Cotton sliver mercerizing process and mercerizing device utilizing same

A production method and technology of sliver, applied in mercerizing of sliver, mercerizing of yarn/thread/filament, removal of liquid/gas/steam by squeeze roller, etc., can solve problems such as inability to perform mercerizing, and improve gloss, Ensuring uniformity and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A production method of 60S / 1 mercerized cotton sliver, comprising the following processing steps:

[0039] 1. Cotton sliver pretreatment: weigh the sliver 250g, immerse the sliver in water and apply pressure to fully soak the sliver, then put the sliver into a dehydrator for dehydration, so that the liquid-carrying rate of the sliver is controlled at 50%;

[0040] 2. Rocking cotton sliver: twist the wet cotton sliver on the spinning machine into 250g, and the frame length is 120cm;

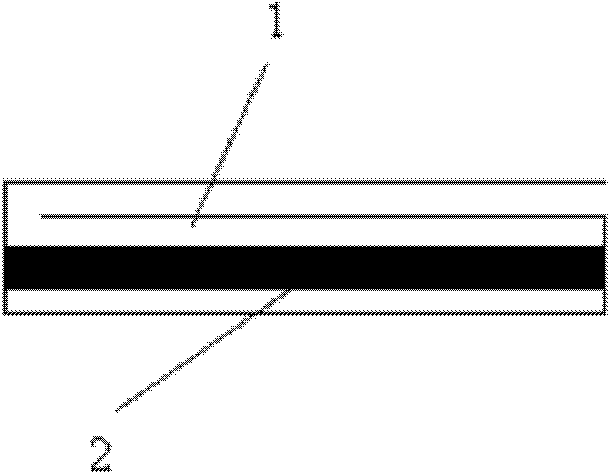

[0041] 3. Wrapping cloth: Wrap twisted cotton sliver in polyester woven cloth, the width of the wrapping cloth is 120cm, and the unfolded length is 57cm, such as figure 1 As shown (1 in the figure is wrapping cloth, 2 is twisted sliver), adopt the wrapping method of one bottom layer and two upper layers;

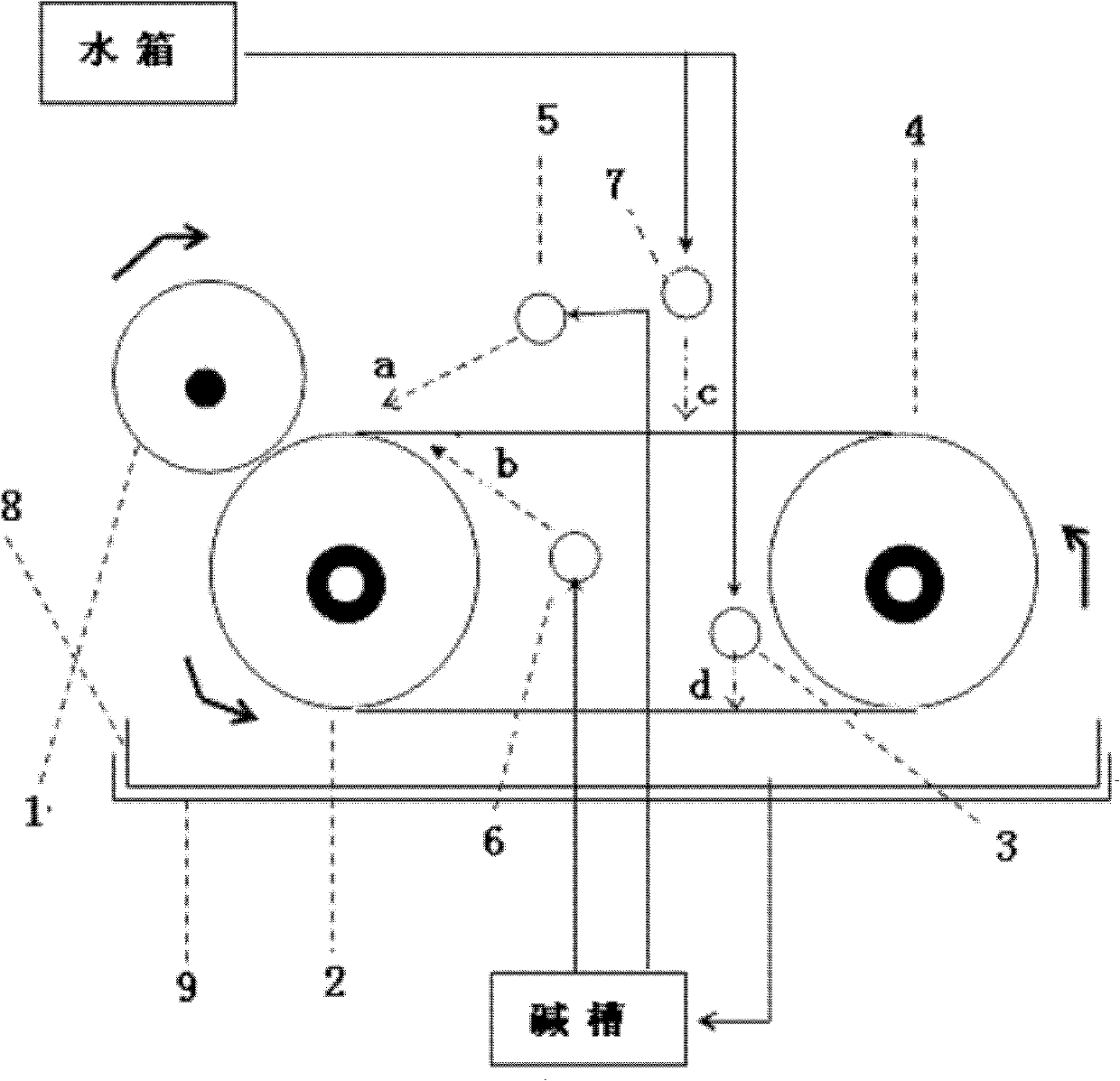

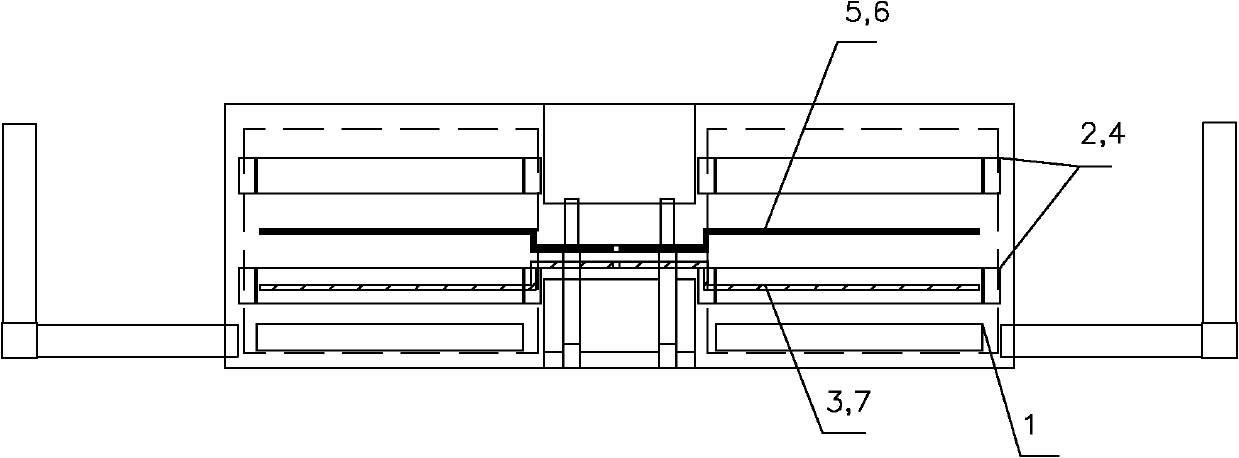

[0042] 4. Mercerizing: On the above-mentioned skein mercerizing machine, mercerizing is carried out by concentrated spraying of alkali and instant extrusion, wherein the concentration of...

Embodiment 2

[0053] A production method of 70S / 1 mercerized cotton sliver, comprising the following processing steps:

[0054] 1. Cotton sliver pretreatment: weigh 500g cotton sliver, immerse in water and apply pressure to make the sliver fully soaked, then put the sliver into a dehydrator for dehydration, so that the liquid-carrying rate of the sliver is controlled at 55%;

[0055] 2. Rocking cotton sliver: twist the wet cotton sliver on the spinning machine into 500g, and the frame length is 130cm;

[0056] 3. Wrapping cloth: Wrap twisted cotton sliver in polyester woven fabric, the width of the wrapping cloth is 130cm, and the unfolded length is 63cm. The bottom layer is wrapped in one layer and the upper layer is wrapped in two layers;

[0057] 4. Mercerizing: On the improved skein mercerizing machine, mercerizing is carried out by means of concentrated alkali spraying and instant extrusion, in which the alkali concentration is 28 degrees Baume, the time of alkali spraying and alkali e...

Embodiment 3

[0059] A production method of 80S / 1 mercerized cotton sliver, comprising the following processing steps:

[0060] 1. Cotton sliver pretreatment: weigh the sliver 1000g, immerse it in water and apply pressure to make the sliver fully soaked, then put the sliver into a dehydrator for dehydration, so that the liquid-carrying rate of the sliver is controlled at 60%;

[0061] 2. Rocking cotton sliver: twist the wet cotton sliver on the spinning machine to 1000g, and the frame length is 140cm;

[0062] 3. Wrapping cloth: Wrap twisted cotton sliver in polyester woven fabric, the width of the wrapping cloth is 140cm, and the unfolded length is 72cm. The bottom layer is wrapped in one layer and the upper layer is wrapped in two layers;

[0063] 4. Mercerizing: On the improved skein yarn mercerizing machine, concentrated alkali spraying and instant extrusion are used for mercerizing, in which the alkali concentration is 30 degrees Baume, the alkali spraying time is 160s, the stretching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com