Patents

Literature

69results about How to "Guaranteed stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

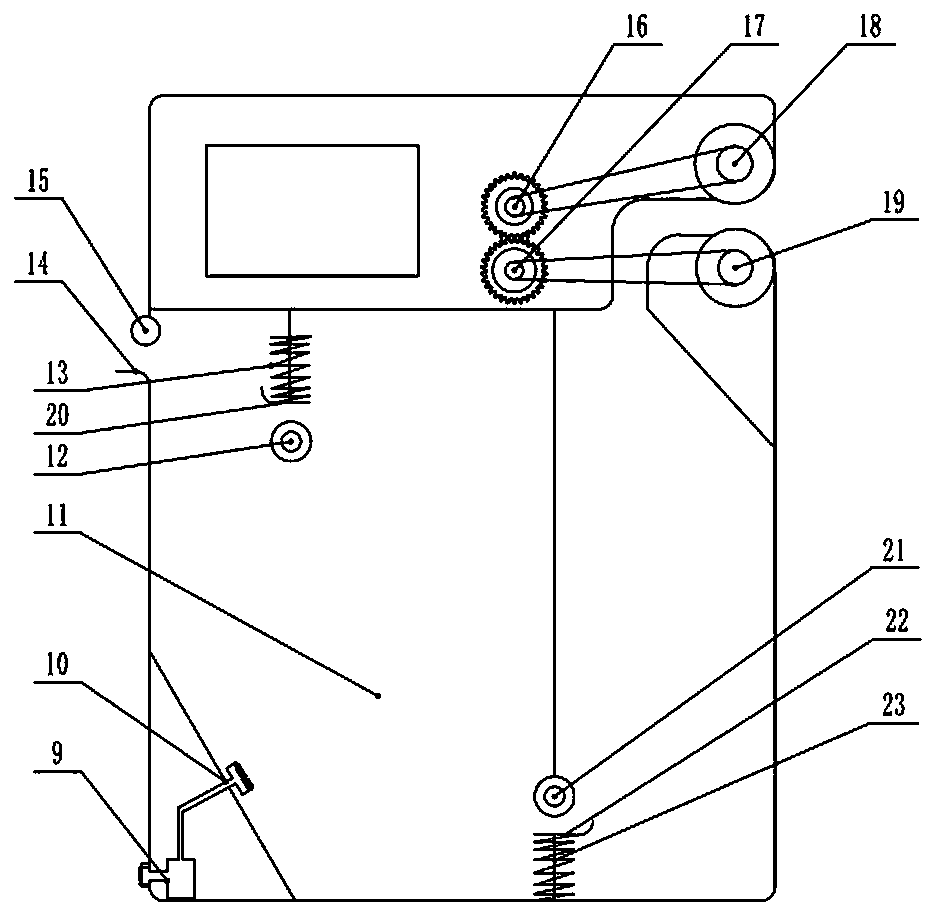

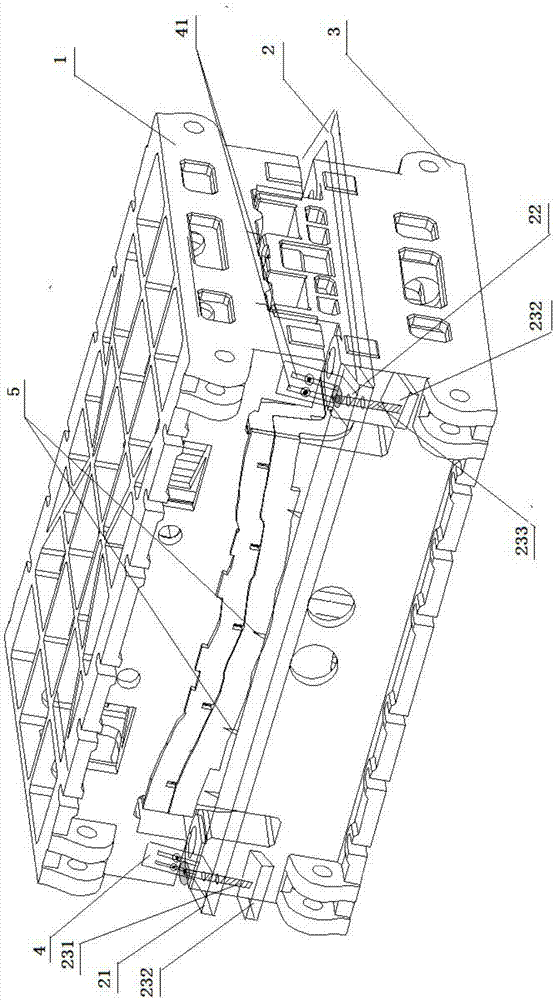

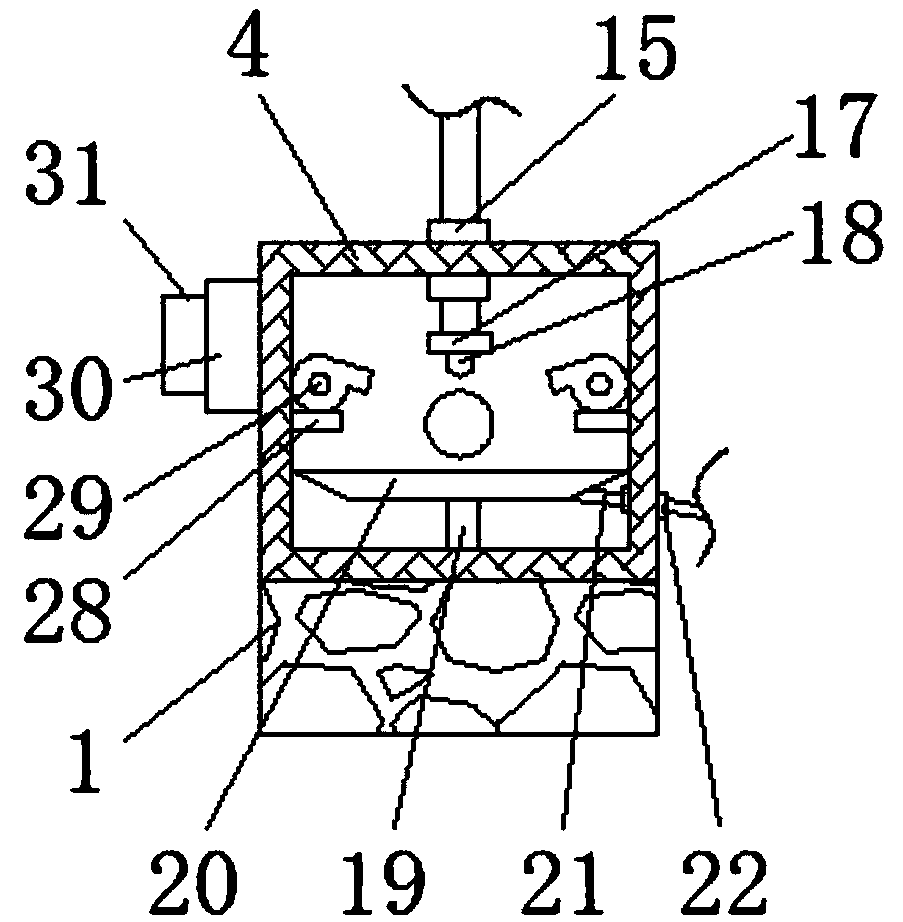

Extract and mechanical properties measurement method of bone trabecula and measurement mechanism

InactiveCN101158679AAvoid damageSubsequent measurement results are authentic and reliableUsing mechanical meansMaterial analysisMeasurement deviceBiomechanics

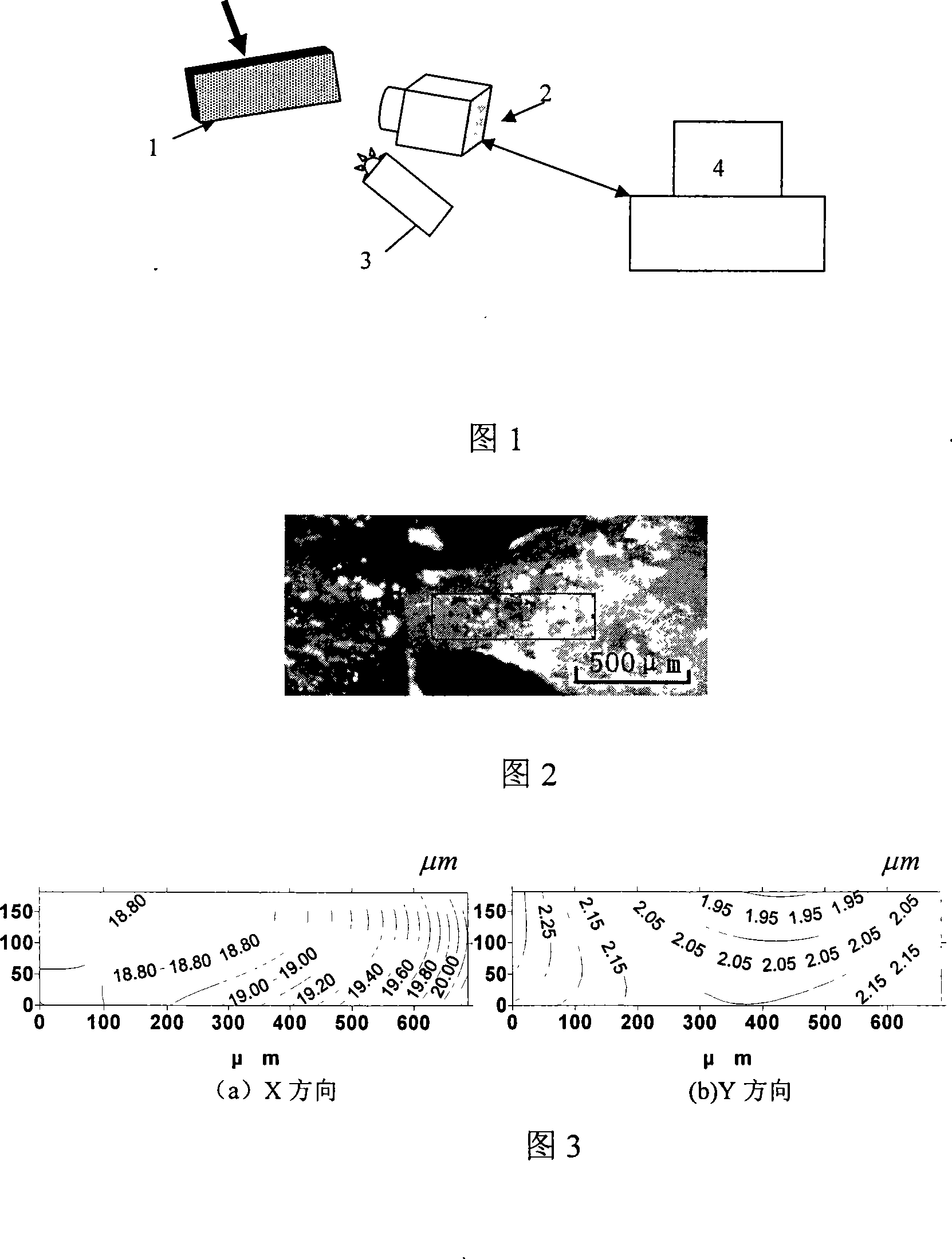

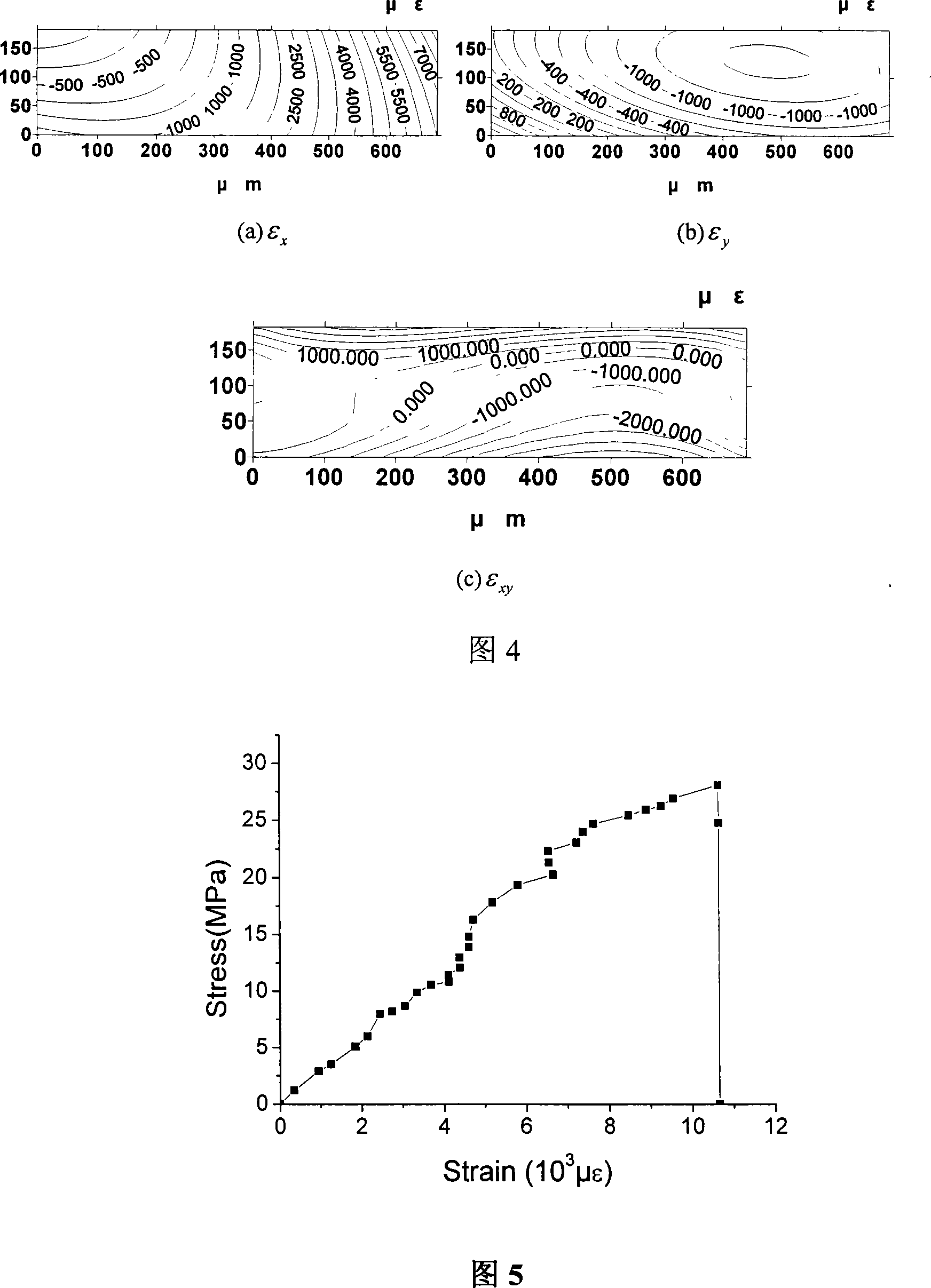

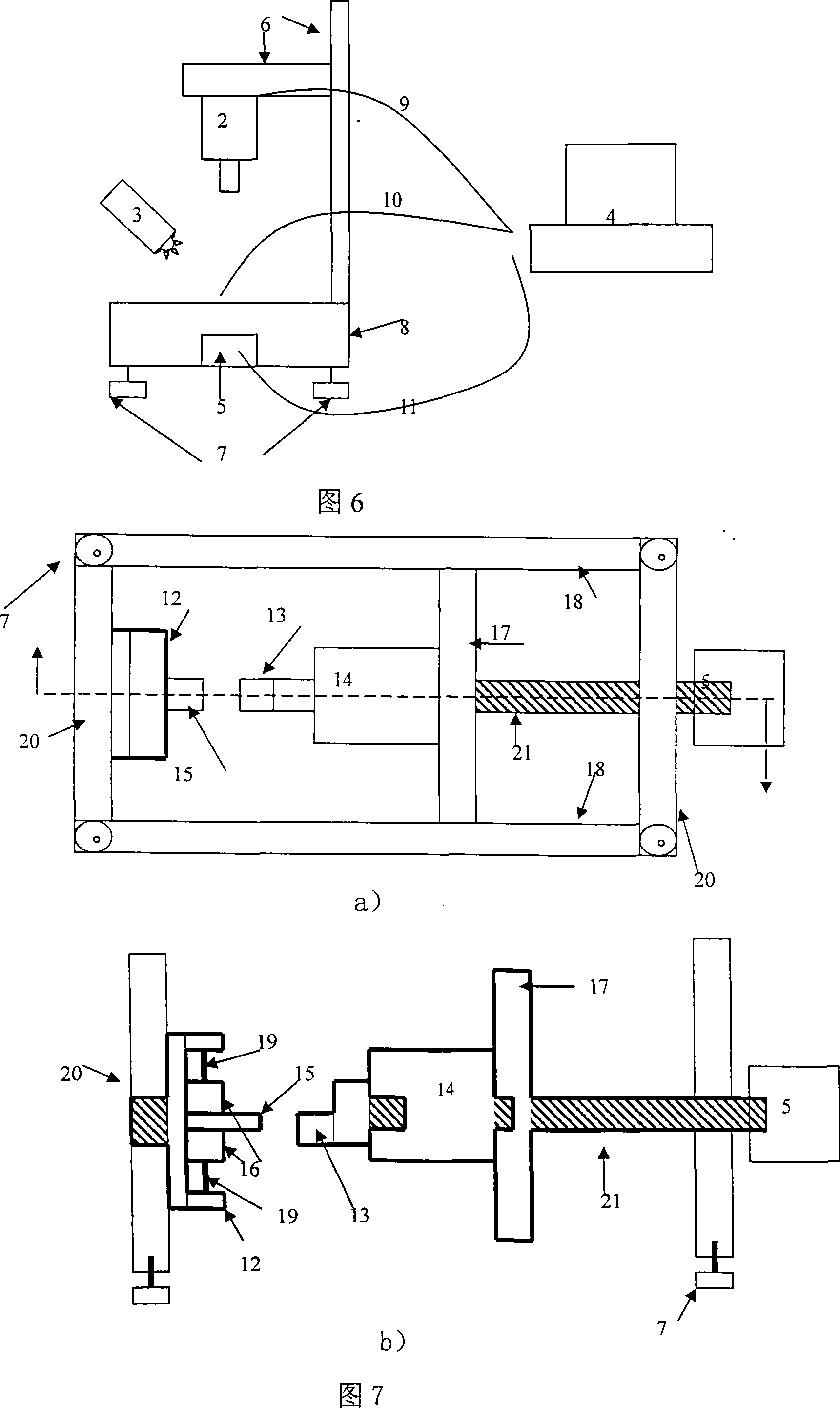

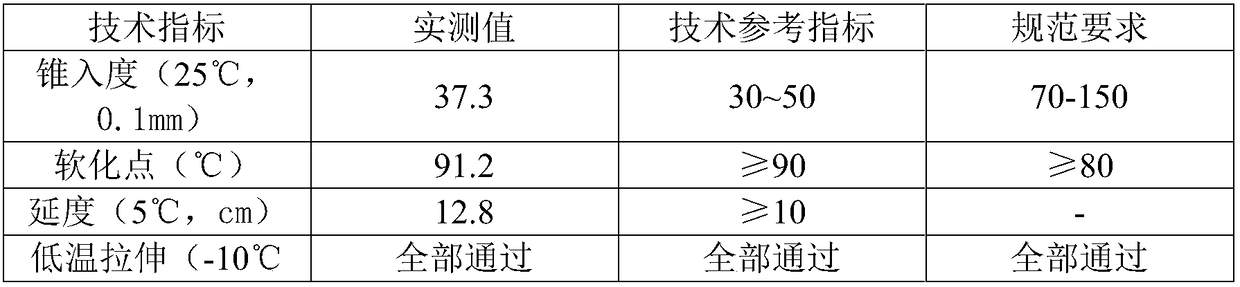

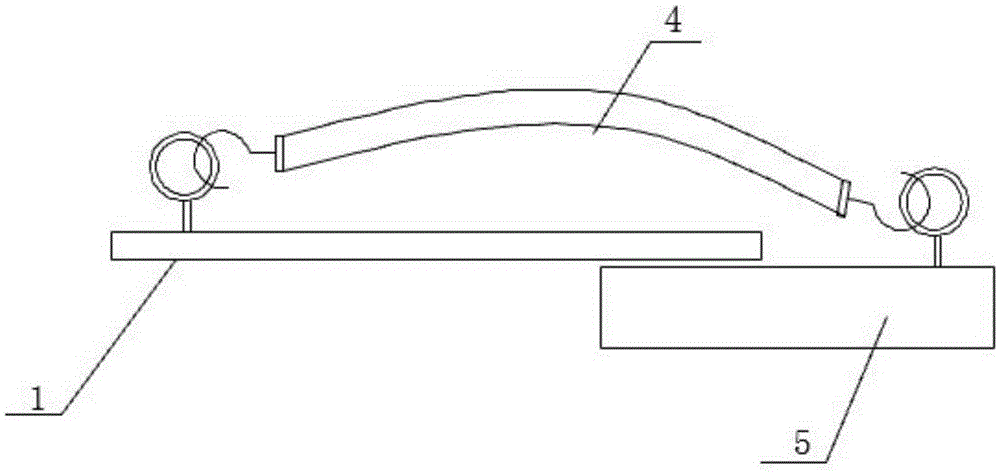

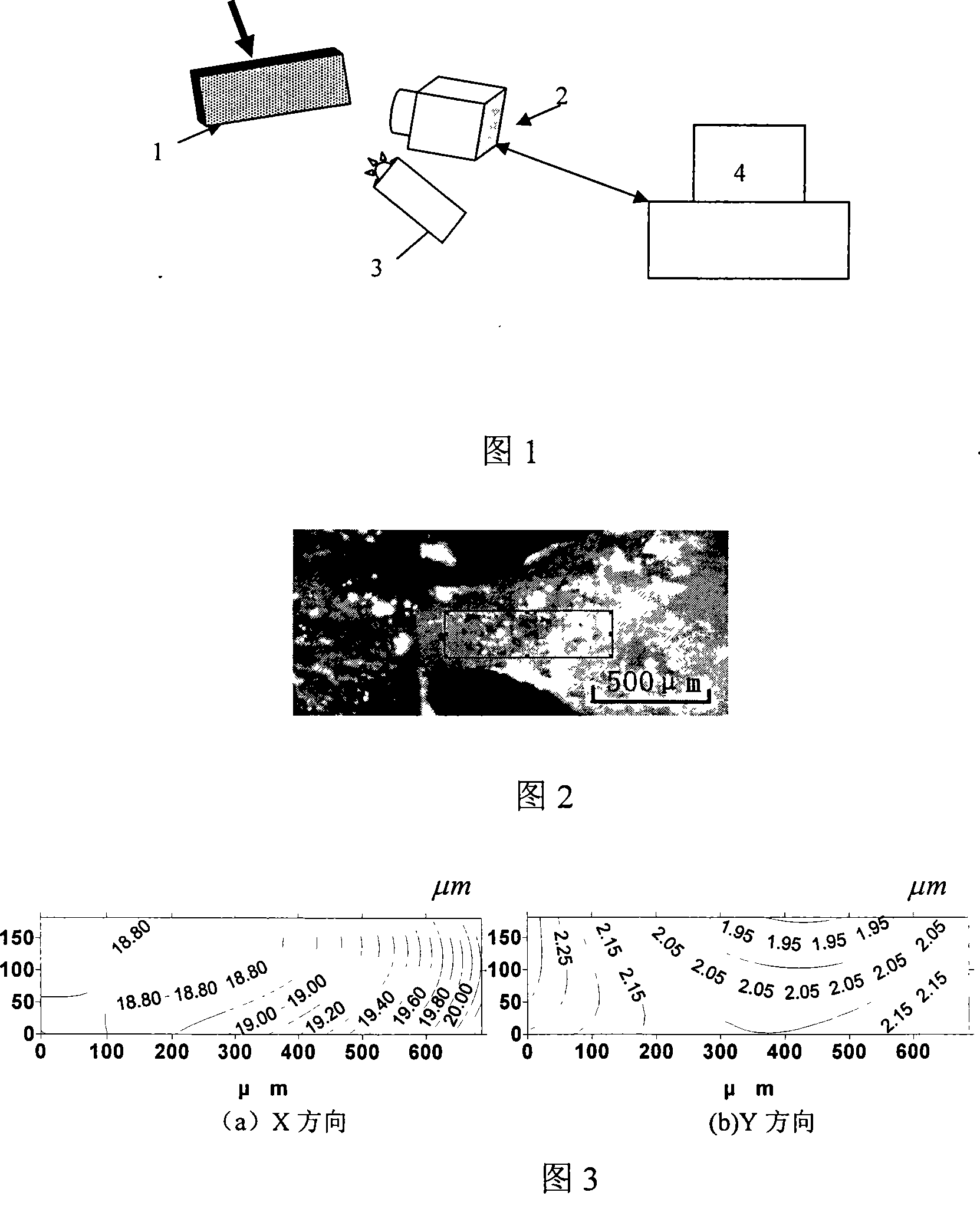

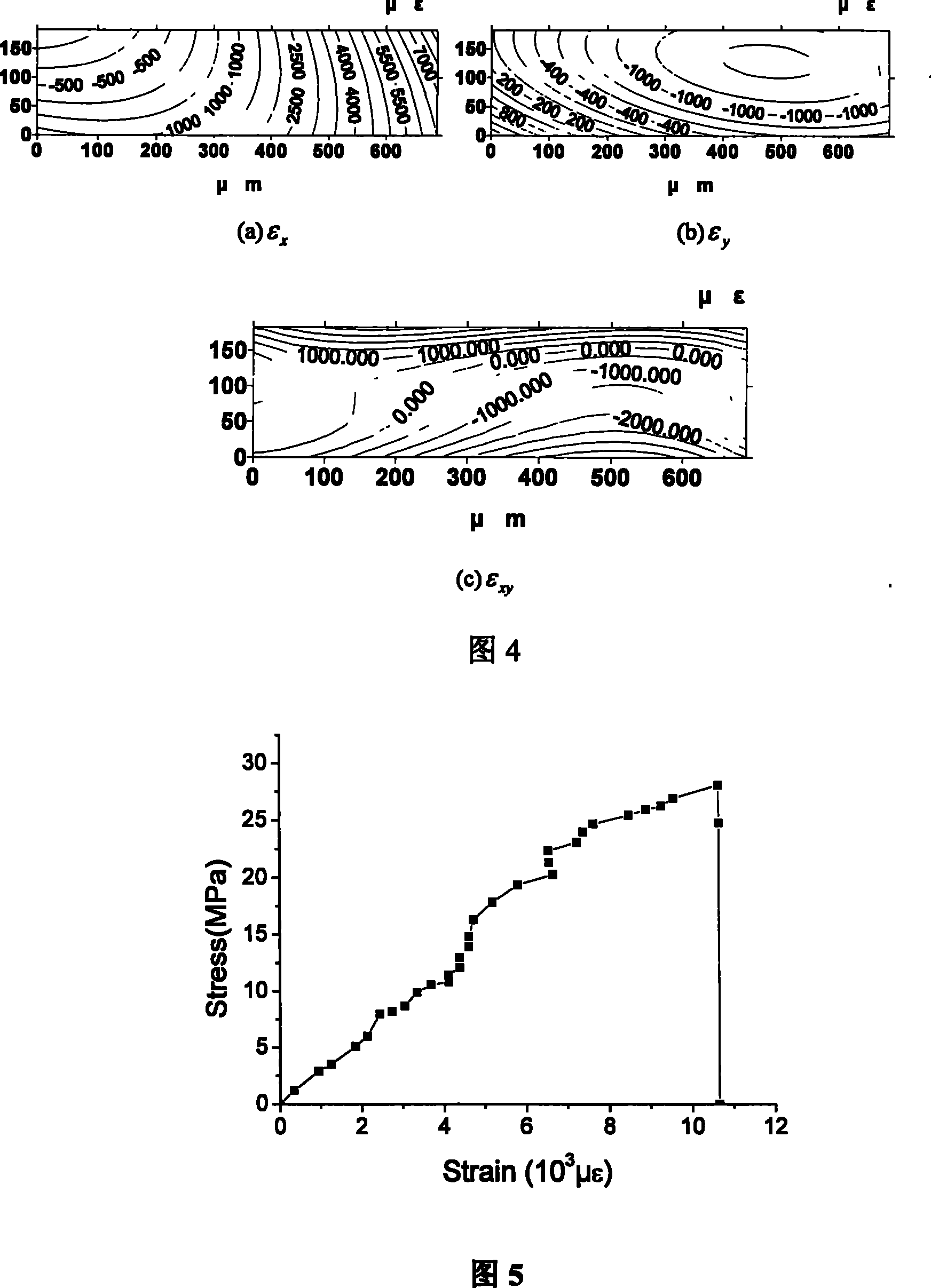

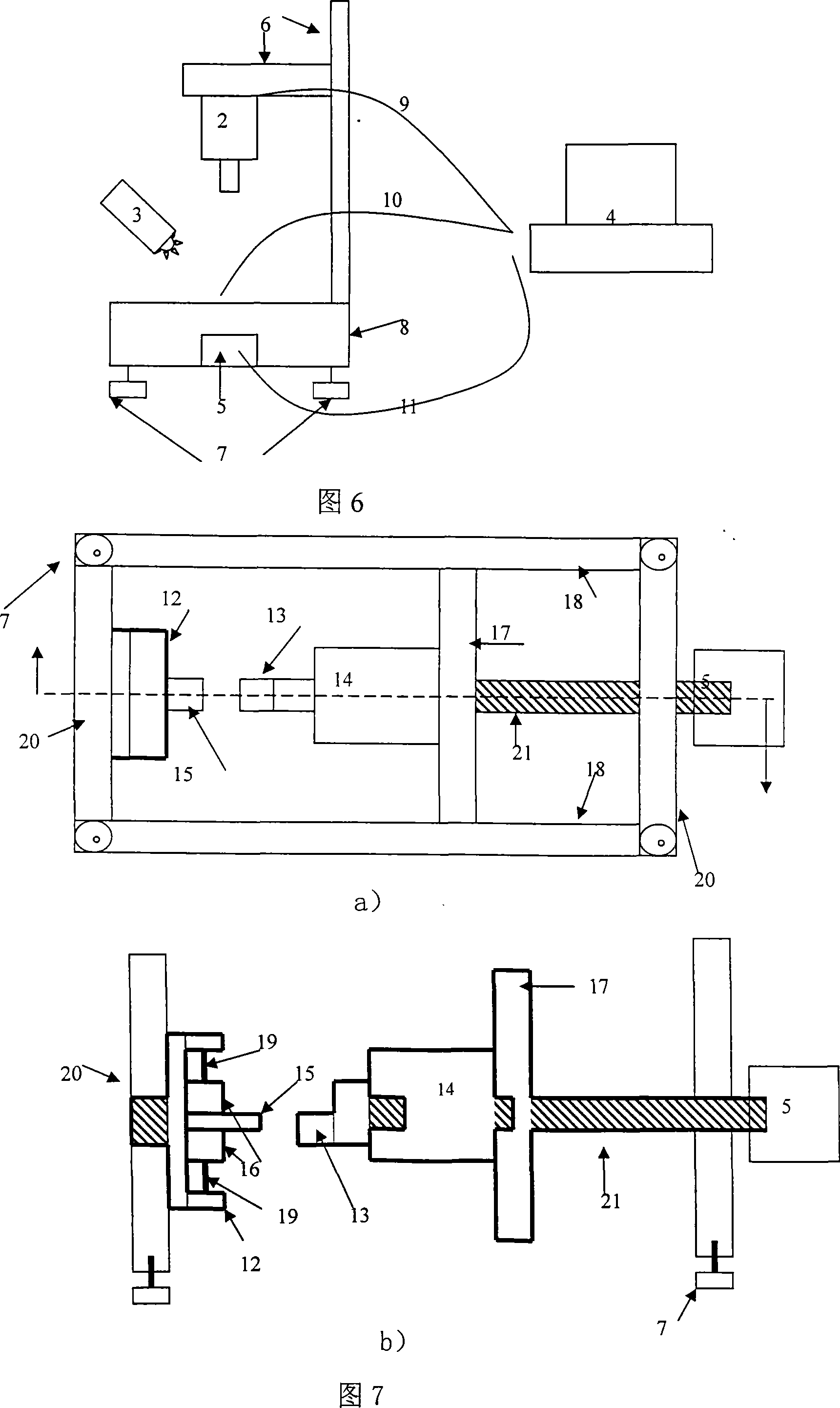

The invention relates to an extracting of a bone trabecula and a test method and a device of mechanical property, which belongs to the biological mechanics experiment technical field. The method comprises: 1. the bone is cut into a plurality of small blocks at the length of the bone trabecula; 2. the marrow in the middle of each small spongy bone block is rejected clearly and the spongy bone structure is only left; 3. a small spongy bone block which has an intact bone trabecula is chosen and the bone trabecula around the intact bone trabecula is cut away; 4. the bone trabecula is stretched and compressed at the direction paralleled with a loading force, and the two ends of the bone trabecula are fixed; 5. the CCD camera is aimed to the bone trabecula so as to lead the picture of the bone trabecula in the CCD to be clear; 6. the displacement of the stretching or compressing of the bone trabecula is controlled; 7. the picture and the load of the bone trabecula in each time quantum are recorded synchronously; 8. the displacement field and the strain field of each load is worked out according to DSCM; namely the poisson ratio of the material and the strain curve of the strain of the bone trabecula can be obtained. The invention can minimize the damage greatly, and lead a plurality of mechanical property parameters to be more correct.

Owner:TSINGHUA UNIV

Method for processing mercerized cotton strip

ActiveCN102493142AGuaranteed alkaline dippingGuaranteed stretchMercerising of sliversLiquid/gas/vapor removalPolymer scienceSpinning

The invention relates to a method for processing a mercerized cotton strip in the weaving field. The method comprises the following production steps: processing a cotton strip, and manufacturing into the required shape; shaking the cotton strip: shaking the processed cotton strip into the twisting shape according to the set circle number and a frame length, tying and fixing; and mercerizing: mercerizing the cotton strip on a hank-mercerizing machine according to the specific technology. According to the method for processing a mercerized cotton strip, which is disclosed by the invention, the industrial problem that the cotton fiber can not be mercerized is mainly solved, a feasible full set of processing method for mercerizing, dyeing and spinning the cotton strip is provided, and cotton silk mercerization, cotton wool mercerization and high-depth color spinning can become true.

Owner:无锡市鳌尊生态科技有限公司

C/C-MC composite of mixed matrix thermal structure and preparation method thereof

The invention relates to a C / C-MC composite of a mixed matrix thermal structure and a preparation method thereof, in particular to a novel high-performance thermal structure composite for bearing and a preparation method thereof, and belongs to the technical field of carbon / carbon composite manufacturing. 45-degree fibers are introduced into the plane direction of carbon cloth laminated sewn structure textile, and on the basis of guaranteeing the stretching, compressing, bending and other performance of the material, the shearing performance of the material is improved, and the bearing performance of the material under complex loads is enhanced. By means of matching design of a complex matrix and introduction of the control technology and the fiber interface protection technology, the oxidation resistance of the material is improved, and integration of the bearing strength and heat-proof function of the material is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

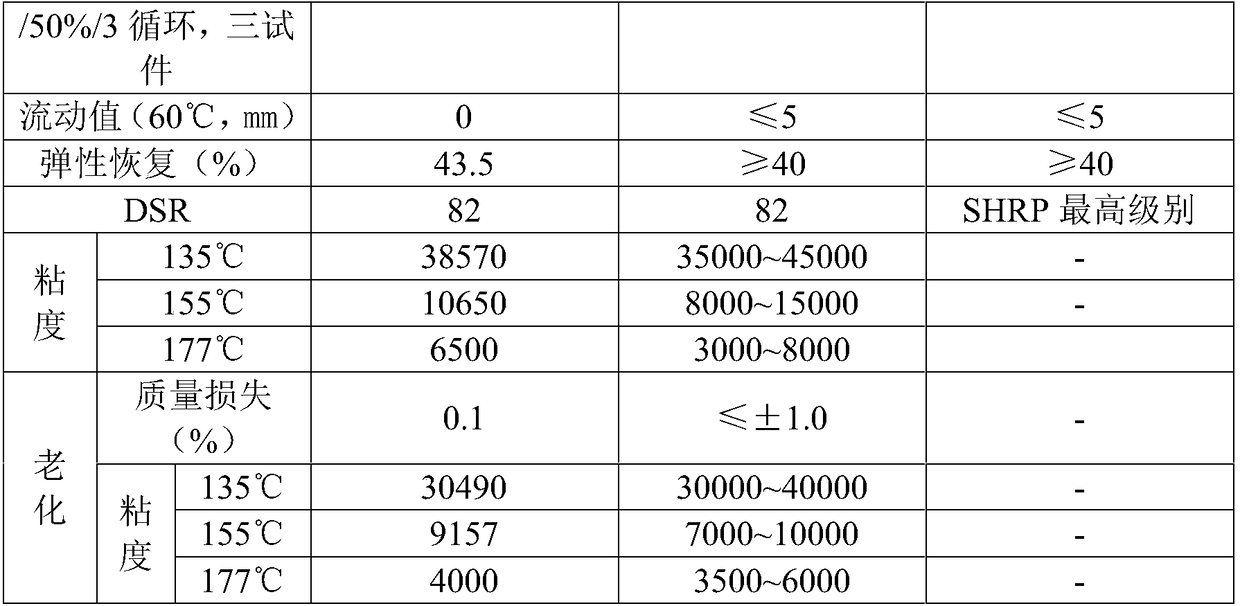

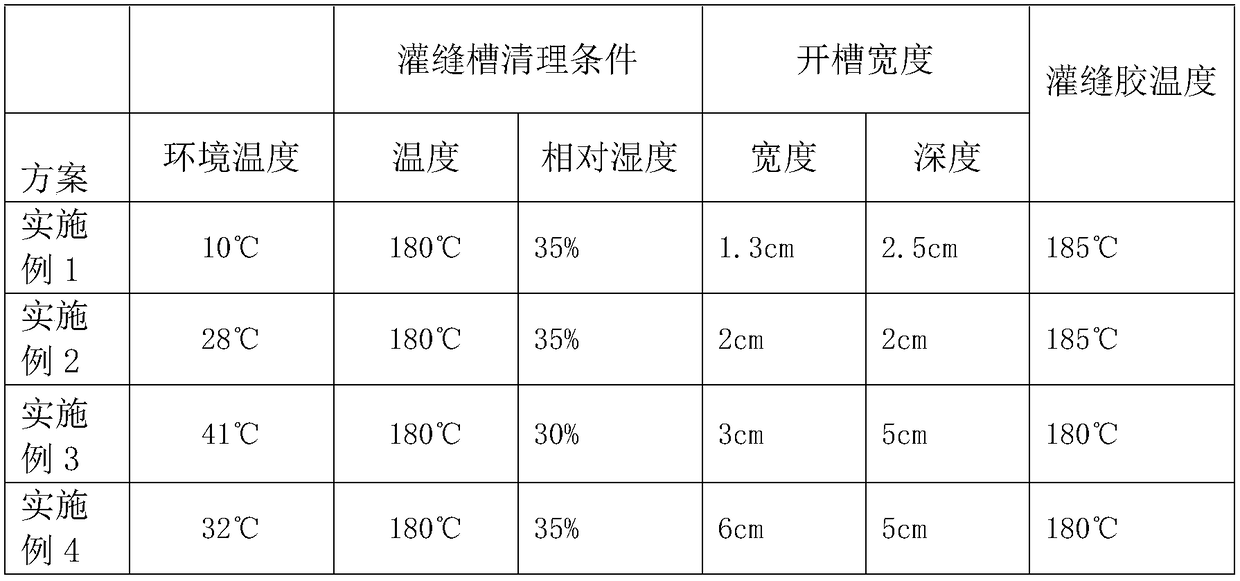

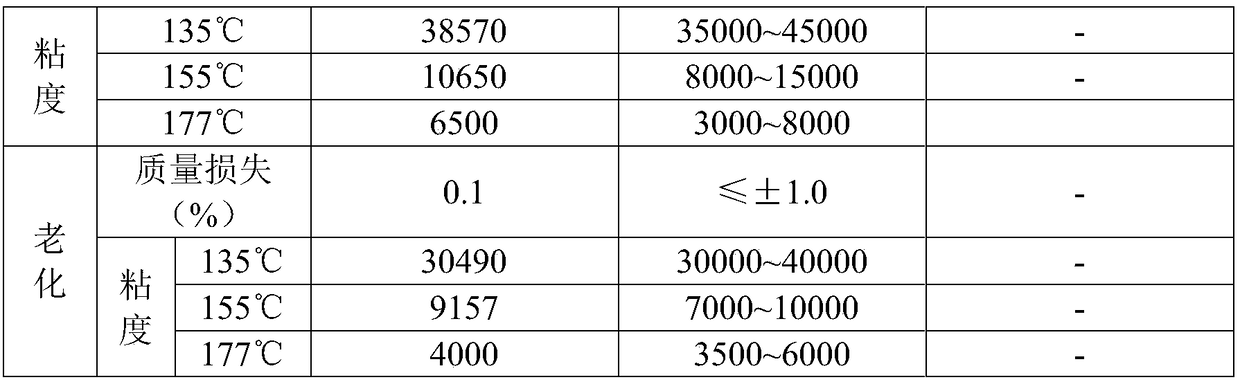

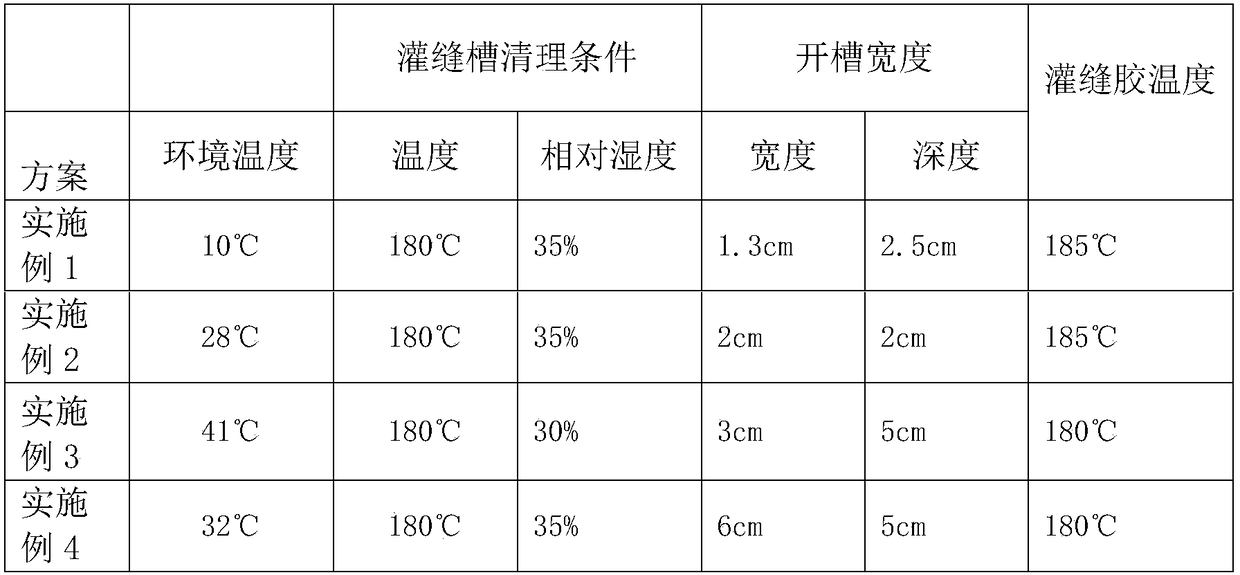

Road crack filling and repairing process

InactiveCN108118577AGuaranteed full integrationGuaranteed sealing effectPaving detailsRoads maintainenceFilling materialsHigh pressure

The invention discloses a road crack filling and repairing process. The key point of the technical scheme is as follows: the road crack filling and repairing process comprises the following steps: cutting and slotting, namely cutting and slotting a pavement according a standard operation for damaged cracks of the pavement, wherein the slot width is 1.3-3cm, the slot depth is smaller than 3cm, paving dry pebbles in the lower part of the pavement when the slot width is 3-6cm, and carrying out glue filling and cap sealing in 2cm in the upper part, wherein a dustproof operation is adopted in the process; filling crack cleaning, namely cleaning a filling slot by high pressure hot wind of a heat spray gun, wherein the temperature of the heat spray gun is set at 1500 DEG C, the pressure of an airsource is 0.2-0.5MPa, and the filling crack cleaning speed is 10m / min in summer and 5m / min in winter; carrying out crack filling operation, namely injecting filling glue into the filling slot througha filling machine, and controlling the height of the filling layer to be not lower than about 0.5cm of the pavement; and cooling and maintaining, namely after the filling operation, paving dry sand,lime powder and the like to the surface of the filling material during maintenance and vibrating, compacting and floating the pavement, wherein the road can come into use within about 10-20min. The road crack filling and repairing process can be used for repairing micro cracks of the pavement quickly, so that the service life of the road is prolonged, and the maintenance cost is lowered.

Owner:ZHONGSHAN YILUMEI ROAD MAINTENANCE TECH CO LTD

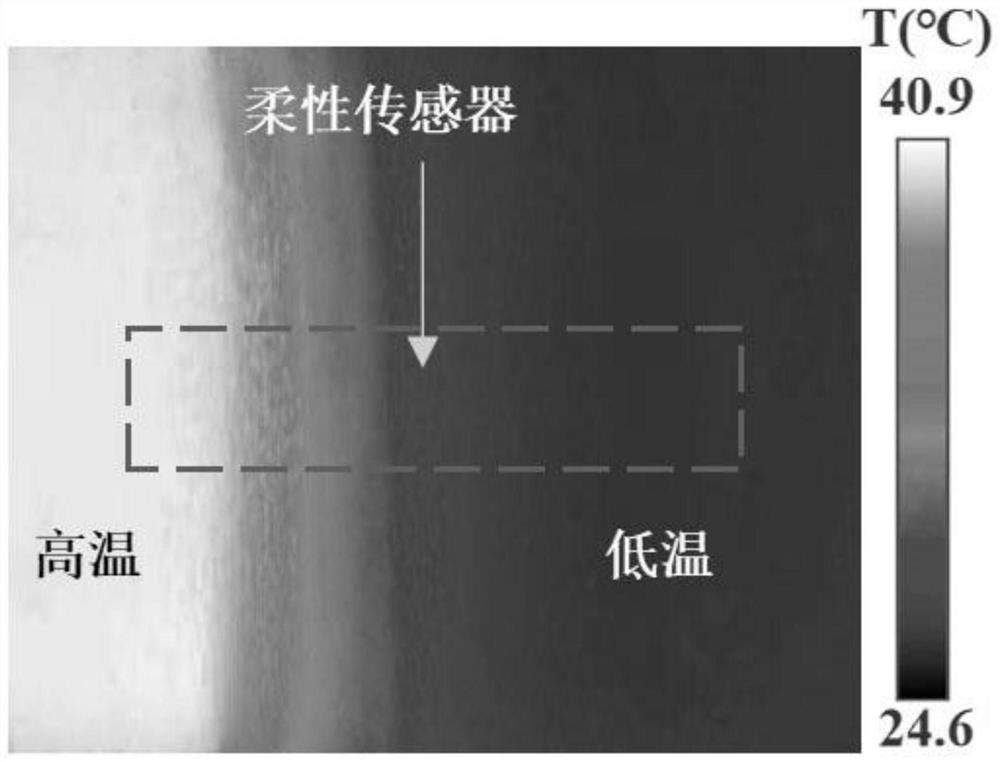

Preparation method of laser-induced graphene flexible strain-temperature two-parameter sensor

PendingCN112361953ASimple structureThe preparation process is green, environmentally friendly and pollution-freeThermometers using electric/magnetic elementsUsing electrical meansPhysicsThin membrane

The invention relates to a preparation method of a laser-induced graphene flexible strain-temperature two-parameter sensor, wherein the method comprises the steps: preparing a preset pattern on a polyimide film by using laser to obtain patterned laser-induced graphene (LIG); uniformly mixing and stirring a PDMS solution according to a ratio of A to B of 10:1, standing for 30 minutes until bubblescompletely disappear, coating the prepared LIG with the PDMS, putting the coated LIG into a heating box at the temperature of 85 DEG C, heating for 120 minutes for curing, taking out after curing, melting the hydrosol with clear water to obtain a flexible material separated from a glass slide, and uncovering the PDMS to peel the LIG from the PI film; and finally, coating with conductive silver adhesive, and bonding a wire to obtain the flexible patterned graphene strain-temperature two-parameter sensor. The preparation method provided by the invention does not need a complex processing technology, is suitable for large-scale preparation and refined pattern processing, has no requirement on an operation environment, and is simple to operate. Wide application prospects are realized in the field of medical health wearable devices.

Owner:HEBEI UNIV OF TECH

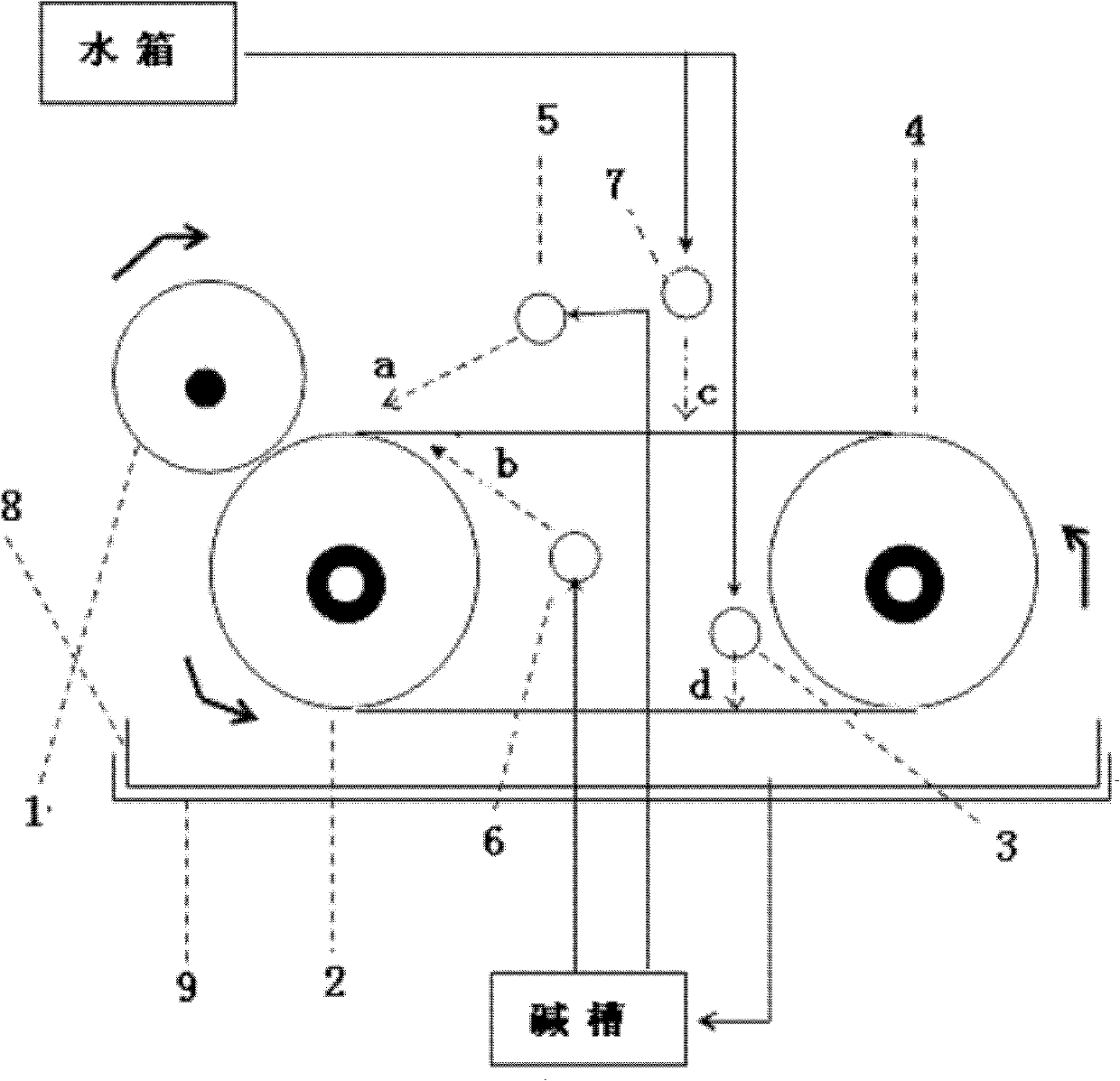

Cotton sliver mercerizing process and mercerizing device utilizing same

InactiveCN102704225AImprove spinning efficiencyHigh glossMercerising of yarns/threads/filamentsMercerising of sliversComposite materialPolymer chemistry

Disclosed are a cotton sliver mercerizing process and a mercerizing device utilizing the same, which belong to the technical field of textile technology. The cotton sliver mercerizing process includes: a, cotton sliver pretreatment step including dewing cotton slivers and dewatering the same or squeezing water out of the same to form wet cotton slivers with certain liquid content; b, a cotton sliver reeling step including reeling the wet cotton slivers on a reeling machine and fixing the cotton slivers by lay bands; c, a covering step including wrapping the reeled cotton slivers with the wrapping cloth integrally; and d, a mercerizing step realized by concentrated spraying and instant squeezing. The sliver cottons are mercerized effectively by dewing to reinforce and by means of concentrated spraying and instant squeezing, and alkali content of the cotton slivers is controlled all the time, so that the cotton slivers cannot be dissolved due to excessive swelling, and the difficult problem of failure in mercerizing the cotton slivers without twist is solved. In addition, the mercerized cotton slivers are bright, smooth and fluffy, and dye color yield is increased by 20%-30%.

Owner:WUXI NON SIZING TECH

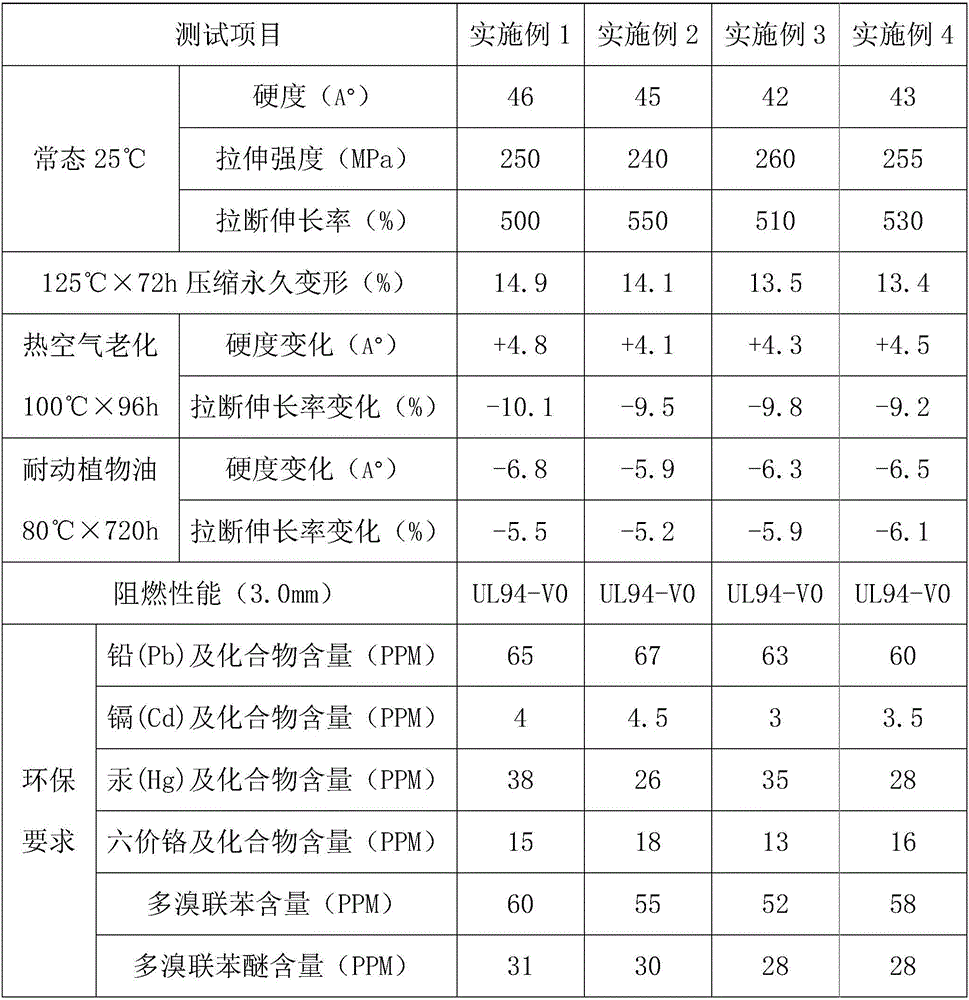

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

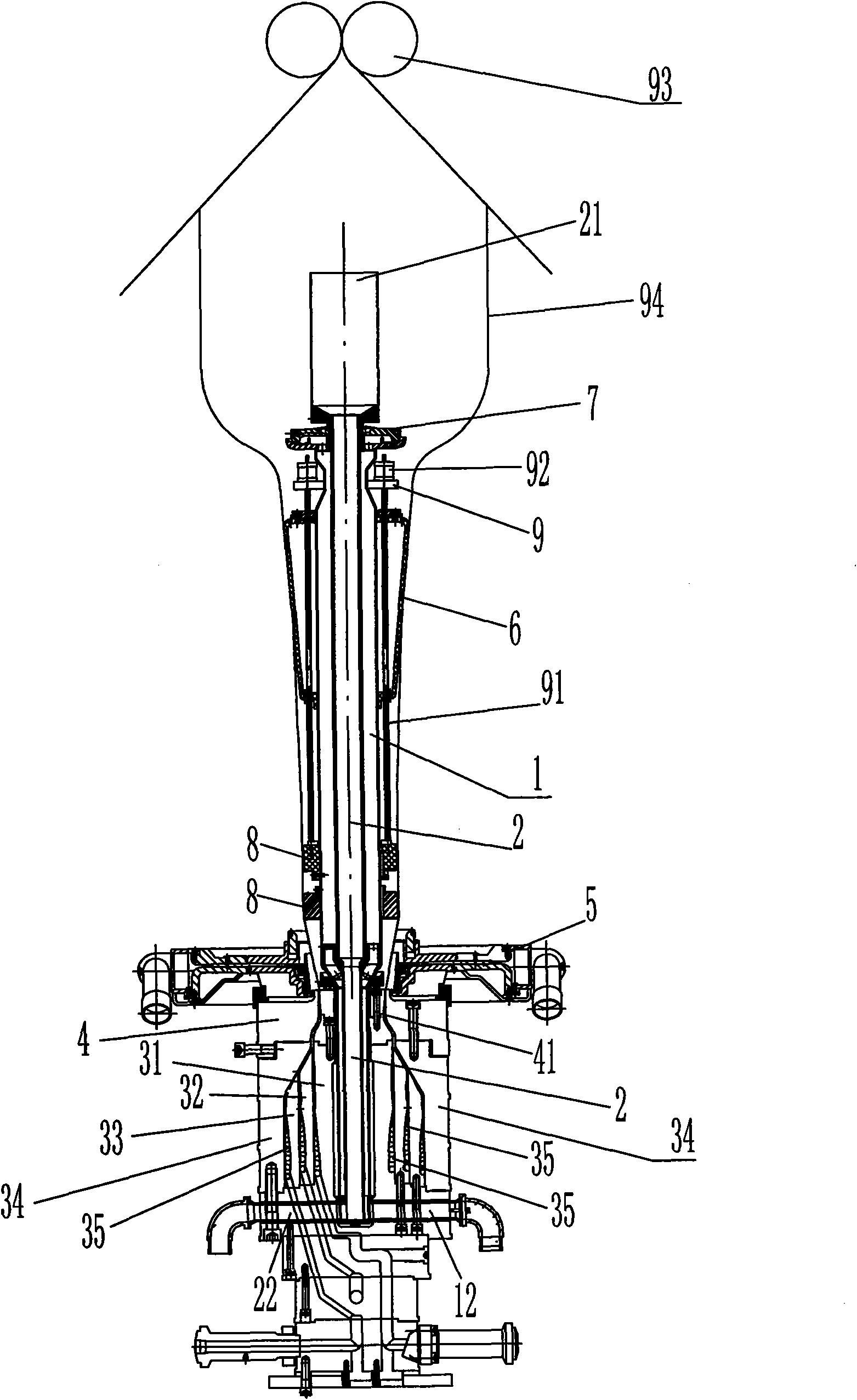

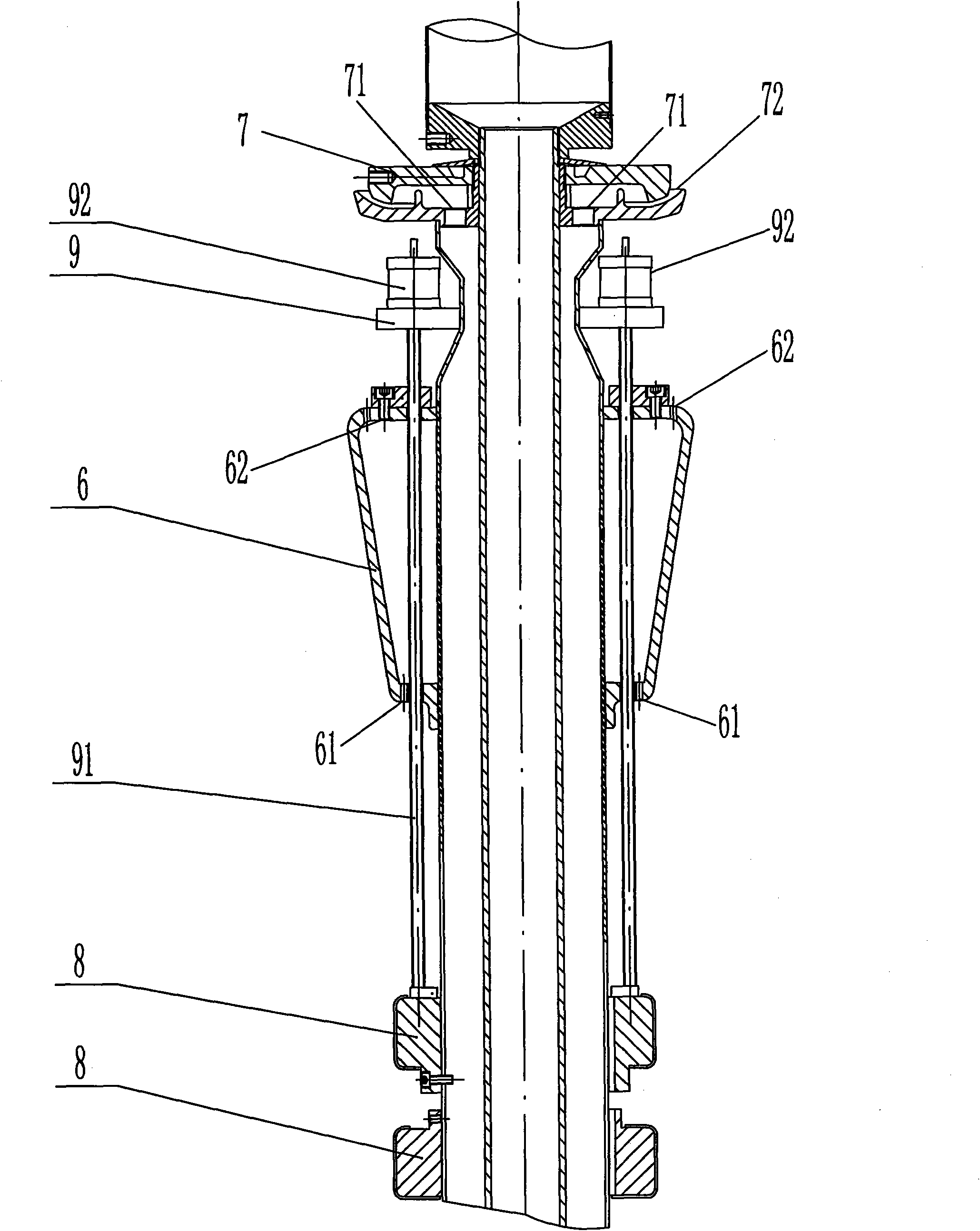

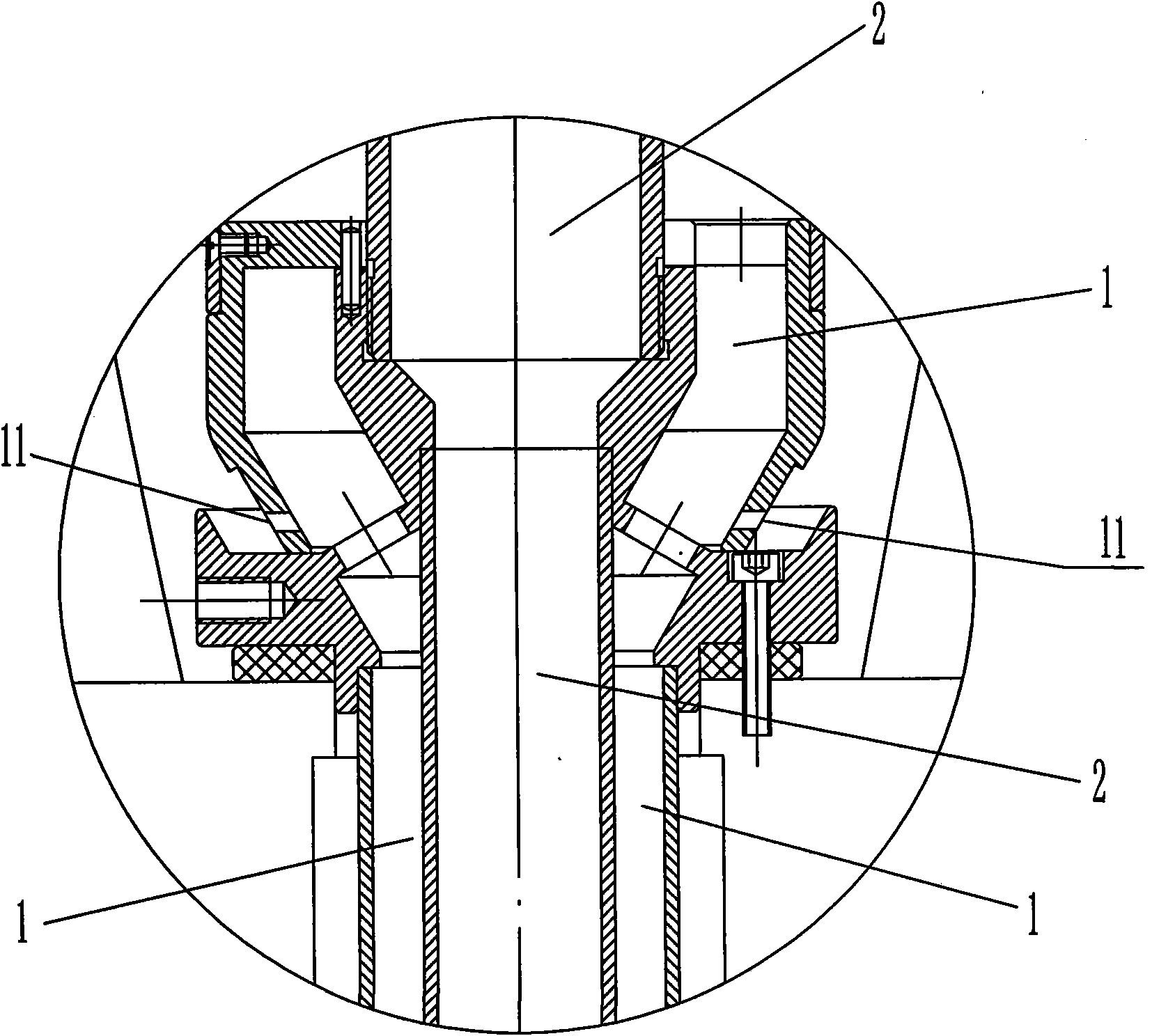

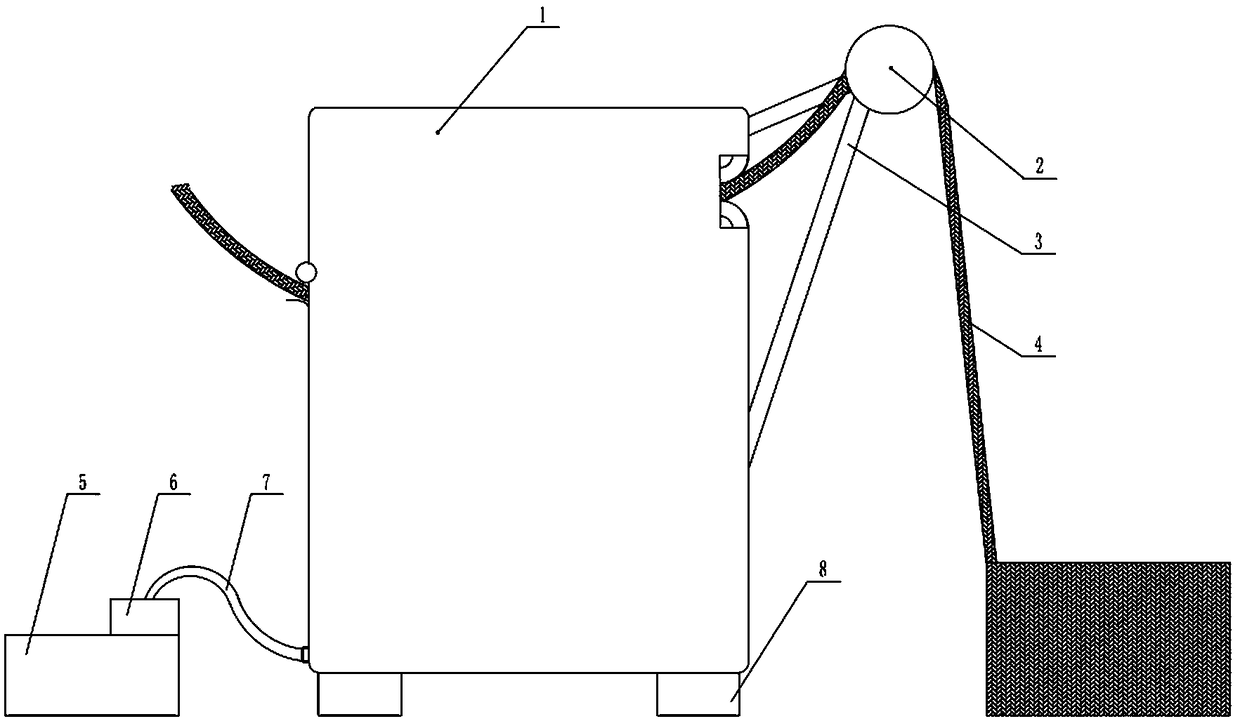

Stone paper blowing production equipment

ActiveCN101929100ANo stretching effectImprove mechanical propertiesInorganic fibres/flakesNeck ringsAerospace engineering

The invention discloses stone paper blowing production equipment, which comprises a machine head. The center of the machine head is provided with a central air exhaust straight pipe; a circular stretching bar is arranged on a neck ring mold and has a taper with a large upper part and a small lower part; the side surface of the circular stretching bar is coated with a cloth material; the diameter of the upper end of the circular stretching bar is larger than that of a ring extruding port; an internal cooling air ring is arranged on the circular stretching bar; a central air inlet straight pipe extends from the center of the machine head upwards and passes through the circular stretching bar; the upper end of the central air inlet straight pipe is communicated with an air inlet of the internal cooling air ring; an air outlet of the internal cooling air ring is positioned at the periphery of the air inlet; the central air exhaust straight pipe extends from the center of the machine head upwards and passes through the circular stretching bar and the internal cooling air ring; and the upper opening of the central air exhaust straight pipe is positioned above the internal cooling air ring. The stone paper blowing production equipment can make a stone paper membrane extruded from the neck ring mold raised for a certain distance and then blown and stretched, and can make the stone paper membrane fully cooled.

Owner:GUANGDONG JINMING MACHINERY

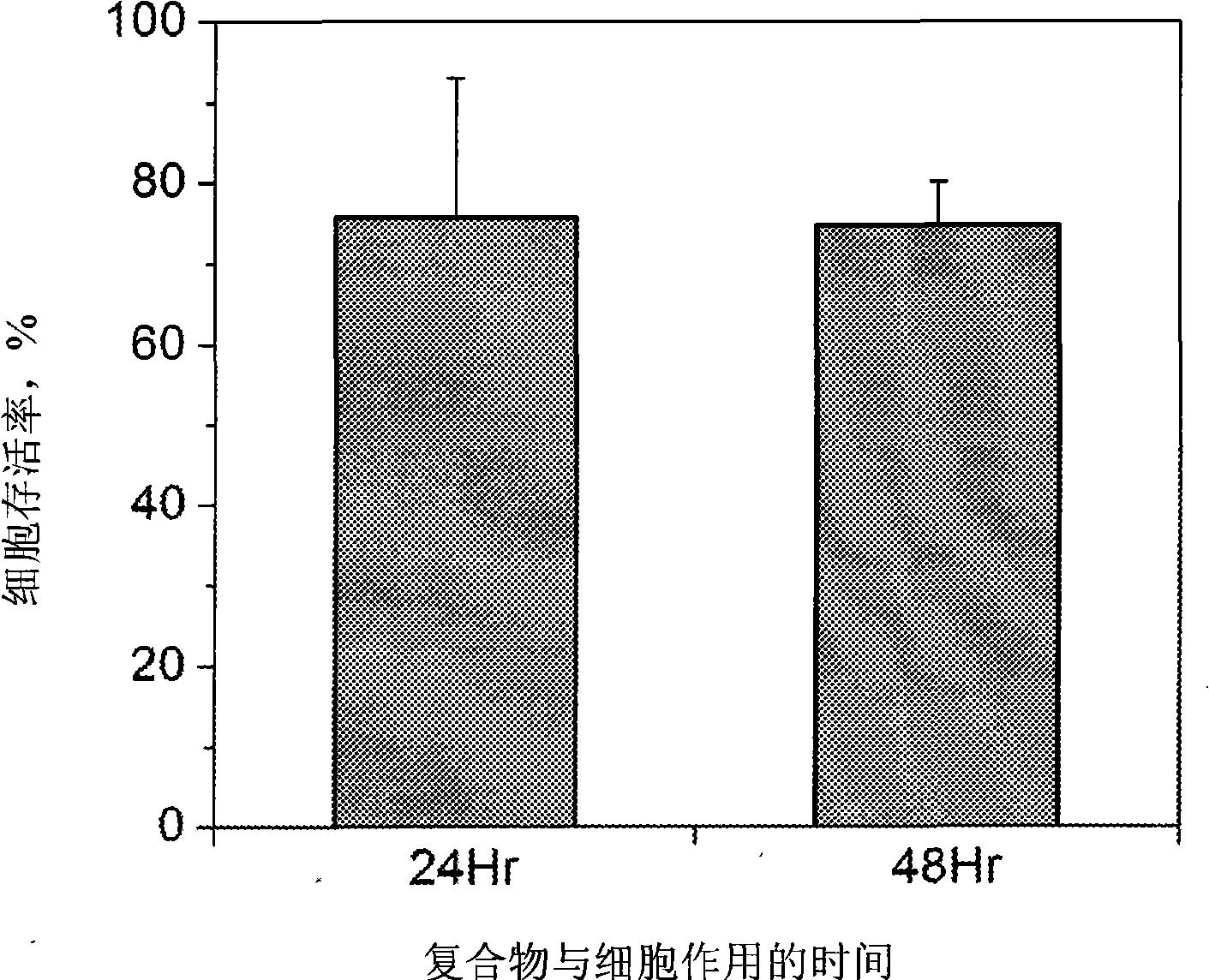

Gene vector system containing targeted shading system, preparation and use thereof

InactiveCN101302532AImprove performanceLow toxicityVector-based foreign material introductionGene deliveryCytotoxicity

The invention relates to a gene delivery system containing a target shielding system and a preparation method and application thereof. The gene delivery system consists of a shielding system with a target ligand, a cation polymer material and plasmid DNA, wherein, the cation polymer material and the plasmid DNA are compounded to form compound particles, and the shielding system with the target ligand is shielded on the surface of the compound through electrostatic effect. The gene delivery system containing the target shielding system can transfer a loaded genic material into cells to realize the expression of the genic material and finish a transfection process, and the targeting of gene transfection can be improved. The preparation method has the advantages that: the target ligand is grafted onto the shielding system; on the one hand, the targeting strategy can not affect the compound ability of a cationic polymer to the DNA, on the other hand, the targeting strategy can also guarantee that the target ligand is extended to the periphery of the gene delivery system so as to improve the combination efficiency of the target ligand and a cell surface receptor. The highest transfection efficiency of the gene delivery system to a HeLa cell is 73 percent, and the toxicity of the cell is small.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Tow flavoring device and flavoring method for flavoring cigarette filter rods

The invention discloses a tow flavoring device for flavoring cigarette filter rods, which comprises a buffer chamber and a perfuming mechanism, the wire inlet of the buffer chamber is provided with afeed driving mechanism, A thread inlet is communicated with the buffer chamber through a feeding passage, two groups of elastic guide mechanisms are arranged in the buffer chamber in the direction from the wire inlet to the wire outlet, Two sets of elastic guide mechanisms are staggered vertically, and the fragrance adding mechanism comprises a fragrance adding nozzle arranged in a buffer chamber,and the fragrance adding nozzle is arranged toward a tow between two adjacent sets of elastic guide mechanisms. The invention also discloses a tow fragrance adding method for fragrance adding of a cigarette filter rod, comprising a loose tow and a tow fragrance adding; The invention can automatically carry out uniform fragrance addition to the tow, At that same time, the buff effect of the loosetow before flavoring effectively improve the self-looseness of the tow, enhances the filtering efficiency of the formed nozzle rod, and has positive effect on reducing tar, reducing harm and stabilizing the suction resistance of cigarette. The invention can avoid the harm of harmful chemical gases caused by the burning of spices with tobacco shreds to the health of consumers, and effectively improve the self-looseness of the tow before flavoring.

Owner:CHINA TOBACCO HENAN IND

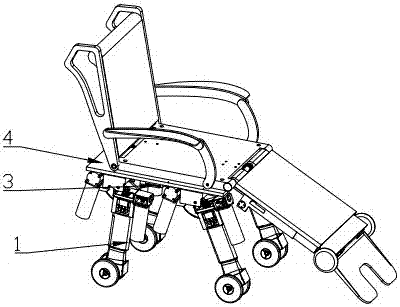

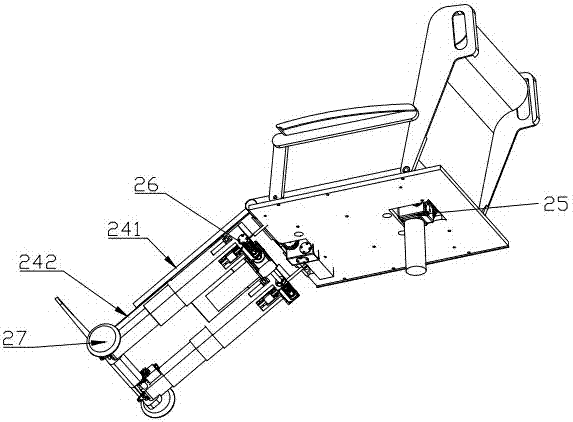

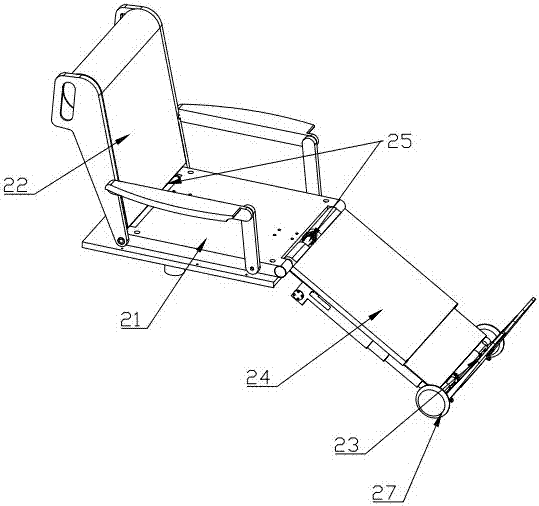

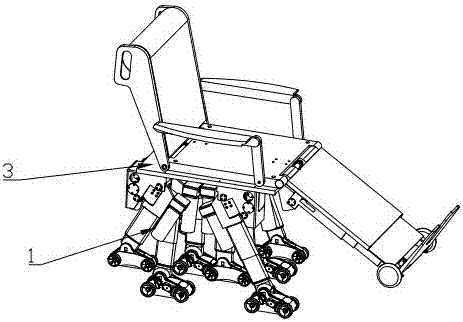

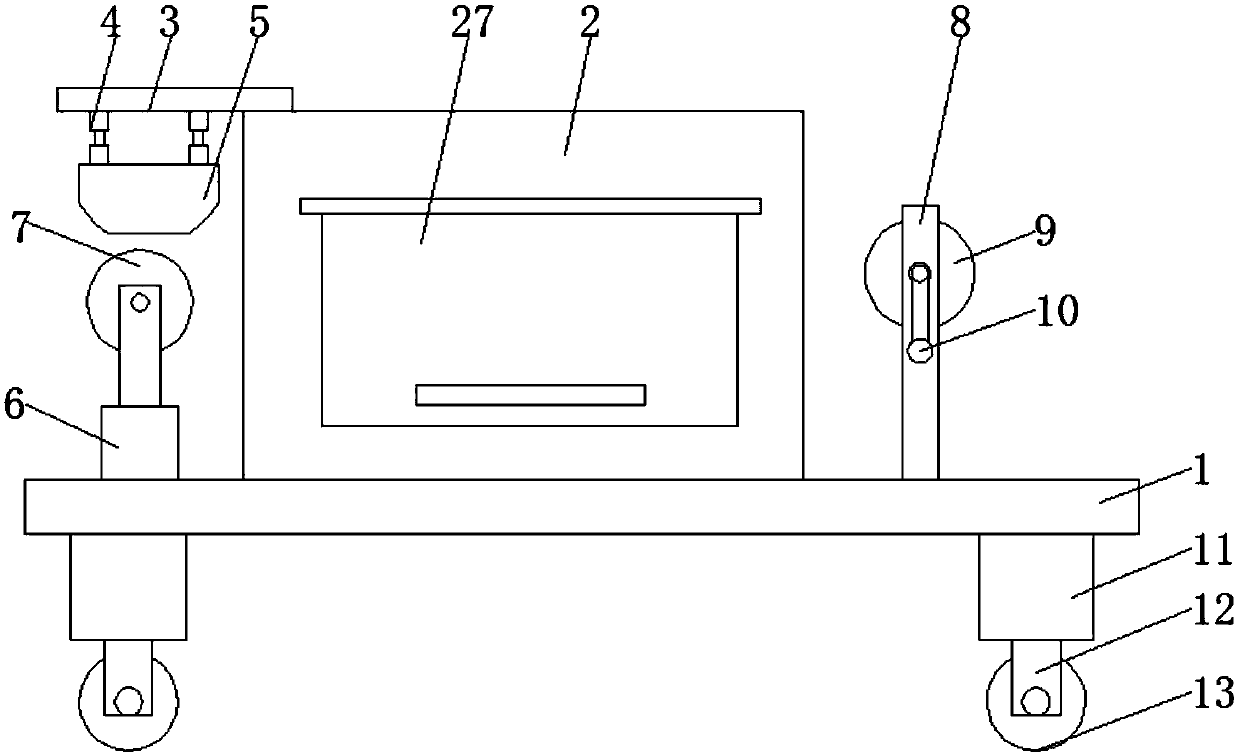

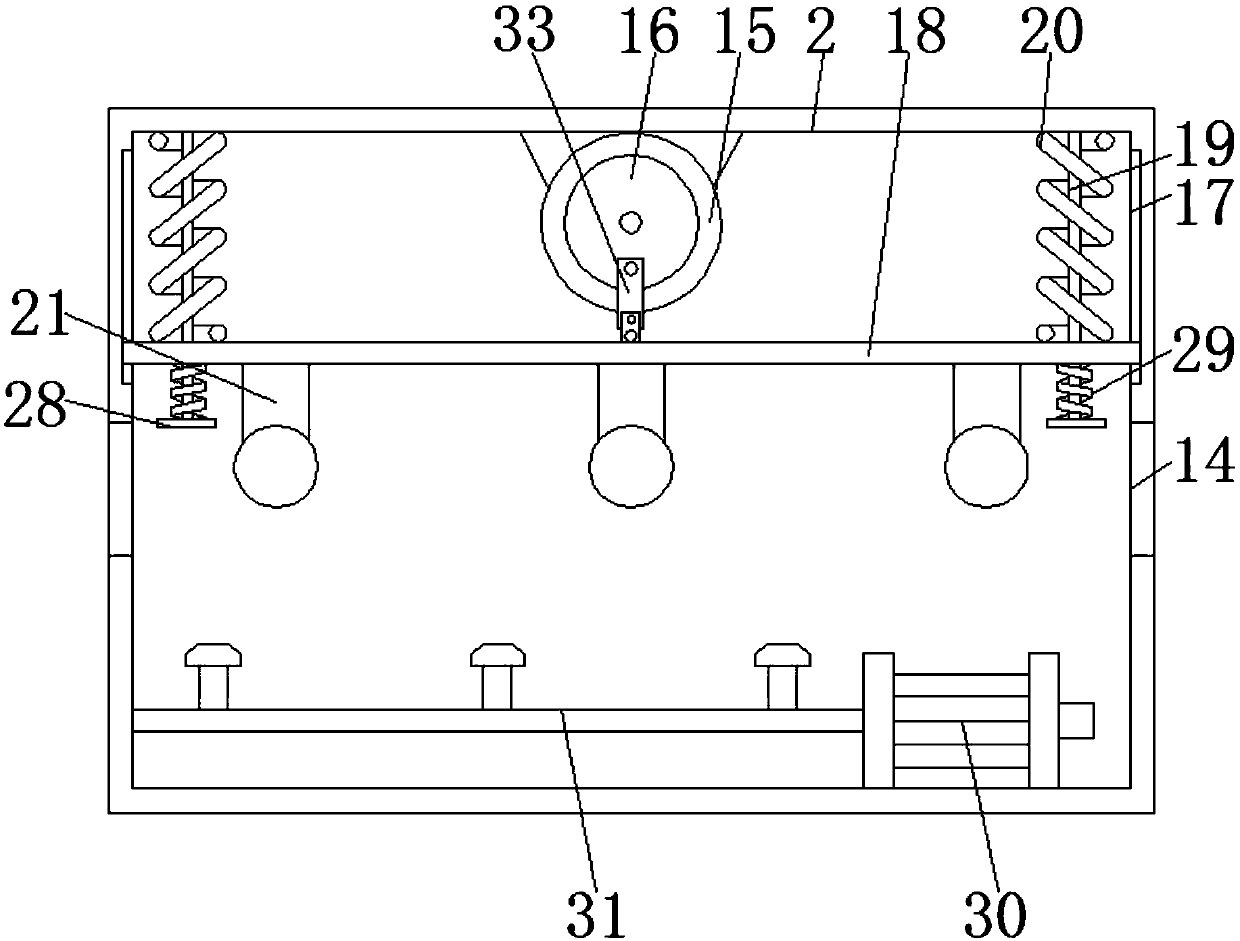

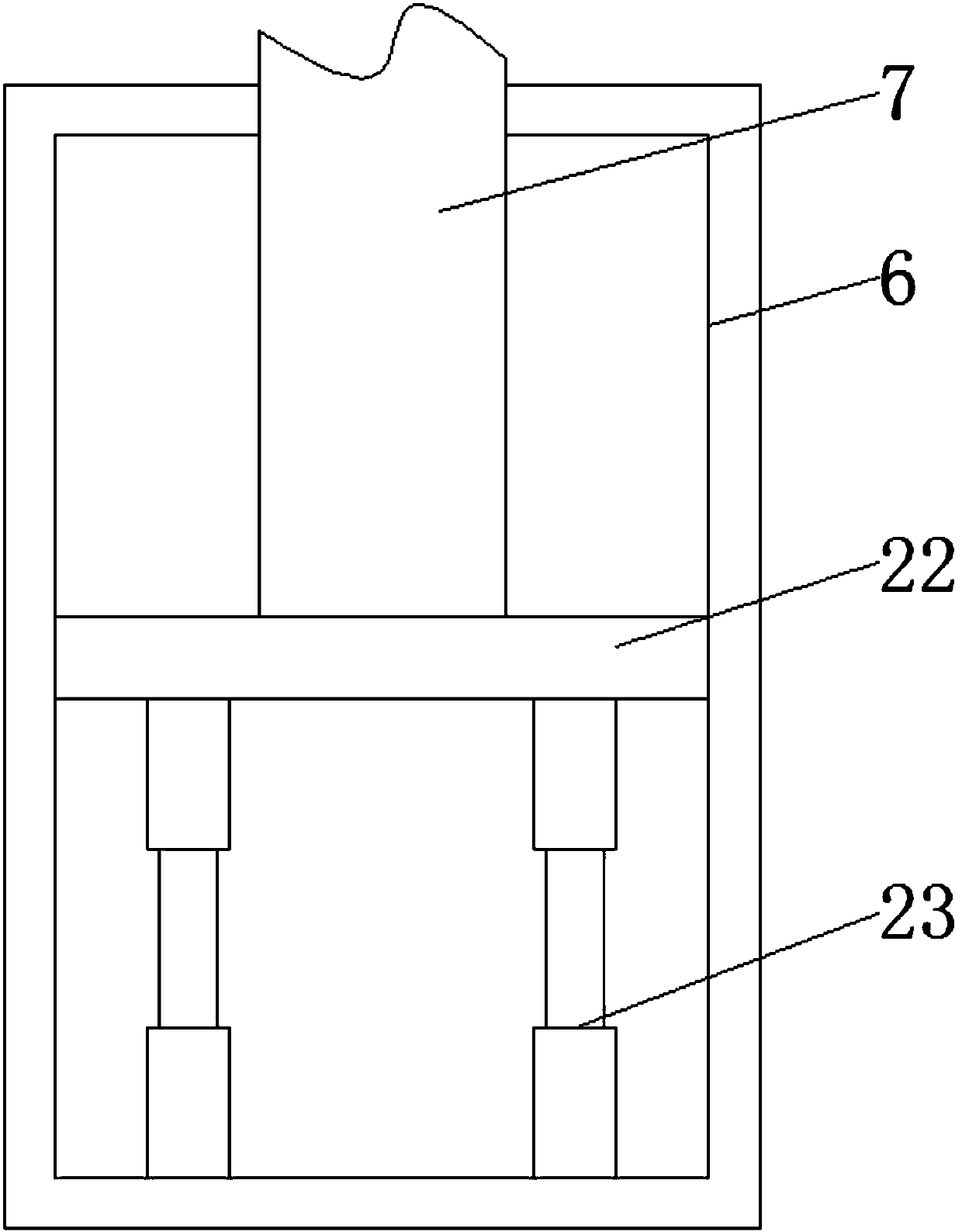

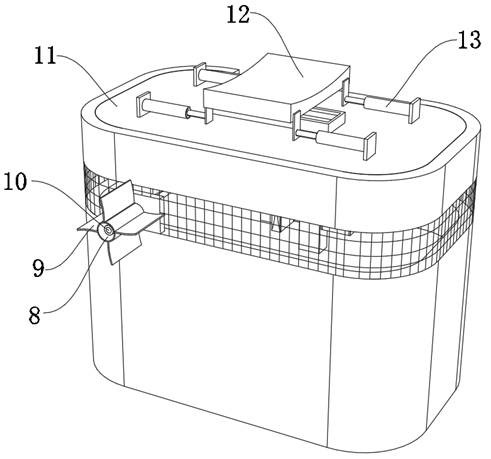

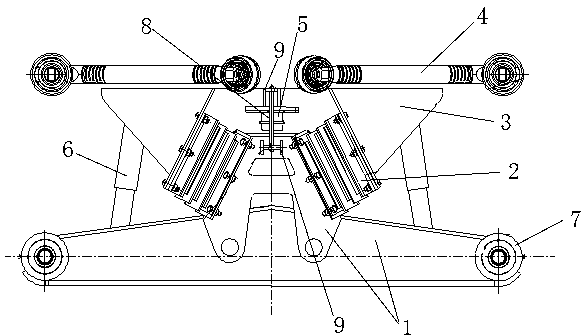

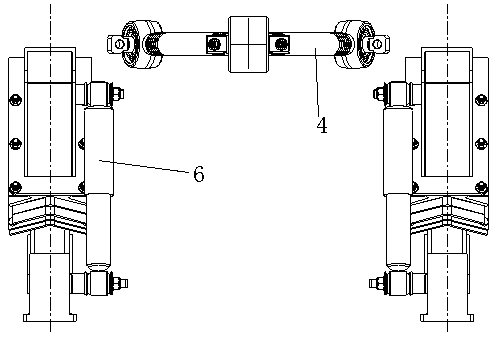

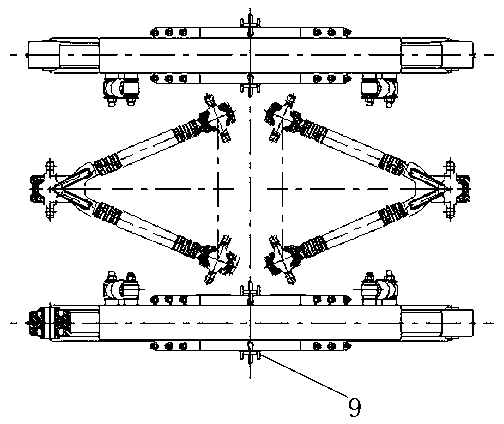

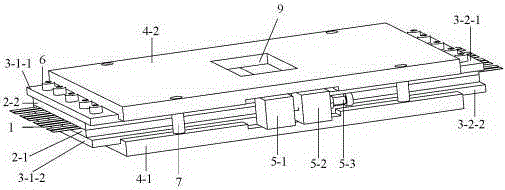

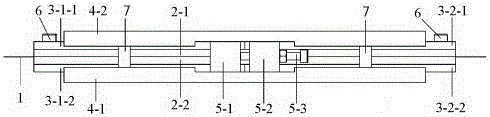

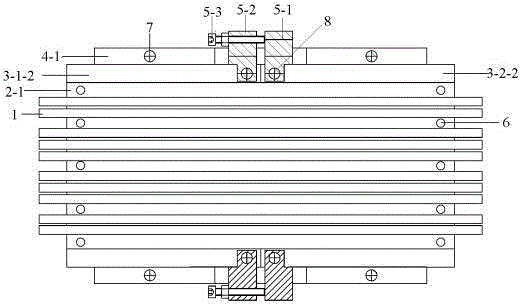

Wheeled obstacle-surmounting robot

PendingCN107307950AGuaranteed stretchGuaranteed Strength CapabilityWheelchairs/patient conveyanceMechanical engineeringRoboty

Provided is a wheeled obstacle-surmounting robot. A telescopic support cylinder comprises a plurality of sleeves which are sleeved with each other sequentially and slidably matched with each other, wherein the sleeves comprises an upper sleeve body, a plurality of middle sleeve bodies and a lower sleeve body, and a mounting frame is arranged at the upper end of the upper sleeve body; a scissor-fork linkage mechanism is arranged in the sleeves, and the lower end of the scissor-fork linkage mechanism is connected with the lower sleeve body; the upper end of the scissor-fork linkage mechanism extends out of the upper sleeve body and is connected with a first drive transmission mechanism which drives the scissor-fork linkage mechanism to expand and contract, and the first drive transmission mechanism is mounted at a mounting frame; the mounting frame is hinged to a connecting piece. According to the wheeled obstacle-surmounting robot, the scissor-fork linkage mechanism is better in telescopic adjustment ability and faster in telescopic adjustment speed, and meanwhile is also arranged in the sleeves which are sleeved with each other sequentially and slidably matched with each other; through the combination of the scissor-fork linkage mechanism and the sleeves, not only can the telescopic range and the telescopic speed be ensured, bu also the strength capability can be ensured; therefore, the support effect is more stable and tighter, the obstacle-surmounting ability of a ladder-climbing and obstacle-surmounting robot is stronger, and the obstacle-surmounting speed is faster.

Owner:嘉兴崎创精密零部件有限公司

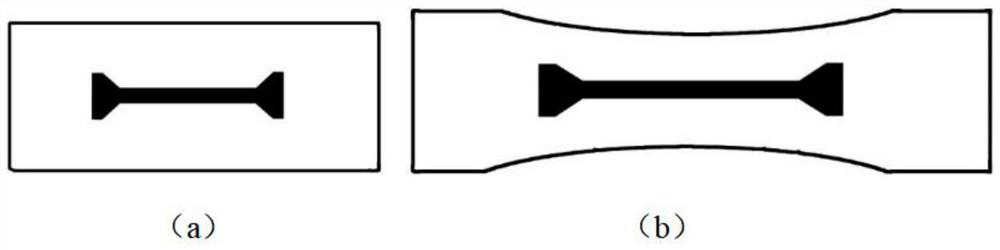

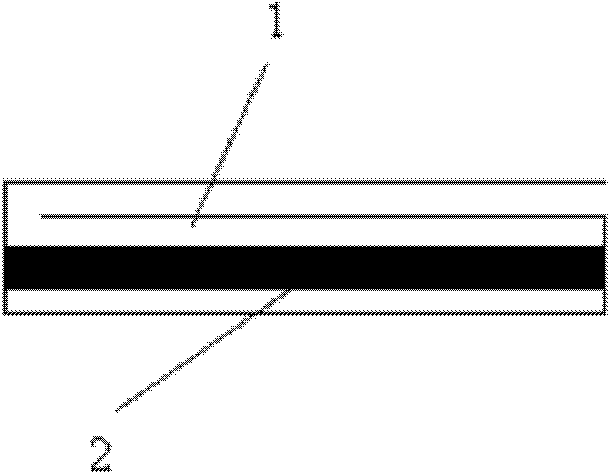

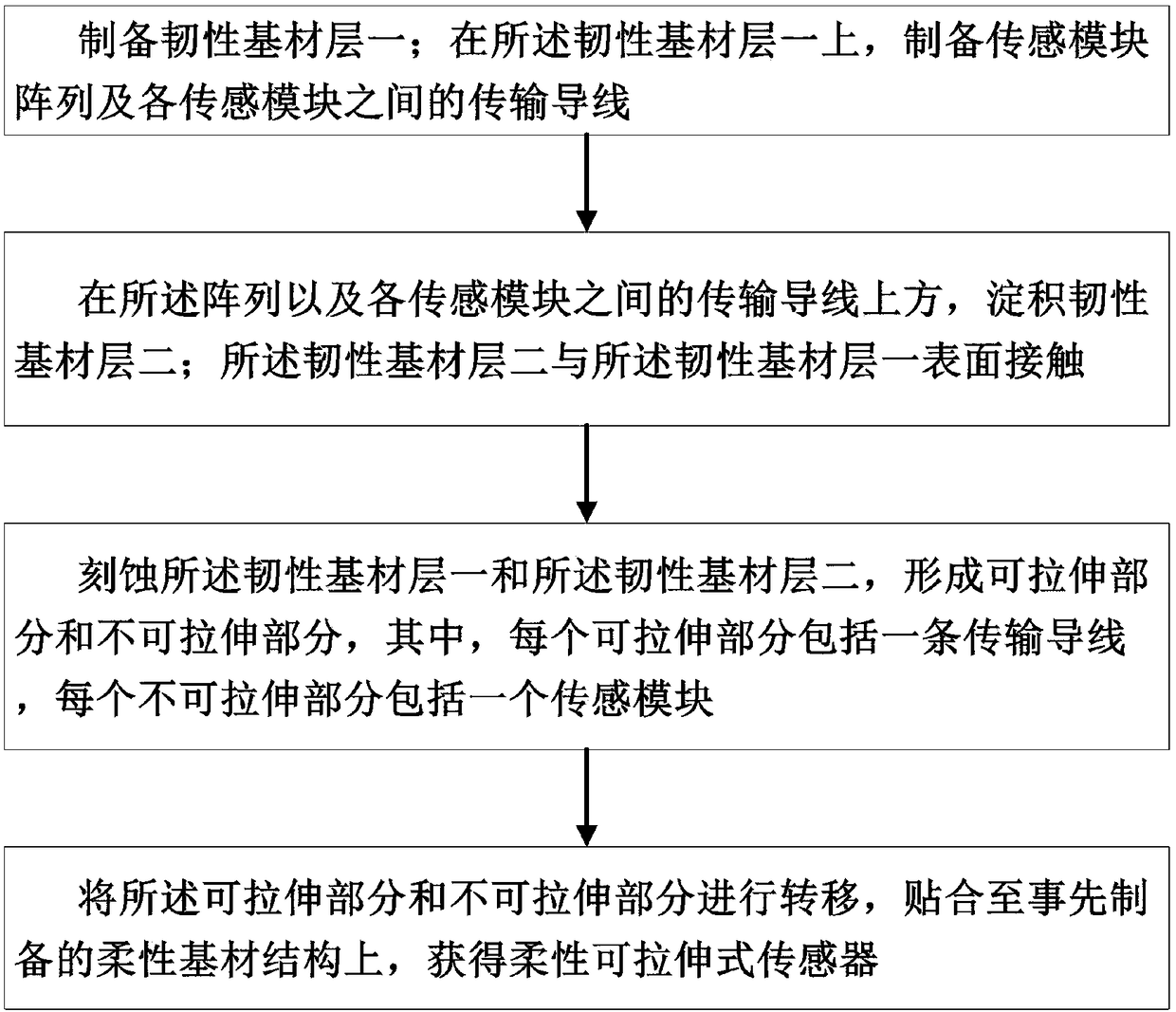

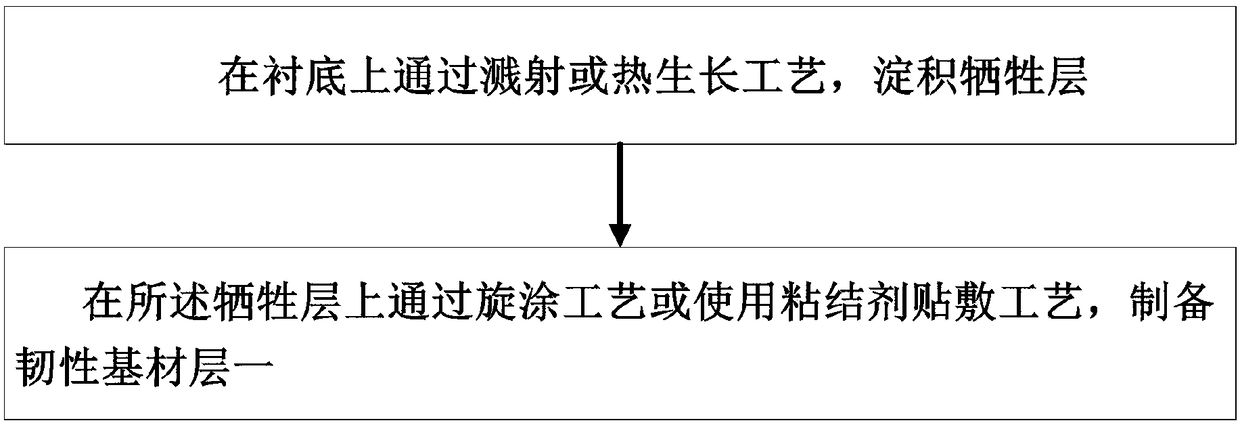

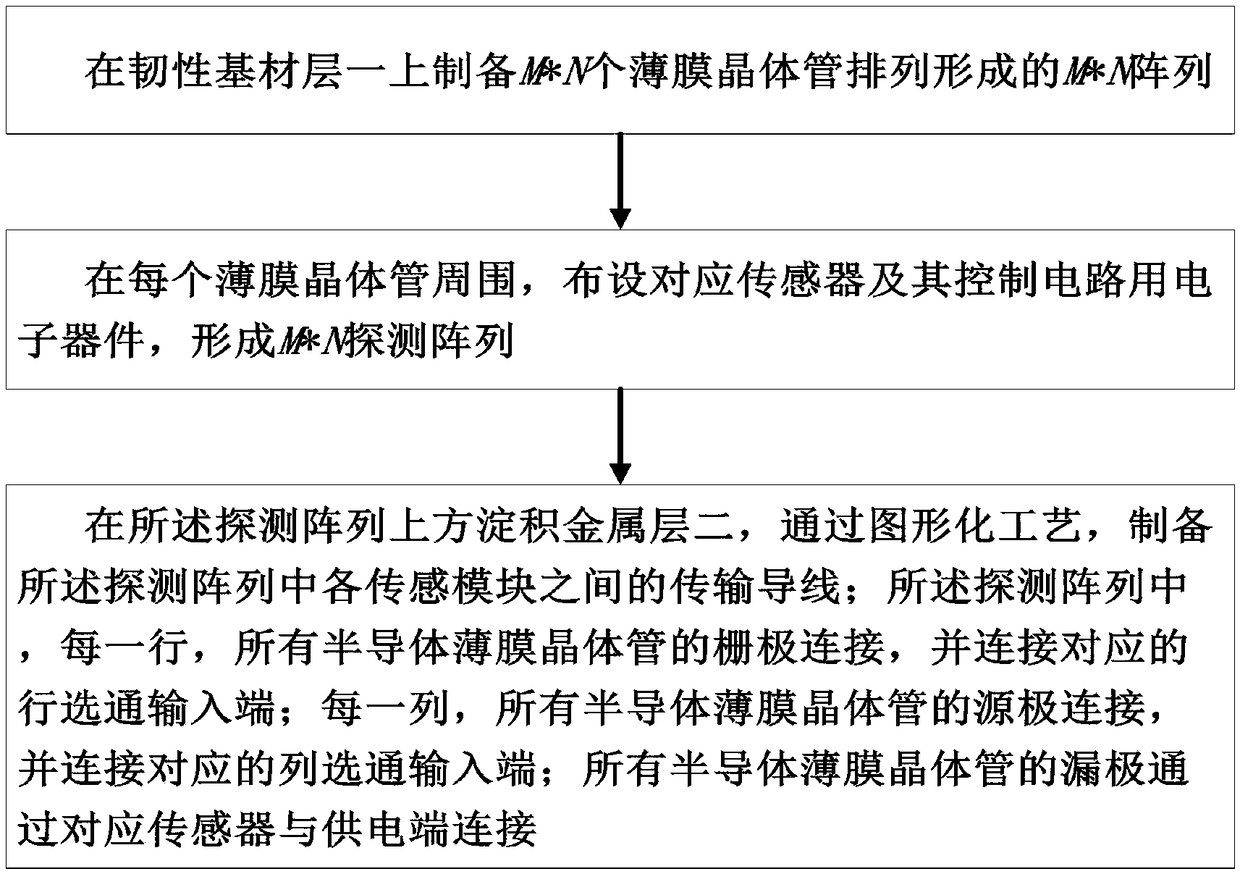

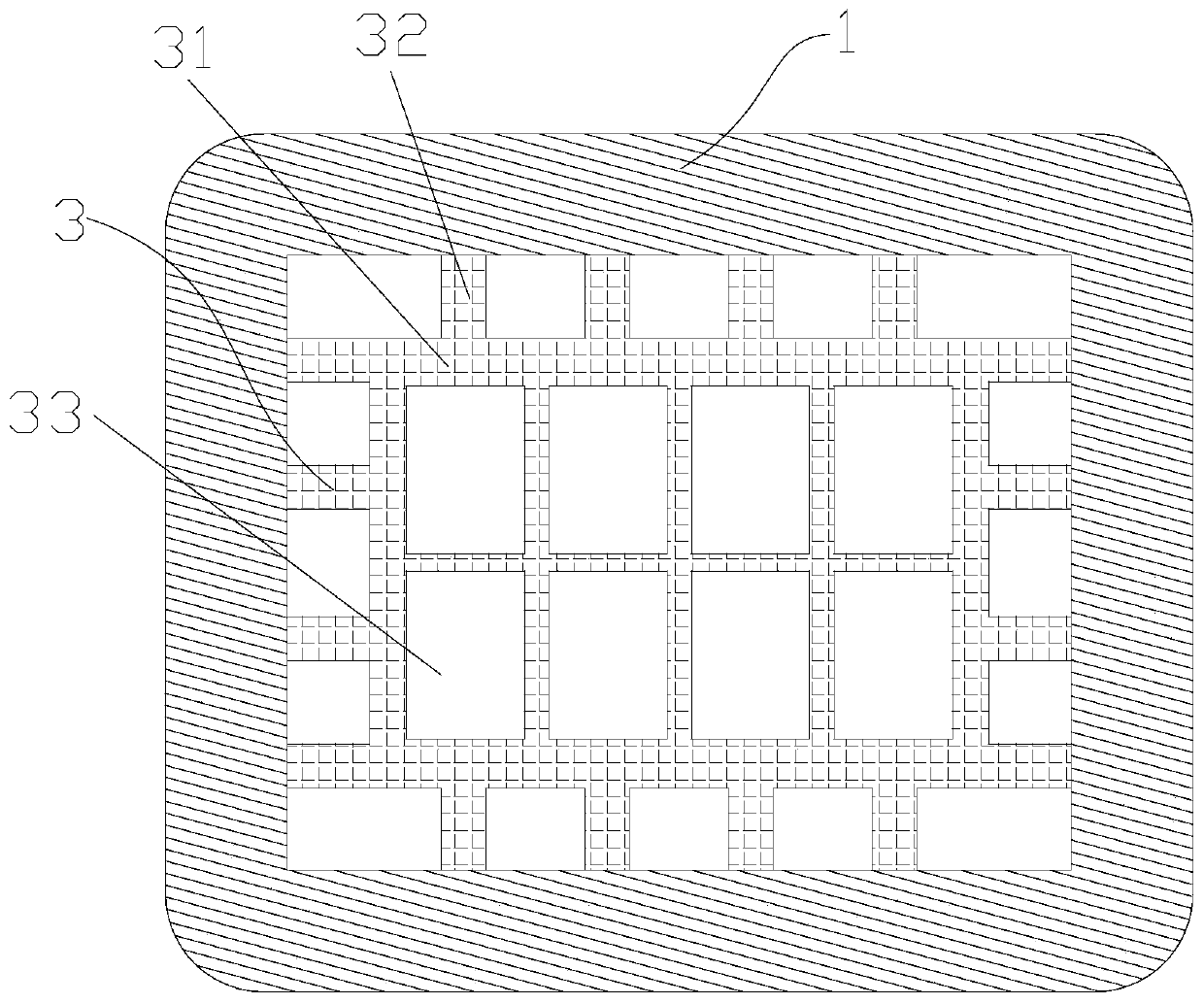

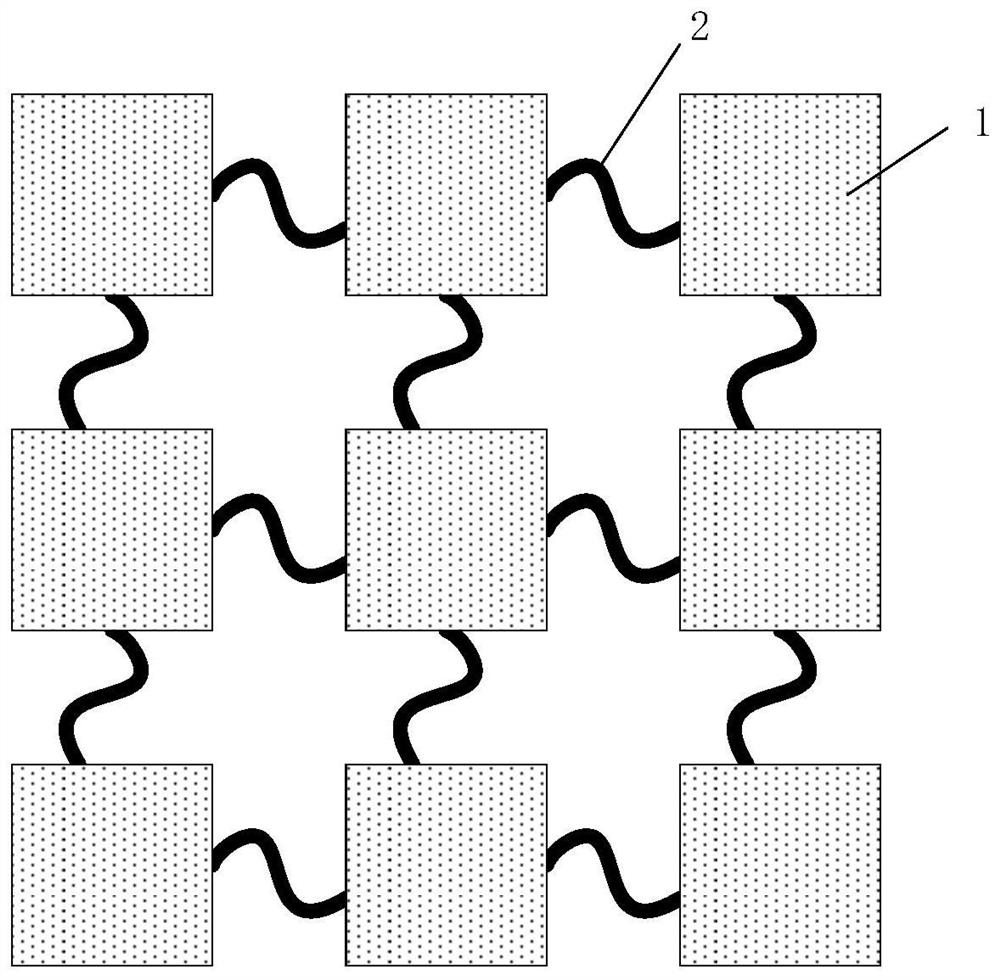

Preparation method of flexible stretchable sensor

ActiveCN109374023ADoes not affect the detection functionAvoid deterioration of electrical performanceSemiconductor/solid-state device manufacturingConverting sensor output electrically/magneticallyComputer moduleElectrical performance

The invention, which belongs to the technical field of sensor preparation, relates to a preparation method of a flexible stretchable sensor so that problems that the existing flexible stretchable sensor is easy to damage, the detection result is inaccurate, and the circuit design is unreasonable can be solved. The preparation method comprises the following steps: preparing a flexible base materiallayer I; preparing an M*N detection array formed by arranging M*N sensing modules as well as a transmission wire; preparing a stretchable portion and a non-stretchable portion of a flexible stretchable sensor; and transferring the stretchable portion and the non-stretchable portion and enabling the portions to be in contact with a pre-prepared flexible base material structure to obtain a flexiblestretchable sensor. When the flexible stretchable sensor is in use, the flexible stretchable sensor realizes the macroscopic stretching function by the stretchable portion but the detecting functionof the non-stretchable portion is not affected. On the basis of the structural design of the non-stretchable portion, the electrical performance variation of the sensing module during the stretching process is avoided and thus the number reading becomes stable, reliable, and sensitive.

Owner:BEIJING MECHANICAL EQUIP INST

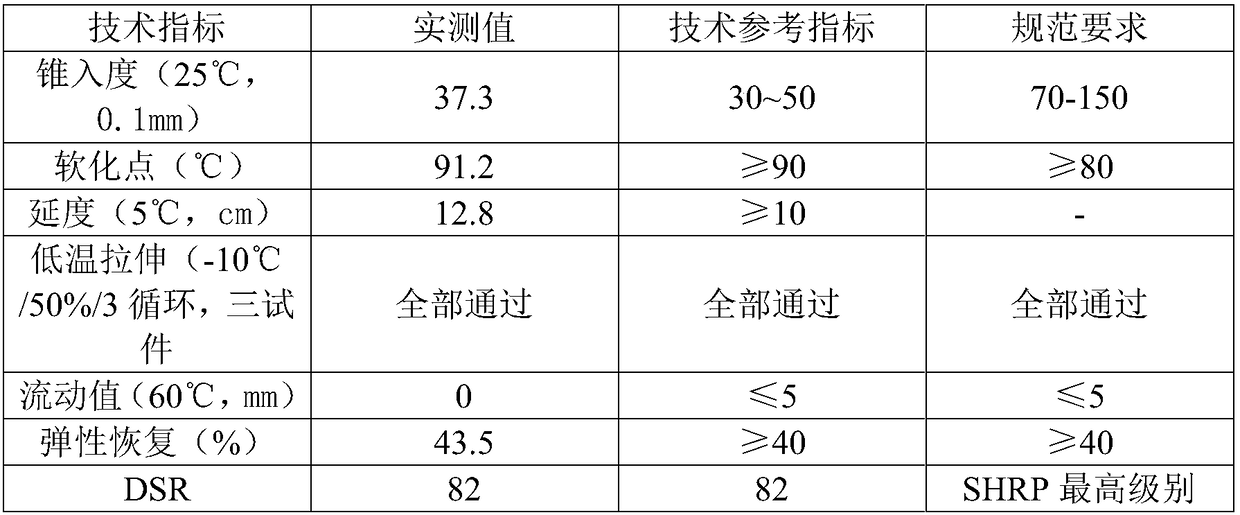

Joint-filling adhesive and road-joint repairing process applying same

InactiveCN108316116AGood acid and alkali resistanceGood tensile strengthMineral oil hydrocarbon copolymer adhesivesBituminous material adhesivesChemistryPetroleum

The invention discloses joint-filling adhesive and a road-joint repairing process applying the same. The joint-filling adhesive is characterized in that the joint-filling adhesive is prepared from themain components: petroleum asphalt, petroleum resin and alkyd resin with the proportion being (2-2.2):(1-1.5):(0.1-0.3), and in operation, the temperature is controlled to 180-195 DEG C all the time.A special hot-melting kettle provides high-temperature joint-filling adhesive in operation, the temperature is controlled to be 180-195 DEG C, and the mean temperature difference is within + / -3 DEG C, so that the complete filling of telescopic joints can be ensured; simultaneously, the joint-filling adhesive adopts petroleum asphalt, petroleum resin and alkyd resin as main components, the viscosity of the joint-filling adhesive can be controlled to be 360-390mPa.S, and the fluidity is better. The road-joint repairing process applying the joint-filling adhesive has the beneficial effects thatfast repairing for small joints of roads is realized, the service life of the road is prolonged, and the maintenance cost is reduced; simultaneously, due to dustless operation, the operation environment is greatly improved.

Owner:ZHONGSHAN YILUMEI ROAD MAINTENANCE TECH CO LTD

Device for preparing polyhydroxyalkanoate fibers

InactiveCN102108563AGuaranteed stretchReduce crystallinityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentFiberHydroxy fatty acid

The invention discloses a method for preparing polyhydroxyalkanoate fibers. The method comprises the following steps: (1) melting polyhydroxyalkanoates and extruding to obtain primary polyhydroxyalkanoate fibers; (2) crystallizing the primary polyhydroxyalkanoate fibers at 0 DEG C to 50 DEG C until reaching the balance of crystallization, and obtaining crystallization-balanced fibers; and (3) thermally treating the crystallization-balanced fibers and stretching; and thermally setting the shape of the crystallization-balanced fibers after stretching and obtaining the polyhydroxyalkanoate fibers. With the method, the crystallization-balanced fibers are treated thermally, so that the defect that the crystallization time is so long that the crystallization is balanced and direct stretching can not be conducted is solved. The breaking strength of polyhydroxyalkanoate fibers prepared with the method provided by the invention is 50-300MPa and the polyhydroxyalkanoate fibers have great tenacity.

Owner:TSINGHUA UNIV

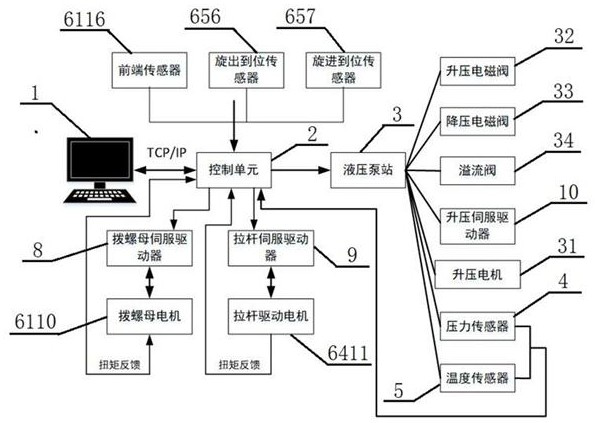

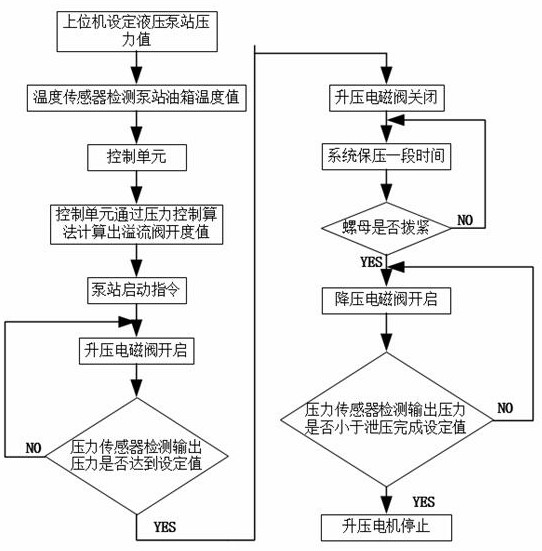

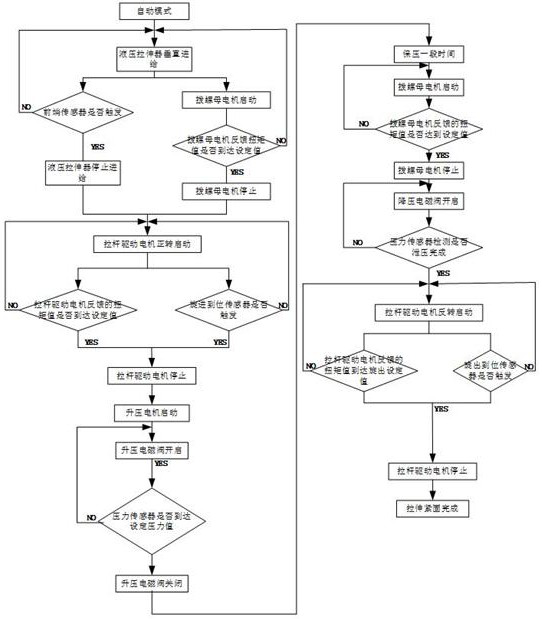

Automatic bolt stretching fastening system and method

ActiveCN113043002AImprove work efficiencyFully automatedMetal working apparatusControl engineeringHydraulic pump

The invention discloses an automatic bolt stretching fastening system and method. The system comprises an upper computer, a control unit, a hydraulic pump station, a pressure sensor, a temperature sensor, a hydraulic stretcher, a front end sensor, a screwing-in in-place sensor and a screwing-out in-place sensor, and the upper computer is connected with the control unit. The control unit is connected with the hydraulic pump station, the pressure sensor, the temperature sensor, the hydraulic stretcher, the front end sensor, the screwing-in in-place sensor and the screwing-out in-place sensor, and the hydraulic pump station is further connected with the hydraulic stretcher. Compared with the working process of a traditional manual stretcher, full automation of the whole bolt stretching fastening process is achieved, the working efficiency of the bolt stretcher and the assembling quality of large parts are greatly improved, the labor intensity of workers is reduced, and the labor cost is reduced.

Owner:东方电气集团科学技术研究院有限公司

Mask assembly and preparation method thereof

ActiveCN110004407ASmall flatnessHigh shape accuracy or position accuracyVacuum evaporation coatingSputtering coatingEngineeringUltimate tensile strength

The invention provides a mask assembly and a preparation method thereof. The mask assembly comprises a frame-shaped frame, a main mask and an auxiliary mask, wherein the main mask and the auxiliary mask are laminated, the outer peripheral region of the main mask and the peripheral region of the auxiliary mask are respectively connected with the inner peripheral region of the frame-shaped frame, aplurality of process holes are formed in the main mask, at least one avoiding hole is formed in the auxiliary mask, and the process holes are aligned with a part of areas in the corresponding avoidinghole; the stretching force between the auxiliary mask and the frame-shaped frame is larger than the stretching force between the main mask and the frame-shaped frame, and the frame-shaped frame and the auxiliary mask are in advance formed a assembly not easy to deform again and high in strength; after the main mask is connected to the first state frame-shaped frame again, the first state frame-shaped frame does not generate obvious deformation again, so that the flatness error of the main mask is small, the shape precision of the process holes of the main mask and the position precision relative to the frame-shaped frame are high.

Owner:BOE TECH GRP CO LTD +1

Automobile carpet mold pressing device with tensioning function

InactiveCN106881851AIncrease productivityImprove product qualityDomestic articlesEngineeringMechanical engineering

The invention discloses an automobile carpet mold pressing device with a tensioning function. The automobile carpet mold pressing device with the tensioning function is characterized by comprising a pressing plate frame, a lifting base and a screw assembly, the pressing plate frame is of a frame structure matched with an automobile carpet in outline shape, lifting limiting bases are arranged on two opposite frame bodies of the pressing plate frame, through holes are formed in the lifting limiting bases, the screw assembly is matched with the through holes in the lifting limiting bases, the pressing plate frame is connected with an upper mold of an automobile carpet mold through the screw assembly, and tensioning screws are fixedly distributed on the two opposite sides of the pressing plate frame. Heads of the tensioning screws face the direction of the upper mold, and the gap between the inner side of the pressing plate frame and the automobile carpet mold is equal to the thickness of the automobile carpet. According to the device, the production efficiency and the product quality of the automobile carpet mold pressing molding are improved, and consistency of the automobile carpet product is ensured.

Owner:HEFEI LIANGJUN AUTOMOTIVE MATERIALS CO LTD

Method for raising Xinshan wax tree seedlings by cutting

InactiveCN104920033AShort dipping timeStrong growthPlant cultivationCultivating equipmentsWaxSeedbed

Owner:李小海

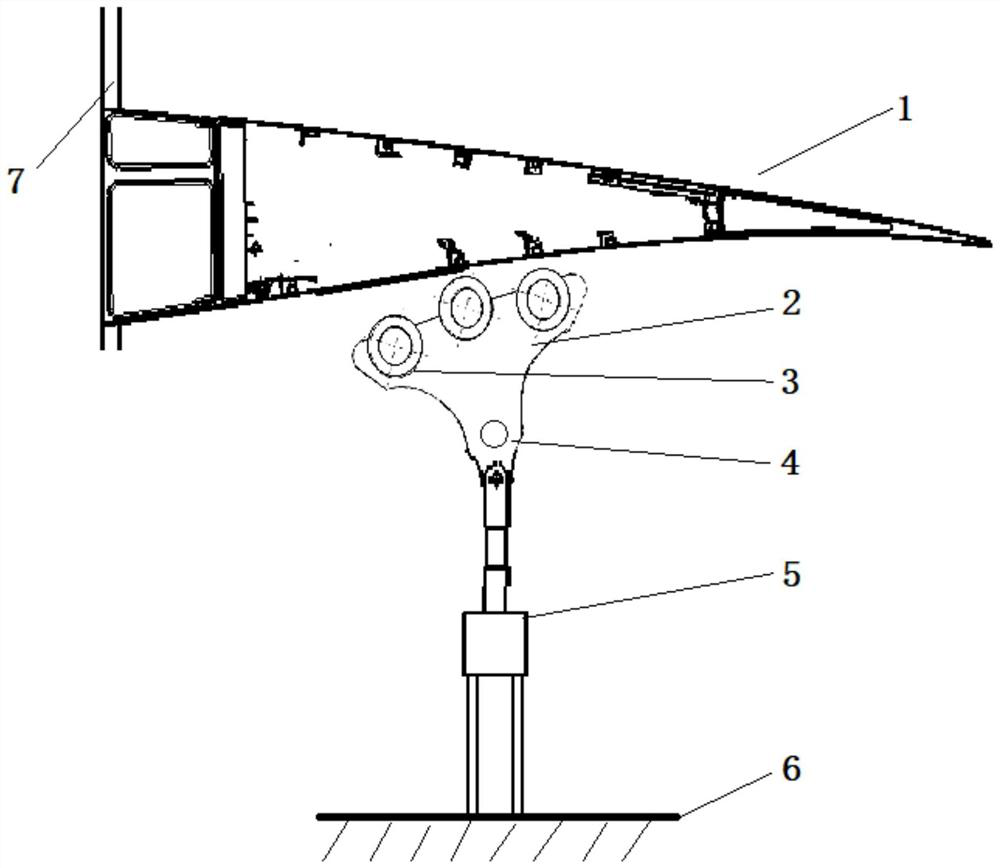

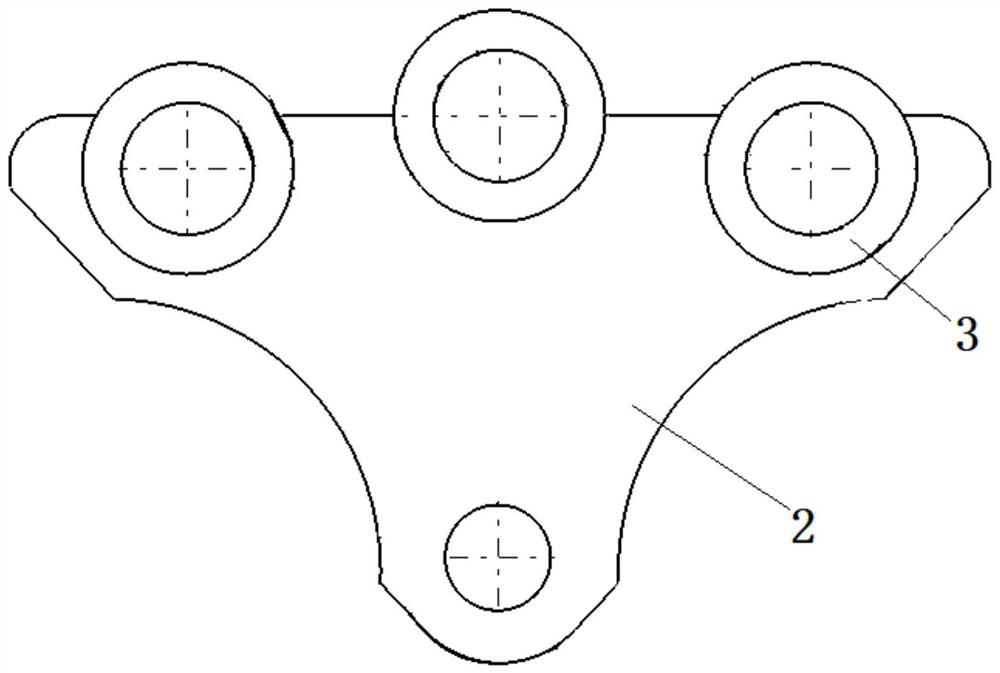

Follow-up loading device for movable airfoil of aircraft

ActiveCN114509251AFollow-up loading implementationAccurately reflect loading problemsMachine part testingFlight vehicleControl system

The invention belongs to the technical field of aircraft motion mechanism tests, and particularly relates to a follow-up loading device for a movable airfoil of an aircraft, and the device comprises a test piece fixing device which is used for fixing the movable airfoil; the loading actuating cylinder is fixed on the terrace and is positioned at the bottom of the movable wing surface; the follow-up loading head is hinged with a loading rod of the loading actuating cylinder and can rotate around a hinged joint, in addition, at least three loading rollers are embedded at the top end of the follow-up loading head, and the outer wheel surfaces of the loading rollers are in linear contact with the movable wing surface; the driving device is used for driving the movable airfoil to deflect; the angle sensor is used for detecting the deflection angle of the movable airfoil in real time; and the control system is used for controlling the movable wing surface and the loading actuating cylinder. According to the follow-up loading device for the movable airfoil of the aircraft, follow-up loading of the movable airfoil movement mechanism is achieved by adjusting the self-adaptive follow-up loading head, and the loading problem of a flap and slat structure system in all flight attitudes can be accurately reflected.

Owner:CHINA AIRPLANT STRENGTH RES INST

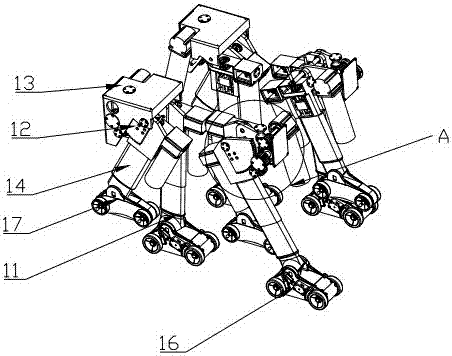

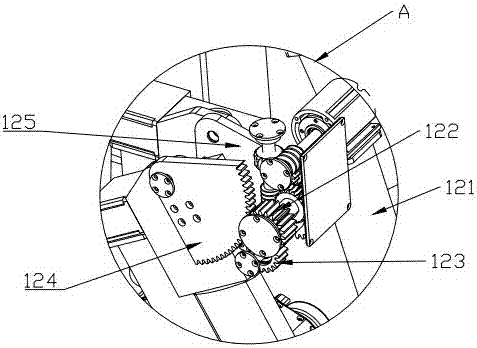

Stair-climbing and obstacle-crossing robot

PendingCN107307951AGuaranteed stretchGuaranteed Strength CapabilityWheelchairs/patient conveyanceManipulatorStructural engineeringMechanical engineering

The invention provides a stair-climbing and obstacle-crossing robot. The stair-climbing and obstacle-crossing robot is characterized in that the structures of second telescoping support cylinders are same as those of first telescoping support cylinders, each first telescoping support cylinder comprises a plurality of sleeves, wherein the sleeves are arranged in a sleeved mode in sequence, and the sleeves are in slipping fit with each other. Each group of sleeves comprises the upper sleeve, the middle sleeves and the lower sleeve, wherein an installation frame is installed at the upper end of the upper sleeve. A scissor-fork type connecting rod mechanism is arranged in each group of sleeves, the lower ends of the scissor-fork type connecting rod mechanisms are connected with the lower sleeves respectively, the upper ends of the scissor-fork type connecting rod mechanisms extend out of the upper sleeves respectively, the scissor-fork type connecting rod mechanisms are connected with first drive transmission mechanisms driving the scissor-fork type connecting rod mechanisms to extend and retract respectively, the first drive transmission mechanisms are installed on the installation frames respectively, and the installation frames are hinged to connecting pieces respectively. The stair-climbing and obstacle-crossing robot has the advantages that the scissor-fork type connecting rod mechanisms have better telescopic adjustment capacity and higher telescopic adjustment speed, meanwhile, the strength capacity is ensured, the supporting is more stable and firmer, the stair-climbing and obstacle-crossing capacity of the stair-climbing and obstacle-crossing robot is higher, and the speed in the stair-climbing and obstacle-crossing processes is higher.

Owner:嘉兴崎创精密零部件有限公司

Textile machinery drying device facilitating spin-drying

InactiveCN107702496AEasy to dryImprove work efficiencyDrying gas arrangementsDrying machines with progressive movementsEngineeringSlide plate

The invention provides a drying device for textile machinery which is convenient for drying, and relates to the field of machinery. The drying device for textile machinery that is convenient for drying includes a base, a box body is fixedly installed on the top of the base, a fixing plate is fixedly installed on the top of the box body, and both sides of the bottom of the fixing plate are fixedly installed with A buffer rod, the end of the buffer rod away from the fixing plate is fixedly connected through a pressure block. The drying device for textile machinery that is convenient for drying, through the improvement of the box, the motor is set to drive the connecting rod on the turntable to move, so that the slide plate moves, and the limit rod limits the slide plate, so Under the action of the spring and the return spring, the protruding rod can blow and dry the textiles inside the box, and at the same time, the hot air blower can blow air on the textiles through the air pipe, thus achieving the effect of rapid drying of the textiles and improving the quality of the textiles. The working efficiency of the drying device for textile machinery is improved.

Owner:赵顺豪

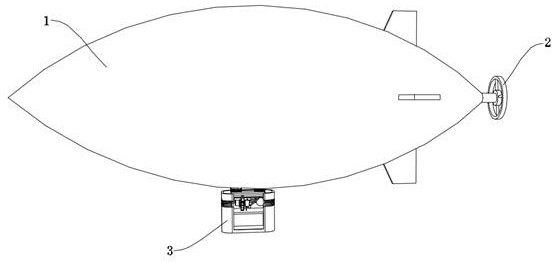

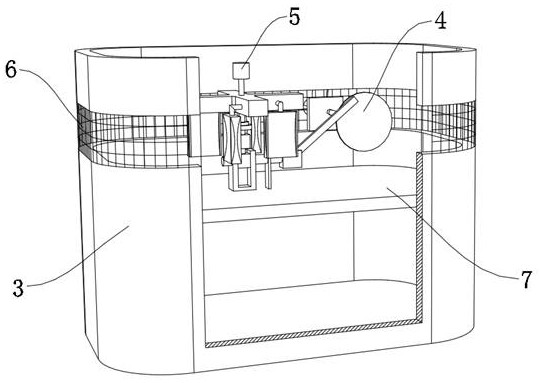

Gravity center balancing device of airship and adjusting method of gravity center balancing device

The invention discloses a gravity center balancing device of an airship and an adjusting method of the gravity center balancing device, and relates to the technical field of airship gravity center balancing devices. The gravity center of the airship is balanced; the gravity center balancing device comprises an air bag body and a cockpit, the air bag body and the cockpit are connected through a damping assembly, a driving system is arranged at the tail of the air bag body, a cover plate is arranged on the inner wall of the cambered surface of the cockpit, a first hollow cylinder is arranged on the outer wall of the bottom of the cover plate, and an adjusting ball is movably connected to the inner wall of the first hollow cylinder; the adjusting method of the gravity center balancing device comprises the following steps that when the airship is in a standby state, the clamping disc is used for limiting and clamping the chuck, so that the cross-shaped clamping seat is in a horizontal static state. The driving system can be used for driving the air bag body and adjusting the direction of the air bag body, and the vibration reduction assembly can effectively reduce impact on a cockpit caused by wind power at the high altitude.

Owner:湖北航特航空飞行器有限公司

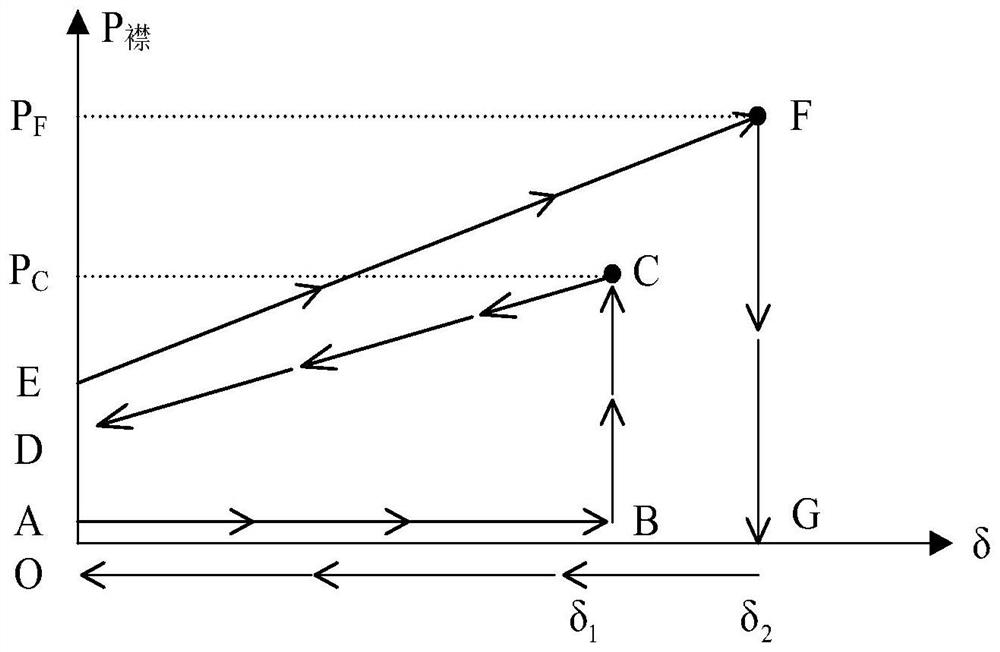

Autocrane hoisting manner and autocrane rubber suspension system

ActiveCN103192674AGuaranteed stretchImprove tensile stress conditionsResilient suspensionsPivoted suspension armsStress workingEngineering

Disclosed are an autocrane hoisting manner and an autocrane rubber suspension system. A limit strip is disposed between a saddle and a balance beam of the autocrane rubber suspension system or between the balance beam and a frame of an autocrane. Hoisting of the autocrane is completed by the aid of the limit strip. The limit strip bears downward tensile force of unsprung mass and changes from loose state to a stretching state. When hoisting is completed, the limit strip changes from the stretching state to the loose state, and tires of the autocrane bear the downward tensile force of the unsprung mass. During hoisting, the limit strip is stretched to bear most tensile load so as to guarantee that the stretching of a rubber spring is in a reasonable range, stretching stress working conditions of the rubber spring are improved, and accordingly reliability of the rubber suspension system is improved.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

New energy battery with anti-collision protection shell

InactiveCN113540656AImprove the anti-collision effectGuaranteed stretchCell component detailsNew energyBattery cell

The invention relates to the technical field of new energy batteries, in particular to a new energy battery with an anti-collision protection shell. The new energy battery comprises a new energy battery body, the new energy battery body is placed in a shell, the upper end of the shell is rotatably connected with a sealing cover through a hinge, the outer side surface of the shell is provided with a mounting groove, a rubber edge is pasted on the surface of the inner wall of the mounting groove, an abutting plate is movably arranged in the mounting groove, a flange of an integrated structure is fixedly installed at the end of the inner side of the abutting plate, the flange is connected with the rubber edge in a pasted mode, an elastic piece is arranged in the shell and located in the middle of the mounting groove, the elastic piece comprises a threaded sleeve, connecting rings, a spring, a hose and a supporting plate, the threaded sleeve is in threaded connection with the interior of the shell, the two ends of the threaded sleeve are in threaded connection with the connecting rings, and the outer ends of the connecting rings are connected with the hose in a pasted mode. The battery is good in anti-collision effect and worthy of popularization.

Owner:苏州泛像汽车技术有限公司

Annealing device of medium wire drawing machine

InactiveCN108396131AEasy to useGuaranteed stretchFurnace typesHeat treatment furnacesCopper wireDrive motor

The invention discloses an annealing device of a medium wire drawing machine . The annealing device comprises a base, wherein a first supporting rod, a stretching box, an annealing cylinder, a secondsupporting rod and a driving motor are fixedly connected with the upper surface of the base in sequence from left to right. A first rotating shaft is rotatably connected to the top of the first supporting rod, a wire feeding roller is arranged outside the first rotating shaft in a sleeving mode, and an annealing sleeve is overlapped on the inner wall of the annealing cylinder. A heating coil is arranged inside the annealing sleeve, a first through hole is formed in the left side surface of the annealing sleeve, and a second through hole is formed in the right side surface of the annealing sleeve. The annealing device of the medium wire drawing machine medium wire drawing machine medium wire drawing machine is provided with the annealing sleeve, the heating coil, a heat insulation board, aspray head, a water distribution pipe, a water receiving tray, a blower, a water inlet pipe, a water outlet pipe, a first pipe sleeve and a second pipe sleeve so that a copper wire can be annealed atthe same time after being stretched, simultaneous stretching and annealing are ensured, convenience is provided to the use of workers, and the working efficiency is improved.

Owner:SUZHOU JIN JU SONG MECHANICAL & ELECTRICAL CO LTD

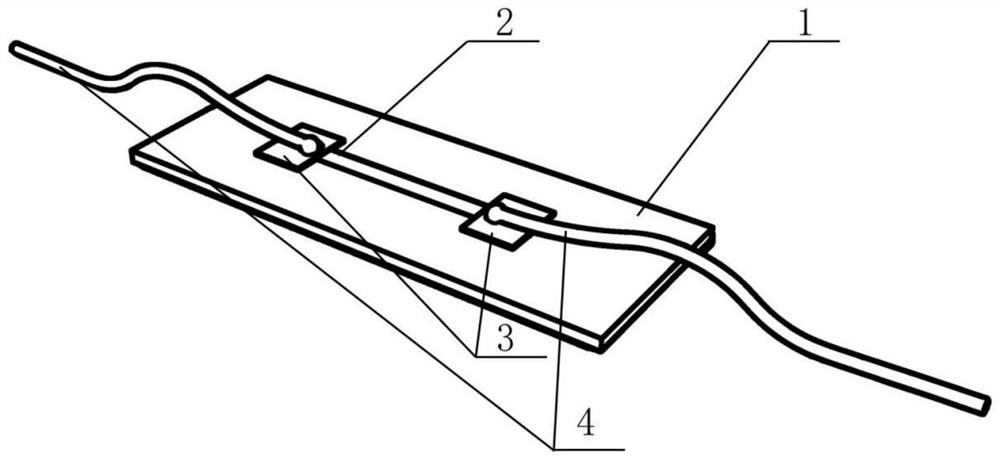

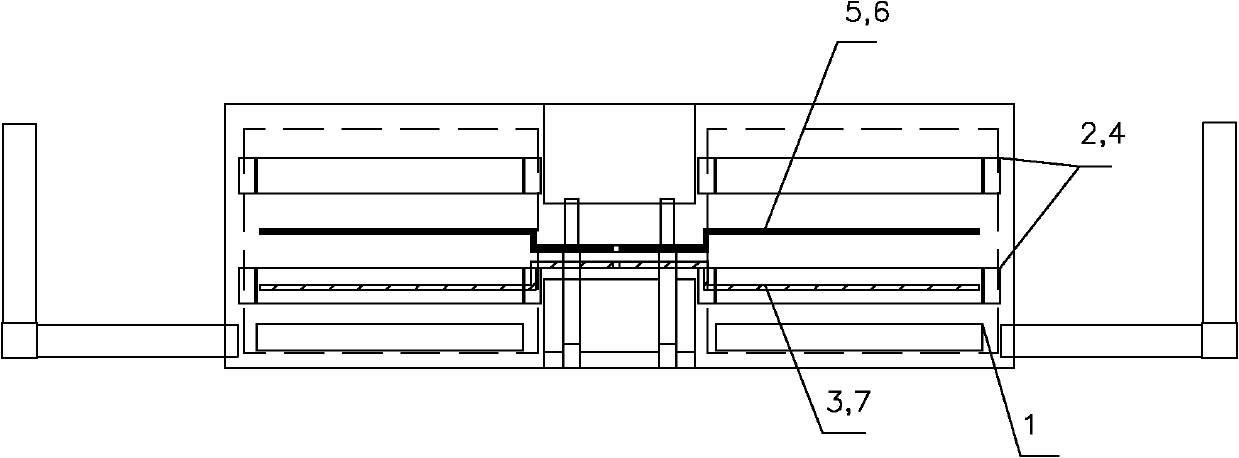

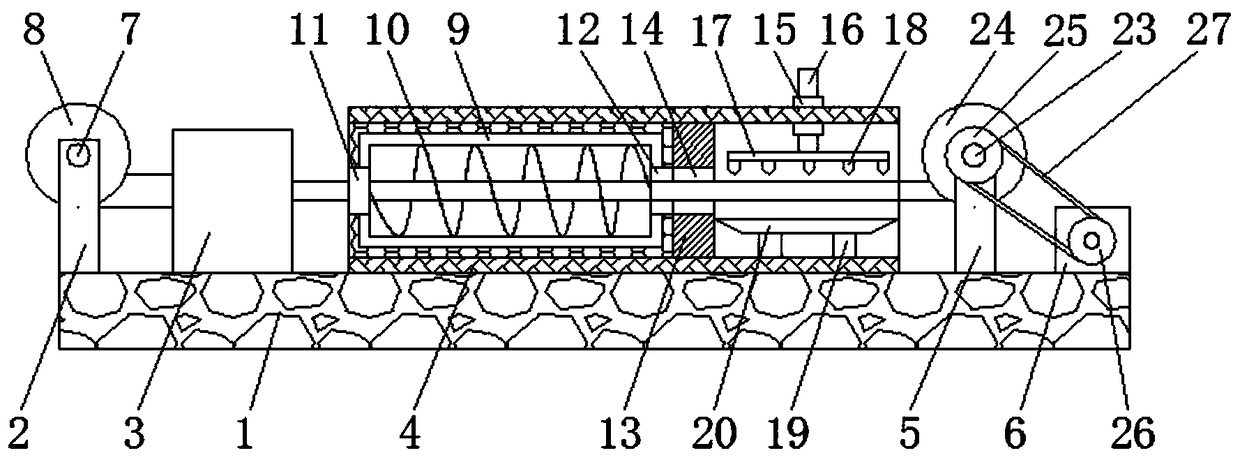

Device and method for preparing fiber in-plane buckling in-situ strength test sample

ActiveCN105258994AGuaranteed stretchGuaranteed flexibilityPreparing sample for investigationIn planeSet screw

The invention discloses a device and a method for preparing a fiber in-plane buckling in-situ strength test sample and belongs to the field of preparation of composite materials. The device mainly comprises flexible silica gel plates, mobile clamps, set screws and clamp motion control mechanisms. During working, a unidirectional prepreg is laid between the upper flexible silica gel plate and the lower flexible silica gel plate in the guide rail direction, and the two silica gel plates are arranged between the left mobile clamp and the right mobile clamp; the set screws are tightened, so that the mobile clamps, the silica gel plates and the prepreg tows are tightly contacted nearby the clamping screws; the screw-out amount of adjusting screws is changed, the mobile clamps drive the silica gel plates to generate expected elastic tensile deformation, the adjusting screws are screwed out, the flexible silica gel plates are retracted, the prepreg tows generate axial compression deformation, and accordingly, in-plane buckling is produced. According to the device and the method, the preparation of the fiber in-plane buckling in-situ strength test sample with controllable deformation can be realized, and the defect that the fiber buckling test sample is difficult to acquire under non-geodesic laying according to the existing test standard is overcome.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

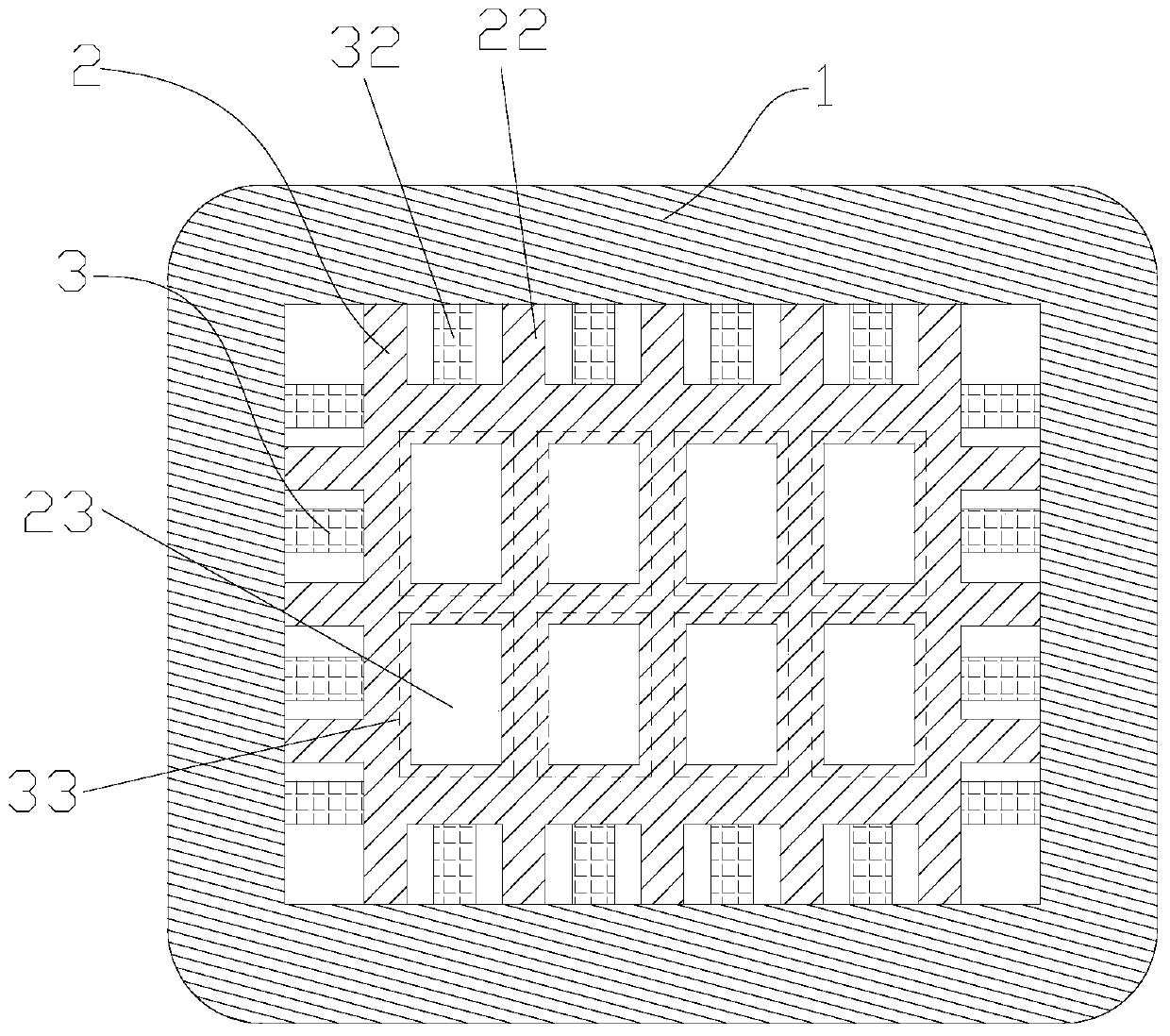

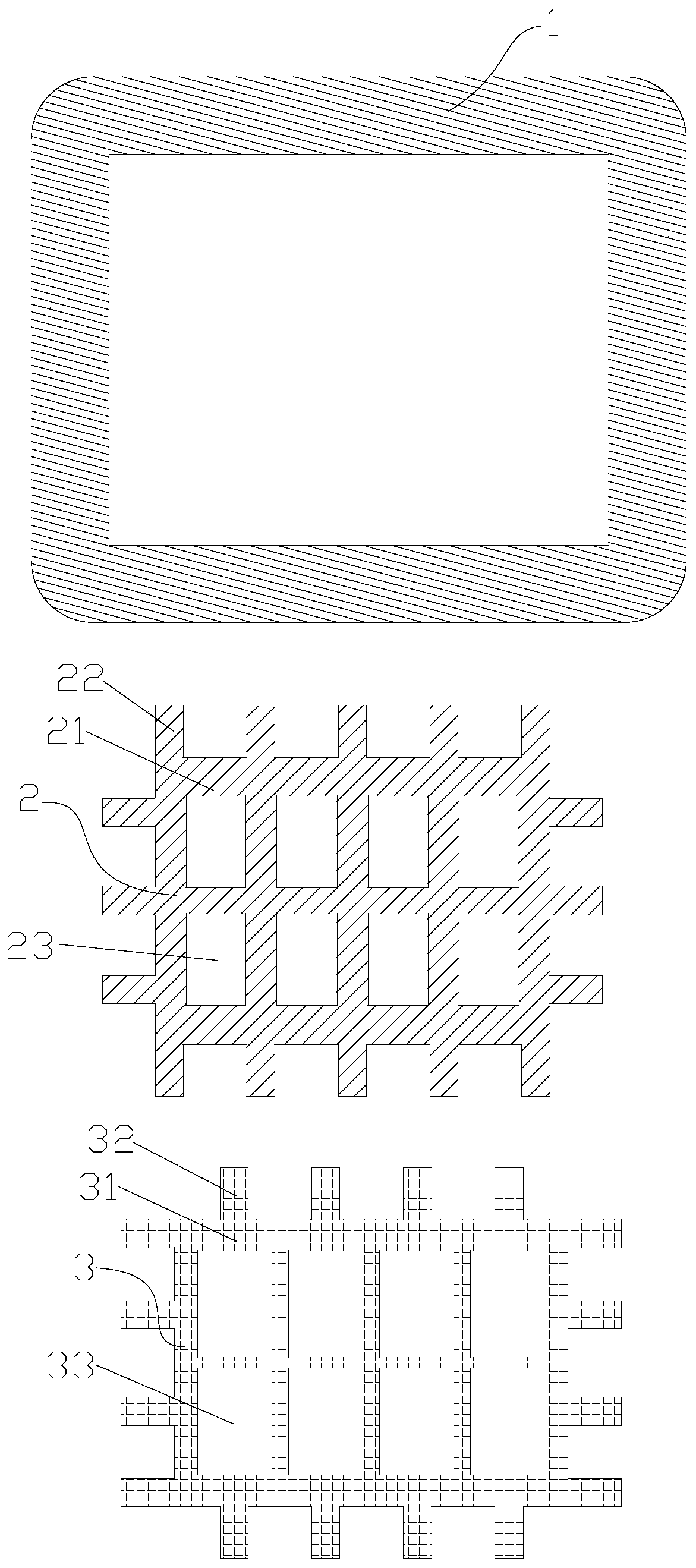

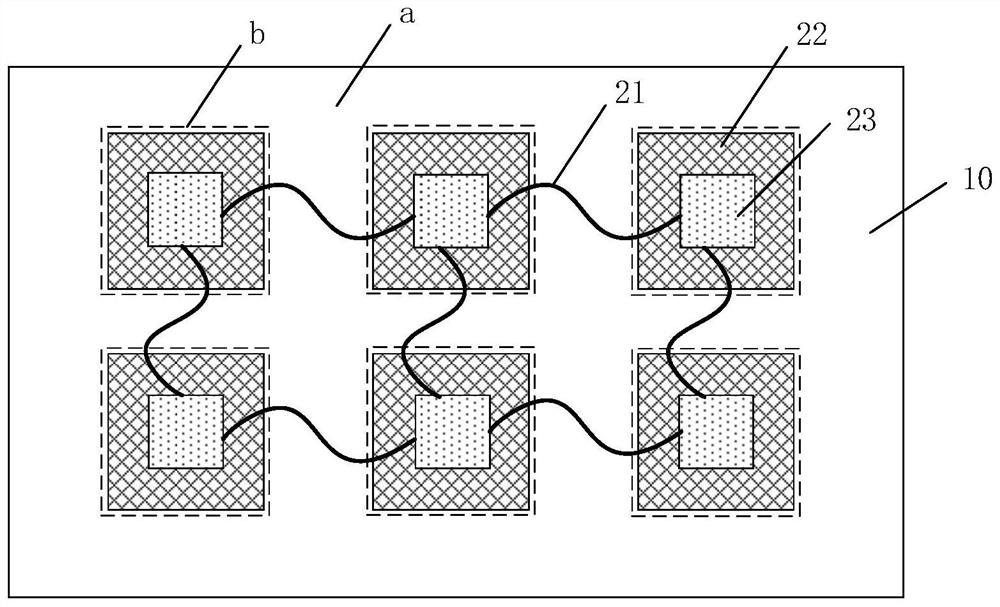

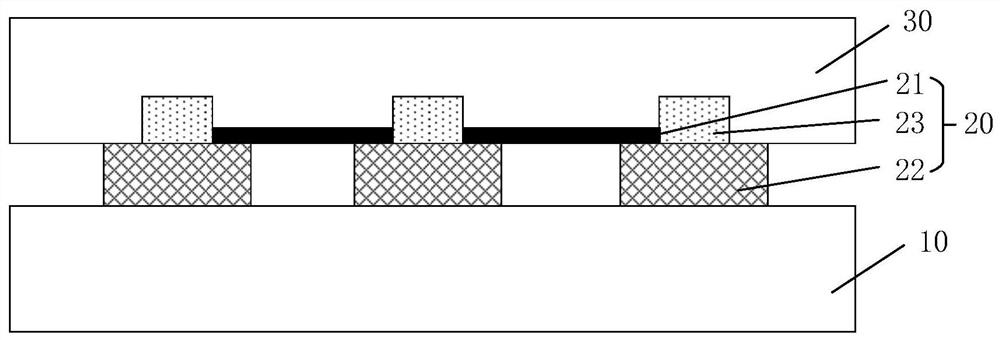

Stretchable display panel, manufacturing method thereof and stretchable display device

The invention discloses a stretchable display panel, a manufacturing method thereof and a stretchable display device. The stretchable display panel includes: a first elastic layer; a display layer arranged on the first elastic layer, wherein the display layer comprises a first area and a plurality of second areas, stretchable wires are arranged in the first area, an elastic supporting part and pixel units arranged on the elastic supporting part are arranged in each second area, and any two adjacent pixel units are connected through the stretchable wires; and a second elastic layer arranged onthe display layer, wherein the second elastic layer at least wraps the pixel units and the stretchable wires. According to the scheme provided by the invention, the stretching rate of the stretchabledisplay panel can be improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

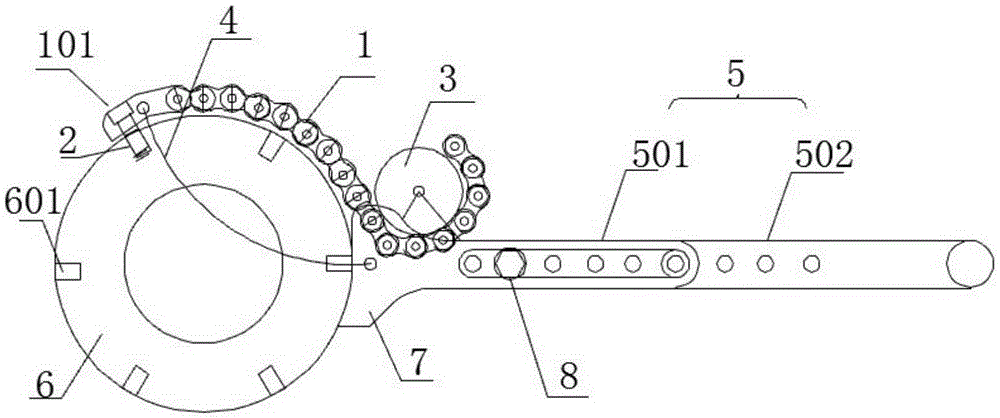

Flexible hook spanner

The invention discloses a flexible hook spanner. The flexible hook spanner is applicable to mounting and dismounting of machine tool spindle connecting rod nuts with different sizes and comprises a handle and a working part arranged at the front end of the handle, wherein the working part comprises a chain, a hook head, a chain wheel and a limiting block, the chain wheel is meshed with the chain and used for increasing / decreasing the length of the chain, and the limiting block is used for limiting rotation of the chain wheel. The flexible hook spanner can realize mounting and dismounting of connecting nuts with different diameter specifications by the aid of the flexible characteristic of the chain, and in combination with the replaceable characteristic of a clamping hook of the hook spanner, the spanner can be adapted to aperture sizes of nut unthreaded holes with different diameters.

Owner:WUHAN TIANHE TECH

Extract and mechanical properties measurement method of bone trabecula and measurement mechanism

InactiveCN101158679BAvoid damageSubsequent measurement results are authentic and reliableUsing mechanical meansMaterial analysisMeasurement deviceBiomechanics

The invention relates to an extracting of a bone trabecula and a test method and a device of mechanical property, which belongs to the biological mechanics experiment technical field. The method comprises: 1. the bone is cut into a plurality of small blocks at the length of the bone trabecula; 2. the marrow in the middle of each small spongy bone block is rejected clearly and the spongy bone structure is only left; 3. a small spongy bone block which has an intact bone trabecula is chosen and the bone trabecula around the intact bone trabecula is cut away; 4. the bone trabecula is stretched and compressed at the direction paralleled with a loading force, and the two ends of the bone trabecula are fixed; 5. the CCD camera is aimed to the bone trabecula so as to lead the picture of the bone trabecula in the CCD to be clear; 6. the displacement of the stretching or compressing of the bone trabecula is controlled; 7. the picture and the load of the bone trabecula in each time quantum are recorded synchronously; 8. the displacement field and the strain field of each load is worked out according to DSCM; namely the poisson ratio of the material and the strain curve of the strain of the bone trabecula can be obtained. The invention can minimize the damage greatly, and lead a plurality of mechanical property parameters to be more correct.

Owner:TSINGHUA UNIV

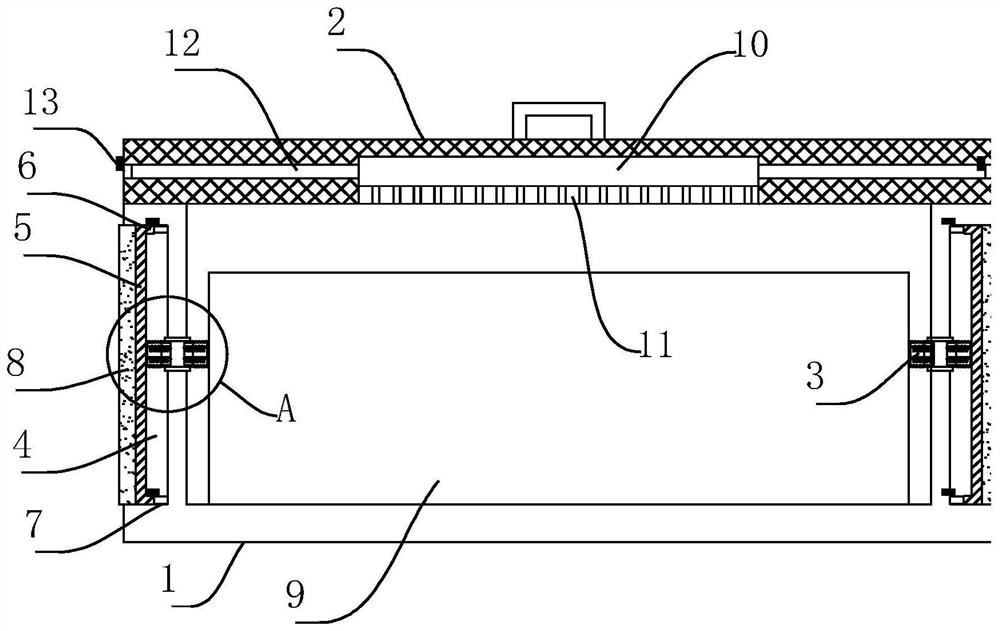

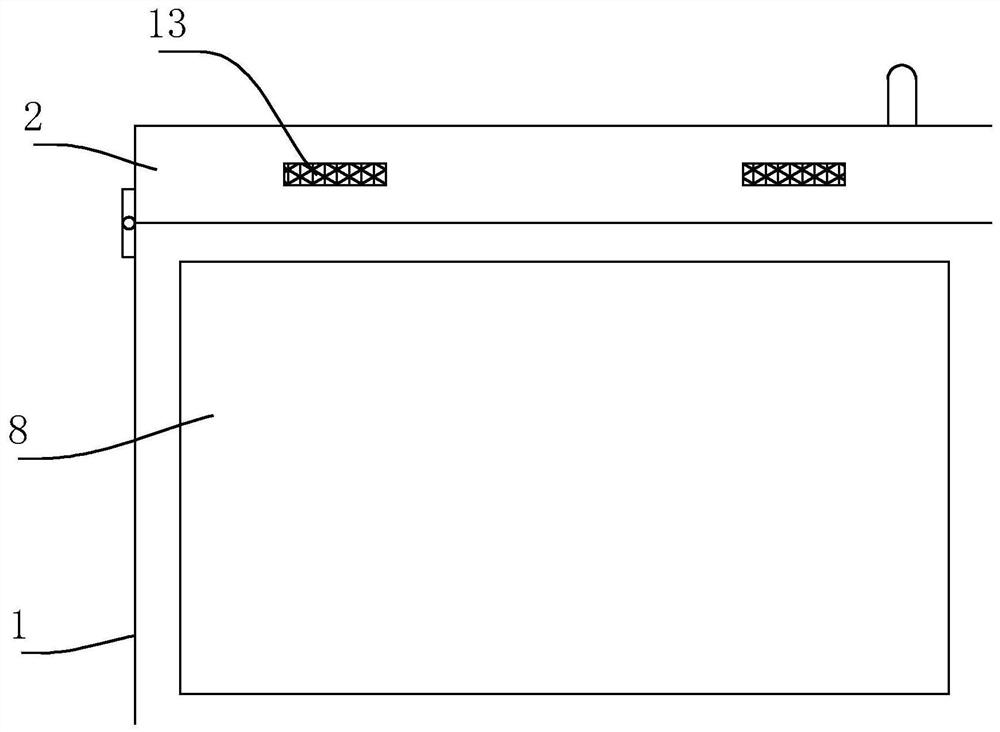

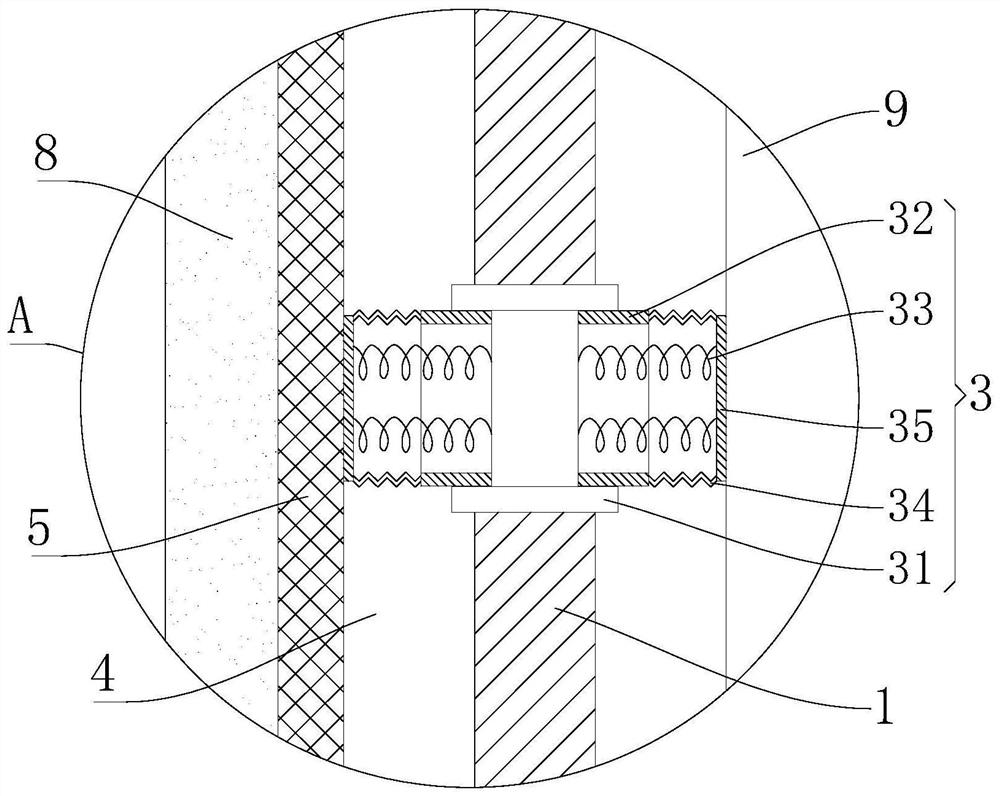

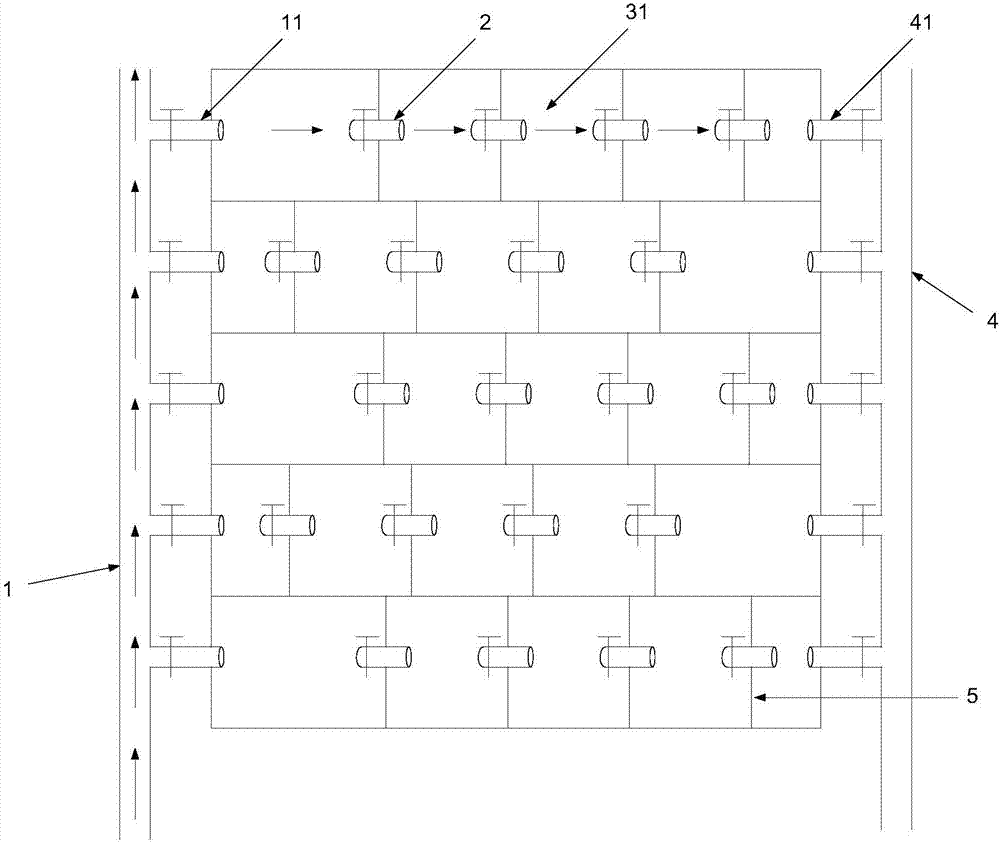

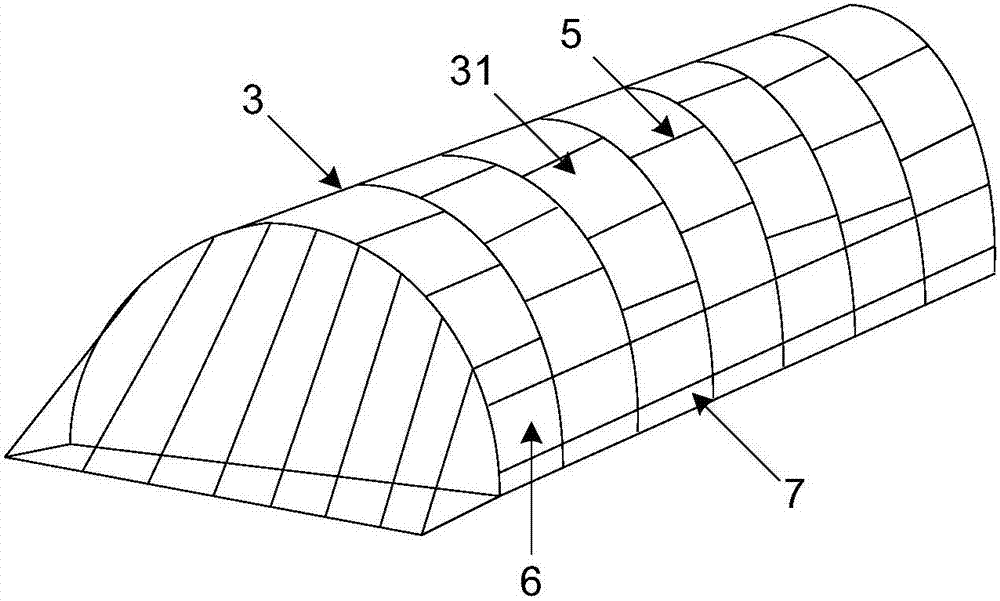

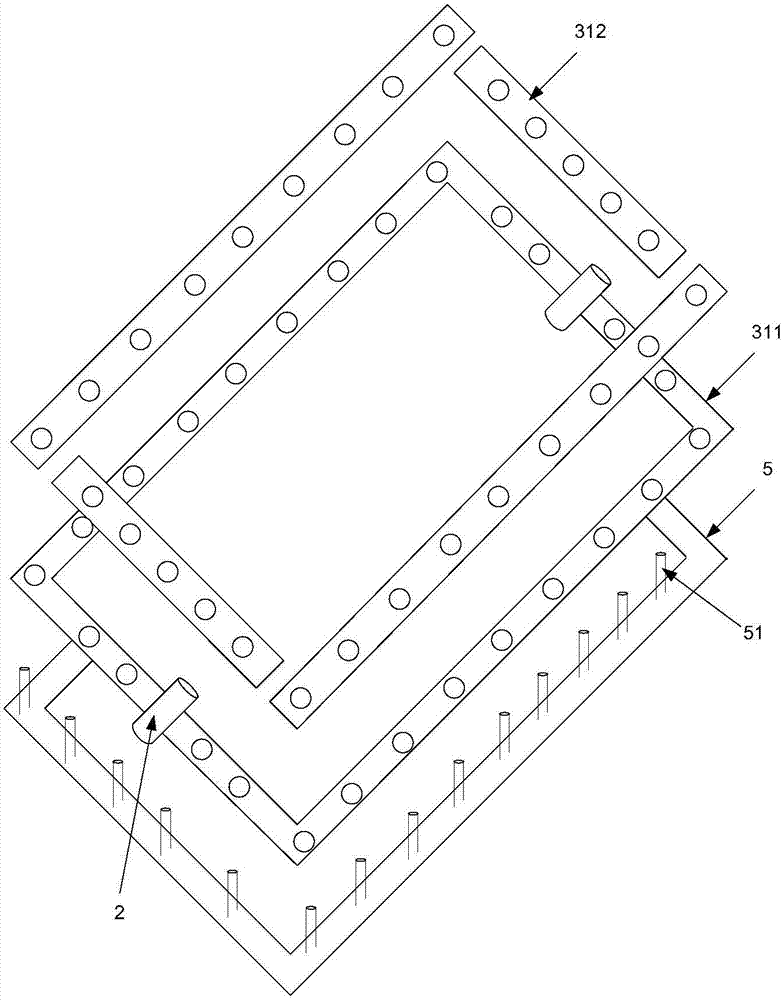

Multi-layer plastic transmitting film integrated sunshine greenhouse

PendingCN107018822AImprove insulation effectGood light transmissionClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention provides a multi-layer plastic transmitting film integrated sunshine greenhouse, and belongs to the technical field agricultural facility. The sunshine greenhouse comprises an air intake compression pipe, an air intake pipe, a multi-layer plastic greenhouse body and an exhaust pipe; the air intake compression pipe is arranged on the long bottom edge of one side of the multi-layer plastic greenhouse body, the exhaust pipe is arranged on the long bottom edge of the other side of the multi-layer plastic greenhouse body, a plurality of air inflation branch pipes are arranged on the air intake compression pipe, a plurality of exhaust branch pipes are arranged on the exhaust pipe, and the air inflation branch pipes and the exhaust branch pipes correspond one by one. The sunshine greenhouse is suitable for the fields of agricultural plantation, cultivation and winter construction, and has the characteristics of being convenient to dismantle and maintain, long in service life, etc.

Owner:马庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com