Automatic bolt stretching fastening system and method

A fastening and bolting technology, which is applied in the field of automatic bolt tensioning and fastening system, can solve problems such as no corresponding prompts and dangers, and achieve the effects of improving stability, reducing labor intensity, and ensuring tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

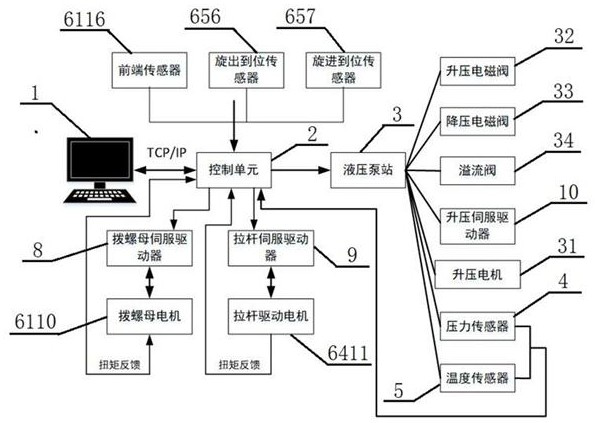

[0058] Refer to the attached figure 1 , this embodiment discloses an automatic bolt tensioning and fastening system, including a host computer 1, a control unit 2, a hydraulic pump station 3, a pressure sensor 4, a temperature sensor 5, a hydraulic tensioner 6, a front sensor 6116, a screw out In-position sensor 656 and screw-in in-position sensor 657; wherein:

[0059] The upper computer 1 is connected with the control unit 2 for real-time monitoring of the stretching process of the hydraulic stretcher 6 and realizing human-computer information interaction;

[0060] The control unit 2 is respectively connected with the hydraulic pump station 3, the pressure sensor 4, the temperature sensor 5, the hydraulic tensioner 6, the front sensor 6116, the screw-in sensor 657 and the screw-out sensor 656, and the control unit 2 is the key of the system. The control center is used to receive and fuse the signals transmitted by the hydraulic pump station 3, the pressure sensor 4, the tem...

Embodiment 2

[0070] This embodiment discloses an automatic bolt tensioning and fastening system. On the basis of Embodiment 1, this embodiment makes further limitations on the hydraulic tensioner 6. Figure 4 and Figure 5 , the hydraulic stretcher 6 includes a stretcher support assembly 61, a stretching cylinder and a pull rod assembly 62, a stretch cylinder rear end assembly 63, a pull rod drive assembly 64 and a stretcher connection assembly 65, and the above-mentioned components are from front to back Connect sequentially, the tensioner support assembly 61 is located at the front end of the device, and the tensioner connection assembly 65 is located at the end, that is, the rear end of the tensioner support assembly 61 is connected to the front end of the stretching cylinder and the pull rod assembly 62, and the stretching cylinder And the rear end of the pull rod assembly 62 is connected with the front end of the stretching cylinder rear end assembly 63, the rear end of the stretch cy...

Embodiment 3

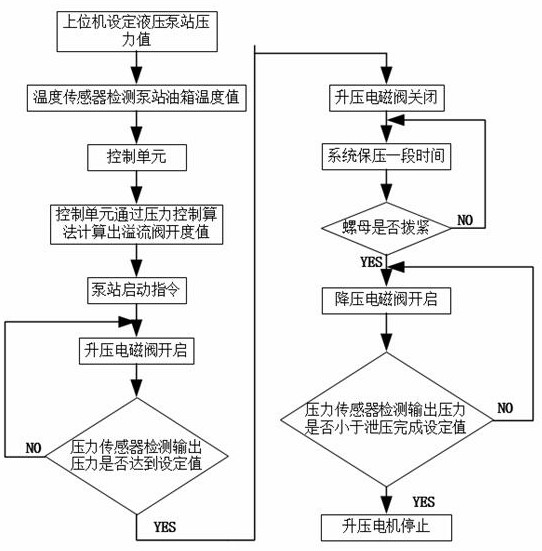

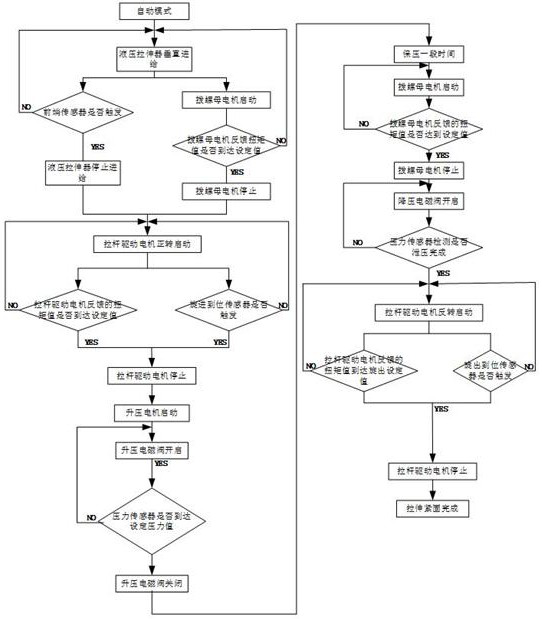

[0093] Refer to the attached image 3 , this embodiment discloses an automatic bolt tensioning and fastening method, which is realized based on the above-mentioned automatic bolt tensioning and fastening system, and specifically includes the following steps:

[0094] A. The operator first calculates the pressure value and pump station speed corresponding to the hydraulic pump station 3 according to the pre-tightening force required by the model of the bolt to be stretched, and then inputs the corresponding parameter value of the pump station through the host computer 1;

[0095] B. The control unit 2 controls the pressure through the pressure setting value of the pump station sent by the host computer 1, the actual pressure value of the hydraulic oil in the hydraulic pump station 3 detected by the pressure sensor 5, and the temperature value of the hydraulic oil detected by the temperature sensor 4. The algorithm calculates the opening value of the overflow valve 34, and sends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com