest efficiencyMeasurement device

The invention relates to a high-precision clamping force measuring apparatus which comprises a pressure measuring device. The pressure measuring device comprises a mechanics sensor and a left bearing shaft and a right bearing shaft coaxially mounted at the two ends of the mechanics sensor; the pressure measuring device is coaxially mounted on a horizontal base; a left linear bearing and a right linear bearing are coaxially fixed at the two ends of the base respectively; the left bearing shaft and right bearing shaft at the two ends of the mechanics sensor are correspondingly mounted in the left linear bearing and right linear bearing in a sliding manner respectively; and the left linear bearing and right linear bearing are coaxially arranged. The high-precision clamping force measuring apparatus provided by the invention has a scientific and reasonable design, a simple structure and high reliability, is convenient to operate, and effectively improves the measurement accuracy; and moreover, as the bearing shaft has certain expansion amount, the pressure measuring device is effectively protected from damage, and the test efficiency is improved.

Owner:CHINA PACKAGING RES & TEST CENT

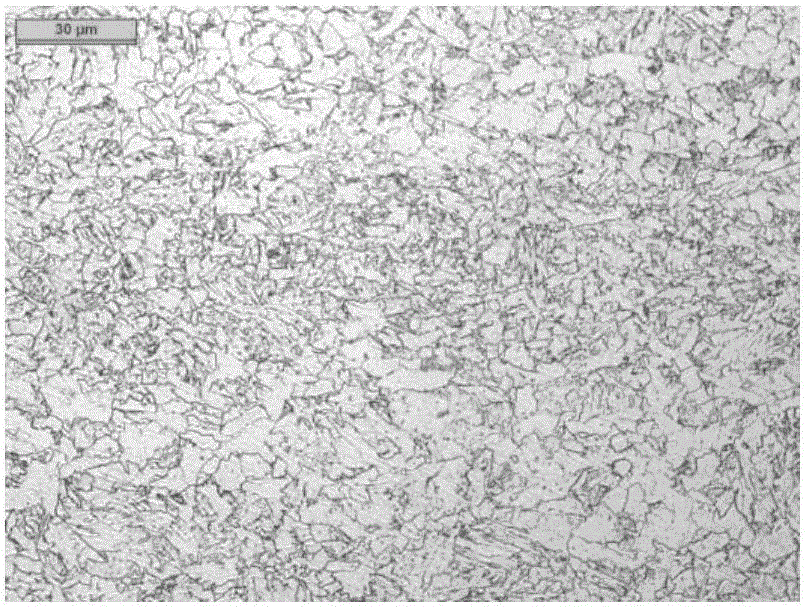

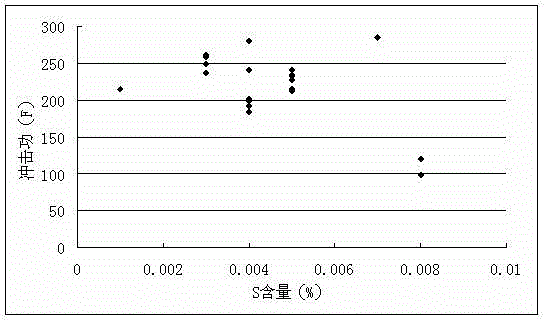

Low-temperature pipeline steel used for LNG transmission trunk line and preparation method thereof

A low-temperature pipeline steel for LNG gas transmission main line and a preparation method thereof, belonging to the technical field of pipeline steel. The weight percent of its chemical composition is: C: 0.03-0.08wt%, Nb: 0.05-0.08wt%, Si: 0.15-0.30wt%, Mn: 1.40-1.65wt%. First smelting, then continuous casting, the steel billet is reheated and then rolled and cooled on the 4300-5500mm production line; after that, the pipe is made and welded through the expanded diameter welded pipe production line. The advantage is that the comprehensive performance is good, and it is suitable for the construction of the transmission pipeline after LNG gasification.

Owner:SHOUGANG CORPORATION

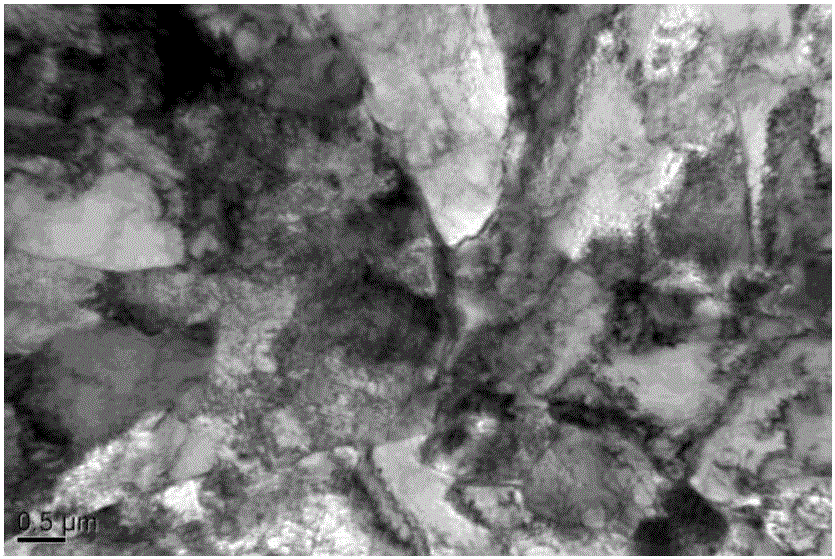

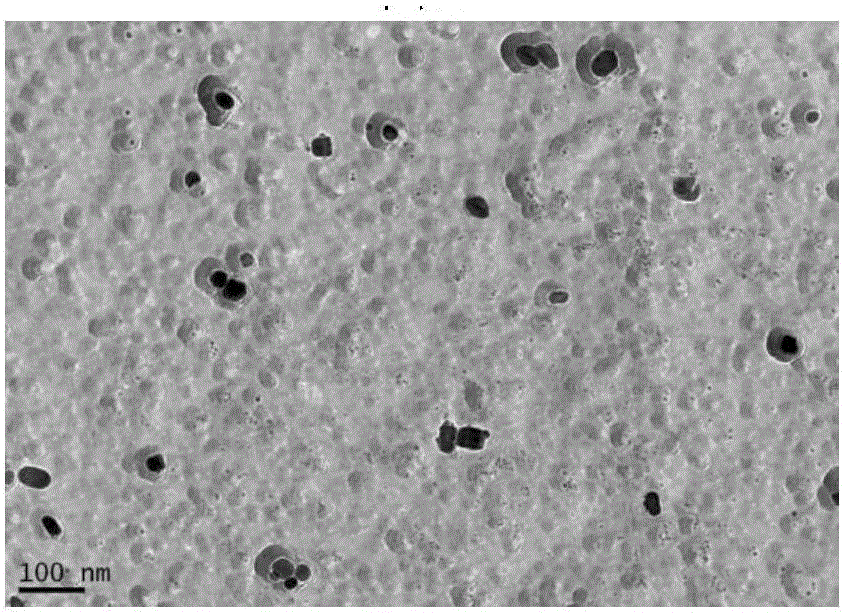

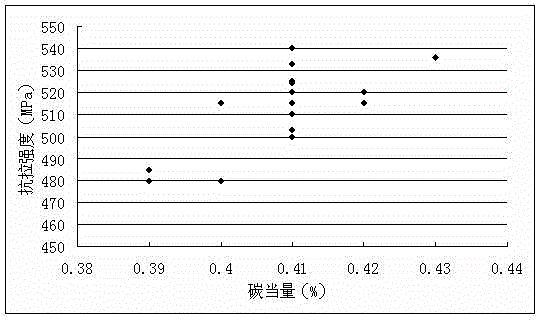

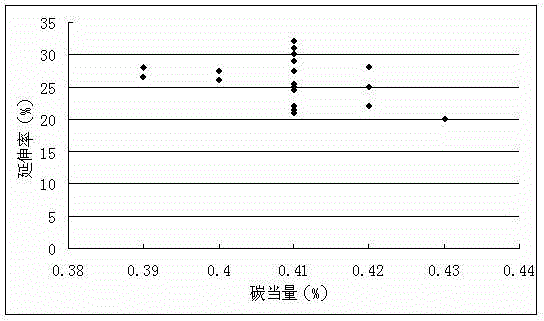

Q345 Z-direction extra-thick low-alloy high-strength structure steel plate and production method thereof

InactiveCN103469074BGuaranteed strength performanceImprove impact toughnessSheet steelChemical composition

The invention discloses a Q345 Z-direction extra-thick low-alloy high-strength structure steel plate with thickness of 50-70mm. The steel in the steel plate comprises the following chemical components in percentage by weight: 0.15-0.16% of C, 0.27-0.32% of Si, 1.39-1.45% of Mn, 0.010-0.013% of P, 0.001-0.007% of S, 0.029-0.049% of Al, 0.056-0.064% of V, 0.013-0.016% of Ti, 0.012-0.014% of Nb and the balance of Fe, wherein the carbon equivalent is 0.40-0.42. Meanwhile, the invention also discloses a production method of the Q345 Z-direction extra-thick low-alloy high-strength structure steel plate. With good comprehensive performance and high impact toughness, the Q345 Z-direction extra-thick low-alloy high-strength structure steel plate disclosed by the invention particularly has the advantages of good Z-direction performance, stable product quality, high product percent of pass and the like.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Method for preparing ceramsite from coal-based solid waste

PendingCN114478048AEfficient use ofLow costCeramic materials productionCeramicwareSocial benefitsEconomic benefits

The invention discloses a method for preparing ceramsite by using coal-based solid waste, which comprises the following steps: classifying according to different plasticity of coal-based solid waste raw materials to obtain ceramsite raw materials; and after drying the ceramsite raw material, arranging an auxiliary combustion area in an interval of 800-1000 DEG C for decarburization, and roasting in an interval of 1000-1200 DEG C. The coal-based solid waste is efficiently utilized, an optimized roasting method is adopted, the full-solid waste ceramsite product is prepared, and the mechanical property of the product is excellent; and the process is simple, is suitable for industrial popularization and application, can be used as a building lightweight aggregate or a building gravel material, and has excellent environmental benefits, economic benefits and social benefits. The method is suitable for the field of coal-based solid waste utilization.

Owner:北京蚯蚓科技有限公司 +2

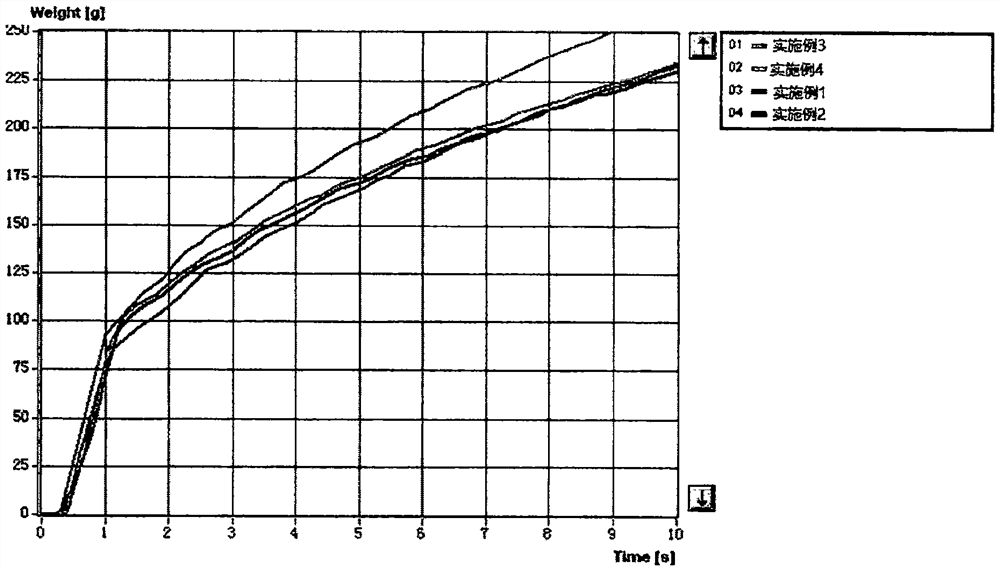

Method for improving papermaking drainage performance by adopting microfibrillated fibers

ActiveCN113106775AGuaranteed strength performanceIncrease filler contentSurfactants additionPaper recyclingWater filterPapermaking

The invention provides a method for improving the water filtering performance of paper by adopting microfibrillated fibers, and particularly relates to a method for forming a compound by adopting the microfibrillated fibers and fine components and then filling the compound into a papermaking process, so that the water filtering performance and the retention performance of the paper can be improved, the ash content in the paper can be effectively improved, and the use amount of paper pulp fibers can be reduced. Under the same paper making process conditions, the content of the filler in the paper can be increased on the premise that the strength performance of the paper is guaranteed, the papermaking water filtration and retention performance of the paper can be effectively improved, and the problem that the water filtration performance is reduced due to the fact that microfibrillated fibers are used for a papermaking system is effectively solved. The microfibrillated fibers and fine components obtained through white water recovery are adopted to form a compound to be used for paper filling, and the use amount of fresh paper pulp can be effectively reduced.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

High-precision clamping force measuring apparatus

ActiveCN102519641AGuaranteed strength performanceExtended service lifeApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention relates to a high-precision clamping force measuring apparatus which comprises a pressure measuring device. The pressure measuring device comprises a mechanics sensor and a left bearing shaft and a right bearing shaft coaxially mounted at the two ends of the mechanics sensor; the pressure measuring device is coaxially mounted on a horizontal base; a left linear bearing and a right linear bearing are coaxially fixed at the two ends of the base respectively; the left bearing shaft and right bearing shaft at the two ends of the mechanics sensor are correspondingly mounted in the left linear bearing and right linear bearing in a sliding manner respectively; and the left linear bearing and right linear bearing are coaxially arranged. The high-precision clamping force measuring apparatus provided by the invention has a scientific and reasonable design, a simple structure and high reliability, is convenient to operate, and effectively improves the measurement accuracy; and moreover, as the bearing shaft has certain expansion amount, the pressure measuring device is effectively protected from damage, and the test efficiency is improved.

Owner:CHINA PACKAGING RES & TEST CENT

Splicing type construction method of wall

ActiveCN114809373AImprove construction efficiencyShorten construction timeDischarging arrangementWallsArchitectural engineeringFixed Beam

The invention discloses a splicing type construction method of a wall body. The splicing type construction method comprises the following steps that column bodies on the two sides of the wall body are fixed to the tops of corresponding column bodies below the wall body; when the distance between the two column bodies is smaller than or equal to one meter, the two column bodies are fixedly connected through transverse ribs; when the distance between the two column bodies is larger than one meter, the tops of the adjacent lower-layer beam bodies and the two column bodies are spliced and fixed through connecting pieces and at least one prefabricated wallboard horizontal pre-tightening tie bar or vertical pre-tightening tie bar; a fixed beam body is placed on the top between the two column bodies in the extending direction of the wall body; when the distance between the two column bodies is smaller than or equal to one meter, the screw rods at the bottoms of the beam bodies are fixedly connected with the screw rods at the tops of the adjacent lower-layer beam bodies through vertical ribs; cast-in-place concrete C is conducted on the wall defined by the column bodies and the beam bodies and the area located outside the prefabricated wall panel; and after the cast-in-place concrete C is solidified, wall building and forming are completed. According to the splicing type construction method of the wall, the building construction efficiency can be improved, the wall is firm and stable, the integration effect is good, and the good anti-seismic effect is achieved.

Owner:CHINA CIVIL ENG CONSTR CORP +2

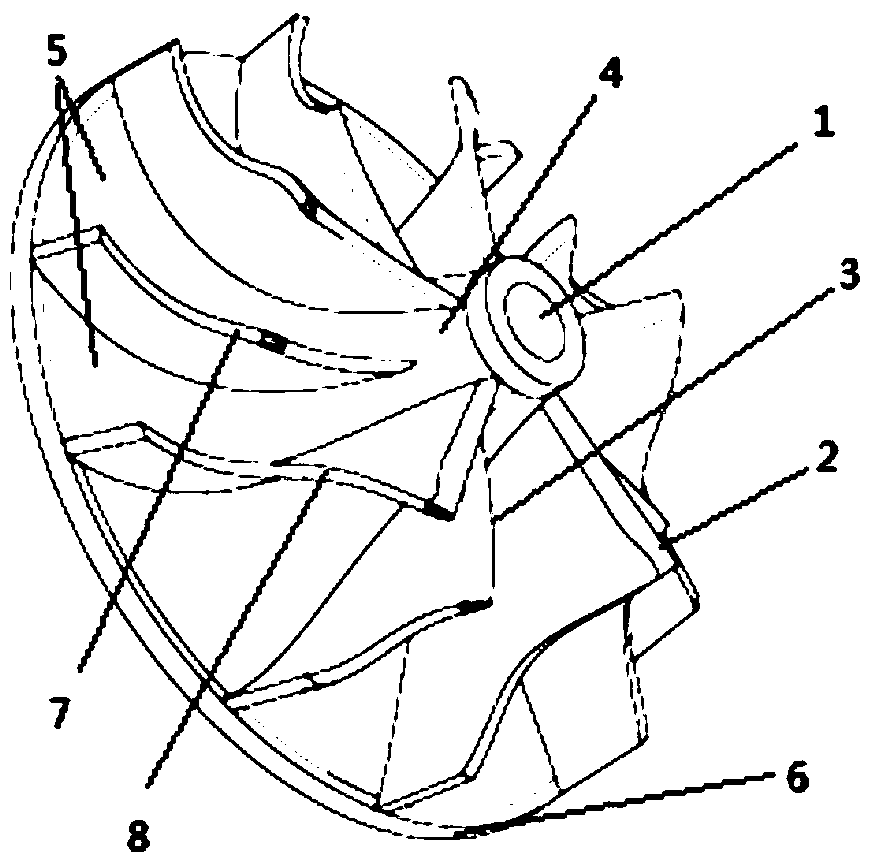

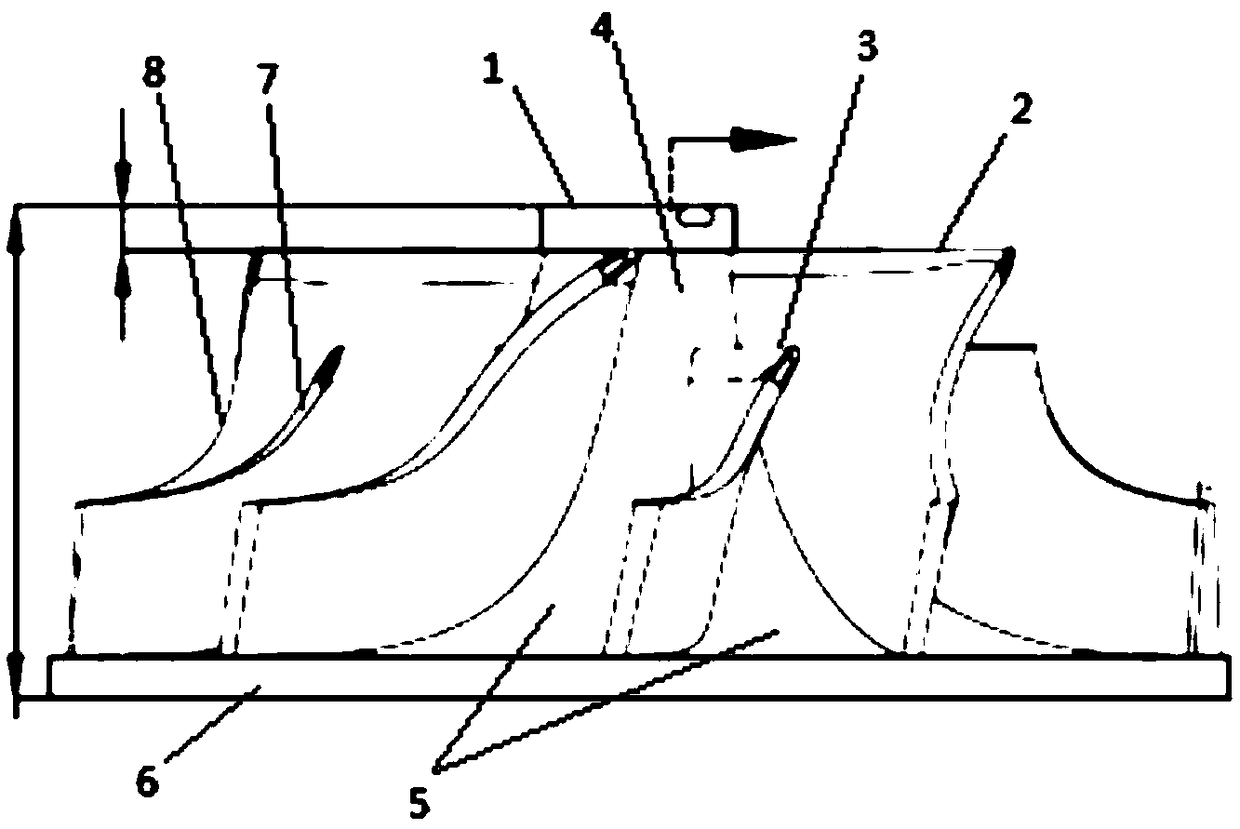

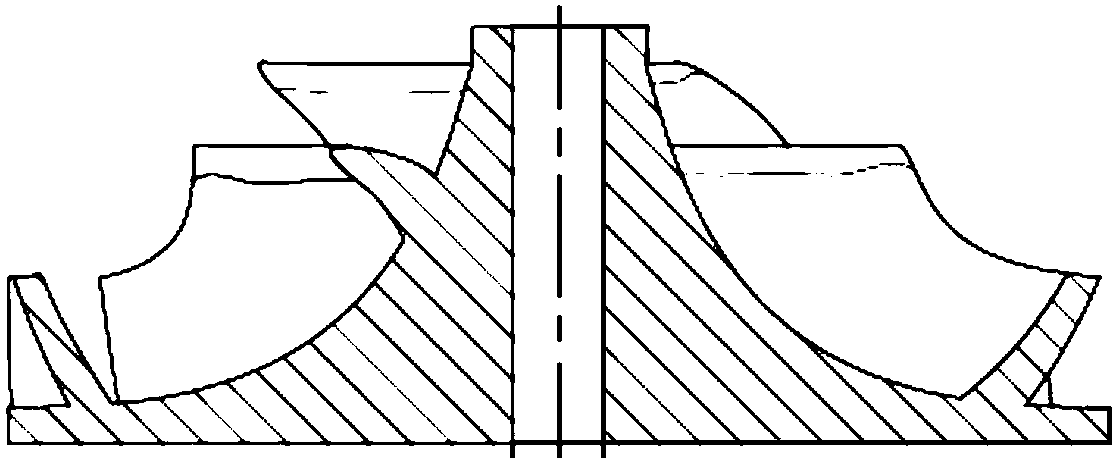

2K cold compressor impeller

The invention discloses a 2K cold compressor impeller. The 2K cold compressor impeller is characterized by comprising an impeller rear cover plate (6), a plurality of main blades (2) and a plurality of flow dividing blades (3); the upper surface of the impeller rear cover plate (6) is a U-shaped arc surface with the center protruding upwards, and the center is provided with a rotation shaft connecting port (1); the parts extending from the lower edges of the outer sides of the main blades (2) to the upper edges are downward-protruding arcs matched with the U-shaped arc surface of the impellerrear cover plate (6); the parts extending from the lower edges of the outer sides of the flow dividing blades (3) to the upper edges are downward-protruding arcs matched with the U-shaped arc surfaceof the impeller rear cover plate (6); the main blades (2) and the flow dividing blades (3) are distributed on the U-shaped arc surface of the impeller rear cover plate (6) in a staggered manner; a helium outlet (5) is formed in the inner sides of every two adjacent main blades (2), and a helium inlet (4) is formed by the outer side of each main blade (2) and the outer side of the corresponding adjacent flow dividing blade (3).

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

A phase-change roof self-insulating ceramsite concrete

ActiveCN105036627BGuaranteed strength performanceGood energy storageSolid waste managementExpanded clay aggregatePhase change

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

A kind of multi-component coating starch and its production process

ActiveCN106243234BGuaranteed strength performanceImprove water retentionPaper coatingCoatingsAcetic anhydrideEnzymatic degradation

The invention discloses a multielement coating starch. In the multielement coating starch, the dry-basis content is 50%, the viscosity is 200-500cp, the water content in a finished product is less than or equal to 14.0%, the pH value is 6.0-8.0, the substitution degree is 0.035-0.060, the carboxyl accounts for 1.0-2.0% and the acetyl accounts for 1.0-2.0%. The multielement coating starch comprises the following components of: native starch, sodium hypochlorite, a cationic etherifying agent, anhydrous sodium sulphate, acetic anhydride, hydrochloric acid, enzymes, tap water and a proper amount of sodium hydroxide, wherein the sodium hypochlorite accounts for 3.0-4.0% of the mass of the dry basis in the native starch; the cationic etherifying agent accounts for 5.0-8.0% of the mass of the dry basis in the native starch; the acetic anhydride accounts for 4.0-6.0% of the mass of the dry basis in the native starch; the anhydrous sodium sulphate accounts for 3.0-6.0% of the mass of the dry basis in the native starch; and the hydrochloric acid accounts for 1.0-3.0% of the mass of the dry basis in the native starch. The multielement coating starch disclosed by the invention has the advantages that many types of functional groups are adopted, the content of the functional groups is high, the environment-friendly effect is achieved, and petroleum base can be substituted to synthesize latex. Simultaneously, the invention also discloses a production process of the multielement coating starch. The production process is characterized by comprising the five steps of oxidation, esterification, etherification, enzymatic degradation and finished-product preparation.

Owner:山东米能生物科技有限公司

Annealing process for high-strength hardware bolts

ActiveCN108300846AGuaranteed strength performanceImprove annealing qualityFurnace typesHeat treatment furnacesRoom temperatureFree cooling

The invention discloses an annealing process for high-strength hardware bolts. The multiple hardware bolts are put into a high-temperature furnace for preheating treatment at first, and the preheatingtemperature is 120-160 DEG C; then the temperature inside the high-temperature furnace is controlled with the heating speed of 50-90 DEG C / h to conduct heating for 1-2 hours and then stop heating, cooling with the furnace is conducted for 10-15 min, heating is conducted for 1-2 hours with the heating speed of 50-90 DEG C / h, cooling with the furnace is conducted for 15-20 min, then heating is conducted with the heating speed of 100-120 DEG C / h till the temperature is 680-720 DEG C finally, and heat preservation is conducted for 2-3 hours; and cooling with the furnace is conducted for 1.5-2.5 hours, then the temperature inside the high-temperature furnace is controlled with the cooling speed of 10-30 DEG C / h to conduct cooling for 20-40 min, cooling with the furnace is conducted till the temperature is below 540-560 DEG C, and then the high-temperature furnace is opened and naturally cooled to the room temperature. In this way, the annealing quality can be greatly improved, the machining difficulty is reduced for the subsequent process, and the strength performance of the hardware bolts is further ensured.

Owner:SUZHOU TEXIN PRECISION ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com